#SCADA Development

Explore tagged Tumblr posts

Text

Low-Code Revolution: Building Rapid Industrial Applications with Ignition Perspective

Coding Fatigue Is Real — and It’s Slowing Down Innovation

Think about your last software project on the plant floor. Did it stall due to scarce dev resources? Did it take months to go from concept to screen?

You're not alone.

Many manufacturing teams feel stuck between complex custom code and one-size-fits-all SCADA systems. But there’s a better way now — one that brings speed, flexibility, and control back to your team:

Welcome to the low-code industrial automation movement.

What Is Low-Code—and Why Does It Matter for SCADA?

Low-code platforms let your team design and deploy industrial apps with minimal hand-coded logic. Instead of building everything from scratch, you use intuitive drag-and-drop tools and reusable components to get from prototype to production — fast.

In a world where operational agility is gold, this means:

· Less reliance on rare developer skills

· Shorter turnaround for new interfaces

· More ownership at the plant level

When paired with a powerful SCADA app builder like Ignition Perspective, low-code goes from a buzzword to a breakthrough.

Why Industrial Teams Are Embracing Low-Code SCADA Platforms

1. Speed Without Sacrifice Build mobile-responsive HMIs, dashboards, and control views in hours — not weeks. With Perspective’s web-based design, updates roll out in real time across devices.

2. Flexibility to Fit Your Flow Need a maintenance dashboard that works on a tablet? Or a KPI tracker that updates in real time from your MES? You can build exactly what you need — and tweak it as you go.

3. Collaboration Without Silos Your engineering, IT, and operations teams can work together in one visual environment. No more passing code between departments or waiting for dev bandwidth.

4. Rapid SCADA Deployment Across Plants Low-code tools make it easier to scale — and standardize — apps across multiple facilities, reducing complexity and improving visibility from top floor to shop floor.

Real-World Wins: When Custom Meets Quick

One operations head at a packaging manufacturer recently shared their experience:

“We rolled out a downtime tracker built in Perspective — no external developers, no long wait. Just a clean interface our team actually uses, deployed across three sites in two weeks.”

That's the promise of industrial application development powered by low-code: solutions that feel tailored, yet deploy like off-the-shelf tools.

Technology Is Just the Start — People Make It Work

Behind every dashboard and alert is a team trying to solve real challenges. That's why great low-code tools don’t just empower faster builds — they empower your people to lead digital transformation on the ground.

Whether you’re an engineer tired of waiting on IT or a plant manager with a dozen apps on your wishlist, the right low-code SCADA platform helps you move from idea to impact faster.

Your Plant, Your Pace, Your Platform

This isn’t about replacing your existing systems overnight. It’s about augmenting them with agile tools that make everyday work easier — from operator screens to executive insights.

Low-code in industrial automation isn’t a trend. It’s a response to a clear need: speed, flexibility, and control — without sacrificing stability.

Ready to Explore What You Could Build in a Week?

Let’s talk about your SCADA goals and explore how Ignition software SCADA combined with low-code development can help you bring them to life faster and smarter.

0 notes

Text

SCADA | SCADA Integrator | SCADA Programmer | SCADA Development

Introduction:

In the realm of industrial automation, Supervisory Control and Data Acquisition (SCADA) systems play a pivotal role in orchestrating complex processes and providing real-time insights. Syscom Automation, a distinguished provider of automation solutions, stands at the forefront in delivering transformative SCADA solutions. This overview explores the significance of Syscom Automation's expertise in SCADA, emphasizing their commitment to revolutionizing industrial control and monitoring.

1. SCADA Mastery:

Syscom Automation exhibits mastery in the design, implementation, and optimization of SCADA systems. Their expertise in SCADA technology positions them as leaders in delivering comprehensive solutions that empower industries with efficient control and centralized data visualization.

2. Comprehensive SCADA Offerings:

Syscom Automation offers a comprehensive suite of SCADA solutions, tailored to meet the diverse needs of industries in the United Arab Emirates (UAE). From real-time process monitoring to data analysis and control system visualization, their SCADA offerings cover the entire spectrum of industrial requirements.

3. Advanced SCADA Technologies:

Syscom Automation stays at the forefront of technological advancements, incorporating advanced SCADA technologies into their solutions. This includes the integration of smart functionalities, data analytics, and connectivity features, providing clients with state-of-the-art SCADA systems that align with modern industrial demands.

4. Customization for Industry-Specific Applications:

Recognizing the uniqueness of each industry, Syscom Automation customizes SCADA solutions to address specific challenges and requirements. Whether it's manufacturing, utilities, energy, or infrastructure, their SCADA systems are engineered to provide tailored solutions that enhance operational efficiency.

5. Real-time Monitoring and Control:

Syscom Automation's SCADA solutions enable real-time monitoring and control of industrial processes. The systems offer a centralized platform where operators can visualize, analyze, and control various elements of the industrial environment, fostering informed decision-making and responsive actions.

6. Integration with PLC and DCS Systems:

Syscom Automation ensures seamless integration of SCADA systems with other automation components such as Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS). This integration creates a cohesive control environment, streamlining operations and enhancing the overall efficiency of industrial processes.

7. Scalability and Future-Readiness:

Syscom Automation designs SCADA solutions with scalability in mind, ensuring that the systems can grow alongside the evolving needs of clients. Their forward-looking approach makes certain that SCADA implementations are future-ready, ready to adapt to emerging technologies and industry trends.

8. Expert Training and Ongoing Support:

Syscom Automation goes beyond system deployment by offering expert training and ongoing support. This ensures that clients and their teams are proficient in utilizing and maintaining the SCADA systems, fostering self-sufficiency and ensuring long-term success.

Conclusion:

Syscom Automation's expertise in SCADA solutions epitomizes a commitment to innovation and efficiency in industrial control. As the UAE continues its industrial evolution, Syscom Automation remains a reliable partner, providing transformative SCADA solutions that empower industries to achieve new heights of control, visibility, and operational excellence.

0 notes

Text

SCADA Development Software: The Backbone of Industrial Automation

If you’re in the industrial automation space, you already know how crucial SCADA (Supervisory Control and Data Acquisition) systems are. They’re the unsung heroes behind manufacturing plants, power grids, water treatment facilities—you name it. But here’s the thing: a SCADA system is only as good as the software powering it. That’s why choosing the right SCADA development software provider is a game-changer.

Why SCADA Development Software Matters

Think of SCADA software as the brain of an industrial operation. It collects real-time data, monitors equipment, and even triggers alerts when something goes wrong. Whether it’s tracking temperature levels in a food processing plant or managing an entire oil refinery, SCADA software gives operators the power to make informed decisions quickly.

But not all SCADA solutions are created equal. A clunky, outdated system can slow down operations and cause unnecessary headaches. That’s why modern SCADA development software focuses on intuitive interfaces, cloud integration, and advanced analytics.

What to Look for in a SCADA Development Software Provider

So, how do you find the right provider? Here are a few things to consider:

Customization – No two industries have the same needs. A good provider will offer flexibility to tailor solutions to your specific requirements.

Scalability – Your business will grow (hopefully!), and your SCADA system should be able to grow with it.

Security – Cybersecurity threats are real. A strong SCADA provider prioritizes data protection.

At the end of the day, investing in a high-quality SCADA development software provider means smoother operations, better efficiency, and fewer surprises. And in the industrial world, that’s worth its weight in gold.

0 notes

Text

Industrial Alarm Management Application

#industrial reporting solution#industrial reporting software#industrial reports development company#reporting tool for industrial automation#reporting software for industrial automation#Scada reporting software#report generation in Scada#best reporting software#Scada report generation#best reporting tools#industrial automation reporting tool#reporting tool for Scada#web based reporting tools#web based reporting software#automated reporting and data analysis software#Batch Reporting Application#Data Log Reporting Application#MKT Analysis#MKT Analysis reports development#Market Analysis application#Alarm Reporting Application

0 notes

Text

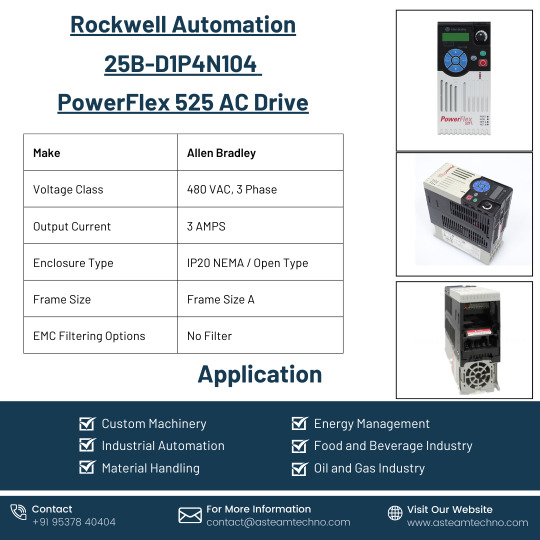

Rockwell Automation 25B-D1P4N104

The Rockwell Automation 25B-D1P4N104 is a part number for a specific variable frequency drive (VFD) within the Allen-Bradley PowerFlex 525 series. The PowerFlex 525 is a compact, versatile, and cost-effective drive designed to control motors in a wide range of industrial applications.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#powerflex525#application#technical#development#engineering#programs

1 note

·

View note

Text

Investment Secured for Electricity Distribution System Improvement

Announcement of concessional loans and grant amounts by the Asian Development Bank, the European Union, and the Norwegian government, with a total of NPR 72.93 billion secured. Kathmandu — An investment of NPR 72.93 billion (USD 537 million) has been secured to expand, improve, and modernize the transmission and distribution system to make electricity supply within the country reliable and…

#(SASEC)#Arnaud Cauchois#Asian Development Bank#cross-border electricity trade capacity#distribution system#electricity transmission#Kulman Ghising#national transmission#Norwegian government#SCADA

0 notes

Text

Top 5 Factors to Consider When Choosing Switchgear in Qatar

The energy infrastructure in Qatar is evolving rapidly, driven by ambitious development plans, a booming construction sector, and growing demand for reliable and efficient power distribution systems. As such, selecting the right switchgear — an essential component in electrical distribution networks — is more important than ever. Whether for industrial, commercial, or residential projects, choosing the appropriate switchgear can significantly impact safety, operational reliability, and long-term costs.

In this article, we explore the top five factors to consider when choosing switchgear in Qatar, keeping in mind the country’s unique climatic, industrial, and regulatory environment.

1. Environmental and Climatic Conditions

Why It Matters:

Qatar’s climate is characterized by extreme heat, high humidity, and frequent dust storms, which can adversely affect the performance and longevity of electrical equipment.

What to Consider:

· Ingress Protection (IP) Ratings: Choose switchgear with high IP ratings (e.g., IP65 or above) to ensure resistance to dust and moisture.

· Temperature Tolerance: Equipment should be capable of operating in ambient temperatures above 45°C without derating.

· Corrosion Resistance: Opt for enclosures made from stainless steel or coated with anti-corrosive materials to withstand coastal and desert environments.

Tip:

Ask for switchgear that has been tested and certified for desert and tropical climates to ensure long-term reliability.

2. Compliance with Local Regulations and Standards

Why It Matters:

Qatar’s construction and energy sectors are tightly regulated. Non-compliance with local codes can lead to project delays, penalties, or unsafe installations.

What to Consider:

· Kahramaa Regulations: Ensure the switchgear complies with Qatar General Electricity & Water Corporation (Kahramaa) specifications.

· International Standards: Equipment should meet IEC (International Electrotechnical Commission) or ANSI standards for design and performance.

· Vendor Certifications: Choose manufacturers and suppliers who are approved by local authorities and have a track record of regulatory compliance.

Tip:

Request documentation and third-party certification to verify compliance before purchase.

3. System Voltage and Current Ratings

Why It Matters:

Mismatched ratings can lead to equipment failure, increased downtime, or even safety hazards.

What to Consider:

· Voltage Level: Identify whether your application requires low-voltage (LV), medium-voltage (MV), or high-voltage (HV) switchgear.

· Short-Circuit Withstand Capacity: The switchgear must handle the maximum fault current expected in the system.

· Load Type and Growth: Consider both current and future load expansions when sizing the switchgear.

Tip:

Conduct a detailed load analysis with a qualified electrical engineer to ensure proper equipment sizing.

4. Reliability and Safety Features

Why It Matters:

Switchgear is central to ensuring electrical safety and minimizing power outages, especially in critical infrastructure.

What to Consider:

· Arc Flash Protection: Look for internal arc classification (IAC) and arc-resistant features.

· Automation and Remote Monitoring: Smart switchgear with SCADA integration can improve uptime and facilitate preventive maintenance.

· Redundancy and Segmentation: Ensure the switchgear design allows for maintenance without shutting down the entire system.

Tip:

Consider intelligent switchgear with diagnostic features to enable predictive maintenance and minimize human error.

5. Availability of Local Support and Spare Parts

Why It Matters:

Even the best switchgear can require maintenance or part replacement. Having quick access to support minimizes downtime and operational losses.

What to Consider:

· Local Service Network: Choose brands with authorized service centers or partners in Qatar.

· Spare Parts Availability: Ensure that spare parts can be sourced locally with minimal lead time.

· Training and Technical Support: Ask about operator training, maintenance contracts, and emergency response services.

Tip:

Opt for suppliers with a strong presence in the GCC region and a proven track record in Qatar’s market.

Conclusion

Choosing the right switchgear in Qatar requires a thoughtful evaluation of environmental, regulatory, technical, and logistical factors. With the right equipment, businesses and developers can ensure electrical safety, regulatory compliance, and long-term operational efficiency in one of the world’s most challenging climates.

When evaluating options, always consider:

· Local conditions and regulatory landscape

· Equipment ratings and design

· Vendor support and technical reliability

By focusing on these core considerations, stakeholders can make informed, cost-effective, and future-ready decisions for their electrical infrastructure projects in Qatar.

#electrical equipment#qatar#switchgear#electrical#911 abc#arcane#artists on tumblr#batman#cats of tumblr#cookie run kingdom

2 notes

·

View notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

3 notes

·

View notes

Text

purOS Satınalma Yönetimi

tediye nedir

muhtasar nedir

smma nedir

mutabakat nedir

crm nedir

erp açılımı

iskonto nasıl hesaplanır

kurumsal fatura nedir

irsaliye nedir

iskonto nedir

kreatif ne demek

yapay zeka seslendirme

Kiosk Nedir?

Özel yazılım

yazılım hizmetleri

yazılım geliştirme

mrp yazılımı

mrp modülü

mrp sistemi

mrp programı

mrp nedir

mrp açılımı

malzeme ihtiyaç planlama

satın alma yazılımı

satın alma programı

teklif yönetimi yazılımı

tedarikçi sipariş yönetimi

satın alma programları

satın alma yönetim programı

satın alma sistemi

satın alma sistemi programı

siparişli satın alma sistemi

satın alma modülü

merkezi satın alma sistemi

tedarik yönetim sistemi

satın alma ve talep yönetimi

satın alma ve tedarikçi yazılımı

tedarik zinciri yönetim programı

kurumsal satın alma sistemi

kurumsal satın alma programı

satın alma bilgi sistemi

satın alma yönetim programı

muhasebe yazılımları

müşteri ilişkileri yönetimi

enflasyon muhasebesi nedir

kdv hesaplama

adsense nedir

tevkifat nedir

p2p nedir

satın alma süreci

yazılım programları

scada nedir

scada yazılımı nedir

github nedir

işletmelerde verimlilik nedir

ik portalı nedir

erp nedir

erp sistemi nedir

erp programı nedir

satınalma yazılımı

purOS blog

purOS hizmetleri

malzeme yönetimi

teslimat yönetimi

sipariş yönetimi

teklif yönetimi

talep yönetimi

satınalma sistemi faydaları

purOS ne fayda saglar

purOS sektörler

neden purOS

satın alırken kazanın

yazılımı keşfedin

satınalma yönetimi

purOS hakkında

purOS

yazılım

instagram mavi tık nasıl alınır

yüzde hesaplama

developer nedir

google translate kullanımı

kümülatif vergi matrahı google trends nedir

5 notes

·

View notes

Text

Rattan Industrial – Premier Distillery Plant Manufacturer Delivering Turnkey Alcohol Production Solutions in India

The demand for high-efficiency, sustainable, and fully automated alcohol production facilities is growing rapidly in India and globally. At the center of this transformation is Rattan Industrial India Pvt. Ltd., a leading distillery plant manufacturer known for its engineering excellence, innovative designs, and turnkey project delivery.

With decades of industry experience and a deep understanding of the distillation process, Rattan Industrial has become a trusted partner for clients looking to set up or modernize ethanol and liquor production plants.

Complete Turnkey Distillery Solutions

As a full-service distillery plant manufacturer, Rattan Industrial offers end-to-end solutions that cover every stage of plant development—from concept to commissioning. Their distillery systems are engineered to optimize yield, ensure product consistency, and meet stringent environmental and safety standards.

Rattan’s core offerings include:

Molasses-based and grain-based distillery plants

Fermentation systems with high conversion efficiency

Distillation columns (multi-pressure, vacuum, and azeotropic)

Evaporation and dehydration units

Effluent treatment systems (ETP/ZLD) for environmental compliance

Steam and boiler systems, utility pipelines, and automation

Each plant is designed for scalability, allowing businesses to expand capacity without interrupting operations.

Expertise Across Multiple Applications

Rattan Industrial’s distillery plants cater to a wide range of alcohol production needs, including:

Ethanol production for fuel blending (biofuel segment)

Extra Neutral Alcohol (ENA) for beverages and pharmaceuticals

Rectified Spirit (RS) for industrial and medicinal use

Country liquor and branded IMFL (Indian Made Foreign Liquor) production

Whether you're setting up a small-scale plant or a large integrated unit, Rattan provides tailored engineering backed by process know-how.

Why Choose Rattan Industrial?

Custom-Engineered Plants: Every project is designed to meet your raw material availability, production goals, and regulatory needs

Advanced Automation: PLC/SCADA systems for real-time control and monitoring

Eco-Friendly Design: Focus on zero liquid discharge (ZLD), energy efficiency, and waste minimization

On-Time Execution: Turnkey project management with dedicated teams for civil, mechanical, and commissioning work

Strong Service Network: Pan-India support with remote diagnostics and preventive maintenance options

Setting Industry Benchmarks

Rattan Industrial isn’t just building plants—they are building the future of alcohol manufacturing in India. By combining world-class engineering with deep process knowledge, they ensure every plant delivers:

Higher alcohol recovery

Reduced steam and energy consumption

Longer equipment life with minimal downtime

Easy integration with bottling and storage infrastructure

Partner with the Best

If you're looking for a reliable, experienced, and future-ready distillery plant manufacturer in India, Rattan Industrial is the partner you can trust. With successful installations across India and a growing global footprint, Rattan is helping entrepreneurs, corporations, and government projects set new benchmarks in distillery performance.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

SCADA development | SCADA development in Dubai, UAE

Introduction

Supervisory Control and Data Acquisition (SCADA) systems are at the heart of industrial automation, enabling efficient monitoring and control of industrial processes. we will explore the process of SCADA development and the key steps involved in building robust and reliable automation systems.

Understanding SCADA Development

SCADA development involves the design, implementation, and integration of software and hardware components to create a fully functional SCADA system. The goal is to develop a system that can collect, process, and display real-time data from industrial processes, allowing operators to monitor and control them effectively.

Key Steps in SCADA Development

Requirements Gathering: The first step in SCADA development is understanding the specific requirements of the client or organization. This involves identifying the processes to be monitored and controlled, the desired functionality of the system, and any regulatory or compliance requirements.

System Design: Based on the requirements, the next step is to design the architecture of the SCADA system. This includes determining the hardware components, such as sensors and actuators, and the software applications, such as HMI (Human-Machine Interface) and database systems, that will be used.

Database Design: SCADA systems generate a large amount of data, so designing an efficient and scalable database structure is crucial. The database should be able to handle real-time data acquisition and provide quick access to historical data for analysis.

Software Development: SCADA software development involves creating the necessary applications for data acquisition, real-time monitoring, alarming, and control. This can include developing communication protocols, graphical user interfaces, and integrating with hardware devices.

Integration with Hardware: SCADA systems interface with various hardware devices, such as PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units), to collect data and control industrial processes. The development team ensures seamless integration between the software and hardware components.

Testing and Validation: Rigorous testing is essential to ensure the system functions as intended. This includes verifying data accuracy, testing alarms and alerts, and validating control functions. The system is tested under different scenarios and conditions to ensure reliability and responsiveness.

Installation and Commissioning: After successful testing, the SCADA system is installed and commissioned in the operational environment. This involves setting up the hardware, configuring the software, and establishing network connections.

Training and Support: End-user training is an important aspect of SCADA development. Operators need to be familiar with the system, understand how to access and analyze data, and effectively utilize the control functions. Ongoing technical support is also provided to address any issues or concerns that may arise.

Benefits of SCADA Development

Improved Efficiency: SCADA systems automate manual tasks, reducing human errors and increasing operational efficiency.

Real-time Monitoring: SCADA provides real-time data visualization, empowering operators to make informed decisions quickly.

Increased Productivity: With SCADA systems, processes can be optimized for maximum productivity, reducing downtime and boosting output.

Enhanced Safety: SCADA systems monitor and alert operators to potential hazards or abnormal conditions, improving overall safety in industrial environments.

Data Analysis for Optimization: SCADA systems store historical data, which can be analyzed for process optimization, predictive maintenance, and troubleshooting.

Conclusion

SCADA development is a complex and iterative process that requires a deep understanding of industrial processes, software development, and hardware integration. With careful planning, design, and implementation, a robust and reliable SCADA system can be built. The benefits of SCADA development include increased efficiency, improved productivity, enhanced safety, and the ability to harness valuable data for optimization.

If you are considering SCADA development for your organization, we have a team of experts ready to assist you. Contact us today to explore how SCADA can transform your industrial automation processes.

0 notes

Text

Why Siemens HMI is a Game-Changer in Automation

In the present days of industrial developments, there has been an unusual demand for intelligent, reactive, and reliable interfaces. At the core of this innovation lies the Siemens HMI solution, an interface bridging the gap between human operators and complex machines. From managing a small production setup to a fully automated facility, Siemens offers HMI panels for differing operational requirements.

A real-world example of Siemens HMI in action can be seen in aviation - learn how Siemens HMI is streamlining airport baggage handling systems with precision and automation.

Why Choose Siemens HMI?

The Siemens HMI technology ensures that your machines are not simply connected, but intelligent, intuitive, and easy to control. Under the SIMATIC series, Siemens offers a range of HMI systems allowing operators to easily monitor, control, and adjust a machine's processes. Whether it's changing the temperature in a food processing unit or setting the speed of motors in a manufacturing plant — Siemens HMI gives you utmost control and real-time data access.

These HMI solutions are flexible and scalable. As your needs for production grow, your Siemens SIMATIC HMI system will be able to grow with you to support new functions, new users, and new machines.

Explore the Power of Siemens SIMATIC HMI

The Siemens SIMATIC HMI portfolio ranges from simple key panels to high-performance interface panels with multi-touch capabilities. With a fast processor, high-resolution display, and intuitive navigation controls, these panels ensure quick operation for the most demanding applications.

Besides the fast speed, Siemens HMI panels also promise a long life supported by frequent firmware updates and enhanced security features, making sure that your investment stays secure and ready for the future.

Touchscreens That Are Really Easy to Use with Siemens SIMATIC Panel Touch

The days of clunky buttons with limited interaction are over. The Siemens SIMATIC panel touch range brings the highest level of touch capability with easy navigation, gesture support, and brilliant displays. These panels are ideal for control systems that demand both time sensitivity and ease of access.

Touch panels make for great user experience, letting you make fast adjustments to the workings of machines yourself, view detailed information, and recognize faults, all at a glance. And built rugged, they work their way almost everywhere into the industries of oil & gas, pharmaceuticals, food & beverage, and logistics, to name a few.

Learn more in Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Integration Made Easy

Seamless integration with other Siemens automation products such as PLCs and SCADA systems is one of the principal advantages of using Siemens SIMATIC HMI systems. Incidentally, this causes efficient consolidations in industrial control systems-and alongside that, lesser maintenance-related stresses and minimized error rates.

Apart from the support for communication protocol offered by Siemens HMI panels making it rather easy to interface with third-party systems should there be a need for such interaction, it is this flexibility that makes Siemens a very popular choice among system integrators and plant managers all over the world.

For deeper insights, check out Human Machine Interface Siemens: Improving Operational Productivity.

Real Results from Every Industry

The Siemens HMI systems have proved their efficacy in real-time situations ranging from factory automation and process control to building management and energy monitoring. With fast boot-up times, customizable user interfaces, and sophisticated data visualization, these panels greatly enhance operational productivity and machine availability.

Conclusion

If your plan is to improve control in industrial automation with Naksh Technology Solutions LLP or to update a rather dated set of operator interfaces, then consider picking Siemens HMI systems. The company provides a whole range of solutions, which include Siemens SIMATIC HMI and Siemens SIMATIC panel touch, so you can count on market-leading innovativeness, reliability, and performance.

Smart HMI is a big difference; Siemens means technology plus efficiency.

0 notes

Text

Advantages and Disadvantages of Pressure Switch Compared to Traditional Mechanical Models

Technological Advancements in Pressure Switch Manufacturing

Pressure Switch Factory products often incorporate technologies in pressure sensing, allowing for enhanced functionality and integration with modern systems. Unlike traditional mechanical pressure switches that rely on physical deformation of diaphragms or bellows to trigger electrical contacts, modern factory-produced versions may use electronic sensors and microcontrollers. This results in greater accuracy, faster response times, and a wider range of customization.

Improved Precision and Control

One of the primary advantages of pressure switches from a specialized Pressure Switch Factory is their ability to offer high precision in pressure detection. Digital or electronic models can detect subtle pressure variations and offer tight switching differentials. Mechanical models, though reliable in many industrial applications, typically have broader switching bands and lower sensitivity, which can limit their usefulness in high-precision or automated environments.

Enhanced Integration with Smart Systems

Pressure switches developed by a modern Pressure Switch Factory are often designed to be compatible with PLCs, SCADA systems, and IoT platforms. This level of integration allows real-time monitoring, remote control, and data logging—features not typically available in older mechanical designs. As a result, smart pressure switches are better suited for predictive maintenance and system optimization.

Durability and Environmental Resistance

Many factory-engineered pressure switches are designed for demanding environments, offering high protection ratings such as IP67 or IP68. They often come with enhanced resistance to vibration, corrosion, and extreme temperatures. While traditional mechanical switches may still perform well in harsh conditions, they often require more frequent calibration and are susceptible to mechanical wear over time.

User-Friendly Features and Adjustability

Modern pressure switches from reputable factories usually feature user-friendly interfaces such as digital displays, LED indicators, or keypad settings for quick adjustments. These features make setup and troubleshooting much easier than with mechanical models, which often require manual tools and disassembly for any change in pressure settings.

Higher Initial Cost and Complexity

Despite the benefits, pressure switches from advanced factories generally come at a higher initial cost. Their electronic components, smart features, and digital interfaces contribute to increased pricing. Additionally, installation and setup may require technical expertise, which can be a barrier for small operations or users accustomed to the simplicity of mechanical models.

Power Dependency and Potential for Electronic Failure

Electronic pressure switches from a Pressure Switch Factory typically rely on a constant power source. This makes them unsuitable for applications where power reliability is a concern. In contrast, mechanical pressure switches are self-powered and continue functioning without external energy, which can be a critical advantage in certain safety systems or remote locations.

Maintenance and Service Considerations

Factory-produced smart pressure switches usually require less frequent maintenance due to fewer moving parts, but if they do fail, repairs may be more complex and expensive. Mechanical switches, on the other hand, are easier to service in-house and have a longer history of field-proven reliability. This simplicity can be particularly valuable in low-tech environments or for backup systems.

Conclusion

Pressure switches manufactured by a modern Pressure Switch Factory offer a wide array of benefits, including precision, smart system compatibility, and environmental durability. However, these advantages must be balanced against potential drawbacks such as higher costs, dependency on power, and increased complexity. When choosing between electronic and traditional mechanical pressure switches, the decision should be based on the specific needs of the application, the available infrastructure, and the level of automation desired.

Two modes can be switched. “Manual Mode” automatically starts and stops the electric water pump according to the set pressures, and also displays real-time pressure. Time mode used for filling up the water tower, the time setting will be changed as 0.1H,0.2H …0.9H, 1H, 2H …24H. Water shortage alarm.

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Innovation in Flow Control: Insights from a Premier Butterfly Valve Manufacturer

In the complex world of material handling solutions, precise and reliable flow control is paramount to operational efficiency and safety. Butterfly valves, with their versatile design and robust performance, play a critical role across numerous industries. Understanding the nuances of their design, application, and the continuous advancements made by leading producers is essential for businesses seeking optimal performance. This deep dive into the world of industrial valves offers insights from Meto Systems, a premier butterfly valve manufacturer dedicated to pushing the boundaries of technology in flow control. We explore how continuous innovation by a top-tier butterfly valve manufacturer directly translates into enhanced system reliability and optimized material handling processes for our clients.

Advanced Materials Drive Butterfly Valve Manufacturer Excellence

The foundation of superior flow control begins with the materials used, and a top-tier butterfly valve manufacturer like Meto Systems consistently pioneers in this area. Innovations in alloy compositions, specialized coatings, and resilient elastomers significantly enhance valve durability, corrosion resistance, and operational lifespan. These advancements are crucial for applications involving abrasive slurries, high temperatures, or corrosive chemicals common in material handling. By meticulously researching and integrating cutting-edge materials, every butterfly valve manufacturer aims to deliver products that withstand the harshest environments, ensuring sustained performance and reducing the need for frequent maintenance. This commitment to material science is a hallmark of a premier butterfly valve manufacturer.

Precision Engineering from a Leading Butterfly Valve Manufacturer

Precision engineering is at the heart of every high-performing butterfly valve, a core competency for any reputable butterfly valve manufacturer. From the intricate machining of valve bodies and discs to the meticulous assembly of sealing components, accuracy directly impacts a valve's ability to provide leak-tight shut-off and precise flow regulation. Meto Systems employs advanced manufacturing techniques, including CNC machining and robotic assembly, to achieve unparalleled consistency and quality in every unit. This dedication to exact specifications ensures optimal performance across diverse industrial applications, making our reputation as a leading butterfly valve manufacturer well-deserved.

Smart Actuation by an Innovative Butterfly Valve Manufacturer

The efficiency and control of butterfly valves are significantly amplified by intelligent actuation systems, an area where an innovative butterfly valve manufacturer truly excels. Modern actuators offer not just on/off functionality but also proportional control, allowing for precise regulation of flow rates based on process demands. Integration with PLC and SCADA systems enables remote operation, diagnostic monitoring, and predictive maintenance capabilities. Meto Systems, as a forward-thinking butterfly valve manufacturer, develops and integrates sophisticated actuation solutions that enhance automation, reduce human intervention, and improve overall operational safety in material handling systems.

Custom Solutions from a Versatile Butterfly Valve Manufacturer

Many industrial applications demand more than off-the-shelf solutions, requiring a versatile butterfly valve manufacturer capable of delivering customized designs. From unique flange configurations and specialized seat materials to valves designed for extreme pressures or temperatures, the ability to tailor products to specific client needs is invaluable. Meto Systems prides itself on its engineering flexibility, collaborating closely with clients to understand their precise requirements and develop bespoke butterfly valve solutions. This dedication to customization solidifies our position as a responsive and adaptable butterfly valve manufacturer, ensuring that every valve precisely fits its intended application.

Quality Control: A Pillar for Every Butterfly Valve Manufacturer

Rigorous quality control processes are non-negotiable for any reputable butterfly valve manufacturer. From the initial inspection of raw materials to hydrostatic testing of finished products, every stage of manufacturing must adhere to stringent quality standards. Certifications such as ISO 9001 demonstrate a commitment to consistent quality management systems. Meto Systems implements a multi-stage inspection protocol, ensuring that every butterfly valve leaving our facility meets the highest performance and reliability benchmarks. This unwavering commitment to quality ensures that as a butterfly valve manufacturer, we deliver dependable components for critical material handling applications.

Global Reach and Support from a Premier Butterfly Valve Manufacturer

For industries operating on a global scale, partnering with a butterfly valve manufacturer that offers extensive reach and comprehensive support is crucial. This includes efficient logistics, readily available spare parts, and responsive technical assistance regardless of geographical location. Meto Systems has established a robust global network to ensure that our clients receive timely support and access to our full range of products and services wherever they are. Our commitment as a butterfly valve manufacturer extends beyond product delivery, encompassing a dedication to long-term client success and operational continuity.

Future Trends Shaped by a Visionary Butterfly Valve Manufacturer

The landscape of flow control is constantly evolving, driven by advancements in automation, data analytics, and sustainability. A visionary butterfly valve manufacturer continuously invests in research and development to anticipate future industry needs and integrate emerging technologies. This includes exploring smart sensors for real-time monitoring, materials for enhanced durability in harsh environments, and designs that minimize energy consumption. Meto Systems remains at the forefront of these innovations, ensuring that our products continue to set benchmarks for efficiency and reliability in material handling solutions. We are a butterfly valve manufacturer shaping the future of industrial flow control.

Conclusion

The relentless pursuit of innovation is what sets a premier butterfly valve manufacturer apart in the competitive landscape of material handling solutions. Meto Systems is dedicated to engineering excellence, utilizing advanced materials, embracing smart actuation, and offering customized solutions, all underpinned by unwavering quality control. Our global reach and commitment to supporting future trends ensure that our clients benefit from the most reliable and efficient flow control components available. Partnering with an industry leader like Meto Systems means investing in the long-term performance and sustainability of your operations. Our mission as a leading butterfly valve manufacturer is to provide not just products, but solutions that empower your business to achieve unprecedented levels of productivity and safety.

0 notes

Text

What You Can Specialize in and Pursue After B.Tech in Electrical and Electronics Engineering

Pursuing a B.Tech in Electrical and Electronics Engineering (EEE) opens up a world of opportunities in one of the most versatile and evergreen branches of engineering. From core electrical roles to cutting-edge electronics, automation, and IT sectors, the scope for growth and specialization is vast. If you're looking for a b tech electrical and electronics engineering college in UP, it’s important to understand not just the curriculum but also the career avenues and industry demands linked to your degree.

Why Choose Electrical and Electronics Engineering?

EEE is a discipline that merges two major areas of engineering—Electrical Engineering, which deals with the study and application of electricity and electromagnetism, and Electronics Engineering, which focuses on circuits, devices, and integrated systems. This powerful combination equips students with a diverse skill set applicable in numerous industries.

When you choose a reputed btech college in UP that offers specialization in EEE, you benefit from practical exposure, strong technical foundations, and placement support that align with your career goals.

Popular Specializations After B.Tech in EEE

After graduating from a b tech electrical and electronics engineering college in UP, students can either pursue higher education or dive straight into industry roles. Some choose to specialize further by opting for M.Tech, MS, or professional certifications. Here are some of the popular specializations:

1. Power Systems Engineering

This specialization focuses on generation, transmission, and distribution of electric power. Students can work with power generation companies, government utilities, or in energy infrastructure projects.

2. Control and Automation

With the rise of smart factories and Industry 4.0, automation is booming. This field deals with control systems, robotics, PLCs, and SCADA systems, offering roles in manufacturing and tech-driven industries.

3. Embedded Systems and VLSI Design

Ideal for students interested in microelectronics, embedded system design, and chip manufacturing. This is a great path if you're inclined toward product design and development.

4. Renewable Energy

As the world shifts toward clean energy, specialists in solar, wind, and hybrid systems are in demand. A focus on renewable energy systems prepares you for a sustainable engineering future.

5. Telecommunication Systems

This specialization covers wireless communication, optical fiber technologies, and network systems—ideal for roles in telecom giants and network companies.

Career Opportunities After B.Tech in EEE

Graduating from a top btech college in UP with a degree in EEE means you’ll have access to roles across various sectors, including:

Electrical Engineer in power plants, utilities, and infrastructure projects

Electronics Engineer in semiconductor and electronics manufacturing

Automation Engineer in industries using robotics and automated systems

Embedded Systems Developer in hardware and IoT product companies

Telecom Engineer in network operations, 5G rollout, and telecom services

Design Engineer for electrical layouts, PCB design, and embedded systems

Government Jobs through GATE, UPSC, and public sector undertakings (PSUs)

You can also explore careers in research organizations, startups, and IT companies that require electronics and hardware expertise.

Choosing the Right College Matters

To unlock these opportunities, choosing the right college is crucial. A good b tech electrical and electronics engineering college in UP not only provides academic knowledge but also offers hands-on lab training, industry exposure, internships, and placement assistance.

When you study at one of the top btech colleges in UP, you benefit from a strong alumni network, active campus recruitments, skill development programs, and access to modern research facilities. These factors significantly boost your confidence and employability in competitive job markets.

Conclusion

B.Tech in Electrical and Electronics Engineering is more than just a degree—it's a gateway to diverse, dynamic, and future-focused careers. Whether you want to innovate in electronics, lead energy solutions, or automate the next industrial revolution, your journey begins with choosing the right btech college in UP that aligns with your goals. So take the first step today—explore the top btech colleges in UP and find the EEE program that powers your passion and profession.

0 notes