#Conveyors

Text

6 Aesthetic And Practical Tips For Warehouse Optimization

A well-optimized warehouse can increase productivity, reduce labor costs, improve safety, and enhance overall performance. In this article, we’ll explore six aesthetic and practical tips for optimizing your warehouse.

2 notes

·

View notes

Text

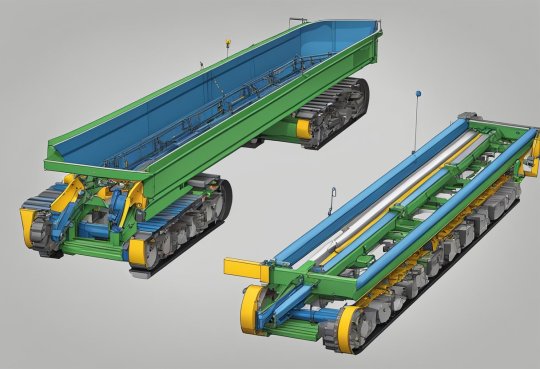

🦾 FLEXIBLE AUTOMATION. PALLETIZING SYSTEM

🦾 Automation ... Flexible palletising system with 6 pallet stations.

Automation Systems.

• 7-axis robot manipulator ... 6-axis + Linear Motion Track RTU Transfer Unit.

• 6 Conveyors for feeding plastic container boxes.

• 6 Centering system on each of the conveyors including load cells for automatic weighing "waiting position".

• 1 Gantry-type palletizing robot... to pick up and position the empty pallet at the appropriate station (1-6).

• 6 Automatic pallet stations (empty pallet loading / finished pallet unloading).

• PC - PLC - SCADA control system.

• Enclosures of the entire installation... preventing access to the different areas of workstation and guaranteeing protection (locking the position of guarding and fencing... electromagnetic technology...)

Remarks.

• Container detection in centering conveyor "waiting position".

• Empty Pallet Gantry Robot.

The Gantry-type palletizing robot picks up the empty pallet from the pallet stack and deposits it in the corresponding empty station (1-6).

Capacity to pick up to 3 pallets simultaneously.

If at a certain moment 2 or 3 stations are empty of pallets (e.g. empty stations 2-4-5-6), the robot will pick up 3 pallets from the stack and deposit them individually in stations 2-4-5... the next priority operation will be to position a pallet in station 6.

This increases the performance and efficiency of the system.

• Control system determines the destination pallet of each "waiting position".

• 7-axis robot decides the shortest and correct path for the next operation.

• Optimised movements of the robot in its transfer to the palletising area to ensure optimum CG (center of gravity) and maximum - optimum speed during its travel through the transfer unit.

• "Open system" for integration of a 2nd second manipulator... if req'd.

• Storage of all the robot operating data (times, weights, cycles...) with a view to making, if necessary, constant operational improvements.

🔧 Maintenance Program.

To improve maintenance operations, an exclusive maintenance zone "Zone 0" is planned in the Transfer RTU.

The transfer module (7th axis) positions the robot in this area when an anomaly is detected in its normal operation... and when any of the intervals specified in the maintenance program are reached (robot, RTU, stations...).

This program works independently ... collecting data from the palletizing station and the robot.

Some aspects or circumstances that are considered:

• Position deviation: if the robot operates outside the expected parameters.

• Repeatability problems: if the robot is unable to perform repetitive cycles or movements.

• Control software alterations.

• Safety issues... problems that may affect safety.

Data A014 - Flexible Palletising System

#TAEVision#engineering#automation#integration#robot#robotics#7th axis#RTU#RTU Robot Transfer Unit#RTU Transfer Unit#RTU Assembly Robotics#transfer unit#TransferUnit#7th axis transfer unit#position table#PositionTable#linear motion track#track motion#conveyors#automatic pallet stations#PC#PLC#SCADA#enclosures#guarding and fencing

2 notes

·

View notes

Text

#GrainHandlingEquipment#Manufacturer#MaterialHandlingEquipments#RostfreiSteels#conveyorbelt#Slidinggates#Conveyors#beltdrives#MaterialHandlingEquipmentsManufacturers

0 notes

Text

Screw Conveyors Manufacturers In India

Understanding Screw Conveyors:

Screw conveyors, often called auger conveyors, are pivotal in the realm of bulk material handling. Their simplicity, efficiency, and adaptability make them indispensable in a variety of industries. From agriculture and food processing to mining and manufacturing, screw conveyors facilitate the smooth movement of materials, contributing to operational efficiency and productivity. In this blog, we’ll explore the fundamentals of screw conveyors, their design features, applications, and benefits, and provide insights into choosing the right system for your needs.

What Is a Screw Conveyor?

A screw conveyor is a mechanical device used to transport bulk materials from one location to another. It consists of a helical screw blade (or auger) that rotates within a trough or tube. As the screw turns, it moves the material along the conveyor’s length. The design may include various configurations, including horizontal, inclined, or vertical, depending on the application and material characteristics.

Key Components and Design Features

1. Screw Blade (Auger): The central component of a screw conveyor, the screw blade, comes in different styles, including standard flight, ribbon flight, and sectional flight, each suited to specific materials and handling needs. The blade's design influences the efficiency and capacity of the conveyor.

2. Trough or Tube: The screw blade is enclosed in a trough or tube that guides the material flow. The trough can be open or covered, depending on whether the conveyor needs to be enclosed to prevent spillage or contamination.

3. Drive Mechanism: The drive mechanism, usually a motor connected to a gearbox, powers the rotation of the screw blade. The choice of motor and gearbox depends on the required capacity and material characteristics.

4. Bearings and Supports: Bearings support the screw shaft and ensure smooth rotation. Proper bearing selection and maintenance are crucial for the conveyor’s longevity and performance.

5. Inlets and Outlets: These are the entry and exit points for materials. Their design affects the efficiency of material transfer and can be customized based on the application.

Types of Screw Conveyors

1. Horizontal Screw Conveyors: Ideal for transporting materials along a horizontal plane, these conveyors are commonly used in bulk handling applications like grain and cement.

2. Inclined Screw Conveyors: Used to move materials at an angle, inclined screw conveyors are suitable for applications where the material needs to be lifted to a higher elevation, such as in aggregate handling and recycling.

3. Vertical Screw Conveyors: Designed for vertical transport, these conveyors are used to lift materials to significant heights. They are often employed in industries where space is limited but vertical movement is essential.

4. Shaftless Screw Conveyors: These conveyors lack a central shaft, which allows them to handle sticky or viscous materials that might otherwise cause problems with traditional screw conveyors. They are often used in wastewater treatment and food processing.

Applications of Screw Conveyors

Screw conveyors are versatile and can be found across a wide range of industries:

1. Agriculture: In agriculture, screw conveyors are used to transport grains, feed, and other bulk materials. Their ability to handle large volumes and varying types of grains makes them essential for efficient farm operations.

2. Food Processing: The food industry relies on screw conveyors to move ingredients, finished products, and by-products. Their ability to transport food gently and hygienically is crucial for maintaining product quality.

3. Mining: In mining, screw conveyors transport minerals, ores, and other materials from extraction points to processing areas. Their robustness and ability to handle abrasive materials are essential in this sector.

4. Manufacturing: Screw conveyors are used in manufacturing facilities to move raw materials, intermediate products, and waste. Their adaptability allows for integration into various production lines and systems.

5. Waste Management: In waste management, screw conveyors transport waste materials and recyclables. Their capacity to handle diverse waste types and their durability are key for effective waste processing.

Advantages of Screw Conveyors

1. Simplicity and Reliability: Screw conveyors are straightforward in design and operation, making them highly reliable for continuous material handling. Their simplicity also means lower maintenance costs and fewer breakdowns.

2. Versatility: They can handle a wide range of materials, from fine powders to bulk solids and even some liquids.

3. Compact Design: Screw conveyors have a compact design, which allows them to fit into tight spaces and be integrated into existing systems with minimal modifications.

4. Controlled Feeding: The design of screw conveyors enables precise control over the flow of materials, which is essential for processes requiring accurate dosing or blending.

5. Customizable: Screw conveyors can be customized in terms of size, material, and configuration to meet specific operational needs and challenges. This flexibility ensures that the conveyor system aligns with unique application requirements.

Choosing the Right Screw Conveyor

Selecting the right screw conveyor involves several considerations:

1. Material Characteristics: Understand the type of material you will be handling. Consider factors such as particle size, density, abrasiveness, and moisture content. Different screw designs and materials may be required based on these characteristics.

2. Capacity Requirements: Determine the required capacity of the conveyor, which depends on the volume of material you need to move and the desired transfer rate.

3. Installation Space: Evaluate the available space for installation. Screw conveyors come in various configurations, so choosing a design that fits within your spatial constraints is important.

4. Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Ensure the conveyor system is built to withstand these conditions.

5. Maintenance and Support: Choose a manufacturer or supplier that offers robust support and maintenance services. Regular maintenance is crucial for ensuring the longevity and performance of the screw conveyor system.

Conclusion

Screw conveyors are integral to modern material handling systems, providing a reliable and efficient means of transporting bulk materials across various industries. Their versatility, simplicity, and ability to handle a range of materials make them a valuable asset in any operation that involves moving products or ingredients.

By understanding the fundamental design features, types, applications, and advantages of screw conveyors, you can make informed decisions about implementing these systems in your operations. Whether you need a standard model or a custom solution, choosing the right screw conveyor and manufacturer will enhance your material handling processes and contribute to the overall efficiency and productivity of your business.

0 notes

Text

The Optidrive E3 NEMA 4X series has an outdoor rated enclosure that is dust tight and washdown ready!

Direct Mounting - Install directly on your processing equipment and be sure of protection from dust, contaminants and high‑pressure washdown.

Locally Customizable - Flat front to terminal cover with mounting points for switches and an internal PCB.

Coated Heatsink as Standard - Ideal for hygiene based operations requiring washdown, such as food and beverage.

Switched Models - Simply wire up the drive, turn the inbuilt potentiometer and the motor will start running, allowing immediate energy savings.

#variablefrequencydrives#vfd#acdrives#nema4x#outdoor#tough#pumps#fans#conveyors#mixers#farm#agriculture#marine#wastewater#oilindustry#torque#speed#controls#invertek#optidrive

0 notes

Text

#IndiaWarehousingShow#Seimitsu#ITOHDenki#Automation#MaterialHandling#IWS#iws2024#seimitsu#Conveyors#ITOH#itohdenki#exhibition#delhincr#india#japan#delhi

0 notes

Text

Explore the essential details and top-notch qualities of Rough Top Belts! 🛠️🔍 From surface texture to construction materials and pattern types, uncover the advantages of these versatile solutions. Discover why they're not just effective but also the most cost-effective option! 💼🔝

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#automation#industry#materialhandling#belts#manufacturing#conveyorrollers

0 notes

Text

#Construction Equipment Market#Construction Equipment#Forklifts#Cranes#Conveyors#Hoists#Concrete Mixer & Pavers#Construction Pumps#Road Rollers#Backhoe Loaders#Skid Steer Loaders#Crawler/Track Loaders#Wheeled Loaders#Motor Graders#Bulldozers#Trencher#Motor Scrappers#Earth Moving Equipment#Concrete and Road Construction Equipment#Material Handling Equipment

0 notes

Text

Wire conveyor belts, Barbed Wire, Rubber Conveyor belts: versatile, durable & essential for various industries. Discover their advantages & applications. For more information visit: Wire Conveyor Belt

#Wire Mesh#Rubber Conveyor Belt#Conveyor Belt#Vibrating Screen#Wedge Wire Screen#Wedge Wire Panel#Barbed Wire#Chain Link Fencing#Perforated Sheet#Conveyors#Wire Conveyor Belt#Wire Mesh Manufacturers#Vibrating Screen Manufacturers#Wedge Wire Screen Manufacturers#Wedge Wire Panel Manufacturers#Chain Link Fencing Manufacturers#Perforated Sheet Manufacturers#Conveyor Belt Manufacturers#Wire Conveyor Belt Manufacturers#Rubber Conveyor Belt Manufacturers#Conveyors Manufacturers#Barbed Wire Manufacturers

0 notes

Text

Lifting Plough Assembly: Calculations for Conveyor System Loads and Forces

Lifting plough assemblies are a crucial component of conveyor systems that aid in the efficient transfer of bulk materials. These assemblies are used to divert materials from the conveyor belt to various discharge points, ensuring that the materials are delivered to their intended location. The design and calculation of lifting plough assemblies require a thorough understanding of the forces…

View On WordPress

#acceleration load#belt conveyor#conveyor motor#conveyor speed#conveyors#dead load#flat belt conveyor system#friction load#impact load#lifting plough assembly#live load

0 notes

Text

Titan material handling pvt. Ltd provide Conveyors at best cost, It Is the best conveyors manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Conveyors#conveyors manufacturers#conveyor manufacturer in pune#conveyor manufacturer in India#AndhraPradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore#Hubli#Maharashtra

0 notes

Text

Titan material handling pvt. Ltd provide Conveyors at best cost, It Is the best conveyors manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

Invertek Drives Optidrive IP20 rated variable frequency drives have compact, robust enclosures built for panel/cabinet mounting and can operate in applications up to 122°F (50°C).

#variablefrequencydrive#vfds#acdrive#automation#industrial#commercial#manufacturing#hvac#refrigeration#pumps#fans#conveyors#mixers#ventilation#irrigation#invertek#optidrive

0 notes

Text

DKT Engineering

Our PVC & PU Conveyor Belt Product line covers genral and food grade bekts that are used in nearly every industry abd come in a variety of sizes and varieties

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#konvey#automation#industry#materialhandling#belts#manufacturing#conveyorrollers#quarry#industrial#beltconveyor#quarrylife#bearing#conveyorbelts#pvcbelt#beltsplicer#vulcanising#r#enduroply#qpiltd#fabrication#quality#conveyoridlers

0 notes

Text

#IndiaWarehousingShow#Seimitsu#ITOHDenki#Automation#MaterialHandling#IWS#iws2024#seimitsu#Conveyors#ITOH#itohdenki#exhibition#delhincr#india#japan#delhi

0 notes

Text

Revolutionize your business operations by harnessing the power of warehouse conveyors. Streamline material handling, reduce labor costs, and eliminate bottlenecks in your workflow. From simple to advanced automation solutions, our conveyors optimize processes, enhance productivity, and maximize space utilization.

0 notes