#Engine component manufacturing

Explore tagged Tumblr posts

Text

Engine Component Manufacturing and New Machining Services: Precision for Modern Performance

A high-performance vehicle, aircraft, or industrial machine starts with its engine components. The evolution of engine component manufacturing has been driven by the need for tighter tolerances, improved materials, and higher durability. Today, the industry is embracing new machining services to meet growing demands for speed, precision, and efficiency. CNC machining and additive manufacturing are among the new technologies changing how we produce engine parts. This blog explores SYRONTECH's key aspects of engine component manufacturing and the latest machining services that are shaping the future.

The Importance of Engine Component Manufacturing

Pistons, crankshafts, cylinder heads and valves all face harsh pressures and temperatures when they are in use. Building modern engines relies on very strong valves, do not wear easily and are perfectly matched. They are made using set tools, require top-quality resources and are overseen by strong quality control measures. Machining mistakes as small as a few microns may result in failure or a loss of efficiency for engines. For this reason, precision must be included, not just chosen at will. The individual quality of each component helps to determine the engine’s overall performance.

Materials Used in Engine Components

Modern engineers use different advanced materials to build engine parts. Aluminum alloys are often used because they are lightweight and are found in car engines. Both steel and cast iron are popular for their good strength and ability to resist wear in tough engines. Heat resistance and low weight have made it possible for titanium and ceramic composites to find use in aerospace engine construction. Every material needs unique work methods, its tools, and special cooling during machining. It is important to use the right material for the engine’s better performance.

Traditional vs. Modern Machining Techniques

For decades, turning, milling, grinding and drilling have been common ways to make parts for engines. They get the job done, yet they take longer and are not suited for complex shapes. New Machining Services now use CNC (Computer Numerical Control) machines for higher precision and repeatability. CNC systems automate the cutting process based on digital models, reducing errors and production time. Multi-axis CNC machines can create intricate shapes that were once impossible to achieve. These new methods are faster, more efficient, and ideal for complex engine designs.

CNC Machining in Engine Component Production

CNC machining is revolutionizing the manufacturing of engine components. It allows manufacturers to produce complex parts with high accuracy and tight tolerances. With 3-axis, 4-axis, and 5-axis capabilities, CNC machines can perform multiple operations in a single setup. This improves consistency and reduces material waste. For example, CNC milling can produce cylinder heads with intricate cooling channels, while CNC turning can precisely shape crankshafts and camshafts. The use of CAD/CAM software enhances the design and simulation process before production begins.

Additive Manufacturing for Prototyping and Small Batches

Additive manufacturing, or 3D printing, is gaining popularity in engine component development. It’s ideal for prototyping and producing small batches quickly without the need for custom tooling. Engineers can test different designs before mass production, reducing time and cost. For example, metal 3D printing is used to create turbocharger components and heat exchangers with complex internal structures. Although not yet common for mass production, additive manufacturing is valuable for innovation and design flexibility in engine development.

Surface Finishing and Coating Technologies

Surface finishing is crucial to engine component performance. After machining, parts often require polishing, honing, or coating to improve durability and efficiency. Surface treatments like nitriding, chrome plating, or ceramic coatings enhance hardness, reduce friction, and resist corrosion. These processes are especially important for moving parts like pistons and valve stems. Automated finishing systems ensure uniformity and reduce the risk of human error. The right finishing technique extends the lifespan of engine components and supports reliable engine operation.

Conclusion

The future of engine component manufacturing lies in precision, speed, and innovation. New machining services like CNC, additive manufacturing, and automation are enabling the production of smarter, stronger, and more efficient engine parts. Material science and surface finishing techniques are also evolving to meet modern performance demands. Whether in automotive, aerospace, or industrial sectors, these advancements are helping engineers push the boundaries of engine design. For companies like SYRONTECH, investing in next-generation machining services, the road ahead is full of opportunity and growth.

#Engine component manufacturing#CNC machining#additive manufacturing#3D printing#surface finishing#SYRONTECH#engine parts#precision machining#aerospace engine components#automotive engine parts.

1 note

·

View note

Text

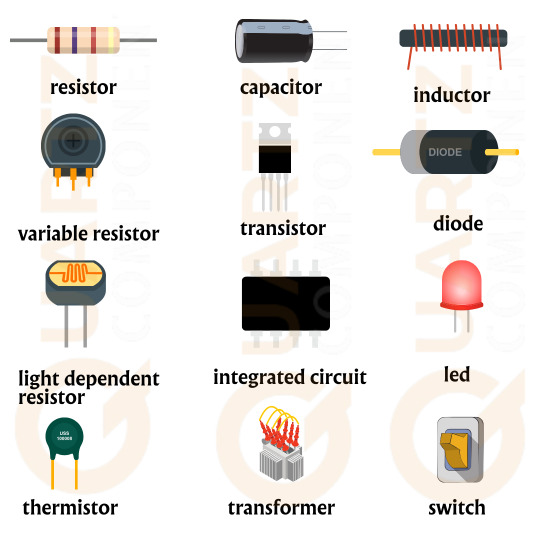

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

13 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Microelectromechanical Systems Mems Supplier | Shenzhen Informic Electronic Limited

Working with a trusted Microelectromechanical Systems MEMS Supplier like Shenzhen Informic Electronic Limited offers key benefits, including access to cutting-edge technology, high-quality components, and reliable performance for advanced electronics. We provide innovative MEMS solutions tailored to meet the unique needs of engineers and manufacturers. Visit us.

#MEMS Supplier China#Microelectromechanical Systems Components#MEMS Technology Provider#High-Performance MEMS Solutions#MEMS for Electronics Manufacturing#Trusted MEMS Distributor#MEMS Components for Engineers#Shenzhen MEMS Manufacturer#Custom MEMS Solutions#Advanced MEMS Electronics Supplier

0 notes

Text

Application of steel fibres for concrete reinforcement

In the continually changing landscape of construction and civil engineering, the need for strong and high-performance materials has never been more pronounced. One such development that has revolutionized concrete reinforcement is the application of steel fibres in concrete. Ranging from strengthening mechanical properties to enhancing crack resistance and durability, steel fibres are quickly becoming an essential part of contemporary infrastructure. This blog is going to discuss the uses of steel fibres in concrete reinforcement, their kind, advantages, and why Kinetic Industries is a name to be reckoned within steel fibre suppliers and manufacturers.

What Are Steel fibres?

Steel fibres are discrete lengths of steel, short in nature, which are randomly oriented and distributed in the concrete mixture. They serve as crack arresters and add post-cracking strength, thereby making the concrete tougher and more resilient. They are usually between 0.25 mm and 1 mm in diameter and are available in different shapes like hooked, crimped, or straight.

These fibres are produced from high-tensile wire, cut sheet, or even melt-extracted stainless steel, and are added to concrete in certain proportions based on structural demands.

Steel fibre Reinforced Concrete: A Game-Changer

When steel fibres are introduced into concrete, they form Steel fibre Reinforced Concrete (SFRC). The composite material significantly enhances the resistance of concrete against cracking, fatigue, and impact loading. SFRC performs particularly well in applications where the use of conventional rebar reinforcement is not possible or economical.

At Kinetic Industries, we design high-performance concrete steel fibres up to international specifications to suit a broad range of industrial and infrastructure applications.

Applications of Steel fibres in Concrete

Applications of steel fibres are numerous and cut across different industries because of their unique performance traits. Some of the most prevalent applications include:

1. Industrial Floors and Pavements

SFRC is best suited for industrial flooring because of its capacity to withstand intense wheel loads as well as thermal shock. Warehouses, loading docks, and airport pavements significantly gain from the toughness provided by steel fibre reinforcement.

2. Tunnels and Underground Structures

Subways, underground parking garages, and tunnels are usually subjected to severe environmental conditions. Steel fibres in concrete improve load capacity and reduce maintenance.

3. Precast Concrete Components

Precast components such as wall panels, manholes, and pipes utilize concrete steel fibres to increase resistance to mechanical stress and damage during handling.

4. Shotcrete Applications

In civil engineering applications like slope stabilization, mining, and tunnel linings, steel fibre reinforced concrete in shotcrete form provides improved adhesion and structural strength.

5. Bridges and Dams

Structural requirements for bridges and dams call for concrete that resists tensile and flexural stress. Stainless steel fibres added to the concrete guarantee durable performance even under severe loading conditions and exposures.

Benefits / Advantages of Steel fibres

The benefits of steel fibres in reinforcing concrete are far-reaching:

Better Crack Resistance

Steel fibres assist in regulating micro-cracks and avoid their progression to macro-cracks.

Better Flexural Strength

Steel fibre reinforced concrete exhibits greater flexural strength, minimizing the necessity for traditional reinforcement.

Longer Durability and Longevity

Steel fibres enhance the impact resistance, fatigue resistance, and toughness of concrete, making it ideal for aggressive environments.

Earlier and Quicker Construction

With the use of steel fibres, the requirement for conventional reinforcement bars can be eliminated or minimized, reducing on-site time and labor expenses.

Lower Maintenance Expenses

Steel fibre reinforced concrete structures have lower maintenance throughout their lifespan because of enhanced structural integrity.

Steel fibres Types

There are various types of steel fibres, each suitable for particular structural demands:

Hooked-End fibres:

These are the most widely used, providing maximum bonding with the concrete matrix.

Crimped fibres:

Used to increase frictional bonding and are suitable for general applications.

Straight fibres:

Typically utilized in applications requiring lower strength or where mixing uniformity is desired.

Stainless Steel fibres:

Corrosion-resistant and suitable for marine or chemically aggressive environments.

We at Kinetic Industries produce and supply an extensive range of steel fibre varieties to fulfill your exact construction requirements.

Why should Kinetic Industries be Your Steel fibre Supplier?

As one of the major steel fibre producers and suppliers, Kinetic Industries offers innovative reinforcement solutions with reliability and economy. We are dedicated to innovation in product quality as well as application technology. Our series of engineering parts and industrial parts, such as concrete steel fibre, are strictly tested for durability and performance under the most severe conditions.

With Kinetic Industries, you benefit from:

Professional technical assistance

Tailor-made fibre solutions

Bulk transportation and logistics support

Environmental sustainability commitment

Steel fibre Reinforcement in the Indian Economy

India’s developing infrastructure and industrial sector is placing a gargantuan order for high-performance building materials. According to recent studies, the international market for steel fibre reinforced concrete is projected to grow phenomenally, and India is at the center of this boom.

Construction companies are increasingly abandoning conventional reinforcement in favor of steel fibres for reinforcing concrete, particularly for metro rail construction, smart cities, industrial parks, and road building. At Kinetic Industries, we are happy to facilitate this expansion with efficient and innovative reinforcement products.

The use of steel fibres in reinforcing concrete is revolutionizing the way we construct and safeguard infrastructure. Greater strength, lower maintenance, and cost-saving benefits are no longer an option—steel fibres are becoming a requirement.

Whether it’s constructing tunnels, industrial flooring, or precast parts, Kinetic Industries has the appropriate types of steel fibres and solutions specific to your project requirements.

Are you ready to elevate your construction projects to the next level?

Collaborate with Kinetic Industries — a top steel fibre manufacturer and supplier in India.

#steel fibers for concrete#Steel Fibers#Concrete Steel Fiber#Steel fibers types#steel fibers for concrete reinforcement#stainless steel fibers#steel fiber manufacturers#steel fiber Suppliers#steel fiber reinforced concrete#steel fiber reinforcement#industrial components#engineering components

0 notes

Text

CNC Machining Manufacturer in Pune – ANJALI T. PRECISION

In the ever-evolving world of manufacturing, precision, efficiency, and innovation have become the pillars of modern industry. Pune, often referred to as the engineering and manufacturing hub of India, is home to several leading CNC machining companies. Among them, ANJALI T. PRECISION stands out as a trusted name in the field of CNC Machining and precision components manufacturing.

Who We Are – About ANJALI T. PRECISION

Established with a vision to deliver world-class CNC machining services, ANJALI T. PRECISION has earned a solid reputation as a leading CNC Machining Manufacturer in Pune. Our company is known for its commitment to quality, advanced technological infrastructure, and client-centric approach. With years of industry experience, we have been consistently delivering high-precision, complex, and cost-effective components to diverse industries including automotive, aerospace, electronics, defense, and industrial equipment.

What is CNC Machining?

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It enables the creation of precise and complex parts with tight tolerances and smooth finishes.

At ANJALI T. PRECISION, we specialize in:

CNC Turning

CNC Milling

VMC (Vertical Machining Center) operations

Drilling and Tapping

Custom CNC Machining Solutions

Our Services

1. CNC Turning and Milling

Our state-of-the-art CNC turning and milling machines produce high-accuracy components for critical applications. We work with a wide range of materials including stainless steel, aluminum, brass, copper, and various engineering plastics.

2. Prototype to Production

Whether it's a single prototype or full-scale production, we have the expertise and resources to support both short-run and high-volume requirements.

3. Custom Component Manufacturing

We specialize in customized parts as per client drawings and specifications. Our skilled engineers and machinists ensure top-notch output at every stage.

4. Quality Inspection and Assurance

Our in-house quality control processes include 3D measuring tools, surface roughness testers, height gauges, and other advanced inspection instruments. We strictly follow ISO quality standards to ensure zero-defect products.

Why Choose ANJALI T. PRECISION?

✔ Advanced Infrastructure

Our modern manufacturing facility in Pune is equipped with cutting-edge CNC machines and tools, allowing us to meet the most demanding machining requirements.

✔ Experienced Workforce

We have a team of highly trained engineers, CNC programmers, and operators who are passionate about delivering perfection.

✔ On-Time Delivery

We understand the importance of deadlines. Our streamlined workflow ensures timely deliveries without compromising on quality.

✔ Competitive Pricing

By optimizing our operations and processes, we offer the most competitive rates in the industry.

✔ End-to-End Solutions

From design review and raw material sourcing to machining, finishing, and final inspection – we offer complete CNC machining solutions under one roof.

Industries We Serve

Automotive

Aerospace

Medical Equipment

Defense & Military

Textile Machinery

Robotics & Automation

Electronics & Electrical

Heavy Engineering

Customer-Centric Approach

At ANJALI T. PRECISION, every client is important. We believe in building long-term partnerships based on trust, transparency, and technical excellence. Our support team ensures clear communication, quick response times, and personalized services to meet your project goals.

CNC Machining in Pune – The ANJALI T. PRECISION Advantage

Pune’s strategic location, skilled workforce, and proximity to major OEMs make it an ideal hub for CNC machining. With ANJALI T. PRECISION, you're not just hiring a manufacturer; you're partnering with a team that is committed to engineering excellence and precision craftsmanship.

Contact Us

ANJALI T. PRECISION – CNC Machining Manufacturer in Pune 📍Address: Gate 1652, 3M Industrial Estate, 1652, Dehu - Alandi Rd, Patilnagar, Chikhali, Pimpri-Chinchwad, Maharashtra 412114 📞 Phone: 092256 34833 📧 Email: [email protected] 🌐 Website:https://www.anjalitprecision.com/

Looking for a Reliable CNC Machining Partner in Pune?

Contact ANJALI T. PRECISION today and let us help you turn your designs into high-quality, precision-engineered reality.

#CNC Machining Manufacturer in Pune#CNC Machining Services Pune#Precision CNC Components#CNC Turning and Milling Pune#Custom CNC Parts Manufacturer#VMC Machining Services#CNC Job Work Pune#CNC Precision Engineering#Anjali T. Precision Pune#CNC Components Supplier India.

0 notes

Text

Reducing Friction Costs: PTFE Applications in Automotive Manufacturing

In the competitive world of automotive manufacturing, reducing friction costs isn��t just about improving efficiency—it’s about gaining a strategic advantage. Polytetrafluoroethylene (PTFE), commonly known as Teflon, has emerged as a game-changing material that significantly lowers friction-related expenses while enhancing vehicle performance and longevity. This article explores the innovative…

#automotive manufacturing#bearings#coatings#engine components#friction reduction#fuel systems#PTFE#seals#Teflon

0 notes

Text

#Engine Mounting Bracket#Engine Mounting Bracket Parts Supplier in India#automotive component manufacturers#auto parts Manufacturers In India#EV parts Manufacturing

0 notes

Text

#Aerospace & Defense Springs Market#Springs for Aerospace Applications#Defense Industry Components#Market Research Report#Aerospace Springs Demand#High-Performance Springs#Precision Engineering Components#Aircraft Suspension Systems#Military Equipment Springs#Market Size and Forecast#Spring Manufacturing Industry#Lightweight Springs for Aerospace#Durable Defense Springs#Technological Advancements in Springs#Global Aerospace Industry Trends#Competitive Landscape#Spring Applications in Defense#Emerging Markets for Aerospace Springs#High-Strength Alloy Springs#Aerospace Component Supply Chain

0 notes

Text

Find Reliable Automobile Engineering Components Manufacturers Near You

Find reliable Automobile Engineering Components Manufacturers Near You with G.M. Hi-Tech, a trusted name in precision automotive parts. Offering high-quality, durable, and advanced engineering solutions, G.M. Hi-Tech ensures top performance and efficiency for all your automotive needs. Partner with industry experts committed to innovation and excellence. Choose G.M. Hi-Tech for superior engineering components today!

0 notes

Text

Engine Component Manufacturing Companies in India: Sansera Engineering

Sansera Engineering is a leading name among engine component manufacturing companies in India, known for its expertise in producing high-quality, precision-engineered components for a range of industries, including automotive, aerospace, and industrial machinery. The company specializes in critical engine parts such as connecting rods, rocker arms, crankshafts, and camshafts, manufactured to meet stringent global standards. With advanced forging, machining, and assembly capabilities, Sansera delivers components that enhance engine performance, efficiency, and durability. By combining state-of-the-art technology, robust quality control, and a commitment to sustainability, Sansera Engineering continues to set benchmarks in engine component manufacturing, making it a trusted partner for global OEMs and tier-one suppliers.

0 notes

Text

Custom Metal Fabrication Solutions That Keep Aerospace Advancing

The aerospace industry is a demonstration of human ingenuity where each joint, part, and structure needs to function in perfect unison at high altitude and extreme speeds. At the heart of this marvel lies metal fabrication, a craft that has developed into a fundamental aspect of aircraft engineering, shaping the future of air travel with unparalleled precision and purpose.

The growth of industrial fabrication has changed the way we construct the skies. What once relied heavily on manual labour has now shifted toward smarter, more precise techniques. This shift is especially crucial in the aerospace industry, where even the smallest component plays a significant role in flight safety and performance.

#customised metal fabrication#metal fabrication solutions#metal fabrication#aerospace metal fabrication aerospace components#aerospace engine parts fabrication services in India.#custom aerospace metal fabrication services in India#precision aircraft component manufacturing in Ahmedabad

0 notes

Text

#Precision Machined Components#CNC Machining#Custom Machined Parts#Pune Manufacturing#Metal Fabrication#High-Precision Engineering#ANJALI T. PRECISION

0 notes

Text

Get the Best in Agriculture: Reliable Rotavator Components from Ludhiana

Agriculture is the backbone of our economy, and ensuring its success starts with reliable equipment. When it comes to sourcing durable, efficient, and high-quality rotavator components, SBJ Nirmal Products in Ludhiana stands out as a trusted name in the industry. In this blog, we’ll delve into what makes SBJ Nirmal Products the go-to choice for farmers worldwide.

Introduction to SBJ Nirmal Products and Its Mission

At SBJ Nirmal Products, our mission is simple yet impactful: to empower farmers with top-notch agricultural components that enhance productivity and minimize equipment downtime. With decades of expertise in manufacturing rotavator parts, we’re committed to quality, innovation, and customer satisfaction.

Why Choose Ludhiana for Agricultural Components?

Ludhiana, often referred to as the "Manchester of India," is a hub for industrial excellence. Its well-established infrastructure, skilled workforce, and commitment to quality make it the perfect base for manufacturing agricultural components.

A Hub of Quality Manufacturing: Ludhiana's factories are renowned for precision engineering and consistent quality.

Global Reach from a Local Base: From Ludhiana, SBJ Nirmal Products serves customers not only in India but also in Bangladesh, Nepal, Sri Lanka, and beyond.

The Importance of Reliable Rotavator Components

Reliable components are crucial for maximizing efficiency in agriculture. Here’s why:

Enhancing Agricultural Productivity: Quality rotavator parts ensure smooth soil preparation, leading to better crop yields.

Reducing Equipment Downtime: Durable components reduce the frequency of repairs, saving time and money.

SBJ Nirmal Products: A Legacy of Excellence

With over 4,500 rotavator parts in our portfolio, SBJ Nirmal Products has built a legacy of trust and excellence.

Trusted by Farmers Worldwide: Our components are designed to meet the diverse needs of farmers across the globe.

Key Features of Our Rotavator Components

At SBJ Nirmal Products, every component is crafted with precision and attention to detail. Here are some standout features of our rotavator parts:

Durability and Longevity: Built to withstand tough agricultural conditions, our components last longer, offering unmatched value.

Precision Engineering: Our parts are manufactured to exact specifications, ensuring perfect compatibility with a wide range of rotavator models.

Cost-Effectiveness: We provide high-quality products at competitive prices, making advanced agricultural technology accessible to all.

A Deep Dive into Popular Rotavator Components

Our extensive range of rotavator parts includes some of the most sought-after components in the market:

Crown Pinions: Designed for optimal torque and smooth operation, these are essential for high-performance rotavators.

Stub Axles: Known for their robustness, our stub axles ensure stability and reliability during field operations.

Rotavator Blades: Crafted from high-grade materials, these blades deliver efficient soil cutting and mixing, enhancing field preparation.

SBJ Nirmal’s Commitment to Quality and Innovation

Quality and innovation are the cornerstones of our manufacturing process. Here’s how we ensure excellence:

ISO-Certified Manufacturing Processes: Our production facilities adhere to the highest international standards.

Use of Advanced Technologies: From CAD design to CNC machining, we leverage cutting-edge technology to deliver superior products.

Sustainable Practices in Component Manufacturing

We are dedicated to sustainable manufacturing practices that benefit both the environment and the community:

Eco-Friendly Materials: Our components are made using materials that are sustainable and recyclable.

Minimizing Waste and Maximizing Efficiency: Advanced manufacturing techniques help us reduce waste and optimize resource use.

Testimonials: Farmers Speak About SBJ Nirmal Products

Our commitment to quality and service has earned us glowing reviews from farmers worldwide:

Real-Life Stories of Success: Many farmers have shared how our rotavator parts have transformed their operations.

Positive Feedback from Around the Globe: From India to Nepal, our customers praise the durability and efficiency of our products.

How to Purchase from SBJ Nirmal Products

We make it easy for farmers and dealers to access our products:

Online Ordering Options: Our website offers a seamless ordering experience, complete with detailed product descriptions and specifications.

Dealer Networks in India and Beyond: Our extensive network ensures prompt delivery and reliable after-sales support.

Conclusion: Elevate Your Farming Efficiency with SBJ Nirmal Products

When it comes to reliable, high-quality rotavator components, SBJ Nirmal Products in Ludhiana is a name you can trust. With a legacy of excellence, a commitment to innovation, and a focus on sustainability, we are dedicated to empowering farmers worldwide. Choose SBJ Nirmal Products and experience the difference in agricultural efficiency and productivity.

#rotavator components#reliable agricultural parts#SBJ Nirmal Products#rotavator parts manufacturer#Ludhiana agricultural parts#high-quality rotavator components#durable rotavator parts#precision engineering in agriculture#cost-effective rotavator parts#crown pinions#stub axles#rotavator blades#sustainable manufacturing#ISO-certified rotavator parts#global rotavator parts supplier#rotavator parts in India#buy rotavator components online#agricultural productivity#farming efficiency#trusted rotavator parts

0 notes

Text

Dasset Engineering: Your Partner in Automotive Spare Parts Excellence

For superior engine performance and reliable fastening solutions, Dasset Engineering is a trusted manufacturer, supplier, and wholesaler of automotive spares across India. Specializing in automotive spare parts manufacture, exporter, and supplier, Dasset Engineering delivers premium cylinder liners, cylinder blocks, crankshafts, connecting rods, pistons, and high-quality stainless-steel screws.

Premium Engine Components for Superior Performance

We manufacture premium cylinder liners designed to enhance engine efficiency and durability. Our product range includes cylinder blocks, crankshafts, connecting rods, and pistons, crafted with high-grade materials and advanced technology to meet modern engine demands.

Our cylinder liners ensure excellent heat dissipation, wear resistance, and longevity, making them ideal for industrial and automotive applications. From heavy machinery to performance engines, Dasset Engineering has you covered.

High-Quality Stainless-Steel Screws

Dasset Engineering also offers a diverse range of machine screws, self-tapping screws, self-drilling screws, and other specialized fasteners under the "Dasset Engineering" brand.

Made from 202, 304, and 316-grade stainless steel, these screws provide outstanding corrosion resistance and strength, suitable for industrial, construction, and domestic use.

Advanced Manufacturing and Quality Assurance

We use cutting-edge techniques and equipment in our manufacturing processes, ensuring every product meets the highest standards. Our quality control team conducts stringent checks at every stage to deliver flawless performance. Premium materials like 202, 304, and 316-grade stainless steel guarantee durability and reliability.

Why Choose Dasset Engineering?

Extensive Product Range: From engine components to fasteners, we cater to diverse needs.

Top Quality: Rigorous quality checks ensure outstanding performance.

Industry Expertise: Advanced manufacturing processes and a skilled team set us apart.

Trusted Wholesaler: Renowned for reliability and excellence across India.

Conclusion

Dasset Engineering is your go-to partner for automotive spare parts manufacture, exporter, and supplier in India. Whether you need durable engine parts or reliable fastening solutions, our products deliver unmatched quality and performance.

Trust Dasset Engineering to elevate your projects with premium components and fasteners - because quality isn’t just a promise, it’s our commitment.

#Dasset Engineering#Automotive spare parts manufacturer in India#Trusted wholesaler of automobile spares#Automotive spare parts exporting and supplying#High-quality connecting rods and pistons#Advanced engine components manufacturing

0 notes

Text

Shalin Design Provides CAD Design and Drafting Services for Mechanical Industries

Shalin Designs has established itself as a trusted provider of CAD design and drafting services for the mechanical industry. Specializing in both 2D and 3D CAD services for mechanical engineering, the firm supports manufacturers and mechanical engineers in streamlining design processes and enhancing product development.

Meeting Industry-Specific CAD Design Needs

Mechanical industries often rely on precise, well-structured designs, whether it's for mechanical product CAD design services or mechanical CAD drafting services for components and machinery. Shalin Designs understands these unique demands and delivers solutions tailored to meet exact specifications.

Our expertise extends across a wide spectrum of services:

Mechanical CAD Modeling Services: Create highly accurate models for parts, assemblies, and systems.

CAD Drafting for Mechanical Components: Convert ideas into detailed drawings that streamline the manufacturing process.

Mechanical Product CAD Drafting Services: Develop technical drawings and schematics for production.

Custom CAD Design for Mechanical Engineers: Support engineers with specialized, custom designs that meet industry standards.

Our clients frequently seek 3D CAD modeling for mechanical parts, particularly in industries where complex geometries and precision are paramount.

Why Shalin Designs Excels in CAD Drafting and Design

Unlike other providers, Shalin Designs places a focus on efficient project turnaround without compromising accuracy. Our use of cutting-edge CAD software and our team of experienced drafters and engineers ensures you receive detailed designs, ready for manufacturing. With CAD drafting for industrial machinery and mechanical products, we offer innovative solutions for both simple and complex projects.

Moreover, outsourcing CAD design services to us can help mechanical industries overcome resource challenges. Our clients from the USA, UK, Canada, and Australia frequently benefit from outsourcing as it cuts down costs and speeds up time-to-market.

The Benefits of CAD Design for the Mechanical Industry

Mechanical engineers rely on CAD design not only for accuracy but for visualization. Tools like 2D and 3D CAD services empower engineers to model their parts and components from every angle before committing to physical prototypes. This minimizes error and leads to more efficient production.

Furthermore, with mechanical CAD design solutions offered by Shalin Designs, firms can easily adapt designs for manufacturing processes. For instance, our mechanical part CAD design and drafting enables manufacturers to execute the production of components with confidence that the designs are correct.

How Our Services Support Manufacturers

One of the most critical aspects of mechanical design is ensuring compatibility between all parts. Shalin Designs offers CAD drafting for mechanical components that are easy to modify or scale for various production runs. This makes us an invaluable partner for companies dealing with production at different volumes.

When creating mechanical CAD drawings for manufacturing, precision is everything. Our designs offer clarity and precision, whether for large-scale industrial machinery or smaller mechanical parts. Clients often outsource CAD drafting to ensure they receive high-quality, production-ready designs at competitive rates.

Learn more about the How Mechanical CAD Drafting Services Enhance Manufacturing

Outsourcing CAD Design for Mechanical Engineering: A Strategic Choice

Outsourcing your mechanical CAD design needs can provide numerous advantages. Shalin Designs has worked with multiple industries and clients around the globe, offering mechanical CAD modeling services and CAD drafting for industrial machinery at scale. Our extensive experience allows us to handle projects with varying degrees of complexity, ensuring efficient and cost-effective results.

Companies looking to scale their operations or reduce internal workloads often turn to us for mechanical design and drafting outsourcing. By leveraging our expertise, your team can focus on core activities while we take care of the design process. Top 10 Benefits of Outsourcing Mechanical CAD Design Services.

Tools and Technology at Shalin Designs

We utilize the latest CAD software, ensuring precision and flexibility in all designs. Our mechanical CAD services extend to 2D drawings for documentation and 3D models that help visualize complex assemblies. This dual approach allows our clients to transition seamlessly from design to production.

Client Success Story: Helping a Mechanical Firm Streamline its Design Process

One of our clients, a mid-sized mechanical manufacturing firm, approached us to design CAD models for a new line of machinery. Their in-house team struggled with the complexity of the project and deadlines were approaching fast. Shalin Designs stepped in, providing mechanical product CAD drafting services and 3D CAD modeling for mechanical parts that helped them meet their launch date.

Not only did we deliver detailed designs, but our input allowed them to catch a critical error in one of the assembly layouts, saving them substantial costs during manufacturing. This example illustrates the importance of working with experienced CAD design professionals who understand the intricacies of mechanical components.

Conclusion

Shalin Designs is your trusted partner for mechanical CAD design and drafting services. Whether you're in need of custom CAD design for mechanical engineers, or seeking to outsource your CAD drafting for the mechanical industry, we have the expertise and resources to meet your needs.

Contact us today to learn how our services can help your business achieve more efficient design workflows, reduce production errors, and improve overall project outcomes.

#CAD Design for Mechanical Industry#Mechanical CAD Drafting Services#3D CAD Modeling for Mechanical Parts#Mechanical Engineering CAD Services#CAD Drafting for Mechanical Components#Mechanical Design and Drafting Outsourcing#CAD Design for Manufacturing Industry#Mechanical CAD Design Solutions#2D and 3D CAD Services for Mechanical Engineering#Mechanical Product CAD Design Services#Mechanical CAD Modeling Services#Outsource CAD Drafting for Mechanical Industry#CAD Drafting for Industrial Machinery#Mechanical Part CAD Design and Drafting#Custom CAD Design for Mechanical Engineers#Mechanical Product CAD Drafting Services#Mechanical CAD Drawings for Manufacturing#Shalin Designs

0 notes