#Inventory Control Systems

Explore tagged Tumblr posts

Text

Automated Inventory Tracking System: Revolutionizing Supply Chain Efficiency

Effective inventory management is crucial if you want to remain competitive in today's fast-paced corporate environment. An automated inventory tracking system is increasingly becoming the backbone of effective supply chain operations, allowing businesses to streamline processes, minimize errors, and optimize resource allocation. This blog explores the pivotal role that automated systems play in modern inventory management, highlighting their impact on supply chains, key components, and the technological advancements driving their evolution.

Understanding Automated Inventory Tracking Systems

Automated inventory tracking systems are a sophisticated blend of hardware and software designed to monitor and manage inventory levels, orders, and deliveries. These systems utilize technologies such as barcodes, RFID tags, and IoT devices to provide real-time data on stock movements. By automating the tracking process, businesses can significantly reduce the manual labor involved, decrease the likelihood of human error, and ensure accurate inventory counts at all times.

The Role of Technology in Inventory Management

Technology is at the heart of any automated inventory tracking system. With the advent of Artificial Intelligence (AI) and machine learning, these systems have become more intelligent, capable of predicting stock requirements, identifying trends, and even automating reordering processes. Cloud computing further enhances the accessibility and scalability of inventory systems, allowing for seamless integration across multiple locations and real-time data sharing.

Components of an Automated Inventory Tracking System

An automated inventory tracking system comprises several critical components:

Barcodes and RFID Tags: These are used to label products and track their movement through the supply chain. Barcodes are scanned manually or via automated systems, while RFID tags can be read automatically as products pass through specific checkpoints.

Inventory Management Software: This software is the brain of the system, processing data collected from barcodes, RFID tags, and other sources to provide insights into inventory levels, product locations, and more.

IoT Devices: Internet of Things (IoT) devices are increasingly used in automated inventory systems to monitor conditions such as temperature and humidity, particularly in industries like pharmaceuticals and food and beverage.

Cloud Computing: Cloud-based inventory systems enable real-time data access, enabling companies to keep an eye on inventory from a single, central platform across several locations.

Advantages of Automated Inventory Tracking Systems

Putting in place an automated inventory tracking system has a number of significant benefits.

Increased Accuracy: Automation reduces the potential for human error, ensuring more accurate inventory counts and reducing discrepancies.

Cost Savings: By optimizing inventory levels, businesses can reduce storage costs and avoid overstocking or stockouts.

Enhanced Efficiency: Automated systems streamline inventory management processes, freeing up staff to focus on more strategic tasks.

Real-Time Data: Access to real-time inventory data allows businesses to make informed decisions quickly, improving responsiveness to market changes.

Challenges in Implementing Automated Inventory Systems

Although there are obvious advantages to using an automated inventory tracking system, there may be implementation difficulties:

Initial Costs: The initial investment in hardware, software, and training can be significant, particularly for small businesses.

Integration with Existing Systems: Ensuring that the new automated system integrates smoothly with existing Warehouse management solutions and ERP is essential for success

Employee Training: It can take a lot of time and money to properly train staff members to use the new system.

Future Trends in Automated Inventory Management

The future of automated inventory tracking systems is promising, with several trends set to shape the industry:

AI and Machine Learning: These technologies will continue to enhance the predictive capabilities of inventory systems, enabling even more accurate demand forecasting and inventory optimization.

Blockchain Technology: Blockchain could revolutionize inventory tracking by providing a secure, transparent ledger for all inventory movements, reducing fraud and increasing accountability.

Advanced Robotics: It is anticipated that more robotics will be used in warehouses, automating more of the picking, packing, and shipping procedures.

FAQs for Automated Inventory Tracking System

Q1. What is an automated inventory tracking system?

A. An automated inventory tracking system uses technology like barcodes, RFID tags, and software to monitor and manage inventory levels in real time, reducing the need for manual counts and improving accuracy.

Q2. How does an automated inventory tracking system improve efficiency?

A. By automating the tracking process, businesses can streamline inventory management, reduce errors, and free up staff to focus on other tasks, thereby improving overall operational efficiency.

Q3. What are the key components of an automated inventory tracking system?

A. Key components include barcodes or RFID tags for labeling products, inventory management software for processing data, IoT devices for monitoring conditions, and cloud computing for real-time data access.

Q4. Are there any challenges associated with implementing an automated inventory tracking system?

A. Yes, challenges include the initial cost of implementation, the need for system integration, and the time and expense of training employees to use the new system.

Q5. What future trends are expected in automated inventory management?

A. Future trends include the increased use of AI and machine learning, the adoption of blockchain technology for secure inventory tracking, and the integration of advanced robotics in warehouses.

Q6. How can a business benefit from an automated inventory tracking system?

A. A business can benefit through increased inventory accuracy, cost savings, enhanced efficiency, and access to real-time data for better decision-making.

Conclusion

In an era where efficiency and accuracy are paramount, an automated inventory tracking system offers a powerful solution for businesses looking to streamline their operations and maintain a competitive edge. By embracing the technological advancements driving these systems, companies can optimize their inventory management processes, reduce costs, and improve overall supply chain performance. As the industry continues to evolve, the integration of AI, machine learning, and other cutting-edge technologies will further enhance the capabilities of these systems, making them an indispensable tool for businesses across all sectors.

#Automated Inventory Management#Real-Time Inventory Tracking#Inventory Control Systems#Supply Chain Optimization#Data-Driven Inventory#Warehouse Automation

0 notes

Text

Navigating Efficiency: Unveiling the Power of a Warehouse Management System

In the intricate landscape of supply chain management, where precision and speed are paramount, the role of a Warehouse Management System (WMS) emerges as a beacon of efficiency. Let's embark on a journey to unravel the significance of WMS and its pivotal role in orchestrating seamless operations in the dynamic world of warehousing.

Understanding the Warehouse Management System (WMS)

A Warehouse Management System is the linchpin that streamlines and optimizes the various facets of warehouse operations. In an era where the ebb and flow of inventory are crucial considerations for businesses, a robust WMS becomes indispensable for maintaining control and fostering agility.

Key Functions of a Warehouse Management System:

Inventory Control and Tracking: At the heart of a WMS lies the capability to maintain real-time visibility into inventory. From the moment stock arrives at the warehouse to its departure for delivery, a WMS provides meticulous tracking, ensuring that businesses are well-informed about their stock levels.

Order Fulfillment Optimization: WMS enhances order fulfillment by optimizing the picking and packing processes. Through intelligent algorithms, it dictates the most efficient routes for order picking, minimizing travel time and maximizing efficiency.

Space Utilization and Layout Planning: Efficient use of warehouse space is a game-changer. WMS aids in strategic layout planning, ensuring that goods are stored in a way that maximizes space utilization and facilitates swift retrieval during order processing.

Real-time Reporting and Analytics: Informed decision-making is empowered by real-time reporting and analytics. WMS provides actionable insights into warehouse performance, allowing businesses to identify trends, forecast demand, and optimize their operations continually.

The Harmony of Integration: Inventory Control System and Transportation Management System

To truly unlock the potential of a Warehouse Management System, businesses often integrate it with other critical systems. Two noteworthy integrations are Inventory Control Systems and Transportation Management Systems (TMS).

Inventory Control System Integration:

Inventory control system complement WMS by providing a comprehensive overview of stock levels and movement. Integration ensures that the information shared between the systems is seamless, allowing for a synchronized approach to managing inventory.

Transportation Management System Integration:

When integrated with a Transportation Management System, WMS becomes a part of an end-to-end logistics solution. This integration facilitates coordinated planning for transportation, ensuring that goods move seamlessly from the warehouse to their final destination.

Choosing the Right Warehouse Management System:

Scalability: Opt for a WMS that can scale with your business. As your inventory and order volumes grow, the system should seamlessly adapt to evolving needs.

User-Friendly Interface: A user-friendly interface is crucial for the successful implementation of a WMS. Your team should be able to navigate the system effortlessly, minimizing training time.

Integration Capabilities: Look for a WMS that integrates seamlessly with other systems, such as Inventory Control Systems and Transportation Management Systems. Integration ensures a holistic approach to supply chain management.

In conclusion, a Warehouse Management System is not just a tool; it's a strategic asset for businesses aiming to achieve operational excellence in their warehousing processes. By embracing the capabilities of WMS and integrating it with complementary systems, businesses can navigate the complexities of modern supply chain management with finesse, ensuring efficiency, accuracy, and customer satisfaction.

FOR ORIGINAL POST :- https://blague-courte.com/navigating-efficiency-unveiling-the-power-of-a-warehouse-management-system

0 notes

Text

DP X DC WRITING PROMPT #22

✦

Bring on the Night

What if Danny's white hair and green eyes showed up under blacklight? No nightclubs for him... of course, knowing him, he'd definitely still go.

Imagine someone from the DC universe gaining a crush on the mysterious alt looking dude but he's impossible to find outside of nightlife parties.

To make it more interesting, what if the nightclub he frequents is actually owned by him? Even more interesting if the nightclub is used as a sort of no man's land where ghosts and humans knowingly/unknowingly peacefully mingle with each other? Some of the more ghostly individuals are also Danny's employees and humans just see them as enthusiastically trying to fit the theme of the club. What exactly is that theme? You decide.

I feel like Danny would just make a really good host and it would easily fit in with his obsession to protect. Like a side project/hussle, but for ghostly core health.

Also think of it as kinda like vacation time for his rogues from trying to throttle him. They get a nice, safe space to freely feed into their individual obsessions without wrecking anything/anyone.

✦

List of roles are in the tags but can changed around however anyone pleases. Just thought this would be a fun idea for anyone to pick up and run with.

#dp x dc#dc x dp#danny owns a nightclub cause why not#he hosts both humans and ghosts#ember's band frequently plays there#skulker could be the part-time bouncer#he keeps watch for creeps and other less than legal activities#technus controls the lights and sound systems#dark danny is the bar tender#box ghost keeps track of non-human friendly inventory#tucker is in charge of human friendly inventory#he's also co-manager with sam#danny phantom crossover#dp crossover#dp x dc crossover#dp x dc prompt#writing prompt#prompt

1K notes

·

View notes

Text

you can pry these two trios from my cold dead hands

#luka... listen to me you're my one last hope#also dont get me wrong... i love sashisu but i feel like#personally#gojo geto and riko fit luka hyuna and hyun-woo more#MAYBE im looking into it too much but it makes sense to me#like after riko/hyunwoos death each pairs paths seperate#luka is “perfect” gojo is “perfect”#hyuna and geto are in their little cult group things#OKAY IT MAKES SENSE IN MY HEAD...#just hyuna isnt evil#idk what to tag this#jujutsu kaisen#alien stage#satoru gojo#suguru geto#riko amanai#luka alnst#hyuna alnst#hyunwoo alnst#hidden inventory arc#jjk#alnst#omg hyuna isn't in a cult btw.. i didnt mean it like that#im pretty sure gojo and luka were both sheltered or smth idk it's late i can't think of shared traits rn#other than status#but gojo def has more control of the system hes in than luka does#azr3na

28 notes

·

View notes

Text

played the demo for banquet for fools (dev. hannah and joseph games, launching into early access on september 30th).

i honestly just wanted to share this since this left a very positive impression on me and has all the hallmarks of a turbo lofi production with basically no exposure. so i might as well share in case anybody else wants to check it out.

banquet for fools is a party-based arpg that takes place in a fictional island called invimona. the game casts you as asal in the first act, who immediately gets to work as the other people around them are attacked (and attacking each other, as if they are being compelled to). it is after the first act that you create your four party members who are sent to investigate what happened in the first act.

the combat is simple but an interesting spin on the arpg, formula incorporating a sort of active time battle system that sees a bar fill up until you can perform an action, letting you move around freely as you do so and switch between party members. from what i could tell, currently only basic attacks are implemented, but there seems to be an interesting magic system that allows you to create your own spells. the character creator is surprisingly beefy. you can create characters of any of 5 races that sound interesting from the blurbs. stats and traits are based on a combination of race and sex (which is a slider that features 6 or so combinations of body type and height), in a way that reminds me of morrowind. you can assign stats and skills based on predefined archetypes or you can make your own custom archetype. during conversations, dialogue choices are assigned to each party member depending on their stats and skills. and the art style is gorgeous; it reminds me of claymation. an issue is that it seems that cutscenes are pre-rendered which may be associated with the limited resolutions which i wish were expanded.

overall i found it very interesting, albeit very vague at this point. i do believe the presentation of information could stand to be improved. but there is something very unique and interesting in this title that grabbed my attention. i'll be sure to keep an eye on it!

#p#gaming log#banquet for fools#im so intrigued ngl#so happy this got beamed into my sphere of consciousness#oh and i'd say currently it's very whack on the steam deck. i had to run it on ge proton due to the pre-rended video codecs#and it has no controller support yet. it will probably change as controller support is added#i also like the grid based inventory system#afaik this probably takes place in the same world as previous game by these devs and you can import that save. i'll have to look into it

40 notes

·

View notes

Text

Get Organized: ERPNext Distribution by Sigzen Makes It Easy

In today’s fast-paced Running a business can be tough, especially when things get messy. But what if there was a way to make it all simpler. That’s where ERPNext Distribution comes in. This awesome tool helps you manage your stuff like inventory, deliveries, and ordering without any hassle. It’s like having a helper for your business tasks. With ERPNext Distribution, you can say goodbye to…

View On WordPress

#Business Automation#ERP Integration#ERP Software Solutions#Inventory Management System#Procurement Management#Resource Planning#Stock Control#Workflow Optimization

2 notes

·

View notes

Text

im not the only one getting homestuck vibes from this. right. right.

#.txt#genloss#genloss spoilers#like. the room setup. the inventory system. the fact that he’s literally Stuck In The Home. it even has grandmother’s ashes!#<- guy who only thinks about homestuck Getting a lot of homestuck vibes from this…..#EDIT WAIT ALSO THE CONTROLLING ACTIONS THING THATS HUGE. COME ON

8 notes

·

View notes

Text

Revolutionize Logistics: Explore Warehouse Management Software Benefits

In the ever-evolving landscape of supply chain logistics, businesses are constantly looking for smarter ways to optimize their warehouse operations. Enter the game-changing technology of Warehouse Management Software (WMS). These digital tools are reshaping how warehouses operate, bringing enhanced efficiency, precision, and cost savings. If your logistics system still relies heavily on manual tracking or fragmented tools, it’s time to explore the full spectrum of Warehouse Management Software Benefits.

A major advantage of warehouse management software is its ability to provide real-time inventory tracking. Gone are the days of paper logs and spreadsheets. With WMS, you can monitor inventory levels, shipments, and stock movement as they happen. This visibility not only improves operational planning but also minimizes the risk of overstocking or stockouts.

Operational efficiency is another key benefit. WMS automates processes such as picking, packing, and shipping, drastically reducing the time required to fulfill orders. This directly leads to faster delivery times and improved customer satisfaction. Businesses that adopt these systems often see a measurable boost in productivity within weeks of implementation.

In terms of cost reduction, WMS can streamline labor allocation, ensuring your workforce is always focused on high-priority tasks. The software's built-in analytics help managers identify bottlenecks and areas where time and resources are being wasted. This allows for informed decisions that enhance performance and profitability.

Accuracy is critical in warehousing. By integrating technologies like barcode scanning and RFID tagging, WMS significantly lowers the risk of human error during inventory counts and order fulfillment. These features help ensure that your records are accurate and your customers receive the right products on time.

On a broader scale, WMS acts as the digital backbone of a smart supply chain. It integrates with ERP systems, eCommerce platforms, and transportation management systems, creating a seamless flow of data across your business operations.

The bottom line? The Warehouse Management Software Benefits are far too impactful to ignore. Whether you're running a small storage facility or a large distribution center, adopting WMS could be the key to staying competitive in an increasingly fast-paced market.

Take the first step toward a more agile, data-driven warehouse today—and watch your supply chain transform from a cost center into a value-driving asset.

#inventory control system#warehouse automation#logistics optimization#real-time inventory#supply chain software#barcode scanning#stock management.

0 notes

Text

#warehouse management software#inventory software for small business#restaurant inventory management software#pos and inventory system for small business#pos with inventory management#barcode inventory management system#warehouse management system software#pos and inventory software#stock control inventory#retail store management system#stock management software#stock warehouse management system#pharmacy stock management system#stock control and inventory#stock and invoice software

0 notes

Text

Advanced Biometric & Access Control Solutions in dubai and saudi arabia

#rfid and ble solutions in dubai#fingerprint technologies in dubai#facial recognition solutions in dubai#access control solutions in dubai#asset management system in dubai#inventory management system in dubai

0 notes

Text

Boost Retail Profits by Mastering Stock Control and Inventory Accuracy

In retail and logistics, stock control isn't just a process – it's the foundation of profitability. Without accurate inventory management, businesses risk losing sales, damaging their reputation, and increasing operational costs. Yet, many retailers overlook the importance of precise stock tracking until it directly affects their bottom line.

Imagine walking into a store, only to find the product you need is out of stock. Frustrated, you leave and purchase from a competitor instead. Now multiply that experience by hundreds or thousands of customers. This common scenario highlights the hidden dangers of poor stock accuracy.

In this article, we'll dive into the costs of inventory inaccuracy and explore practical strategies for improving stock control. Whether you're a small business or a large retailer, mastering inventory management is essential for long-term growth.

The Real Cost of Poor Inventory Accuracy

Stock control failures impact businesses on multiple levels, from lost sales to inefficient operations. Addressing this challenge is critical to staying competitive and ensuring customer satisfaction.

The Visible Costs:

Lost Sales Opportunities: A missing item translates to missed revenue. Stockouts often drive customers to competitors, especially during peak shopping periods.

Overstocking Issues: Overstocking ties up capital, increases warehousing costs, and leads to markdowns. Excess inventory also contributes to product obsolescence, further eating into profits.

Operational Setbacks: Employees spending hours fixing stock discrepancies results in wasted labor and reduced productivity. These disruptions create ripple effects throughout the supply chain.

The Hidden Costs:

Customer Churn and Loyalty Loss: Customers who consistently encounter stockouts are less likely to return. Data shows that 84% of shoppers will leave a retailer after multiple poor experiences.

Reputation Damage: Inconsistent stock control can lead to negative reviews and word-of-mouth backlash. Trust is difficult to regain once it's broken.

Supply Chain Disruptions: Poor inventory tracking results in incorrect reordering, exacerbating stock issues and disrupting the flow of goods.

Fact: Retailers with inventory accuracy rates below 70% often face profit losses amounting to billions annually. Addressing this issue early can save businesses substantial amounts over time.

Strategies to Improve Stock Control

1. Adopt RFID Technology Radio Frequency Identification (RFID) technology offers a game-changing solution for retailers looking to improve stock accuracy. Unlike traditional barcodes, RFID tags allow for item-level tracking throughout the supply chain, offering real-time insights into stock movement.

Learn more about the benefits of RFID Technology in Retail

Retailers who implement RFID experience up to 99% inventory accuracy, drastically reducing stock discrepancies and enhancing operational efficiency. This technology is particularly valuable for industries dealing with high-value or frequently moving items.

2. Implement Cycle Counting Cycle counting involves counting small segments of inventory at regular intervals rather than conducting full stock audits. This method allows businesses to spot and correct discrepancies early without disrupting daily operations.

For more on audit strategies, explore our Efficient Cycle Count Solutions

By focusing on high-turnover products or areas with frequent errors, businesses can systematically improve inventory accuracy over time. Cycle counting helps minimize stockouts and reduces overall labor costs.

3. Use Predictive Analytics for Inventory Management Predictive analytics is transforming how businesses approach stock control. By analyzing past sales data, market trends, and customer demand patterns, predictive analytics can forecast future inventory needs with remarkable accuracy.

This technology enables retailers to align stock levels with demand, reducing the risk of overstocking or understocking. Predictive analytics optimizes inventory flow, ensuring that the right products are available at the right time.

Leveraging Technology for Better Inventory Control

Advanced Inventory Management Systems (IMS) Investing in modern inventory management systems can significantly streamline stock control. IMS platforms integrate with POS (Point of Sale) systems, allowing for seamless inventory tracking across multiple sales channels.

These systems provide real-time updates and improve data accuracy, ensuring that businesses can react quickly to changing inventory needs. IMS platforms also incorporate AI and machine learning, further enhancing demand forecasting and minimizing errors.

Pro Tip: Retailers leveraging Inventory Optimization with Slimstock see reduced errors and improved operational efficiency.

Actionable Tips for Improving Inventory Accuracy

Integrate RFID for High-Value Stock: Start by tagging high-value or fast-moving products to ensure accurate tracking. Expand usage as the benefits become evident.

Schedule Regular Cycle Counts: Develop a cycle counting schedule that prioritizes frequently fluctuating stock. This prevents discrepancies from accumulating.

Train Employees in Stock Control Best Practices: Regular training helps ensure that staff members understand the importance of accurate inventory management.

Leverage Predictive Analytics: Work with technology providers to implement predictive analytics tailored to your specific business model. This reduces guesswork and improves forecast precision.

Upgrade to IMS Platforms: Modern inventory management systems reduce manual errors and provide better data visibility. Choose platforms that integrate seamlessly with your existing tech stack.

For more actionable tips, check out How Accurate Inventory Records Impact Business.

Real-World Success Story

A regional electronics retailer faced mounting losses due to frequent stockouts and overstocking. After integrating RFID technology and adopting regular cycle counting, the company achieved a 25% increase in inventory accuracy. This improvement led to a 12% boost in annual sales and significantly reduced warehousing costs.

Additionally, by implementing predictive analytics, they refined their stock replenishment processes, cutting down excess inventory by 18%. The combination of technology and improved practices not only increased profits but also enhanced the customer experience.

Final Thoughts and Call to Action

Mastering stock control is not just about reducing losses—it’s about unlocking new growth opportunities. By adopting RFID, cycle counting, and predictive analytics, retailers can stay ahead of competitors, minimize operational waste, and maximize profitability.

Want to take your stock control to the next level? Explore how Altavant Consulting can help streamline your inventory management process and enhance your bottom line. Visit our website or book a consultation today to learn more.

#Stock control#Inventory accuracy#Cycle counting#RFID technology#Inventory management systems#Predictive analytics for inventory#How to improve inventory accuracy#inventorymanagement#altavantconsulting#retailefficiency#rfidtechnology#retailinnovation#retailsolutions#customerexperience#datadrivendecisions#goodfaithreceiving#octoplus

0 notes

Text

Maximize operational efficiency and inventory control with VastEdge’s cutting-edge warehouse management system (WMS).

#warehouse management system#WMS software#inventory control tools#logistics optimization#supply chain software

0 notes

Text

Implementing Real-Time Intelligent in Transportation Systems

Long wait periods and unpredictability provide many problems for transportation systems, especially bus networks for Intelligent Transportation Systems. These issues reduce public transit's efficacy and efficiency, which causes commuter annoyances and subpar operations for transportation authorities. Numerous factors, including traffic congestion, unanticipated events, and insufficient information, contribute to uncertainty and lengthy wait times in transportation networks.

As a result, passengers frequently have to wait for long periods of time at bus stops due to erratic bus arrival and departure times.

In addition to being inconvenient for passengers, lengthy wait times deter people from using public transit, which increases the use of private vehicles, causes traffic, and raises environmental issues. Our study intends to create methods and tools to lessen waiting times and uncertainty in bus transit systems in order to address these problems.

#Intelligent Transportation Systems#Electrical Lighting Supply in Doha#Tunnel SCADA#Gulf Business Qatar#Top Road Network Surveys in Qatar#Asset Management in Qatar#Top Tunnel Management System in Qatar#Tunnel Operations and Maintenance#Tunnel Maintenance Qatar#Congestion Charging Qatar#Tolling System Qatar#O&M Services Qatar#O&M Framework Contractor Qatar#Access Control System Qatar#Asset Inventory Survey Qatar#ROMDAS#Road Surveys

0 notes

Text

Efficient Warehouse Storage Solutions for Supermarkets & Food Processing Equipment - Global Automation Ltd

Discover essential warehouse storage strategies, including pallet racking systems, mezzanine floors, and temperature-controlled storage. Optimize space and maintain product quality in supermarkets and food processing with Global Automation Ltd’s tailored solutions.

#Warehouse storage solutions#Pallet racking systems#Mezzanine floors warehouse#Temperature-controlled storage#Warehouse shelving systems#Supermarket storage strategies#Food processing equipment storage#Commercial refrigeration solutions#Inventory management software#Optimizing warehouse space

0 notes

Text

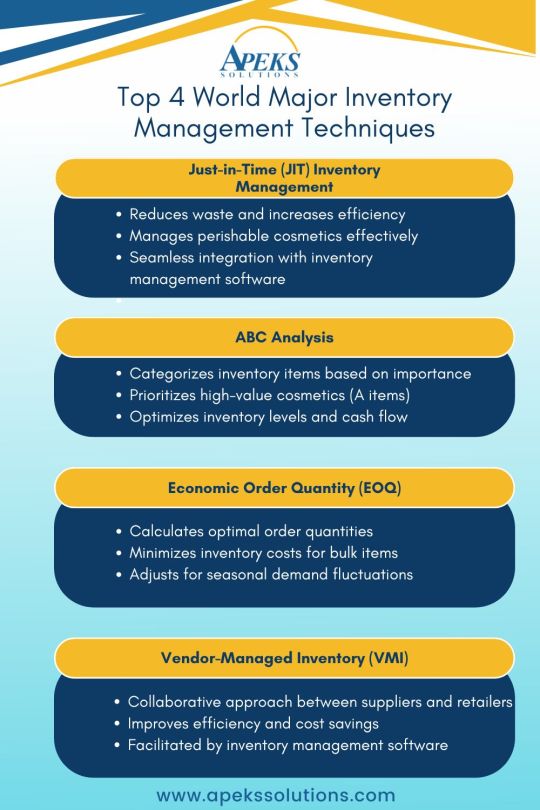

Top 4 World Major Inventory Management Techniques

Explore the Top 4 World Major Inventory Management Techniques that are transforming how businesses manage their stock and streamline operations. From Just-In-Time (JIT) to Economic Order Quantity (EOQ), these proven strategies help companies optimize inventory levels, reduce costs, and improve overall efficiency. By integrating these techniques with inventory management software, businesses can gain better control of their inventory, automate processes, and boost productivity. Perfect for businesses of all sizes looking to enhance their inventory control and maximize results!

#Inventory management techniques#Inventory control methods#Top inventory strategies#Just-in-time inventory (JIT)#Economic Order Quantity (EOQ)#Inventory management software#Stock optimization techniques#Supply chain management#Inventory tracking systems#Inventory management solutions

0 notes