#mold plastic parts

Text

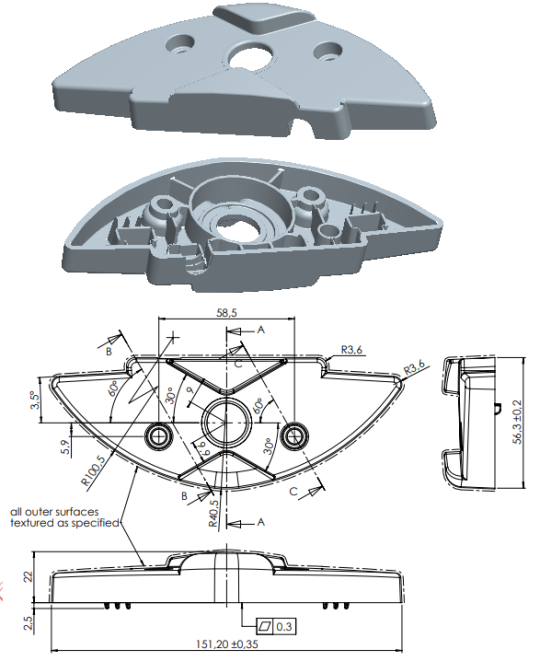

Key Points of Injection Mold Design for End Cover of Wall Hanger

See Figure 1 for wall mount end cap products. Maximum dimensions of product are 151.20 mm * 56.30 mm * 24.50 mm; average thickness of plastic part is 2.50 mm, material of plastic part is PA6 + 30GF, shrinkage rate is 1.005, and weight of plastic part is 48.75 grams. Technical requirements for plastic parts are that there should be no defects such as peaking, underfilled injection molding, flow…

View On WordPress

#Cowhorn gate#demoulding slope#Die structure#Die structure diagram#Dutch mold#European injection molds#European molds#German HASCO standards#injection and etching#injection mold design#Key Points of Injection Mold Design#mold design#Mold Design Specification Book#mold plastic parts#mold standard parts#mold structure#plastic part#Sub-gate#underfilled injection molding

0 notes

Text

Take time to see them... Plaskon brand plastic materials ad - 1945.

#vintage clocks#vintage timepieces#clocks#wall clocks#vintage wall clocks#plastics#molded plastic#plaskon#plaskon plastics#plastic products#libbey-owens-ford glass company#chemical companies#chemical industry#industrial design#plaskon products#plaskon clocks#plaskon cabinets#plaskon cases#plaskon parts#plaskon company

5 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

it's cool to have my parts come in and test them out and see the phenomena from my injection molding textbook play out in front of me. look at that! it breaks right at that stress concentration! or when overloaded here, it breaks right at the weld line! there's shrinkage here and here! even stuff like anisotropic strength due to the orientation of the glass fibers and the polymer strands is right there in front of my eyes. yes!! yes!!

#friendly neighborhood mechanical engineer#blorbos (parts 2-10459 and 2-10460) from my shows (Plastic Part Design for Injection Molding: An Introduction#2nd edition. Robert A Malloy)

10 notes

·

View notes

Text

Month 4, day 3

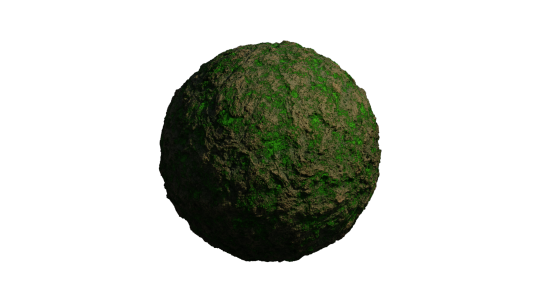

Tonight we did a mossy ground texture :D

I'm going to cause ~problems~ with this >:3 Visorian problems~

#the great artscapade of 2024#art#my art#blender#blender render#procedural textures#blender 3D#cycles render#my roommate has issued me a challenge#or rather a suggestion#plastic!#which should be relatively easy enough to do but he specifically wanted with surface imperfections#like from the molding process on Gunpla parts#(he's the reason I'm doing that untitled Gunpla comic if anyone remembers the character expression sheets I did for that in '22)#so I'll see if I can find a tutorial for something similar and see if I've absorbed enough lessons to make it >:3

3 notes

·

View notes

Text

i love making posts on my rick shades blog that are just me doing my stupid and silly me things, bc i have the smallest chance of people calling ME rick shades, and just that possibility makes me sit there with glee bc i get to imagine rick doing the same stupid shit i do. on the other hand i am scared of ppl assuming im just a rick shades rp blog, which is not the case. like rp blogs are perfectly fine, but im just a silly little guy who relates far too much to a silly little FICTIONAL guy

anyways this started about me getting platonic crushes on people, im sitting here like kicking my legs and twirling my hair like OMGGG WHAT IF WE WERE FRIENDSSS WE SHOULD BE FRIENDSSSS

#wizard.txt#like i loved the gatorlyte post#ill draw myself as rick for a joke#its funny#and i do have many things wrong with me#i have been told to not eat mold#ive eaten plastic#when i was a child i ate a mud pie#ive gotten food poisoning from expired fruit snacks#the funny part about that is while i was eating them#i was w/ my partner#and i was like 'babe.... these fruit snacks kinda taste weird...'#'oh well! they prolly changed recipes its not bad'#the next day i threw up LMAO#ive also eaten expired whip cream#knowing it was expired#i am a very smart man but i lack a lot of common sense

11 notes

·

View notes

Text

hold on i gotta be emo

#txt#drug use/drug abuse mention#man im dissociating so hard right now and i feel like im losing it#i just need my strength to be witnessed#im fitting fangs rn#and the molding stuff comes in little plastic capsuls#and the amount of powder in the capsule#as well as the act of opening the capsule and getting everything out of it#its kind of fuckjng#fucking with me#it looks just like europa#i always forget about this part w fangs#probably for a reason

4 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Some pics of my Christmas tree this year!

The tree itself is an artificial tree with black leaves. The ornaments are all painted with fluorescent paint and the lights are UV fairy lights. It looks so dang cool all lit up at night.

#christmas#christmas tree#christmas 2022#happy holidays#merry shitscram#fluorescent paint#neon paint#ultraviolet#it doesn't show much#but I also customized the tree topper#it was just gold accent with orange plastic over the lights#but I did a wash with black paint on the gold part#and then painted black lines on some ridges molded into the star#that helped give it a bit more depth#I think I'm gonna try to remove some lights from the star for next year though#because it overpowers the rest

2 notes

·

View notes

Text

About time I did some rework on my 3D printable clamp.

#ooc#and this one's gonna look so much better than the old blue one#eventually might customize it more with unnecessary details just to flex#maybe a diamond plate surface finish or 'mock plastic molding' structural ribs around the holes and edges of the part#it's adapted from a metal stock design#you can mix things up when adapting those metal designs for 3D printing#the process is different so understanding those differences can unlock so many possibilities for a new design#you can print complicated shapes that can't be easily done with a mill or lathe#don't let subtractive techniques hold you back!#💫❤️🌹🌞❤️❤️🌼 I fucking love making things#I'm on legal amphetamine sorry

2 notes

·

View notes

Text

Precision Mechanical Components china

Looking for precision mechanical components in China? Look no further than Hsmolds.net. With a reputation for quality and reliability, Hsmolds offers a wide range of precision mechanical components to suit your needs. From CNC machining to injection molding, they have the expertise to deliver top-notch products at competitive prices. Explore their catalog today for your manufacturing needs.

0 notes

Text

Summary of common interview questions for mold design engineers. A total of 91 common knowledge points that must be known

1. Common shrinkage rates of plastic materials?Answer: ABS, PC, PMMA, PS, PA66+30GF: 1..005POM, PVC, PE: 1.020PP, PET, PBT: 1.015-1.0202. Common defects in plastic parts?Answer: Glue deficiency, cloak, bubbles, shrinkage, weld marks, black spots, bubbles, stripes, warping, delamination, peeling, etc.;3. Commonly used plastic mold steel?Answer: 718, 738, S136, NAK80, SKH51, SKD61, 2344, 8407,…

View On WordPress

#Default accuracy of UG#defects in plastic parts#Die-casting molds#electric spark machining#injection molding molds#injection pressure#mold design engineers#Mold designer#mold engineer#mold maker#mold manufacturing#mold structures#plastic molds#plastic product#plug-through#product designer#punch-through#shrinkage rates of plastic materials#two-color mold#What is a PL surface#What is a pouring system#What is a weld mark#What is bone position#What is discharge machining#What is function of air discharging groove#What is overcutting#What is pillow position#What is plastic deformation#What is undercut

0 notes

Text

10 Plaskon parts in every Kelvinator refrigerator. Plaskon plastic parts ad - 1937.

#vintage refrigerators#vintage appliances#plastics#molded plastic#plaskon#plaskon plastics#plastic products#libbey-owens-ford glass company#chemical companies#chemical industry#industrial design#plaskon products#plaskon parts#vintage kitchens#vintage kitchen appliances#kitchen appliances#refrigerators#kelvinator refrigerators#kelvinator#plaskon company

5 notes

·

View notes

Text

Plastic Part Design For Injection Molding

Injection Molding is one of the most common techniques used in plastics manufacturing in that parts are ‘injected’ into molds to form parts with specific dimensions. This process depends on the plastic part design considerations to achieve efficiency in meeting performance goals and the aesthetical and the cost of these parts. This article reviews the fundamental design features of a plastic part…

0 notes

Text

The automotive industry, historically known for its reliance on heavy metals and non-renewable resources, has been gradually shifting towards a more eco-friendly approach. The adoption of automotive plastic molding technology is a testament to this transformation. By replacing traditional materials with lightweight, recyclable plastics, the industry is not only reducing its carbon footprint but also enhancing the performance and efficiency of vehicles.

The process of automotive plastic molding involves the use of advanced techniques to shape and form plastics into various components of a vehicle. These components, ranging from interior trims to exterior panels, are designed to meet the stringent requirements of the automotive industry. The use of plastics in automotive molding offers numerous advantages, including reduced weight, improved fuel efficiency, and enhanced durability.

One of the key benefits of automotive plastic molding is its lightweight nature. Plastics are significantly lighter than traditional materials such as steel and aluminum. This reduction in weight leads to improved fuel efficiency, which in turn reduces the overall emissions produced by vehicles. As a result, the adoption of this technology is a step towards achieving the industry's goal of reducing its environmental impact.

Another advantage of automotive plastic molding is its recyclability. Unlike metals, plastics can be easily recycled and repurposed, reducing the need for extracting new raw materials. This not only conserves natural resources but also minimizes waste generation. The automotive industry's commitment to using recyclable materials is a clear indication of its dedication to sustainable practices.

0 notes

Text

Premium Plastic Injection Molding Parts Supplier

Explore PTMS Mold’s extensive gallery of plastic injection molding parts. We specialize in producing high-quality components tailored to your specifications. Our advanced manufacturing processes and rigorous quality control ensure every part meets your exact requirements. Trust PTMS Mold for reliable, precise, and durable plastic injection molded parts for a variety of applications.

0 notes