#European injection molds

Text

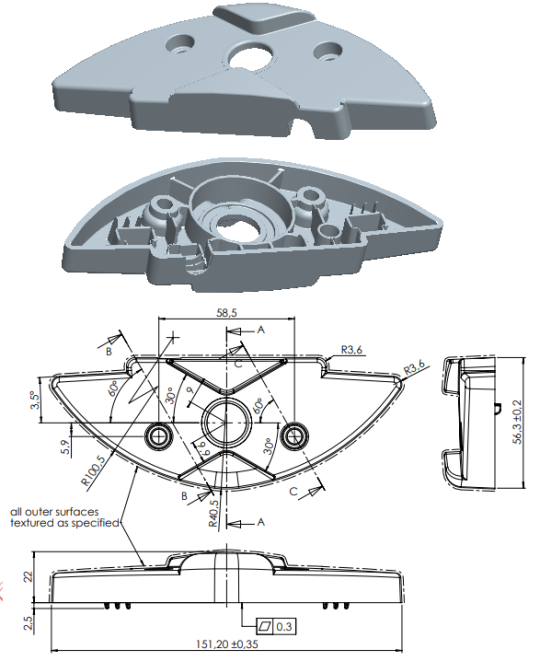

Key Points of Injection Mold Design for End Cover of Wall Hanger

See Figure 1 for wall mount end cap products. Maximum dimensions of product are 151.20 mm * 56.30 mm * 24.50 mm; average thickness of plastic part is 2.50 mm, material of plastic part is PA6 + 30GF, shrinkage rate is 1.005, and weight of plastic part is 48.75 grams. Technical requirements for plastic parts are that there should be no defects such as peaking, underfilled injection molding, flow…

View On WordPress

#Cowhorn gate#demoulding slope#Die structure#Die structure diagram#Dutch mold#European injection molds#European molds#German HASCO standards#injection and etching#injection mold design#Key Points of Injection Mold Design#mold design#Mold Design Specification Book#mold plastic parts#mold standard parts#mold structure#plastic part#Sub-gate#underfilled injection molding

0 notes

Text

ayooo I made this like a year ago and posted it on my original blog, I thought I'd post it here cause why not lol?

⊶⊷⊶⊷

I've loved the RE games for a while now, but recently I realized I didn't know the lore that well.

Now, there are plenty of thorough videos online that lay out the lore of the games, but my silly little brain has a hard time following along. So I wrote it out in a way that made sense to me.

I haven't played all the games myself, so if something is incorrect, I’m sorry. Additionally, I left some content out to keep it as simple and comprehensible as possible!

(obv images are not mine)

⊶⊷⊶⊷

RESIDENT EVIL CHARACTER LINK

Mother Miranda lives in an Eastern European village. In 1919 the Spanish flu claimed her only daughter. In a state of depression, Mother Miranda finds herself deep within a cave network underneath her village, hoping to find the sweet relief of death and be with her daughter once more. This is where she discovers a unique mold (a form of mutamycete) with regenerative properties. She spends the next several decades researching the mold in hopes of using it to reincarnate her daughter.

In 1951, a British medical student by the name of Oswald E. Spencer discovered Mother Miranda’s research. He basically becomes very interested in the human genome and goes off on his own to run his own experiments for the next few years.

In 1962 Oswald E. Spencer hired a man named George Trevor to build him a mansion in the Arklay Mountains, so he could continue his research privately.

Later, Oswald E. Spencer joins forces with two other men, James Marcus, and Edward Ashferd. The trio sets off to Africa to find a unique flower, the “Stairway to the Sun”, which has regenerative properties. Using this flower, the men synthesize the Progenitor Virus.

In 1968, Oswald E. Spencer, James Marcus, and Edward Ashferd, co-founded Umbrella Corp. This “pharmaceutical company” was really just a front for their viral bioweapon research.

Above is the Umbrella Corp. Emblem

Shortly afterward, Edward Ashferd gets frustrated with his two partners and moves to Antarctica where he starts up his own Umbrella research labs. Oswald E. Spencer dislikes this and has Edward Ashferd injected with the Progenitor Virus, killing him.

Oswald E. Spencer is working on Project W. where he kidnaps children and injects them with the Progenitor Virus, in hopes of building a race of loyal superhuman soldiers. All of the test subjects die, except for one, Albert Wesker.

In 1987, James Marcus and his assistants William Birkin and Albert Wesker created the T-Virus, by combining leech DNA with the Progenitor Virus. Shortly after this, the facility gets shut down(?), and the trio moves back to Oswald E. Spencer’s lab in the Arklay Mountains.

Back at the Arklay Umbrella lab, William Birkin discovers that ~10% of the population is naturally immune to their viruses. So he created Bio Organic Weapons (BOW’s). His work with BOW’s is refined into making specific BOW’s, aka Tyrants.

(Late 1998) James Marcus is working with his own strand of the T-Virus, and he creates his “Queen Leech”. Oswald E. Spencer dislikes this as well and tries to kill James Marcus. This attempt fails. James Marcus’s body along with his Queen Leech are dumped into a sewage area, where the Queen Leech eats James Marcus’s body, and absorbs his consciousness. This sort of reincarnates James Marcus.

In the 1990s, Umbrella expanded, and Oswald E. Spencer commissioned a new lab facility to be constructed underneath Raccoon City.

(William Birkin created the G-Virus around this time.)

In 1996, S.T.A.R.S (Special Tactics and Rescue Service) was created. It is technically under Raccoons Cities jurisdiction, but it's privately funded by Umbrella Corp. so they can have control over it. Albert Wesker gets assigned as Captain to the S.T.A.R.S Alpha team.

In 1998, Rebbeca Chambers stumbled across a train wreck filled with James Marcus’s infected leeches. She ends up finding, and killing the Queen Leech (remember James Marcus’s consciousness is intertwined with the Queen Leech).

(Still 1988) S.T.A.R.S Alpha team is on a mission. Jill Valentine and Chris Redfield discover Umbrella Corp.’s experiments and learn that Albert Wesker is a traitor. They fight, and Albert Wesker injects himself with the T-Virus, and escapes.

Raccoon City’s water supply is contaminated with the T-Virus. This infects the whole town and turns them into zombies. Umbrella uses this situation to test out their new BOW, a Tyrant named Nemesis. Nemesis targets Jill Valentine. With the help of Carlos Oliviera, they escape the Tyrant and Raccoon City before it is nuked so the virus doesn't spread.

At the same time, there's a girl by the name of Claire, she's searching for her brother Chris Redfield in Raccoon City.

(All you need to know is through RE from here on out, she keeps searching for her brother and getting into dangerous situations where different viruses are present.)

Anyway, Claire meets Leon Kennedy, and they go to the Raccoon City Police Department (RPD). The two get separated and Leon Kennedy finds the G-Virus. He meets a woman named Ada Wong, an independent mercenary who's trying to get her hands on the G-Virus, and sell it. (She actually does this). Claire and Leon Kennedy escape Raccoon City through a sewer before it’s nuked.

It's now 2004, Leon Kennedy was deployed to a village in Spain to rescue the U.S. president's daughter who was kidnapped. The village is plagued by the Las Plagas Virus, which has something to do with the Los Illuminados Cult. Ada Wong shows up and grabs a sample of the Las Plagas Virus to sell to Albert Wesker. Leon Kennedy saves the president's daughter, defeats the Los Illuminados, and escapes the island.

(2006) Chris Redfield and Jill Valentine find Oswald E. Spencer’s location, and they go to his house. When they get there, they find Albert Wesker had just killed Oswald E. Spencer. (This is cause Wesker found out he was the product of Project W).

Basically, Albert Wesker kidnaps Jill Valentine for a while and uses her as his test subject/mind-controlled dummy. (Eventually, she breaks free from Albert Wesker's mind-control)

Around this time, the B.S.A.A. was created. The Bioterrorism Security Assessment Alliance. (This is because bioweapons are being made worldwide)

Above is the Umbrella Corp. Emblem

Shortly afterward, Edward Ashferd gets frustrated with his two partners and moves to Antarctica where he starts up his own Umbrella research labs. Oswald E. Spencer dislikes this and has Edward Ashferd injected with the Progenitor Virus, killing him.

Oswald E. Spencer is working on Project W. where he kidnaps children and injects them with the Progenitor Virus, in hopes of building a race of loyal superhuman soldiers. All of the test subjects die, except for one, Albert Wesker.

In 1987, James Marcus and his assistants William Birkin and Albert Wesker created the T-Virus, by combining leech DNA with the Progenitor Virus. Shortly after this, the facility gets shut down(?), and the trio moves back to Oswald E. Spencer’s lab in the Arklay Mountains.

Back at the Arklay Umbrella lab, William Birkin discovers that ~10% of the population is naturally immune to their viruses. So he created Bio Organic Weapons (BOW’s). His work with BOW’s is refined into making specific BOW’s, aka Tyrants.

(Late 1998) James Marcus is working with his own strand of the T-Virus, and he creates his “Queen Leech”. Oswald E. Spencer dislikes this as well and tries to kill James Marcus. This attempt fails. James Marcus’s body along with his Queen Leech are dumped into a sewage area, where the Queen Leech eats James Marcus’s body, and absorbs his consciousness. This sort of reincarnates James Marcus.

In the 1990s, Umbrella expanded, and Oswald E. Spencer commissioned a new lab facility to be constructed underneath Raccoon City.

(William Birkin created the G-Virus around this time.)

In 1996, S.T.A.R.S (Special Tactics and Rescue Service) was created. It is technically under Raccoons Cities jurisdiction, but it's privately funded by Umbrella Corp. so they can have control over it. Albert Wesker gets assigned as Captain to the S.T.A.R.S Alpha team.

In 1998, Rebbeca Chambers stumbled across a train wreck filled with James Marcus’s infected leeches. She ends up finding, and killing the Queen Leech (remember James Marcus’s consciousness is intertwined with the Queen Leech).

(Still 1988) S.T.A.R.S Alpha team is on a mission. Jill Valentine and Chris Redfield discover Umbrella Corp.’s experiments and learn that Albert Wesker is a traitor. They fight, and Albert Wesker injects himself with the T-Virus, and escapes.

Raccoon City’s water supply is contaminated with the T-Virus. This infects the whole town and turns them into zombies. Umbrella uses this situation to test out their new BOW, a Tyrant named Nemesis. Nemesis targets Jill Valentine. With the help of Carlos Oliviera, they escape the Tyrant and Raccoon City before it is nuked so the virus doesn't spread.

At the same time, there's a girl by the name of Claire, she's searching for her brother Chris Redfield in Raccoon City.

(All you need to know is through RE from here on out, she keeps searching for her brother and getting into dangerous situations where different viruses are present.)

Anyway, Claire meets Leon Kennedy, and they go to the Raccoon City Police Department (RPD). The two get separated and Leon Kennedy finds the G-Virus. He meets a woman named Ada Wong, an independent mercenary who's trying to get her hands on the G-Virus, and sell it. (She actually does this). Claire and Leon Kennedy escape Raccoon City through a sewer before it’s nuked.

It's now 2004, Leon Kennedy was deployed to a village in Spain to rescue the U.S. president's daughter who was kidnapped. The village is plagued by the Las Plagas Virus, which has something to do with the Los Illuminados Cult. Ada Wong shows up and grabs a sample of the Las Plagas Virus to sell to Albert Wesker. Leon Kennedy saves the president's daughter, defeats the Los Illuminados, and escapes the island.

(2006) Chris Redfield and Jill Valentine find Oswald E. Spencer’s location, and they go to his house. When they get there, they find Albert Wesker had just killed Oswald E. Spencer. (This is cause Wesker found out he was the product of Project W).

Basically, Albert Wesker kidnaps Jill Valentine for a while and uses her as his test subject/mind-controlled dummy. (Eventually, she breaks free from Albert Wesker's mind-control)

Around this time, the B.S.A.A. was created. The Bioterrorism Security Assessment Alliance. (This is because bioweapons are being made worldwide)

Above is the Umbrella Corp. Emblem

Shortly afterward, Edward Ashferd gets frustrated with his two partners and moves to Antarctica where he starts up his own Umbrella research labs. Oswald E. Spencer dislikes this and has Edward Ashferd injected with the Progenitor Virus, killing him.

Oswald E. Spencer is working on Project W. where he kidnaps children and injects them with the Progenitor Virus, in hopes of building a race of loyal superhuman soldiers. All of the test subjects die, except for one, Albert Wesker.

In 1987, James Marcus and his assistants William Birkin and Albert Wesker created the T-Virus, by combining leech DNA with the Progenitor Virus. Shortly after this, the facility gets shut down(?), and the trio moves back to Oswald E. Spencer’s lab in the Arklay Mountains.

Back at the Arklay Umbrella lab, William Birkin discovers that ~10% of the population is naturally immune to their viruses. So he created Bio Organic Weapons (BOW’s). His work with BOW’s is refined into making specific BOW’s, aka Tyrants.

(Late 1998) James Marcus is working with his own strand of the T-Virus, and he creates his “Queen Leech”. Oswald E. Spencer dislikes this as well and tries to kill James Marcus. This attempt fails. James Marcus’s body along with his Queen Leech are dumped into a sewage area, where the Queen Leech eats James Marcus’s body, and absorbs his consciousness. This sort of reincarnates James Marcus.

In the 1990s, Umbrella expanded, and Oswald E. Spencer commissioned a new lab facility to be constructed underneath Raccoon City.

(William Birkin created the G-Virus around this time.)

In 1996, S.T.A.R.S (Special Tactics and Rescue Service) was created. It is technically under Raccoons Cities jurisdiction, but it's privately funded by Umbrella Corp. so they can have control over it. Albert Wesker gets assigned as Captain to the S.T.A.R.S Alpha team.

In 1998, Rebbeca Chambers stumbled across a train wreck filled with James Marcus’s infected leeches. She ends up finding, and killing the Queen Leech (remember James Marcus’s consciousness is intertwined with the Queen Leech).

(Still 1988) S.T.A.R.S Alpha team is on a mission. Jill Valentine and Chris Redfield discover Umbrella Corp.’s experiments and learn that Albert Wesker is a traitor. They fight, and Albert Wesker injects himself with the T-Virus, and escapes.

Raccoon City’s water supply is contaminated with the T-Virus. This infects the whole town and turns them into zombies. Umbrella uses this situation to test out their new BOW, a Tyrant named Nemesis. Nemesis targets Jill Valentine. With the help of Carlos Oliviera, they escape the Tyrant and Raccoon City before it is nuked so the virus doesn't spread.

At the same time, there's a girl by the name of Claire, she's searching for her brother Chris Redfield in Raccoon City.

(All you need to know is through RE from here on out, she keeps searching for her brother and getting into dangerous situations where different viruses are present.)

Anyway, Claire meets Leon Kennedy, and they go to the Raccoon City Police Department (RPD). The two get separated and Leon Kennedy finds the G-Virus. He meets a woman named Ada Wong, an independent mercenary who's trying to get her hands on the G-Virus, and sell it. (She actually does this). Claire and Leon Kennedy escape Raccoon City through a sewer before it’s nuked.

It's now 2004, Leon Kennedy was deployed to a village in Spain to rescue the U.S. president's daughter who was kidnapped. The village is plagued by the Las Plagas Virus, which has something to do with the Los Illuminados Cult. Ada Wong shows up and grabs a sample of the Las Plagas Virus to sell to Albert Wesker. Leon Kennedy saves the president's daughter, defeats the Los Illuminados, and escapes the island.

(2006) Chris Redfield and Jill Valentine find Oswald E. Spencer’s location, and they go to his house. When they get there, they find Albert Wesker had just killed Oswald E. Spencer. (This is cause Wesker found out he was the product of Project W).

Basically, Albert Wesker kidnaps Jill Valentine for a while and uses her as his test subject/mind-controlled dummy. (Eventually, she breaks free from Albert Wesker's mind-control)

Around this time, the B.S.A.A. was created. The Bioterrorism Security Assessment Alliance. (This is because bioweapons are being made worldwide)

Albert Wesker moves on and tries to make West Africa a diseased wasteland. Chris Redfield and the B.S.A.A. team up to go to stop him. This is where they discover the Uroboros Virus. (This is an RNA virus in the Progenitor family. It was engineered by Albert Wesker). Chris Redfeild and the B.S.A.A successfully kills Albert Wesker.

In 2012, there was this thing called the C-Virus, which can mutate bodies while keeping their consciousness. For a while Umbrella Corp.'s was under some heat, but they revived themselves as “Neo Umbrella”. Neo Umbrella unleashes the C-Virus (in China?) and basically, Raccoon City happens all over again.

There is this crime syndicate called “The Connections”. They strike a deal with Mother Miranda, she gives them her mold and the DNA of her daughter hoping they would help revive her. The Connections use the E-Type Mutamycete mold to create bioweapons out of children. This gave birth to the genetically modified human Eveline, who had mind-controlling and regenerative powers. The B.S.A.A. caught wind of this, and The Connections loaded a research team with Eveline onto a cargo boat to ship her somewhere safer. Eveline infected the whole cargo ship with her mold, killing everyone except Eveline's direct handler, a researcher named Mia Winters.

The cargo ship wreckage landed somewhere along the coast of Dulvey Parish, Louisiana. An old man by the name of Jack Baker found Eveline and Mia Winters and took the two back to his house to take care of them. Eveline infected the whole Baker family.

Mia Winters sends an email to her husband, Ethan Winters. He drives to Dulvey Parish, Louisiana to save his wife. Unfortunately, Ethan Winters gets killed pretty quickly, but he gets revived by Eve’s mold. Eveline turns into a big mold monster, and Ethan Winters does his best to fight it, until Chris Redfield comes in and saves the day.

Fast forward a few years, Ethan and Mia Winters have a baby named Rosemary (Rose) Winters. Somehow Mother Miranda finds out about this and decides that Rose Winters is the perfect candidate to use to resurrect her daughter. So Mother Miranda kidnaps Rose and Mia Winters and brings them back to her old Eastern European village. Ethan Winters goes to save his family. He fights a bunch of Mother Miranda's experiments (i.e. Lady Dimitrescu, Heisenberg, Lycans, Dona Beneviento, etc...), and eventually, Chris Redfield comes to try and save the day again. But Ethan Winters sacrifices himself for his family and blows up the whole village.

Fast forward again, it's 2037. Rose Winters is a teenager now, and she has Mutamycete mold powers. She hates that she's different, and wants to get rid of them. She is told if she enters the Mutamycete mold’s consciousness, she might find a way to rid herself of these powers. Now everyone who's ever been in contact with the Mutamycete mold is trapped/a part of the mold consciousness. Inside, she fights off Mother Miranda one last time, meets her father, and then decides to keep her mold powers.

⊶⊷⊶⊷

Again, I did leave some games/content out, but I hope this was enjoyable and/or useful and easy enough to understand!

- sourlemonsprout<3

#las plagas#los illuminados#s.t.a.r.s.#t virus#re8 village#re village#re8#re7#re4#re2#re4 remake#RPD#raccoon city#lady dimitrescu#lord heisenberg#resident evil#RE#lore#RE lore#ethan winters#ada wong#leon kennedy#clair redfield#chris redfield#jill valentine#albert wesker#rebecca chambers#leon s kennedy#mother miranda#resident evil games

26 notes

·

View notes

Text

What Is Hemp?

It’s A Trillion Dollar Cash Crop.

youtube

Hemp is a name given to a strain of the cannabis plant.

Hemp is a name given to cultivars of the cannabis plant (Cannabis sativa) that have been selected over many generations for fiber and seed production. Most hemp cultivars contain less than 1.5% THC, a narcotic compound that has the potential for abuse in high concentrations. Cannabis sativa cultivars selected and developed for their drug properties, referred to as marijuana, or dagga, can have a THC content of 3%-25%. Hemp is a bast fiber, producing its fibers in the stalk similar to flax, kenaf, and sun hemp.

Multiple Uses

Hemp fiber and seed are used to produce a wide range of commodities including food and beverage products, fiberboard, insulation, paper, composites, textiles, carpets, animal bedding and feed, cosmetics, body-care products, soaps, paints, fuels, and medicines.

Hemp Seed Food and Beverage Products

Hemp seed contains about 25% protein, 30% carbohydrates, & 15% insoluble fiber. Hemp seed is reported to contain more easily digestible protein than soybeans. Hemp seed contains all 8 amino acids essential to human nutrition. Hemp seed is high in calcium, magnesium, phosphorus, potassium, carotene, sulfur, iron and zinc, as well as Vitamins A, E, C, B1, B2, B3, and B6.

Hemp seed imported into the United States or Canada must be steam sterilized at between 180 degrees F and 212 degrees F for 15 minutes to prevent sprouting. Many US facilities receive imported viable seed under customs bond, steam it, and release it to the consignee or customer with a Certificate of Sterilization.

Hemp food and beverage products include hemp oil and seed, flour, pasta, cheese, tofu, salad dressings, snacks, sweets, hemp protein powders, soft drinks, beer, and wine. Hemp beer can be made from the seed, flowers, sprouts, and seed cake that is a by-product of oil pressing. Hemp beer is produced and sold in Europe and the United States of America.

Hemp Oil

Hemp seed is 25% to 35% oil, and is one of the oils lowest in saturated fats (8%). Hemp seed oil is the richest source of polyunsaturated essential fatty acids (80%). Hemp seed oil is the only common edible seed oil containing Omega-6 Gamma-Linolenic Acid. Hemp seed oil is very fragile and not suitable for cooking.

Pressed hemp seed oil must be bottled immediately under oxygen-free conditions, and must be refrigerated in dark, airtight containers.

Fiberboard

Hemp fiberboard tested by Washington State University Wood Materials and Engineering Laboratory proved to be two and one half times stronger than wood MDF composites, and the hemp composite boards were three times more elastic.

Hemp herds can be used in existing mills without major changes in equipment. Russia, Poland and other Eastern European countries already manufacture composite boards from hemp and other plant materials.

Pulp and Paper

The major use of hemp fiber in Europe is in the production of specialty papers such as cigarette paper, archival paper, tea bags, and currency paper. The average bast fiber pulp and paper mill produces 5,000 tons of paper per year. Most mills process long bast fiber strands, which arrive as bales of cleaned ribbon from per-processing plants located near the cultivation areas.

Composites

Until the 1930’s, hemp-based cellophane, celluloid and other products were common, and Henry Ford used hemp to make car doors and fenders. Today hemp herds can be used to make new plastic and injection-molded products or blended into recycled plastic products. Hemp fibers are introduced into plastics to make them stiffer, stronger and more impact resistant. Hemp plastics can be designed that are hard, dense, and heat resistant, and which can be drilled, ground, milled, and planed.

Hemp plastic products currently made include chairs, boxes, percussion instruments, lampshades, bowls, cups, spectacles, jewelry, skateboards, and snowboards.

Hemp Animal Care

Hemp horse bedding and cat litter are produced and sold in Europe. After oil is extracted from the hemp seed, the remaining seed cake is about 25% protein and makes an excellent feed for chicken, cattle, and fish. Chickens fed hemp seed on a regular basis have been found to produce more eggs, without the added hormones used in most poultry plants.

Fuels

Hemp seed oil can be combined with 15% methanol to create a substitute for diesel fuel which burns 70% cleaner than petroleum diesel. Hemp stalks are rich in fiber and cellulose, making them conducive for conversion into ethanol and methanol fuels that have a higher octane than gasoline and produce less carbon monoxide. These biomass fuels are also free from sulfur, and do not require the addition of lead and benzene used to boost octane and improve engine performance in fossil fuels. Ethanol holds condensation, eliminating oxidation and corrosion, and is reported to reduce carbon dioxide emissions by more than 30%.

Hemp has been studied in Ireland as a biomass fuel to generate electricity. Hemp has been reported to yield 1000 gallons of methanol per acre year. Hemp stalk can be converted to a charcoal-like fuel through a thermochemical process called pyrolysis. Henry Ford operated a biomass pyrolitic plant at Iron Mountain, Michigan in the mid-20th.

Paints and Varnishes and Binders

Until the 1930's, most paints were made from hemp seed oil and flax seed oil. Hemp oil makes a durable, long lasting paint that renders wood water-resistant. Hemp herds have the potential to make glues for composite construction products that are non-toxic and superior to binders currently used. With this technology, industry can produce composite products where all components are derived from hemp.

Markets for Hemp Pulp

Some paper manufacturers already have the equipment to process decorticated hemp fiber into paper. The leading European supplier of non-wood pulp, Celesa, currently produces about 10,000 tons per year of pulp from hemp. The use of hemp pulp in blends with recycled fiber of other non-wood fibers is growing. Tests by several European pulp and paper producers suggest that hemp pulp may replace cotton cost effectively in several specialty paper applications.

Potential Markets for Medical Application of Low-THC Hemp Cultivars

Many cannabis medicines have been produced using cannabis cultivars high in THC, and there has been medical research into cannabis that is low in THC and high in CBD. CBD is a cannabinoid that does not have many of the psychoactive effects associated with THC. CBD has been used to treat the following medical conditions: epilepsy, dystonic movement disorders, inflammatory disorders, pain, chronic insomnia, chorea, cerebral palsy, and Tourette's syndrome. According to a July 1998 report by the National Institute of Health, CBD may hold promise for preventing brain damage in strokes, Alzheimer’s disease, Parkinson’s disease and even heart attacks and has been found to prevent brain cell death in an experimental stroke model.

Please share this with your friends.

youtube

#hemp farming#hemp foods#hemp fuel#industrial hemp#hemp plastic#hemp paper#hemp fibers#hemp seeds#hemp prohibition

4 notes

·

View notes

Text

Mitsubishi Debonair V AMG version.

AMG is a tuning manufacturer in West Germany that specializes in German luxury cars. Its technical capabilities are widely recognized and highly evaluated by the general public. 3000 Royal AMG is a full-fledged European sporty sedan forged by this prestigious tuner.

■AMG aero parts consist of front bumper spoiler, front grille, side step panel, door protection panel, rear spoiler, rear bumper spoiler, rear end panel, and wheel cut molding.

A form that further refines the aerodynamics of the original body. The impression of its styling can be said to be a splendid fusion of personality and sporty image. Equipped with low-profile tires and aluminum wheels and electronically controlled suspension to support fast and safe driving. From the day you own this car, highway dominance will be yours. The interior also features an AMG-designed steering wheel. The Debonair V3000 Royal AMG is full of Senmou's European spirit in both its exterior and interior.

Body Color: Sarajevo White

■ Seat color: Gray (optional leather seats are beige)

■ Interior base color: Gray

Pictured from left: AMG design steering wheel, AMG design aluminum wheels & 205/60R15-89H tires, dual exhaust pipes.

Debonair V3000 Royal AMG Cyclone V6 3000 engine ELC 4-speed full automatic with OD Main equipment Air conditioning & audio remote control switch Cruise control Auto lighting control 205/60R15-89H tires

Front 5-layer laminated glass (bronze) Electric retractable door mirror Soft touch heater control AMG aero parts Driver's seat power seat Rear power seat AMG Steering wheel ELR seat belt with electric tension reducer Dual auto air conditioner (microcomputer)

MITSUBISHI DEBONAIR V 3000 ROYAL AMG

The Debonair V3000 Royal AMG, which gives the image of driving on the European autobahn. The exterior, suspension, and equipment all feature high-quality specifications unique to this car.

ENGINE BOX

Unprecedented responsiveness and quietness. Advanced driving with Cyclone V6 engine.

What the times demand from engines is not just high power or low-speed torque. It is the response performance that can pick up the power you want when you need it, and the quietness that makes you feel the high quality. In other words, it can be said that it is a high-performance car that truly values the sensibilities of the rider. Mitsubishi's cyclone engine was born by refining everything to meet such demands. And the Cyclone V6 3000 engine of the Debonair V3000 Royal AMG is a proud power unit that stands at the top of them. Achieved new performance and excellent quietness in the entire range from low speed to high speed while achieving compactness and weight reduction. In addition, ECI-MULTI (Multi-Point Injection), which always supplies the best air-fuel mixture and controls accurate fuel injection timing and appropriate ignition timing for each of the six cylinders, is also adopted. Also, in each process of intake, combustion and exhaust, advanced technologies such as manifolds with optimal shape and diameter, dual exhaust system and compact combustion chamber are incorporated.

BOTTOM INFO SECTIONS FROM LEFT

door-linked high-tilt steering,

Light operability created by ELC4A/T with OD.

A driver's seat that secures a wide field of vision and enhances safety. The electronically controlled power steering employs door-linked high-tilt steering that hops up when the driver's side door is opened to facilitate boarding and exiting. Equipped with a cruise control that automatically maintains the set vehicle speed, an ELC 4-speed full automatic transmission with OD that electronically controls for smooth shifting, and a steering audio remote control switch that allows remote control of audio from the steering wheel. As an option, a hands-free car telephone is also available, which allows you to talk without having to use both hands.

The spaciousness of the interior of the FF and its excellent quietness make it a truly relaxing place to live.

Debonair V achieves top-class spaciousness in the interior and trunk room with the FF (front wheel drive) system. Beneran instrument panel pads with a leather touch and urethane-injected floor mats that create a soft feel further enhance the quality of living. The driver's seat and rear seats are equipped with electric power seats that can be adjusted steplessly. In addition, the adoption of a flush body and triple weatherstripping achieves excellent quietness, and is equipped with a high-power audio system with Diatone ASS that adds value to a quiet space.

Optional leather seats are also available.

Safety and reliability brought by electronically controlled suspension and 4-wheel ventilated disc brakes.

Equipped with an electronically controlled suspension that automatically controls suspension characteristics and vehicle height to provide stable driving with consistently high marginal performance. The braking system is equipped with 4-wheel ventilated disc brakes with excellent heat dissipation. The body uses high-quality paint to improve durability and rigidity, integrally molded doors, and new anti-corrosion steel plates. In addition, the front five-layer laminated glass that reduces the impact on the driver in the event of an accident, and ETACS, which electronically controls various timers and alarms, protects irreplaceable safety from all angles.

Door-linked high-tilt steering (with memory) Auto door lock High-power audio with Diatone ASS (B speaker Audio steering remote control switch Electric suspension AMG aluminum wheels Electronic control power steering 4-wheel pentillated disc brakes

36 notes

·

View notes

Photo

Pressure Molding: Ceresana Report on the European Market for Plastic Injection Molding

From raw material directly to finished part: Injection molding is one of the most important processes in the plastics industry. "3D printing may be faster and does not require expensive molds," says Oliver Kutsch, Ceresana's managing director: "But injection molding is still unbeatable when it comes to cost-effectively producing plastic products of virtually any size or shape in huge quantities." Ceresana has studied the European market for injection-molded plastics: Last year, nearly 12.9 million tonnes of plastics were processed in Europe using this method.

Further information about the new market study “Plastic Injection – Europe”: https://www.ceresana.com/en/market-studies/industry/plastic-injection-europe/

#plastics#injection#molding#Plastic Processing#processing#packaging#producers#production#industry#chemical#manufacturers

2 notes

·

View notes

Text

Masterbatch Market Report: Industry Manufacturers Analysis 2024-2030

Masterbatch Industry Overview

The global masterbatch market size was valued at USD 6.24 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030.

The replacement of metal with plastics in the end-use industries, including automotive and transportation, building and construction, consumer goods, and packaging, is expected to be a key factor driving the global market in the forecast period.

Gather more insights about the market drivers, restrains and growth of the Masterbatch Market

The product is available in solid and liquid forms and is used for imparting color and enhancing valuable properties of polymers such as antistatic, antifog, antilocking, UV stabilizing, and flame retardation. Various carrier polymers, such as polypropylene, polyethylene, polyvinyl chloride, and polyethylene terephthalate, are preferred along with the product for use in injection molding and extrusion processes.

The rising demand from the packaging industry in the U.S. is expected to boost market growth. There has been considerable growth in the packaging market in the U.S. on account of growth in the e-commerce business. In the U.S., there are approximately 16,806 plastic manufacturing facilities spread across 50 states. The increasing use of plastic in consumer goods, building & construction, automotive, and other sectors is anticipated to boost the growth of masterbatch in the country in the forecast period. Consumer goods manufacturers are providing attractive product packaging to attract a large number of customers to boost sales of their products. Different types of masterbatch are used in combination with polymers to make attractive packaging, which is projected to increase product demand in the forecast period.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

The global ceramic coating market size was estimated at USD 10.37 billion in 2023 and is expected to grow at a CAGR of 8.4% from 2024 to 2030.

The global anti-slip coatings market size was estimated at USD 149.17 million in 2023 and is estimated to grow at a CAGR of 6.6% from 2024 to 2030.

Key Companies & Market Share Insights

The market is fragmented, with several global and regional players. Key players in the market comply with the regulatory policies and are engaged in research & development activities to develop innovative products. For instance, Hubron International became a corporate member of The Graphene Council, the world’s largest community for graphene researchers, developers, producers, academics, and scientists. Since Hubron International is involved in masterbatch/compounding of graphene materials and has technologies available for the processing of 2D materials, the growing usage of 2D materials in the thermoplastic arena for providing lightweight products is expected to strengthen Hublon International’s position in the masterbatch market. Most key industry players are integrated across the value chain, posing entry barriers for new market players. Some prominent players in the global masterbatch market include:

In November 2023, The investment firm Koinos Capital, headquartered in Milan, established the Impact Formulators Group by merging the operations of two Italian companies specializing in masterbatch and additives manufacturing, namely Masterbatch S.r.l. and Ultrabatch S.r.l.

In November 2023, TER Chemicals and Momentive have mutually agreed to extend their current distribution agreement for high-performance additives in polymer modification. This expansion encompasses all European countries, with the exception of Iberia and the UK. The portfolio offered includes multifunctional masterbatches, anti-block agents, light diffusers, crosslinkers, and coupling agents. These products aim to provide customers with effective solutions to enhance the performance of their products and address various processing challenges.

In May 2023, Tosaf Color Service introduced a new masterbatch carrier system. The recently launched masterbatch carrier system by Tosaf Color Service is fully compliant with widely recognized food contact standards, as asserted by the company. This compliance extends to the guidelines set forth by the German Federal Institute for Risk Assessment (BfR) and aligns with the intricate and diverse regulatory frameworks of the United States and China, including the standards of the Food and Drug Administration (FDA) and China Food Safety Law.

Key Masterbatch Companies:

Schulman, Inc.

Ampacet Corporation

Cabot Corporation

Clariant AG

Global Colors Group

Hubron International Ltd.

Penn Color, Inc.

Plastiblends India Ltd.

PolyOne Corporation

Tosaf Group

Recent Developments

In June 2023, Ampacet announced the launch of PET UVA, a masterbatch that offers protection to the packaging contents from harmful UV light, thereby keeping the food fresher, extending product shelf life, and limiting waste. The company also offers UVA in PP and PE.

In June 2023, Ampacet unveiled the introduction of a new additive - AA Scavenger 0846, designed particularly for restricting the acetaldehyde levels in both PET and rPET bottles. This product launch was aimed at supporting the sustainability efforts of the company in the packaging industry by encouraging the use of recycled materials and reducing waste.

In April 2023, Penn, Color, Inc. announced the commencement of its world-class facility in Rayong Province, Thailand in order to expand its manufacturing capabilities. The objective of this new plant was to enable the company to deliver high-quality colorant & additive masterbatches across the Asia-Pacific market.

In May 2023, Cabot Corporation launched its new aerogel particles portfolio - ENTERA, which acts as a thermal insulation additive for enabling the development of ultra-thin thermal barriers for Li-ion EV batteries. The portfolio comprises three products that can be integrated into different thermal barrier forms, including, sheets, blankets, pads, foams, films, and coatings.

In March 2023, Cabot Corporation announced the launch of its sustainable solutions platform - EVOLVE. This platform was aimed at developing sustainable reinforcing carbons for varied industries and curating materials that enable a more sustainable future by leveraging circular value chains & materials recovered from worn tires, bio-based and renewable materials, and processes that limit greenhouse gas emissions.

In October 2022, Clariant launched new additive solutions at K 2022 to reinforce more sustainable plastics and decrease resource use. These new developments include Licowax AS 100 TP - an anti-scratch additive for polypropylene and thermoplastic olefins formulations, AddWorks AGC 970 - a light stabilizer for polyethylene agricultural films, and Licocare RBW 560 TP Vita a bio-based wax for injection molded polyester compounds.

Order a free sample PDF of the Masterbatch Market Intelligence Study, published by Grand View Research.

0 notes

Text

Are Plastic Shims Safe for Use in Food-Related Applications?

Introduction

Plastic shims are versatile tools used for leveling, aligning, and spacing in various industries. However, when it comes to food-related applications, ensuring their safety is paramount. This article explores the types of plastic shims, the materials used, and the regulations governing their use in food environments. We'll also examine potential risks, best practices, and future trends to provide a comprehensive understanding of whether plastic shims are safe for use in food-related applications.

What are Plastic Shims?

Plastic shims are thin, wedge-shaped pieces of plastic used to fill small gaps, provide support, or ensure proper alignment. They are commonly used in construction, manufacturing, and maintenance tasks. In food-related applications, plastic shims must meet stringent safety standards to prevent contamination and ensure consumer safety.

Types of Plastic Shims

Plastic shims come in various shapes, sizes, and materials, each suited for different applications. Common types include:

Flat Shims: Used for leveling and aligning surfaces.

Wedge Shims: Tapered to provide incremental adjustment.

Custom Shims: Tailored to specific requirements and dimensions.

Materials Used in Plastic Shims

The materials used in plastic shims determine their suitability for food-related applications. Common materials include:

Polyethylene (PE): Known for its chemical resistance and low moisture absorption, making it a popular choice for food applications.

Polypropylene (PP): Offers high fatigue resistance and chemical stability.

Polyvinyl Chloride (PVC): Provides good mechanical strength and durability but may pose risks if not food-grade certified.

Food Safety Standards and Regulations

Ensuring plastic shims are safe for food-related applications involves adhering to various safety standards and regulations.

FDA Regulations: In the United States, the Food and Drug Administration (FDA) regulates materials that come into contact with food. Plastic shims must comply with FDA guidelines to be deemed safe.

European Food Safety Authority (EFSA) Standards: In Europe, EFSA sets the safety standards for materials used in food contact applications.

Plastic Shims and Food Contact

Plastic shims can be used in food-related applications in two main ways:

Direct Contact: Where the shim directly touches food products. Materials used must be certified food-safe.

Indirect Contact: Where the shim does not directly touch food but is used in the vicinity of food processing equipment.

Advantages of Using Plastic Shims

Plastic shims offer several benefits in food-related applications:

Durability: Resistant to moisture, chemicals, and corrosion.

Cost-effectiveness: Generally more affordable than metal or custom shims.

Flexibility: Easy to cut, shape, and install.

Potential Risks and Concerns

Despite their advantages, there are potential risks associated with using plastic shims in food-related applications:

Chemical Leaching: Non-food-grade plastics may leach harmful chemicals into food.

Physical Contamination: Shims that break or degrade can contaminate food with plastic particles.

Comparing Plastic Shims to Other Materials

When considering shims for food-related applications, it's essential to compare plastic shims with alternatives:

Metal Shims: Offer superior strength and durability but are more expensive and prone to corrosion.

Wooden Shims: Generally not recommended for food applications due to their porosity and potential for bacterial growth.

Manufacturing Processes for Food-Safe Plastic Shims

Producing food-safe plastic shims involves careful selection of materials and manufacturing processes to ensure compliance with safety standards. Processes include:

Injection Molding: Ensures uniformity and precision.

Extrusion: Allows for continuous production of shims with consistent quality.

Certifications and Testing

To guarantee safety, plastic shims must undergo rigorous testing and certification:

Third-Party Testing: Independent laboratories test for chemical safety and physical integrity.

Certification Marks: Look for marks indicating compliance with FDA or EFSA standards.

Case Studies of Plastic Shims in Food Applications

Several industries successfully use plastic shims in food-related applications:

Food Processing Plants: For aligning machinery and ensuring proper spacing.

Packaging Industries: To maintain the integrity of packaging lines and equipment.

Best Practices for Using Plastic Shims in Food Applications

To minimize risks and ensure safety, follow these best practices:

Cleaning and Maintenance: Regularly clean shims to prevent contamination.

Regular Inspections: Check for wear and damage to replace shims before they pose a risk.

Industry Examples and Applications

Plastic shims are used in various food-related industries, including:

Beverage Production: To align bottling machines and conveyors.

Bakery Operations: For leveling ovens and cooling racks.

Innovations in Plastic Shims

Recent innovations focus on improving the safety and sustainability of plastic shims:

Eco-friendly Materials: Development of biodegradable and recyclable plastics.

Advanced Manufacturing Techniques: Use of 3D printing for custom, food-safe shims.

Disposal and Environmental Impact

Consideration of the environmental impact of plastic shims is crucial:

Recycling: Opt for recyclable materials to reduce waste.

Biodegradability: Use biodegradable shims where possible to minimize environmental impact.

Future Trends in Food-Safe Plastic Shims

The future of plastic shims in food-related applications looks promising with trends such as:

Increased Use of Bioplastics: Growing demand for sustainable materials.

Enhanced Safety Standards: Stricter regulations to ensure consumer safety.

How to Choose the Right Plastic Shim for Your Application

When selecting plastic shims for food-related applications, consider:

Material Safety: Ensure the material is food-grade certified.

Application Requirements: Choose the right type and size for your specific needs.

Regulatory Compliance: Verify compliance with relevant safety standards.

Common Misconceptions about Plastic Shims in Food Applications

There are several misconceptions about using plastic shims in food applications:

All Plastics are Unsafe: Not all plastics pose a risk; food-grade plastics are safe for use.

Plastic Shims Cannot Be Used in Direct Contact with Food: Properly certified plastic shims can safely be used in direct contact applications.

FAQs about Plastic Shims in Food Applications

Can plastic shims be used in direct contact with food? Yes, if they are made from food-grade materials and comply with relevant safety standards.

What materials are best for food-safe plastic shims? Polyethylene (PE) and Polypropylene (PP) are commonly used due to their chemical resistance and stability.

How can I ensure my plastic shims are safe for food applications? Look for certifications from regulatory bodies like the FDA or EFSA and choose reputable suppliers.

Are there eco-friendly options for plastic shims? Yes, there are biodegradable and recyclable plastic shims available on the market.

What are the risks of using non-food-grade plastic shims in food applications? Non-food-grade plastics can leach harmful chemicals and contaminate food with plastic particles.

How often should plastic shims be inspected in food-related applications? Regular inspections should be conducted to ensure they remain intact and free from wear and damage.

Conclusion

Plastic shims can be safe for use in food-related applications provided they are made from food-grade materials and comply with relevant safety standards. Understanding the types of plastics used, potential risks, and best practices can ensure their safe and effective use in the food industry. By staying informed about regulations and innovations, businesses can confidently use plastic shims to enhance their operations while maintaining the highest standards of food safety.

0 notes

Text

Future Prospects of the Headlight Lens Market

The headlight lens market has seen significant growth in recent years, driven by advancements in automotive technology, increased vehicle production, and a rising emphasis on road safety. This article delves into the current market size, share, industry trends, and future forecasts for the headlight lens industry.

Market Overview

The headlight lens market encompasses the production and distribution of lenses used in vehicle headlights. These lenses are crucial for focusing and directing light from headlamps to ensure optimal visibility for drivers, especially in low-light conditions. The market has been expanding steadily, with a projected compound annual growth rate (CAGR) of 9.11% from 2024 to 2032. This growth is attributed to several factors, including technological advancements, increasing automotive sales, and stringent government regulations regarding vehicle safety.

Market Size and Share

As of 2023, the global headlight lens market is valued at approximately $7.94 billion. The market is segmented based on type, vehicle type, material, and region. The two primary types of headlight lenses are polycarbonate and glass. Polycarbonate lenses dominate the market due to their durability, lightweight nature, and resistance to impact.

In terms of vehicle type, the market is divided into passenger vehicles, commercial vehicles, and two-wheelers. Passenger vehicles hold the largest share, contributing to over 60% of the total market revenue. This dominance is driven by the high production and sales of passenger cars globally.

Geographically, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is the largest market, accounting for over 40% of the global revenue. The region's dominance is due to the presence of major automotive manufacturers in countries like China, Japan, and India, along with increasing vehicle production and sales.

Industry Trends

Several trends are shaping the headlight lens market. Firstly, there is a growing demand for LED and laser headlights, which offer better illumination and energy efficiency compared to traditional halogen lamps. These advanced lighting solutions require specialized lenses to optimize light output and direction.

Secondly, the trend towards autonomous vehicles is influencing the headlight lens market. Autonomous vehicles require sophisticated lighting systems that include advanced lenses for improved visibility and safety. This trend is expected to drive innovation and growth in the market.

Thirdly, there is an increasing focus on aesthetic appeal and design in the automotive industry. Headlight lenses are now being designed to enhance the overall look of vehicles, contributing to the growing demand for customized and aesthetically pleasing lenses.

Technological Advancements

Technological advancements are playing a crucial role in the growth of the headlight lens market. Innovations in materials, such as the development of more durable and lightweight polycarbonate compounds, are enhancing the performance and longevity of headlight lenses. Additionally, advancements in manufacturing processes, such as injection molding and coating technologies, are improving the quality and efficiency of lens production.

Moreover, the integration of adaptive lighting systems in vehicles is driving the demand for advanced headlight lenses. Adaptive lighting systems automatically adjust the headlight beam based on driving conditions, requiring lenses that can effectively manage and direct light.

Regulatory Impact

Government regulations regarding vehicle safety and lighting standards are significantly impacting the headlight lens market. Regulations mandating the use of advanced lighting systems to improve road safety are driving the adoption of high-quality headlight lenses. For instance, the European Union has implemented regulations requiring the use of LED or laser headlights in new vehicles to enhance visibility and reduce accidents.

Future Forecast

The future of the headlight lens market looks promising, with continued growth expected in the coming years. Headlight Lens Market Size was estimated at 7.94 (USD Billion) in 2023. The Headlight Lens Market Industry is expected to grow from 8.66(USD Billion) in 2024 to 17.4 (USD Billion) by 2032. The Headlight Lens Market CAGR (growth rate) is expected to be around 9.11% during the forecast period (2024 - 2032).

One of the key drivers of future growth is the increasing demand for electric vehicles (EVs). EVs require advanced lighting systems to ensure optimal visibility and safety, driving the demand for high-quality headlight lenses. Additionally, the growing trend towards autonomous vehicles is expected to further boost the market.

Another factor contributing to future growth is the increasing focus on sustainability. Manufacturers are developing eco-friendly materials and production processes to reduce the environmental impact of headlight lenses. This trend is expected to drive innovation and growth in the market.

Competitive Landscape

The headlight lens market is highly competitive, with several key players dominating the industry. Major players include companies like Koito Manufacturing Co., Ltd., Varroc Lighting Systems, Valeo, Stanley Electric Co., Ltd., and Magneti Marelli. These companies are focusing on strategic partnerships, mergers and acquisitions, and product innovation to maintain their market position and expand their product portfolio.

Challenges and Opportunities

Despite the positive outlook, the headlight lens market faces several challenges. One of the primary challenges is the high cost of advanced lighting systems, which may limit their adoption in low-cost vehicles. Additionally, the complexity of manufacturing advanced headlight lenses can pose challenges for manufacturers.

However, these challenges also present opportunities for growth. The development of cost-effective manufacturing processes and materials can help overcome the cost barrier and drive the adoption of advanced headlight lenses. Furthermore, the increasing demand for customized and aesthetically pleasing headlight lenses offers significant growth opportunities for manufacturers.

Conclusion

The headlight lens market is assured of significant growth in the coming years, driven by technological advancements, increasing vehicle production, and stringent government regulations. The market offers numerous opportunities for innovation and growth, particularly in the areas of advanced lighting technologies and sustainable production processes. As the automotive industry continues to evolve, the demand for high-quality headlight lenses is expected to rise, contributing to the overall growth of the market.

0 notes

Text

Global Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2030

Bio-based Polycarbonate Market size was valued at USD 75.28 million in 2022, expected to reach USD 145.65 million in 2030 with a CAGR of 8.6% for the forecast period between 2023 and 2030. Conventional polycarbonate resins are made from bisphenol A, which raises the concerns of sustainable goals and innovation shifted to derive alternate polycarbonate from bio or natural resources. Polycarbonates have many applications used alone or blended for numerous sectors like electronics, automotive, housewares, etc. Being produced from natural resources, the features of polycarbonates got enhanced, like delivering excellent optical properties, chemical & UV resistance, higher surface resistance, etc.

Sample report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market/sample-request

Electronics Industry is Augmenting the Bio-based Polycarbonate Market While Concerning the Sustainable Goals

Bio-based polycarbonate copolymer drives the electronics industry by providing sustainable materials and achieving net-zero carbon emissions. It is successively used as a smartphone battery cover, which should be certified by prominent certifications. The bio-based polycarbonate is made of a minimum composition of natural polymers and a maximum content of post-consumer products. Such effective polycarbonates assist in thin-wall injection molding for numerous applications, including electrical housings or health care. SABIC has developed high-performance bio-based polycarbonate that comprises around 21% natural polymers (like vegetable oils) and over 50% post-consumer recycled resin, along with pre-consumer recycled carbon fibers. Substantially the product is halogen free and PIN flame retarded and progressively used for electronics packaging.

Data released by the Static PIB states that the global market industry in 2020 is dominantly estimated at around USD 2.9 trillion, which is almost equivalent to India’s economy. India is growing exponentially, creating a huge production potential of around USD 25 billion in the electronics industry, around 12% of global investment. A survey data published by the Japan Electronics and Information Technology Industries Association JEITA states that the global electronics and IT industries are estimated to rise 5% in 2022, total to USD 3,536.6 billion.

Automotive Industry is Propelling Exceptionally using Bio-based Polycarbonates

Bio-based polycarbonate possesses unique features like incredible optical properties, high transparency, and phenomenal scratch resistance. These properties are substantially important in the perspective of automotive vehicles. Plant-derived polycarbonates are contributing to developing enhanced vehicle features and appearance with extended durability. These polymer formulations develop additional sustainable benefits supporting the economy and reducing product carbon footprint. Mitsubishi Chemical has developed excellent plant-based bicarbonate resin extensively used for automotive exterior and interior parts. Plant-based isosorbide polycarbonates have excellent optical properties and retain high surface hardness and transparency characteristics, imparting vivid colors in the transparent panels.

The demand for cars in South America has increased by 1.8%, accounting for 2.8 million units sold in 2022, where Brazil is contributing majorly to such a segment. In 2022, Indian passenger car sales rose by 23.1%, achieving 3.8 million units due to effective measures taken by the Indian government like lower interest rates. Taking account of 2023, the outlook for the European market is convincingly showing positive trends to create huge growth for the automotive industry.

Roofing Solutions has Effectively Improved by Incorporating Bio-based Polycarbonates

Bio-based Polycarbonate have successively enhanced the roofing and sliding solution from huge malls to large stadiums. The selection of high-strength and durable panels that enable varying heat and light intensity can lead to the proper architecture of such massive constructions. Palram Industries Ltd. is successfully manufacturing polycarbonate flat and corrugated panels for a wide range of applications. Its unique roofing and sliding solutions use proprietary SolarSmart technology which effectively facilitates light penetration selectively. From building huge malls to advancing world-class Olympic stadiums, they have numerous accountings of such projects that provide thermal insulation, heat blocking, chemical resistance, light transmission, and diffusion.

Annual report published by Stadiums Queensland (SQ) stated that during 2021-2022, Stadiums Queensland (SQ) hosted more than 3.4 million patrons across entire venues that substantially contributed more than USD 646 million in economic benefit to the Queensland economy and created around 5,717 FTE jobs for various event-related industries including cleaning, catering, and security.

Impact of COVID-19

The outbreak of COVID-19 has severely impacted numerous sectors and human livelihoods, where every person was vulnerable to infectious disease. The fight against COVID-19 was a challenging operation that evolved every sector to contribute their practices and eradicate the impact. Bio-based polycarbonates are important for developing effective solutions in numerous applications, especially automotive and construction. The pandemic impact was extended to these significant sectors, leading to a complete shutdown of manufacturing units and the delivery of new cars. But after the pandemic, companies invested more to recover the loss during a pandemic, and construction practices also resumed. Therefore, the market for bio-based polycarbonates is on the verge of growing exponentially with such enormous applications.

Bio-based Polycarbonate Chemical Market: Report Scope

“Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Bio-based Polycarbonate Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

0 notes

Text

Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036

A comprehensive analysis of the “Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036” provides an accurate overview and thorough analysis of the market industries in the present and the future. This report provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry. It provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry.

Request Free Sample Copy of this Report @

https://www.researchnester.com/sample-request-6007

Report findings provide valuable insights into how businesses can capitalize on the opportunities provided by these dynamic market factors. It also provides a comprehensive overview of the major players in the industry, including their product offerings, contact and income information, and value chain optimization strategies. Furthermore, it offers an in-depth analysis of the leading businesses in the industry based solely on the strength of their business plans, product descriptions, and business strategies.

Key Findings

Plastic Injection Molding Machine Market has experienced significant growth in recent years, driven by factors such as increasing consumer demand and technological advancements.

The market segmentation analysis revealed several key segments, including Machine Type, Application each with unique characteristics and growth potential.

Regional analysis highlighted the strong performance of Plastic Injection Molding Machine Market in regions such as North America, Europe, and Asia-Pacific, with emerging markets showing promising growth opportunities.

Analyzing the Plastic Injection Molding Machine Market

A thorough understanding of the Plastic Injection Molding Machine Market will provide businesses with opportunities for growth such as customer acquisition, enhancements to their services, and strategic expansions.

By incorporating market intelligence into their operations, businesses can anticipate changes in the economy, assess the effect these factors may have on their operations, and create plans to counteract any negative effects.

Market intelligence helps organizations stay ahead of the curve through insights into consumer behavior, technological advancements, and competitive dynamics.

Using Plastic Injection Molding Machine Market data can provide organizations with an edge in the competitive market and establish prices and customer satisfaction levels.

Request for customization @

https://www.researchnester.com/customized-reports-6007

In a dynamic market environment, business validation helps companies develop business plans and assures their long-term survival and success.

What are the most popular areas for Plastic Injection Molding Machine Market?

The North American continent includes Canada, Mexico, and the United States.

The European Union is made up of the United Kingdom, France, Italy, Germany, the Republic of Turkey, and Russia.

The Asia-Pacific region is comprised of China, Japan, Korea, India, Australia, Vietnam, Thailand, Indonesia, and Malaysia.

The region of Latin America, which includes Brazil, Argentina, and Columbia

In addition to Africa, the Middle East includes South Africa, Egypt, Nigeria, Saudi Arabia and the United Arab Emirates.

Report highlights include:

There is a 360-degree synopsis of the industry in question in this study, which encompasses all aspects of the industry.

The report presents numerous pricing trends for the keyword.

Additionally, the report includes some financial data about the companies included in the competitive landscape.

The study enumerates the key regulatory norms governing the keyword market in developed and developing economies.

Additionally, the keyword report provides definitions of the market terms referred to in the document for the sake of convenience.

Future Potential

In the keyword research report, various primary and secondary sources are used to describe the methodology of conceptualizing the study. It has been discussed in the study what the scope of the report is and what elements it contains in terms of the growth spectrum of the keyword. The document also includes financial data of the companies profiled, along with the current price trends of the keyword.

Access our detailed report at@

https://www.researchnester.com/reports/plastic-injection-molding-machine-market/6007

0 notes

Video

youtube

Lead the injection molding machine industry, choose Haituo, pack and ship!Cooperate with Haituo to move towards a better future and create a bright future!Welcome to Haituo. Haituo Injection Molding Machine is a direct manufacturer factory specializing in manufacturing injection molding machines, established in 1919. Has 20 years of experience in manufacturing injection molding machines, has been an Alibaba gold medal supplier for 13 years, and exports to more than 30 countries. Can provide complete solutions for plastic molding. Haituo brand is a better choice for China.Dear Boss:Nice to meet you! I am Brian, boss of Ningbo Haituo Technology Machinery Co.Ltd.Main Products:Haituo new injection molding machines: HTF series energy saving machine from 60-3000T; U series Two platen, W series European standard, PET preform/crate/PVC special, KS series high speed, Multi-color series machines, supply all spare parts

0 notes

Text

Europe Injection Moulders Market Demands, Analysis, Size, Trends, Revenue by 2033

The Europe injection moulders market is poised for robust growth, with a projected Compound Annual Growth Rate (CAGR) of 4.1% anticipated during the forecast period. This growth trajectory is expected to translate into substantial market value expansion, forecasted to surge from US$ 2,330.1 million in 2023 to a noteworthy US$ 3,481.2 million by 2033.

Injection moulders, also known as injection molding companies or injection moulding firms, are specialized manufacturing entities that use the injection molding process to produce plastic components and products. These companies provide a range of services related to injection molding, catering to various industries and clients. Here's a more detailed definition of "Europe Injection Moulders.

Request Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-17512

Here are some key points to consider for the injection molding market in Europe:

Market Size and Growth: The injection molding market in Europe has historically been significant and is expected to continue to grow. This growth is driven by various industries, including automotive, packaging, healthcare, electronics, and consumer goods.

Automotive Industry: Europe has a strong automotive industry, and injection molding is widely used for manufacturing various automotive components, such as interior and exterior parts, engine components, and electronic systems. Any changes in the automotive sector can significantly impact the injection molding market.

Sustainability: There is a growing emphasis on sustainability and environmental concerns, which is influencing the materials used in injection molding. Biodegradable and recycled materials are becoming more popular, and companies are investing in eco-friendly processes.

Technological Advancements: Injection molding technology is continuously evolving. Advancements in machinery, automation, and 3D printing are enhancing the efficiency and capabilities of injection molding processes.

Regulations: European regulations regarding materials, product safety, and environmental impact are important factors influencing the injection molding market. Compliance with these regulations can be a challenge and an opportunity for manufacturers.

Reshoring: The COVID-19 pandemic highlighted vulnerabilities in global supply chains, leading some companies to consider reshoring or nearshoring manufacturing operations. This may impact the injection molding landscape as well.

Consumer Trends: Consumer preferences and trends in product design can affect the demand for injection-molded products. Customization, aesthetics, and functionality are key considerations.

Competitive Landscape: The injection molding industry in Europe is competitive, with numerous manufacturers and suppliers. Market dynamics, including mergers and acquisitions, can change the competitive landscape.

Raw Material Prices: Fluctuations in the prices of raw materials, such as plastics and additives, can impact production costs and pricing in the injection molding sector.

0 notes

Text

Natural Fiber Composites Market Growth Rate, Revenue & Future Scope: 2030

Natural Fiber Composites Market by Fiber Type (Wood, Cotton, Flax, Kenaf, Hemp, Others), by Technology (Injection Molding, Compression Molding, Others), by Application (Automotive, Electronics, Construction, Others) and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America).

Market Overview

The global Natural Fiber Composites market size was estimated at USD 328.2 million in 2023 and is projected to reach USD 496.4 million in 2030 at a CAGR of 6.1% during the forecast period 2023-2030.

Fiber-reinforced composites are in reasonably high demand. They are not eco-friendly, though, and are pricey. These fibers cannot be recycled or renewed. Regulations for the automobile sector have been introduced in several Asian and European Union nations. In accordance with laws adopted by the European Union in 2006, 80% of cars must be recycled or reused; in the 2015 version, this percentage increased to 85%. A 2015 rule in Japan mandates that 95% of automobiles should be recycled or repurposed. The usage of glass fiber composites is also constrained by limitations including high fiber density, low recyclability, handling dangers, and other issues. Natural fiber composites benefit from the shortcomings of glass fiber composites.

The desire for lighter, safer, more fuel-efficient, and electric automobiles is propelling the market for natural fiber composites. This is explained by the greater strength, stiffness, fracture resistance, and thermal & acoustic insulation properties that these fibers display. NFC technology also lowers the cost of parts used in automotive applications. Composite manufacturing is quickly becoming a more cost-effective option than conventional methods for making vehicle components. This environmentally beneficial approach is aided by plant-based fibers, including bamboo, kenaf, hemp, jute, flax, coir, sisal, and banana.

There have been some positive impacts of the COVID-19 pandemic on the natural fiber composites market, such as the pandemic has led to a greater focus on sustainability and the circular economy, as more people are realizing the importance of preserving natural resources and reducing waste. Companies that make natural fiber composites are in a good position to profit from the growing demand for sustainable products since they provide traditional materials a more ecologically friendly alternative.

Request Sample Pages of Report: https://www.delvens.com/get-free-sample/natural-fiber-composites-market-trends-forecast-till-2030

Delvens Industry Expert's Standpoint

Natural fibers in composites have the potential to further reduce product weight, which might result in reduced transportation-related emissions and fuel use. The use of NFCs in the construction industry is predicted to rapidly expand as a result of the aforementioned factors, Load-bearing structures including beams, roofs, multifunctional panels, water tanks, and pedestrian bridges are made using natural fiber composites. NFCs are also used to create structural beams and frames for pedestrian bridges with light to medium design loads. Moreover, natural fiber composites are utilized to make beams because of their lower cost, lower density, and favorable environmental consequences, such as the need for less energy and carbon dioxide during manufacture compared to synthetic composites,which will fuel market expansion.

Key Findings

By fiber type, Load-bearing structures including beams, roofs, multifunctional panels, water tanks, and pedestrian bridges are made using natural fiber composites. NFCs are also used to create structural beams and frames for pedestrian bridges with light to medium design loads. Moreover, natural fiber composites are utilized to make beams because of their lower cost, lower density, and favorable environmental consequences, such as the need for less energy and carbon dioxide during manufacture compared to synthetic composites.

By technology, The market is divided into injection molding, compression molding, and other categories based on technology. In 2022, the category that dealt with injection molding had the biggest market share. A common manufacturing procedure for mass production is injection molding. The popularity of injection molding is largely due to great processability, despite the fact that the reinforcing fiber deteriorates throughout the procedure. The domination of the injection molding market is a result of rising demand for composite materials from the automotive, hardware/apparatus, medical, and bundling industries.

By application, The market is divided into automotive, electronics, construction, and other applications. In 2022, the automotive industry accounted for the highest market share. Automobile manufacturers all over the world have increased their investments as a result of the growing demand for hybrid and electric vehicles. The world's booming automobile business continues to play a significant role in the market expansion for natural fiber composites.

The market is divided into four regions based on geography: North America, Europe, Asia-Pacific, and LAMEA. With a sizable population and a developing middle class, the Asia-Pacific area is one of the regions of the globe that is expanding the quickest. The Asia-Pacific region is experiencing rapid industrialization, which is driving demand for lightweight and high-performance materials.

Make an Inquiry Before Buying: https://www.delvens.com/Inquire-before-buying/natural-fiber-composites-market-trends-forecast-till-2030

Regional Analysis

North America to Dominate the Market

Natural fiber composites are increasingly used in a variety of industries, including automotive, electrical & electronics, and building & infrastructure, which is primarily driving the growth of the natural fiber composites market in Asia Pacific. Countries like China, India, and Japan dominate the market in these end-use industries.

The Asia Pacific area is the leader in the world's building and construction sector, which enjoys significant growth there due to substantial infrastructure development activities in the majority of countries. Large-scale infrastructure projects, building & construction projects, as well as civil and environmental applications, are being funded by emerging economies including China, India, Japan, Malaysia, Indonesia, and South Korea.

Competitive Landscape

Trec Company, Inc.

FlexForm Technologies

Fiberon Technologies, Inc.

The AZEK Company LLC

Polyvlies

Procotex

DuPont

GreenCore Composites Inc.

Meshlin Composites Zrt

GreenGran B.V.

UPM

Plasthill Oy

Green Dot Bioplastics Inc

Tecnaro GmbH

Jelu-werkJ

Ehrler GmbH & Co.

Bcomp Ltd.

Lingrove Inc