#industrial components

Explore tagged Tumblr posts

Text

The Essential Role of Alloys in Heavy-Duty Machinery: Uni Deritend’s Commitment to Reliability

In heavy-duty machinery, alloys play a crucial role in ensuring that components can withstand the toughest environments. Whether it’s construction equipment, automotive parts, or aerospace components, the strength, durability, and performance of these materials are critical. Uni Deritend has long been a leader in providing advanced alloy solutions that meet the demanding needs of various industries.

Uni Deritend specializes in producing high-performance nickel alloys, stainless steel alloys, and aluminum alloys that offer exceptional strength, heat resistance, and corrosion resistance. These properties are essential for parts that must endure extreme conditions like high pressures, intense temperatures, and constant wear.

With decades of expertise in investment casting and precision manufacturing, Uni Deritend ensures that every component is reliable, durable, and capable of performing at the highest standards. Their use of cutting-edge casting technologies and a commitment to quality control make them a trusted partner in providing reliable components for heavy-duty machinery.

At Uni Deritend, we continue to push the boundaries of alloy innovation to meet the future demands of industrial engineering and keep machinery running smoothly and efficiently.

#Alloy Solutions#Heavy-Duty Machinery#Industrial Components#Precision Casting#Nickel Alloys#Stainless Steel Alloys#Industrial Engineering

0 notes

Text

Application of steel fibres for concrete reinforcement

In the continually changing landscape of construction and civil engineering, the need for strong and high-performance materials has never been more pronounced. One such development that has revolutionized concrete reinforcement is the application of steel fibres in concrete. Ranging from strengthening mechanical properties to enhancing crack resistance and durability, steel fibres are quickly becoming an essential part of contemporary infrastructure. This blog is going to discuss the uses of steel fibres in concrete reinforcement, their kind, advantages, and why Kinetic Industries is a name to be reckoned within steel fibre suppliers and manufacturers.

What Are Steel fibres?

Steel fibres are discrete lengths of steel, short in nature, which are randomly oriented and distributed in the concrete mixture. They serve as crack arresters and add post-cracking strength, thereby making the concrete tougher and more resilient. They are usually between 0.25 mm and 1 mm in diameter and are available in different shapes like hooked, crimped, or straight.

These fibres are produced from high-tensile wire, cut sheet, or even melt-extracted stainless steel, and are added to concrete in certain proportions based on structural demands.

Steel fibre Reinforced Concrete: A Game-Changer

When steel fibres are introduced into concrete, they form Steel fibre Reinforced Concrete (SFRC). The composite material significantly enhances the resistance of concrete against cracking, fatigue, and impact loading. SFRC performs particularly well in applications where the use of conventional rebar reinforcement is not possible or economical.

At Kinetic Industries, we design high-performance concrete steel fibres up to international specifications to suit a broad range of industrial and infrastructure applications.

Applications of Steel fibres in Concrete

Applications of steel fibres are numerous and cut across different industries because of their unique performance traits. Some of the most prevalent applications include:

1. Industrial Floors and Pavements

SFRC is best suited for industrial flooring because of its capacity to withstand intense wheel loads as well as thermal shock. Warehouses, loading docks, and airport pavements significantly gain from the toughness provided by steel fibre reinforcement.

2. Tunnels and Underground Structures

Subways, underground parking garages, and tunnels are usually subjected to severe environmental conditions. Steel fibres in concrete improve load capacity and reduce maintenance.

3. Precast Concrete Components

Precast components such as wall panels, manholes, and pipes utilize concrete steel fibres to increase resistance to mechanical stress and damage during handling.

4. Shotcrete Applications

In civil engineering applications like slope stabilization, mining, and tunnel linings, steel fibre reinforced concrete in shotcrete form provides improved adhesion and structural strength.

5. Bridges and Dams

Structural requirements for bridges and dams call for concrete that resists tensile and flexural stress. Stainless steel fibres added to the concrete guarantee durable performance even under severe loading conditions and exposures.

Benefits / Advantages of Steel fibres

The benefits of steel fibres in reinforcing concrete are far-reaching:

Better Crack Resistance

Steel fibres assist in regulating micro-cracks and avoid their progression to macro-cracks.

Better Flexural Strength

Steel fibre reinforced concrete exhibits greater flexural strength, minimizing the necessity for traditional reinforcement.

Longer Durability and Longevity

Steel fibres enhance the impact resistance, fatigue resistance, and toughness of concrete, making it ideal for aggressive environments.

Earlier and Quicker Construction

With the use of steel fibres, the requirement for conventional reinforcement bars can be eliminated or minimized, reducing on-site time and labor expenses.

Lower Maintenance Expenses

Steel fibre reinforced concrete structures have lower maintenance throughout their lifespan because of enhanced structural integrity.

Steel fibres Types

There are various types of steel fibres, each suitable for particular structural demands:

Hooked-End fibres:

These are the most widely used, providing maximum bonding with the concrete matrix.

Crimped fibres:

Used to increase frictional bonding and are suitable for general applications.

Straight fibres:

Typically utilized in applications requiring lower strength or where mixing uniformity is desired.

Stainless Steel fibres:

Corrosion-resistant and suitable for marine or chemically aggressive environments.

We at Kinetic Industries produce and supply an extensive range of steel fibre varieties to fulfill your exact construction requirements.

Why should Kinetic Industries be Your Steel fibre Supplier?

As one of the major steel fibre producers and suppliers, Kinetic Industries offers innovative reinforcement solutions with reliability and economy. We are dedicated to innovation in product quality as well as application technology. Our series of engineering parts and industrial parts, such as concrete steel fibre, are strictly tested for durability and performance under the most severe conditions.

With Kinetic Industries, you benefit from:

Professional technical assistance

Tailor-made fibre solutions

Bulk transportation and logistics support

Environmental sustainability commitment

Steel fibre Reinforcement in the Indian Economy

India’s developing infrastructure and industrial sector is placing a gargantuan order for high-performance building materials. According to recent studies, the international market for steel fibre reinforced concrete is projected to grow phenomenally, and India is at the center of this boom.

Construction companies are increasingly abandoning conventional reinforcement in favor of steel fibres for reinforcing concrete, particularly for metro rail construction, smart cities, industrial parks, and road building. At Kinetic Industries, we are happy to facilitate this expansion with efficient and innovative reinforcement products.

The use of steel fibres in reinforcing concrete is revolutionizing the way we construct and safeguard infrastructure. Greater strength, lower maintenance, and cost-saving benefits are no longer an option—steel fibres are becoming a requirement.

Whether it’s constructing tunnels, industrial flooring, or precast parts, Kinetic Industries has the appropriate types of steel fibres and solutions specific to your project requirements.

Are you ready to elevate your construction projects to the next level?

Collaborate with Kinetic Industries — a top steel fibre manufacturer and supplier in India.

#steel fibers for concrete#Steel Fibers#Concrete Steel Fiber#Steel fibers types#steel fibers for concrete reinforcement#stainless steel fibers#steel fiber manufacturers#steel fiber Suppliers#steel fiber reinforced concrete#steel fiber reinforcement#industrial components#engineering components

0 notes

Text

Shiv Sai Enterprises: The One-Stop Shop for Ball & Roller Bearings, Oil Seals & Grease

High-quality parts are essential for lifetime and performance in both industrial machines and vehicle maintenance. We at Shiv Sai Enterprises are proud to be your one-stop shop for all of your needs related to grease, oil seals, and ball and roller bearings. Our large collection guarantees that you will find the appropriate product for every application, whether you work in manufacturing, auto repair, or machinery service.

Shiv Sai Enterprises commitment to excellence ensures that our clients receive the best in performance and value. Partner with us for your essential mechanical component needs and experience unmatched service. The supplier company is located in Amritsar, Ludhiana, Jalandhar, Patiala, Bathinda, and Pathankot, and is one of the leading sellers of listed products.

Why Choose Shiv Sai Enterprises?

Wide Range of Products: We offer stability and duration by offering a large selection of ball bearings, roller bearings, oil seals, and industrial grease from top manufacturers. We can supply you with high-speed, precise bearings or strong seals.

Premium Quality Assured: We understand that substandard components can lead to operational inefficiencies and costly downtimes. That’s why we source our products from trusted manufacturers, ensuring that every item meets industry standards for superior performance.

Expert Guidance & Support: Are you sure which is better for your purposes, a seal or a bearing? Our knowledgeable staff is always on hand to provide expert advice and help you choose the best products for your specific requirements.

Competitive Pricing: We are dedicated to offering premium goods at reasonable costs so that companies of all kinds can get the greatest industrial solutions without going over cost.

Reliable and Timely Delivery: Time is money, and we respect yours. Our streamlined supply chain ensures prompt and hassle-free delivery, so you never have to worry about delays in your projects.

Our Product Categories

1. Ball & Roller Bearings

Bearings are essential for smooth mechanical motion. We stock a wide variety, including:

Deep groove ball bearings

Angular contact bearings

Tapered roller bearings

Spherical roller bearings

2. Oil Seals: Oil seals prevent leaks and contamination in machinery. We provide high-performance seals for different industrial and automotive applications, ensuring longevity and efficiency.

3. Industrial Grease & Lubricants: Proper lubrication enhances machine efficiency and extends lifespan. Our range of high-quality grease and lubricants helps maintain friction-free performance.

Serving a Wide Range of Industries

We proudly serve businesses across multiple industries, including:

Automotive & Transportation

Manufacturing & Engineering

Construction & Heavy Equipment

Power Generation & Oil Refineries

Get in Touch

We at Shiv Sai Enterprises are dedicated to providing premium goods and outstanding customer service. We can help you whether you need a single bearing or large industrial supplies. Contact us immediately and experience reliability like none before!

📞 Call us at: 8700621262

📍 Visit us at: 61 No, 2nd Floor, Taj Building, G.B. Road, Delhi-110006 Delhi, Delhi, (India)

📧 Email us at: [email protected]

Stay ahead in your industry with Shiv Sai Enterprises – The Trusted Name in Bearings, Oil Seals, and Grease!

#Leading Manufacturer#Rubber Oil Seals#Grease Lubrication System#Mechanical Components#industrial Components#Quality Products

0 notes

Text

Quality Filters, Bearings, and Electrical Components | TGP India

Explore a wide range of top-notch filters, bearings, and electrical components at TGP India. Find reliable solutions for your industrial needs.

0 notes

Text

DISTRIBUTORS OF SEMICONDUCTORS AND INDUSTRIAL COMPONENTS.

FOR MORE VISIT:

0 notes

Photo

MAURIZIO CATTELAN / UNTITLED, 2001 Couple of elevators (scale 1:7,5), stainless steel, electronic components 35 x 59.5 x 26.3 cm | 23 1/2 x 33 3/4 x 18 inch

#mauri zcatelan#installation#stainless steel and electronic components#contemporary#industrial design#mechanism#beatrex mechanism#2001#surrealism

4K notes

·

View notes

Text

#animated gif#animated gifs#gif#gifs#old advertisements#old ads#retro#old film#golden components#rotating#spinning#ignore the wires#looping gif#I SAID IT'S A LOOPING GIF#60s#KPLY Industries

20 notes

·

View notes

Text

Post-2018 revisions Bochum Components (& Elektra) but they're a German Industrial band. What do we think of this one

#starlight express#stex components#Aggrotech‚ EBM‚ Industrial Metal... that's all that they would play#Joule would be the guitarist. Volta the synth player. Wrench the drummer. Killerwatt on da bass. Elektra on vocals#i need to make an entire post about this ooh lord

14 notes

·

View notes

Text

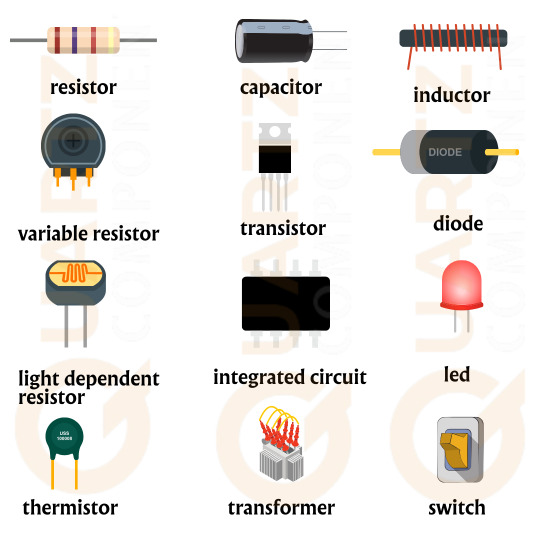

IMPORTANT QUESTIONS OF ELECTRONICS FOR COMPETITIVE TEST PREP. ❤️

Impact of Semiconductor Technology on Everyday Life Discuss the influence of semiconductors on modern communication and connectivity. Explain how they power artificial intelligence and machine learning. Highlight the role of semiconductors in the development of advanced medical technologies. The primary knoledge you nee to know about curcuits , diode , register and transister , also know about , how does it works?

LEARN ABOUT NETWORKING WITH SEMI-CONDUCTOR 👈

The most used semiconductor material is silicon, which is widely used in producing integrated circuits (ICs), also known as microchips. These chips contain multiple transistors, which act as switches that allow the flow of electricity to be controlled, enabling complex electronic functions.

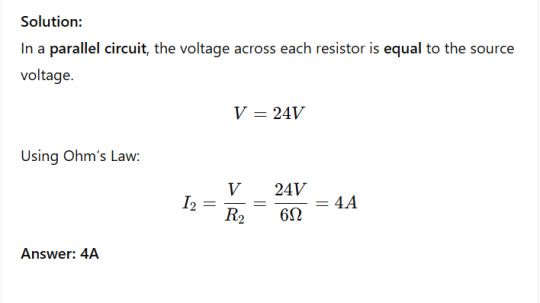

Current in a Parallel Circuit

Problem:vA 24V battery is connected to three resistors in parallel: R₁ = 4Ω, R₂ = 6Ω, and R₃ = 12Ω. Find the current through R₂.

JOIN US WITH US FOR FREE VIDEO TUTORIAL 👈

#electronics components#electronics store#electronics manufacturing#electronics industry#appliances#surfaces#semiconductor#technologie#electricalsafety#network marketing#network security#services#online tutoring#online education#online courses#digital learning

3 notes

·

View notes

Text

Shiv Sai Enterprises: Trusted Wholesaler of Industrial Bearings & Seals

Shiv Sai Enterprises is a leading manufacturer and wholesaler of ball bearings, roller bearings, rubber oil seals, and grease lubrication systems in India. Serving Amritsar, Ludhiana, Jalandhar, Patiala, Bathinda, and Pathankot, we deliver essential mechanical components with unmatched service. Contact us for more details.

#Leading Manufacturer#Rubber Oil Seals#Grease Lubrication System#Mechanical Components#industrial Components#Quality Products#Grease

0 notes

Text

i'm not a DNI person but actually do not fw me if you're like this

#what a pretentious POS#fuck gatekeeping!!! if you wanna use the sadgrl layout do it!!#if you wanna collect blinkies and buttons from gifcities DO IT!!#gatekeeping fucking OLD WEB DESIGN is LOSER BEHAVIOR and will NOT be tolerated at melis industries#newsflash - my neocities is based on the sadgrl layout#heavily modified and customized#BUT is has helped me learn CSS and HTML!!! it is a GODSEND!#sadgrl and yesterweb in general is a GODSEND!!#i've looked at how people create navigation buttons and other components#and applied these tactics to my own site!#old web is about taking inspiration from each other!!!#FUCK this commenter!

21 notes

·

View notes

Text

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

13 notes

·

View notes

Text

https://salesdji.com/

Dj International EST. 1995 and Based In Delhi have been serving in the Semiconductor and the Industrial Components Industry for more than 25 years. We Distribute products all over India with efficient and fast shipping to all states. our Products are: IGBT(INSULATED GATE-BIPOLAR TRANSISTOR),IPM(INTELLIGENT POWER MODULE),SNUBBER MODULE,FAST RECOVERY DIODES,AC CAPACITORS Know more: https://salesdji.com/

1 note

·

View note

Text

Connectors Market 2025: Size, Growth, and Key Players Analysis

Global Connectors Market: Insights, Trends, and Future Outlook

The global connectors market is experiencing unprecedented growth, driven by technological advancements and the increasing need for reliable, high-speed connectivity across industries. As digital transformation accelerates, the demand for high-performance connectors—capable of facilitating seamless communication between electronic devices—continues to surge. From telecommunications and data centers to automotive and industrial automation, connectors play a crucial role in ensuring the functionality of modern infrastructure.

In this article, we explore the key drivers, challenges, market dynamics, and segment-wise opportunities in the global connectors market, providing a comprehensive overview to guide industry stakeholders, investors, and decision-makers.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40612-global-connectors-market

Key Drivers of Growth in the Connectors Market

1. Telecommunications and High-Speed Data Transmission

The increasing demand for high-speed data transmission, particularly in telecommunications, is a primary driver of market growth. With the expansion of 5G networks, the need for connectors capable of handling higher frequencies and bandwidth is critical. Connectors designed for 5G RF applications are essential for enabling faster and more reliable communication in next-generation wireless infrastructures.

2. Electric Vehicles (EVs)

The automotive sector, especially the growing market for electric vehicles (EVs), is one of the key contributors to the rising demand for advanced connectors. EVs require specialized connectors capable of withstanding high power loads while ensuring safety and reliability in harsh environmental conditions. Connectors used in EV charging systems, battery management systems, and vehicle communication systems must meet stringent standards for durability and performance.

3. Industrial Automation and IoT

The rapid adoption of Industrial Internet of Things (IIoT) technologies and smart manufacturing is driving the demand for high-performance connectors. These connectors are used in a wide range of applications, including factory automation, robotics, and machinery. The need for connectors that can handle high speeds and power densities, while maintaining signal integrity, is growing as industries continue to embrace automation.

4. Data Centers and Cloud Computing

The proliferation of cloud computing and the expansion of data centers are also fueling demand for connectors that support high-speed data transmission. As the volume of data continues to grow exponentially, data centers require connectors that ensure efficient and reliable communication between servers, networking equipment, and storage systems. The fiber optic connectors segment, in particular, is benefiting from the increasing reliance on low-latency communication networks.

5. Consumer Electronics

The surge in demand for consumer electronics, such as smartphones, wearables, and home appliances, is also driving the connectors market. These devices require small, efficient, and durable connectors that can support data transmission, power supply, and device interconnectivity.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40612-global-connectors-market

Challenges Facing the Connectors Market

1. Rising Manufacturing Costs

Advanced connector technologies often come with high manufacturing costs, especially for specialized connectors used in high-speed, high-power applications. These costs can limit the accessibility of connectors in certain industries, particularly those operating with tight margins. Manufacturers must focus on streamlining production processes and adopting cost-effective materials to mitigate this challenge.

2. Competition from Wireless Solutions

While connectors remain crucial for wired communication and power delivery, competition from wireless connectivity solutions is on the rise. The growing adoption of Wi-Fi, Bluetooth, and other wireless protocols is reducing the demand for certain types of connectors, particularly in consumer electronics and some industrial applications.

3. Fluctuating Raw Material Prices

The price volatility of raw materials, such as metals used in connector manufacturing, can impact production costs. For example, fluctuations in the prices of copper and aluminum can affect the cost structure of connectors, leading to challenges in maintaining profit margins.

4. Technological Complexity

As connectors become smaller, faster, and more capable, the design complexity increases. Meeting the performance demands of modern applications, such as ultra-high-speed data transfer, miniaturization, and high-power density, requires continuous innovation and significant investment in research and development.

Connectors Market Trends: Innovations Shaping the Future

1. Miniaturization and Compact Design

One of the most significant trends in the connectors market is the miniaturization of connectors. As devices become smaller, the need for compact connectors that deliver the same level of performance becomes essential. This trend is particularly evident in the consumer electronics and wearable device segments, where connectors must be small enough to fit in slim designs while maintaining signal integrity.

2. Sustainability and Energy Efficiency

With growing environmental concerns, the push for sustainable manufacturing and energy-efficient connectors is intensifying. The industry is increasingly focused on reducing the carbon footprint of connector production and ensuring that products are recyclable. Additionally, energy-efficient connectors are in high demand for applications such as power transmission and electric vehicles, where optimizing energy consumption is a priority.

3. High-Power Connectors for EVs

The electric vehicle (EV) market is driving the development of connectors that can handle higher power densities. High-power connectors are critical for efficient battery management systems and charging stations, ensuring safe and reliable energy transmission in electric vehicles.

4. High-Speed Connectors for Data-Centric Applications

The demand for high-speed connectors is soaring due to the increasing reliance on data-centric applications like cloud computing, 5G, and artificial intelligence (AI). These connectors are designed to handle large volumes of data with minimal signal loss, ensuring that data transfer rates remain high and latency is kept low.

5. Smart Manufacturing and Industry 4.0

As industries embrace Industry 4.0, there is a growing need for connectors that can support smart manufacturing processes. These connectors enable the interconnection of machinery, sensors, and devices in automated environments, facilitating real-time monitoring, control, and data analysis.

Segmental Analysis: Insights into Key Market Categories

1. By Connector Type

The connectors market is segmented into several types, each catering to different industrial needs:

PCB Connectors: These connectors are essential in telecommunications, computing, and consumer electronics, where high-speed data transmission is critical. They are expected to witness significant growth due to the increasing use of printed circuit boards (PCBs) in various applications.

I/O Connectors: Used extensively in computer systems, I/O connectors are fundamental for external device connectivity, such as USB, HDMI, and Ethernet.

Fiber Optic Connectors: With the rise in demand for high-bandwidth applications, the fiber optic connectors segment is set to grow rapidly, driven by the need for low-latency communication.

RF Coaxial Connectors: These connectors are used in radio-frequency applications and are critical for telecommunications and broadcasting.

2. By Application

The connectors market is also segmented by application, with data communication, power transmission, and signal transmission being key areas of focus:

Data Communication: As the need for faster, more reliable data transmission grows, the demand for connectors in data centers, cloud computing, and telecommunication infrastructure is increasing. The data communication segment is expected to see consistent growth, particularly driven by the expanding use of 5G networks and AI technologies.

Power Transmission: With industries moving toward more sustainable and energy-efficient practices, connectors used in power transmission systems are becoming crucial. This segment includes connectors for renewable energy systems, power grids, and electric vehicles.

Signal Transmission: Used in applications such as networking and broadcasting, connectors for signal transmission are vital to maintaining signal quality and ensuring reliable communication.

3. By Geography

Geographically, the connectors market is segmented into North America, Europe, Asia Pacific, South America, and Middle East & Africa:

North America is expected to dominate the market, driven by technological advancements and the increasing demand for high-speed data transmission across industries like telecommunications, automotive, and consumer electronics.

Europe is also poised for significant growth, particularly in the automotive sector, where electrification and the adoption of advanced manufacturing techniques are propelling the demand for connectors.

Asia Pacific is a key market, with countries like China, Japan, and South Korea at the forefront of electronics manufacturing and industrial automation, leading to a rise in connector demand.

Competitive Landscape: Leading Players in the Connectors Market

The global connectors market is highly competitive, with several key players driving innovation and market growth. Leading companies include:

TE Connectivity

Amphenol Communications Solutions

Phoenix Contact

Smiths Interconnect

Samtec

ITT Inc.

Huawei Technologies Co., Ltd.

Nexans SA

These companies are investing heavily in product innovation, partnerships, and technological advancements to maintain their market position. Recent developments include the launch of 5G RF connectors by TE Connectivity and high-performance connectors for wearable devices by FOXCONN in collaboration with BYCHIPS Limited.

Conclusion: A Promising Future for the Connectors Market

The global connectors market is positioned for robust growth, driven by the increasing demand for high-speed data transmission, the rise of electric vehicles, and the rapid expansion of data centers and cloud computing. As industries continue to evolve, connectors will play a pivotal role in ensuring the smooth operation of interconnected systems. With advancements in miniaturization, energy efficiency, and sustainability, the market is expected to see continued innovation and growth in the coming years.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40612-global-connectors-market

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Connectors Market#Market Growth#Global Connectors#Industry Trends#Market Forecast#Connector Technology#Electronic Components#Connector Demand#Automotive Connectors#Industrial Connectors#Market Analysis#Connectors Industry#Key Players#Connector Innovations#Market Insights

1 note

·

View note

Text

Top 5 Automotive Companies and How Metalman Auto Ltd. Supports Them

The automotive industry is dominated by several key players that lead the market in terms of innovation, production, and market share. The top five automotive companies globally are typically considered to be Toyota, Volkswagen Group, Daimler AG (Mercedes-Benz), Ford Motor Company, and General Motors (GM).

How Metalman Auto Ltd. Supports These Automotive Giants

As a leading supplier of high-quality automotive components, Metalman Auto Ltd. is well-positioned to support these top automotive companies. Our expertise in metal fabrication and assembly allows us to provide critical components that meet the specific needs of these manufacturers.

Our Value Proposition:

High-Precision Components: We provide parts that are essential for the safety and performance of vehicles, adhering to the exact specifications required by these top manufacturers.

Collaborative Approach: We work closely with OEMs to understand their needs and provide innovative solutions that enhance vehicle performance and safety.

Sustainable Manufacturing: Our commitment to sustainable practices ensures we contribute positively to the automotive industry’s environmental goals.

By partnering with Metalman Auto, these top automotive companies can enhance their supply chain efficiency and maintain their competitive edge in the global market.

#EV components supplier#Electric car parts manufacturer#Battery components supplier for EVs#Electric vehicle drivetrain parts supplier#EV charging components manufacturer#Electric motor parts supplier#EV battery management system supplier#Electric scooter parts manufacturer#general motors#vintage automobiles#chevrolet#Volkswagen Group#automotive industry#automotive#automotive components#metal fabrication#oems#oemparts#oem manufacturing#oem#metal parts supplier#India automotive components manufacturer#Automobile parts production in India#OEM parts manufacturing in India#Indian automotive parts supplier#Vehicle parts manufacturing industry in India#Made in India automotive components#Indian car parts production#India-based automotive parts manufacturer"

2 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes