#Ethernet IO module

Explore tagged Tumblr posts

Text

Modbus MQTT 2 Ethernet Ports Module for Data Monitoring

The M series Ethernet Remote I/O Module is an industrial class, isolated designed, high reliability, high stability and high precision data acquisition module, embedded 32-Bit High Performance Microprocessor MCU, Integrated 1 Industrial 10/100M adaptive Ethernet module inside. It provides multi I/O, supports standard Modbus TCP, supports modbus master and slave, can be integrated into SCADA, OPC server, and other automation systems. It is design for working in the harsh industrial application environment, widely used in a variety of industrial automation, security monitoring system, automatically measurement and control system.

Features: Model: M160E Digital Inputs: 8 channels Digital Outputs: 8 channels Analog Input: 8 channels Ethernet Port: 2xRJ45 Serial Port: 1xRS485 Protocol: Modbus TCP Master or Slave, TCP/IP, MQTT Dimensions: 82x 40 x 99 mm

0 notes

Text

Februar 2023, Herbst 2024, Januar 2025

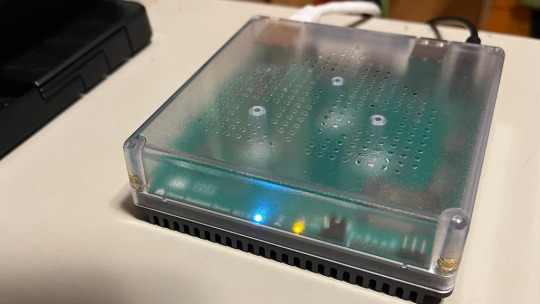

Abenteuer mit Home Assistant Green

Angefixt hat mich unsere Balkonsolaranlage vor zwei Jahren. Die kam mit einem Shelly PM, um Ertrag und Einspeisung zu messen. Das ließ sich dann – eingebunden in das hausinterne WLAN – jederzeit in der App des Herstellers Shelly auf dem Handy ansehen. Neben Zählern und schaltbaren Steckdosen stellt Shelly auch Temperatur- und Feuchtigkeitssensoren her. Eine sehr praktische Sache, um den Überblick darüber zu haben, wie es mit der Luftfeuchtigkeit im Bad nach dem Duschen oder mit der Temperatur im Keller aussieht. Auch das lässt sich in der App von Shelly jederzeit anschauen.

Schon spannend, jederzeit derartige Daten im Blick zu haben. Der nächste Schritt war dann ein über eine schaltbare Steckdose in Betrieb nehmbarer kleiner Batteriespeicher (eigentlich für den Outdoor-Einsatz), um von diesem aus Handys etc. über Nacht Solar laden zu können. Mit der App sind einfache Automatisierungen möglich – immer von 13 bis 14 Uhr laden, beispielsweise. Das funktioniert gut, aber hinterließ bei mir den Wunsch, das doch etwas intelligenter verschalten zu wollen.

Gleichzeitig ist der Blick auf die Daten in der App prima, aber um damit etwas anfangen zu können, etwa für Vergleiche, ist eine Handy-App ein bisschen mühsam zu bedienen.

Im letzten Herbst bin ich dann auf „Home Assistant“ gestoßen. Das ist ein Open-Source-Softwarepaket, das einen Hub für Heimautomatisierung und „Internet of Things“ darstellt. Und das erstaunlich viel kann, fast beliebig erweiterbar ist und so weiter. Ich hatte mir das Paket – das einen Server im Haus-Netz aufsetzt – für meinen Windows-Rechner heruntergeladen, etwas damit herumgespielt, festgestellt, dass auch mein Internetradio und der Nokia-Stick für den Fernseher gefunden werden, und dann beiseite gelegt. Erstens, weil es doch alles etwas komplizierter ist, und zweitens, weil ich meinen Rechner nicht 24/7 laufen lassen wollte.

Die Überlegung, das Paket statt dessen auf einem Raspberry Pi laufen zu lassen, den ich eher 24/7 in Betrieb lassen würde, scheiterte dann daran, dass die bei mir herumliegenden Raspis nicht leistungsstark genug waren. Statt dessen bin ich darauf gestoßen, dass es passgenau Hardware gibt – namentlich „Home Assistant Green“. Das ist der oben abgebildete kleine Computer, der nichts anderes kann und macht, als Home Assistant laufen zu lassen.

Die Installation ist denkbar einfach: Ethernet und Strom anschalten, den Rechner ins Netz hängen und dann – nach etwas Installationswartezeit – unter „homeassistant.local:8123“ aus dem lokalen Netz auf die Weboberfläche von Home Assistant zuzugreifen. Dort können die verschiedenen „smarten“ Geräte eingebunden werden, zum Teil über spezialisierte Plugins und Add-ons. Was da an Daten zusammenkommt, ist dann teilweise erschreckend – auch die Bewegungssensoren meiner iOS-Geräte lassen sich einbinden, und schon habe ich mein ganz persönliches Bewegungsprofil …

Daten aus den Geräten können auf vielfältige Weise dargestellt werden – von schlichten Zahlen bis hin zu grafisch komplexeren Dingen (auch Grafana ließe sich als Add-on einbinden, das habe ich aber noch nicht ausprobiert). Zu allem, was einen Verlauf hat, gibt es automatische Verlaufsdiagramme. Und für häufige Anwendungsfälle (etwa den Energiefluss Netz/PV/Verbraucher) gibt es vorgefertige Übersichten und „Karten“. Sehr viel geht dabei in der Browser-Benutzeroberfläche; darunter liegen Konfigurationsskripte, die im Prinzip auch direkt verändert werden können.

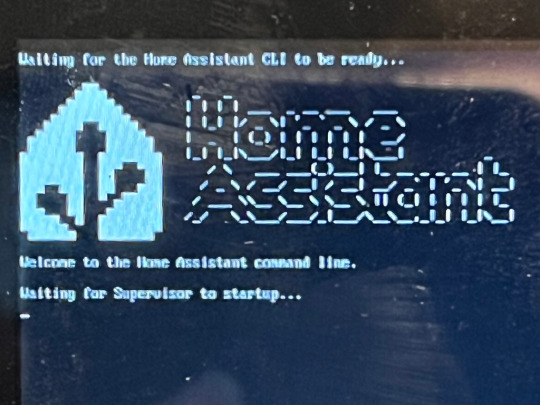

Mit dem Zugriff auf die Skripte lässt sich allerdings auch viel Unsinn anstellen. Beispielsweise hatte ich etwas unvorsichtig eine Konfigurationsdatei verändert (letztlich, um das SSH-Modul zu aktivieren), was dann zur Folge hatte, dass „Home Assistant Green“ gar nicht mehr starten wollte. Zum Glück hat das Gerät für solche Fälle auch USB-Schnittstellen und einen HDMI-Ausgang. Damit landet man dann allerdings zunächst einmal nicht im unterliegenden Linux-System, sondern in einer Command Line, in der nur ein sehr eingeschränktes Befehlsset vorhanden ist. Gefunden habe ich dann zum Glück das Kommando „login“, das eine Shell für das Betriebssystem öffnet. Da konnte ich die vermurkste Konfigurationsdatei dann löschen und die Hardware wieder starten. (Also: nicht blauäugig mit Konfigurationsdateien herumprobieren, ohne zu wissen, was man tut …).

Abgesehen davon wirkt „Home Assistant“ jedoch recht robust. Dienste lassen sich einzeln neu starten, Fehler werden als fehlende Werte dargestellt, und die Anleitungen sind offensiv verlinkt und meist sogar halbwegs verständlich.

Nächster Schritt war für mich dann der Erwerb eines IR-Sensors zum Auslesen meines Stromzählers (bitShake SMR auf Tamota-Basis über MQTT …). Der lässt sich am Stromzähler befestigen, liest die dortige SML-Schnittstelle aus und gibt dann den aktuellen Stromverbrauch ins Hausnetz. Um die Werte nutzen zu können, musste ich zum einen die MQTT-Integration des Home Assistant in Betrieb nehmen (da war die Anleitung eher wenig hilfreich; letztlich musste an drei Stellen ein Nutzer/Passwort eingetragen werden) und zweitens herausfinden, wie Helfer-Templates funktionieren – die Daten kommen einheitslos an, und erst wenn ihnen über ein solches Template die Einheit „kWh“ und das Subsystem „Energy“ zugewiesen wird, können die Energie-Dashboards damit etwas anfangen. So richtig viel allerdings noch nicht: ohne PIN für den Zähler wird nur der kumulierte Verbrauchs- bzw. Einspeisewerte in kWh zurückgegeben, der sich entsprechend langsam ändert. Zeitlich höher aufgelöste Werte brauchen eine PIN, die ich hoffentlich vom lokalen Netzbetreiber bekomme. Erst dann ergibt das Energieflussdiagramm wirklich Sinn …

Das andere, was ich mit etwas Herumprobieren hingekriegt habe, was aber nur indirekt mit dem Home Assistant zu tun hat, ist das Einrichten einer dynamischen DNS-Zuweisung (mit Herumgebastle an den Router-Einstellungen). Das ermöglicht es, auf die Home-Assistant-Oberfläche auch von außerhalb des lokalen Netzes zuzugreifen, also z.B. unterwegs mit dem Handy, ohne zusätzliche Cloudlösungen nutzen zu müssen, die es ansonsten auch gibt. Meine dynamische DNS wollte ewig nicht funktionieren – bis ich herausgefunden habe, dass die Umleitung halt wirklich nur funktioniert, wenn ich von außen (z.B. aus dem LTE-Netz) darauf zugreife. Auch das klappt jetzt also.

Noch nicht wirklich reingefuchst habe ich mich in die Automatisierung. Das kommt dann als nächstes Vorhaben. Dafür gibt es bei Home Assistant eine eigene kleine Programmiersprache, die Sensoren mit Aktionen verknüpfen kann (wenn Zustand X, dann schalte Gerät Y ein – also z.B. meinen Batteriespeicher immer dann, wenn die Balkonsolar-PV optimal ist. Nur: was heißt das genau?). Und vielleicht fallen mir dann auch noch Anwendungsfälle für weitere schaltbare Steckdosen ein. Und dann bräuchte ich dringend noch …

… was ich sagen will: wer möchte, kann tief in die Mischung aus digitaler und dinglicher Welt eintauchen. Bisher scheue ich allerdings noch vor dem ganz großen Schritt hin zu smarten Heizkörperthermostaten, Rollläden, Toastern usw. zurück. Weil eigentlich gar kein Bedarf dafür da ist.

(Till Westermayer, zuerst veröffentlicht hier: blog.till-westermayer.de/index.php/2025/01/25/abenteuer-mit-home-assistant-green/)

#Till Westermayer#IoT#Internet of Things#Balkonsolaranlage#Shelly#Home Assistant Green#Stromzähler#Smart Home#Heimautomatisierung

6 notes

·

View notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Unlocking Industrial Efficiency with Balluff Automation Products

Introduction

In today’s high-speed world of industrial automation, Balluff stands out as a world leader, providing innovative and high-performance solutions for accurate sensing, connectivity, and identification. With a wide reputation for dependability and performance, Balluff products are extremely popular in various industries like manufacturing, logistics, automotive, and many others. In this blog, we will discuss the benefits of Balluff automation products at Aeliya Marine, their uses, and how they are crucial for contemporary industrial processes.

Why Balluff Industrial Automation Products?

Balluff is renowned for its advanced technology, reliability, and intelligent automation solutions that increase productivity and operational efficiency. Balluff automation products offer some of the following benefits:

Highest precision and accuracy in sensing and measurement

State-of-the-art networking and connectivity for smooth communication

Robust and reliable components for harsh industrial environments

Scalability and flexibility to adapt to different applications

Energy efficiency and cost-effectiveness

Key Balluff Products Offered by Aeliya Marine

We at Aeliya Marine offer a comprehensive variety of Balluff automation components designed to serve the needs of industrial automation. Some of the key Balluff components are as follows:

1. Balluff Sensors

Balluff provides an extensive range of industrial sensors such as :

Proximity sensors : Accurately detects metallic and non-metallic objects

Photoelectric sensors : Suitable for object recognition and non-contact detection

Capacitive sensors : Apply to level and material detection

Magnetic sensors : Provide accuracy in motion control applications

2. Balluff RFID Systems

Balluff RFID systems ensure accurate tracking and identification of material, tools, and equipment. They enhance stock control and optimize production flows by providing real-time information collection and asset tracking.

3. Balluff Connectivity Solutions

To provide smooth data exchange among automation devices, Balluff offers high-quality networking modules, cables, and connectors that are compatible with various industrial communication protocols such as IO-Link, Ethernet/IP, and PROFIBUS.

4. Balluff Industrial Power Supplies

Balluff power supplies offer stable voltage regulation and overload protection, providing uninterrupted operation of automation systems.

Applications of Balluff Automation Products

Balluff products are extensively used in a number of industrial applications such as:

Factory Automation : Improving precision and process control in assembly lines

Logistics and Warehousing : RFID-based systems for accurate material tracking and handling

Automotive Industry : High-end sensors and connectivity products for automation of car manufacturing

Food & Beverage Industry : Trusted sensors and traceability systems for food safety enforcement

Oil & Gas : High-performance sensing technology for monitoring and process control

Why Buy from Aeliya Marine?

Aeliya Marine is a reputable distributor of Balluff automation components, providing :

A complete range of quality automation parts

Competitive prices and volume purchasing

Professional technical assistance and advice

Global shipping with rapid and secure delivery

Conclusion

Balluff industrial automation products are essential for optimizing efficiency, improving process control, and enhancing industrial connectivity. Whether you are looking for sensors, RFID systems, power supplies, or networking solutions, Balluff products available at Aeliya Marine ensure you get the best in industrial automation technology.

Explore our collection of Balluff automation products at Aeliya Marine today!

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#Bulluff

0 notes

Text

Rockwell Micrologix Series

MicroLogix PLCs are compact, cost-effective, and are commonly used in small to medium-sized industrial automation applications.

Models in the Series:

MicroLogix 1000: Compact, entry-level PLC with limited I/O capabilities.

MicroLogix 1100: Features built-in Ethernet communication and online editing.

MicroLogix 1200: Offers enhanced I/O capabilities and modular expandability.

MicroLogix 1400: Adds advanced networking, built-in Ethernet/IP, and expanded memory.

MicroLogix 1500: Modular, expandable with higher processing power.

Programming:

Uses RSLogix 500 or Connected Components Workbench (CCW) software.

Ladder logic programming language is primarily used.

Communication:

Supports protocols like Ethernet/IP, DF1, Modbus RTU, and DH485 depending on the model.

Some models include integrated Ethernet ports for remote monitoring and control.

I/O Options:

Digital and analog I/O available.

Expandable I/O modules (available for some models like MicroLogix 1200, 1400, and 1500).

Applications:

Suitable for small-scale automation tasks such as material handling, packaging, HVAC control, and machine automation.

Next Blog on Micrologix Expansion IO's

1 note

·

View note

Text

Siemens 6AG1343-1CX10-2XE0 SIPLUS NET

Siemens 6AG1343-1CX10-2XE0 SIPLUS NET CP 343-1 Lean based on 6GK7343-1CX10-0XE0 with conformal coating, -25??+60 ??C, communications processor for connection of SIMATIC S7-300 to Industrial Ethernet via TCP/IP and UDP, multicast, send/receive with and without RFC1006, fetch/ write, S7 communication (server) PROFINET IO device integrated 2-port switch ERTEC 200, module replacement without PG, SNMP…

0 notes

Text

The industrial landscape is undergoing a metamorphosis, driven by the transformative power of the Internet of Things (IoT) and the dawn of Industry 4.0. At the heart of this revolution lies seamless communication between a myriad of machines and devices that populate the factory floor. This symphony of data exchange hinges on two crucial technologies: Remote Input/Output (I/O) modules and Industrial IoT (IIoT) Gateways. Let's delve into the intricate dance between these technologies and how they unlock the true potential of Industry 4.0.

Demystifying Remote I/O Modules

In today's era of smart work, remote I/O modules serve as extended hands for the factory's control system, enabling signal collection and control from sensors and actuators spread throughout the facility. Connected to a central controller via communication protocols like Modbus or Ethernet, these modules enable real-time monitoring and control, even for distant locations within the factory.

IIoT Gateways: The Vital Link

IIoT Gateways serve as the critical bridge between the bustling industrial world and the ever-evolving information age. IIoT Gateways are devices that serve as intermediaries between sensors, machines, and the cloud in Industrial Internet of Things (IIoT) systems. These gateways collect, process, and transmit data from connected devices to cloud-based platforms for analysis and action. IIoT Gateways play a crucial role in facilitating real-time monitoring, analysis, and control of industrial processes, leading to improved efficiency, productivity, and decision-making in manufacturing environments.

The Power of Integration

Visualise an expansive factory floor adorned with strategically placed sensors and actuators. Remote I/O modules, serving as the backbone, seamlessly collect data from these dispersed devices. The IIoT Gateway assumes the role of the central nervous system, consolidating data from multiple remote I/O modules and perfectly transmitting it to the "brain" – cloud-based analytics and control applications. This harmonious integration heralds a new era of possibilities for Industry 4.0

0 notes

Text

SIMATIC ET 200SP CPU - The Distributed Controllers

Compactness and versatility are combined in the ET 200SP CPUs for distributed controllers.

For conventional and fail-safe applications, distributed controllers are the ideal choice, particularly in the medium performance range for machines with distributed intelligence or series machines with limited space.

The CPUs share many of the same features, including the CPU, as the S7-1500 controller family's CPUs 1511 and 1513. As an illustration, consider the web server, complete symbolic programming, integrated security, integrated system diagnostics, and integrated trace function.

The connection to a higher-level CPU can be completed in precisely the same manner as with a conventional interface module because of the I-Device capabilities. Because of its short signal and encoder wiring, little wiring effort, and noise-resistant design, the ET 200SP station stands out from the competition.

PROFIenergy, isochronous manufacturing, configuration control (option handling), and DP master are among the extra features that the CPUs provide.

There are two kinds of applications for it: Standard CPUs and Failsafe CPUs.

1. Standard CPUs:

Standard CPUs - CPU 1510SP-1 PN and CPU 1512SP-1 PN

For the SIMATIC ET 200SP CPU, two interface modules with an integrated CPU and PROFINET connection are provided.

Connectivity adapters can be freely chosen with bus adapters thanks to the three integrated Ethernet ports. Within discrete manufacturing technology, the CPUs can function as distributed intelligence (PROFINET I-Device) or as a PROFINET IO controller.

The 151*SP CPUs can be expanded decentral via PROFINET with any ET 200 system and with ET 200SP standard modules.

The three ports on the integrated PROFINET IO IRT interface are intended to allow a line structure to be built in the plant via ports 1 and 2, as well as the connection of a PG/PC or HMI device via port 3.

2. Failsafe CPUs

Failsafe CPUs - CPU 1510SP F-1 PN and CPU 1512SP F-1

Standard and safety program processing are made possible by the failsafe ET 200SP CPUs. They meet the functional safety requirements of EN 61508 (2nd Edition) certification and can be used in safety-related applications up to SIL 3 (IEC 62061) and PL e (ISO 13849).

The ET 200SP standard and fail-safe modules, as well as decentralized connectivity via PROFINET / PROFIsafe with any ET 200 system, can be added to the 151*SP F CPUs.

Extra password protection has been implemented for the F configuration and F application in order to enhance IT security.

In discrete manufacturing technology, the CPUs can function as distributed intelligence (PROFINET I-Device) or as a PROFINET IO controller.

The three ports on the integrated PROFINET IO IRT interface are intended to allow a line structure to be built in the plant via ports 1 and 2, as well as the connection of a PG/PC or HMI device via port 3.

To sum up, the SIMATIC ET 200SP CPU provides a lightweight, robust solution for industrial automation requirements. Its excellent performance and smooth integration make it an adaptable option for a range of applications, helping enterprises to increase operational productivity and efficiency.

For more visit here

0 notes

Text

BLIIoT Ethernet/IP Distributed IO Module BL203 Used in Food Process Automation

Introduction

Food Process automation is increasingly becoming an important part of the modern food industry. To improve efficiency, accuracy and traceability, food manufacturers employ advanced automation technologies. In this context, Ethernet/IP Distributed IO Module appear at the forefront of food process automation and play a key role. This article will deeply explore the application of BLIIoT Ethernet/IP Distributed IO Module BL203 in food process automation, emphasizing its advantages, functions and successful cases.

Food Process Automation Overview

Food process automation covers the entire production chain from raw material procurement to final packaging. The main goals of automation are to increase production efficiency, reduce human errors and ensure consistent product quality. The peculiarity of the food industry lies in its diversity and the need to adapt to various food types and production processes. Automation systems must be able to control temperature, humidity, time, speed and other parameters to ensure product safety and quality.

Ethernet/IP Distributed IO Module

Ethernet/IP is an industrial communication protocol that allows real-time communication between different devices. Distributed IO modules are key components for transmitting digital or analog signals from field devices to PLCs or other controllers. These modules transmit data to the control system via the Ethernet/IP network for data processing and control operations. BLIIoT Ethernet/IP Distributed IO Module BL203 offer excellent real-time performance, flexibility and interoperability, making them ideal for food process automation.

Advantages and functions of BLIIoT Ethernet/IP Distributed IO Module BL203

Real-time and High Performance

The Ethernet/IP Distributed IO Module provides fast data transmission and response time to ensure efficient operation of the production process. This is important for parameters in food production that need to be adjusted in a timely manner, such as temperature and humidity.

Data Acquisition and Transmission

These modules can be connected to various field devices such as sensors, valves and motors to transmit data to the control system, allowing it to make timely adjustments and decisions.

Reliability and Fault Tolerance

Food processes require highly reliable automation systems to ensure product consistency. Ethernet/IP Distributed IO Module provide redundancy and fault tolerance, reducing the risk of system failure.

Data Monitoring and Reporting

These modules can monitor key parameters in real time and generate reports so that operators and engineers can view the status of the production process at any time.

Specific Applications in Food Process Automation

Production Line Automation

Ethernet/IP Distributed IO Module are used to control equipment on the production line, such as conveyor belts, filling machines, and packaging machines. This helps increase productivity and reduce human errors.

Temperature and Humidity Control

Accurate control of temperature and humidity is crucial during food processing. These modules are used to monitor and adjust the processing environment to ensure product quality and safety.

Cleaning and Disinfection

Cleaning and disinfection of equipment and piping are critical factors in food safety. Ethernet/IP Distributed IO Module can be used to control the cleaning process and ensure that equipment meets hygiene standards.

Quality Control

Ethernet/IP Distributed IO Module are used to detect and sort unqualified products to ensure product consistency and quality.

In Conclusion

The role of BLIIoT Ethernet/IP Distributed IO Module BL203 in food process automation cannot be ignored. They provide food manufacturers with precise data collection, real-time control and highly reliable automation systems. In an industry with great diversity and high standards, these modules help ensure product consistency and safety, reducing errors and costs in production.

As technology continues to develop, Ethernet/IP Distributed IO Module will continue to evolve to adapt to the new needs of the food industry. Data analysis and intelligent decision-making will provide food manufacturers with more insights and optimization opportunities. While food safety and compliance remain a top priority for the food industry, these modules will continue to provide critical support.

Ethernet/IP Distributed IO Module are key tools for food process automation, helping to increase efficiency, accuracy and traceability. They will continue to drive the food industry towards a smarter, more sustainable future.

More information about BLIIoT Ethernet/IP Distributed Remote IO Module BL203 : https://www.bliiot.com/ethernet-ip-io-module-p00396p1.html

0 notes

Text

Revolutionizing Industrial Automation with the Allen-Bradley 2198-S130-ERS3 and Kinetix 5700 Integrated Motion System

In the ever-evolving landscape of industrial automation, precision and efficiency are paramount. To meet these demands, industry professionals turn to cutting-edge technologies and components that deliver unparalleled performance. One such innovation is the Allen-Bradley 2198-S130-ERS3 Integrated Motion System, in conjunction with the Kinetix 5700 servo drive platform, a dynamic duo that's transforming the industrial automation sector. In this blog, we'll explore the key features and benefits of these solutions, as well as their integration with Allen-Bradley's IO-Link technology.

The Allen-Bradley 2198-S130-ERS3 Integrated Motion System

The Allen-Bradley 2198-S130-ERS3 is at the forefront of integrated motion control systems, designed to streamline processes, enhance productivity, and reduce downtime. This advanced system combines a high-performance servo drive, a motor, and an integrated safety module into a single compact package. Here's what sets it apart:

a. Performance: With its high-speed, high-precision motion control capabilities, the 2198-S130-ERS3 can handle even the most demanding industrial applications. Its advanced algorithms ensure smooth and precise motion, contributing to improved product quality.

b. Compact Design: The integration of multiple components into a single unit results in a more compact footprint, saving valuable space in industrial setups. This design also simplifies installation and reduces wiring complexity.

c. Safety: Safety is paramount in industrial environments. The integrated safety module in the 2198-S130-ERS3 provides advanced safety features, including safe torque-off functionality, to protect both personnel and equipment. 2. The Kinetix 5700 Servo Drive Platform

The Kinetix 5700 servo drive platform is designed to complement the 2198-S130-ERS3, providing precise and reliable motor control. Key features and benefits include:

a. Scalability: The Kinetix 5700 platform offers scalability, making it suitable for a wide range of applications. It can be configured to meet the specific needs of your automation system, whether you're running a single machine or an entire production line.

Advanced Diagnostics: With built-in diagnostics and predictive maintenance capabilities, the Kinetix 5700 helps reduce downtime by identifying potential issues before they lead to failures. This proactive approach enhances overall system reliability.

c. Energy Efficiency: The platform's energy-efficient design ensures that you're getting the most out of your motor control systems while minimizing energy consumption and costs.

Integration with Allen-Bradley IO-Link Technology

To further enhance connectivity and data exchange capabilities, both the 2198-S130-ERS3 and the Kinetix 5700 are compatible with Allen Bradley IO link technology. IO-Link is an open standard that facilitates communication between industrial sensors, actuators, and controllers. Here's how it benefits your automation system:

a. Real-Time Data: IO-Link allows for real-time data exchange, enabling operators and maintenance personnel to monitor the health and performance of connected devices. This data can be used to optimize processes, reduce downtime, and improve overall efficiency.

b. Remote Configuration: IO-Link devices can be configured remotely, saving time and effort during setup and maintenance. Changes and adjustments can be made without physical access to the devices.

c. Seamless Integration: IO-Link is designed to seamlessly integrate with existing industrial networks, including EtherNet/IP and PROFINET, ensuring compatibility with your automation infrastructure.

Conclusion

The Allen-Bradley 2198-S130-ERS3 Integrated Motion System and the Kinetix 5700 servo drive platform represent a significant leap forward in industrial automation technology. Their performance, compact design, safety features, and compatibility with IO-Link technology make them invaluable assets for industries seeking to optimize their automation processes.

As automation continues to play a crucial role in increasing productivity and maintaining competitive advantages, these advanced solutions from Allen-Bradley are poised to revolutionize the way industrial processes are controlled and monitored. Whether you're looking to enhance precision, improve efficiency, or reduce downtime, the 2198-S130-ERS3 and Kinetix 5700 Integrated Motion System, along with IO-Link technology, offer a comprehensive and innovative solution to meet your needs.

Get more information of ROC Automation

0 notes

Text

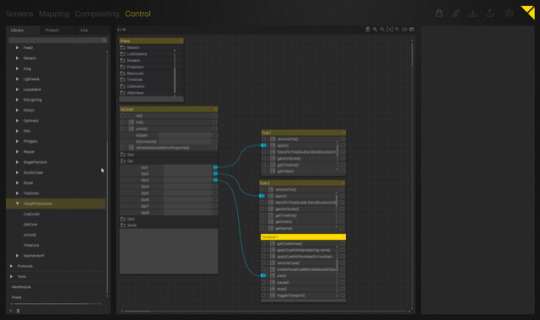

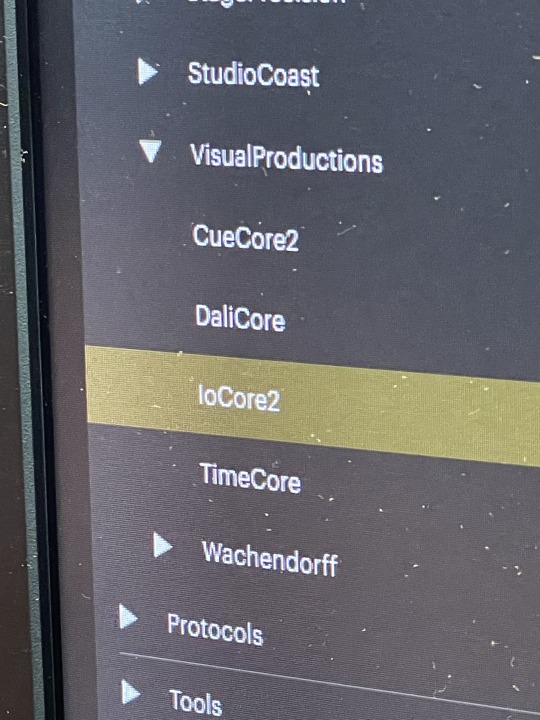

Pixera Media Server solutions & Visual Productions

The Pixera Media Server system is a compact yet extremely powerful media server range with many flexible options, including Visual Productions integration!

With Pixera, usability is key. The real-time media processing, compositing and management solution exists of high performance server hardware and innovative software applications. Pixera playout solutions are being used in museums, interactive installations, immersive experiences, theme parks, houses of worship and in many other markets across the globe.

A dedicated module within the PIXERA control interface allows for easy access to the compact IoCore2 unit‘s inputs and outputs. The IoCore2 is a network-based solid-state interface for GPIO signals. It features eight GPI ports that can be configured as digital contact-closures or analog 0-10V level inputs. The IoCore2 also has eight GPO ports that are fitted with potential free relay switches. Furthermore, it has a RS-232 port, a bi-directional DMX-512 port and supports many Ethernet based protocols.

When including an IoCore2 in your system, you instantly add interactivity to your immersive environment. Think of changing video content when crossing a photo electric beam, pushing a button changes screen or information, and much more.

When using CueCore2 with Pixera, you can even add automated lighting control, whether it be simple white lights or advanced RGBW lights which will enhance the atmosphere with subtle colour changes.

A DALI controlled lighting system? Include control of groups or intensity with DaliCore, integrated in Pixera Control IO.

Synchronising video content with audio? Converting timecode? Pixera can control and sync up audio- and video content across multiple screens when integrated with Visual Productions' TimeCore: compatible with all major timecode formats and all major frame rates.

0 notes

Text

ARMxy Cortex-A53 based Computers BL340 for Wind Farm Monitoring

Hardware Support for Wind Farm Monitoring Needs

High-Performance Processor: The BL340 is equipped with the Allwinner T507-H quad-core ARM Cortex-A53 processor (up to 1.4GHz), supporting real-time data processing for monitoring wind turbine operational status and data analysis.

Flexible I/O Configuration:

(1)X and Y Series IO Boards support interfaces such as RS485, RS232, DI/DO, AI/AO, enabling connections to wind turbine sensors (e.g., vibration, temperature, rotational speed) and actuators (e.g., braking systems).

(2)For example, Y51/Y53 (PT100/PT1000) can be used for precise temperature monitoring, while Y95/Y96 (PWM output and pulse counting) are suitable for wind speed and rotor speed measurement.

Communication Interfaces:

(1)Provides 1-3 10/100M Ethernet ports, supporting networked device communication within the wind farm for centralized data management.

(2)The Mini PCIe interface supports 4G/WiFi modules, ensuring remote data transmission to cloud platforms, ideal for remote wind farms.

Environmental Durability: Certified for operation from -40°C to 85°C and with IP30 protection, it is well-suited for the harsh environments of wind farms.

Software Support for Energy Production Optimization

BLloTLink Protocol Conversion Software: Supports protocols like Modbus, MQTT, and OPC UA, enabling seamless integration with wind farm equipment, mainstream industrial SCADA systems, or cloud platforms (e.g., AWS IoT, Thingsboard) for data collection, analysis, and optimization.

BLRAT Remote Access: Facilitates remote monitoring and maintenance, reducing on-site maintenance costs and improving wind farm operational efficiency.

Real-Time Operating System: Supports Linux-RT-4.9.170, ensuring low-latency data processing for real-time turbine status monitoring.

Qt-5.12.5 GUI Tool: Enables the development of intuitive user interfaces for on-site personnel to monitor and operate the system.

Docker and Node-Red Support: Simplifies the rapid development of IoT applications for wind farm monitoring.

Typical Application Scenarios

Condition Monitoring: Collects data from sensors on vibration, temperature, and hydraulic pressure to analyze equipment health, predict maintenance needs, and extend equipment lifespan.

Energy Optimization: Leverages edge computing to analyze wind speed and power output, dynamically adjusting turbine angles or loads to maximize energy production efficiency.

Fault Diagnosis: Uses AI modules (e.g., Y31 AIN Modules) to detect abnormal vibrations or mechanical faults, providing early warnings to minimize downtime.

Cloud Integration: Uploads operational data to the cloud via 4G/WiFi for long-term trend analysis, optimizing the energy management strategy of the entire wind farm.

Customization and Scalability

Modular Design: Users can select different SOMs (e.g., SOM341: 16GB eMMC + 2GB DDR4) and IO boards (e.g., X23: 4 RS485 + 4 DI/DO) to meet specific monitoring requirements.

Development Support: Offers extensive development examples (e.g., Node-Red, MQTT, CAN) to accelerate the creation of customized monitoring applications.

Long-Term Support: Shenzhen Beilai provides customized R&D and long-term after-sales support to ensure continuous system optimization.

Practical Benefits

Enhanced Reliability: Real-time monitoring and predictive maintenance reduce wind turbine failure rates.

Optimized Energy Output: Data-driven adjustments to operational parameters improve power generation efficiency.

Reduced Operating Costs: Remote management and automated monitoring minimize manual intervention and maintenance costs.

Strong Environmental Adaptability: DIN35 rail mounting and rugged aluminum alloy casing suit the complex environments of wind farms.

Example Configuration

For wind farm monitoring, a recommended configuration is:

Model: BL342B-SOM341-X23-Y51-Y95

(1)Hardware: 3 Ethernet ports, 16GB eMMC, 2GB DDR4, 4 RS485, 4 DI/DO, 2 PT100 temperature sensors, 4 PWM outputs + pulse counters.

(2)Functions: Supports multi-device networking, temperature monitoring, wind speed measurement, and remote data transmission.

Software: Ubuntu 20.04 + BLloTLink + Node-Red for data collection, protocol conversion, and IoT application development.

Conclusion

The ARMxy BL340 series embedded industrial computer, with its high-performance hardware, flexible I/O configuration, robust software support, and industrial-grade reliability, provides an ideal solution for wind farm monitoring. It not only enables real-time management of wind turbines but also optimizes energy production through data analysis and remote maintenance, reducing operational costs. It is a core component for the intelligent operation of wind farms.

0 notes

Video

youtube

Epson Pro EX9220 Projector Review – PROS & CONS – 1080P + WUXGA Projector

Epson Pro EX9220 1080p+ WUXGA 3,600 lumens color brightness (color light output) 3,600 lumens white brightness (white light output) wireless Miracast HDMI MHL 3LCD projector

Pro-Quality, Widescreen, Wireless Full HD Portable Projector with Miracast Boasting premium features and connectivity, the Pro EX9220 wireless portable projector allows you to present with confidence. Delivering 3,600 lumens of color/white brightness (1), it projects bold, colorful images, even in well-lit spaces. Featuring 1080p+ WUXGA resolution (1920 x 1200) — 4.5x more than SVGA — the Pro EX9220 achieves outstanding image quality. And, it offers robust wireless connectivity — including screen mirroring with Miracast — as well as HDMI and MHL.

More Accurate, Vivid Color, Even in Well-Lit Rooms 3,600 lumens of equal color and white brightness (1).

Pro-Quality Projector 1080p+/WUXGA resolution (1920 x 1200) offers 4.5x more resolution than SVGA for Full HD 1080p content.

Wireless Screen Mirroring Mirror device photos, videos and apps using Miracast (Android/Windows 8.1+; iOS requires AirPlay).

Wireless Project from your laptop, tablet, or smartphone without plugging into the projector, so you can move freely about the room.

Share HD Videos Directly from your Wireless Device Supports MHL-enabled devices for mirroring and charging .

Fast Wireless Setup for your Mobile Device Just scan the on-screen QR code using your phone or tablet.

Fast, Easy Setup with Epson Get up and running in no time with easy image adjustments and convenient control.

Compatible with the Latest Laptops and Media Players Supports HDMI, the standard in connectivity, for digital video and audio with just one cable.

What's in the box Pro EX9220 projector power cable computer cable (VGA) USB cable wireless LAN module soft carrying case projector remote control batteries User Manual CD Quick Setup Sheet

Product Description Boasting premium features and connectivity, the Pro EX9220 wireless portable projector allows you to present with confidence. Delivering 3,600 lumens of color/white brightness (1), it projects bold, colorful images, even in well-lit spaces. Featuring 1080p+ WUXGA resolution (1920 x 1200) — 4.5x more than SVGA — the Pro EX9220 achieves outstanding image quality. And, it offers robust wireless connectivity — including screen mirroring with Miracast — as well as HDMI and MHL (2). Works with the latest laptops and media players — supports HDMI, the standard in connectivity, for digital video and audio in one cable

1. Color brightness (color light output) and white brightness (white light output) will vary depending on usage conditions. Color light output measured in accordance with IDMS 15.4; white light output measured in accordance with ISO 21118. 2. Includes one Mobile High-Definition Link (MHL) HDMI port. 5. For wireless functionality, including via the Epson iProjection App, the projector must be configured on a network, either through the Ethernet port on the projector (check model specifications for availability) or via a wireless connection. Check your owner’s manual to determine if a wireless LAN module must be purchased separately to enable a wireless connection. Not all Epson projectors are able to be networked. The Epson iProjection App does not support all files and formats. See our official site for details. 6. Depending on your MHL device, charging may not be supported. 7. Based on TFCinfo: U.S. Projector Brand Customer Perception and Preference Study, Multimedia Projectors 2017. 8. For convenient and reasonable recycling options, visit our official site. 9. SmartWay is an innovative partnership of the U.S. Environmental Protection Agency that reduces greenhouse gases and other air pollutants and improves fuel efficiency.

0 notes

Text

Online Water Level Indicator - Ktronics

An online water level indicator is a system that allows you to monitor the water level in a tank or container remotely, usually via the internet. It provides real-time information about the water level, enabling you to keep track of water levels even when you are not physically present near the tank. This type of system can be helpful in various applications, such as water storage tanks, reservoirs, or even in agricultural irrigation systems. Online Water Level Indicator

To build an online water level indicator, you'll need some components and programming skills. Here's a general outline of how you could create such a system:

Components required:

1. Water Level Sensor: Choose a suitable water level sensor that can accurately measure the water level in the tank. There are various types of sensors available, such as ultrasonic, pressure-based, capacitive, or float sensors.

2. Microcontroller: You'll need a microcontroller to interface with the water level sensor, read the data, and send it to the internet. Popular choices include Arduino, Raspberry Pi, or ESP8266/ESP32-based boards.

3. Internet Connectivity: For online monitoring, you need a way to connect your microcontroller to the internet. This can be achieved using Wi-Fi, Ethernet, or even cellular connectivity, depending on the available infrastructure and your preference.

4. Power Supply: Provide a stable power supply to the microcontroller and other components. Depending on the chosen board, this might be a USB power source, batteries, or an external power adapter.

5. Display (optional): If you also want to view the water level locally, you can add an LCD or LED display to the system. Online Water Level Indicator

6. Enclosure: To protect the electronics from environmental factors, consider housing the components in a suitable enclosure.

Steps to build:

1. Set up the Microcontroller: Begin by setting up your chosen microcontroller with the necessary programming environment. For example, if you're using Arduino, install the Arduino IDE, or if you're using a Raspberry Pi, set up Raspbian OS.

2. Connect the Water Level Sensor: Connect the water level sensor to the microcontroller following the sensor's datasheet and pinout information.

3. Program the Microcontroller: Write the code to read data from the water level sensor and send it to the internet. For internet connectivity, you'll need to use relevant libraries or APIs, like Wi-Fi libraries for ESP8266/ESP32 or Ethernet libraries for Ethernet-enabled boards.

4. Set up an Online Dashboard: Create an online dashboard to display the water level data. You can use platforms like Thingspeak, Adafruit IO, or Blynk, which offer easy-to-use interfaces for data visualization.

5. Establish Internet Connectivity: Configure your microcontroller to connect to your Wi-Fi network or set up the necessary cellular connectivity if using a cellular module.

6. Test and Troubleshoot: Upload the code to your microcontroller and test the system. Make sure the water level readings are accurate and the online dashboard displays the data correctly.

7. Install the System: Install the water level indicator on the tank or container where you want to monitor the water level. Ensure the water level sensor is properly positioned to provide accurate readings.

8. Monitor Remotely: Now you can access the online dashboard from any device with internet connectivity to monitor the water level in real-time.

Remember to consider safety precautions while working with water and electrical components. Also, be mindful of security when connecting devices to the internet; use secure protocols and implement proper authentication if required.

#Doublemotorsequentialtimer#Waterlevelcontrollersinchennai#Waterlevelcontrollersinomr#Waterlevelcontrollersinvelachery#Watercontrollersinannanagar

0 notes

Text

How Siemens Siprotec 5 6MD86 Bay Controller Protection Relay Can Help Increase Your Grids Productivity

In the dynamic landscape of power distribution, ensuring the smooth and efficient operation of electrical grids is of utmost importance. To achieve this, grid operators are constantly seeking innovative solutions that can boost productivity while maintaining a high level of protection for critical assets. This article explores how the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay can play a pivotal role in enhancing grid productivity. By seamlessly integrating advanced protection and control functionalities, this cutting-edge relay offers unparalleled reliability and performance, empowering grid operators to optimize their network's efficiency and ultimately contribute to a more sustainable and reliable power supply.

A Brief Overview Of Siemens Siprotec 5 6MD86 Bay Controller Protection Relay

The Siemens Siprotec 5 6MD86 Bay Controller is a protection relay device designed to provide comprehensive protection and control functionalities for electrical systems at various voltage levels, ranging from distribution to transmission. The Siemens Siprotec 6MD86 Bay Controller serves as a control and automation device with optional protection features, suitable for various voltage levels from distribution to transmission. As part of the SIPROTEC 5 family, it offers a wide range of protection functions from the SIPROTEC library, sharing identical parameters with protection devices. Its adaptable hardware design allows precise alignment with different process data requirements.

The 6MD86 Bay Controller is equipped with flexible hardware, allowing it to adapt precisely to different process data requirements, making it a versatile and effective solution for ensuring the stability and security of critical power systems. Its advanced automation capabilities enable seamless integration into control systems, enhancing the overall efficiency and reliability of electrical networks.

Functions of Siemens 6MD86 Bay Controller Protection Relay

Integrated bay controller with versatile protection function from medium to extra-high voltage

Control of switching devices

Synchrocheck, switchgear interlocking protection and switch related protection functions, such as circuit-breaker failure protection and automatic reclosing

Integrated electrical Ethernet RJ45 for DIGSI 5 and IEC 61850 (reporting and GOOSE)

Up to 4 pluggable communication modules usable for different and redundant protocols (IEC 61850, IEC 60870-5-103, IEC 60870-5-104, DNP3 serial and TCP, Modbus TCP, PROFINET IO)

Secure serial protection data communication, also over great distances and all available physical media (fibre-optic cable, 2-wire connections and Communication Networks)

Capturing operational measured variables and protection function measured values to evaluate the plant state, support commissioning, and analyze faults

Phasor Measurement Unit (PMU) synchrophasor measured values and IEEE C37.118 protocol integrated

Powerful fault recording (buffer for a max. record time of 80 s at 8 kHz or 320 s at 2 kHz)

Auxiliary functions for simple tests and commissioning

Flexibly adjustable I/O quantity structure within the scope of the SIPROTEC 5 modular system

How The Relay Works To Monitor And Protect Grid Assets

Siemens Siprotec 5 6MD86 Bay Controller Protection Relay is a sophisticated device designed to monitor and protect various assets within an electrical grid. Its primary function is to detect abnormal conditions or faults that may occur in the grid and take prompt actions to mitigate potential risks, ensuring the safety and stability of the entire power distribution system. Here's how the relay works to monitor and protect grid assets:

Fault Detection: The relay continuously monitors the grid for any abnormal conditions, such as overcurrent, undercurrent, overvoltage, Undervoltage, frequency deviations, etc. When it detects a fault or an irregularity beyond the predefined threshold, it triggers an alarm to notify operators of the issue.

Data Acquisition: The relay collects real-time data from various sensors and instruments installed throughout the grid. This data includes voltage levels, current flow, power factor, and other essential parameters. The relay processes this data to analyze the grid's operating condition.

Event Logging: The relay maintains a detailed log of events and disturbances that occur within the grid. This log provides valuable information for post-event analysis and helps engineers to understand the root cause of disruptions and take preventive measures.

Fast Tripping Mechanism: In the event of a fault, the relay's primary objective is to isolate the affected section of the grid quickly. It sends a tripping signal to the circuit breaker associated with the faulty segment, allowing it to open within milliseconds. This rapid tripping prevents the fault from spreading and causing cascading failures in the system.

Communication Capabilities: The Siprotec 5 6MD86 is equipped with communication interfaces that enable seamless integration into Supervisory Control and Data Acquisition (SCADA) systems and other grid management platforms. This allows for remote monitoring, control, and diagnostics, enhancing the overall grid management efficiency.

Real-time Condition Monitoring: The relay continuously monitors the health and performance of critical grid assets, such as transformers and circuit breakers. It provides real-time diagnostics and alerts operators of any abnormalities or degradation in equipment performance, enabling predictive maintenance and extending asset lifespan.

In summary, the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay works as an intelligent guardian of the electrical grid, vigilantly monitoring its health, detecting faults, and responding rapidly to protect valuable assets. Its ability to identify and isolate faults swiftly, coupled with advanced communication and diagnostic features, helps power utilities maintain grid stability, enhance productivity, and ensure a reliable power supply to consumers.

Conclusion

In conclusion, the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay stands as a game-changer for power utilities, playing a vital role in enhancing grid productivity and ensuring a reliable and secure power distribution system. By adopting these cutting-edge protection relay technologies, power utilities can pave the way for a smarter, more efficient, and sustainable energy future.

Discover the ultimate offer on the Siemens Siprotec 5 6MD86 Bay Controller Protection Relay from Reliserv Solution, your authorized Supplier and Channel Partner for SIEMENS Numerical Relays, Automation Products, Power Quality Meters & Instruments, MV Switchgear Spares, and PSS SINCAL Software. As the leading Siemens Siprotec 5 Relays supplier and exporter in Mumbai, Maharashtra, we pride ourselves on providing top-notch products and services to various industries and panel builders.

Feel free to get in touch with us at +917506112097 or email your requirements to [email protected]. At Reliserv Solution, we deal with a wide range of products, including the Siemens 6MD86 Bay Controller Protection Relay, ensuring that you have access to cutting-edge technology and reliable solutions. Don't miss out on this fantastic opportunity and contact us today for the best deals! Please click here.

#siemens#Siprotec5#protection#numerical#relays#electricalsafety#powerprotection#industrialautomation#panelbuilders#powerquality#electricalsolutions#energyefficiency#smartgrid#powerdistribution#electricalengineering

0 notes

Text

Alienware M17x - R1 Series Driver Download

System Information Alienware m17x - R1 Series: -Operating System: Microsoft Windows 7 Ultimate (64-bit) -Processor : Intel Core 2 Extreme X9000 @ 2.79 GHz -1 processor, 2 cores -Processor ID: GenuineIntel Family 6 Model 23 Stepping 6 -Processor Package: Socket P (478) -L1 Instruction Cache: 32 KB x 2 -L1 Data Cache: 32 KB x 2 -L2 Cache: 6144 KB -L3 Cache: 0 KB -Motherboard: ASUSTeK Computer Inc. F17 -Northbridge: Intel PM965 C0 -Southbridge: Intel 82801HBM (ICH8-M) B1 -BIOS: American Megatrends Inc. 306 -Memory: 4096 MB DDR2 SDRAM 333MHz

Alienware M17x - R1 Series Driver Download

Company Size

S

M

L

Get drivers and downloads for your dell alienware m17x. Released in 2008, this gaming laptop featured intel processing and dual amd graphics cards. I tried and the sent me an m17x key and didnt have an m17-r1 key. First aw 17 model post dell, still rocks with a 4870 crossfire setup, but if you are looking for one, better go with an r2and update it.

This will help if you installed an incorrect or mismatched driver. Problems can arise when your hardware device is too old or not supported any longer. Creative Labs Integrated Webcam Driver Alienware M17x Integrated Webcam Driver Alienware M17x Webcam Driver Alienware Alienware M17x Alienware Notebooks Creative Labs.

Install Alienware M17xR3 laptop drivers for Windows 10 x64, or download DriverPack Solution software for automatic drivers intallation and update. This beta driver has not been fully validated and has been made available in order to improve your gameplay experience with newer game releases; however some features.

Read all ALIENWARE m17x - R1 Series reviews

Alienware M17x Driver

ALIENWARE m17x - R1 Series Features

2-in-1

4K Resolution

AMD

ARM

All-in-One

Android

Backlit Keyboard

Bluetooth

Built-In Microphone

Chrome OS

Discrete GPU

ENERGY STAR Certified

Front-Facing Camera

HDMI Output

Headphone Jack

Intel

LCD Display

LED Display

Linux

Mac

Multi-Touch

Numeric Keypad

Point of Sale

Rack mounted

Rugged

SD Card

SSD

Small form factor

Smartphone

Thin client

Touch screen

Tower

VGA Output

Wi-Fi 1 (802.11b)

Wi-Fi 2 (802.11a)

Wi-Fi 3 (802.11g)

Wi-Fi 4 (802.11n)

Wi-Fi 5 (802.11ac)

Wi-Fi 6 (802.11ax)

Windows

iOS

Alienware M17x - R1 Series Driver Download 64-bit

vista x64-bit driver

canon mf 4410 x64-bit driver

lenovo acpi vpc2004 x64-bit driver

canon lbp 3200 64 bit x64-bit driver

ecs g31t m7 v1 0 lan driver x64-bit driver

fsb 1333 g31t m7 v1 0 chipset driver x64-bit driver

dell vostro 1015 x64-bit driver

canon mf 4400 x64-bit driver

atheros wireless lan driver x64-bit driver

realtek ethernet drivers x64-bit driver

canon lbp 810 x64-bit driver

dell optiplex 380 ethernet x64-bit driver

dell inspiron n5110 sm bus controller x64-bit driver

dell optiplex 780 drivers x64-bit driver

canoscan lide 20 x64-bit driver

canoscan 3000ex x64-bit driver

asus epu 6 engine utility x64-bit driver

realtek 8112l x64-bit driver

atheros ar8112 10 100 lan x64-bit driver

nvidia mcp78 chipset driver x64-bit driver

qualcomm gobi 2000 3g module driver x64-bit driver

gigabyte g41 lan driver xp download x64-bit driver

ecs g31t m7 v1 0 chipset driver x64-bit driver

canon mf3110 64 bit x64-bit driver

atheros ar8132 x64-bit driver

dell optiplex 790 sm bus controller x64-bit driver

canon laserbase mf5730 mf5750 mf5770 x64-bit driver

canon lbp 5200 64 bit x64-bit driver

ati radeon x1250 driver x64-bit driver

dell vostro 1000 drivers x64-bit driver

1 note

·

View note