#Advanced engine components manufacturing

Explore tagged Tumblr posts

Text

Dasset Engineering: Your Partner in Automotive Spare Parts Excellence

For superior engine performance and reliable fastening solutions, Dasset Engineering is a trusted manufacturer, supplier, and wholesaler of automotive spares across India. Specializing in automotive spare parts manufacture, exporter, and supplier, Dasset Engineering delivers premium cylinder liners, cylinder blocks, crankshafts, connecting rods, pistons, and high-quality stainless-steel screws.

Premium Engine Components for Superior Performance

We manufacture premium cylinder liners designed to enhance engine efficiency and durability. Our product range includes cylinder blocks, crankshafts, connecting rods, and pistons, crafted with high-grade materials and advanced technology to meet modern engine demands.

Our cylinder liners ensure excellent heat dissipation, wear resistance, and longevity, making them ideal for industrial and automotive applications. From heavy machinery to performance engines, Dasset Engineering has you covered.

High-Quality Stainless-Steel Screws

Dasset Engineering also offers a diverse range of machine screws, self-tapping screws, self-drilling screws, and other specialized fasteners under the "Dasset Engineering" brand.

Made from 202, 304, and 316-grade stainless steel, these screws provide outstanding corrosion resistance and strength, suitable for industrial, construction, and domestic use.

Advanced Manufacturing and Quality Assurance

We use cutting-edge techniques and equipment in our manufacturing processes, ensuring every product meets the highest standards. Our quality control team conducts stringent checks at every stage to deliver flawless performance. Premium materials like 202, 304, and 316-grade stainless steel guarantee durability and reliability.

Why Choose Dasset Engineering?

Extensive Product Range: From engine components to fasteners, we cater to diverse needs.

Top Quality: Rigorous quality checks ensure outstanding performance.

Industry Expertise: Advanced manufacturing processes and a skilled team set us apart.

Trusted Wholesaler: Renowned for reliability and excellence across India.

Conclusion

Dasset Engineering is your go-to partner for automotive spare parts manufacture, exporter, and supplier in India. Whether you need durable engine parts or reliable fastening solutions, our products deliver unmatched quality and performance.

Trust Dasset Engineering to elevate your projects with premium components and fasteners - because quality isn’t just a promise, it’s our commitment.

#Dasset Engineering#Automotive spare parts manufacturer in India#Trusted wholesaler of automobile spares#Automotive spare parts exporting and supplying#High-quality connecting rods and pistons#Advanced engine components manufacturing

0 notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Microelectromechanical Systems Mems Supplier | Shenzhen Informic Electronic Limited

Working with a trusted Microelectromechanical Systems MEMS Supplier like Shenzhen Informic Electronic Limited offers key benefits, including access to cutting-edge technology, high-quality components, and reliable performance for advanced electronics. We provide innovative MEMS solutions tailored to meet the unique needs of engineers and manufacturers. Visit us.

#MEMS Supplier China#Microelectromechanical Systems Components#MEMS Technology Provider#High-Performance MEMS Solutions#MEMS for Electronics Manufacturing#Trusted MEMS Distributor#MEMS Components for Engineers#Shenzhen MEMS Manufacturer#Custom MEMS Solutions#Advanced MEMS Electronics Supplier

0 notes

Text

#Aerospace & Defense Springs Market#Springs for Aerospace Applications#Defense Industry Components#Market Research Report#Aerospace Springs Demand#High-Performance Springs#Precision Engineering Components#Aircraft Suspension Systems#Military Equipment Springs#Market Size and Forecast#Spring Manufacturing Industry#Lightweight Springs for Aerospace#Durable Defense Springs#Technological Advancements in Springs#Global Aerospace Industry Trends#Competitive Landscape#Spring Applications in Defense#Emerging Markets for Aerospace Springs#High-Strength Alloy Springs#Aerospace Component Supply Chain

0 notes

Text

"For [Tanner] Green, the chief engineer at Not a Wheelchair, this is one of the thousand complications standing between his team and a rather lofty goal: upending the manual wheelchair marketplace.

If you’ve heard of Not a Wheelchair, it’s likely because of its owners, Zack Nelson, the star of the 8.8-million-subscriber YouTube channel JerryRigEverything, and his wife Cambry, a para and manual wheelchair user. The Nelsons got into the mobility equipment business a few years ago when they released The Rig, an electric, adaptive off-road device with a simple yet robust and functional design priced significantly lower than anything else on the market. Now, they’re bringing that same ethos to manual wheelchairs.

Not a Wheelchair aims to offer a base-model, custom manual wheelchair at a similar or better quality than most of the insurance-approved wheelchairs in the U.S. for $999.

Yes, that’s just under $1,000 for everything — wheels, handrims, tires, side guards and rigid, angle-adjustable backrest included. And the company plans to have a turnaround time of weeks, rather than the monthslong slog that it typically takes from order to delivery.

When I first heard about this, it sounded awesome and a bit far-fetched. It’s hard to find a pair of quality wheelchair wheels for less than $500. Same with a rigid backrest. How were they going to offer both, plus a custom wheelchair frame without compromising on quality? I drove to their headquarters in Utah to find out...

So how does Not a Wheelchair’s base model chair stack up to other options on the market? I hate to sound like a preacher, but … it’s totally reasonable! It hits the mark of being at least as good, if not better, than the majority of insurance-approved wheelchairs in the U.S.

Touring the factory, I saw other prototypes scattered all around the facility. There’s a beefier, four-wheel drive version of The Rig that the company just launched. There’s a track wheelchair that’s still in development. It’s clear that Not a Wheelchair doesn’t intend to stop at a simple, manual wheelchair. Inexpensive components, more advanced electric off-road devices, power assist, it’s all on the table. “We’re just really excited to see where this leads,” says Green."

youtube

-Article and video via New Mobility, October 1, 2024

#wheelchair#mobility aid#wheelchair user#disabilties#disability#disabled#accessibility#mobility support#good news#hope#Youtube

3K notes

·

View notes

Text

The Automotive Elastomer Market is Led by the APAC Region

The automotive elastomers market was USD 34.6 billion in 2023, and it will power at a compound annual growth rate of 5.7% by the end of this decade, to touch a value of USD 50.6 billion in 2030. The industry is mainly boosted by the growing requirement for novel cars and growing per-capita income. Also, governments’ strict standards and guidelines to reduce pollution levels, surge mileage, and…

View On WordPress

#automotive components#Automotive Elastomer Market#Automotive Industry#Design Flexibility#Durability#Elastic Materials#Elastomer Innovations#Industry Insights#Market dynamics#market trends#Material Engineering#Sealing Applications#Technological advancements#Tire Manufacturing#Vehicle Performance

0 notes

Text

adventures in aerospace

So I recently started working at Large Aircraft Manufacturer. (LAM) The plant I work at employs 30,000 people. The company as a whole employs 170,000. Usually you only hear about LAM when something goes wrong. But no matter how bumbling it seems from the outside, it's way worse on the inside.

Three months after my first day, I have been "graduated" from "training." In reality, I'm still completely worthless on the floor: the training center has given me a paltry subset of the production certificates I need to actually to do my assigned job. A commonly cited statistic at LAM is that a hundred men a day are retiring, each one representing decades of experience, walking out the door, forever. The training center is in the unenviable position of managing a generational replacement, and have resorted to shoveling heaps of zoomers through as fast as possible. (As one of the few people with a visible hairline and who is not wearing a Roblox graphic tee; I am frequently mistaken for an instructor, and asked where the bathroom is, what time the next class starts, etc)

In theory, the training center knows what shop I'm assigned to, and can simply assign me all the required classes. In practice, they do the absolute minimum amount of training in a desperate attempt to relive the crowding in their handful of computer labs and tell graduates to pick up their certs later.

Of course, the irresistible force of the schedule meets the immovable object of the FAA. If you don't have the required production certificate to perform a particular job, you don't touch the airplane. Full stop, end of story.

And so the curtain opens on the stage. It reveals a single senior mechanic, supervising a mechanic who finally received all the certs and is being qualified on this particular job, surrounded by another three trainees. Trainees are less than nothing, absolute scum. At best we can fetch and carry. Mostly we are expected to stay out of the way. And the senior mechanic is only senior in title. He is one of six assembler-installers who is certified to actually work on the plane, out of twenty people on the crew, and spends every day with a permanent audience. He is 23 years old.

("Mechanic"? If you think the jargon at your job is bad, try joining a company that's a century old. Assembler-installers are universally referred to as "mechanics", despite doing work that's nothing like what a car mechanic does, and who are generally paid far worse than FAA certified A&P mechanics. Mechanics are the 11 bravos of LAM, grunts, the single largest category of worker. The tip of the spear. Hooah!)

Large Aircraft Manufacturer is in a dilly of a pickle. All of its existing airframe designs are hilariously antiquated. It tried designing a brand new plane from a clean sheet, and lost billions of dollars to a decade-long integration hell. After that, to save money, it tried just tacking bigger engines on an older design without changing anything else, and the stupid things plowed into the ground in an excruciatingly public manner.

LAM is now trying a middle road. It is upgrading one of its designs that is merely middle aged, rather than ancient, and with proven, de-risked components built in-house, rather than scattering them to subcontractors across the world. And it's still blowing past deadlines and burning billions of dollars LAM really doesn't have to spare.

This is the program I've been assigned to.

Advanced Midbody - Carbon Wing has taken the bold step of just tacking on carbon fiber wings to a conventional aluminum fuselage. Shockingly, AMCW is now stuck in lightning strike testing, due to that troublesome join between conductive aluminum and conductive...ish carbon fiber. But LAM, confident as ever, or perhaps driven by complaints of its customers, has announced that full rate production will begin just next year. Thus the tide of newhires. According to the schedule, we're supposed to jerk from one wingset a month to one wingset a week. That's not going to happen, but, oh well, orders from above move down at the speed of thought, while reality only slowly trickles upwards.

"120 inch pounds? Really?"

I startle upright. I have observed one hundred pi bracket installs, and I will observe a hundred more before I can touch aircraft structure. This is the first disagreement I've witnessed. A more advanced trainee is questioning the torque spec on a fastener. It is not an entirely foolish question-- most sleeve bolts we use are in the 40 in-pounds range. Doubling it that is unusual. I cough the dust off my unused vocal cords and venture an opinion.

"Well hey I could look it up? I guess"

The lead mechanic glances at me, surprised that I'm still awake, then looks away. Excuse enough for me!

I unfold myself from the stool I've been sitting on for the last four hours then hobble over to the nearest Shared Production Workstation.

We do not get Ikea-style step by step instructions on how to put together the airplane. Like any company that's been around for long enough, LAM is a tangled wad of scar tissue, ancient responses to forgotten trauma. If you state a dimension twice, in two different places, then it is possible for an update to only change one of those dimensions, thereby making the engineering drawing ambiguous. Something real bad must have happened in the past as a result of that, so now an ironclad rule is that critical information is only stated once, in one place, a single source of truth.

As a result, the installation plan can be a little... vague. Step 040 might be something like "DRILL HOLE TO SIZE AND TORQUE FASTENERS TO SPEC". What hole size? What torque spec?

Well, they tell you. Eventually.

(Image from public Google search)

You are given an engineering drawing, and are expected to figure out how things go together yourself. (Or, more realistically, are told how it's done by coworkers) Step by step instructions aren't done because then dozens of illustrations would have to be updated with every change instead of just one, and drawings are updated surprisingly frequently.

Fasteners are denoted by a big plus sign, with a three letter fastener code on the left and the diameter on the right, like so: "XNJ + 8"

To get the actual part number, we go to the fastener callout table:

(Note the use of a trade name in the table above. There is nothing a mechanic loves more than a good trademark. Permanent straight shank fasteners are always called HI-LOKs™. It's not a cable tie, it's a Panduit™. It's not a wedgelock, it's a Cleco™. Hey man, pass me that offset drill. What, you mean a Zephyr™? Where'd the LAMlube™ go? This also means you have to learn the names of everything twice, one name on the installation plan, and one name it's referred to in conversation.)

We find XNJ on that table, and fill in the diameter: BACB30FM8A. Now we look up the spec table for that fastener:

The eagle eyed among you might note that there is no "diameter: 8" on that table. As a LAM mechanic, you are expected to simply know that "diameter" is measured in 32nds of an inch, which simplifies down to 1/4.

(LAM preserves many old-school skills like fraction reduction and memorizing decimal equivalents like this, like flies caught in amber. Not least is the universal use of Imperial units. Many American manufacturers have been browbeaten into adding parenthetical conversions. Not LAM! Any risk at all of a mechanic seeing a second number and using it by accident is too great, and anyway, it violates SSOT. Lengths are in inches and feet, weights are in pounds, volume is in gallons and if you don't like it then you can go eat shit!)

After 10 minutes of following references, I arrive at that table, print it off, highlight the correct row, and hand it off to my senior mechanic.

"Great, thanks."

Gratified that I have enhanced shareholder value, I sit back down, and immediately fall asleep. Another day living the dream.

(next post in this series)

425 notes

·

View notes

Note

Hello! First of all, thank you for the wonderful content! It's a real joy, and an enrichment, food for both the brain and the heart! I was wondering if through your treasures, you could find some writing notes/words/concepts/vocabulary relating to genetic engineering? Like...creating a virus, and a vaccine for it, modifying the virus so it has certain specific effects.... Thank you in advance!

Writing Notes: Virus & Vaccine

References How Viruses Work; Replication Cycle; Mutation, Variants, Strains, Genetically Engineering Viruses; Writing Tips; Creating your Fictional Virus & Vaccine

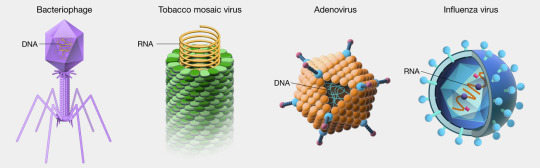

Virus - an infectious microbe consisting of a segment of nucleic acid (either DNA or RNA) surrounded by a protein coat.

It is a tiny lifeform that is a collection of genes inside a protective shell. Viruses can invade body cells where they multiply, causing illnesses.

It cannot replicate alone; instead, it must infect cells and use components of the host cell to make copies of itself. Often, a virus ends up killing the host cell in the process, causing damage to the host organism.

Well-known examples of viruses causing human disease include AIDS, COVID-19, measles and smallpox. Examples of viruses:

Viruses are even smaller than bacteria and can invade living cells—including bacteria. They may interfere with the host genes, and when they move from host to host, they may take host genes with them.

Bacteriophages (also known as phages)—viruses that infect and kill bacteria.

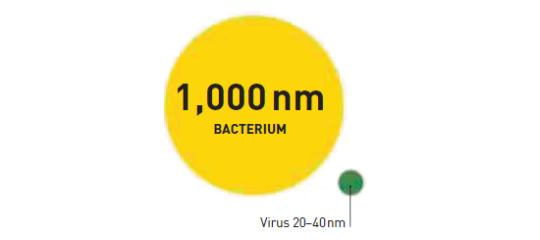

Size differential between virus and bacterium

Viruses are measured in nanometers (nm).

They lack the cellular structure of bacteria, being just particles of protein and genetic material.

How Viruses Work

Viruses use an organism’s cells to survive and reproduce.

They travel from one organism to another.

Viruses can make themselves into a particle called a virion.

This allows the virus to survive temporarily outside of a host organism. When it enters the host, it attaches to a cell. A virus then takes over the cell’s reproductive mechanisms for its own use and creates more virions.

The virions destroy the cell as they burst out of it to infect more cells.

Viral shedding - when an infected person releases the virus into the environment by coughing, speaking, touching a surface, or shedding skin.

Viruses also can be shed through blood, feces, or bodily fluids.

Virus Replication Cycle

While the replication cycle of viruses can vary from virus to virus, there is a general pattern that can be described, consisting of 5 steps:

Attachment – the virion attaches to the correct host cell.

Penetration or Viral Entry – the virus or viral nucleic acid gains entrance into the cell.

Synthesis – the viral proteins and nucleic acid copies are manufactured by the cells’ machinery.

Assembly – viruses are produced from the viral components.

Release – newly formed virions are released from the cell.

Mutations, Variants, and Strains

Not all mutations cause variants and strains. Below are definitions that explain how mutations, variants, and strains differ.

Mutation - errors in the replication of the virus’s genetic code; can be beneficial to the virus, deleterious to the virus, or neutral

Variants - viruses with these mutations are called variants; the Delta and Omicron variants are examples of coronavirus mutations that cause different symptoms from the original infection

Strains - variants that have different physical properties are called strains; these strains may have different behaviors or mechanisms for infection or reproduction

Genetically Engineering Viruses

Using reverse genetics, the sequence of a viral genome can be identified, including that of its different strains and variants.

This enables scientists to identify sequences of the virus that enable it to bind to a receptor, as well as those regions that cause it to be so virulent.

Vaccine - a special preparation of substances that stimulate an immune response, used for inoculation

Vaccines & Fighting Viruses with Viruses

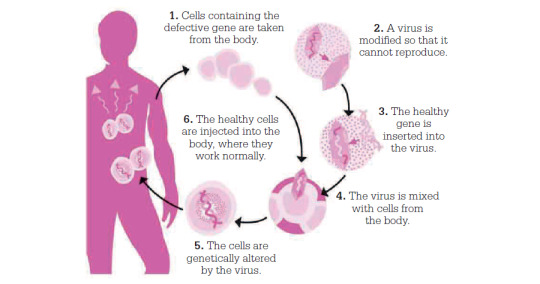

Common pathogenic viruses can be genetically modified to make them less pathogenic, such that their virulent properties are diminished but can still be recognized by the immune system to produce a robust immune response against. They are described as live attenuated.

This is the basis of many successful vaccines and is a better alternative than traditional vaccine development which typically includes heat-mediated disabling of viruses that tend to be poorer in terms of immunogenicity.

Viruses can also be genetically modified to ‘fight viruses’ by boosting immune cells to make more effective antibodies, especially where vaccines fail. Where vaccines fail, it is often due to the impaired antibody production by B-cells, even though antibodies can be raised against such viruses – including HIV, EBV, RSV & cold-viruses.

Related Articles: Modified virus used to kill cancer cells ⚜ Genetic Engineering ⚜ Engineering Bacterial Viruses ⚜ Benefits of Viruses

A Few Writing Tips

As more writers look to incorporate infectious diseases into their work, there are quite a few things writers should keep in mind:

Don’t anthropomorphize. Really easy to do, but scientifically wrong. Viruses don’t want to kill you; bacteria don’t want to infect you; parasites don’t want to make your blood curdle. None of these things are big enough to be sentient to want to do anything. They just do it (or don’t do it).

Personal protective equipment. This includes wearing gloves, lab coats, safety glasses, and tying your hair back if it’s long. It is the same as Edna Mode’s “no capes.” Flowing hair looks cool all the way to the explosive ball of flames that engulfs someone’s head.

Viruses are small. You can’t see viruses down a normal microscope—they need a special microscope called an electron microscope. These are highly specialized and take a long time to make the preparations to be able to see the virus. Normally viruses are detected by inference—measuring part of them using an assay that can amplify tiny amounts of material, for example PCR.

Viruses don’t really cause zombie apocalypses.

Vaccines work. But they take time. The best vaccine in the world will still only prevent infections two weeks after it is given. Drugs are quicker, but still take some time. But the good news is an infection is not going to kill you (or turn you into a zombie) quickly, so they both have time to work.

Scientists use viruses as a vector to introduce healthy genes into a patient’s cells:

Your Fictional Virus & Vaccine

When creating your own fictional virus, research further on the topic and consider choosing a specific one as your basis/inspiration.

Here's one resource. For some of them, you'll need a subscription to access, but those that are available give you a good overview of the virus, as well as treatment options.

You can do the same for creating your fictional vaccine:

Here's one resource. And here's one on vaccine developments.

Sources: 1 2 3 4 5 6 7 8 9 10 11 12 13 ⚜ Writing Notes & References

Lastly, here's an interesting article on how science fiction can be a valuable tool to communicate widely around pandemic, whilst also acting as a creative space in which to anticipate how we may handle similar future events.

Thanks so much for your kind words, you're so lovely! Hope this helps with your writing. Would love to read your work if it does :)

#writing notes#virus#vaccine#writeblr#dark academia#spilled ink#writing reference#writing prompt#literature#science#writers on tumblr#creative writing#fiction#novel#light academia#lit#writing ideas#writing inspiration#writing tips#science fiction#writing advice#writing resources

131 notes

·

View notes

Text

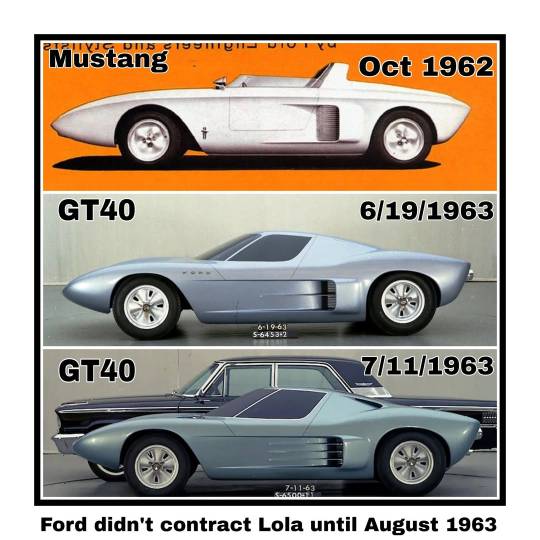

Evolution of a Legend: The Ford GT40's Origins in the Mustang-I

Before partnering with Lola on the GT Mk6 in August 1963, Ford's vision for the GT40 was heavily influenced by the sleek design of the Mustang-I. The prototype Ford GT's exterior was essentially based on the Mustang-I, showcasing a striking resemblance between the two. Notice the date on the picture.

As the project progressed, Ford opted to merge the best of both worlds. They took the redesigned Lola GT Mk6 chassis and wrapped the Mustang-I-inspired body around it, ultimately giving birth to the iconic Ford GT40. This fusion of design and engineering expertise would go on to create a racing legend.

TIMELINE:

October 7, 1962 - Mustang at Watkins Glen

October 20, 1962 - Mustang at Laguna Seca

October 26, 1962 - Lola Mk6 showed up incomplete at the London Car Show

January 1963 - Lola Mk6 first shown at UK Olympia Racing Car Show. Showed up three days late and incomplete

Feb 1963 - Enzo Ferrari sends Ford an offer

May 11, 1963 - The silver Mk6 was the first MK6 GT to be raced, entering two races in May of 1963

May 22, 1963 - Ferrari backed out of deal w/Ford

June 1963 - High Performance and Special Models Operation Unit was formed and a basic design was made

June 12, 1963 - GT Program book, circulated internally on June 12th, just 21 days after Ferrari ended deal

June 19, 1963 - the first GT40 clay model is photographed

July 1963 - Advanced Concept Department- Special Vehicle Activity (SVA) was formed

July 1963 - initially models were wind tunnel tested

July 4, 1963 - HFII was planning to be in Maranello signing a $10 million contract with Enzo Ferrari that would give Ford Motor Co. half the Italian sports car manufacturer

July 12, 1963 - full size clay model is pictured next to Corvette and Jaguar

July 17, 1963 - The decision to go with a european firm was approved

July 1963 - a selection of vendors was made by the end of July

August 1963 - a workshop was established in Broadley’s garage in Bromley, south of London

August 1963 - two Lola Mk6 were tested by Ford till early November

September 1963 - FAV opens in Slough, England

September 1963 - the center of activity was therefo removed from Dearborn to England, together with a nucleus of Ford engineers, car layouts, power pack components and full-size models.

October 4, 1963 - a Ford GT clay model is photographed outside at Ford's Design Studio in Dearborn

Oct 1963 - Design engineers were sent to England in mid October

October 23, 1963 - a Ford GT body is photographed outside with a Ford stripe on the rocker

Nov 1963 - The final shape models were sent to England in early November

Nov 1963 - Component testing was completed by the end of November

March 16, 1964 - first gt40 delivered

April 1st, 1964 the first prototype Ford GT was completed and photographed. The first 12 "prototype" vehicles carried serial numbers GT-101 to GT-112. Production GT40s Mk I and Mk II began with GT40P/1000.

April 15 , 1964 - GT40 time trials in Le Mans in mid-April,

After disappointing race results, the engineering team was moved in 1964 to Dearborn, Michigan, USA, to design and build cars by its advanced developer, Kar Kraft.

70 notes

·

View notes

Photo

Boeing B-29 Superfortress

The Boeing B-29 Superfortress was a four-engined, long-range bomber of the United States Air Force. The largest of all Second World War (1939-45) bombers, B-29s were used to strike Japanese targets from the summer of 1944. In August 1945, the B-29s 'Enola Gay' and 'Bockscar' each dropped an atomic bomb on Hiroshima and Nagasaki, respectively, thereby ending the war.

Development

In the 1930s, the United States Army Air Corps (USAAC) required a long-range strategic bomber that could attack enemy targets thousands of miles from the aircraft's home base. One of the problems to make such an aircraft a reality was to find engines which were powerful enough for the task. The project to design and build a long-range, high-altitude precision bomber, or VLR (Very Long Range) as such aircraft became known, was greatly accelerated following the invasion of Poland in 1939 by Nazi Germany and the outbreak of WWII. In January 1940, five aircraft companies were tasked with designing a VLR bomber. Four companies came back with a design proposal: Consolidated, Douglas, Lockhead, and Boeing. After two of the companies later withdrew, only Consolidated and Boeing won construction contracts in September 1940. Ultimately, each company built three prototypes. Boeing's construction plans were more advanced since it had already been working on modifications of its existing Boeing B-17 Flying Fortress design. Boeing received an order of 1,500 VLRs and promised these aircraft would be ready within three years.

Following the Japanese attack on Pearl Harbour in Hawaii, home of the US Pacific naval fleet, on 7 December 1941, the need for VLRs in the vast theatre of the Pacific Ocean suddenly became a necessity. The first Boing VLR prototype, called XB-29, flew on 21 September 1942. The very large wings of the craft were designed to help it land at lower speeds, and tricycle landing gears helped bear the tremendous weight. 14 test aircraft began to fly from June 1943. The planes were built at four principal plants: Renton, Wichita, Marietta, and Omaha. Boeing, Bell, and Martin were just three of the main companies involved, but there were thousands of others providing components and partial assembly. The B-29 project "was the largest aircraft manufacturing project undertaken in the USA during World War II" (Mondey, 29). It was also the most expensive. From the autumn of 1943, the first B-29 bombers were delivered to US air bases.

B-29 Superfortress in Flight

US Air Force (Public Domain)

Continue reading...

48 notes

·

View notes

Text

U.S. Approves Foreign Military Sale for South Korean F-15K Upgrade

The State Department has approved the possible sale of components that will allow South Korea to upgrade its F-15K Slam Eagle fleet to a configuration similar to the F-15EX Eagle II.

Stefano D'Urso

F-15K upgrade

The U.S. State Department has approved on Nov.19, 2024, a possible Foreign Military Sale (FMS) to the Republic of Korea of components that will allow the upgrade of the country’s F-15K Slam Eagle fleet. The package, which has an estimated cost of $6.2 billion, follows the decision in 2022 to launch an upgrade program for the aircraft.

The State Department has approved the possible sale of components that will allow South Korea to upgrade its F-15K Slam Eagle fleet to a configuration similar to the F-15EX Eagle II.The F-15KThe new capabilities

The Slam Eagles are the mainstay of the Republic of Korea Air Force’s (ROKAF) multirole missions, with a particular ‘heavy hitting’ long-range strike role. According to the available data, the country operates 59 F-15Ks out of 61 which were initially fielded in 2005. In 2022, the Defense Acquisition Program Administration (DAPA) approved the launch of an upgrade program planned to run from 2024 to 2034.

In particular, the Defense Security Cooperation Agency’s (DSCA) FMS notice says a number of components were requested for the upgrade, including 96 Advanced Display Core Processor II (ADCP II) mission system computers, 70 AN/APG-82(v)1 Active Electronically Scanned Arrays (AESA) radars, seventy 70 AN/ALQ-250 Eagle Passive Active Warning Survivability System (EPAWSS) electronic warfare (EW) suites and 70 AN/AAR-57 Common Missile Warning Systems (CMWS).

In addition to these, South Korea will also get modifications and maintenance support, aircraft components and spares, consumables, training aids and the entire support package commonly associated with FMS. It is interesting to note that the notice also includes aerial refueling support and aircraft ferry support, so it is possible that at least the initial aircraft will be ferried to the United States for the modifications before the rest are modified in country.

A ROKAF F-15K Slam Eagle drops two GBU-31 JDAM bombs with BLU-109 warhead. (Image credit: ROKAF)

The components included in the possible sale will allow the ROKAF to upgrade its entire fleet of F-15Ks to a configuration similar to the new F-15EX Eagle II currently being delivered to the U.S. Air Force. Interestingly, the Korean configuration will also include the CMWS, currently not installed on the EX, so the F-15K will also require some structural modifications to add the blisters on each side of the canopy rail where the sensors are installed.

“This proposed sale will improve the Republic of Korea’s capability to meet current and future threats by increasing its critical air defence capability to deter aggression in the region and to ensure interoperability with US forces,” says the DSCA in the official notice.

The upgrade of the F-15K is part of a broader modernization of the ROKAF’s fighter fleet. In fact, the service is also upgrading its KF-16s Block 52 to the V configuration, integrating a new AESA radar, mission computer, self-protection suite, with works expected to be completed by 2025. These programs complement the acquisition of the F-35 Lightning II and the KF-21 Boramae.

Ulchi Freedom Shield 24

A ROKAF F-15K Slam Eagle, assigned to the 11th Fighter Wing at Daegu Air Base, takes off for a mission on Aug. 20, 2024. (Image credit: ROKAF)

The F-15K

The F-15K is a variant of the F-15E Strike Eagle built for the Republic of Korea Air Force’s (ROKAF) with almost half of the components manufactured locally. The aircraft emerged as the winner of the F-X fighter program against the Rafale, Typhoon and Su-35 in 2002, resulting in an order for 40 F-15s equipped with General Electric F110-129 engines. In 2005, a second order for 21 aircraft equipped with Pratt & Whitney F100-PW-229 engines was signed.

The Slam Eagle name is derived from the F-15K’s capability to employ the AGM-84H SLAM-ER standoff cruise missiles, with the Taurus KEPD 350K being another weapon exclusive to the ROKAF jet. The F-15K is employed as a fully multi-role aircraft and is considered ad one of the key assets of the Korean armed forces.

With the aircraft averaging an age of 16 years and expected to be in service until 2060, the Defense Acquisition Program Administration (DAPA) launched in 2022 an upgrade program for the F-15Ks. The upgrade, expected to run from 2024 to 2034, is committed to strengthening the mission capabilities and survivability of the jet.

The F-15K currently equips three squadrons at Daegu Air Base, in the southeast of the country. Although based far from the demilitarized zone (DMZ), the F-15K with its SLAM-ER and KEPD 350 missiles can still hit strategic targets deep behind North Korean borders.

An F-15K releases a Taurus KEPD 350K cruise missile. (Image credit: ROKAF)

The new capabilities

It is not yet clear if the F-15K will receive a new cockpit, since its configuration will be similar to the Eagle II. In fact, the F-15EX has a full glass cockpit equipped with a 10×19-inch touch-screen multifunction color display and JHMCS II both in the front and rear cockpit, Low Profile HUD in the front, stand-by display and dedicated engine, fuel and hydraulics display, in addition to the standard caution/warning lights, switches and Hands On Throttle-And-Stick (HOTAS) control.

Either way, the systems will be powered by the Advanced Display Core Processor II, reportedly the fastest mission computer ever installed on a fighter jet, and the Operational Flight Program Suite 9.1X, a customized variant of the Suite 9 used on the F-15C and F-15E, designed to ensure full interoperability of the new aircraft with the “legacy Eagles”.

The F-15K will be equipped with the new AN/APG-82(V)1 Active Electronically Scanned Array (AESA) radar. The radar, which has been developed from the APG-63(V)3 AESA radar of the F-15C and the APG-79 AESA radar of the F/A-18E/F, allows to simultaneously detect, identify and track multiple air and surface targets at longer ranges compared to mechanical radars, facilitating persistent target observation and information sharing for a better decision-making process.

F-15K upgrade

A ROKAF F-15K Slam Eagle takes off for a night mission during the Pitch Black 2024 exercise. (Image credit: Australian Defense Force)

The AN/ALQ-250 EPAWSS will provide full-spectrum EW capabilities, including radar warning, geolocation, situational awareness, and self-protection to the F-15. Chaff and flares capacity will be increased by 50%, with four more dispensers added in the EPAWSS fairings behind the tail fins (two for each fairing), for a total of 12 dispenser housing 360 cartridges.

EPAWSS is fully integrated with radar warning, geo-location and increased chaff and flare capability to detect and defeat surface and airborne threats in signal-dense and highly contested environments. Because of this, the system enables freedom of maneuver and deeper penetration into battlespaces protected by modern integrated air defense systems.

The AN/AAR-57 CMWS is an ultra-violet based missile warning system, part of an integrated IR countermeasures suite utilizing five sensors to display accurate threat location and dispense decoys/countermeasures. Although CMWS was initially fielded in 2005, BAE Systems continuously customized the algorithms to adapt to new threats and CMWS has now reached Generation 3.

@TheAviationist.com

21 notes

·

View notes

Text

Ultracompact fiber-tip sensor achieves high sensitivity in magnetic field and temperature measurements

Magnetic field sensing plays a pivotal role in numerous fields of medical, transportation and aerospace. The optical fiber-based magnetic field sensor possesses outstanding characteristics of compactness, long-distance interrogation, low cost and high sensitivity, which has attracted intensive interest. However, the fiber-based magnetic field sensor is generally affected by the temperature perturbation. Recently, although the temperature crosstalk can be effectively eliminated by integrating multiple sensing elements, it is at the cost of increasing the size of the whole sensing components, and the different spatial location of multiple elements could cause the measurement errors in the multi-parameter discriminative sensing. In a new paper published in Light: Advanced Manufacturing, a team of scientists, led by Professor Limin Xiao from Advanced Fiber Devices and Systems Group, Key Laboratory of Micro and Nano Photonic Structures (MoE), Key Laboratory for Information Science of Electromagnetic Waves (MoE), Shanghai Engineering Research Center of Ultra-Precision Optical Manufacturing, School of Information Science and Technology, Fudan University, China, and co-workers have developed an ultracompact multicore fiber (MCF) tip probes for magnetic field and temperature discriminative sensing.

Read more.

18 notes

·

View notes

Text

ESA delivers again: ESM-3 departs for US to power Artemis III

ESA’s third European Service Module (ESM-3), for NASA’s Artemis III mission, has departed from the Airbus facility in Bremen, Germany, and will soon leave Europe on its way to the United States. This marks a critical milestone in Europe's continued contribution to humankind’s return to the Moon.

Manufactured in Italy, assembled in Germany, and built with components sourced from over 20 companies across more than 10 European countries, ESM-3 embodies the spirit of international collaboration. The module will now make its way to NASA’s Kennedy Space Center port aboard the transport ship Canopée, a journey that will take approximately 12 days across the Atlantic Ocean.

The European Service Module is an essential component of NASA’s Orion spacecraft, providing power, propulsion and life-support systems for astronauts during their deep space missions. This marks the third such module delivered by ESA, following the successful Artemis I mission and the ongoing preparations for Artemis II.

The journey of ESM-3 began in Turin, Italy, at Thales Alenia Space, where the module’s structural backbone was constructed. This complex structure supports 11 km of wiring, 33 engines, four tanks of propellant and solar arrays that can generate enough electricity to power two households.

Following assembly in Bremen, the module’s main engine—an engine with a legacy of nine Space Shuttle missions—was installed earlier this year.

Upon arrival at Kennedy Space Center, ESM-3 will be integrated with the Crew Module Adapter and the Crew Module itself. Rigorous testing will follow to ensure that everything is ready for the Artemis III mission, which aims to land astronauts on the Moon for the first time since the Apollo era.

This departure represents a key step in ESA’s partnership with NASA, demonstrating Europe's commitment to advancing human exploration beyond Earth.

10 notes

·

View notes

Text

Precision in Every Punch: Why FinePunch is India’s Trusted Name in Sheet Metal Solutions

In a world where precision drives performance, FinePunch.in stands out as a symbol of reliability and innovation in sheet metal fabrication. With a legacy built on trust, craftsmanship, and continuous improvement, FinePunch delivers high-quality, customized metal components tailored for modern industrial needs.

🔩 Who Are We? At FinePunch, we specialize in producing metal dustbins, lockers, tool cabinets, panels, and custom fabrications for industries spanning manufacturing, healthcare, education, and logistics. With cutting-edge CNC technology and a skilled workforce, every product that leaves our facility meets the highest standards of durability and precision.

⚙️ What Makes Us Different?

🛠 State-of-the-Art Technology We use advanced tools and CNC machines to guarantee consistency and detail.

💡 Customization with Purpose No two businesses are the same. We help design exactly what your operations require.

🌱 Sustainable Manufacturing We believe in responsible production—reducing waste, using recyclable materials, and optimizing processes.

🇮🇳 Made in India, Built for the World Supporting Indian manufacturing while delivering global standards.

✨ Whether you're upgrading your facility’s hygiene with stainless steel dustbins or securing assets with precision-built lockers, FinePunch ensures that every detail is engineered for performance.

📸 [Include a few product images or behind-the-scenes shots from the workshop] People love seeing real materials and craftsmanship—make it visual and industrial chic!

📞 Need something built your way? Visit www.finepunch.in or DM us right here to start a project that lasts.

#MadeWithPrecision | #FinePunchIndia | #FabricationExperts

#MetalFabrication#IndustrialDesign#FinePunch#SheetMetal#MadeInIndia#Manufacturing#Engineering#PrecisionTools

2 notes

·

View notes

Text

Revolutionizing Wire Harness Production with Automated Crimping Technology

The modern manufacturing landscape increasingly hinges on automation to boost both efficiency and accuracy. A standout innovation driving this transformation is the advent of automatic wire cutting and crimping machines. These sophisticated systems offer a host of compelling advantages, fundamentally reshaping the way wire harnesses are produced.

At the core of these machines' appeal is their ability to combine blazing-fast operation with a remarkably streamlined wire changeover process. Unlike older, more labor-intensive methods, these automated solutions harness cutting-edge Computer Numerical Control (CNC) technology. This allows for precise, computer-managed adjustments to both the leading and trailing wire ends, eliminating the need for tedious manual tweaks to cutting and stripping lengths. What's more, the integration of electrically controlled blades drastically simplifies the engineering challenges typically associated with adapting to different wire specifications. This built-in flexibility enables swift transitions between various wire types and dimensions, a critical factor in maximizing production agility and minimizing costly downtime.

Precision and Efficiency Through Digital Control

The operational backbone of automatic wire cutting and crimping machines lies in a fully digital and mathematically driven control system. Every crucial parameter—from cutting and stripping lengths to blade values, semi-stripping settings, and terminal crimping specifications—can be precisely configured via an intuitive interface. This comprehensive digital mastery, particularly the electrically adjustable blades, not only supercharges production efficiency but also positions these machines at the forefront of automation compared to other models. For instance, single-head automatic wire crimping machines are adept at handling multiple tasks: wire cutting, single-end stripping, double-end stripping, and single-end crimping, all executed with remarkable speed, stability, and intelligence. Their touchscreen interface further refines the setup experience, making all adjustments fully digitized and straightforward.

Workforce Optimization and Cost Savings

The advanced automation inherent in these machines empowers manufacturers to optimize their workforce deployment. By taking over repetitive and intricate tasks, these systems free up human capital, allowing employees to focus on more strategic, value-added activities. This shift often translates into significant reductions in overall operational costs. Another key benefit is the modular design of these machines. Their reliance on standardized components not only simplifies initial setup but also dramatically cuts down on ongoing maintenance expenses, thanks to readily available and easily replaceable parts. Equipped with cutting-edge electrical controls and proprietary software, these machines boast a highly user-friendly Human-Machine Interface (HMI). This accessibility means that even operators with minimal specialized training can efficiently manage complex wire processing, including wire and terminal changes, effectively "democratizing" the operation of such sophisticated equipment.

Conclusion

In essence, automatic wire cutting and crimping machines represent a monumental leap forward in manufacturing technology. Their synergy of high-speed performance, CNC-driven precision, electrically controlled blades, and intuitive digital interfaces offers compelling advantages over traditional approaches. These machines stand out across various categories of terminal equipment and have secured widespread adoption in today's market, garnering widespread acclaim from users for their innovative design and robust performance.

For in-depth technical resources on automatic terminal crimping machines, explore our specialized page.

2 notes

·

View notes

Text

Shaping the Future: Insights into the Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and…

View On WordPress

#advanced forming technology#advanced materials#aerospace industry#automotive components#ceramic components#engineering ceramics#high-pressure manufacturing#industrial manufacturing#industry trends#isostatic pressing#isostatic pressing applications#isostatic pressing process#manufacturing efficiency#market growth#material compaction#metal parts production#powdered metals#precision engineering

0 notes