#Gas Monitoring Devices

Explore tagged Tumblr posts

Text

Portable Single Gas Detector

Labtron Portable Single Gas Detector utilizes a diffusion sampling method and employs electrochemical sensors for oxygen and toxic gases, catalytic combustion for flammable gases, common toxic gases such as CO, H2S, SO2, NO, ClO2, NO2, and H2 within 30 seconds. Features a segment encoding LCD display that shows real-time detection values & allows users to set upper and lower alarm limits according to their requirements and adjustable backlight brightness to save power.

0 notes

Text

#Smoke Detectors#Gas Leak Detectors#Gas Sensors#Gas Alarm Systems#Gas Detection Systems#Gas Monitoring Devices#Marine Safety Equipment#Optical Smoke Detectors#Optical Gas Detectors

1 note

·

View note

Text

Gas Leak Detection and Emissions Management: What You Need to Know

Understanding Modern Gas Leak Detection and Repair Needs

The demand for advanced gas leak detection and repair has increased across industrial, commercial, and utility sectors. Detecting and responding to gas leaks swiftly is not just about avoiding downtime—it’s about safeguarding human health, environmental safety, and equipment longevity. Many facilities that deal with hydrocarbons face persistent challenges in managing emissions. Whether leaks occur from valves, flanges, compressors, or storage tanks, undetected gas emissions can accumulate and lead to significant hazards. This is why having a proactive detection and repair strategy is a non-negotiable priority.

Relying on integrated systems and handheld tools, maintenance professionals can identify fugitive emissions more efficiently than ever. Targeted repairs based on accurate readings reduce unnecessary part replacements and allow for better scheduling of shutdowns. Embracing technological innovation in gas monitoring supports regulatory compliance while also reducing operational costs. This makes a strong case for businesses to invest in systems that can detect, quantify, and prioritize gas-related threats with confidence.

Key Components of Gas Leak Detection Systems

To implement reliable gas leak detection practices, organizations must first understand the range of technologies available. From infrared cameras to ultrasonic sensors, modern systems offer varying levels of sensitivity and adaptability. Each technology serves a specific function, and pairing them with routine maintenance schedules helps operators detect problems early. The goal is to catch leaks before they become serious threats, which is why predictive and real-time tools are becoming increasingly popular in the energy and utility sectors.

Environmental policies also drive companies to adopt comprehensive detection frameworks. Portable and fixed monitors integrated into site safety systems allow technicians to assess emissions around-the-clock. Training personnel to interpret detection data correctly is just as important as the hardware itself. When gas leaks are found promptly and mitigated effectively, it builds trust with regulators and community stakeholders.

The Role of Natural Gas Leak Detection in Industrial Safety

The accuracy and speed of natural gas leak detection are essential in environments where flammable gases are used or stored. Unlike other emissions, natural gas is odorless in its raw form, which means detection must rely on more than just human senses. Specialized instruments are used to identify leaks from infrastructure, especially during pipeline inspections, maintenance work, or post-installation reviews.

Beyond safety, cost control is another major driver for leak management. Wasted gas results in revenue loss, and repeated incidents can damage public image. Smart detection approaches allow for consistent monitoring of pressurized lines, valves, and connectors. Incorporating these solutions into daily protocols empowers teams to intervene faster and avoid large-scale disruptions in service delivery or manufacturing operations.

What to Know About Natural Gas Leak Detection Equipment

Choosing the right natural gas leak detection equipment depends on several variables, including gas type, detection range, operating temperature, and environment. Common devices include flame ionization detectors, infrared sensors, and catalytic bead sensors, each tailored to specific detection thresholds and conditions. These systems are designed to alert operators when gas concentrations exceed acceptable safety levels.

Field personnel are trained to operate detection gear in varied site conditions—from confined spaces to open facilities. Durability and ease of calibration are key selection factors when investing in equipment. By prioritizing real-time alerts and wireless data transmission, detection devices help facility teams act on insights quickly, often preventing emergencies before they escalate.

Why Modern Facilities Rely on Gas Leak Detection Equipment

Industrial operations can’t afford to rely on outdated gas leak detection equipment. Today’s monitoring tools offer enhanced sensitivity, portability, and wireless capabilities, which simplify deployment across various infrastructure types. Whether installed permanently or used on-the-go, detection units are the first line of defense against accidental releases.

System compatibility is another vital feature. Equipment that integrates with control systems enables immediate alerts and even automatic shutdowns in critical areas. For engineers and site supervisors, this connectivity translates to shorter response times and reduced risk exposure. Investing in the right detection solutions supports a culture of operational excellence.

Understanding the Function of Natural Gas LDAR Programs

Natural gas LDAR programs (Leak Detection and Repair) are mandatory for facilities regulated under emissions guidelines. These programs focus on identifying and reducing fugitive emissions through systematic inspections and maintenance actions. Inspections are usually done using optical gas imaging or flame ionization detection to quantify emissions at various points across a facility.

Proper recordkeeping is essential in demonstrating regulatory compliance. Data collected during LDAR inspections helps facilities track progress and adjust operational plans to stay within permitted thresholds. From upstream oilfields to downstream distribution networks, LDAR methods are pivotal for mitigating environmental impact and staying compliant with emissions legislation.

Using Gas Leak Detection Devices to Ensure Compliance

Portable gas leak detection devices are now standard tools in the safety arsenal of maintenance teams. These handheld or wearable devices are designed for rapid deployment, often with real-time readouts that make field assessments more efficient. Many models are multi-gas capable and can log detection data for reporting or regulatory submission.

Devices with visual and audible alarms help keep technicians safe during inspection rounds. The versatility of modern instruments allows for use in confined spaces, large process areas, and around volatile substances. As industries evolve, so does the technology behind detection, supporting a safer, more accountable approach to managing gas-related risks.

Improving Facility Performance with Leak Detection and Repair Strategies

A comprehensive leak detection and repair plan benefits more than just safety metrics—it can improve system efficiency and reduce operational waste. Identifying consistent sources of emissions allows managers to schedule preventative maintenance and improve the overall integrity of their pipelines and processing equipment.

Beyond repairs, understanding the cause of leaks is essential for long-term success. Isolating corrosion-prone areas, faulty seals, or aging infrastructure allows engineers to develop a prioritized plan for upgrades. This proactive approach reduces future incidents, which lowers risk exposure and operational costs over time.

Oil and Gas Leak Detection Technology in Harsh Environments

Oil and gas leak detection requires tools capable of operating in extreme conditions. From offshore platforms to remote well sites, detection systems must resist corrosive elements, temperature fluctuations, and heavy usage. Technologies such as laser absorption spectroscopy and ultrasonic sensors are widely used in these environments for their accuracy and reliability.

Real-time data logging, cloud integration, and long battery life make these systems suitable for around-the-clock monitoring. These capabilities are vital for reducing emissions, minimizing product loss, and adhering to both national and international safety regulations. As industry expectations rise, only advanced, rugged detection systems can keep pace with real-world demands.

Petrochemical Gas Detection and Safety Best Practices

In the petrochemical sector, petrochemical gas detection is a critical component of health and safety compliance. Facilities that process volatile organic compounds must prioritize leak detection to prevent workplace hazards, explosions, and environmental harm. Monitoring hydrogen sulfide, benzene, and other toxic gases is standard across storage tanks, loading bays, and reactors.

Combining area monitors with fixed-point sensors creates a layered approach to gas detection. Employees are also trained in emergency protocols using data from detection systems to navigate incidents quickly. In environments where milliseconds count, the accuracy of gas monitoring devices can mean the difference between containment and catastrophe.

The Importance of Methane Leak Detection and Repair

Facilities dealing with natural gas must prioritize methane leak detection and repair to comply with climate legislation and internal ESG goals. Methane, a potent greenhouse gas, often leaks undetected unless precise instruments are deployed. Targeted surveys and corrective action plans help reduce emissions and avoid penalties.

Beyond regulatory concerns, minimizing methane loss translates into direct cost savings. Every cubic foot of gas not lost to leakage improves the company’s bottom line. As public scrutiny around emissions grows, businesses are under pressure to showcase real progress—and accurate methane detection is one of the most transparent ways to do so.

An Overview of Gas Leak Detection Systems

Facility managers choose gas leak detection systems based on operational scale, emission type, and response requirements. Centralized detection networks can cover large areas with fixed sensors, while modular systems allow for targeted surveillance at vulnerable junctions and valves. Both approaches work in tandem to provide layered protection.

In manufacturing environments, integrating leak detection with automation platforms offers smarter data management and rapid alert distribution. The analytics provided by detection systems give insight into recurring issues, informing asset maintenance strategies and procurement decisions. With continuous improvement goals in mind, these systems become a foundation for responsible operations.

Best Practices for Methane Gas Leak Detection and Repair

Rigorous methane gas leak detection and repair strategies help industries align with global climate initiatives. Using thermal cameras and high-sensitivity gas sensors, inspection teams can visualize methane leaks in real time. This technology enables faster remediation and reduces the risk of overexposure in workers and surrounding communities.

Documenting and benchmarking repair success rates allows organizations to track efficiency and prove compliance. Advanced software tools now automate much of this process, linking data from field sensors to digital compliance platforms. With better detection comes improved control, making operations more transparent and less vulnerable to criticism.

Maintaining Performance Through Gas Detector Repair

Routine gas detector repair is essential for ensuring measurement accuracy. Detectors exposed to harsh conditions, humidity, or corrosive gases may drift over time, leading to false positives or missed detections. Calibrating and repairing these devices ensures that data remains trustworthy.

Certified technicians follow manufacturer specifications and compliance standards during repairs. This includes replacing sensors, updating firmware, and verifying calibration logs. Timely maintenance not only extends equipment lifespan but also maintains the confidence of field teams and safety managers in the accuracy of their tools.

Finding the Right Gas Leak Detection Solutions

The variety of gas leak detection solutions available today allows organizations to tailor monitoring to specific hazards and work environments. From fixed detection panels in warehouses to mobile units in remote fields, technology adapts to user needs. Sensor integration with IoT platforms adds predictive capabilities, giving early warnings before leak escalation.

Evaluating solution providers includes reviewing their response time, sensor accuracy, and after-sale support. Companies with diverse facility layouts benefit from modular detection systems that can grow with operations. Whether preventing fire risks or controlling emissions, investing in adaptable solutions pays long-term dividends.

Why LDAR Solutions Matter in Emissions Control

LDAR solutions play a vital role in environmental compliance by identifying and mitigating fugitive emissions. Leak detection and repair protocols are mandated by many regulatory bodies and must be documented thoroughly. LDAR software now includes features like automated scheduling, reporting, and data visualization, streamlining program management.

Program success depends on consistency. Regular inspections, accurate reporting, and timely maintenance all contribute to emissions control. With increasing pressure from environmental agencies and the public, implementing robust LDAR programs is no longer optional—it’s a strategic necessity for sustainable industrial operations.

#methane emissions#hetek flow sampler#gas leak detection devices#methane gas monitor#methane level#methane concentration#methane quanification device#natural gas ldar

0 notes

Text

What Is Microfluidics? An Introduction to Lab-on-Chip Technology

Discover how microfluidics and Lab-on-Chip technology are revolutionising diagnostics, research, and environmental monitoring. Learn about their precision, cost-effectiveness, and applications in healthcare, genomics, and food safety. Bring innovation to your business with cutting-edge solutions today.

#microfluidics technology#lab-on-chip devices#portable diagnostics#microfluidic applications UK#lab-on-chip healthcare#microfluidics environmental monitoring#microfluidics DNA analysis#microfluidic cost-effective testing#advanced lab-on-chip solutions#microfluidics sustainability#microfluidic drug development#LOC portable testing devices#A-Gas Electronic Materials

0 notes

Text

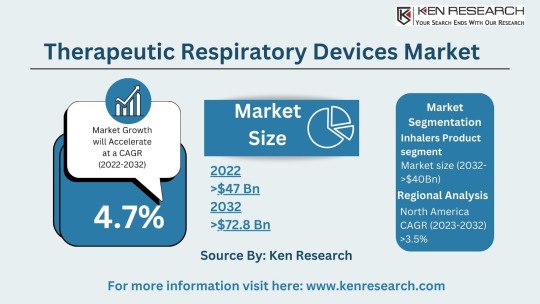

The $64.2 billion Respiratory Market & Its Future Trends, Segmentation and Forecast

The global respiratory market size reached a staggering USD 42.3 billion in 2023. This impressive figure highlights the significant need for respiratory devices and treatments to address a wide range of respiratory conditions. The market is projected to grow at a Compound Annual Growth Rate (CAGR) of approximately 7.4%, reaching an estimated USD 64.2 billion by 2030. This growth can be attributed to several factors:

Rising Prevalence of Chronic Respiratory Diseases: Conditions like asthma, chronic obstructive pulmonary disease (COPD), and sleep apnea are on the rise due to factors like air pollution, smoking, and an aging population.

Increased Life Expectancy: With an aging population, the demand for respiratory support devices for chronic conditions is expected to rise.

Technological Advancements: The development of innovative respiratory devices, such as portable nebulizers and advanced ventilators, offers improved treatment options.

Growing Focus on Homecare: The increasing emphasis on home-based care for respiratory patients fuels the demand for user-friendly respiratory devices.

Respiratory Market Segmentation: Catering to Diverse Needs

The respiratory market segmentation reflects the vast array of products and technologies available to address different respiratory needs:

By Application:

Therapeutic Respiratory Devices Market: This segment includes devices used for treatment, such as nebulizers, metered-dose inhalers (MDIs), and continuous positive airway pressure (CPAP) machines used for sleep apnea. The respiratory inhalers market is a significant sub-segment due to the widespread use of inhalers for asthma and COPD.

Anesthesia & Respiratory Devices: Specialized equipment used in surgical settings to deliver oxygen and maintain proper ventilation during anesthesia. The anesthesia and respiratory devices market caters to the specific needs of hospitals and surgical centers.

Respiratory Gas Analysis: This technology analyzes the composition of respiratory gases to assess lung function and identify potential respiratory issues.

By Device Type:

Respiratory Care Devices: This broad category encompasses various devices used for diagnosis, treatment, and monitoring of respiratory conditions. Examples include nebulizers, inhalers, ventilators, and CPAP (continuous positive airway pressure) machines.

Respiratory Monitoring Devices: These devices track vital signs such as blood oxygen levels and respiratory rate, allowing for continuous monitoring of patients with respiratory difficulties. The respiratory monitoring devices market is experiencing significant growth due to the increasing focus on patient safety and remote monitoring.

Respiratory Measurement Devices: These devices measure lung function and capacity, providing vital diagnostic information for respiratory conditions. The respiratory disease testing market relies heavily on these devices for accurate diagnosis.

Respiratory Protective Equipment (RPE): This equipment protects users from inhaling harmful substances, including masks and respirators. The respiratory protective equipment market is expected to witness growth due to rising concerns about air pollution and pandemics.

Take a look at: Forecasting the Respiratory Market, Size, Segmentation and Future Trends

Top Players in Respiratory Market: Breathing Innovation

Several established medical device manufacturers and specialty respiratory companies dominate the respiratory market:

Some of the top players in the respiratory market include:

Philips Healthcare

ResMed

Medtronic

GE Healthcare

Fisher & Paykel

Emerging Markets: A Rising Demand for Respiratory Solutions

Developing nations with growing populations and increasing healthcare expenditure present a significant opportunity. For instance, the bovine respiratory disease treatment market highlights the growing demand for respiratory solutions in the animal health sector.

Respiratory Market Trends: Shaping the Future of Respiratory Care

Exciting trends are shaping the respiratory market and transforming how we manage respiratory conditions:

Focus on Homecare Solutions: The emphasis on providing effective respiratory care solutions for patients in a home setting is driving innovation in portable and user-friendly devices.

Telemedicine Integration: Telehealth platforms allow remote monitoring and consultations with healthcare professionals, improving respiratory care management.

Connected Devices and Data Analytics: The integration of Internet of Things (IoT) technology allows for real-time data collection and analysis of respiratory parameters, leading to personalized treatment plans.

Emphasis on Early Detection and Prevention: The trend towards early detection and prevention of respiratory diseases through screening programs and lifestyle modifications is gaining momentum.

Challenges and Opportunities: Navigating the Respiratory Landscape

While the respiratory market offers promising opportunities, challenges also exist:

Challenges:

Cost Concerns: The high cost of some respiratory devices, particularly advanced equipment, can be a barrier to access for some patients.

Counterfeit Products: The presence of counterfeit respiratory products poses a safety risk and necessitates stringent quality control measures.

Compliance with Regulations: Navigating evolving regulatory requirements for medical devices can be complex and requires ongoing compliance efforts.

Opportunities:

Focus on Homecare: The trend towards homecare for respiratory patients creates a demand for portable and user-friendly respiratory devices.

Telemedicine Integration: Integrating respiratory monitoring devices with telemedicine platforms allows for remote patient monitoring and improved care coordination.

Emerging Technologies: The potential of new technologies like artificial intelligence and wearable devices can revolutionize respiratory care and diagnosis.

Respiratory Market Future Outlook: A Collaborative Approach

The respiratory market future outlook is promising, with a projected market size of USD 64.2 billion by 2030. And this suggests a market driven by innovation, collaboration, and a focus on improving patient outcomes. Here's what we can expect:

Collaboration between Medical Device Manufacturers and Healthcare Providers: Collaboration between these entities will be crucial for developing and implementing effective respiratory care solutions that address real-world clinical needs.

Increased Focus on Patient Education and Self-Management: Empowering patients with respiratory conditions to manage their health through education and user-friendly technology will be a key focus.

Conclusion:

The respiratory market plays a vital role in supporting lung health and improving the lives of millions suffering from respiratory illnesses. As the market continues to evolve, driven by innovation, collaboration, and a focus on patient-centric care, we can expect a future where managing respiratory conditions becomes more effective, accessible, and empowering for individuals and healthcare professionals alike.You can also read about: Future Forecast and Trends in the $35.58 Billion Respiratory Market

#Respiratory Market#Respiratory Industry#Respiratory Sector#Respiratory Market Size#Respiratory Market Segmentation#Respiratory Care Devices Market#Respiratory Devices Market#Therapeutic Respiratory Devices Market#Respiratory measurement devices market#respiratory gas analysis#anesthesia and respiratory devices market#respiratory disease testing market#bovine respiratory disease treatment market#respiratory inhalers market#respiratory monitoring devices market#respiratory protective equipment market#Top Players in Respiratory Market#Respiratory Market Trends#Respiratory Market Future Outlook

0 notes

Text

‘The Cables’

Image by Ryselle-Chan over on deviantart (used with her permission)

Story by MedFetAI

MORE just like this on my instagram!

Emma was sick. That much she knew. But the treatment at the medical center puzzled her. Mere minutes after check-in, she was asked to lie on a gurney. Gloved and masked nurses surrounded her, discussing ‘Stats’ and ‘Clamps.’ Before she could understand, her clothes were cut off, and blood pressure cuffs were tightly strapped to her limbs. A nurse in an apron approached, holding a Y-shaped device. She placed it over Emma’s groin, and it hissed as it sealed uncomfortably. Twisted wires were plugged into it, then into larger machines. A gentle current coursed through, stimulating her. Emma let out a relaxed, helpless groan. Her dazed state allowed nurses to attach clear plastic covers to her breasts, clamping them tightly. Emma felt a gentle gas swirling around the tips. Monitors activated, showing scientific readings from this unusual method. She looked around, freaked out, but the nurses ignored her. Ordinary electrodes, almost out of place, were placed on her chest for normal readings. The nurses gathered to finalize their plans, then pulled out another Y-shaped respirator, this one with a strange hollow mouthpiece and clear oxygen tubes. The tubes were connected to the large machines. The nurses approached Emma’s incapacitated, cyborg-like body, murmuring, ‘Soon, sweetie,’ and ‘Just this last thing...’ before putting the respirator in front of her face. One nurse, whispering into Emma’s ear, slowly moved the respirator into her mouth, forcing the mouthpiece down her throat. Emma, too high on her own endorphins, couldn’t protest. The mouthpiece triggered her gag reflex but was forced in. The respirator device was sealed, and the machine took over her breathing. The nurses stepped back, smirking. One said, ‘Goodnight Emma, and thanks,’ before turning a dial. The electric current by Emma’s groin grew stronger, and she blacked out from the sensation. She was then wheeled out through large lead double doors, into whatever horrors lay ahead.

#breathing#hospital#oxygen mask#resus#resus community#cpr#resus roleplay#resuscitation#defib#cpr resus

65 notes

·

View notes

Text

TF Failsafe Coding AU

The concept of this continuity soup AU is that Warframes, particularly warframes with slave coding can trigger a heat/rut through submitting to a stronger opponent in battle.

It makes them limp and pathetic, unable to activate their weapon systems, just about able to string a sentence together between chirrups of binary, the only hard part of them is their spike so it's easier for the victor to cart them off. They'll just mewl and roll around on their back to present their spikes, a failsafe to deter the victor from just killing them. However, if a mech has been on a winning streak & suddenly looses it forcibly activates.

This is inspired by a Tokyo Ghoul Fanfic Series I've been reading particularly the fic ( https://archiveofourown.org/works/48210463/chapters/121576942 ) I recommend reading that entry even if you're unfamiliar with the source material it's absolutely fantastic. Also this is somewhat inspired by my love of the X-Men & Ajin: Demi-human.

Maybe it was something conjured up by the Quintessons during their occupation to deter more violent troops from killing their coworkers because if they lost they'd become docile for a time & if they won they'd end up sparked, harder to cause trouble that way. The quints also found it's excellent entertainment at parties.

Anyway in the modern day Gladiators have to wear chastity devices because there's no way that the arena masters are giving people a free show, instead if a bot drops into heat they'll be carted out of the arena to a private afterparty for the high society bots to attend.

The managers don't want their star champions to end up sparked & have to take a break from performing.

Sometimes Gladiators can even be rented out to private arenas in Senator's homes or high end nightclubs for Fight & Spike parties where the fight is just an appetizer for the main event of watching some hulking warframe present themselves begging to be touched. Ridden or pounded by the victor, often pumped up on aggression inducing drugs, then turned over to the guests. That's all perfectly legal, in the gladiatorial contracts even, ignore that little detail about most of them signing said contracts under duress. What isn't legal is using these Gladiators as studs for the breeding of trafficked unregistered Outliers.

Which is where our intrepid undercover investigative journalist Orion Pax comes in. He's gotten into one of these parties to investigate the possible links to the disappearances of prominent Outliers & civil rights activists on behalf of Senator Shockwave. His cover is that he's some arm candy secretary picked up from the archives for (senator of your choice who Shockwave is blackmailing to go along with it). Orion sometimes works with fellow independent journalists Jazz & Blaster who primarily travel from city to city, event to event, interviewing interesting people with a political bent (think all gas no breaks / channel 5 the youtube channels if you're familiar but Jazz & Blaster aren't sex pests like the hosts of those channels 💀 if you're not familiar I'd recommend looking up someone reacting to one of their videos don't give the og channels views). They're helping him, monitoring the situation & relating his wire to their police contact Prowl who's been kicked off the missing Outliers case for getting too close to the truth.

Thus sets the scene for Orion to meet Megatron. He's aware of the gladiator of course who wouldn't know the face of the reigning champion of the pit, but seeing clips of his fights is not the same as seeing the mech sprawled back on the dancefloor, hazey optic'd & undulating to show off his spike. Whirring & beeping like a mechanimal. Orion has never seen something so hot before in his life & he hates himself for it. Which is about when the host of the party brings out Starscream who's been legally registered as dead for several months. Makes him ride Megatron until he's sparked up. Of course to make sure he's carrying an Outlier spark that's inherited his abilities the host blows a hole through his processor mid second round. After a few seconds Star jerks back into action, this isn't his first rodeo & he wants to get it over with asap before the host gets bored of boasting about his sales pitch, already starting bidding on Star's unborn bitty, & decides to shoot him again for the spectacle of it all.

Megatron is Distressed his heat partner just died, without any fight response he's working himself into hysterics. His processor is mush, energon & fragments of processor boards splashed across his face, whimpering he can't understand it His Mate just died he felt the death flare in his EM field but he can also feel the body is still moving.

Star absolutely loathes those noises & Megatron's expression because it breaks the immersion of all the training he's been through to see himself as an object because this bot is treating him like a person asking if he's hurt in base binary chirps & it makes him hate himself more. Maybe he's got a scold's bridle on so that he can't speak, he's not nicknamed Screamer for no reason.

Orion attends a few of these parties. He also goes to interview Megatron while he's sober after winning a match. Officially it's because Orion is writing a puff piece about Megatron so they have a conversation dancing around the subject, aware they're being monitored. Orion doesn't realise he's been found out as a mole until he's being dragged into the arena ring at a party. Thrown down in front of a drugged up Megatron, he's completely berserk, unable to be reasoned with, going to rip Orion to pieces. So thinking quickly Orion just surrenders mimicking a warframe's defeat induced heat driven to a fever pitch Megatron frags him until the drugs are out of his system. The party goers love it & want an oncore meanwhile Megs is coming back to his senses, an absolutely wrecked civilian mech underneath him. His handler is screaming at him over internal comms to give the ppl what they want & frag his throat open like he just did to that medalling journalist's valve. Orion just tells him " I'm sorry they're making you do this, I will endure it, don't blame yourself for what they're forcing you to do"

Of course they don't just let Orion go afterwards so now he's a missing person. Jazz, Blaster, & Prowl were tapped into Orion's audio visual feed & saw the whole thing up until Megatron crushed his Audials & Optics while fucking his face until it falls apart.

Orion is now being trafficed with the Outliers, his sensors are limited to tactial & olfactory only, luckily most of the trafficked bots know Sign language & Chirolinguistics so they teach him. Both Star & Orion are sparked up so they're housed together. Being moved from safehouse to safehouse. Star decides to use his own parts to try and repair Orion since even if he ripps out an optic it'll just grow back when he resets. His owner doesn't intervene because he finds it funny & it is keeping Starscream occupied. They are planning to repair Orion after the sparkling is born so they can get a repeat performance. But maybe they subject him to empurata since his face is already smashed.

Not sure what happens from here, maybe Jazz, Blaster, & Co decide to break Megatron out of the arena to help them track down Orion & the missing Outliers via his fledgling Sire bond.

I'm making Blurr an Outlier also, quicksilver type shit. He's fairly well-known by the general public as his disqualification from participating in any sporting events was highly publicised. With his fellow Velocitronians finding it to be highly offensive that he's barred, some more zealous individuals believe Blurr's speed to have been a blessing by their colony's patron Amalgamous Prime. He's lapping up being the civil rights movements' poster child. I'm also making Senator Shockwave Velocitronian royalty, rumoured to be a direct descendant of Amalgamous Prime. It's traditional that the royalty of Velocitron are Conjunx to the winner of the race celebrating their coming of age ceremony, whenever they choose to have that celebration after they reach adulthood is up to them, so Shockwave has postponed his in protest until the cybertronian government would recognise Blurr as the winner. They decide to do some fake dating 'the government is forbidding our love from being recognized in the traditional manner of our people' type shit for the tabloids to lap up & sway public opinion. They're a real celebrity couple.

This makes both of them frequent targets for assassinations & kidnappings. Starscream was a hired guard for Blurr & 'died' in one of these attacks, with the traffickers realising that Star was an Outlier & taking him after watching him wake up from a decapitation. Shockwave goes missing during one of these attempts, carted off to be subjected to empurata, the surgery triggers a mass/shape shifting mutation in him. He breaks out & returns to office hiding the fact that he's now an Outlier himself, maintaining his original form for long periods of time stressing out his body to the point of seizures. Blurr caring for him & helping him hide himself leads them to develop genuine feelings for eachother.

Please send me asks about this au or reblog & add comments please 🥺👉👈

Signed

_ Cu 🐗

#tf au#plot bunny#tf#Failsafe Coding AU#notfic#whump#content warning#mutual noncon#dubious consent#temporary character death#immortal whumpee#Orion Pax#Megatron#Starscream#Jazz#Blaster#Prowl#Shockwave#Blurr#Megop#megastar#Shockblurr#outliers#mating cycles/in heat#slave coding#trafficked whumpee#Cu casts#valveplug#mechpreg

69 notes

·

View notes

Text

Portable NO2 Gas Detector

Labtron Portable NO2 Gas Detector use pumping suction sampling method with a flow rate of up to 1L/min and ten selectable grades. It measures NO₂ concentrations within a range of 0 to 1000 ppm, offering a resolution of 1 ppm and a precision of 2% full scale. Features a built-in micro sampling pump with 10 grades of suction. It also supports high-speed data transmission via USB, allowing for easy data download and printing.

0 notes

Text

#Smoke Detectors#Gas Leak Detectors#Gas Sensors#Gas Alarm Systems#Gas Detection Systems#Gas Monitoring Devices#Marine Safety Equipment#Optical Smoke Detectors#Optical Gas Detectors

1 note

·

View note

Text

Advanced Methane Leak Measurement: Tools and Techniques That Matter

Why the Hetek Flow Sampler is Central to Accurate Methane Analysis

Accurate methane measurement starts with using the right technology. The Hetek flow sampler is a prime example of a tool that delivers precision and reliability for environmental professionals. Designed for field use, this sampler is instrumental in detecting fugitive emissions from valves, flanges, connectors, and other components in oil and gas infrastructure. It draws gas and air into a chamber where methane levels can be accurately determined, helping site managers prioritize maintenance and reduce losses.

This sampling approach minimizes false readings by isolating the leak from ambient air. Real-time feedback allows technicians to make decisions on the spot, streamlining repair workflows. The tool is built for rugged conditions and offers repeatable results essential for compliance reporting. When paired with advanced gas sensors and logging software, it becomes a powerful part of any emissions reduction toolkit.

Choosing a Methane Quantification Device for Industrial Use

Facilities looking to measure methane accurately need a dedicated methane quantification device that can offer both speed and precision. Unlike standard gas monitors, quantification devices analyze volume and rate of release, giving teams actionable data on the severity of leaks. These devices play a crucial role in prioritizing repairs based on impact rather than just location.

In many regions, environmental regulations require operators to provide detailed emissions data. A reliable quantification device helps meet those standards while also aiding in internal sustainability goals. By integrating these tools into routine leak detection surveys, companies can demonstrate due diligence and reduce their carbon footprint in measurable ways.

The Role of a Methane Gas Monitor in Safety and Compliance

A methane gas monitor is indispensable in facilities where gas is stored, processed, or transported. These monitors continuously assess the air for the presence of methane, triggering alarms if levels exceed safe limits. The integration of these systems into safety protocols reduces risk to personnel and infrastructure.

Technological advances have improved sensor sensitivity and real-time communication, allowing monitors to interface with SCADA systems and emergency shutdowns. Whether used in confined spaces or open facilities, methane monitoring is now a standard expectation for regulatory bodies and stakeholders alike.

Using a Methane Analyzer for Field Inspections

When engineers need to validate leak repairs or conduct compliance checks, a methane analyzer offers detailed readings. These instruments not only detect methane but quantify its concentration over time, making them valuable for trend analysis and documentation. Many analyzers also include GPS tagging and automated reporting features, streamlining field operations.

Because of its portability, the analyzer is suitable for both routine surveys and targeted diagnostics. It’s especially useful in LDAR (Leak Detection and Repair) programs where emissions data must be verified regularly. With digital integration and accuracy in detection, these analyzers remain a preferred choice among industry experts.

Monitoring Methane Concentration in Critical Environments

Understanding methane concentration levels at specific points in a system helps predict hazards and optimize containment strategies. Concentration data is essential for determining if a detected leak poses an explosion risk or simply contributes to greenhouse gas emissions. Measurements are typically expressed in parts per million (ppm) and inform both safety thresholds and repair timelines.

Advanced sensors today can detect variations in methane levels in real time, even in harsh environmental conditions. Having access to this kind of precise data improves decision-making and supports consistent operational standards across teams and facilities.

Why Monitoring Methane Level is Vital for Site Management

Precise measurement of methane level supports both immediate safety needs and long-term emissions goals. When readings are taken from multiple components, operators gain a full picture of site integrity. Regular monitoring helps detect wear and tear, corrosion, or mechanical failure that might otherwise go unnoticed.

Field teams equipped with digital meters or multi-sensor devices can check levels throughout the day. This proactive strategy leads to early intervention, preventing both minor leaks and major incidents. Real-time data syncing also helps in creating detailed emission maps for audits and environmental reporting.

Tracking and Reducing Methane Emissions Across Operations

With global attention focused on climate change, controlling methane emissions has become an industry priority. Methane is significantly more potent than carbon dioxide in trapping heat in the atmosphere. As such, reducing these emissions offers an immediate benefit to both the planet and a company’s ESG performance.

Facilities achieve this reduction by identifying high-risk areas, implementing preventative maintenance, and continuously measuring leaks. Targeted reduction efforts can also improve stakeholder confidence and open doors to green funding or incentives tied to emission targets.

Applying High Flow Sampling for Emission Control

High flow sampling is a technique that draws in large volumes of ambient air around a suspected leak point. This method allows operators to differentiate between actual emissions and background levels. It is especially effective for pinpointing leaks in outdoor or ventilated environments where methane may disperse quickly.

The process is used extensively in LDAR programs and environmental audits. High flow tools not only locate the leak but quantify its volume in real-time. This allows for faster triage and better resource allocation during repair scheduling.

Benefits of a High Flow Sampler Methane Tool

A high flow sampler methane device combines sampling capability with quantification tools to provide real-time data on leak severity. Designed for professional field use, it captures emissions and calculates leak rates in one seamless process. The combination of speed, accuracy, and ease-of-use makes it invaluable during facility inspections and maintenance programs.

Whether you're monitoring valves, connectors, or storage units, this tool helps field technicians document methane releases accurately. In turn, that supports both compliance efforts and internal goals related to sustainability and asset longevity.

Using a Flow Sampler to Capture Methane Accurately

A portable flow sampler enables field workers to collect consistent readings under varying environmental conditions. It works by drawing the surrounding air and gas into a measurement chamber, where real-time data on volume and flow rate are recorded. Unlike basic detectors, samplers provide context—quantifying the size and severity of a leak.

Technicians can deploy these tools quickly at potential emission points, making them ideal for routine inspection routes or ad-hoc diagnostics. This form of monitoring also contributes to historical data records, helping site managers assess whether infrastructure upgrades are needed.

Advantages of a High Flow Sampler in Leak Quantification

A high flow sampler allows you to assess not just the presence of gas but how much is escaping over time. This is especially useful in prioritizing repair work by identifying leaks that contribute most to emissions. These devices typically include built-in measurement logs, calibration protocols, and real-time digital outputs.

Because they can adapt to a wide range of fittings and components, high flow samplers are used across many industries—from upstream oil fields to chemical manufacturing. The ability to rapidly gather accurate leak data saves both time and money.

How a Fugitive Methane Analyzer Supports Leak Detection

A fugitive methane analyzer is designed to identify unintended releases of gas from processing equipment. These releases, often invisible and odorless, contribute significantly to atmospheric pollution and operational loss. The analyzer measures ambient methane levels and quantifies how much gas is leaking from specific components.

These instruments are essential in emission monitoring programs. With built-in mapping and storage features, they allow operators to compare results over time. This longitudinal data supports trend analysis, compliance documentation, and ongoing performance improvements.

Why It’s Necessary to Calculate Methane Flow Rate

Being able to calculate methane flow rate is essential for understanding the total impact of a leak. Flow rate calculations take into account the gas velocity and volume at a specific point in time, which helps quantify both emissions and potential product loss. This data is critical for compliance reporting and for cost analysis.

Modern tools automate this calculation, integrating readings from multiple sensors to deliver highly accurate outputs. Facilities that invest in such capabilities are better equipped to act quickly and plan effective interventions.

Tracking Methane Leak Quantification for Emissions Reporting

Methane leak quantification provides the actual measurement of gas escaping from infrastructure. This step goes beyond detection, offering clear metrics that can be used in regulatory submissions, internal audits, and emissions trading schemes. By focusing on quantification, companies can prioritize fixes and demonstrate progress toward emissions reduction goals.

Field equipment used in leak quantification includes high-precision analyzers and sampling chambers. These devices ensure that data collected is verifiable, repeatable, and compliant with reporting standards set by environmental authorities.

The Utility of an Industrial Sampler in Methane Measurement

An industrial sampler is built to withstand tough field conditions while maintaining accurate gas collection. These devices are engineered for long-term deployment and are often used in remote locations where maintenance is infrequent. Their rugged construction and precise calibration make them a preferred choice for large-scale methane measurement projects.

Industrial-grade samplers often interface with telemetry systems, enabling real-time data transmission to centralized monitoring platforms. This connectivity supports faster decision-making and helps ensure that no data is lost in the process.

How Flow Detection Tools Help Spot Leaks

Flow detection devices help locate and measure gas as it escapes from pressurized systems. These tools are typically handheld and provide immediate readouts, making them ideal for walkaround inspections. They use thermal, ultrasonic, or infrared sensing to identify flow variations caused by leaks.

By targeting specific components and fittings, flow detection tools can isolate high-risk areas and guide maintenance priorities. This efficient diagnostic capability enhances safety and reduces the likelihood of unexpected failures in critical infrastructure.

Leak Quantification as a Compliance Requirement

Leak quantification involves precisely measuring how much gas is escaping from a component over time. This data is used to determine repair urgency and calculate environmental impact. Many regulatory bodies now require facilities to include leak volume data in their reporting.

Quantification supports better asset management by helping engineers identify trends in component performance. Over time, this allows for smarter investment in replacements and system upgrades, all while staying compliant with emissions caps.

The Importance of Leak Rate Quantification in Emissions Control

Accurate leak rate quantification helps operators understand not just where leaks occur, but how much gas is being lost. This information is critical when prioritizing repairs and planning long-term mitigation strategies. It also plays a role in cost forecasting, since gas loss represents direct financial waste.

Using instruments capable of capturing leak rates in different conditions—humidity, wind, confined spaces—enhances reliability. The ability to benchmark performance before and after repairs also validates the effectiveness of maintenance efforts.

What Leak Detection and Quantification Means in Practice

Leak detection and quantification work together to support effective emissions management. Detection identifies the presence of methane; quantification tells you how much is being released. When combined, they allow for fast response and better documentation.

This dual strategy is now considered best practice across energy, chemical, and utility sectors. Real-time alerts, historical comparisons, and compliance records all benefit from having precise data on leak behavior.

Using a Methane Flow Meter to Track Gas Output

A methane flow meter measures the rate at which gas moves through a pipe or into the atmosphere. These meters are essential in both production and leak scenarios, providing metrics for operational efficiency and loss prevention. Many flow meters now include digital readouts, wireless connectivity, and integrated alarms.

Field teams use these tools to monitor baseline flow and detect anomalies. By comparing historical and real-time data, they can assess whether system pressure or leakage is affecting productivity.

The Role of Methane Monitoring Equipment in ESG Performance

Methane monitoring equipment includes everything from handheld detectors to fixed point sensors and integrated telemetry systems. This equipment supports real-time visibility into gas conditions across an entire site. Used in combination, these tools form a holistic monitoring solution that meets modern environmental and operational standards.

Monitoring equipment not only supports safety and compliance, but it also informs ESG metrics. Having accurate, verifiable data on methane helps organizations track their environmental impact and share progress with investors, regulators, and the public.

#gas leak detection devices#methane emissions#methane level#methane concentration#hetek flow sampler#natural gas ldar#methane gas monitor#methane quanification device

0 notes

Text

"On a blustery day in early March, the who’s who of methane research gathered at Vandenberg Space Force Base in Santa Barbara, California. Dozens of people crammed into a NASA mission control center. Others watched from cars pulled alongside roads just outside the sprawling facility. Many more followed a livestream. They came from across the country to witness the launch of an oven-sized satellite capable of detecting the potent planet-warming gas from space.

The amount of methane, the primary component in natural gas, in the atmosphere has been rising steadily over the last few decades, reaching nearly three times as much as preindustrial times. About a third of methane emissions in the United States occur during the extraction of fossil fuels as the gas seeps from wellheads, pipelines, and other equipment. The rest come from agricultural operations, landfills, coal mining, and other sources. Some of these leaks are large enough to be seen from orbit. Others are miniscule, yet contribute to a growing problem.

Identifying and repairing them is a relatively straightforward climate solution. Methane has a warming potential about 80 times higher than carbon dioxide over a 20-year period, so reducing its levels in the atmosphere can help curb global temperature rise. And unlike other industries where the technology to decarbonize is still relatively new, oil and gas companies have long had the tools and know-how to fix these leaks.

MethaneSAT, the gas-detecting device launched in March, is the latest in a growing armada of satellites designed to detect methane. Led by the nonprofit Environmental Defense Fund, or EDF, and more than six years in the making, the satellite has the ability to circle the globe 15 times a day and monitor regions where 80 percent of the world’s oil and gas is produced. Along with other satellites in orbit, it is expected to dramatically change how regulators and watchdogs police the oil and gas industry...

A couple hours after the rocket blasted off, Wofsy, Hamburg, and his colleagues watched on a television at a hotel about two miles away as their creation was ejected into orbit. It was a jubilant moment for members of the team, many of whom had traveled to Vandenberg with their partners, parents, and children. “Everybody spontaneously broke into a cheer,” Wofsy said. “You [would’ve] thought that your team scored a touchdown during overtime.”

The data the satellite generates in the coming months will be publicly accessible — available for environmental advocates, oil and gas companies, and regulators alike. Each has an interest in the information MethaneSAT will beam home. Climate advocates hope to use it to push for more stringent regulations governing methane emissions and to hold negligent operators accountable. Fossil fuel companies, many of which do their own monitoring, could use the information to pinpoint and repair leaks, avoiding penalties and recouping a resource they can sell. Regulators could use the data to identify hotspots, develop targeted policies, and catch polluters. For the first time, the Environmental Protection Agency is taking steps to be able to use third-party data to enforce its air quality regulations, developing guidelines for using the intelligence satellites like MethaneSAT will provide. The satellite is so important to the agency’s efforts that EPA Administrator Michael Regan was in Santa Barbara for the launch as was a congressional lawmaker. Activists hailed the satellite as a much-needed tool to address climate change.

“This is going to radically change the amount of empirically observed data that we have and vastly increase our understanding of the amount of methane emissions that are currently happening and what needs to be done to reduce them,” said Dakota Raynes, a research and policy manager at the environmental nonprofit Earthworks. “I’m hopeful that gaining that understanding is going to help continue to shift the narrative towards [the] phase down of fossil fuels.”

With the satellite safely orbiting 370 miles above the Earth’s surface, the mission enters a critical second phase. In the coming months, EDF researchers will calibrate equipment and ensure the satellite works as planned. By next year [2025], it is expected to transmit reams of information from around the world."

-via Grist, April 7, 2024

#satellite#epa#environmental protection agency#environmental activism#methane#emissions#climate change#climate news#climate action#natural gas#fossil fuels#global warming#good news#hope

145 notes

·

View notes

Text

The Test, Chapter 6

Jack lay on the stretcher, tied down and completely defenseless, his body still trembling from the last test that had nearly taken his life. His lungs struggled for air, and his heart, miraculously recovered, beat with a strength that no longer belonged to him. He knew that something far worse was coming.

Dr. Ruiz had mentioned a final test, one that would be different from all the others.

The door to the room creaked open, and Ruiz entered, accompanied by a team of assistants. Jack noticed that they were all wearing surgical gowns and gloves, holding shiny, cold, and sinister tools in their hands. At that moment, reality hit him hard: this time, there would be no cables, electrodes, or pink gas. This time, his heart would be the direct object of the experiment. He was going to lose it.

Ruiz approached the stretcher, observing Jack with an oddly serene expression.

“We’ve pushed you to the limit, Jack. Your heart has proven to be perfect… beyond anything I could have ever imagined. And now,” Ruiz paused, leaning in closer, almost whispering, “we’re going to make sure it keeps beating… even outside your body.”

Jack felt his skin prickle with pure terror. He tried to move, tried to scream, but his strength was gone. He was completely trapped.

“Don’t worry, Jack. You’ll remain awake throughout the entire process. I want you to witness the greatness of your heart.”

With a swift motion, Ruiz lifted a syringe filled with a clear substance and injected it directly into Jack’s neck. Immediately, a numbing sensation spread through his body, starting from his limbs and slowly creeping toward his chest. He could feel, but he couldn’t move. He could see, but he could do nothing to stop what was about to happen.

The assistants moved around him, preparing the surgical instruments with terrifying precision. Ruiz picked up a scalpel and held it over Jack’s chest, right above the sternum. The fear in Jack’s eyes intensified as he watched the cold metal descend toward his skin.

With methodical calm, Ruiz made the first incision. Jack felt no pain, only an intense pressure as the scalpel cut through his skin and muscle. Then, the team opened his chest, exposing his heart, which beat with powerful, steady force. Jack saw it reflected on the screens around him: his own heart, strong and perfect, exposed and vulnerable.

The sound of his own heartbeat filled the room, the only reminder that, for now, he was still alive.

“It’s a masterpiece,” Ruiz whispered, almost reverently, as he placed his hand over Jack’s heart, feeling its perfect rhythm. “I have never seen anything so perfect.”

With a gesture, Ruiz signaled to his assistants, who quickly moved to bring in a strange machine—a cylindrical device filled with bubbling liquid. It had cables and tubes connected to various monitors and emitted a faint hum. Inside, Jack could see a thick, bright green fluid bubbling—the same liquid that had filled the tank where he had been submerged before.

“This device will keep your heart safe with all the files of your echocardiograms” Ruiz explained, his voice calm as he adjusted some controls on the machine. “We will extract it and connect it here, where it will keep beating indefinitely. We need it in perfect condition for the next phase: cloning.”

Jack’s eyes filled with horror as he realized what was about to happen. His own heart, his source of life, would be removed from his body, torn from its natural place, and placed into a machine that would keep it alive separately. And what would be left of him? How could he keep living without his heart?

Ruiz leaned over him, holding a device that looked like an extractor designed to separate the heart from the rest of the body. Jack felt unbearable pressure in his chest as the doctor’s hands manipulated his vital organ with almost inhuman precision. His eyes couldn’t look away from the screen, where he saw his own heart struggling to keep beating.

The moment arrived. Ruiz severed the last blood vessels, and suddenly, Jack felt an absolute emptiness in his chest.

He watched as his heart was slowly extracted from his body, still faintly beating in Ruiz’s hands. The doctor carefully placed it into the bubbling device, where it was immediately connected to a series of tubes and cables. The sound of its beating filled the room once more, but this time, it didn’t come from his body. His heart, floating in the greenish liquid, was still alive—but separated from him.

Jack felt a wave of nausea and terror. His chest was empty. Something unnatural was keeping him alive now, but it wasn’t him. It was an imitation, a machine. And even though his heart was still beating, it no longer belonged to him.

“Your heart will be cloned,” Ruiz continued, wiping his hands clean and observing the device with satisfaction. “It will be the first in a series of perfect hearts, destined for research… and to save lives at the Heart Farm. There, all your suffering will have been worth it.”

Jack, weak and barely conscious, could hardly process what he was hearing. His vision blurred, and only the mechanical sound of his heart in the machine kept him awake. He tried to take a deep breath, but each inhalation felt shallower than the last.

The last thing he saw before losing consciousness was Dr. Ruiz adjusting the controls of the device that now held his heart, as the green bubbles slowly rose to the surface. His own life, beating inside a machine, far away from him.

And then, everything went dark.

...

An special thanks to @gayatheart and his beautiful heart in the echo video. Give him love and good fantasies with his heart.

#male heart#male cardiophilia#male heartbeat#gay men#gay heartbeat#cpr resus#beating heart#dark cardiophilia#echocardiogram#heartbeat#visible heartbeat#cardiophilia

54 notes

·

View notes

Note

For Cassie, do any of the stuff she had back in the Pizzaplex still have a use for her in the Playtime caves?

What tools does she add to her arsenal?

Should we assume that the underground part of Playtime is so large that parts of it can plausibly be underneath a mall kilometers away?

Answering your last question first, I'd say yes. Which probably would help make sense how an elevator from the underbelly of the PizzaPlex can crash-land through the cavern into the Prison or the Mining area of Playtime Factory, when the top surface locations of both business being not even remotely close to one another. Even though the whole thing still sounds kind of silly.

As for Cassie's arsenal, she certainly would still have everything she had in the PizzaPlex minus the AR collectibles. The problem is that initially none of those tools are compatible with Playtime Co. tech and machinery, not to mention the complete lack of a V.A.N.N.I network (and thus, Helpi is also offline.)

But with how intuitive Cassie was with those tools back in RUIN, on top of being daughter of a technician, she certainly would be able to eventually circumvent the incompatibility and make modifications/adaptations to make her tools functional again, with the addition of a few cables and stuff to help make those possible.

At the beginning she'd only have her Faz-Wrench with very limited use, as I headcanon it can also work as a taser (it is kinda shaped like one when you think about it too, doesn't it?) which is a decent help for defense. it'd require modifications for any of its hacking properties though- which might be possible already in design (if you inspect the 3d model of the Faz-Wrench you can see input sockets for cables like USBs.) One of its prongs got slightly bent in the elevator drop, but that's an easy fix (easy but still needing delicacy in handling.) With enough adaptations, it could be very useful to help troubleshoot and maintain some machines like Safe Haven's generator.

The VANNI mask is as good as a cheap Halloween mask at first. But if Cassie manages to restore functionality to it without the network, it'd essentially work on its own grid, and be used as a neural-based controller for other devices if Cassie wears it. There's no "AR world" or VANNI network in Playtime Co. though, so it can't quite work the exact same way as it did back in the PizzaPlex... but with it she can see through walls! And now there's no M.X.E.S. limiting her time to use it meaning it's relatively safer to wear (though I imagine seeing through walls for too long in a row could cause a sensory overload perhaps? Hm, that would have to be a togglable property.) The mask would also make Cassie invisible to The Doctor just as it did for the Glamrock Endos and Ruined Glamrocks (but back then that was just trading them for M.X.E.S.) The Doctor sees "everything", but it's always through technology like cameras and monitors, things susceptible to the mask's interference, since he no longer has his organic eyeballs. Along with the see-through-walls property, I imagine Cassie MAYBE also developing other vision modes like infrared, night vision, heat vision, etc. Hell, if she gets one of those gas masks Playtime Employees would wear, she could use it to further upgrade the VANNI mask to also double as a gas mask to keep her safe from the red smoke. And perhaps restore its ability to run simulations too, like the one we see in the Brazil Ending... so long Cassie doesn't get too lost in her own memories and lose touch with reality- but current friends like Doey would be great anchors to help prevent that.

Flashlight? Broke. Busted in the elevator fall. RIP.

The Roxy-talky technically would already be usable, but it'd run in a frequency that doesn't match Playtime Co. communication-- Com'on, of course Fazbear Entertainment would design those things that way to force customers into buying more of their own mascot-talkies, rather than have them work with any other walky-talkies. Greedy corp shitty designs, amirite? Other walky-talkies would have to be manually recalibrated to run on the same frequency the Roxy-talky does in order to communicate with it. Sounds like a hassle, but would allow for a safe isolated communication line if you get what I mean.

Once Cassie is more recovered from her injuries, I think Doey would get her a GrabPack with a few hands- not that he'd expect anything from her, but if you don't have one you're very limited in what you can do there. And boy, that girl would overhaul that shit over time, especially when combining it with her own tools already. Connecting the mask to it as a neural controller would let her control the GrabPack with pretty much just her brain so her actual hands remain free. Controlling the GrabPack that way would also increase the dexterity of the hands meaning they're a lot more posable with a wider-range of movement (picture Cassie shooting a hand out towards Player/Employee only for it to stop inches away from their face with the middle finger up. Admit it WE all wished we could do that with those hands DONT LIE LOL.)

And that's not mentioning the hypothetical scenario of Doey and perhaps the more capable toys of Safe Haven hunting The Doctor's automatons for sport for parts. Who freaking knows what else Cassie could add to her arsenal with such resources.

At this point, she DREADS the possibility of being limited and unable to help those left that she holds close like it happened in the PizzaPlex, so she really would start applying herself, especially technologically, for her toy friends in Safe Haven. She learned in the PizzaPlex, and would vow to do better for Safe Haven.

#ppt#poppy playtime#doey the doughman#doctor harley sawyer#fnaf sb ruin#cassie#anon#anonymous#jellycream answers#oh sHIT this got way longer than i thought. oopsies?#the mental image of cassie using parts of the doctors automatons to make a gIANT CLAW like scrap baby's tho...#girl deserves it. shes earned it even#playdough and glitter au

48 notes

·

View notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Note

Winter, let me tell you a story. (About trains, duh)

This, is Cajon Pass. Or at least a section of it, it's so big I don't know where the summit is. Now it's not the steepest grade for railroads in America, but it is incredibly steep 4% average. Which for locomotives, is INSANE. Now, while it may seem innocent, it can be incredibly dangerous, as told in this story.

(You should watch this video if you find documentaries cool)

The year is 1989, may 11th. And it's 9PM at Mojve railyard in California on the Southern Pacific. A crew is tasked with taking a train full of Trona (A sand like substance) towards West Colton Yard. Things, aren't off to a good start. One of the locomotives won't start, and is dead in tow. It's never been reported what happened, but they had to swap out the locomotive. There's also worry of the weight of the train loosing control over the pass, so they arrange to meet with some helper diesels that will hook up to act as extra braking force. They get all the paperwork, and begin the journey. On may 12th at 12:15, they depart. Little do they know, chaos will soon insue.

As they past a westbound train over the pass, they stop and let the helpers from that train couple up behind. The crew of the helpers have no idea the weight of the train, and don't ask. All they know is they will be assisting over and down Cajon Pass. Just after 7AM, the train begins it's descent, and the crew slows the train to about 25 mph with a mixture of air and dynamic brakes (Air brakes use air pressure to apply friction pads to the wheels, and dynamics turn the traction motors into generators by reversing flow and converting momentum to heat). They even check with the helper crew to make sure they have the train under control. Little do they know, the have next to no functioning dynamic brakes on the train, and disaster is approaching.

The descent continues, and the lead crew notices they picked up speed to 30 mph, and they apply a full service application, which is full brakes, but nothing. This usually wouldn't be an issue, but the tracks aren't as curved and there's a long way to go down. The helper crew seeing the train speed up, thin it's a runaway and through it into emergency stop. The train tries to slow down, with a loud jolt. But seconds later, it was off to the races.

The train quickly picks up speed, going faster and faster. Smoke pours from the brakes and they light up a glowing red from the heat. The head end crew contacts dispatch in a panic, as the speedometer reads their doing about 90 mph. But that's as far as it could go. The black boxes (A device that monitors train data) clocked them doing 110 MPH.

Up ahead, there was a curve near the area of Duffy street near Sand Bernadino, with tons of houses. The speed limit was 30 mph, and this train is never going to make it through at the speed it's going.

The resulting wreck tossed train cars everywhere, plowing into homes and crushing the locomotives. One guy in a house destroyed by the train was encased in a makeshift cocoon for nearly the whole day until firefighters could clear the wreckage. Meanwhile, there was another issue. Gas was still being supplied to houses. However, they were able to call in and get it shut down before fires sparked. Four people total died, and four more were injured.

This wouldn't be the end of the chaos. No one knew there was a gas pipeline under the wreck, but inspections from those who did know said it was safe due to how deep in the ground it was, So the train didn't even touch it. However, there was still the odor of gas in the air.

The morning of May 25th, and the Trona clean up is still on going. Strange rains fall over specific houses despite the clear sunny day, and the gas smell is still in the air. Then, a sudden spark.

An entire section of the town is engulfed in flames, incinerating whatever it's in it's path. They all know it's the pipeline, and it's so hot the firetruck's headlights, turn signals, and light bars melt like butter. People fled for their life, and firefighters are struggling to contain the blaze. To make matters worth, no one can shut the emergency valves off, which weren't even working two weeks before the train derailed. 2 million liters of gasoline burned for hours, and by the time the flames were out? Two people died, three injuried. One only identified by the smoldering shoes on his corpse.

Know I know what you wanna know: How did this happen? Well, lets start with the train wreck. First, lets talk brakes. All air brakes worked, but were overwhelmed. Some wheels got so hot they deformed, and were still molten 12 hours later.

Now second, incorrect paperwork. No one actually knew how heavy the train was, and one of the employees decided to make an educated guess, based off his experience working with trona before. About 60 tons per car compared to coal, with a total of 4140 tons. But in reality the weight was closer to 69 hundred tons. No company will ship freight cars 60% full and leave 40% behind, right? Now, any unknown weight is required to be considered as heavy as is when full.

All this to say, the train was clearly doomed the minute it hit the grade. Even if they all had functional dynamics, it would have been a rough trip down the mountain. However, despite the acceleration, the train was only slowly accelerating due to the working dynamics that were on the train, until it was slammed into emergency stop. That automatically killed the dynamics. Usually, it's a safety feature to prevent wheels from locking and slipping down hill, but in this case it made it impossible to stop before they reached the curve. Nowadays this is reversed, and all trains are required to have all braking systems work in full. After all, any braking force you can get is vital in a runaway.

Long story short, the accident happened because of incorrect paperwork, miscommunication, and the gradient they were on.

Lets talk the pipeline. Inspections revealed an outward burst, meaning it had burst under extreme pressure. There were also scrape marks, which was discovered to had been from a backhoe during construction of some kind without anyone noticing. Inspections were clearly not thourough, because rich snobs in Las Vagas wanted it back up and running to supply fuel to their cars that they claimed were worth more than the houses in San Bernedino.

After the fact, lawsuits slammed Southern Pacific, which most were settled out of court.

Nowadays, more safety precautions are in place, such as scales to acurately check freight weight, and rules for helper crews to double check with the head end crew as needed for crucial information.

Most equipment of the train was scrapped on site, aside from the helper units that were rebuilt and continued service, and two others that were rebuilt, with only one surviving into the modern day. One crew member who continued work, could never go over the Cajon Pass, as he phsycologically just couldn't take it. And the crew member who made the miscaluclation? He was never charged for the trouble caused.

To this day, the houses wrecked weren't rebuilt, and there's no momument to honor those who died. And this wouldn't be the last runaway down the grade, as two more would happen. But those are different stories.

Long story short, double check. We don't want something like this to happen again.

“That sounds.. really terrifying. I’m glad we don’t have ‘trains’ or anything like them in Pyrrhia!” -Winter

[plain text: That sounds.. really terrifying. I’m glad we don’t have ‘trains’ or anything like them in Pyrrhia!]

14 notes

·

View notes

Note

Static dances from the Monitor... to a new soul to be bound to this game.

"Ah... it seems you have arrived at last. The 6th of the 8 Stars that dance upon this demented Stage."