#compact PLCs

Explore tagged Tumblr posts

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Allen-Bradley PLC Families

🌐Website :- https://asteamtechno.com 👉Contact us :- +91 95372 40404 📧Email :- [email protected]

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#types of plc#Micrologix#controllogix#compactlogix#compact design

0 notes

Link

0 notes

Text

DB9 connector is a widely used electrical connector. Recognizable by its distinctive D-shaped metal shell and 9-pin configuration, the DB9 connector has been a staple in electronics for decades, especially for serial communication.

What Is a DB9 Connector?

The DB9 connector features a D-shaped shell to ensure proper orientation when connecting. The 9 pins (or sockets in female versions) are arranged in two rows, with 5 pins on the top and 4 on the bottom. This compact design is suitable for low-profile applications.

The connector comes in two main types:

DB9 Male Connector: Have pins and are typically used on cables.

DB9 Female Connector: Have sockets and are often found on equipment or devices.

Key Features of DB9 Connectors

Durable Construction: The metal shell provides mechanical strength and shields against electromagnetic interference (EMI).

Compact Design: Ideal for devices where space is limited.

Versatile Applications: Commonly used for RS-232 serial communication, connecting peripherals like mice, keyboards, and modems.

Customization: Can support different pin configurations and wiring for varied uses.

Common Applications of DB9 Connectors

Serial Communication: Widely used in RS-232 interfaces to connect computers, printers, and industrial equipment.

Automation and Control Systems: Frequently seen in programmable logic controllers (PLCs) and industrial machines.

Networking Equipment: Used in switches, routers, and legacy systems.

Testing and Prototyping: Found in diagnostic and development tools for electronics.

DB9 Pinout Diagram

Here’s a standard pinout for a DB9 connector used in RS-232 communication:

Advantages of DB9 Connectors

Reliable Connection: Secure locking mechanism ensures a stable link.

Broad Compatibility: Works with many legacy and modern devices.

Easy Maintenance: Simple design allows for straightforward repairs or replacements.

8 notes

·

View notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

📐 Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note

Text

Know About the Versatility and Efficiency of PM Fiber Splitters

Devices known as PM fiber splitters are made to divide an incoming optical signal into two or more output signals while maintaining the input signal's polarization. Specialized optical fibers that preserve the polarization of light passing through them are used to accomplish this. PM Fiber Splitter guarantees that the polarization state stays constant during the splitting process, in contrast to traditional fiber splitters, which are susceptible to polarization variations.

PM Fiber Splitters' Operation

An optical fiber that maintains polarization is the central component of a PM fiber splitter. These fibers are designed to direct and restrict light in a way that maintains the light's polarization condition. Usually, tension is added to the fiber core to do this, producing a birefringent effect. The fast and slow axes are the two orthogonal polarization states that occur from this splitting of light as it passes through the fiber. A birefringent element in a PM fiber splitter divides entering light into its fast and slow axis components as soon as an optical signal arrives.

Uses for PM Fiber Splitters

PM fiber splitters and PM PLC Splitter are utilized in fiber optic communication systems for signal splitting and routing in telecommunications networks. They are essential in spreading optical signals to several locations with the least amount of signal loss and impairments caused by polarization.

Sensing and Instrumentation: PM fiber splitters are used in many different types of instrumentation and sensing applications, including optical gyroscopes and interferometric sensors. Since polarization effects can create errors, their ability to sustain polarization makes them perfect for preserving the integrity of optical sensor systems.

Benefits

PM fiber splitters offer constant performance in polarization-sensitive applications by preserving the polarization state of input signals. This is one of its key advantages.

Low Insertion Loss: By reducing signal attenuation and increasing system efficiency, these splitters have low insertion loss.

High Reliability: PM fiber splitters have a solid reputation for durability and dependability, which makes them appropriate for long-term deployment in difficult applications.

Compact Design: Because PM Fiber Splitter usually has small sizes, it is simple to incorporate them into optical systems that already exist without taking up a lot of room.

3 notes

·

View notes

Text

Timing Relay Market Demand, Regional Insights & Growth Projections 2025-2034

Timing Relay Market size is expected to see substantial growth, increasing from USD 619.23 million in 2024 to USD 1.05 billion by 2034, at a CAGR of over 5.4%. By 2025, the industry revenue is estimated to be USD 649.88 million.

Growth Drivers & Challenge

The timing relay market is witnessing significant growth, primarily driven by the increasing demand for automation across industrial and commercial applications. One of the major growth drivers is the rising adoption of automated control systems in manufacturing facilities, process industries, and power distribution systems. Timing relays are essential components in automation systems as they help manage time-delayed operations in various processes such as conveyor belts, lighting systems, and motor controls. As industries worldwide focus on increasing operational efficiency and reducing downtime, the demand for reliable timing relays that support these objectives has surged. Their ability to precisely control time-dependent electrical functions makes them indispensable in modern industrial setups.

Another critical factor contributing to market growth is the expanding infrastructure in emerging economies. With growing investments in smart grids, transportation networks, and commercial buildings, the need for reliable electrical control systems has intensified. Timing relays are used extensively in HVAC systems, lighting control, elevators, and security systems within infrastructure projects, which fuels their demand. Additionally, technological advancements have led to the development of programmable and digital timing relays, which offer improved accuracy, enhanced functionalities, and compatibility with modern control systems. These innovations are encouraging end-users to upgrade legacy systems and adopt more efficient, compact, and cost-effective timing solutions.

However, the market is not without its challenges. One of the key obstacles is the presence of alternatives such as programmable logic controllers (PLCs) that can perform more complex functions, including timing operations. Although timing relays are cost-effective and simpler to use for basic functions, PLCs offer greater flexibility, scalability, and integration with industrial automation networks. In scenarios where advanced control and monitoring are required, the preference may shift toward PLCs, potentially limiting the market scope for standalone timing relays. Additionally, the lack of awareness about the specific benefits of timing relays in some developing regions may restrict their adoption.

Request for a free sample report @ https://www.fundamentalbusinessinsights.com/request-sample/13387

Regional Analysis

North America

North America holds a strong position in the timing relay market, backed by a well-established industrial base and advanced automation infrastructure. The United States, in particular, has a high concentration of manufacturing facilities, automotive production units, and energy distribution networks that rely on timing relays for efficient operations. The region's focus on enhancing productivity through automation and smart manufacturing practices has further driven the demand for reliable and programmable timing relays. Additionally, the replacement of outdated electrical systems with modern, automated alternatives is contributing to steady market growth. The presence of leading automation companies and strong investment in R&D also play a crucial role in driving innovation in the regional market.

Europe

Europe represents a significant market for timing relays, supported by stringent regulations regarding energy efficiency, safety, and automation in industrial processes. Countries such as Germany, the UK, and France are prominent users of timing relays across sectors like automotive, energy, and building automation. The European Union’s focus on digital transformation and Industry 4.0 initiatives is pushing manufacturers to upgrade their control systems with more sophisticated and precise timing solutions. Furthermore, the region's emphasis on renewable energy integration and smart grid development has opened new avenues for timing relay applications in grid monitoring and load management systems. The demand for compact, multifunctional, and digitally controlled relays is particularly strong in Europe.

Asia Pacific

Asia Pacific is emerging as the fastest-growing region in the timing relay market, fueled by rapid industrialization, urban development, and infrastructure expansion. Countries like China, India, Japan, and South Korea are investing heavily in manufacturing, power distribution, and transportation systems, all of which require advanced electrical control components. The rise of smart factories, increased focus on energy management, and government support for industrial automation are major factors boosting the market. China’s dominance in the electronics and machinery manufacturing sectors further amplifies the demand for timing relays. Meanwhile, growing construction activity in both residential and commercial sectors across the region is creating additional opportunities for relay applications in lighting, HVAC, and access control systems.

Segmentation Analysis

By Type

The timing relay market is segmented by type into on-delay, off-delay, one-shot, and cyclic timers. On-delay timers are the most commonly used and are widely deployed in applications requiring a delay before activating a device or function. They are ideal for sequential operations in manufacturing and processing plants. Off-delay timers, which maintain output for a preset time after the input is removed, are often used in safety mechanisms and lighting control. One-shot timers are suited for single-cycle applications such as alarms and system resets. Cyclic timers, which alternate between on and off states, find usage in repetitive processes such as blinking lights or automated spraying systems. The increasing preference for multifunctional and programmable timing relays is pushing manufacturers to offer solutions that combine multiple timing modes within a single unit.

Browse complete report summary @ https://www.fundamentalbusinessinsights.com/industry-report/timing-relay-market-13387

By End User

Based on end user, the market is segmented into industrial, commercial, and residential sectors. The industrial segment holds the largest market share due to the widespread use of timing relays in process automation, machinery control, and power management systems. Industries such as manufacturing, automotive, oil and gas, and mining rely on timing relays to ensure precise control over time-based operations, improving both safety and efficiency. The commercial segment is growing steadily, driven by applications in building automation systems, HVAC control, and lighting management in offices, malls, hospitals, and educational institutions. In the residential sector, although the usage is relatively limited, timing relays are being increasingly incorporated into smart home devices, automated lighting, and energy-saving systems, indicating potential growth as home automation becomes more mainstream.

Browse related reports @

About Fundamental Business Insights:

Fundamental Business Insights is global market research and consulting company which is engaged in providing in depth market reports to its various types of clients like industrial sectors, financial sectors, universities, non-profit, and corporations. Our goal is to offer the correct information to the right stakeholder at the right time, in a format that enables logical and informed decision making. We have a team of consultants who have experience in offering executive level blueprints of markets and solutions. Our services include syndicated market studies, customized research reports, and consultation.

Contact us:

Robbin Fernandez

Head of Business Development

Fundamental Business Insights and Consulting

USA: +1–415–800–3393

Email: [email protected]

0 notes

Text

ntroducing the 60 L SHW Extraction System from PURE5™: A game-changer in botanical processing—uses superheated water under pressure to extract cannabinoids and terpenes without solvents. Built with food-grade stainless steel, ASME flanges, PTFE seals, and PLC controls for safety and automation. Extraction meets elegance.

1 note

·

View note

Text

AHU PLC BASED CONTROL SYSTEM I AHU controllers i NX-ERA JET PLC

#AHU CONTROLLER#AHU PLC CONTROLLER SYSTEM#NX-ERA JET PLC#COMPACT PLC#MICRO PLC#IEC 61131-3 standards PLC#MODULAR PLC#PLC control systems#programmable logic controller#Messung’s PLC-based AHU systems#NX-ERA JET#PLC#industrial automation#plc controller#plc automation#industry 4.0#messung plc

0 notes

Text

Rockwell Automation CompactLogix System

The Rockwell Automation CompactLogix system is a mid-range Programmable Logic Controller (PLC) family designed by Allen-Bradley (Rockwell Automation). It provides scalability, flexibility, and high performance, making it suitable for small to mid-sized industrial automation applications.

#automation#trending#viral#tumblr trends#bestdeals#trendingnow#viralpost#allen bradley#rockwell automation#plc#compact design#compactlogix

1 note

·

View note

Text

Zig Zag Paver Block Manufacturer in Mumbai: Durable and Stylish Solutions with Ultra Blocks

For homeowners, builders, and architects in Mumbai seeking durable and visually appealing paving solutions, zig zag paver blocks are an excellent choice. As a premier Zig Zag Paver Block Manufacturer in Mumbai, Ultra Blocks offers high-quality, eco-friendly, and cost-effective paver blocks designed to enhance outdoor spaces. Serving Mumbai, Navi Mumbai, Thane, and Raigad, Ultra Blocks combines innovation, sustainability, and superior craftsmanship to meet the demands of modern construction projects.

What Makes Zig Zag Paver Blocks Special?

Zig zag paver blocks are renowned for their interlocking design, which provides both strength and aesthetic versatility. Here’s why they stand out:

High Load-Bearing Capacity: The unique zig zag shape ensures excellent load distribution, making these blocks perfect for driveways, parking lots, and high-traffic areas.

Aesthetic Appeal: Available in a range of colors, textures, and patterns, zig zag paver blocks add elegance to residential, commercial, and public spaces.

Weather Resistance: Built to withstand Mumbai’s humid climate and heavy monsoons, these blocks are resistant to cracking, fading, and abrasion.

Low Maintenance: Their interlocking design minimizes weed growth and ensures easy cleaning, reducing long-term maintenance costs.

Eco-Friendly: Ultra Blocks uses sustainable materials and processes to create environmentally responsible paver blocks.

Why Choose Ultra Blocks as Your Zig Zag Paver Block Manufacturer in Mumbai?

At Ultra Blocks, we are committed to delivering top-tier zig zag paver blocks that meet the highest industry standards. Here’s what makes us the preferred choice in Mumbai:

1. Advanced Manufacturing Technology

Our state-of-the-art facility uses Columbia machines from the USA with automated PLC-based operations, hydraulic compaction, and supersonic vibration. This ensures precision-crafted zig zag paver blocks with up to M50 grade strength and superior durability.

2. Uncompromising Quality

Quality is at the heart of our operations. Our dedicated R&D and Quality Assurance teams conduct rigorous testing in our advanced laboratory to ensure every block meets strict standards for strength, dimensional accuracy, and aesthetic consistency.

3. Sustainable Practices

Ultra Blocks prioritizes environmental responsibility by using recycled concrete and abundant natural raw materials. Our resource-efficient manufacturing process minimizes waste, producing blocks that are both eco-friendly and high-performing.

4. Diverse Product Range

In addition to zig zag paver blocks, we manufacture:

Concrete Paving Blocks

Hollow Blocks

Solid Blocks

Kerb Stones

This variety allows us to cater to a wide range of construction needs, from small residential projects to large-scale commercial developments.

5. Customer-Focused Service

We understand that every project is unique. Our team provides personalized solutions, competitive pricing, and timely delivery to ensure a seamless experience. Whether you’re a contractor or a homeowner, Ultra Blocks is here to support your vision.

Applications of Zig Zag Paver Blocks in Mumbai

Zig zag paver blocks are versatile and suitable for various applications, including:

Residential Driveways and Pathways: Create durable and stylish entrances to your home.

Commercial Spaces: Ideal for malls, office complexes, and public squares due to their strength and aesthetic appeal.

Landscaping Projects: Enhance gardens, parks, and courtyards with vibrant colors and creative patterns.

Parking Areas: Support heavy vehicular loads with ease, ensuring long-lasting performance.

Public Infrastructure: Perfect for sidewalks, plazas, and pedestrian zones in urban settings.

Benefits of Partnering with Ultra Blocks

Choosing Ultra Blocks as your Zig Zag Paver Block Manufacturer in Mumbai comes with several advantages:

Local Expertise: With a strong presence in Mumbai, Navi Mumbai, Thane, and Raigad, we understand the region’s unique construction needs.

Custom Solutions: We offer tailored paver block designs to match your project’s specifications.

Competitive Pricing: High-quality products at affordable rates ensure excellent value for money.

Reliable Delivery: Our efficient logistics network guarantees on-time delivery across the region.

Transform Your Outdoor Spaces with Ultra Blocks

Mumbai’s rapid urban growth calls for innovative and reliable construction materials. Ultra Blocks meets this demand with zig zag paver blocks that combine functionality, durability, and style. Whether you’re revamping a residential driveway or designing a commercial plaza, our paver blocks are the perfect solution.

Ready to get started? Contact Ultra Blocks today!

Phone: +91-8082559002

Website: https://ultrablocks.in/

Service Areas: Mumbai, Navi Mumbai, Thane, Raigad

Our team is ready to provide expert advice, free quotes, and customized paving solutions to bring your vision to life.

Conclusion As a trusted Zig Zag Paver Block Manufacturer in Mumbai, Ultra Blocks is dedicated to delivering premium paving solutions that enhance the beauty and functionality of outdoor spaces. With advanced technology, a commitment to quality, and a focus on sustainability, we are proud to serve Mumbai’s construction industry. Visit Ultra Blocks today to explore our range of zig zag paver blocks and discover how we can elevate your next project with durable, stylish, and eco-friendly solutions.

0 notes

Text

Automatic Effervescent Tablet Press Market Size, Key Trends & Market Opportunities

Global Automatic Effervescent Tablet Press Market Overview The Global Automatic Effervescent Tablet Press Market is experiencing significant growth due to the rising demand for health supplements, pharmaceutical effervescent formulations, and nutraceuticals. As of 2024, the market is valued at approximately USD 620 million and is expected to grow at a CAGR of 6.8% from 2025 to 2030, reaching over USD 920 million by the end of the forecast period. Key market players are investing in advanced machinery to meet the increasing production demands, driven by consumer preference for fast-dissolving dosage forms. Moreover, the adoption of Industry 4.0 technologies in pharmaceutical manufacturing is further enhancing equipment efficiency, precision, and output capacity. Global Automatic Effervescent Tablet Press Market Dynamics Drivers: The market is primarily driven by increasing consumer awareness regarding health and wellness, growing demand for quick-dissolving medication, and the surge in geriatric and pediatric populations who prefer easy-to-swallow alternatives. Regulatory encouragement for automation and process validation also fuels growth. Restraints: High initial investment costs, complex maintenance requirements, and limited availability of skilled technicians act as barriers for small- to mid-sized pharmaceutical manufacturers. Additionally, fluctuations in raw material prices can impact equipment affordability. Opportunities: Technological advancements in servo-driven systems, AI-based tablet monitoring, and sustainable manufacturing practices offer significant opportunities. Expanding pharmaceutical sectors in emerging economies like India, Brazil, and Southeast Asia present untapped growth avenues for market players. Technology, Regulations, and Sustainability: The integration of advanced PLC systems, real-time data analytics, and GMP-compliant designs are reshaping production lines. Regulatory frameworks such as FDA, EMA, and WHO are pushing for higher safety and accuracy standards. Sustainability trends emphasize energy-efficient tablet press machines and low-waste production systems, encouraging manufacturers to upgrade or replace legacy systems. Download Full PDF Sample Copy of Global Automatic Effervescent Tablet Press Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=376239&utm_source=PR-News&utm_medium=366 Global Automatic Effervescent Tablet Press Market Trends and Innovations The market is witnessing rapid innovation, with a shift toward high-speed rotary presses that support continuous manufacturing. Key trends include the development of compact, modular designs, multi-layer tablet compression capabilities, and automatic weight control systems. IoT-enabled presses are enabling predictive maintenance and operational efficiency. Collaborations between pharmaceutical equipment manufacturers and formulation developers are resulting in customized, application-specific machines tailored for effervescent production lines. Smart factory initiatives and digital twin technologies are also being piloted to enhance production scalability and compliance. Global Automatic Effervescent Tablet Press Market Challenges and Solutions Challenges: Supply chain disruptions, especially in sourcing precision components and control systems, have impacted equipment availability. Pricing pressures from generics and increasing regulatory scrutiny pose additional burdens on manufacturers. Adapting legacy systems to meet current validation and audit standards remains a persistent challenge. Solutions: Strengthening supplier networks, investing in local component sourcing, and implementing lean manufacturing processes can mitigate supply chain risks. Manufacturers are also focusing on modular retrofitting options and lifecycle service contracts to reduce costs and extend equipment life. Regulatory alignment through digital compliance tracking and real-time documentation tools helps streamline audits and inspections.

Global Automatic Effervescent Tablet Press Market Future Outlook Looking ahead, the global automatic effervescent tablet press market is poised for robust growth, driven by increasing health supplement adoption, technological integration, and global regulatory harmonization. By 2030, digitalized, energy-efficient machines capable of real-time monitoring and self-calibration are expected to dominate new installations. Growth will be especially prominent in emerging markets, where pharmaceutical infrastructure development and favorable investment policies are creating fertile ground for expansion. As the demand for personalized medicine and nutraceuticals rises, the market will continue evolving toward high-performance, adaptive, and sustainable tablet press solutions. Key Players in the Global Automatic Effervescent Tablet Press Market Global Automatic Effervescent Tablet Press Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. SaintyCo Mark Maker SED Pharma TRUSTAR PHARMA & PACKING EQUIPMENT Aligned Machinery UPMACH SINOPHAM Wenzhou GF-TECH Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=376239&utm_source=PR-News&utm_medium=366 Global Automatic Effervescent Tablet Press Market Segments Analysis and Regional Economic Significance The Global Automatic Effervescent Tablet Press Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Automatic Effervescent Tablet Press Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. By Capacity By Automation Level By Output Shape And Size By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/automatic-effervescent-tablet-press-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768

Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/womens-health-diagnostics-market/ https://www.verifiedmarketresearch.com/ko/product/whiskey-market/ https://www.verifiedmarketresearch.com/ko/product/whey-protein-market/ https://www.verifiedmarketresearch.com/ko/product/vinyl-ester-market/ https://www.verifiedmarketresearch.com/ko/product/thyroid-cancer-drugs-market/

0 notes

Text

Can an automatic paper bag machine be customized for different bag sizes and shapes?

In today’s packaging industry, flexibility is power. Whether you're supplying grocery stores, fashion retailers, food delivery services, or pharmacies, each client may require paper bags of different sizes, styles, and shapes. To stay competitive and meet diverse customer needs, manufacturers need a machine that does more than just produce paper bags—it must adapt, scale, and deliver variety.

This leads to a common question we hear at Prakash Machineries Pvt. Ltd: Can an automatic paper bag machine be customized for different bag sizes and shapes? The short answer is—absolutely yes.

Modern paper bag machines are built with flexibility in mind. In this article, we’ll explore how our advanced automatic paper bag machines can be customized to produce a wide range of bag dimensions and formats, and how this capability benefits your business.

Why Customization Matters in Paper Bag Production

As the demand for eco-friendly alternatives to plastic continues to rise, different industries are looking for tailored paper bag solutions. For example:

A restaurant may need medium-sized square bottom bags with handles for food deliveries.

A retail outlet might want printed shopping bags in multiple sizes.

A pharmacy may prefer flat, compact bags for lightweight items.

A grocery store might need heavy-duty flat bottom bags in bulk.

Without customization, you’d need separate machines or manual setups for each size—which reduces efficiency and increases cost. This is where a customizable automatic paper bag machine offers a major competitive edge.

How Automatic Paper Bag Machines Offer Customization

Modern automatic paper bag machines, especially those from Prakash Machineries Pvt. Ltd, are engineered for flexibility. Here’s how they enable quick and easy customization:

1. Adjustable Forming Plates and Tubes

The forming unit is the heart of the bag-making process. By changing or adjusting the forming plate and tube, you can produce bags of different widths and gusset sizes. This allows you to create small, medium, and large paper bags using the same machine.

Adjustable Parameters Include:

Bag width

Bag length

Bottom width (flat or square)

Side gusset width (for volume capacity)

With tool-less adjustments or quick-change mechanisms, switching between bag sizes becomes a matter of minutes—not hours.

2. PLC-Controlled Settings for Size Variability

Our machines are equipped with PLC-based touchscreen interfaces that allow operators to input desired bag dimensions with ease. You can set the length, bottom width, and cutting parameters electronically, ensuring precise output every time.

This not only enhances accuracy but also reduces the chances of human error during changeovers.

3. Multi-Format Bag Production

Advanced machines are capable of producing various types of paper bags from a single setup. These include:

Flat bottom bags for groceries and medicine

Square bottom bags for retail and takeaway

V-bottom/satchel bags for bakery and pharmacy use

Handle bags (twisted rope or flat handle)

Printed bags with custom branding

The ability to switch between formats on the same machine gives your business a huge advantage in catering to different market segments.

4. Compatible with Various Paper Grades and Roll Widths

To accommodate different bag shapes and weights, our machines can process multiple paper types such as:

Kraft paper

White or brown recycled paper

Coated/laminated paper for moisture resistance

With adjustable roll holders and web aligners, you can easily switch between different paper rolls and thicknesses, ensuring compatibility with diverse applications.

5. Optional Add-Ons for Advanced Features

At Prakash Machineries Pvt. Ltd, we offer machines with optional modules that can be integrated based on your product line:

Handle pasting units for retail carry bags

Inline flexographic printing units for branded bags

Window patching units for bakery or gift bags

Lamination compatibility for water-resistant bags

These upgrades can be added at the time of purchase or later as your business grows.

Benefits of Customization for Your Business

Having a customizable paper bag machine opens up numerous advantages:

✅ Serve Multiple Industries

Adapt your product offering to cater to retail, food service, healthcare, and more.

✅ Improve Profit Margins

Produce premium, value-added bags like printed or handled bags that command higher prices.

✅ Stay Competitive

Offer a wide variety of bag sizes to meet changing customer demands and stand out from competitors with limited options.

✅ Scale Seamlessly

Start with basic production and expand your capabilities without replacing your machine.

✅ Faster Order Fulfillment

Switch between sizes and designs quickly to fulfill small or bulk orders efficiently.

Why Choose Prakash Machineries Pvt. Ltd?

At Prakash Machineries Pvt. Ltd, we specialize in delivering machines that are not only durable and high-speed, but also highly customizable. Our paper bag machines are designed to adapt to your production requirements, offering:

Precision-engineered forming systems

Easy-to-use control panels

Servo-driven mechanisms for accuracy

Modular designs for future upgrades

We also provide complete training, technical support, and after-sales service to ensure your team can operate the machine to its full potential.

Conclusion: One Machine, Endless Possibilities

In a dynamic and growing market, versatility is key. A customizable automatic paper bag machine allows you to stay ahead of trends, expand your customer base, and increase your profits—all without investing in multiple machines.

Whether you're launching a new production line or upgrading your current setup, the ability to produce different bag sizes and shapes on one machine is a smart, future-proof investment.

Ready to make your paper bag production more flexible and profitable? Contact Prakash Machineries Pvt. Ltd today to explore our range of customizable automatic paper bag machines—engineered for performance, precision, and scalability.

#manufacturer#paper bag manufacturer#square bottom#machines#paper bag#flexo#v bottom#bags#paper#dan and phil#cake#chris sturniolo#cooking#critical role#baking#alien stage#chocolate#delicious#breakfast

1 note

·

View note

Text

Automatic Strapping Machine Market Overview: Trends and Forecast 2025–2030

The Automatic Strapping Machine Market is entering a transformative period driven by rapid industrial automation, booming e-commerce, and an urgent need for efficient, sustainable packaging solutions. These machines, used to apply a strap around products or packages for secure transportation and storage, are increasingly vital across sectors like logistics, food & beverage, pharmaceuticals, and manufacturing.

As industries prioritize operational efficiency and consistent packaging quality, automatic strapping machines are becoming essential equipment in modern production and distribution environments. From high-speed logistics hubs to palletizing in heavy industries, the demand for automated, smart, and cost-effective strapping solutions is expected to grow steadily through 2030.

Market Size and Forecast (2025–2030)

The Automatic Strapping Machine Market is projected to grow at a compound annual growth rate (CAGR) of 6% to 8% between 2025 and 2030.

The global market value is expected to exceed USD 4 billion by 2030, driven by automation in packaging processes, labor shortages, and demand for operational efficiency.

Asia-Pacific is anticipated to lead in volume, while North America and Europe will drive innovation and premium automation solutions.

Key Market Trends

1. Rise of Automation in Packaging Lines

Manufacturers and warehouses are upgrading from manual and semi-automatic to fully automatic strapping machines to:

Reduce manual labor

Enhance packaging speed

Ensure uniformity and reliability

2. Booming E-commerce and Logistics

The surge in parcel shipments and warehousing activity is fueling demand for machines that can handle high throughput, variable sizes, and fast turnaround.

3. Focus on Sustainable Packaging

Companies are shifting toward recyclable strapping materials and energy-efficient machines to meet environmental regulations and reduce waste.

4. Smart Technology Integration

Strapping machines with IoT, remote diagnostics, data analytics, and PLC control systems are in demand, especially in smart factories and Industry 4.0 environments.

5. Customization and Versatility

Modern machines are designed to handle a variety of product sizes, shapes, and materials across different industries.

Regional Market Overview

North America

Strong adoption of automation in warehousing and 3PL operations

High demand for smart and network-integrated strapping machines

Asia-Pacific

Dominates global volume due to manufacturing and export activity

Fast-growing e-commerce and food packaging sectors in India and Southeast Asia

Europe

Focused on sustainability and compliance with EU packaging efficiency norms

Higher investment in fully automatic systems for long-term ROI

Market Segmentation Snapshot

SegmentTrendsBy TypeIncreasing preference for fully automatic over semi-automaticBy End UseLogistics, food, industrial packaging, and pharmaBy MaterialShift toward recyclable plastic straps and PETBy OperationRise in PLC-based, programmable machines

Competitive Landscape

The market features a mix of global manufacturers and regional players offering specialized solutions. Major players are investing in:

R&D for smart technology integration

Partnerships with packaging OEMs and automation firms

After-sales services and remote maintenance tools

Leading Companies include:

Signode Industrial Group

Mosca GmbH

StraPack Inc.

FROMM Packaging Systems

Transpak Equipment Corp.

Opportunities and Growth Drivers

E-commerce growth demanding rapid, secure parcel handling

Labor shortages encouraging automation in warehouses and factories

SME adoption in developing economies with compact, cost-efficient models

Integration with warehouse management systems (WMS) and smart logistics solutions

Challenges

High initial investment in fully automatic systems

Maintenance and training requirements for advanced machinery

Infrastructure limitations in rural and developing regions

Market Outlook 2025–2030

Increased penetration in small and mid-sized enterprises due to compact machine designs and leasing models

Adoption of AI and robotics for predictive maintenance, real-time adjustments, and autonomous operation

Eco-friendly innovation: solar-powered machines, biodegradable straps, and energy-saving features

Regional manufacturing hubs emerging in Southeast Asia, Latin America, and Africa

Conclusion

The Automatic Strapping Machine Market is on a robust growth trajectory, propelled by automation trends, packaging standardization, and increasing demand for efficiency across global supply chains. As businesses embrace smarter, faster, and more sustainable packaging solutions, automatic strapping machines will remain at the forefront of industrial and logistics transformation from 2025 to 2030.

0 notes

Text

How the Strapping Machine Industry is Adapting to Smart Manufacturing

The global packaging industry is undergoing rapid transformation, driven by increasing demand for efficiency, automation, and sustainability. At the heart of this evolution lies the strapping machine market—a sector playing a pivotal role in securing and bundling products across various industries including logistics, food and beverage, e-commerce, pharmaceuticals, and manufacturing.

Understanding Strapping Machines:

Strapping machines are specialized equipment designed to apply a strap around a product or package to secure it during storage or transit. These machines are instrumental in reducing labor costs, minimizing damage during handling, and increasing packaging speeds. They are commonly used in conjunction with other end-of-line packaging solutions.

Strapping machines can be categorized based on:

Operation Type: Manual, semi-automatic, and fully automatic

Strap Material: Polypropylene (PP), polyester (PET), and steel

Application Areas: Carton packaging, palletizing, bundling, and unitizing

Key Market Drivers:

Surge in E-commerce Activities: The rise of online retail has significantly boosted the need for secure, fast, and scalable packaging solutions.

Focus on Operational Efficiency: Manufacturers seek automation solutions like strapping machines to reduce human intervention and increase throughput.

Global Trade Growth: Expanding international logistics and warehousing infrastructure fuel the need for reliable and high-speed strapping systems.

Sustainability and Waste Reduction: Modern strapping machines help reduce material wastage by ensuring precise strap placement and tensioning.

Market Trends and Developments:

Smart Packaging Equipment: Integration of IoT, AI, and PLC-based systems for real-time diagnostics, maintenance alerts, and performance optimization.

Modular and Customizable Machines: Rising demand for modular strapping solutions that can be tailored for different packaging line requirements.

Eco-Friendly Strapping Materials: Increasing adoption of biodegradable and recyclable strapping materials in response to environmental regulations.

Compact and Mobile Machines: Portable strapping machines are gaining popularity among SMEs for their affordability and ease of use.

Regional Insights:

While mature markets like North America and Western Europe continue to adopt advanced automatic strapping systems, emerging economies in Asia-Pacific and Latin America are witnessing increased installations due to industrial expansion and modernization in the logistics and manufacturing sectors.

Challenges in the Market:

High Initial Costs: Advanced automatic strapping systems can require substantial capital investment.

Maintenance and Skill Requirements: Skilled operators and regular maintenance are essential to ensure long-term efficiency.

Fragmented End-User Needs: Varying packaging formats across industries necessitate versatile and adaptable machine configurations.

The future of the strapping machine market appears promising, with continued investment in automation and smart manufacturing. As industries strive to streamline their packaging lines, strapping machines will become increasingly integral to achieving high-speed, low-waste, and secure packaging.

Moreover, with advancements in sensor technology and digital integration, next-generation strapping systems are expected to offer predictive maintenance, remote monitoring, and seamless integration into Industry 4.0 frameworks.

0 notes

Text

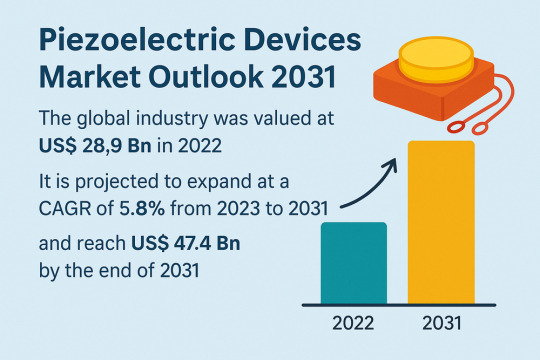

Versatile Applications Power Global Piezoelectric Devices Market to USD 47.4 Bn by 2031

The global piezoelectric devices market was valued at USD 28.9 Bn in 2022 and is anticipated to reach USD 47.4 Bn by 2031, expanding at a CAGR of 5.8% during the forecast period (2023–2031). Piezoelectric devices, which convert mechanical stress into electrical signals and vice versa, are becoming indispensable across a wide array of industries including consumer electronics, automotive, industrial automation, and healthcare. Their ability to deliver high sensitivity, quick response, and energy efficiency has made them critical components in modern technological systems.

Market Drivers & Trends One of the primary growth drivers is the increasing consumption of piezoelectric devices in consumer electronics, such as smartphones, wearables, and touchscreen interfaces. Additionally, automotive advancements, especially in electric and autonomous vehicles, are fueling demand for precision sensors and actuators based on piezoelectric technology.

Another key trend is the integration of piezoelectric materials in energy harvesting applications, enabling the capture of ambient vibrations or movements to power small devices. Moreover, the miniaturization of electronic components and the growing demand for compact, energy-efficient solutions across sectors continue to support market expansion.

Key Players and Industry Leaders The global market is moderately fragmented, with key players focusing on technological innovation and strategic collaborations. Prominent companies include:

APC International Ltd.

Cedrat Technologies S.A

CeramTec GmbH

Ionix Advanced Technologies

KEMET Corporation

KYOCERA Corporation

L3harris Technologies, Inc.

Morgan Advanced Materials plc

Nanomotion Ltd.

Physik Instrumente (PI) GmbH & Co. KG

Piezo Kinetics, Inc.

piezosystem jena GmbH

These companies are investing heavily in R&D to develop next-generation piezoelectric materials and solutions.

Discover essential conclusions and data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=34574

Recent Developments

KAIST, April 2023: Developed wearable piezoelectric sensor for continuous blood pressure monitoring.

SFedU, March 2023: Created piezoelectric generators from carbon nanotubes for urban noise-to-energy applications.

Piezo Motion Corp., March 2021: Acquired Discovery Technology International to diversify into precision piezoelectric motors.

Latest Market Trends

Wearable Sensors for Health Monitoring: In April 2023, KAIST developed a highly sensitive wearable piezoelectric blood pressure sensor, paving the way for real-time health monitoring applications.

Energy Harvesting Innovations: Russian researchers at SFedU have developed piezoelectric generators based on nitrogen-alloyed carbon nanotubes to transform urban vibrations into usable power.

Affordable Precision Motors: In March 2021, Piezo Motion Corp. acquired Discovery Technology International, expanding its offering of affordable, energy-efficient piezoelectric motors.

Market Opportunities The piezoelectric devices market offers numerous growth opportunities:

Expansion in healthcare monitoring devices and smart wearable sensors.

Increased deployment in automotive sensors for braking, collision detection, and autonomous navigation.

Adoption in industrial automation for process monitoring and control.

New applications in IoT and smart home devices, from vibration sensors in washing machines to alert systems in refrigerators.

As the demand for real-time data, energy efficiency, and miniaturization continues, piezoelectric devices are poised to benefit substantially.

Future Outlook The market is set to witness sustainable and diversified growth driven by continuous advancements in material sciences, nanotechnology, and integration capabilities. Emerging economies, particularly in Asia Pacific, are likely to lead due to expanding manufacturing bases, government incentives, and growing demand for smart consumer devices and electric vehicles.

Market Segmentation The market is segmented as follows:

By Type

Piezoelectric Sensors

Piezoelectric Actuators (Stack, Strip, Shear, Tube)

Piezoelectric Motors

Piezoelectric Generators

Piezoelectric Transducers

Others (Transformers, Resonators)

By Material

Piezoelectric Crystals

Piezoelectric Ceramics

Piezoelectric Polymers

Piezoelectric Composites

By Element

Discs

Rings

Plates

By Application

Sonar

Acceleration Sensors

Smartphones

Machining Tools

Others (NDT, surgical tools)

By End-use Industry

Aerospace & Defense

Automotive

Consumer Electronics

Industrial & Manufacturing

Others (Healthcare, Oil & Gas)

Regional Insights

Asia Pacific dominated the market in 2022 with 42.1% share, owing to high demand for electric vehicles, smartphones, and the presence of several manufacturers in China, Japan, South Korea, and India.

North America held 28.05% share, led by technological innovations, strong R&D investments, and the presence of major players such as APC International and Morgan Advanced Materials.

Europe continues to be a steady contributor, especially in the automotive and industrial automation sectors.

Latin America, Middle East & Africa are emerging markets, expected to witness moderate growth due to improving infrastructure and industrialization.

Why Buy This Report?

In-depth market forecast and analysis from 2023 to 2031.

Comprehensive segmentation and regional outlook for informed decision-making.

Competitive landscape assessment, including company profiles, strategies, and recent developments.

Insights into technological advancements and emerging applications.

Support for strategic investment planning and new product development.

Frequently Asked Questions

1. What is the current size of the global piezoelectric devices market? The market was valued at US$ 28.9 Bn in 2022.

2. What is the projected market size by 2031? The market is expected to reach US$ 47.4 Bn by 2031, growing at a CAGR of 5.8%.

3. Which region dominates the global market? Asia Pacific leads the market, accounting for over 42% share in 2022.

4. What are the major applications of piezoelectric devices? Key applications include smartphones, automotive sensors, healthcare monitoring devices, sonar systems, and machining tools.

5. Who are the key players in the market? Leading companies include KYOCERA Corporation, KEMET Corporation, APC International Ltd., CeramTec GmbH, Morgan Advanced Materials plc, among others.

6. What are the future growth opportunities? Major opportunities lie in wearable health tech, energy harvesting, autonomous vehicles, and smart home devices.

Explore Latest Research Reports by Transparency Market Research: GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

Silicon Carbide MOSFETs Market: https://www.transparencymarketresearch.com/silicon-carbide-mosfets-market.html

GaAs Photodiode Market: https://www.transparencymarketresearch.com/gaas-photodiodes-market.html

Semiconductor Plating System Market: https://www.transparencymarketresearch.com/semiconductor-plating-system-market.html About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes