#High Speed Slitter Rewinder Machine

Explore tagged Tumblr posts

Text

A Heavy-Duty slitter rewinder machine is an integral part of converting wide rolls into smaller widths of material with high accuracy. The heavy-duty type is meant to deal with tougher materials, processing those smoothly while maintaining the best quality.

the Heavy-Duty Slitter Rewinder Cylinder Machine cuts and rewinds materials such as paper, plastic films, laminates, and foils with unmatched precision. Krishna Engineering Works the reputed name worldwide as a manufacturer and exporter of industrial machinery-supplies the best Slitter Rewinder Machines with excellent durability, precision, and ease of operation.

#krishnaengineeringworks#slitter rewinder machine#machine#manufacturer#machinemanufacturer#industry#export#supplier#machinery#industrial#heavy duty slitter rewinder machine#packaging industry#paper machinery#paper industry

2 notes

·

View notes

Text

Jandu PPM - Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a leading Slitting and Rewinding Machine manufacturer and offers an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper. Key Features of Slitting and Rewinding Machines Latest in Design Good Performance Simple in Operating Easy Maintenance High Speed Contact for Slitter and Rewinder…

0 notes

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market: https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders 2) By Material: Paper, Polymers, Foil, Other Materials 3) By Slitter Blade: Large Circular Blade, Fixed Band Blade 4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales 5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth .............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Pelican Rotoflex with gravure press and turret slitter — hall 10/C03

Pelican Rotoflex, a leading manufacturer of converting machinery, will be present at drupa 2024 with its Solomark 6450 rotogravure press and the latest Acrostar turret slitter. While the rotogravure press will just be showcased at the two printing units, there will be a live demonstration of the Acrostar turret slitter.

Sanat Gandhi, senior technical executive, Pelican Rotoflex, said, “Due to certain restrictions on the usage of inks and solvents at the drupa 2024 exhibiting hall, we will not be able to present any live demonstration of Solomark 6450. Visitors, however, can witness a live demonstration of our recently launched turret slitter.”

Led by ELS technology, the Solomark 6450 rotogravure press operates at a speed of up to 450 m/min and offers excellent web processing capabilities for various films, including thinner, and more sustainable substrates. The machine is equipped with a unique semi-floation dryer with 3D and 2D hole technology for quick drying and a high-efficiency ventilation module that ensures minimal solvent residue on the substrate.

With a changeover of rewinder within 30 seconds regardless of the number of rewinds, the Acrostar turret slitter is characterized by closed-loop tension control on the rewinder with load cell feedback, which ensures consistent high-quality finished rolls. Its innovative shaft support design extends the life of the differential shaft, even under rotational loads, thus enhancing durability and reliability.

Pelican Rotoflex will be present at drupa 2024, in hall 10/C03

0 notes

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Link

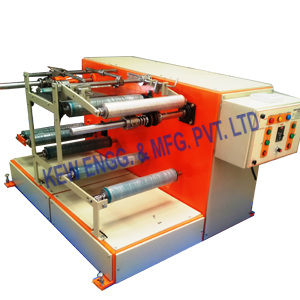

Our successfully Manufacturing, Exporting & Supplying all types of High Speed Slitting Rewinding Machine, We are Manufacturer of Slitter Rewinder Machines for Paper, Stretch / LDPE / BOPP Film, Slitting Rewinding Machine. High Speed Slitting Rewinding Machine for processing of different kinds of materials like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film, etc. KEW High Speed Slitting Rewinding Machines are Cantilever Type which incorporates a range of superior design feature that ensure the highest possible quality.

#High Speed Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#High Speed Slitter Rewinder Machine

2 notes

·

View notes

Link

KEW ENGG MFG PVT LTD Trim Rewinder includes many features for high reliability of trim winding. Trim Rewinder is used for any winding and unwinding application that reduces material waste to guide the web and achieves high productivity with minimal manpower. Trim Rewinder Machine are highly appreciated by our customers and are widely used in a number of demanding applications in the converting industry.

#Trim Rewinder Machine#Trim Rewinder#Trim Winder#Trim Winder Machine#Trim Winder For Slitting Machine#Slitter Trim Winding Machine#High Speed Trim Winder Machine#High Speed Auto Trim Rewinder#Trim Film Rewinder#Semi-Automatic Trim Winder

1 note

·

View note

Link

We are experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. High speed and heavy duty Automatic Slitting Rewinding Machine Manufacturer on demand of client’s requirement and machine specific application and material. Slitting of all types of Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Surface Slitting Rewinding Machine, Label Slitting Rewinding Machine, Cantilever Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine.

#Automatic Slitting Rewinding Machine#Automatic Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Mini Cantilever Slitter Rewinder Machine#Rubber Slitter Rewinder Machine#Cantilever Slitter Rewinder Machine#Label Slitting Rewinding Machine#Surface Slitting Rewinding Machine#High Speed Slitting Rewinding Machine#Woven Sack Slitting Rewinding Machine#Plastic Slitting Rewinding Machine

2 notes

·

View notes

Link

Our High Speed Slitting Rewinding Machine successfully Manufacturing, Exporting & Supplying all types of Heavy duty Slitter Rewinder Machine with international standards of quality. Our High Speed Slitting Rewinding Machine required for its accurate slitting and rewinding premium qualities with meeting International Standarad. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Non-Woven Fabric, Paper Board, Adhesive Tape, Film Ribbon etc.

#High Speed Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#High Speed Slitting Rewinding Machine Manufacturer#Thermal Paper Slitting Rewinding#Rubber Roller Manufacturer

2 notes

·

View notes

Link

High Speed Slitting Rewinding Machine Manufacturer, Customer requirement and Customer need application related high speed Slitting Rewinding Machine for processing of different kinds of materials like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Non-Woven Fabric, Paper Board, Adhesive Tape, Film Ribbon, Textile Cloth, Nylon Fabric, Micro Tape, Coated Paper, Ice Cream Cup Paper, Fax Roll, Laminated Film, Cling Film, Duct Tape, Mask Tape, Rubber, Tarpaulin, Tube, etc. makes us most experienced manufacturer, exporter & supplier of Slitter Rewinder Machine.

#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinder Machine#Slitting Rewinder Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding#high speed Slitting Rewinding Machine

1 note

·

View note

Link

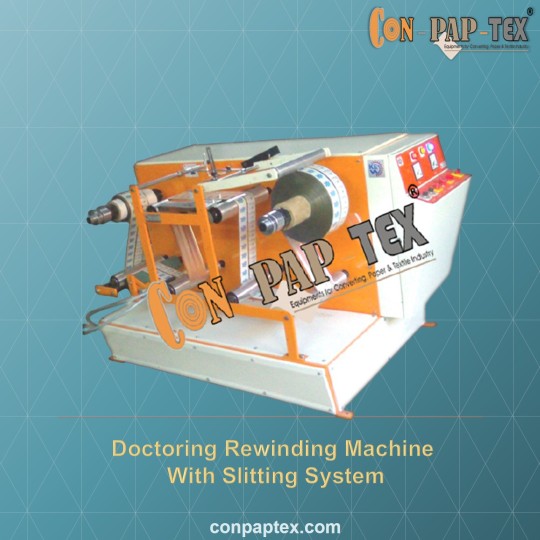

We CON PAP TEX are been successfully Manufacturing, Exporting & Supplying all types of Doctoring Rewinding Machine with Slitting System and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Expandable Shaft. Doctoring Rewinding Machines for different industries and for different applications per client’s requirement. Doctoring Rewinding Machines like, Standard Doctoring Rewinding Machine, Doctoring Rewinding Machine with Slitting System, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding etc.

#Doctoring Rewinding Machine with Slitting System#Winding Rewinding Machine for Inkjet Printer#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding with Slitter System#Doctoring Rewinding#Doctoring Slitting Rewinding#Film Winding Rewinding for Batch Coding#Winding Rewinding for Batch Printing#Winding Rewinding with Thermal Transfer Overprinter#Inspection Doctoring Slitting

1 note

·

View note

Text

Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a professional slitting and rewinding machine manufacturer and supplier in Delhi, India.

Key Features of Slitting and Rewinding Machines

Latest in Design

Good Performance

Simple in Operating

Easy Maintenance

High Speed

Contact for Slitter and Rewinder Machine

Company: Jandu Printing and Packaging Machines

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#janduppm

1 note

·

View note

Link

We have been successfully Manufacturing, Exporting & Supplying various types of Rubber Slitter Rewinder Machine, Paper Slitter Rewinder Machines, Rotogravure Printing Machine, Cantilever Slitter Rewinder Machine, HDPE Slitter Rewinder Machine, Shaft Winder Slitter Rewinder Machine, Inspection Slitter Rewinder Machine, Duplex Slitter Rewinder Machine, High Speed Slitting Rewinding Machine, Automatic Slitting Rewinding Machine. Different types of Rubber Sheets are used for applications for making Rubber Rolls, Tyres, Fabric, Rotogravure Printing Machine etc.

#Rubber Slitter Rewinder Machine#Rubber Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machines#Slitting Rewinding#Rotogravure Printing Machine#HDPE Slitter Rewinder Machine#Shaft Winder Slitter Rewinder Machine#Inspection Slitter Rewinder Machine#High Speed Slitting Rewinding Machine#Automatic Slitting Rewinding Machine

0 notes

Link

We offer wide range of heavy duty Doctoring Rewinding Machine Manufacturer, exporter, and supplier, high speed Doctor Slitter Rewinder machine. Our Doctoring Rewinding is highly used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC and many more. We also manufacturing of Doctoring Rewinding Machine, Doctoring Rewinding Machine Table Top, High Speed Doctoring Rewinding Machine, Heavy Duty Doctoring Rewinding Machine, Doctoring Slitting Rewinding Machine, Winding Rewinding Machine.

#Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Rewinding Machine Manufacturer#Doctor Rewinder Machine#Doctor Rewinder Machines#Doctor Rewinder Machine Manufacturer#Doctoring Rewinding#Winding Rewinding#Winding Rewinding Machine#Winding Rewinding Machines#Doctor Rewinder#Doctor Slitter Rewinder#High Speed Doctoring Rewinding Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Slitting Rewinding Machine

0 notes

Link

Krishna Engineering Works is biggest manufacturer of high reliability of trim winder. Trim Winder machine is fully mechanical controlled traversing, Trim winder is variable speed motor running under closed loop tension control from a precision dancer. For more information visit our website krishnaengineeringworks.com or contact us at [email protected]

5 notes

·

View notes