#SCADA Visualization

Explore tagged Tumblr posts

Text

Low-Code Revolution: Building Rapid Industrial Applications with Ignition Perspective

Coding Fatigue Is Real — and It’s Slowing Down Innovation

Think about your last software project on the plant floor. Did it stall due to scarce dev resources? Did it take months to go from concept to screen?

You're not alone.

Many manufacturing teams feel stuck between complex custom code and one-size-fits-all SCADA systems. But there’s a better way now — one that brings speed, flexibility, and control back to your team:

Welcome to the low-code industrial automation movement.

What Is Low-Code—and Why Does It Matter for SCADA?

Low-code platforms let your team design and deploy industrial apps with minimal hand-coded logic. Instead of building everything from scratch, you use intuitive drag-and-drop tools and reusable components to get from prototype to production — fast.

In a world where operational agility is gold, this means:

· Less reliance on rare developer skills

· Shorter turnaround for new interfaces

· More ownership at the plant level

When paired with a powerful SCADA app builder like Ignition Perspective, low-code goes from a buzzword to a breakthrough.

Why Industrial Teams Are Embracing Low-Code SCADA Platforms

1. Speed Without Sacrifice Build mobile-responsive HMIs, dashboards, and control views in hours — not weeks. With Perspective’s web-based design, updates roll out in real time across devices.

2. Flexibility to Fit Your Flow Need a maintenance dashboard that works on a tablet? Or a KPI tracker that updates in real time from your MES? You can build exactly what you need — and tweak it as you go.

3. Collaboration Without Silos Your engineering, IT, and operations teams can work together in one visual environment. No more passing code between departments or waiting for dev bandwidth.

4. Rapid SCADA Deployment Across Plants Low-code tools make it easier to scale — and standardize — apps across multiple facilities, reducing complexity and improving visibility from top floor to shop floor.

Real-World Wins: When Custom Meets Quick

One operations head at a packaging manufacturer recently shared their experience:

“We rolled out a downtime tracker built in Perspective — no external developers, no long wait. Just a clean interface our team actually uses, deployed across three sites in two weeks.”

That's the promise of industrial application development powered by low-code: solutions that feel tailored, yet deploy like off-the-shelf tools.

Technology Is Just the Start — People Make It Work

Behind every dashboard and alert is a team trying to solve real challenges. That's why great low-code tools don’t just empower faster builds — they empower your people to lead digital transformation on the ground.

Whether you’re an engineer tired of waiting on IT or a plant manager with a dozen apps on your wishlist, the right low-code SCADA platform helps you move from idea to impact faster.

Your Plant, Your Pace, Your Platform

This isn’t about replacing your existing systems overnight. It’s about augmenting them with agile tools that make everyday work easier — from operator screens to executive insights.

Low-code in industrial automation isn’t a trend. It’s a response to a clear need: speed, flexibility, and control — without sacrificing stability.

Ready to Explore What You Could Build in a Week?

Let’s talk about your SCADA goals and explore how Ignition software SCADA combined with low-code development can help you bring them to life faster and smarter.

0 notes

Text

Design and Implementation of Manufacturing Factory SCADA UI

Full video: 2D/2.5D Digital Twin Factory | SCADA | Factory Assembly Line | スマートファクトリー - YouTube

0 notes

Text

How to Solve Overheating Issues in Electrical Panels

Electrical panels are the nerve centers of industrial, commercial, and residential power systems. Their reliability is crucial, yet one of the most common and dangerous issues that can arise is overheating. Left unaddressed, overheating in electrical panels can lead to equipment failure, costly downtime, fires, or even fatal accidents. Understanding the root causes and adopting preventive as well as corrective measures is essential to ensure electrical safety and operational efficiency.

Causes of Overheating in Electrical Panels

To solve the problem of overheating, we must first identify its sources. Some of the most common causes include:

1. Loose or Corroded Connections

Electrical current encounters resistance at loose or oxidized joints. This resistance generates heat, especially under load, leading to localized hotspots which may not be visible until failure occurs.

2. Overloaded Circuits

Each circuit is rated for a specific current. Drawing more current than the rated capacity results in excess heat generation within breakers, busbars, and wires.

3. Inadequate Ventilation

Poor airflow in and around the panel restricts natural or forced heat dissipation. In high ambient temperature environments, this can quickly push the panel beyond safe thermal limits.

4. Improper Component Sizing

Undersized breakers, conductors, or transformers struggle to handle load currents, leading to thermal stress and degradation over time.

5. Dust and Contamination

Dust accumulation acts as an insulating layer, trapping heat inside components. Combined with humidity or oil vapors, this can further degrade insulation and create tracking paths.

How to Identify Overheating Problems

1. Thermal Imaging

Using infrared thermography is one of the most effective ways to detect hotspots. It provides a non-contact, real-time temperature map of the panel and highlights abnormally heated components.

2. Manual Temperature Monitoring

For panels without thermal sensors, regularly measuring surface temperatures using contact thermometers can provide early warnings of rising heat levels.

3. Visual Inspection

Signs like discoloration, melted insulation, or the smell of burning plastic indicate overheating. Ensure regular visual checks are part of your maintenance routine.

Solutions to Overheating in Electrical Panels

1. Tighten and Maintain Electrical Connections

Schedule regular maintenance to tighten terminals and busbar connections. Apply proper torque settings using calibrated tools to avoid over- or under-tightening.

2. Balance and Distribute Loads

Ensure that the load across phases is balanced. Uneven distribution causes one phase to overwork, which leads to overheating and inefficiency.

3. Upgrade Panel Capacity

If the electrical demand exceeds the panel’s rated capacity, consider upgrading to a higher-rated panel or adding sub-panels to spread the load.

4. Enhance Cooling and Ventilation

· Install forced ventilation systems like exhaust fans or panel coolers.

· Use heat exchangers or air conditioners in environments with high ambient temperatures.

· Ensure adequate spacing between panels and walls for natural convection.

5. Use Appropriately Rated Components

All breakers, fuses, contactors, and wiring must match the system’s voltage and current ratings. Derate components appropriately if operating in high-temperature environments.

6. Install Thermal Sensors or Smart Monitoring

Modern panels can be equipped with thermal sensors that provide real-time data to a building management system (BMS) or SCADA. This allows predictive maintenance before issues escalate.

Preventive Measures and Best Practices

· Design with Expansion in Mind: Avoid loading a panel to its full capacity. Always leave a 20–30% margin for future growth and safety.

· Implement a Routine Maintenance Schedule: Quarterly or bi-annual inspections reduce the risk of unexpected failures.

· Train Maintenance Personnel: Staff should be equipped to detect early signs of thermal distress and follow lockout/tagout (LOTO) procedures.

· Keep Panels Clean and Sealed: Use gasketed enclosures in dusty environments and clean panels regularly to prevent dust build-up.

Conclusion

Overheating in electrical panels is a preventable issue that, if neglected, can have severe consequences. By adopting systematic inspection routines, upgrading infrastructure as needed, and leveraging modern monitoring technologies, businesses and facility managers can safeguard both equipment and personnel. The key is proactive action: identify, analyze, correct, and prevent — the four pillars of managing thermal risk in electrical systems.

7 notes

·

View notes

Text

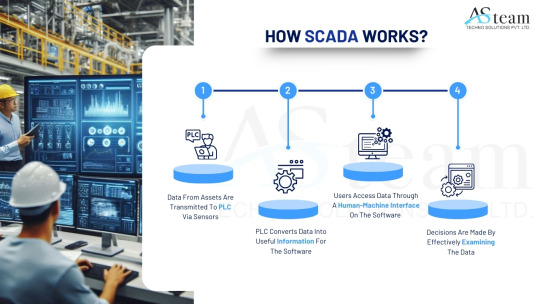

How SCADA Works?

Supervisory Control and Data Acquisition (SCADA) systems are critical in managing and monitoring industrial processes across various industries, including manufacturing, utilities, transportation, and energy.

Field Devices

At the process level, field devices like sensors, meters, and actuators are used to monitor variables like voltage, flow, temperature, and pressure. These gadgets collect information and carry out system-directed operations.

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs)

The SCADA software and the field devices are connected by RTUs and PLCs. After gathering information from the sensors, they transmit it to the control center. Additionally, the SCADA system may send them orders to modify settings or control actuators.

Communication Infrastructure

Strong communication networks are necessary for SCADA to transmit data between the control center and field equipment. This infrastructure can be wireless (such as satellite, radio, and cellular networks) or wired (such as Ethernet and fiber optics).

Centralized Control Station

SCADA software, which analyzes data, creates visualizations, and gives operators tools to monitor and manage operations, is housed in the control station.

Human-Machine Interface (HMI)

The SCADA system's user interface is called the HMI. Operators can engage with the system and make well-informed decisions because to its graphical depictions of processes, warnings, and trends.

#automation#SCADA#PLC#HMI#Automation#Technology#business and industry sectors#business#industrial automation#soft starter#software#software engineering

3 notes

·

View notes

Text

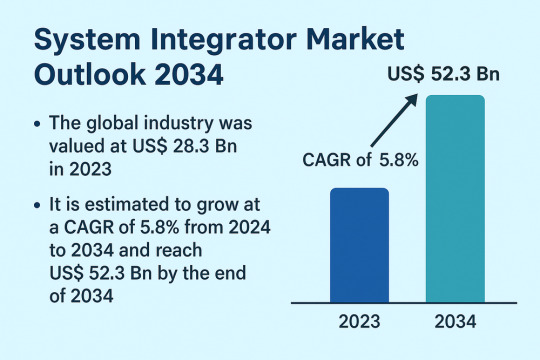

Automation and Integration Needs Power Robust Growth in System Integrator Market

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Why Siemens HMI is a Game-Changer in Automation

In the present days of industrial developments, there has been an unusual demand for intelligent, reactive, and reliable interfaces. At the core of this innovation lies the Siemens HMI solution, an interface bridging the gap between human operators and complex machines. From managing a small production setup to a fully automated facility, Siemens offers HMI panels for differing operational requirements.

A real-world example of Siemens HMI in action can be seen in aviation - learn how Siemens HMI is streamlining airport baggage handling systems with precision and automation.

Why Choose Siemens HMI?

The Siemens HMI technology ensures that your machines are not simply connected, but intelligent, intuitive, and easy to control. Under the SIMATIC series, Siemens offers a range of HMI systems allowing operators to easily monitor, control, and adjust a machine's processes. Whether it's changing the temperature in a food processing unit or setting the speed of motors in a manufacturing plant — Siemens HMI gives you utmost control and real-time data access.

These HMI solutions are flexible and scalable. As your needs for production grow, your Siemens SIMATIC HMI system will be able to grow with you to support new functions, new users, and new machines.

Explore the Power of Siemens SIMATIC HMI

The Siemens SIMATIC HMI portfolio ranges from simple key panels to high-performance interface panels with multi-touch capabilities. With a fast processor, high-resolution display, and intuitive navigation controls, these panels ensure quick operation for the most demanding applications.

Besides the fast speed, Siemens HMI panels also promise a long life supported by frequent firmware updates and enhanced security features, making sure that your investment stays secure and ready for the future.

Touchscreens That Are Really Easy to Use with Siemens SIMATIC Panel Touch

The days of clunky buttons with limited interaction are over. The Siemens SIMATIC panel touch range brings the highest level of touch capability with easy navigation, gesture support, and brilliant displays. These panels are ideal for control systems that demand both time sensitivity and ease of access.

Touch panels make for great user experience, letting you make fast adjustments to the workings of machines yourself, view detailed information, and recognize faults, all at a glance. And built rugged, they work their way almost everywhere into the industries of oil & gas, pharmaceuticals, food & beverage, and logistics, to name a few.

Learn more in Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Integration Made Easy

Seamless integration with other Siemens automation products such as PLCs and SCADA systems is one of the principal advantages of using Siemens SIMATIC HMI systems. Incidentally, this causes efficient consolidations in industrial control systems-and alongside that, lesser maintenance-related stresses and minimized error rates.

Apart from the support for communication protocol offered by Siemens HMI panels making it rather easy to interface with third-party systems should there be a need for such interaction, it is this flexibility that makes Siemens a very popular choice among system integrators and plant managers all over the world.

For deeper insights, check out Human Machine Interface Siemens: Improving Operational Productivity.

Real Results from Every Industry

The Siemens HMI systems have proved their efficacy in real-time situations ranging from factory automation and process control to building management and energy monitoring. With fast boot-up times, customizable user interfaces, and sophisticated data visualization, these panels greatly enhance operational productivity and machine availability.

Conclusion

If your plan is to improve control in industrial automation with Naksh Technology Solutions LLP or to update a rather dated set of operator interfaces, then consider picking Siemens HMI systems. The company provides a whole range of solutions, which include Siemens SIMATIC HMI and Siemens SIMATIC panel touch, so you can count on market-leading innovativeness, reliability, and performance.

Smart HMI is a big difference; Siemens means technology plus efficiency.

0 notes

Text

Basic SCADA programming - How can beginners get started without feeling overwhelmed?

Even a simple SCADA setup can control PLCs, connect RTUs, and provide clear visualizations. But where should you begin, and what should you avoid?

Full step-by-step guide here: https://maxelectric.vn/huong-dan-lap-trinh-scada-co-ban-cho-nguoi-moi-bat-dau-a155.html

0 notes

Text

Why Is a Gas Leak Detector Crucial for Industrial Safety?

In today's industrial landscape, safety is paramount—especially in environments where hazardous gases are present. From manufacturing units to chemical plants and oil refineries, ensuring early detection of gas leaks can prevent accidents, save lives, and maintain regulatory compliance. At the forefront of this safety revolution is Uniphos Envirotronic Solutions, a trusted name known for its cutting-edge gas leak detectors and reliable gas transmitters.

The Importance of Gas Detection Systems

Toxic and combustible gases, if left undetected, can lead to catastrophic consequences including explosions, health hazards, and environmental damage. This is where high-quality gas leak detectors and gas transmitters play a vital role. These devices continuously monitor the environment, identify gas leaks in real-time, and trigger alerts for immediate corrective action.

Uniphos Envirotronic Solutions: Pioneering Safety and Innovation

Uniphos Envirotronic Solutions is one of India’s leading manufacturers and global suppliers of gas detection and environmental monitoring instruments. With over three decades of experience, Uniphos has developed a comprehensive range of safety devices that are tailored to meet the demanding needs of various industries.

Gas Leak Detectors: Accuracy Meets Durability

Uniphos offers a versatile portfolio of gas leak detectors that are designed to detect a wide range of toxic and flammable gases. These detectors feature advanced sensing technology, high sensitivity, and fast response times. Ideal for confined spaces, manufacturing floors, and chemical storage areas, these detectors ensure round-the-clock safety with minimal maintenance.

Key Features:

Real-time monitoring

Audible and visual alarms

Rugged design for harsh environments

Compatibility with multiple gas types

Gas Transmitters: Reliable Data for Centralized Control

In addition to detectors, gas transmitters by Uniphos are essential components in an integrated gas monitoring system. These devices accurately convert gas concentrations into electrical signals, which can then be read and analyzed by control systems.

Uniphos gas transmitters are known for:

High-precision sensor technology

Compatibility with SCADA/DCS systems

Long service life and stability

Easy integration and calibration

Applications Across Industries

The products by Uniphos are used across a broad range of sectors including:

Oil and gas

Petrochemicals

Water treatment

Pharmaceuticals

Agriculture and food processing

Whether for portable or fixed installations, Uniphos Envirotronic Solutions provides tailor-made solutions to meet specific safety needs.

Conclusion

When it comes to industrial gas detection, the combination of reliability, innovation, and industry expertise makes Uniphos Envirotronic Solutions a preferred partner for safety solutions. By investing in advanced gas leak detectors and gas transmitters, industries can significantly enhance their safety standards and operational efficiency.

0 notes

Text

Implementation of Digital Twin Technology: Bridging the Physical and Digital Worlds

Digital Twin technology is transforming industries by creating dynamic digital replicas of physical assets, systems, and processes. By integrating real-time data with simulation and analytics, digital twins enable better decision-making, predictive maintenance, and operational efficiency. The implementation process requires strategic planning, technological infrastructure, and a clear understanding of desired outcomes.

What Is a Digital Twin?

A digital twin is a virtual representation of a physical object or system across its lifecycle. It uses real-time data to simulate the performance and behavior of the asset. Unlike static 3D models, digital twins are dynamic and continuously updated through inputs from IoT sensors, enterprise systems, and environmental data.

Industries such as manufacturing, aerospace, healthcare, energy, and smart cities are leveraging digital twins to reduce costs, increase productivity, and drive innovation.

Key Steps in Implementing Digital Twin Technology

1. Define Objectives and Scope

Start by identifying the business problems or goals the digital twin is meant to address. These could include:

Predicting equipment failures

Optimizing operations

Enhancing product design

Improving customer experiences

Clearly defining the scope—whether it’s a single machine, an entire facility, or a supply chain—helps align resources and expectations.

2. Establish Data Infrastructure

Reliable data is the foundation of an effective digital twin. This includes:

Historical data for modeling

Real-time sensor data for monitoring

Operational data from ERP, MES, or SCADA systems

Cloud-based platforms are commonly used to integrate, store, and process this data at scale.

3. Select the Right Technologies

A successful implementation requires a combination of technologies:

IoT sensors: Collect physical asset data

Cloud computing: Offers scalability and remote access

Simulation tools: Enable virtual testing and modeling

AI/ML algorithms: Analyze trends and make predictions

AR/VR platforms: Provide immersive visualization and interaction

Selecting technologies that can be integrated smoothly into existing systems is crucial.

4. Develop the Digital Model

Create a digital replica of the physical object using CAD tools and simulation software. Incorporate real-world physics and operational parameters to mirror actual performance.

At this stage, accuracy is vital. A precise model ensures reliability when forecasting behavior or optimizing performance.

5. Enable Real-Time Integration

The true power of a digital twin comes from real-time synchronization. This involves:

Integrating sensors and devices

Using APIs and middleware to connect systems

Enabling feedback loops between the digital and physical environments

This step transforms the model from a static replica into a living, breathing digital twin.

6. Test and Validate the Twin

Before full deployment, rigorously test the digital twin to ensure it matches real-world behavior. Use known scenarios and real-time inputs to confirm accuracy. Identify and resolve any discrepancies between the digital and physical systems.

7. Deploy and Continuously Improve

Once validated, the digital twin can be deployed to monitor and optimize operations. However, it must evolve alongside its physical counterpart. Continuous updates, machine learning enhancements, and sensor recalibrations are essential for long-term effectiveness.

Benefits of Digital Twin Implementation

Predictive Maintenance

By monitoring machinery in real time, digital twins detect early signs of wear or failure. Maintenance can be scheduled before issues escalate, minimizing downtime.

Operational Efficiency

Simulating different scenarios helps organizations identify bottlenecks, streamline workflows, and increase output without additional resources.

Cost Reduction

Digital prototyping reduces the need for physical models, lowering R&D expenses. Operational savings also arise from reduced breakdowns and energy optimization.

Faster Innovation

Virtual testing accelerates product development cycles. Engineers can iterate quickly, explore multiple configurations, and bring innovations to market faster.

Enhanced Customer Experiences

In retail, automotive, and real estate sectors, digital twins provide immersive virtual interactions, enabling personalized and engaging customer experiences.

Challenges and Considerations

Data Security Risks

Integrating real-time data streams and cloud systems increases exposure to cyber threats. Strong encryption, access controls, and compliance frameworks are necessary.

Data Quality and Availability

Accurate, timely data is essential. Incomplete or incorrect data can mislead simulations and produce poor decisions.

High Initial Investment

Upfront costs for hardware, software, and expertise can be significant. However, long-term gains in efficiency and cost savings often justify the investment.

Skilled Workforce Requirements

Digital twin implementation requires cross-functional expertise, including data scientists, engineers, and IT professionals. Upskilling and hiring may be necessary.

The Future of Digital Twin Technology

Digital twins are evolving rapidly. Integration with generative AI, 5G, and edge computing will unlock new levels of autonomy and intelligence. Soon, entire ecosystems such as smart cities, autonomous supply chains, and connected healthcare systems may function as networks of interconnected digital twins.

This shift represents a move toward real-time, data-driven decision-making at scale—a foundation for the next generation of digital transformation.

Conclusion

The implementation of digital twin technology is a strategic leap toward smarter, more resilient operations. While the process requires planning and investment, the long-term benefits—ranging from cost savings to innovation acceleration—make it a compelling choice for forward-thinking organizations. By merging the physical and digital worlds, digital twins unlock a powerful pathway to future-ready enterprise systems.

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

Top Benefits of Implementing ABB Freelance Solutions in Bangalore’s Manufacturing Plants

Modern manufacturing plants in Bangalore are continually seeking ways to boost productivity, increase reliability, and maintain compliance with evolving industry standards. One technology that has gained widespread adoption is ABB Freelance Solutions in Bangalore, a compact Distributed Control System (DCS) designed to offer DCS-level reliability with PLC-like flexibility. As automation advances further, integrating Robotic vision solutions in Bangalore alongside ABB Freelance can deliver even greater benefits. This article explores the key advantages of adopting ABB Freelance in manufacturing facilities and highlights how pairing it with robotic vision enhances operational excellence.

1. Cost-Effective Scalability

Traditional DCS platforms often come with high upfront costs and complex licensing models. ABB Freelance, however, provides a modular architecture that allows manufacturers to add control loops and I/O modules gradually, matching budget constraints and production growth. This pay-as-you-grow model ensures that plants only invest in the capacity they need initially, with the option to expand seamlessly. Over time, this translates to significant savings compared to monolithic DCS installations.

2. Rapid Deployment and Reduced Engineering Effort

One of the standout features of ABB Freelance is its intuitive engineering environment, which leverages the System 800xA interface. Preconfigured function blocks, drag-and-drop graphics, and standardized libraries simplify control logic development. As a result, commissioning times shrink dramatically, enabling plants to achieve faster return on investment. Engineers spend less time on tedious coding and more on optimizing processes, making it ideal for Bangalore’s dynamic manufacturing landscape.

3. High Availability and Robust Reliability

Minimizing unplanned downtime is critical in high-value production environments. ABB Freelance offers redundant controllers, hot-swappable I/O modules, and fault-tolerant communication networks. In the event of a hardware failure, the system automatically switches to backup modules without interrupting control processes. This level of reliability is crucial for sectors like pharmaceuticals, water treatment, and food processing, where any interruption can lead to costly production losses or compliance breaches.

4. Seamless Integration with Existing Infrastructure

Most manufacturing plants in Bangalore already have legacy PLCs, SCADA systems, or fieldbus networks in place. ABB Freelance excels at integrating with these existing components through backplane communication and standardized protocols such as Profibus, Modbus, and Ethernet/IP. This interoperability allows plants to modernize their control strategy without ripping out perfectly functional equipment. Furthermore, combining Freelance with Robotic vision solutions in Bangalore—which rely on real-time process data—enhances quality control and reduces manual inspection tasks.

5. Unified Operations and Situational Awareness

ABB Freelance utilizes the System 800xA HMI to deliver a unified control platform where operators can monitor process variables, alarms, and trends from a single interface. This centralized view improves situational awareness and reduces operator training time. When integrated with robotic vision systems, operators gain real-time visual feedback on product quality, enabling quick adjustments and reducing scrap rates. The synergy between control data and vision analytics empowers teams to make data-driven decisions.

6. Simplified Maintenance and Diagnostics

Built‑in diagnostics and asset management tools are hallmarks of ABB Freelance. The system continually monitors hardware health—tracking I/O status, network performance, and controller integrity—and generates proactive alerts. Maintenance teams receive advance warning of potential issues such as sensor drift or network degradation, allowing them to intervene before failures occur. When combined with robotic vision systems that also self-diagnose camera alignment or lighting anomalies, plants achieve a comprehensive predictive maintenance strategy that drastically limits unscheduled shutdowns.

7. Enhanced Safety and Regulatory Compliance

Safety is paramount in manufacturing, and ABB Freelance includes safety controller options that integrate seamlessly into the DCS framework. Plants can implement safety interlocks, emergency shutdown sequences, and fail-safe architectures without deploying separate safety PLCs. This integrated safety approach simplifies compliance with international standards such as IEC 61511. Moreover, pairing automated vision inspection—through Robotic vision solutions in Bangalore—ensures critical safety checks (e.g., weld seam verification or seal integrity) occur consistently, meeting strict regulatory mandates.

8. Future-Proof Architecture

Industry 4.0 demands connected, data-centric ecosystems. ABB Freelance supports Industrial Internet of Things (IIoT) protocols and cloud connectivity, making it straightforward to integrate with higher-level analytics platforms, MES, or ERP systems. As production scales or new technologies emerge, Freelance’s open architecture adapts rapidly. Likewise, robotic vision systems can leverage the same networked infrastructure to feed image and quality data into enterprise analytics, enabling continuous improvement and innovation.

Conclusion

Implementing ABB Freelance Solutions in Bangalore’s manufacturing plants offers clear advantages: cost-effective scalability, fast deployment, high availability, and seamless integration with legacy systems. When paired with Robotic vision solutions in Bangalore, plants gain an additional layer of quality assurance and data-driven process control. As a leading engineering service provider in the region, Madox Technologies excels at delivering turnkey ABB Freelance installations and integrating advanced vision technologies to create smarter, safer, and more efficient production environments. By embracing these combined solutions, Bangalore’s manufacturers can maintain a competitive edge in an increasingly automated world.

visit for more info https://madox.in/product/cobot-welder/

0 notes

Text

Digital Management System for Copper Mine Factory | Web UI Design

Demo Collection: https://hightopo.com/demos/en-index.html

1 note

·

View note

Text

Top 5 Must-Have Accessories for Every Electrical Panel

An electrical panel is the nerve center of any low-voltage power distribution system — responsible for delivering electricity safely and efficiently to various circuits. While the breakers and busbars often take the spotlight, it’s the accessories that enhance functionality, safety, monitoring, and reliability. Whether you’re an OEM, panel builder, or facility manager, equipping your panels with the right accessories can make all the difference.

In this article, we explore the top 5 must-have accessories for every electrical panel, based on industry best practices and real-world applications.

1. Cable Ducts and Trunking Systems

Purpose:

Cable ducts (also called wiring ducts or trunking) are essential for organizing and routing internal panel wiring. They prevent clutter, minimize the risk of short circuits, and make future maintenance more manageable.

Key Benefits:

· Improved safety through wire separation and insulation

· Neat, professional layout that meets electrical standards

· Ease of troubleshooting during inspections or servicing

Common Types:

· Slotted PVC ducts

· Halogen-free wiring ducts (for safety-critical environments)

· Flexible ducts for tight corners

Pro tip: Always select ducts with sufficient space for future cable additions — typically 20–30% free space is recommended.

2. Terminal Blocks and Marking Systems

Purpose:

Terminal blocks serve as connection points between internal and external wiring, ensuring a secure and modular setup. Combined with proper marking systems, they allow clear identification of circuits and functions.

Key Benefits:

· Safe and reliable wire termination

· Clear labeling for faster diagnostics

· Scalable for expansions and upgrades

Essential Variants:

· Feed-through terminal blocks

· Grounding terminals

· Fuse terminal blocks

· DIN-rail mounted marking strips or markers

Tip: Use color-coded terminals and labels according to IEC or local wiring codes for better clarity.

3. Panel Meters and Monitoring Devices

Purpose:

Modern electrical panels are not just passive distribution points — they are smart monitoring stations. Panel meters and current monitoring devices help track voltage, current, frequency, and power consumption.

Key Benefits:

· Real-time data for preventive maintenance

· Improved energy efficiency

· Quick response to load imbalance or faults

Popular Options:

· Digital voltmeters and ammeters

· Multi-function energy analyzers

· Load monitoring relays

Advanced choice: Consider smart monitoring units with Modbus or Ethernet communication for integration with BMS or SCADA systems.

4. Control and Signaling Devices

Purpose:

Control and signaling accessories like push buttons, selector switches, and pilot lights are critical for human-machine interaction. They allow operators to control, signal, and monitor operations within or from the front of the panel.

Key Benefits:

· Improved operator control and feedback

· Quick visual status indication

· Enhanced safety through emergency stop functions

Must-Have Components:

· Illuminated push buttons (Start/Stop)

· Pilot lights (for voltage presence or fault status)

· Emergency stop buttons

· Audible buzzers for alerts

Best Practice: Use IP65-rated front-panel devices for industrial environments to ensure durability and resistance to dust and moisture.

5. Surge Protection Devices (SPD)

Purpose:

Electrical surges — whether from lightning or switching operations — can damage panel components or connected equipment. SPDs protect against transient over voltages.

Key Benefits:

· Prevents costly downtime and equipment failure

· Increases the lifespan of electronics and controls

· Meets compliance with IEC 61643 or UL 1449 standards

Selection Tips:

· Choose SPDs according to system voltage (230V/400V) and risk level

· Type 1 for external surge protection, Type 2 for internal panel protection

· Consider combined Type 1+2 for comprehensive safety

Smart move: Pair SPDs with monitoring modules to track surge counts and SPD health.

Final Thoughts

When designing or upgrading your electrical panel, these five accessory categories are not just optional — they’re essential. They improve safety, functionality, compliance, and operational efficiency. Whether you’re building panels for industrial, commercial, or residential applications, investing in high-quality accessories will yield long-term benefits.

At Daleel Trading, we supply trusted low-voltage switchgear accessories from leading brands like Civaux — ensuring your panels are equipped with components that meet international standards.

Ready to upgrade your panel accessories?

Contact us today to learn more about our product range or request a consultation with our technical team.

6 notes

·

View notes

Text

What Is the difference Between SCADA and HMI

SCADA (Supervisory Control and Data Acquisition) and HMI are both crucial elements in industrial automation, but they serve different roles. SCADA is a comprehensive system used to monitor, control, and analyze industrial processes across multiple locations. It integrates hardware and software to gather real-time data from sensors, devices, and PLCs, allowing operators to manage large-scale operations remotely. HMI (Human-Machine Interface) is a user interface, on the other hand, that links a human operator to the machinery or equipment. It displays process data visually—such as alarms, trends, and system status—enabling operators to interact directly with machines. While HMI is a component of SCADA systems, SCADA includes additional layers like data logging, communications infrastructure, and centralized control, making it more expansive and network-oriented than a standalone HMI.

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#human machine interface#GIF#trending know#solutions provider#solutions#scada software#software.

1 note

·

View note

Text

Automated Insights: The Future of Solar Drone Panel Inspection with AI

The sheer volume of data generated by solar drone panel inspection can be overwhelming. Thousands of high-resolution images and thermal scans per flight quickly accumulate, posing a significant challenge for manual analysis. This is where Artificial Intelligence (AI) and Machine Learning (ML) are stepping in, transforming the future of solar panel inspection from a data collection exercise into a powerhouse of automated, actionable insights.

AI isn't just a buzzword in this context; it's the critical ingredient that unlocks the full potential of drone-collected data, enabling unprecedented efficiency, accuracy, and predictive capabilities in solar drone panel inspection.

The Data Deluge and the Need for AI:

Imagine a large utility-scale solar farm with 100,000 panels. A drone inspection might capture 50,000 to 100,000 images. Manually reviewing each image for subtle defects, distinguishing between various types of anomalies, and cross-referencing them with thermal data is an arduous and error-prone task. This manual bottleneck limits the frequency and scalability of comprehensive inspections.

AI addresses this challenge head-on by automating the analysis process.

How AI Supercharges Solar Drone Panel Inspection:

Automated Defect Detection and Classification:

AI algorithms, particularly deep learning models like Convolutional Neural Networks (CNNs), are trained on vast datasets of solar panel images (both visual and thermal) containing various types of defects (cracks, hotspots, soiling, delamination, snail trails, etc.).

Once trained, these algorithms can automatically scan new inspection data, identify anomalies, and classify them with remarkable speed and accuracy. They can distinguish between a bird dropping (which might cause a small hotspot) and a more critical cell failure, prioritizing issues based on severity.

Precise Localization:

Coupled with GPS and RTK/PPK data from the drone, AI can precisely pinpoint the location of each identified defect on the solar farm map, down to the specific panel and even the individual cell. This eliminates guesswork for maintenance crews.

Quantitative Analysis and Severity Assessment:

AI can go beyond simple detection. For thermal anomalies, it can quantify the temperature difference, providing a measure of the hotspot's severity. For soiling, it can estimate the percentage of panel coverage.

This quantitative data allows operators to understand the impact of each defect on power production and prioritize repairs based on potential energy loss.

Predictive Maintenance:

This is one of the most exciting advancements. By analyzing historical inspection data collected over time, AI can identify patterns of degradation and predict when a panel is likely to fail or significantly degrade.

For example, if a micro-crack is detected, AI can monitor its progression over subsequent inspections and flag it for proactive repair before it leads to a catastrophic failure. This allows for planned maintenance, minimizing unscheduled downtime.

Automated Reporting and Trend Analysis:

AI-powered platforms can automatically generate comprehensive inspection reports, complete with maps, visual and thermal images of defects, classification, and recommended actions.

They can also track changes over time, highlighting degradation rates, the effectiveness of repairs, and overall farm performance trends. This data is invaluable for long-term asset management and investment decisions.

Integration with Existing O&M Systems:

The goal is seamless integration. AI insights from solar drone panel inspection can feed directly into a solar farm's existing asset management or SCADA (Supervisory Control and Data Acquisition) systems, creating a unified dashboard for operations and maintenance.

The Human Element: Still Crucial:

While AI automates much of the heavy lifting, the human element remains crucial. Skilled human operators are needed to:

Pilot the Drones: Despite increasing autonomy, human intervention is still required for safe and effective flight operations, especially in challenging conditions.

Validate AI Findings: Human experts often review critical AI-flagged anomalies to ensure accuracy and provide nuanced interpretations.

Diagnose Complex Issues: AI can detect symptoms, but complex problems may still require human expertise for definitive diagnosis and repair planning.

Develop and Train AI Models: Data scientists and engineers are essential for continuously improving and training AI algorithms.

The Future is Intelligent and Autonomous:

The future of solar drone panel inspection is undeniably tied to greater AI integration. We can expect:

Increased Autonomy: Drones that can plan their own missions, execute flights, and return to base with minimal human intervention, perhaps even conducting "drone-in-a-box" operations.

Real-time Edge Computing: Drones processing data on board in real-time, providing immediate alerts to operators in the field.

Swarm Robotics: Fleets of drones working collaboratively to cover vast areas even faster.

Deeper Predictive Capabilities: More sophisticated AI models that can predict not just failures, but also optimal cleaning schedules, the impact of shading, and the best times for specific maintenance actions.

By leveraging AI, solar drone panel inspection is evolving from a mere inspection tool into an intelligent asset management system, enabling solar farm operators to maximize efficiency, reduce costs, and ensure the long-term profitability of their renewable energy investments. The intelligent skies are indeed paving the way for a more sustainable and efficient energy future.

0 notes

Text

How Siemens HMI Drives Smarter Automation in Every Sector

In the current fast industrial world scenario, HMI systems are increasingly becoming well-known for boosting productivity and operational visibility. Siemens HMI is considered one of the trusted and innovative interface technologies and is hence widely implemented in industries. With engineering prowess, advanced user-friendly interfaces, and top-of-the-line integration with automation systems, Siemens HMI finds increasing repetition in setting efficiency and control parameters for industries.

A real-world example of Siemens HMI in action can be seen in aviation - learn how Siemens HMI is streamlining airport baggage handling systems with precision and automation.

What Does Siemens HMI Mean?

Siemens HMI, or Human Machine Interface by Siemens, spans a wide array of graphical user interface systems that allow machine operators to engage with industrial equipment. These applications are designed to present real-time data to operators, accept inputs from users, and provide monitoring and control of machinery in areas such as manufacturing, automotive, food processing, and so forth.

From basic panel solutions to sophisticated multi-touch systems, Siemens comprises the entire spectrum of the Siemens SIMATIC HMI product line so that one can rely on them for their bona fide reputation for practicality, ease of use, and application flexibility.

Features and Benefits of Siemens SIMATIC HMI

The HMI product line by Siemens caters to the requirements of applications ranging from simple to highly complex. The reasons why Siemens SIMATIC HMI enjoys such widespread usage are:

High-Resolution Displays: Designed for better clarity and faster decision-making by the operator.

Touch Functionality: Superior touchscreen systems of the Siemens SIMATIC panel offer an intuitive user experience based on multi-touch gestures.

Robust Design: These specially designed HMIs are intended to survive in the harshest of industrial environments with assured longevity.

Flexible Configuration: The configuration or setup flexibility with Siemens PLC and SCADA systems streamlines automation workflows.

Security and User Management: Protecting the machine operation entails product-based user roles and access control.

Whether you want something as simple as an operator panel or a complicated multi-touch panel for fine machine visualization, Siemens is there to fulfill your HMI needs.

Learn more in Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Siemens SIMATIC Panel Touch: Smart, Modern, and Interactive

Amongst highly preferred ranges in HMI offerings from Siemens, the Siemens SIMATIC panel touch series stands out. These panels incorporate the latest modern touch-screen technology to enhance user interface with speedy response time and smooth execution. Being made in different sizes and configurations, these allow operators to access key performance indicators, diagnostics, and control functions on a single screen.

These SIMATIC touch panels can be configured in many ways as they support a large number of communication protocols and data formats, thereby also supporting other automation systems besides Siemens PLCs.

Applications of Siemens HMI in Industry

Siemens HMI systems are employed in various industries:

Manufacturing: Control and testing of production lines in real-time.

Automotive: Control for smooth robot and assembly line interactions.

Food and Beverage: Control of temperature, flow rates, and machine health.

Pharmaceutical: Batch consistency, and data logging for compliance.

In all the above applications, the Siemens SIMATIC HMI series assists operators in timely interventions, reducing downtime, and maintaining quality control.

For deeper insights, check out Human Machine Interface Siemens: Improving Operational Productivity.

Conclusion

For any business wanting to digitize and modernize its industrial operations, Siemens HMI systems come as a perfect solution by Naksh Technology Solutions LLP. With the versatility, reliability, and performance offered by the Siemens SIMATIC HMI along with the contemporary user experience provided by the Siemens SIMATIC panel touch devices, industries can create intelligent operations effortlessly.

While considering an upgrade or perhaps a fresh implementation of the HMI system, Siemens should be the first point of contact for future-ready industrial automation.

0 notes