#Human-Robot Collaboration (Cobots)

Explore tagged Tumblr posts

Text

Advanced robotics is transforming engineering by automating complex tasks with AI and machine learning. Industries like healthcare, manufacturing, and logistics benefit from intelligent machines that enhance efficiency and precision. Unlike traditional automation, AI-powered robots adapt, learn, and improve over time. At M.Kumarasamy College of Engineering (MKCE), students engage with cutting-edge robotics through hands-on projects. The institution’s labs foster innovation in autonomous systems and adaptive algorithms. Emerging trends like swarm robotics and soft robotics are revolutionizing automation. MKCE integrates interdisciplinary learning, merging robotics with AI and mechanical engineering. Industry partnerships ensure students gain real-world exposure to advanced technologies. The college also emphasizes sustainable robotics solutions for a greener future. As robotics continues to evolve, MKCE remains at the forefront of this transformative field.

To know more : https://mkce.ac.in/blog/advanced-robotics-as-the-next-frontier-in-engineering-automation/

#private college#best engineering college in karur#mkce college#best engineering college#top 10 colleges in tn#engineering college in karur#mkce#mkce.ac.in#engineering college#libary#AI-Powered Automation#Smart Factories#Green Automation#Robotics and Sustainability#Next-Gen Robotics#Robotics Research Projects#Robotics Hackathons#Hands-on Robotics Learning#Robotics Lab Innovations#Robotics Engineering#Edge Computing in Robotics#Human-Robot Collaboration (Cobots)

0 notes

Text

The Impact of Robotics on the Future of Work

Robotics and Automation The rapid advancement of robotics and automation technologies has raised questions about the future of work and the potential impact on employment. As robots become increasingly sophisticated and capable, it is crucial to understand how they will shape the workforce and what implications this may have for individuals and society as a whole. In this article, we will…

View On WordPress

#Automated Workforce#Automation and Job Displacement#Cobots#Collaborative Robotics#Human robot interaction#Impact of Robotics#Robotics and Automation

0 notes

Text

Coral restoration efforts usually involve transplanting tiny corals, cultivated in nurseries, on to damaged reefs.

However the work can be slow and costly, and only a fraction of the reefs at risk are getting help.

In the shallow waters of the Abrolhos Islands, [Marine biologist Taryn Foster] is testing a system she hopes will revive reefs more quickly...

It involves grafting coral fragments into small plugs, which are inserted into a moulded base. Those bases are then placed in batches on the seabed....

Ms Foster has formed a start-up firm called Coral Maker and hopes that a partnership with San Francisco-based engineering software firm Autodesk will accelerate the process further.

Their researchers have been training an artificial intelligence to control collaborative robots (cobots), which work closely alongside humans.

"Some of these processes in coral propagation are just repetitive pick and place tasks, and they're ideally suited to robotic automation," says Ms Foster.

A robotic arm can graft or glue coral fragments to the seed plugs. Another places them in the base, using vision systems to make decisions about how to grab it.

"Every piece of coral is different, even within the same species, so the robots need to recognise coral fragments and how to handle them," says Nic Carey, senior principal research scientist at Autodesk.

"So far, they're very good at handling the variability in coral shapes."

75 notes

·

View notes

Text

Robotics and Automation: Redefining Industries and Job Opportunities

Robotics and automation are revolutionizing Industries and job landscapes, transforming factories, warehouses, and operating rooms. These technologies enable precise machinery assembly, autonomous drone retrieval, and unparalleled precision in surgery. They are not science fiction but the pulse of innovation.

Industries are shedding their old skins, embracing the boundless capabilities of Automation. Manufacturing plants are adopting robotic arms that assemble complex products with surgical precision, slashing error rates and boosting production beyond human limitations. Agriculture, too, is undergoing a Digital Metamorphosis, with autonomous tractors navigating fields autonomously, ensuring optimal planting and harvesting. The evidence is resounding automation doesn’t replace industries; it elevates them.

But let’s talk numbers hard, impressive facts that showcase the prowess of Robotics and Automation. Did you know that industrial robots can boost j by a staggering 85%? That’s not just a number; it’s a testament to the extraordinary potential of these machines to elevate industries to heights previously unattainable. And when we look at job opportunities, the narrative isn’t one of loss but transformation. For every routine task that a robot takes over, a universe of opportunities blooms for individuals skilled in designing, Programming, and maintaining these robotic wonders.

The story of Robotics and automation is one of collaboration of humans and machines joining forces to achieve feats that neither could accomplish alone. Picture a warehouse where cobots glide alongside their human counterparts, tackling heavy lifting while the humans orchestrate the symphony of operations. It’s a dance of ingenuity, where Technology enhances human potential instead of overshadowing it.

Did you know that 65% of companies adopting automation have reported increased Employee Satisfaction? As machines handle mundane tasks, human workers are freed to explore creativity, innovation, and problem-solving, breathing new life into their roles.

While the road to this transformative Future is undeniably paved with challenges, think about the need for reskilling and adapting to the rapid pace of change the possibilities that unfold are breathtaking. And the beauty of it all? It’s not a distant fantasy; it’s happening right now, right here.

From Tesla’s advanced robotic manufacturing to Amazon’s intricate delivery network, the robots are not just coming they’re already here, shaping the world we live in and forging a path towards an exciting and dynamic tomorrow.

In the grand tapestry of progress, the threads of robotics and automation are weaving a story of boundless potential. Industries are letting go of previous limitations, and career opportunities are expanding into uncharted areas. It’s a story about how technology and people can work together to open up new possibilities. In light of this, keep in mind that robotics and automation are already here and hold great promise when you consider the environment around you.

“The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency.” — Bill Gates

#artificial intelligence#automation#robotics#robots#tech#technology#education#school#future#digital world#coding for kids#programming#coding#coder#ai#jobs#workplace#tumblog#futurism#android#machine#innovation

2 notes

·

View notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.

10-Voice and Wearable Technologies: Wearable devices and voice-guided picking systems can provide workers with real-time information and instructions, improving accuracy and efficiency.11-Automated Packaging Solutions: These systems automate the packaging process by selecting the appropriate box size, sealing packages, and applying labels, reducing manual labour and ensuring consistent packaging quality.

1 note

·

View note

Link

#adaptiveautomation#AIrobotics#hybridskillmodels#IndustrialAI#productivitymetrics#regionalinnovation#SmartManufacturing#workforcedevelopment

0 notes

Text

Area Sensors Market Drivers Fueling Automation, Safety, and Industrial Efficiency Worldwide

The area sensors market is rapidly evolving, driven by a combination of technological advancements, rising automation demands, and the growing need for enhanced safety solutions across industries. Area sensors are devices designed to detect objects or monitor movement within a specific field, often used in manufacturing, packaging, robotics, and logistics. Their ability to improve operational efficiency, prevent accidents, and enable smart automation makes them a critical component in modern industrial systems.

Increasing Demand for Industrial Automation

One of the most prominent drivers of the area sensors market is the increasing reliance on industrial automation. As industries move toward smart factories and Industry 4.0 standards, the need for intelligent sensing solutions has become essential. Area sensors play a vital role in tasks like part detection, conveyor belt monitoring, and machine safety. They enable non-contact detection, reducing mechanical wear and tear while enhancing production speed and accuracy.

Manufacturing facilities across sectors such as automotive, electronics, food and beverage, and pharmaceuticals are investing heavily in automation. These investments naturally boost the adoption of area sensors, which ensure process optimization and real-time quality control.

Rising Focus on Workplace Safety

Safety regulations and standards have tightened globally, prompting industries to incorporate more advanced safety measures. Area sensors are crucial for establishing safety zones around dangerous machinery and automating shut-off functions when objects or personnel are detected within hazardous zones. This not only protects workers but also minimizes equipment damage and operational downtime.

The incorporation of light curtains and area monitoring sensors in assembly lines and robotic work cells ensures compliance with occupational safety standards while maintaining productivity. As awareness of workplace safety grows, the demand for reliable and responsive area sensors continues to rise.

Integration with Robotics and Smart Systems

Robotic systems, particularly collaborative robots (cobots), are becoming mainstream in modern production environments. These robots require precise and safe interaction with humans and surroundings. Area sensors provide the spatial awareness and detection needed for such seamless integration, helping robots avoid collisions and operate efficiently within shared workspaces.

Moreover, the rise of smart homes and IoT-based systems has extended the relevance of area sensors beyond industrial use. In consumer electronics and home automation, these sensors are used for motion detection, security monitoring, and energy management, further expanding their market footprint.

Technological Advancements in Sensor Design

Continuous innovation in sensor technologies is another key driver of the area sensors market. Manufacturers are developing sensors that are more compact, energy-efficient, and capable of high-resolution detection. Features like wireless communication, remote monitoring, and easy integration with PLCs and industrial networks are becoming standard.

Advancements in materials and optics have enhanced the performance of photoelectric and ultrasonic area sensors, enabling them to function accurately in challenging environments such as high humidity, dust, or varying lighting conditions. These technological improvements are increasing adoption across various industries, reinforcing the market’s growth trajectory.

Expansion of Logistics and E-commerce Sectors

The global boom in e-commerce and logistics has created a need for faster and more accurate material handling and sorting processes. Area sensors are pivotal in automating these operations, enabling real-time package detection, alignment, and verification.

Automated warehouses and distribution centers deploy a range of area sensors to ensure efficient workflow, from conveyor tracking to automated guided vehicle (AGV) navigation. As e-commerce continues to expand globally, particularly in emerging markets, the demand for such smart sensor solutions is expected to rise significantly.

Environmental and Energy Efficiency Goals

Sustainability and energy efficiency are increasingly influencing industrial practices. Area sensors contribute to this goal by enabling smarter, more controlled processes. For instance, sensors can help detect idle machinery or inefficient workflows, allowing adjustments that reduce energy waste.

In sectors like building automation, area sensors are employed to control lighting, HVAC, and security systems based on occupancy, thereby optimizing energy use. As industries strive to meet environmental goals, sensor-enabled systems are gaining importance, adding another layer of demand for the area sensors market.

In conclusion, the area sensors market is poised for sustained growth, fueled by a combination of automation, safety, technological innovation, and smart system integration. As industries across the globe continue to evolve and embrace digital transformation, area sensors will remain a foundational element, enabling smarter, safer, and more efficient operations.

0 notes

Text

Factory Automation by Servotech for Modern Manufacturing

In an era where efficiency, speed, and precision are the cornerstones of successful manufacturing, factory automation has emerged as a game-changing force. Servotech, a leading innovator in automation solutions, is at the forefront of this industrial evolution. By integrating cutting-edge technology into manufacturing workflows, Servotech is transforming traditional production facilities into smart, efficient, and highly productive environments.

What is Factory Automation?

Factory automation involves the use of control systems—such as computers, robotics, and information technologies—to operate equipment and processes in manufacturing with minimal or no human intervention. It includes everything from automated machinery and sensors to artificial intelligence and machine learning applications that monitor and optimize operations.

The Role of Servotech in Modern Factory Automation

Servotech is a trailblazer in designing and delivering customized automation systems tailored to the unique needs of modern manufacturers. The company’s solutions encompass a wide range of applications, from assembly line automation to smart data analytics, helping businesses streamline operations and improve quality standards.

By combining innovation, engineering excellence, and a deep understanding of industry-specific challenges, Servotech empowers manufacturers to stay competitive in an increasingly digitized marketplace.

Key Features of Servotech's Factory Automation Solutions

1. Advanced Robotics Integration

Servotech integrates advanced robotics into manufacturing systems to handle repetitive, hazardous, or precision-dependent tasks. These robots are capable of operating around the clock, improving productivity and reducing operational costs. Collaborative robots (cobots), designed to work alongside humans safely, are also a core offering.

2. Intelligent Control Systems

The backbone of factory automation is intelligent control. Servotech deploys PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and DCS (Distributed Control Systems) to ensure seamless communication between machines and systems.

These controls allow real-time monitoring, quick decision-making, and effective process adjustments, minimizing downtime and maximizing output.

3. IoT-Enabled Smart Manufacturing

Servotech embraces the Industrial Internet of Things (IIoT) by embedding smart sensors and connected devices within factory setups. This connectivity facilitates:

Real-time performance tracking

Predictive maintenance

Remote diagnostics

Data-driven decision-making

With IoT, factories become more agile and capable of self-optimization.

4. Custom Automation Solutions

No two manufacturing processes are identical. Servotech provides tailored automation solutions specific to the client’s industry, product type, and production scale. Whether it’s automotive, electronics, pharmaceuticals, or food processing, their systems are designed to enhance efficiency and ensure compliance with industry standards.

Benefits of Servotech’s Factory Automation Systems

1. Increased Productivity and Efficiency

Automated systems significantly reduce the time required to perform repetitive tasks. Servotech’s solutions accelerate production cycles, increase throughput, and eliminate bottlenecks.

2. Consistent Quality and Precision

Human error is a significant source of defects in manual manufacturing. Servotech’s automation ensures precision and repeatability, leading to higher product quality and reduced waste.

3. Cost Savings

Though the initial investment in automation can be substantial, the long-term cost savings are significant. Servotech’s systems reduce labor costs, minimize material wastage, and lower energy consumption through optimized processes.

4. Enhanced Safety

By automating dangerous or strenuous tasks, Servotech reduces the risk of workplace injuries. Robots and machines handle hazardous materials or high-temperature processes, ensuring worker safety and regulatory compliance.

5. Scalability and Flexibility

Modern manufacturing demands adaptability. Servotech’s modular and scalable automation systems can be easily upgraded or reconfigured to meet changing production needs or market demands.

Real-World Applications of Servotech Automation

Automotive Industry

Servotech's automation solutions are instrumental in assembling components with high accuracy, managing inventory in real time, and ensuring consistent output quality in vehicle production.

Electronics Manufacturing

Micro-level precision is critical in electronics. Servotech offers robotic soldering, PCB handling, and automated inspection systems that enhance speed and accuracy.

Pharmaceutical Production

From sterile manufacturing to packaging, Servotech ensures compliance with stringent regulatory standards while maintaining efficiency and cleanliness in pharmaceutical environments.

Food and Beverage

Automated packaging, labeling, and quality control systems from Servotech enhance hygiene, reduce spoilage, and meet diverse product specifications in the food sector.

Why Choose Servotech for Factory Automation?

1. Proven Expertise

Servotech has a strong track record of delivering reliable and scalable automation projects across various sectors. Their team comprises skilled engineers, system integrators, and industry consultants.

2. Innovative Technology

Servotech invests heavily in R&D, ensuring that their solutions incorporate the latest technologies like AI, machine vision, edge computing, and more.

3. End-to-End Support

From consultation and system design to installation, training, and after-sales service, Servotech provides comprehensive support throughout the automation journey.

4. Sustainability Focus

Servotech’s solutions are engineered to be energy-efficient and environmentally sustainable, helping manufacturers reduce their carbon footprint while improving profitability.

Future of Manufacturing with Servotech

As we move further into the Fourth Industrial Revolution (Industry 4.0), factory automation will become not just a competitive advantage, but a necessity. Servotech is committed to driving this change by providing intelligent, adaptable, and future-ready automation solutions.

In the future, we can expect:

More AI-integrated automation

Increased use of digital twins for simulation and optimization

Fully autonomous production lines

Seamless integration with enterprise-level ERP and CRM systems

Servotech is already working on these advancements, ensuring its clients are not only ready for the future—but leading it.

Conclusion

Factory automation is redefining modern manufacturing by improving productivity, quality, safety, and sustainability. Servotech stands out as a leader in this space, offering customized, cutting-edge solutions that help industries meet the demands of today and the challenges of tomorrow.

Whether you're a large-scale manufacturer or a growing enterprise, Servotech can help you transition to a smarter, more efficient production model. With their expertise, innovation, and customer-centric approach, your journey toward intelligent manufacturing begins here.

0 notes

Text

Future Bots

Robotics is a rapidly evolving field that blends mechanical engineering, electronics, computer science, and artificial intelligence to create machines capable of performing tasks traditionally done by humans. From industrial robots assembling cars to autonomous drones and robotic assistants in healthcare, robotics is transforming every major industry. These machines can operate with precision, consistency, and efficiency, often in environments too dangerous or repetitive for humans. Modern advancements include humanoid robots, AI-powered bots that learn from their environment, and collaborative robots (cobots) that work alongside people. Robotics is not just about automation; it's about creating intelligent systems that adapt and improve over time. As technology advances, robots are becoming more accessible, versatile, and integrated into daily life. They play key roles in space exploration, surgery, manufacturing, and even education. The future of robotics holds exciting possibilities, pushing the boundaries of innovation and reshaping how we interact with machines and the world around us.

0 notes

Text

Revolutionizing Foundries with Robotics: How Smart Automation is Transforming Industrial Manufacturing

Foundries are some of the most demanding environments in the manufacturing world—characterized by extreme heat, heavy materials, and labor-intensive processes. As the push toward Industry 4.0 gains momentum, robotics and smart automation are redefining what’s possible in these settings. Companies like LeisterTech are leading this transformation by integrating robotics with their high-performance machinery, including lining vibrators, scrap transfer trolleys, hydraulic pushers, and lifting magnets.

Why Foundries are Ideal for Robotics

Robotics brings consistency, safety, and operational efficiency to environments where precision and reliability are essential. In foundries, robots can take over tasks that are repetitive, dangerous, or require high levels of accuracy. Here's how:

1. Material Handling with Precision

Robots equipped with advanced gripping technologies are capable of moving hot billets, heavy molds, and castings with exceptional control. When paired with LeisterTech’s robust lifting magnets, these systems ensure safe, accurate, and efficient handling of ferrous materials—reducing downtime and workplace hazards.

2. Streamlined Casting and Mold Filling

Automated arms can perform complex tasks like molten metal pouring with enhanced safety and precision. These systems, when used alongside LeisterTech’s specialized lining vibrators, help ensure that every mold is evenly filled and compacted—boosting the quality and consistency of final castings.

3. Cleaning, Finishing, and Post-Casting Automation

After casting, components often need grinding, deburring, or polishing. Robots can handle these tasks with consistent results, speeding up the post-production process. Integration with LeisterTech’s hydraulic pusher systems allows for seamless workflow transitions, reducing manual labor and increasing throughput.

4. Inspection & Quality Control

With built-in vision systems and AI algorithms, robots can scan cast components for defects in real time. These insights become even more powerful when combined with data from smart equipment like LeisterTech’s scrap transfer trolleys, enabling predictive maintenance and enhanced process control.

Benefits of Integrating Robotics with LeisterTech Machinery

Increased Productivity: Robotic systems can operate continuously and precisely, supporting equipment like LeisterTech’s shearing and pusher tools for high-volume, automated production.

Improved Safety: Robotics minimizes the need for human presence in high-risk zones, particularly when dealing with molten metals or heavy components.

Scalability & Flexibility: Robotic systems can adapt to different workflows, making them a natural extension of multi-functional equipment such as LeisterTech’s scrap handling solutions.

Data-Driven Efficiency: By collecting and analyzing operational data, robotics enhances predictive maintenance and real-time process optimization.

Innovations Driving Robotic Adoption in Foundries

Collaborative Robots (Cobots): Designed to work safely alongside human workers, cobots are ideal for hybrid automation setups where both manual skill and machine precision are required.

AI & Machine Learning: Advanced robotics use AI to learn from real-world operations, improving over time and adapting to various production variables.

Vision & Sensing Technologies: High-resolution cameras and smart sensors enable robots to perform tasks like alignment, defect detection, and complex part identification with unmatched accuracy.

The Road Ahead: Robotics in the Smart Foundry

As foundries evolve into smart factories, the integration of robotics with IoT-enabled machinery will become the industry standard. From green automation powered by renewables to smarter material handling, the future is geared toward sustainable, intelligent production.

Final Thoughts

The fusion of robotics and traditional foundry equipment is not just a trend—it’s the future of industrial manufacturing. Through strategic integration with advanced systems like LeisterTech’s lining vibrators, scrap transfer solutions, hydraulic pushers, and lifting magnets, manufacturers can elevate safety, efficiency, and output. As the foundry sector embraces smart automation, LeisterTech stands at the forefront—offering reliable, innovative solutions for the next generation of industrial production.

0 notes

Text

Why AI in Manufacturing Is Becoming Essential for Competitive Edge in the Fourth Industrial Revolution?

The Fourth Industrial Revolution, or Industry 4.0, is not just a buzzword—it's a tectonic shift in how we design, produce, and deliver goods. At the heart of this revolution lies Artificial Intelligence (AI), fundamentally changing the manufacturing landscape. From predictive maintenance and quality control to autonomous systems and supply chain optimization, AI in manufacturing is no longer a luxury—it's a necessity.

In this blog, we’ll explore why adopting AI in manufacturing is vital to stay competitive, and how it's redefining productivity, innovation, and operational agility.

1. The Role of AI in the Fourth Industrial Revolution

The Fourth Industrial Revolution combines cyber-physical systems, IoT, cloud computing, and AI to create intelligent, interconnected factories. While previous revolutions focused on mechanization, electricity, and digitalization, Industry 4.0 leverages real-time data and machine intelligence to improve decision-making and efficiency.

AI acts as the brain of smart factories, enabling:

Autonomous decision-making

Real-time analytics

Process optimization

Adaptive learning from production data

2. Boosting Operational Efficiency Through Predictive Maintenance

One of the most immediate and measurable benefits of AI in manufacturing is predictive maintenance. Traditional maintenance models are reactive (fix when broken) or scheduled (maintain regardless of condition), both of which incur high costs.

With AI, manufacturers can:

Predict equipment failures before they happen

Minimize downtime and unplanned outages

Reduce repair costs and extend asset lifespans

Machine learning algorithms analyze sensor data to flag potential issues early, ensuring continuous production flow and reduced waste.

3. Improving Quality with AI-Powered Visual Inspection

AI-enabled computer vision systems are replacing manual inspection with far greater accuracy and speed. Cameras, paired with deep learning models, detect:

Micro-defects

Pattern deviations

Surface irregularities

This ensures zero-defect manufacturing, enhances product consistency, and reduces recalls. Moreover, these systems learn and improve over time, making them a long-term quality assurance asset.

4. Smarter Supply Chains and Inventory Management

Global disruptions and shifting consumer demands have made supply chain agility a top priority. AI brings predictive and prescriptive capabilities to:

Forecast demand with greater accuracy

Optimize inventory levels and logistics routes

Identify supplier risks and bottlenecks in advance

By automating supply chain decisions with AI, manufacturers can avoid stockouts, reduce excess inventory, and improve order fulfillment rates.

5. Enabling Mass Customization with AI and Robotics

In the past, large-scale production meant sacrificing customization. AI has changed the game by:

Powering flexible manufacturing systems

Integrating with collaborative robots (cobots) for agile production

Adapting production lines in real-time based on customer preferences

This opens doors for personalized products at scale, helping brands meet niche demands without compromising efficiency.

6. Optimizing Energy Consumption and Sustainability Goals

Manufacturers are under pressure to reduce their carbon footprint. AI-driven energy management platforms can:

Monitor and optimize power usage across machines and facilities

Identify inefficiencies and recommend corrective actions

Balance sustainability with productivity

This not only reduces energy bills but aligns manufacturing operations with ESG (Environmental, Social, and Governance) goals.

7. Empowering Workforce with AI-Augmented Decision-Making

Contrary to fears of job loss, AI in manufacturing is augmenting human capability. AI supports workers by:

Providing real-time insights and data visualization

Assisting in complex decision-making

Enhancing safety through smart alerts and risk detection

With AI copilots and digital twins, workers become more productive, informed, and empowered.

8. Accelerating Time-to-Market for New Products

Speed is a competitive advantage. AI helps shorten product development cycles by:

Analyzing market trends and customer data

Simulating product designs before physical prototyping

Automating testing and feedback loops

This ensures faster innovation, reduced R&D costs, and timely response to market opportunities.

9. Real-World Applications: AI Success Stories in Manufacturing

Across industries, leading manufacturers are embracing AI:

BMW uses AI for quality assurance and logistics optimization.

Siemens applies AI for predictive maintenance and process automation.

GE leverages digital twins to monitor equipment performance globally.

These case studies prove that AI isn't theoretical—it's driving tangible results today.

10. Competitive Advantage: AI Is the New Industrial Currency

In Industry 4.0, data is the new oil, and AI is the engine that runs on it. Companies that integrate AI into their manufacturing ecosystems gain:

Cost savings

Agility to respond to market changes

Innovation leadership

Customer-centric production capabilities

Failing to adopt AI means risking obsolescence in a world that's rapidly digitizing.

Conclusion

As the Fourth Industrial Revolution accelerates, AI in manufacturing is no longer optional—it’s the foundation of competitive advantage. Whether you're a small plant or a global enterprise, now is the time to modernize your operations, harness real-time intelligence, and position yourself as a forward-thinking industry leader.

0 notes

Text

What are the Top Examples, Use Cases, And Benefits of AI in Manufacturing

The rapid evolution of technology has ushered in a new era for industries worldwide, with artificial intelligence in manufacturing leading the charge. These revolutions are revolutionizing the methods of product development and delivery and go to unheard-of levels of automation, precision and added value. Manufacturers are now integrating AI to solve problems, to foresee a breakdown, and enhance workflows.

From advanced robots to predictive maintenance, artificial intelligence-powered solutions are transforming established procedures. Examining useful applications, prominent use cases, and the many advantages AI presents to firms negotiating a more competitive market, this article explores how this technology is changing the manufacturing sector.

How does AI enhance efficiency in manufacturing?

Organization and productivity have always been the key elements in the structure of manufacturing, and AI cannot be further helpful in the process. AI harnesses significant amounts of data from machine constructs, the production line and the marketplace to discover more efficient ways of functioning.

The global AI in manufacturing market size was valued at USD 8.14 billion in 2019 and is projected to reach USD 695.16 billion by 2032. One main area where the use of AI increases productivity is in the area of predictive maintenance.

Originally, the manufacturers used only a mechanical type of preventive or corrective maintenance, which means that they could only guess when their products were going to fail or could plan for periodic maintenance checks in a timetable that might be unconnected with the actual need.

AI-based systems, on the other hand, provide constant supervision through sensor and analytics and can predict when perhaps a part in the machinery might fail. This means that damages can be effected and sorted early enough without much time being lost to equipment breakdowns hence improving on its durability.

Automation by AI Robotics also adds to efficiency through removing hardworking and repetitive tasks. For example, robots that are incorporated with AI can either build, bond, or even package products with high efficiency and accuracy.

Collaborative robots, or cobots,are designed for joint operation with employees; the concept significantly applies human creativity with robotic precision. This synergy makes it possible for manufacturers to improve productivity by enhancing quality production.

What are real-world examples of AI in manufacturing?

AI is already showing positive returns within diverse manufacturing industries. Here are some noteworthy examples:

1. Predictive maintenance

Companies like GE and Siemens are pioneers in leveraging AI for predictive maintenance. In this way, with the help of data from sensors, their AI systems can predict device failures in advance, days or even weeks. It reduces incidences of a halt on production and allows what has been planned to go on as calendar and time dictate.

2. Quality control

Nowadays, firms like BMW have implemented the use of AI-based computer vision in the production processes. These systems use some form of image recognition to pick up on abnormalities such as scratches, dents, or seemingly off alignments in most instances within milliseconds. This not only improves the quality of the product but also does away with wastages and rework charges.

3. Demand forecasting

AI is useful in demand forecasts, the foundations of which are currently being set. For instance, Unilever recently revealed it uses Artificial Intelligence Algorithms to forecast customers’ demand of their products based on previous sales records, conditions and trends. This makes it possible to achieve the right stock, to accommodate the right stock without some vices such as overstock or out of stock problems.

4. Supply chain optimization

Amazon’s supply chain success is a testament to the power of AI. The mechanisms of algorithms based on machine learning allow the e-commerce giant to enhance the control over stock, storage facilities, and delivery. This level of optimization helps to minimize operational cost whilst at the same time ensuring short order turnaround.

5. Generative design

Many aerospace companies including Airbus are now using AI in generative design. Specific requirements, including weight, strength and necessity of materials, are entered by engineers and multiple design solutions are provided by an AI. Researchers defined that an AI-optimized design is much lighter yet stronger and cheaper as compared to original designs.

How does AI improve quality and precision?

AI’s assure high quality, and its precision makes the difference for the manufacturer. The previous tools used in quality control were based on the ability of the human eye to inspect the products, this was disadvantageous because the human eye may miss some defects due to tiredness or even carelessness.

AI however is superior when it comes to checking for discrepancies compared to human beings in this case. Within the manufacturing industry, most respondents (59 percent) state that quality control is the most important use case for artificial intelligence.

Examples of AI-driven quality enhancement:

Automotive industry: Tesla has implemented AI surveillance on welds and assemblies that need accuracy as small as micrometers. This gives both structural and product qualities and hence the company’s reputation.

Pharmaceutical manufacturing: It keeps necessary checks upon the medicine production and management of dosages of various medicines so there can be no compromise on the issues of safety and effectiveness.

Apart from the elimination of defective and, therefore, non-saleable products, AI contributes effectively to the achievement of sustainable objectives by cutting unnecessary use of raw materials and energy. For instance, AI control can allow a flexible management of material consumption, guaranteeing that every amount is used optimally without any compromise of quality.

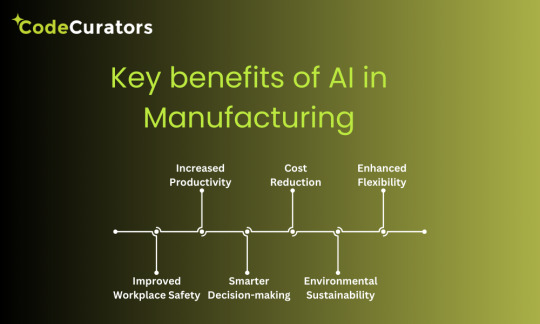

What are the key benefits of AI in manufacturing?

1. Increased productivity

AI automates repetitive procedures and thereby increases the manufacturing rate among the manufacturers. Through continuous functioning without being weary, the use of robots under the AI operations’ umbrella can help increase throughput.

2. Cost reduction

Predictive maintenance minimizes that time as well as the frequency of repairs. AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035. Moreover, AI helps to save material consumption and energy as well these strategies also help in reducing expenses.

3. Enhanced flexibility

Production lines powered by artificial intelligence are incredibly flexible so the same line can produce different variations of a product and changes in market trends can easily be handled as well.

4. Improved workplace safety

AI relieves human workers of dangerous tasks that they used to perform. Hazardous work can be done by robots, and AI systems track the state of the workplace concerning safety in real-time.

5. Smarter decision-making

Real-time analytics and predictive insights let companies decide with knowledge. AI ensures optimal efficiency by helping to maximize everything from inventory levels to manufacturing schedules.

6. Environmental sustainability

Manufacturing sustainability goals are met because AI helps cut down on energy consumption and wastage. For example, skills can be used in the identification of chances of reclaiming raw materials or reducing energy use in the production process.

What challenges exist when implementing AI in manufacturing?

While the benefits are significant, implementing AI is not without challenges:

1. High initial costs

Both complex AI and the environments that support such systems are not inexpensive. The high initial cost is one of the chief concerns many manufacturing companies feel.

2. Data dependency

AI has more dependence on quality data and needs a significant quantity of data for the workspace. To provide the wrong recommendations or forecast, you need to feed the algorithm with inconsistent or inferior data quality.

3. Integration issues

Technologies based on AI can sometimes integrate with existing legacy systems with some level of difficulty and with much necessary reorganization.

4. Workforce adaptation

Workers may need retraining to collaborate with artificial intelligence systems, and change may face opposition.

To overcome these hurdles, manufacturers should consider phased AI implementation, invest in employee training, and prioritize data management.

What Is the Future of AI in Manufacturing?

The future of manufacturing will likely be defined by even deeper AI integration. Emerging trends include:

1. Collaborative robots (Cobots)

These robots will complement man in that they bring into the equation, the mechanical accuracy of a robot and the flexibility of man.

2. Edge AI

AI processing at the edges of networks will be a boon for decision making mechanisms because it will help in the localization of data processing.

3. Sustainability-Focused AI

AI will be responsible for further contributing to the right utilization of energy so as to minimize wastage in the manufacturing firms to meet environmental objectives.

4. Personalized manufacturing

AI will improve the production capacity of manufactures so as to meet the consumers’ demand for personalisation.As AI technologies evolve, their integration with other innovations like IoT, 5G, and blockchain will further revolutionize the manufacturing sector, making it more efficient, innovative, and sustainable.

Conclusion

Artificial intelligence in manufacturing has become instrumental in solving some of the oldest problems facing the industry while providing new opportunities for expansion. From improving speed and accuracy to transforming growth trajectories and enabling more sustainable practices, AI offers endless possibilities. However, despite barriers such as high costs and integration challenges, the advantages significantly outweigh the disadvantages.

The automotive sector, in particular, is gearing up to become smarter, more flexible, and better prepared for the global market as manufacturers increasingly adopt AI technology. For organizations aiming to remain at the forefront of the competitive landscape, leveraging AI in Manufacturing is no longer a luxury but an absolute necessity.

We can assist you if you are prepared to use AI to improve your manufacturing processes. For a consultation on how advanced AI technologies may boost your business’s operations, increase productivity, and promote long-term success, get in touch with us. Together, we can overcome obstacles, take advantage of fresh chances, and establish your company as a leader in the field. Are you prepared to welcome the AI-powered manufacturing of the future? Contact us right now, and together, let us make it happen.

#Evolution of technology#AI in manufacturing#AI powered solutions#benefits of AI in manufacturing#Future of AI in Manufacturing#manufacturer#software engineering

1 note

·

View note

Text

Machine Safety: The New Backbone of Automated Industries

The global machine safety market, valued at USD 5,732.91 Mn in 2024, is poised for robust expansion, projected to grow at a CAGR of 6.07% between 2025 and 2035, ultimately reaching USD 11,146.90 Mn by 2035. According to analysts, as industries transition towards automation and connected manufacturing systems, machine safety has evolved into a strategic business necessity integral to enhancing employee welfare, minimizing downtime, and safeguarding valuable equipment.

Market Overview: Machine safety refers to strategies and technologies that protect workers and machines from operational risks. Core components include emergency stop switches, safety light curtains, sensors, interlocks, and guarding systems. With compliance to standards such as ISO 13849 and OSHA regulations, machine safety initiatives not only reduce liability but also improve overall operational efficiency and productivity.

Gradually, safety measures are no longer just about regulatory compliance but are now deeply embedded into production planning and system design. Dynamic safety solutions that adapt in real-time to changing operational conditions are setting a new standard in the industry.

Market Drivers & Trends

Growing Awareness About Workplace Safety: With industries adopting sophisticated machinery, the risks of injury have increased. Organizations recognize the importance of proactive safety measures, enhancing both employee protection and productivity. Investment in safety training and education, alongside the installation of safety devices, has become standard practice.

Rising Automation Across Industries: Automation is revolutionizing sectors from automotive to food processing. However, increased automation introduces new risks. Advanced machine safety solutions such as intelligent sensors and emergency stop systems are becoming critical to ensure human-machine collaboration is both efficient and safe. Notably, ongoing training and clear risk communication are crucial components of this evolving safety culture.

Key Players:

ABB

Balluff GmbH

Banner Engineering Corp.

Bihl+Wiedemann GmbH

Emerson Electric Co.

Festo AG

HIMA

Honeywell International Inc.

IDEC Corporation

IFM Electronic

Keyence Corporation

Mitsubishi Electric Corporation

Omron Corporation

Pilz GmbH & Co.KG

Rockwell Automation, Inc.

Schneider Electric SE

Sick AG

Siemens AG

Yokogawa Electric Corp

Among Others

Recent Developments

In January 2025, Mitsubishi Electric launched the MELSEC iQR safety local I/O modules RX40NC6S-TS and RY48PT20S-TS, designed to bolster efficiency and reduce safety-related costs in industrial automation.

In December 2023, Balluff GmbH introduced the CIP Safety I/O module, an IP67-rated solution offering safer integration for manufacturing facilities, supporting up to 12 single-channel safe inputs.

These innovations signal a shift toward modular, scalable safety systems capable of meeting the flexible demands of modern production environments.

Latest Market Trends

Integration of AI and Machine Learning: Intelligent safety systems that predict and prevent failures are gaining traction.

Rise of Collaborative Robots (Cobots): Increasing deployment of cobots in manufacturing is amplifying the need for responsive safety technologies.

Wireless Safety Systems: Adoption of wireless emergency stop systems and wireless safety sensors is reducing wiring costs and increasing flexibility.

Access key findings and insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=57021

Market Opportunities

SME Segment: Small and medium enterprises, especially in emerging economies, represent a significant untapped market as governments tighten regulations and offer incentives for safety upgrades.

Retrofitting Legacy Systems: With many industries operating aging equipment, the opportunity to retrofit legacy machines with modern safety solutions is substantial.

Expanding Applications: Beyond manufacturing, machine safety solutions are increasingly being applied in sectors like agriculture, healthcare automation, and construction.

Future Outlook

As Industry 5.0 concepts gain ground, emphasizing human-centric, sustainable, and resilient manufacturing, machine safety technologies will become even more crucial. Analysts predict that companies that invest early in machine safety will not only comply with regulations but also establish themselves as leaders in sustainable, responsible manufacturing practices.

Future market growth will be heavily driven by technological innovation, regulatory enforcement, and the globalization of safety standards.

Market Segmentation

By Components:

Presence Sensing Safety Sensors, Safety Light Curtains, Safety Interlock Switches, Emergency Stop Controls, Safety Controllers/Relays, Two-Hand Safety Controls, Machine Guards, among others.

By Application:

Assembly (38.33% market share in 2024), Material Handling, Metal Working, Packaging, Robotics, Others (Welding, Shielding)

By End-use Industry:

Process Industries: Chemicals, Food & Beverages, Pharmaceuticals, Oil & Gas, etc.

Discrete Industries: Automotive, Aerospace, Electronics, Healthcare.

By Sales Channel:

Direct, Indirect

Regional Insights

East Asia led the global machine safety market in 2024, accounting for 28.13% of total revenue. The region’s dominance stems from being the global manufacturing hub for industries like automotive, electronics, and heavy machinery. Countries like China, Japan, and South Korea are spearheading the adoption of smart factories and stringent safety norms.

Government policies in East Asia strongly emphasize worker safety, boosting demand for high-end machine safety technologies. Local innovations, coupled with international safety standard compliance, have further accelerated growth.

Other rapidly growing regions include North America, Western Europe, and South Asia, driven by increasing regulatory pressure and the proliferation of Industry 4.0 solutions.

Why Buy This Report?

Detailed market segmentation and in-depth analysis.

Insights into key drivers, trends, and opportunities.

Profiles of major industry players and recent innovations.

Regional breakdowns highlighting growth hotspots.

Future forecasts guiding strategic business planning.

Competitive landscape analysis including company market share data.

Cross-segment and cross-regional analysis.

Clear mapping of regulatory frameworks and their impact.

Frequently Asked Questions (FAQs)

1. What was the global machine safety market size in 2024? The market was valued at US$ 5,732.91 Mn.

2. What is the forecasted market size for 2035? The market is projected to reach US$ 11,146.90 Mn by 2035.

3. What is the expected CAGR during 2025–2035? The market is anticipated to expand at a CAGR of 6.07%.

4. Which region holds the largest market share? East Asia is the leading region, accounting for 28.13% of the global market in 2024.

5. Which segment dominated the application segment in 2024? The assembly segment led the market, holding 38.33% of the market share.

6. Who are some key players in the market? Siemens, ABB, Rockwell Automation, Schneider Electric, and Mitsubishi Electric are among the major players.

7. What are the key market opportunities? Opportunities lie in SME adoption, retrofitting legacy systems, and expanding applications across sectors.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

The Future of Distribution Manufacturing in Pune: Trends & Innovations

Pune, a major industrial hub, is witnessing a transformative shift in distribution manufacturing. As industries evolve with technology-driven advancements, the future of distribution manufacturing in Pune is set to be dynamic and growth-oriented. From automation to sustainable production, businesses are embracing cutting-edge trends to stay competitive.

Key Trends Shaping Distribution Manufacturing in Pune

1. Smart Automation & AI Integration

Automation and Artificial Intelligence (AI) are redefining distribution manufacturing in Pune. With the introduction of robotic process automation (RPA), machine learning algorithms, and smart sensors, manufacturers can enhance efficiency, minimize errors, and improve supply chain management. AI-powered analytics enable predictive maintenance, reducing downtime and operational costs.

2. Sustainable & Green Manufacturing

Eco-friendly manufacturing practices are becoming a priority for industries in Pune. The implementation of energy-efficient technologies, waste reduction strategies, and sustainable material sourcing is enhancing the overall environmental impact. Companies are also adopting circular economy models to reduce production waste and increase recyclability.

3. Advanced Supply Chain Management

With rapid digitization, supply chain management is undergoing a transformation. The use of blockchain technology ensures transparency, security, and efficiency in supply chain operations. Cloud-based logistics solutions allow real-time tracking, ensuring seamless inventory management and timely delivery.

4. 3D Printing & Customization

Additive manufacturing, also known as 3D printing, is revolutionizing distribution manufacturing in Pune. Companies can now produce customized components with precision, reducing dependency on mass production. This innovation allows manufacturers to create prototypes faster and optimize designs based on real-time feedback.

5. Industrial IoT (IIoT) Implementation

The Industrial Internet of Things (IIoT) is making manufacturing more connected and data-driven. IIoT enables remote monitoring, predictive maintenance, and efficient workflow optimization. By leveraging real-time data, manufacturers can improve productivity and ensure better quality control.

6. Digital Twin Technology

Digital twins are virtual replicas of physical systems that help manufacturers simulate, analyze, and optimize production processes. This technology minimizes operational risks, enhances efficiency, and ensures accurate forecasting, making it a game-changer for distribution manufacturing in Pune.

Innovations Driving the Future of Distribution Manufacturing in Pune

Robotics and Cobots (Collaborative Robots)

The integration of robotics and cobots is streamlining production lines. These intelligent machines work alongside human workers, increasing precision, reducing labor-intensive tasks, and improving workplace safety. Robotics is expected to further revolutionize distribution manufacturing in the coming years.

Cloud Manufacturing Solutions

Cloud-based platforms are allowing manufacturers to manage operations remotely, ensuring data security and streamlined collaboration. By utilizing cloud manufacturing, companies can optimize production planning and enhance scalability.

AI-Driven Quality Control

AI-powered image recognition and machine learning algorithms are being used for automated quality inspections. This ensures high standards, minimizes defects, and enhances customer satisfaction.

Sustainable Energy Adoption

Renewable energy sources such as solar and wind power are being increasingly integrated into manufacturing processes. This not only reduces carbon footprints but also lowers operational costs in the long run.

The Impact of These Trends on Pune’s Industrial Landscape

The adoption of these trends is transforming Pune into a global manufacturing powerhouse. With government initiatives such as ‘Make in India’ and investments in smart infrastructure, the city is becoming a preferred destination for manufacturing companies. The advancements in distribution manufacturing in Pune are enhancing productivity, job creation, and overall industrial growth.

Conclusion

The future of distribution manufacturing in Pune is being shaped by smart automation, sustainable practices, and cutting-edge innovations. As businesses continue to adopt digital transformation strategies, Pune is set to become a hub of advanced manufacturing technologies. Companies that embrace these trends will gain a competitive edge and contribute to the growth of India’s industrial sector.

By staying ahead of these changes, Pune’s manufacturing industry will continue to evolve, ensuring sustainable development and global competitiveness.

0 notes

Text

Machine Safety Market Responds to Global Workplace Safety Laws and Industrial Digitization Trends

The Machine Safety Market is undergoing significant transformation, driven by increasing automation across industries and rising emphasis on workplace safety regulations. As industries worldwide move towards smart manufacturing and Industry 4.0, the integration of advanced safety systems in machinery has become not just a legal requirement but also a strategic business imperative.

Market Overview

Machine safety refers to the use of safety components and systems to ensure that industrial machines operate safely, protecting both workers and assets. These systems include safety sensors, switches, controllers, relays, interlocks, and emergency stop devices. The goal is to prevent accidents, reduce operational downtime, and ensure compliance with international safety standards such as ISO 13849, IEC 62061, and OSHA regulations.

In recent years, the machine safety market has seen rapid growth across sectors such as manufacturing, automotive, pharmaceuticals, food and beverage, and packaging. The increasing need to maintain operational efficiency while ensuring worker safety has pushed companies to adopt sophisticated safety mechanisms.

Key Drivers

Stringent Government Regulations: Governments and regulatory bodies across the globe are enforcing strict laws and guidelines to protect workers from industrial hazards. These include mandatory installation of safety devices on machinery and regular safety audits.

Growing Automation: The push for automation in manufacturing and industrial operations has led to a rise in the adoption of safety technologies. As machines become more complex and interconnected, integrated safety solutions are essential to prevent risks during machine operation.

Rising Workplace Fatalities and Accidents: Statistics showing injuries or fatalities due to machine-related accidents have prompted companies to invest more in preventive technologies. Ensuring a safe working environment helps in improving employee morale and avoiding costly legal consequences.

Industry 4.0 and Smart Factories: The convergence of physical and digital technologies in smart factories necessitates intelligent safety solutions. Machine safety systems now often include features like remote monitoring, predictive maintenance, and real-time diagnostics.

Market Segmentation

The machine safety market is typically segmented based on:

Component: Including sensors, controllers, relays, interlock switches, and safety modules.

Implementation: Embedded systems and standalone systems.

Application: Robotics, packaging, material handling, and others.

End-user Industry: Automotive, oil & gas, electronics, healthcare, and manufacturing.

Among these, the automotive and manufacturing sectors are the most dominant due to the high degree of mechanization and regulatory oversight.

Regional Insights

Europe currently leads the global machine safety market, largely due to early adoption of safety regulations and widespread use of industrial automation.

North America follows closely, with substantial investment in modernizing factories and compliance with OSHA standards.

Asia-Pacific is anticipated to witness the fastest growth due to expanding industrialization, especially in countries like China, India, and Japan.

Emerging Trends

Integration with IoT: Machine safety systems are increasingly being integrated with Internet of Things (IoT) platforms to enable real-time monitoring and remote diagnostics.

Predictive Safety: Leveraging AI and machine learning to predict potential safety failures before they occur is a growing trend.

Collaborative Robots (Cobots): With the rise of cobots working alongside humans, safety solutions are adapting to ensure seamless human-machine interaction without compromising safety.

Challenges

Despite its growth, the machine safety market faces challenges such as:

High Initial Costs: Installing safety systems can be expensive, especially for small and medium enterprises.

Lack of Awareness: In developing regions, there is limited awareness and understanding of machine safety standards.

Complex Integration: Integrating safety systems into legacy machinery without disrupting production is technically challenging and often costly.

Future Outlook

The future of the machine safety market looks promising. With increasing awareness, technological advancement, and tighter regulations, companies are expected to prioritize safety as a core component of their operational strategy. The market is expected to grow steadily, supported by innovations in AI, IoT, and automation.

#MachineSafety#MachineProtection#IndustrialSafety#WorkplaceSafety#AutomationSafety#SmartManufacturing

0 notes

Text

Robotic Arms Market Drivers: Innovations, Automation, and Key Trends Shaping Future Growth

The robotic arms market has evolved significantly in recent years, marking a transformative shift in industries ranging from manufacturing and healthcare to logistics and aerospace. As we look to the future, several key factors are driving this rapid growth, including advancements in artificial intelligence (AI), automation, and improvements in robotic technology. These elements are not only enhancing the performance of robotic arms but also expanding their applications in numerous sectors. This article delves into the primary drivers that are shaping the growth and evolution of the robotic arms market.

1. Increasing Demand for Automation

The push towards automation is one of the most prominent drivers in the robotic arms market. Companies across industries are adopting robotic arms to replace manual labor, streamline operations, and reduce the potential for human error. Automation enhances productivity, consistency, and efficiency while lowering operational costs. Robotic arms are particularly beneficial in repetitive tasks such as assembly lines, packaging, and material handling, where precision and speed are crucial.

Industries like automotive manufacturing have long been leaders in robotic arm adoption. However, sectors such as food and beverage, electronics, and even healthcare are now also embracing automation solutions, contributing to the market's growth. As more industries recognize the potential of robotic arms to drive productivity, the demand for these advanced machines is expected to continue its upward trajectory.

2. Technological Advancements in AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) have revolutionized the capabilities of robotic arms, allowing them to perform tasks with higher precision, adaptability, and decision-making ability. AI-powered robotic arms can now learn from their environment, adapt to changes, and even self-correct when encountering unexpected situations. This level of intelligence makes robotic arms suitable for a broader range of applications, particularly in environments that require real-time decision-making, such as autonomous vehicles and complex manufacturing processes.

Moreover, the integration of AI enables robotic arms to perform tasks that were once too complex or dangerous for traditional machinery. This includes operations in hazardous environments, such as nuclear plants or deep-sea exploration, where human presence is limited or dangerous.

3. Cost Reduction and Return on Investment

The cost of robotic arms has decreased significantly over the past decade, making them more accessible to small and medium-sized enterprises (SMEs). As the technology has matured, manufacturing costs have been optimized, and the price of robotic arms has become more affordable. This reduction in price has made automation a more attractive option for businesses that previously could not justify the high upfront cost.

Additionally, the return on investment (ROI) offered by robotic arms is a key driver in their adoption. By increasing efficiency, reducing the need for labor, and enhancing the overall quality of products, businesses can see a rapid payback period on their investment. The financial benefits of automation make robotic arms an essential tool for companies looking to remain competitive in an increasingly globalized and fast-paced market.

4. Advancements in Robotics Technology

The continuous improvement in robotic technology itself is a driving factor behind the growth of the robotic arms market. Recent advancements in sensors, actuators, and control systems have made robotic arms more accurate, flexible, and capable of handling a wider variety of tasks. Enhanced sensors allow robotic arms to perform delicate operations, such as precision welding or intricate assembly, with greater reliability and efficiency.

Furthermore, innovations in collaborative robots, or cobots, have expanded the applications of robotic arms. Unlike traditional robotic systems, which operate in isolation, cobots are designed to work alongside human workers in a shared workspace. This collaborative approach allows companies to leverage the strengths of both humans and robots, improving safety and productivity.

5. Growth in E-Commerce and Logistics

The rapid expansion of e-commerce has significantly contributed to the increased demand for robotic arms in the logistics and warehousing sectors. Companies in these industries require fast, reliable, and accurate solutions for order fulfillment, packaging, sorting, and inventory management. Robotic arms provide an ideal solution for automating these tasks, particularly in high-volume environments where speed and precision are paramount.

As e-commerce continues to grow globally, the need for efficient logistics solutions will increase, further driving the adoption of robotic arms in the sector. Robotic arms' ability to handle various materials and perform repetitive tasks quickly will help companies in e-commerce streamline their operations and improve customer satisfaction.

6. Rising Labor Shortages and Workforce Challenges

Labor shortages, particularly in regions with aging populations and declining workforces, are fueling the adoption of robotic arms. As businesses struggle to fill skilled labor positions, robotic arms offer an effective solution by performing tasks traditionally handled by human workers. In addition to addressing labor shortages, robotic arms also help companies cope with rising labor costs and improve workplace safety by reducing the risk of workplace injuries.

In industries such as manufacturing, construction, and agriculture, where labor shortages are particularly acute, robotic arms are playing an increasingly important role in maintaining productivity levels and ensuring business continuity.

7. Sustainability and Environmental Concerns

The growing emphasis on sustainability and environmental conservation has also influenced the rise of robotic arms. Robotic arms can help reduce waste by performing tasks with greater precision and minimizing errors. In sectors like agriculture, robotic arms are being used to optimize resource usage, such as water and fertilizer, while also increasing crop yield.

Furthermore, the ability of robotic arms to operate in hazardous environments, such as hazardous waste disposal or pollution control, allows for more sustainable practices in industries that impact the environment.

Conclusion

The robotic arms market is experiencing rapid expansion, driven by a combination of technological advancements, cost reductions, and increasing demand for automation across industries. As AI and machine learning continue to evolve, robotic arms are becoming more intelligent and versatile, opening up new opportunities for businesses to enhance efficiency and productivity. With the growing need for automation, robotics, and workforce solutions, the future of the robotic arms market looks promising, with significant potential for innovation and growth.

0 notes