#Electronic Components for DIY Projects

Explore tagged Tumblr posts

Text

Top 10 Must-Have ICs for Your Next Electronics Project

Integrated Circuits (ICs) have revolutionized electronics, making complex circuitry compact, affordable, and more reliable. Whether you’re working on a hobby project or designing a professional application, certain ICs are essential for building efficient and functional devices. Here, we’ll go over ten must-have ICs that can elevate your next electronics project.

1. 555 Timer IC

The 555 Timer is a versatile IC known for its wide range of applications, from timing to pulse generation. It’s used in both monostable (one-shot) and astable (continuous) modes, ideal for creating oscillators, timers, and even light flashers. It’s a staple for DIY electronics projects and is compatible with numerous applications.

2. LM317 Voltage Regulator

The LM317 is an adjustable voltage regulator IC that provides a stable output. This IC can regulate voltages from 1.25V to 37V, making it essential for power management in electronic circuits. Ideal for custom voltage needs, it’s useful in battery charging circuits, power supplies, and adjustable voltage systems.

3. ATmega328 Microcontroller

This microcontroller IC powers Arduino boards, making it a favorite among hobbyists and professionals alike. It’s programmable with various I/O pins, analog-to-digital converters, and PWM capabilities, perfect for projects that involve data processing, motor control, or IoT applications.

4. Operational Amplifier (Op-Amp) IC: LM741

The LM741 Op-Amp IC is a general-purpose operational amplifier widely used in analog electronics. It amplifies weak signals and is commonly employed in sensors, audio applications, and signal processing. With a wide frequency response and minimal distortion, it’s an essential IC for audio and measurement circuits.

5. 4017 Decade Counter IC

The 4017 Decade Counter is a popular IC in applications where sequential LED lighting or timing control is required. It’s often used in combination with the 555 Timer to create light chasers or display counters. This IC finds applications in counters, timers, and LED displays.

6. ULN2003A Darlington Transistor Array

For projects involving motors, relays, or high-current components, the ULN2003A is invaluable. This Darlington transistor array provides the necessary current amplification to control multiple loads from a single microcontroller or sensor. It’s often used in stepper motor drivers and relay control applications.

7. NE5532 Audio Amplifier

The NE5532 is an audio amplifier IC with excellent noise performance, making it ideal for high-fidelity audio applications. Its low distortion and wide frequency response suit it well for audio mixing, preamplifiers, and general sound processing tasks. Audio engineers and hobbyists alike rely on this IC for quality sound amplification.

8. LM3915 Dot/Bar Display Driver

If you’re creating visual indicators, the LM3915 is a great choice. This IC is used to drive LED bar graphs or dot displays, making it a favorite for visual VU (Volume Unit) meters or battery level indicators. With its easy cascading options, it’s well-suited for applications needing multiple LED levels.

9. MAX232 Serial Communication IC

The MAX232 is crucial for projects involving RS-232 communication. It converts signals from a serial port to signals suitable for TTL-based digital logic circuits. This IC is essential for any project requiring serial communication, like microcontroller-based systems or data transfer applications.

10. ESP8266 Wi-Fi Module

For IoT projects, the ESP8266 Wi-Fi Module IC is a game-changer. This IC provides Wi-Fi capabilities to microcontroller-based projects, allowing remote control and data monitoring. It’s widely used in smart home applications, sensor networks, and any project that requires wireless data transfer.

Conclusion

These essential ICs provide versatility, reliability, and functionality, which makes them indispensable in electronic projects. Whether you’re building a simple timer, creating complex IoT devices, or designing audio applications, these ICs are vital tools. Stocking up on these components will ensure your toolbox is ready for almost any project that comes your way.

If you’re looking to get started with these ICs, you can find a wide selection and Buy Electronic Components Online from Blizzcartz. For more details and the best prices, check out Electronic Components Online in India.

#Buy Electronic Components Online#Best Prices for Electronic Components in India#Electronic Components for DIY Projects

0 notes

Text

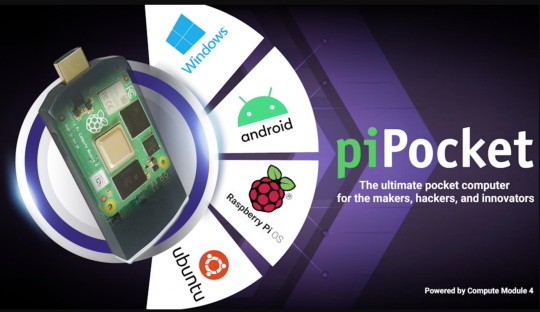

The Ultimate Pocket Computer For Innovators, Coders, Hackers

piPocket is a revolutionary new pocket computer that is perfect for innovators, coders, hackers, and anyone else who wants to create and build amazing things. piPocket is small enough to fit in your pocket, but it is powerful enough to run a wide range of software, including coding environments, development tools, and even full-blown operating systems.

Features

piPocket is packed with features that make it the perfect pocket computer for innovators and creators. Some of the key features of piPocket include:

Powerful processor: piPocket features a powerful quad-core ARM processor that can run even the most demanding applications.

Large memory: piPocket comes with 4GB of RAM and up to 128GB of storage, giving you plenty of space to store your code and projects.

Versatile I/O: piPocket features a variety of I/O ports, including USB-C, HDMI, and micro SD. This allows you to connect piPocket to a variety of devices, including displays, keyboards, and sensors.

Long battery life: piPocket has a long battery life, so you can work on your projects all day long without having to worry about running out of power.

Use Cases

piPocket is perfect for a wide range of use cases, including:

Coding and development: piPocket is the perfect platform for coding and developing software. It comes pre-loaded with a variety of coding environments and development tools, and it is powerful enough to run even the most demanding applications.

Prototyping and testing: piPocket is also a great tool for prototyping and testing new ideas. It is small and portable, so you can take it with you wherever you go, and it is powerful enough to handle even the most complex prototypes.

IoT and embedded systems: piPocket is also a great platform for IoT and embedded systems development. It is small and low-power, making it ideal for battery-powered devices. It also comes with a variety of I/O ports, so you can connect piPocket to a variety of sensors and actuators.

Conclusion

piPocket is the ultimate pocket computer for innovators, coders, hackers, and anyone else who wants to create and build amazing things. It is small, powerful, and versatile, making it the perfect platform for a wide range of use cases.

Check out piPocket on Kickstarter today and learn more about this amazing new product!

2 notes

·

View notes

Text

Buy Electronics Components Online in India – TOMSON ELECTRONICS

Explore our vast collection of electronics components for DIY, Embedded, Robotics, and more. Place order online now for same-day shipping and hyperlocal delivery across India. Discover the top electronics shop in Kerala and Tamilnadu, India.

0 notes

Text

How a Computer Works - Part 1 (Components)

I am about to teach you on a real fundamental, connecting up electronic components level, how a computer actually works. Before I get into the meat of this though (you can just skip down below the fold if you don't care), here's the reasons I'm sitting doing so in this format:

Like a decade or two ago, companies Facebook pushed this whole "pivot to video" idea on the whole internet with some completely faked data, convincing everyone that everything had to be a video, and we need to start pushing back against that. Especially for stuff like complex explanations of things or instructions, it's much more efficient to just explain things clearly in text, maybe with some visual aids, so people can easily search, scan, and skip around between sections. It's also a hell of a lot easier to host things long term, and you can even print out a text based explainer and not need a computer to read it, keep it on a desk, highlight it, etc.

People are so clueless about how computers actually work that they start really thinking like it's all magical. Even programmers. Aside from how proper knowledge lets you get more out of them, this leads to people spouting off total nonsense about "teaching sand to think" or "everything is just 1s and 0s" or "this 'AI' a con artist who was trying to sell me NFTs a month ago probably really is an amazing creative thinking machine that can do everything he says!"

We used to have this cultural value going where it was expected that if you owned something and used it day to day, you'd have enough basic knowledge of how it worked that if it stopped working you could open it up, see what was wrong, and maybe fix it on your own, or maybe even put one together again from scratch, and that's obviously worth bringing back.

I'm personally working on a totally bonkers DIY project and I'd like to hype up like-minded people for when it gets farther along.

So all that said, have a standard reminder that I am completely reliant on Patreon donations to survive, keep updating this blog, and ideally start getting some PCBs and chips and a nice oscilloscope to get that mystery project off the ground.

Electricity probably doesn't work like how you were taught (and my explanation shouldn't be trusted too far either).

I remember, growing up, hearing all sorts of things about electricity having this sort of magical ability to always find the shortest possible path to where it needs to get, flowing like water, and a bunch of other things that are kind of useful for explaining how a Faraday cage or a lightning rod works, and not conflicting with how simple electronics will have a battery and then a single line of wire going through like a switch and a light bulb or whatever back to the other end of the battery.

If you had this idea drilled into your head hard enough, you might end up thinking that if we have a wire hooked to the negative end of a battery stretching off to the east, and another wire stretching off to the east from the positive end, and we bridge between the two in several places with an LED or something soldered to both ends, only the westernmost one is going to light up, because hey, the shortest path is the one that turns off as quickly as possible to connect to the other side, right? Well turns out no, all three are going to light up, because that "shortest path" thing is a total misunderstanding.

Here's how it actually works, roughly. If you took basic high school chemistry, you learned about how the periodic table is set up, right? A given atom, normally, has whatever number of protons in the core, and the same number of electrons, whipping all over around it, being attracted to those protons but repelled by each other, and there's particular counts of electrons which are super chill with that arrangement so we put those elements in the same column as each other, and then as you count up from those, you get the elements between those either have some electrons that don't fit all tight packed in the tight orbit and just kinda hang out all wide and lonely and "want to" buddy up with another atom that has more room, up to the half full column that can kinda go either way, then as we approach the next happy number they "want to" have a little more company to get right to that cozy tight packed number, and when you have "extra" electrons and "missing" electrons other atoms kinda cozy up and share so they hit those good noble gas counts.

I'm sure real experts want to scream at me for both that and this, but this is basically how electricity works. You have a big pile of something at the "positive" end that's "missing electrons" (for the above reason or maybe actually ionized so they really aren't there), and a "negative" end that's got spares. Then you make wires out of stuff from those middle of the road elements that have awkward electron counts and don't mind buddying up (and also high melting points and some other handy qualities) and you hook those in there. And the electron clouds on all the atoms in the wire get kinda pulled towards the positive side because there's more room over there, but if they full on leave their nucleus needs more electron pals, so yeah neighbors get pulled over, and the whole wire connected to the positive bit ends up with a positive charge to it, and the whole wire on the negative bit is negatively charged, and so yeah, anywhere you bridge the gap between the two, the electrons are pretty stoked about balancing out these two big awkward compromises and they'll start conga lining over to balance things out, and while they're at it they'll light up lights or shake speakers or spin motors or activate electromagnets or whatever other rad things you've worked out how to make happen with a live electric current.

Insulators, Resistors, Waves, and Capacitors

Oh and we typically surround these wires made of things that are super happy about sharing electrons around with materials that are very much "I'm good, thanks," but this isn't an all or nothing system and there's stuff you can connect between the positive and negative ends of things that still pass the current along, but only so much so fast. We use those to make resistors, and those are handy because sometimes you don't want to put all the juice you have through something because it would damage it, and having a resistor anywhere along a path you're putting current through puts a cap on that flow, and also sometimes you might want a wire connected to positive or negative with a really strong resistor so it'll have SOME sort of default charge, but if we get a free(r) flowing connection attached to that wire somewhere else that opens sometimes, screw that little trickle going one way, we're leaning everyone the other way for now.

The other thing with electricity is is that the flow here isn't a basic yes/no thing. How enthusiastically those electrons are getting pulled depends on the difference in charge at the positive and negative ends, and also if you're running super long wires then even if they conduct real good, having all that space to spread along is going to kinda slow things to a trickle, AND the whole thing is kinda going to have some inherent bounciness to it both because we're dealing with electrons whipping and spinning all over and because, since it's a property that's actually useful for a lot of things we do with electricity, the power coming out of the wall has this intentional wobbly nature because we've actually got this ridiculous spinny thing going on that's constantly flip flopping which prong of the socket is positive and which is negative and point is we get these sine waves of strength by default, and they kinda flop over if we're going really far.

Of course there's also a lot of times when you really want to not have your current flow flickering on and off all the time, but hey fortunately one of the first neat little electronic components we ever worked out are capacitors... and look, I'm going to be straight with you. I don't really get capacitors, but the basic idea is you've got two wires that go to big wide plates, and between those you have something that doesn't conduct the electricity normally, but they're so close the electromagnetic fields are like vibing, and then if you disconnect them from the flow they were almost conducting and/or they get charged to their limit, they just can't deal with being so charged up and they'll bridge their own gap and let it out. So basically you give them electricity to hold onto for a bit then pass along, and various sizes of them are super handy if you want to have a delay between throwing a switch and having things start doing their thing, or keeping stuff going after you break a connection, or you make a little branching path where one branch connects all regular and the other goes through a capacitor, and the electricity which is coming in in little pulses effectively comes out as a relatively steady stream because every time it'd cut out the capacity lets its charge go.

We don't just have switches, we have potentiometers.

OK, so... all of the above is just sort of about having a current and maybe worrying about how strong it is, but other than explaining how you can just kinda have main power rails running all over, and just hook stuff across them all willy-nilly rather than being forced to put everything in one big line, but still, all you can do with that is turn the whole thing on and off by breaking the circuit. Incidentally, switches, buttons, keys, and anything else you use to control the behavior of any electronic device really are just physically touching loose wires together or pulling them apart... well wait no, not all, this is a good bit to know.

None of this is actually pass/fail, really, there's wave amplitudes and how big a difference we have between the all. So when you have like, a volume knob, that's a potentiometer, which is a simple little thing where you've got your wire, it's going through a resistor, and then we have another wire we're scraping back and forth along the resistor, using a knob, usually, and the idea is the current only has to go through X percent of the resistor to get to the wire you're moving, which proportionately reduces the resistance. So you have like a 20 volt current, you've got a resistor that'll drop that down to 5 or so, but then you move this other wire down along and you've got this whole dynamic range and you can fine tune it to 15 or 10 or whatever coming down that wire. And what's nice about this again, what's actually coming down the wire is this wobbily wave of current, it's not really just "on" or "off, and as you add resistance, the wobble stays the same, it's just the peaks and valleys get closer to being just flat. Which is great if you're making, say, a knob to control volume, or brightness, or anything you want variable intensity in really.

Hey hey, it's a relay!

Again, a lot of the earliest stuff people did with electronics was really dependent on that analog wobbly waveform angle. Particularly for reproducing sound, and particularly the signals of a telegraph. Those had to travel down wires for absurd distances, and as previously stated, when you do that the signal is going to eventually decay to nothing. But then someone came up with this really basic idea where every so often along those super long wires, you set something up that takes the old signal and uses it to start a new one. They called them relays, because you know, it's like a relay race.

If you know how an electromagnet works (something about the field generated when you coil a bunch of copper wire around an iron core and run an electric current through it), a relay is super simple. You've got an electromagnet in the first circuit you're running, presumably right by where it's going to hit the big charged endpoint, and that magnetically pulls a tab of metal that's acting as a switch on a new circuit. As long as you've got enough juice left to activate the magnet, you slam that switch and voom you've got all the voltage you can generate on the new line.

Relays don't get used too much in other stuff, being unpopular at the time for not being all analog and wobbily (slamming that switch back and forth IS going to be a very binary on or off sorta thing), and they make this loud clacking noise that's actually just super cool to hear in devices that do use them (pinball machines are one of the main surviving use cases I believe) but could be annoying in some cases. What's also neat is that they're a logical AND gate. That is, if you have current flowing into the magnet, AND you have current flowing into the new wire up to the switch, you have it flowing out through the far side of the switch, but if either of those isn't true, nothing happens. Logic gates, to get ahead of myself a bit, are kinda the whole thing with computers, but we still need the rest of them. So for these purposes, relays re only neat if it's the most power and space efficient AND gate you have access to.

Oh and come to think of it, there's no reason we need to have that magnet closing the circuit when it's doing its thing. We could have it closed by default and yank it open by the magnet. Hey, now we're inverting whatever we're getting on the first wire! Neat!

Relay computers clack too loud! Gimme vacuum tubes!

So... let's take a look at the other main thing people used electricity for before coming up with the whole computer thing, our old friend the light bulb! Now I already touched a bit on the whole wacky alternating current thing, and I think this is actually one of the cases that eventually lead to it being adopted so widely, but the earliest light bulbs tended to just use normal direct current, where again, you've got the positive end and the negative end, and we just take a little filament of whatever we have handy that glows when you run enough of a current through it, and we put that in a big glass bulb and pump out all the air we can, because if we don't, the oxygen in there is probably going to change that from glowing a bit to straight up catching on fire and burning immediately.

But, we have a new weird little problem, because of the physics behind that glowing. Making something hot, on a molecular level, is just kinda adding energy to the system so everything jitters around more violently, and if you get something hot enough that it glows, you're getting it all twitchy enough for tinier particles to just fly the hell off it. Specifically photons, that's the light bit, but also hey, remember, electrons are just kinda free moving and whipping all over looking for their naked proton pals... and hey, inside this big glass bulb, we've got that other end of the wire with the more positive charge to it. Why bother wandering up this whole coily filament when we're in a vacuum and there's nothing to get in the way if we just leap straight over that gap? So... they do that, and they're coming in fast and on elliptical approaches and all, so a bunch of electrons overshoot and smack into the glass on the far side, and now one side of every light bulb is getting all gross and burnt from that and turning all brown and we can't have that.

So again, part of the fix is we switched to alternating current so it's at least splitting those wild jumps up to either side, but before that, someone tried to solve this by just... kinda putting a backboard in there. Stick a big metal plate on the end of another wire in the bulb connected to a positive charge, and now OK, all those maverick electrons smack into here and aren't messing up the glass, but also hey, this is a neat little thing. Those electrons are making that hop because they're all hot and bothered. If we're not heating up the plate they're jumping to, and there's no real reason we'd want to, then if we had a negative signal over on that side... nothing would happen. Electrons aren't getting all antsy and jumping back.

So now we have a diode! The name comes because we have two (di-) electrodes (-ode) we care about in the bulb (we're just kind of ignoring the negative one), and it's a one way street for our circuit. That's useful for a lot of stuff, like not having electricity flow backwards through complex systems and mess things up, converting AC to DC (when it flips, current won't flow through the diode so we lop off the bottom of the wave, and hey, we can do that thing with capacitors to release their current during those cutoffs, and if we're clever we can get a pretty steady high).

More electrodes! More electrodes!

So a bit after someone worked out this whole vacuum tube diode thing, someone went hey, what if it was a triode? So, let's stick another electrode in there, and this one just kinda curves around in the middle, just kinda making a grate or a mesh grid, between our hot always flowing filament and that catch plate we're keeping positively charged when it's doing stuff. Well this works in a neat way. If there's a negative charge on it, it's going to be pushing back on those electrons jumping over, and if there's a positive charge on it, it's going to help pull those electrons over (it's all thin, so they're going to shoot right past it, especially if there's way more of a positive charge over on the plate... and here's the super cool part- This is an analog thing. If we have a relatively big negative charge, it's going to repel everything, if it's a relatively big positive, it's going to pull a ton across, if it's right in the middle, it's like it wasn't even in there, and you can have tiny charges for all the gradients in between.

We don't need a huge charge for any of this though, because we're just helping or hindering the big jump from the high voltage stuff, and huh, weren't we doing this whole weak current controlling a strong current thing before with the relay? We were! And this is doing the same thing! Except now we're doing it all analog style, not slapping switch with a magnet, and we can make those wavy currents peak higher or lower and cool, now we can have phone lines boost over long distances too, and make volume knobs, and all that good stuff.

The relay version of this had that cool trick though where you could flip the output. Can we still flip the output? We sure can, we just need some other toys in the mix. See we keep talking about positive charges and negative charges at the ends of our circuits, but these are relative things. I mentioned way back when how you can use resistors to throttle how much of a current we've got, so you can run two wires to that grid in the triode. One connects to a negative charge and the other positive, with resistors on both those lines, and a switch that can break the connection on the positive end. If the positive is disconnected, we've got a negative charge on the grid, since it's all we've got, but if we connect it, and the resistor to the negative end really limits flow, we're positive in the section the grid's in. And over on the side with the collecting plate, we branch off with another resistor setup so the negative charge on that side is normally the only viable connection for a positive, but when we flip the grid to positive, we're jumping across the gap in the vacuum tube, and that's a big open flow so we'll just take those electrons instead of the ones that have to squeeze through a tight resistor to get there.

That explanation is probably a bit hard to follow because I'm over here trying to explain it based on how the electrons are actually getting pulled around. In the world of electronics everyone decided to just pretend the flow is going the other way because it makes stuff easier to follow. So pretend we have magical positrons that go the other way and if they have nothing better to do they go down the path where we have all the fun stuff further down the circuit lighting lights and all that even though it's a tight squeeze through a resistor, because there's a yucky double negative in the triode and that's worse, but we have the switch rigged up to make that a nice positive go signal to the resistance free promised land with a bonus booster to cut across, so we're just gonna go that way when the grid signal's connected.

Oh and you can make other sorts of logic circuits or double up on them in a single tube if you add more grids and such, which we did for a while, but not really relevant these days.

Cool history lesson but I know there's no relays or vacuum tubes in my computer.

Right, so the above things are how we used to make computers, but they were super bulky, and you'd have to deal with how relays are super loud and kinda slow, and vacuum tubes need a big power draw and get hot. What we use instead of either of those these days are transistors. See after spending a good number of years working out all this circuit flow stuff with vacuum tubes we eventually focused on how the real important thing in all of this is how with the right materials you can make a little juncture where current flows between a positive and negative charge if a third wire going in there is also positively charged, but if it's negatively charged we're pulling over. And turns out there is a WAY more efficient way of doing that if you take a chunk of good ol' middle of the electron road silicon, and just kinda lightly paint the side of it with just the tiniest amount of positive leaning and negative leaning elements on the sides.

Really transistors don't require understanding anything new past the large number of topics already covered here, they're just more compact about it. Positive leaning bit, negative leaning bit, wildcard in the middle, like a vacuum tube. Based on the concepts of pulling electrons around from chemistry, like a circuit in general. The control wire in the middle kinda works in just a pass-fail sort of way, like a relay. They're just really nice compared to the older alternatives because they don't make noise or have moving parts to wear down, you don't have to run enough current through them for metal to start glowing and the whole room to heat up, and you can make them small. Absurdly small. Like... need an electron microscope to see them small.

And of course you can also make an inverter super tiny like that, and a diode (while you're at it you can use special materials or phosphors to make them light emitting, go LEDs!) and resistors can get pretty damn small if you just use less of a more resistant material, capacitors I think have a limit to how tiny you can get, practically, but yeah, you now know enough of the basic fundamentals of how computers work to throw some logic gates together. We've covered how a relay, triode, or transistor function as an AND gate. An OR gate is super easy, you just stick diodes on two wires so you don't have messy backflow then connect them together and lead off there. If you can get your head around wiring up an inverter (AKA NOT), hey, stick one after an AND to get a NAND, or an OR to get a NOR. You can work out XOR and XNOR from there right? Just build 4 NANDs, pass input A into gates 1 and 2, B into 2 and 3, 2's output into 1 and 3, 1 and 3's output into 4 for a XOR, use NORs instead for a XNOR. That's all of them right? So now just build a ton of those and arrange them into a computer. It's all logic and math from there.

Oh right. It's... an absurd amount of logic and math, and I can only fit so many words in a blog post. So we'll have to go all...

CONTINUED IN PART 2!

Meanwhile, again, if you can spare some cash I'd really appreciate it.

559 notes

·

View notes

Text

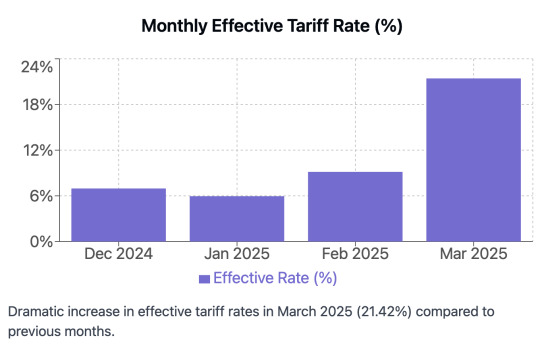

TARIFF TALK! WITH LADYADA 🌍🚢 - Join Ladyada as she breaks down how recent tariff shifts impact electronic component availability and pricing, reshoring trends, and what may happen to engineering/BOM and DIY project costs. Get the inside scoop on navigating supply chain challenges while keeping your builds affordable and excellent! All this week on ASK AN ENGINEER WEDS 8PM ET on all the socials.

#tariffs#electronics#supplychain#ladyada#askanengineer#diyprojects#reshoring#componentprices#engineeringlife#bomcosts#hardwarehacks#techupdate#electroniccomponents#makersmovement#buildsmart#makerlife#electronicsengineering#technews#engineeringtalk#affordablebuilds#openhardware#makerspace#engineering#programming#linux#python#java#software engineering#coding#hardwaredesign

17 notes

·

View notes

Text

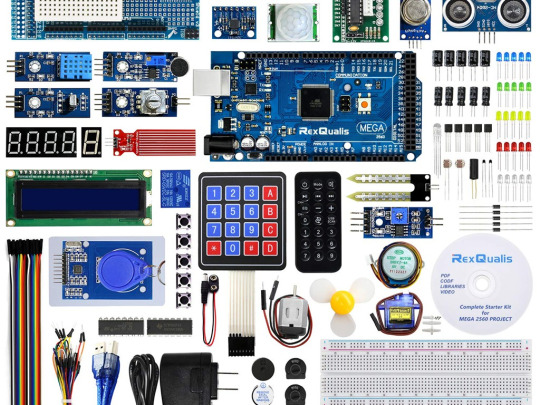

Arduino Mega 2560 Starter Learning Kit

The AINOW Arduino Mega 2560 Starter Learning Kit is an ideal choice for those interested in microcontrollers and electronic components. It includes instructional videos and a guidebook to make learning easy. The tutorials cover basic coding using Arduino software and operating electronic devices. Previous experience is not necessary as the kit teaches coding and working with electronics from the ground up. And, there’s no need for soldering skills – simply plug and play for a fun learning experience.

The main idea is that repetition should be avoided when rephrasing the following paragraph with the same tone.

A fantastic set suitable for all levels, from novice to advanced.

These components have versatile applications and are built for durability.

The kit contains a diverse range of materials to create a multitude of Endless Projects.

An excellent method to gain knowledge on sensors of both analog and digital varieties.

The characteristic is a prominent aspect that sets it apart and makes it stand out.

This kit is ideal for both novices and seasoned professionals in this particular area.

Our selection includes both Analog and Digital Sensors, perfect for those looking to make their own DIY projects.

Discovering the world of microcontrollers is a breeze with Arduino Mega 2560.

Our resources include a User Guide, Codes/Sample Programs & Reference books/Video Tutorials, and other valuable materials.

3 notes

·

View notes

Text

youtube

DIY Sun Tracking Solar Panel Project using Arduino

Are you looking to boost the efficiency of your solar panels? A dual-axis solar tracking system is the perfect solution! Instead of a static panel, this system automatically follows the sun, ensuring maximum energy absorption throughout the day. In this blog, we'll guide you through building your own Arduino-powered solar tracker and show you how it works in action. 🎥✨

🛠️ How Does this Sun Tracking Solar Panel Project Work?

A solar tracking system adjusts the position of the solar panel in two axes (vertical & horizontal) to follow the sun’s movement. This ensures optimal solar exposure, which significantly increases power output compared to fixed panels.

Using Arduino, LDR sensors, and servo motors, we can create a system that continuously detects sunlight intensity and adjusts the panel accordingly. 🌞⚙️

🔹 Components Needed:

🔧 Arduino Uno– The brain of the system 🔧 LDR Sensors – Light intensity detectors 🔧 Servo Motors – For precise panel movement 🔧 Solar Panel – The power generator 🔧 Resistors & Jumper Wires – For connections

📝 Step-by-Step Instructions

1️⃣ Set up the Circuit: Connect LDR sensors, servo motors, and the solar panel to the Arduino. 2️⃣ Upload the Code: Use the provided Arduino sketch to program the tracker. 3️⃣ Test the System: Place it under sunlight and watch the panel follow the sun in real-time! 4️⃣ Optimize & Improve: Adjust sensor placement for better accuracy.

📌 Full Code & Circuit Diagram: https://quartzcomponents.com/blogs/electronics-projects/dual-axis-solar-tracking-system-using-arduino

🔋 Why Use a Solar Tracker?

✅ Increases energy output compared to a fixed panel ✅ Automatically adjusts for optimal sunlight exposure ✅ Enhances efficiency of solar power systems ✅ Perfect for DIY solar enthusiasts & engineers

Whether you're building a home solar system or a DIY electronics project, this Arduino solar tracker is an exciting way to improve energy efficiency!

📢 Share Your Builds!

Tried making this project? Share your solar tracker setup with us in the comments or tag us! We'd love to see your innovation. 🌍⚡

📌 Full Tutorial & Code: 👉 https://quartzcomponents.com/blogs/electronics-projects/dual-axis-solar-tracking-system-using-arduino

1 note

·

View note

Text

Arduino Due vs. Mega: A Comprehensive Comparison

What is Arduino Due and Mega?

The Arduino platform has revolutionized the world of DIY electronics, providing hobbyists and professionals alike with versatile and powerful microcontroller boards. Among the myriad of options, the Arduino Due and Arduino Mega stand out for their advanced features and robust performance. The Arduino Due, introduced in 2012, is the first Arduino board based on a 32-bit ARM core microcontroller, the Atmel SAM3X8E. In contrast, the Arduino Mega, built around the 8-bit ATmega2560 microcontroller, is known for its abundant I/O pins and memory. Understanding the differences between these two boards can help in selecting the right one for specific projects, enhancing both functionality and efficiency.

Processing Power and Performance

The processing capabilities of the Arduino Due and Mega are distinctly different, primarily due to their core microcontrollers. The Arduino Due, with its 32-bit ARM Cortex-M3 processor running at 84 MHz, offers significantly higher processing power compared to the Arduino Mega's 8-bit ATmega2560, which operates at 16 MHz. This difference in architecture and clock speed means that the Due can handle more complex calculations and tasks faster and more efficiently than the Mega. For projects requiring high computational power, such as real-time data processing or handling multiple sensors simultaneously, the Due is the superior choice. However, for simpler tasks, the Mega's processing power may suffice.

Memory and Storage Capabilities

Memory is another critical aspect where the Arduino Due and Mega diverge. The Arduino Due is equipped with 512 KB of flash memory for code storage and 96 KB of SRAM for data. On the other hand, the Arduino Mega has 256 KB of flash memory and 8 KB of SRAM. Additionally, the Due features a Direct Memory Access (DMA) controller, which allows for efficient memory operations, freeing up the CPU to handle other tasks. These memory enhancements make the Due more suitable for applications requiring large codebases and significant data handling, such as advanced robotics or sophisticated control systems. The Mega, with its more modest memory, is ideal for less demanding applications.

Input/Output Capabilities and Expansion

Both the Arduino Due and Mega are renowned for their extensive input/output (I/O) capabilities, yet they cater to different needs. The Mega boasts a whopping 54 digital I/O pins, 16 analog inputs, and 4 UARTs, making it ideal for projects that require multiple sensors, actuators, or communication interfaces. The Due, while offering fewer digital I/O pins at 54, includes 12 analog inputs and 4 UARTs, along with additional features like two DAC outputs for analog signal generation and enhanced PWM capabilities. These features provide the Due with superior analog output capabilities, making it suitable for applications like audio processing or advanced signal generation.

Power Consumption and Compatibility

Power consumption and compatibility are practical considerations when choosing between the Arduino Due and Mega. The Due operates at 3.3V logic levels, which makes it more power-efficient than the Mega, which uses 5V logic levels. This lower voltage operation is beneficial for battery-powered projects where energy efficiency is crucial. However, the 3.3V logic also means that the Due is not directly compatible with 5V components without level shifters. The Mega, with its 5V logic, offers broader compatibility with existing Arduino shields and components, making it a versatile choice for a wide range of projects. Understanding these power and compatibility nuances can help in making an informed decision based on the project's specific requirements.

2 notes

·

View notes

Text

Mastering the Craft: The Ultimate Guide to Split Rivets and Their Applications

Rivets have been the unsung heroes in the world of fasteners, but among them, split rivets stand tall as versatile, reliable, and adaptable connectors. Whether you're an enthusiast in metalworking, a DIY aficionado, or a professional in the manufacturing industry, understanding the ins and outs of split rivets is essential. This comprehensive guide will walk you through everything you need to know about split rivets—applications, best practices, and how to leverage their unique features for various projects.

What are Split Rivets?

Split rivets, also known as bifurcated rivets, are two-piece fasteners consisting of a tubular rivet and a separate, headed pin. The rivet is slotted longitudinally, allowing the pin to expand its legs when inserted, securing materials together. This unique design grants split rivets exceptional flexibility and resilience against vibrations, making them ideal for applications that require a sturdy yet adaptable connection.

Applications of Split Rivets

1. Leather working

In the realm of leather craft, split rivets find their place in securing straps, belts, and decorative elements. Their ability to maintain a strong grip while allowing for movement makes them indispensable in leather goods manufacturing.

2. Metalworking and Automotive Industries

Split rivets play a pivotal role in assembling metal sheets, panels, and components in automotive manufacturing and sheet metal fabrication. Their reliability in withstanding mechanical stress and vibrations makes them a favorite choice.

3. Electronics and Electrical Equipment

Within the electronics industry, split rivets provide secure connections in circuit boards and housing assemblies, ensuring stable and durable constructions despite frequent movements or potential stress.

4. DIY Projects

From repairing household items to creating custom-made accessories, split rivets offer a convenient solution due to their ease of use and adaptability to various materials, making them a staple in DIY enthusiasts' tool kits.

Best Practices for Working with Split Rivets

1. Proper Selection

Choose the right size and material of split rivets based on the application. Factors like material thickness, load-bearing requirements, and environmental conditions should be considered.

2. Preparation and Alignment

Ensure the materials to be riveted are properly aligned and prepared. Drill accurate holes to fit the rivet snugly without causing distortion.

3. Riveting Technique

Insert the pin through the pre-drilled holes and use an appropriate tool to deform the rivet legs evenly. Avoid over-compression, which may weaken the connection.

4. Inspection and Testing

After riveting, inspect the joint for proper deformation and structural integrity. Perform stress tests when necessary to ensure the connection's reliability.

Conclusion

Split rivets are more than just fasteners—they are the silent champions of structural integrity and flexibility in various industries. Their ability to securely join materials while allowing movement makes them a preferred choice across different applications.

Mastering the art of using split rivets involves understanding their capabilities, selecting the right type for the job, and employing proper techniques during installation. Whether you're a seasoned professional integrating split rivets into your projects can elevate the quality and durability of your creations.

So, the next time you're in need of a sturdy yet flexible fastening solution, consider the humble split rivet—the unassuming hero that holds things together, quite literally!

3 notes

·

View notes

Text

Fucking. Continuing on the tags about the Framework and the display panels and the Fairphone. What the fuck is up with the fact that just because I don't live in the US. I can't get this specific kind of DIY-focused panels? The company gets the panels from Shenzhen China.

Why is DIY electronics so incredibly niche? Having to get spare parts for proprietary laptops, if they even have the display available in the first place. And then most diy displays that do sell enough to have dedicated companies are tiny ass 480p or 360p, for tiny ass diy projects that are gimmicky and mostly pointless in the grand scheme of things beyond "hey look i built something with tiny parts".

I just want to have a device that is repairable, upgradable, and relatively modular yeah?

Framework is cool because I could buy the mainboard, some additional components, and then otherwise just. Build my own chassis, apply my own screen, build a fucking cyberdeck if I wanted to, for the novelty.

And Jesus fuck, the fucking bullshit excuse of "oh it's more eco-friendly, its better for the environment to remove the fucking headphone jack, never mind the disposable wireless earbuds or other wireless technology necessary now. Buy our fucking wireless headphones or an even more unnecessarily wasteful USB-C to 3.5mm jack, if you're so desperate for it. So much better than just building it in"

#I just wanna build and design#Learn how to build and design#And also not throw out phones and laptops after not even a year because I fucked it up

2 notes

·

View notes

Text

10 Effective Strategies for Solid Waste Management: Reduce, Reuse, Recycle!

Introduction

Welcome to our blog post on effective strategies for solid waste management! In today's world, where environmental concerns are paramount, adopting proper waste management practices is crucial. By following the three R's: Reduce, Reuse, and Recycle, we can make a significant impact on minimizing waste generation and preserving our planet's resources. Let's dive into the ten strategies that can help us achieve sustainable waste management.

1. Conduct a Waste Audit

According to the Water Treatment Plant Manufacturers in India to effectively manage waste, it's essential to understand the current waste generation and disposal patterns. Conducting a waste audit will provide valuable insights into the types and quantities of waste produced, allowing for targeted interventions.

2. Embrace Source Reduction

3. Promote Reuse and Repurposing

Encouraging reuse and repurposing of items helps reduce waste and extends the lifespan of products. Consider donating or selling unwanted items, participating in local swap events, and embracing creative DIY projects to give new life to old objects.

4. Implement Recycling Programs

Setting up recycling stations and educating employees and the community about proper recycling practices is vital. Ensure clear signage, separate bins for different recyclable materials, and provide educational materials on what can and cannot be recycled.

5. Composting Organic Waste

Composting is an excellent way to manage organic waste, such as food scraps and yard trimmings. It not only reduces waste sent to landfills but also produces nutrient-rich compost that can be used for gardening and landscaping.

6. Encourage Responsible E-Waste Disposal

Electronic waste, or e-waste, requires special handling due to its hazardous components. Educate yourself and others about the proper disposal of electronic devices and consider recycling programs dedicated to e-waste management.

7. Explore Waste-to-Energy Options

Waste-to-energy technologies offer an alternative to traditional waste disposal methods by converting waste into usable energy. Consider exploring options such as incineration, anaerobic digestion, or gasification, while considering the environmental and social impacts.

8. Establish Partnerships with Waste Management Companies

Collaborating with waste management companies that specialize in recycling and waste disposal can provide valuable expertise and services. They can assist with waste collection, recycling processes, and implementing sustainable practices.

9. Educate and Engage the Community

Raising awareness about waste management is crucial for long-term success. Organize community events, workshops, and awareness campaigns to educate people about the importance of proper waste management and involve them in the process.

10. Continuous Monitoring and Improvement

Monitoring waste management practices and tracking progress is essential for identifying areas of improvement. Regularly assess your waste management strategies, analyze data, and make necessary adjustments to achieve better results.

In conclusion, by implementing these ten effective strategies for solid waste management, we can make a significant impact on reducing waste, conserving resources, and creating a cleaner and healthier environment. Let's join hands and work together to embrace the principles of reducing, reusing, and recycling for a sustainable future.

#Waste Management Strategies#10 Ways to Reduce Waste#Waste Reduction and Utilization Strategies#Waste Management Reduce Reuse Recycle#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

Shop Digital Multimeter and Analog Multimeter

Explore branded True RMS digital multimeters and analog multimeters at Tomson Electronics. Get accurate measurements and reliable performance for your electronic projects. Shop now for top-quality multimeters from trusted brands.

#Digital Multimeter#Analog Multimeter#electronic components online store#electronics#electronic projects#diy projects

0 notes

Text

TARIFF TALK! WITH LADYADA 🌍🚢 - Ladyada as she breaks down how recent tariff shifts impact electronic component availability and pricing, reshoring trends, and what may happen to engineering/BOM and DIY project costs. Get the inside scoop on navigating supply chain challenges while keeping your builds affordable and excellent!

#tariffs#electronics#supplychain#ladyada#askanengineer#diyprojects#reshoring#componentprices#engineeringlife#bomcosts#hardwarehacks#techupdate#electroniccomponents#makersmovement#buildsmart#makerlife#electronicsengineering#technews#engineeringtalk#affordablebuilds#openhardware#makerspace#engineering#programming#linux#python#java#software engineering#coding#hardwaredesign

7 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description >> Multipurpose kit: The kit includes a variety of activities like Solar power applications, Art and craft projects, Circuit making practices, Electronics projects, Electrical power utilisation activities, Science and hobby projects, Motor hacks, Robotics, Toys & games, STEM Activities etc.Tutorials provided: Kids can learn to make the projects very easily using simple instruction manual (Booklet), connection diagram and video tutorials. Kids can learn making simple to complex projects at their own using the material and tutorials provided with the kit.Certificate included: Your kids interest in Science experiments & activities is highly appreciated. Kit includes a CERTIFICATE OF APPRECIATION for your kids to appreciate their interest in STEAM activities.Kit4Curious SuperKit: Kit4Curious SuperKit is a most popular series of educational kits among the category. Kit4Curious SuperKit includes 140+ components (Multipurpose, reusable and OK tested) packed in single box so you can setup your own laboratory at your home for Science, hobby and school projects. The kit can be used to make more than 140 projects. Kit includes 140+ items in 1 kit (Including electrical, electronic, hardware, paper templates, booklet, connection diagram etc). You can make 128 DIY (Do It Yourself) projects + 13 exclusive STEAM activities + 3 Solar energy experiments + Endless Innovations. The kit includes connection diagram, Booklet and Tutorials to easily learn and complete the projects and experiments. You can setup your own Science & Fun Laboratory in your home using this kit. You can make your own Science gadgets, Toys, Games and School projects. This kit4Curious kit also includes Art activities like Paper flower, paper pyramid, Paper lantern to decorate your room. You can make them glowing using LED lights provided in the kit. You can also make you school projects with Ideas and material provided with the kit. Best gift option for genius kids. Amazing Science & Fun innovation DIY experiments toy kit for kids boys and girls. 140+ Items 140+ Projects: The kit includes more than 140 items and can be used to perform more than 140 activities. 128 DIY (Do It Yourself) Projects + 13 exclusive STEAM activities + 3 Solar energy experiments. Total 140+ projects in 1 kit [ad_2]

0 notes

Text

Where to Find Trusted Electronic Parts Distributors for High-Quality Circuit Board Components

Constructing a circuit board functions like assembling a puzzle requires correctly alignment to work effectively. Electronic manufactures or producers who work on DIY projects must have high-quality circuit board components to achieve long-term success. This article provides useful approaches to find reliable distributors who supply superior circuit board parts to prevent project issues.

0 notes

Text

Working with ABS? Here’s What You Should Know

You can tell a lot about a material based on how people actually use it, not just what brochures say. ABS plastic sheets, for example, aren’t new. But ask any workshop guy, prototyping engineer, or serious DIY builder—they’ve all got a sheet or two tucked away, ready for action.

There’s a reason for that. ABS (Acrylonitrile Butadiene Styrene) is strong, relatively lightweight, and ridiculously easy to work with. Doesn’t matter if you’re cutting it, drilling it, or heating it to shape—it responds well and forgives small mistakes. It’s one of those materials that sort of disappears once it’s in place. That’s how you know it’s doing its job.

One format I’ve come across often in both hobby and professional work is the 1x8 Abs plastic sheet 4x8. Not too large, not too small—kind of the “just right” option for quick builds or mid-sized projects. Let’s dive into the basics of these sheets and why so many people prefer them.

Why ABS Is the Go-To Plastic for Builders and Makers

ABS isn’t glamorous. You’re not buying it to impress anyone. What you’re getting is reliability. It won’t crack under stress, it doesn’t absorb moisture like wood, and it doesn’t warp out of shape randomly like some thin plastics. Whether you’re doing automotive interiors or building a quick jig for your tools, ABS just works.

The sheet surface is also a big plus. Some come textured, some smooth—you pick what suits your job. The matte finish doesn’t reflect light harshly, which makes it great for signage or visible applications. And for folks who like to paint, it takes color nicely with just a bit of sanding and the right primer.

Sheet Thickness and What It Means for You

Not every project calls for the same thickness. That’s where knowing your specs pays off. A thinner sheet might save weight and cut easily, but you don’t want it buckling under load.

For more demanding work, the 10MM Abs plastic sheet really stands out. It’s thick enough to handle structural loads, support bolts, and hold its shape even when you’re using it in outdoor or rugged setups. I’ve used this thickness for shelving inside a van conversion and it didn’t budge—even with tools stored on top during long trips.

This thickness also gives you the flexibility to do advanced machining if needed. Want to route a groove or make a slot? You’ve got room to play with 10MM. That’s something thinner sheets just can’t handle without snapping or flexing.

Some Smart Ways People Use ABS Sheets

There’s a pretty long list, honestly. But here are some of the real-world uses I’ve seen or done myself:

Custom enclosures for electronics—keeps things safe and doesn’t interfere with signals.

Tool drawer liners—cut it to fit, drop it in, no more clanking tools.

RC and hobby builds—especially when you want lightweight and strong materials.

Wall paneling—interior cladding that’s easy to clean and doesn’t rot.

Protective guards—cover moving parts, hot surfaces, or electrical components.

What’s great is that most of these uses don’t require industrial-grade tools. A decent jigsaw, drill, and some sandpaper will get you through most jobs.

Working with ABS: Not as Hard as It Sounds

If you’ve never worked with ABS, don’t stress—it’s surprisingly user-friendly. Just clamp it down properly before cutting, because it can chatter a bit if it’s loose. A fine-tooth saw or a Dremel works wonders. And if you ever want to bend it, warm it up gently with a heat gun and use gloves to avoid burns.

One time I cut a 125 Abs plastic sheet for a machine cover—it was thick and took a while to cut, but the results were clean. The important thing was taking my time and making sure I wasn’t rushing the blade. You don’t need a CNC to get great results, just patience and sharp tools.

Wrapping Up the ABS Advantage

So, what’s the verdict? ABS sheets are the definition of dependable. Whether you’re tackling a one-off garage fix or assembling parts for an actual product launch, this plastic pulls its weight.

From the handy 1x8 Abs plastic sheet 4x8 for medium-sized builds, to the beefier 10MM Abs plastic sheet for structure and load, to the thicker and more industrial 125 Abs plastic sheet, there’s something for everyone. You don’t need to be a pro to get results—just a little know-how and the right sheet.

FAQs

1. Who is the largest manufacturer of ABS plastic sheets?

If you're serious about quality and reliable supply, Singhal Industries Pvt Ltd is one of the most trusted names in the business. They’ve been leading the ABS plastic sheet game in India for years, offering a wide range of sizes, finishes, and thicknesses, all backed by dependable service and fast delivery.

2. Can ABS plastic sheets be recycled?

Yes, ABS plastic is recyclable. Most industrial recycling facilities can handle it. Just make sure you’re not mixing it with other plastics or coated materials that could interfere with the process.

3. What’s the best way to clean ABS plastic?

Keep it simple: a mild soap solution and a soft cloth will do. Avoid harsh cleaners or abrasive sponges—they can scratch or dull the surface. If it's got oil or grime on it, a little isopropyl alcohol works well too.

0 notes