#Medical Device Reprocessing Market Report

Explore tagged Tumblr posts

Text

#Medical Device Reprocessing Market#Medical Device Reprocessing Market Size#Medical Device Reprocessing Market Report#Medical Device Reprocessing Market growth#Medical Device Reprocessing Market Share

0 notes

Text

#Reprocessed Medical Devices Market#Reprocessed Medical Devices Market Trends#Reprocessed Medical Devices Market Growth#Reprocessed Medical Devices Market Industry#Reprocessed Medical Devices Market Research#Reprocessed Medical Devices Market Report

0 notes

Text

0 notes

Text

Automated Endoscope Reprocessing Market Overview: Global Industry Snapshot

The Automated Endoscope Reprocessing Market has emerged as a pivotal segment within the broader landscape of medical device disinfection and sterilization. As minimally invasive surgeries (MIS) continue to gain traction, the demand for high-level disinfection of endoscopic instruments has become increasingly critical. Automated endoscope reprocessors (AERs) have thus transformed from optional support systems into indispensable components of modern healthcare infrastructure.

What is Automated Endoscope Reprocessing?

Automated Endoscope Reprocessing refers to the use of specialized machines to clean, disinfect, and dry endoscopes after clinical use. The process ensures a standardized, consistent, and safe method of preparing endoscopes for reuse. AERs reduce the risks associated with human error in manual cleaning and provide traceable documentation to meet stringent regulatory compliance standards.

Market Size and Dynamics

The global Automated Endoscope Reprocessing Market has experienced consistent growth over the past decade. This growth is driven by a combination of rising surgical procedures, hospital-acquired infection (HAI) prevention protocols, and global health initiatives pushing for sterilization automation in medical settings. The market is projected to continue expanding from 2025 to 2032 due to:

Increasing geriatric population and chronic illnesses requiring endoscopy

Surge in demand for MIS procedures

Regulatory enforcement for infection control

Rising investment in hospital infrastructure

As of 2024, the market valuation is estimated to be in the range of USD 1.5 to 2 billion, with robust CAGR expectations of around 8–10% through the forecast period.

Key Market Segments

The Automated Endoscope Reprocessing Market can be segmented based on product types, end users, and regions:

Product Types: Single basin, double basin, and advanced multi-cycle units

End Users: Hospitals, ambulatory surgical centers (ASCs), specialty clinics

Geography: North America leads due to strict regulations and advanced hospital facilities, followed by Europe and Asia-Pacific, where rapid infrastructure growth is boosting demand.

Drivers of Market Growth

Several factors fuel the adoption of automated endoscope reprocessors:

Stringent Regulatory Requirements: Regulatory bodies like the U.S. FDA, CDC, and European CE authorities mandate validated cleaning protocols.

HAI Prevention and Patient Safety: AERs reduce the risk of cross-contamination and infection outbreaks.

Growing Demand for Reusable Endoscopes: Single-use scopes are costlier in the long term; thus, proper reprocessing becomes essential.

Operational Efficiency: Automated systems reduce manpower needs and provide traceable reports for compliance audits.

Challenges in the Market

Despite its rapid growth, the Automated Endoscope Reprocessing Market faces several obstacles:

High Initial Investment: The cost of acquiring and maintaining AER systems may be prohibitive for small healthcare providers.

Complexity in Operation and Maintenance: Technical training and ongoing support are critical to ensure safe and correct use.

Infrastructure Gaps in Low-Income Regions: Limited access to utilities and space can hinder adoption in rural or underdeveloped areas.

Competitive Landscape

Major players in the Automated Endoscope Reprocessing Market include:

Olympus Corporation

Getinge AB

Cantel Medical (Steris)

Ecolab Inc.

Advanced Sterilization Products (ASP)

These companies are investing in technological innovation, AI integration, and ergonomically designed units to offer better cleaning efficiency, traceability, and operator convenience.

Global Trends and Future Outlook

Global trends in the Automated Endoscope Reprocessing Market include the adoption of smart reprocessors with integrated software systems for performance monitoring, IoT-based devices for maintenance alerts, and energy-efficient designs to align with green hospital initiatives.

Moreover, the COVID-19 pandemic has led to heightened awareness of sterilization and disinfection in healthcare settings. The resulting surge in sterilization compliance continues to positively influence market growth even in the post-pandemic era.

Conclusion

The Automated Endoscope Reprocessing Market represents a critical aspect of infection control within the healthcare system. With rising emphasis on patient safety, regulatory compliance, and healthcare automation, the market is poised for significant expansion in the coming years. As technology evolves and cost-effectiveness improves, adoption is expected to widen globally—particularly in emerging healthcare markets seeking to enhance their clinical hygiene standards.

0 notes

Text

Titanium Recycling Market Growth Analysis, Market Dynamics 2025

The global Titanium Recycling market was valued at US$ 998.43 million in 2023 and is anticipated to reach US$ 1,812.07 million by 2030, witnessing a CAGR of 9.10% during the forecast period 2024-2030.

Get more reports of this sample : https://www.intelmarketresearch.com/download-free-sample/489/titanium-recycling-market

Titanium recycling is the process of recovering and reprocessing titanium and titanium-based alloys from scrap or used products for use in new applications.

Titanium is a valuable and widely used metal in a variety of industries, including aerospace, automotive, and medical devices, but it can be difficult and expensive to extract from natural sources. As a result, there is a growing interest in recycling titanium and titanium-based alloys to reduce the environmental impact and cost of production.

The major global companies of Titanium Recycling include TIMET, Kymera International, Metraco NV, EcoTitanium (Aubert & Duval), Monico Alloys, Baoji Titanium, Mega Metals, United Alloys and Metals, and Globe Metal, etc. In 2023, the world's top three vendors accounted for approximately 12% of the revenue.

This report aims to provide a comprehensive presentation of the global market for Titanium Recycling, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Titanium Recycling.

The Titanium Recycling market size, estimations, and forecasts are provided in terms of and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Titanium Recycling market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Titanium Recycling companies, new entrants, and industry chain related companies in this market with information on the revenues for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation

By Company

TIMET

Kymera International

Metraco NV

EcoTitanium (Aubert & Duval)

Monico Alloys

Baoji Titanium

Mega Metals

United Alloys and Metals

Globe Metal

Grandis Titanium

Goldman Titanium

Hanwa

Toho Titanium

OSAKA Titanium

Kobe Steel

Dong-A Special Metal

Hansco

Posco

Western Metal Materials

Pangang Group Titanium Metal Materials

Qinghai Supower Tianium

Segment by Type

Titanium Solids

Titanium Turnings

Segment by Application

Titanium Ingot

Steel Industry

Others

By Region

North America

United States

Canada

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Australia

Rest of Asia

Europe

Germany

France

U.K.

Italy

Russia

Rest of Europe

Latin America

Mexico

Brazil

Rest of Latin America

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of MEA

Drivers

The titanium recycling market is driven by increasing demand across aerospace, automotive, and medical industries due to titanium's lightweight and corrosion-resistant properties. Recycling titanium is essential to meet supply challenges and environmental mandates, as primary titanium extraction is energy-intensive. The growing adoption of sustainable manufacturing practices further bolsters market growth. North America and Europe dominate the market due to robust aerospace industries and stringent environmental regulations.

Restraints

Despite its growth potential, the market faces challenges such as high costs associated with titanium scrap processing and limited technological advancements in some regions. The industry also grapples with supply chain issues, particularly in collecting and sorting high-quality scrap.

Opportunities

Emerging economies in Asia-Pacific present lucrative opportunities due to expanding manufacturing bases and increasing awareness about sustainable practices. Innovations in recycling technologies, such as more efficient separation and refinement processes, are anticipated to enhance market dynamics.

Get more reports of this sample : https://www.intelmarketresearch.com/download-free-sample/489/titanium-recycling-market

0 notes

Text

Titanium Recycling Market 2025

The global Titanium Recycling market was valued at 998.43 million US dollars in 2023 and is projected to reach 1,812.07 million US dollars by 2030, growing at a compound annual growth rate of 9.1 percent during the forecast period from 2024 to 2030.

Get free sample of this report at :https://www.intelmarketresearch.com/chemicals-and-materials/489/titanium-recycling-market

Overview of Titanium Recyclin

Titanium recycling involves recovering and reprocessing titanium and titanium-based alloys from scrap or used products to be reused in new applications. Titanium is a highly valuable metal widely utilized in aerospace, automotive, and medical device industries due to its lightweight and corrosion-resistant properties. However, extracting titanium from natural resources is costly and energy-intensive, which has led to increased interest in recycling as a sustainable and cost-effective alternative.

Leading Companies in Titanium Recycling

Key global players in the titanium recycling market include TIMET, Kymera International, Metraco NV, EcoTitanium (Aubert and Duval), Monico Alloys, Baoji Titanium, Mega Metals, United Alloys and Metals, Globe Metal, and others. In 2023, the top three companies accounted for approximately 12 percent of the market revenue.

Market Segmentation

By Company: TIMET, Kymera International, Metraco NV, EcoTitanium, Monico Alloys, Baoji Titanium, Mega Metals, United Alloys and Metals, Globe Metal, Grandis Titanium, Goldman Titanium, Hanwa, Toho Titanium, Osaka Titanium, Kobe Steel, Dong-A Special Metal, Hansco, Posco, Western Metal Materials, Pangang Group Titanium Metal Materials, Qinghai Supower Titanium

By Type: Titanium Solids, Titanium Turnings

By Application: Titanium Ingot, Steel Industry, Others

By Region: North America (United States, Canada), Asia Pacific (China, Japan, South Korea, Southeast Asia, India, Australia), Europe (Germany, France, UK, Italy, Russia), Latin America (Mexico, Brazil), Middle East and Africa (Turkey, Saudi Arabia, UAE)

Market Drivers

The titanium recycling market growth is propelled by rising demand from aerospace, automotive, and medical industries where titanium’s lightweight and corrosion resistance are critical. Recycling is increasingly important to address supply constraints and comply with environmental regulations, as producing titanium from primary sources requires significant energy. The adoption of sustainable manufacturing practices in North America and Europe further supports market expansion.

Market Restraints

Challenges include high costs related to processing titanium scrap and a lack of advanced recycling technologies in some regions. Supply chain difficulties, particularly in collecting and sorting high-quality titanium scrap, also limit market growth.

Market Opportunities

Emerging economies in the Asia Pacific region offer significant growth potential due to expanding manufacturing sectors and increasing focus on sustainability. Technological advancements in recycling methods, including improved separation and refinement processes, are expected to further strengthen market dynamics.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/489/titanium-recycling-market

0 notes

Text

Sterilization Pouches Market is Driven by Stringent Regulatory Standards

Sterilization pouches are medical-grade packaging products designed to maintain sterility of surgical instruments, dental tools, and other healthcare devices until the point of use. Made from breathable, puncture-resistant materials such as medical-grade paper and transparent polymer films, these pouches allow for efficient steam, ethylene oxide, or hydrogen peroxide sterilization processes. Their clear windows enable visual inspection of instrument integrity and chemical indicators, ensuring patient safety and compliance with infection control protocols.

Advantages include barrier protection against microbial contamination, ease of handling, and compatibility with colorimetric sterilization indicators. As healthcare facilities worldwide prioritize patient safety and infection prevention, the demand for reliable Sterilization Pouches Market solutions has surged. Rising awareness of healthcare-associated infections, coupled with stringent regulations from bodies like the FDA and EMA, has underscored the need for standardized sterilization practices. In addition to hospitals and clinics, dental practices and outpatient surgical centers are expanding their use of sterilization pouches to streamline instrument reprocessing workflows and reduce turnaround times.

The sterilization pouches market is estimated to be valued at USD 53.80 Bn in 2025 and is expected to reach USD 88.10 Bn by 2032, growing at a compound annual growth rate (CAGR) of 7.3% from 2025 to 2032. Key Takeaways

Key players operating in the Sterilization Pouches Market are:

-Amcor plc

-Mondi Group

-Berry Global

-3M Company

-Dynarex Corporation

These market companies leverage extensive R&D capabilities and robust distribution networks to innovate pouch materials and expand product portfolios. Amcor plc focuses on sustainable packaging solutions, while Mondi Group emphasizes advanced barrier films that enhance instrument protection. Berry Global and 3M Company invest in market research to optimize pouch design and performance, and Dynarex Corporation targets niche segments with cost-effective, single-use sterilization wraps. Through strategic alliances and mergers, these key players aim to consolidate market share and capitalize on market growth opportunities.

‣ Get More Insights On: Sterilization Pouches Market

‣ Get this Report in Japanese Language: プレハブ建築市場

‣ Get this Report in Korean Language: 살균파우치시장

0 notes

Text

How does risk management factor into ISO 13485 Certification in Kenya?

What is ISO 13485 Certification?

ISO 13485 certification in Kenya is a worldwide standard for quality-management structures in the therapeutic gadget business. It provides the essentials for businesses, including the developing, designing introduction, adjusting and dispersing restorative devices and services.

Certification confirms that your business:

Keeps the consistency of the item and quality

Meets the requirements of the administrative department.

Uses a security approach based on risk and performance

Why is ISO 13485 Certification Imperative in Kenya?

Kenya The Drug Store and Harms Board (PPB) controls restorative devices in Kenya. In compliance with ISO 13485 consultant in Kenya:

Encourages the enrollment of items and endorsement by the PPB

Validity upgrades in contract tenders as well as open segment agreements.

Underpins will send instructions to markets like the EU and the ISO 13485 consultant in Kenya

Shows its commitment to quiet security and item dependability

Reduces the risk of product reviews and non-compliance

Who Ought to Get ISO 13485 Certified in Kenya?

ISO 13485 is perfect for:

Medical device manufacturers

The importers and exporters who deal in equipment for therapeutic use

Wholesalers and distributors

Sterilization benefit providers

Companies are creating software for the use of restorative technology.

Health offices are part of the item Reprocessing.

Steps to Get ISO 13485 Certification in Kenya

1. Hole Analysis:

Find any gaps between your frameworks currently in use and ISO 13485 requirements.

2. Documentation:

Create required documents such as a quality guide, chance management record, and strategies.

3. Framework Implementation:

Implement the standards’ requirements for operations, starting from acquisition up to the generation stage and distribution.

4. Inner Audit:

Conduct internal reviews to determine the framework’s suitability and to ensure compliance.

5. Administration Review:

Senior management assesses the results of reviews and validates preparation for external certification.

6. Certification Audit:

A certified certification body performs a two-stage audit to ensure the certification complies.

7. Certification Issuance:

After a successful test, Your company will be granted ISO 13485 consultant services in Kenya certification, which is typically large for 3 years.

Documents Required for ISO 13485 Certification

Quality method and manual

Risk administration procedures

Plan of product development and advanced files

Traceability records, as well as item labeling

Complaint handling, as well as an input system

Control and assessment of suppliers’ records

Internal Review and Remediation Activity ISO 13485 consultant services in Kenya Reports

Cost of ISO 13485 Certification in Kenya

The shiftings that are fetched are based on these factors:

Company size

Numerous facilities and products

Operation complexity

Certification body chosen

On average, ISO 13485 certification in Kenya costs between KES 200,000 to KES 800,000, which includes discussions, documentation, preparation, and audit.

Benefits of ISO 13485 Certification in Kenya

Made strides in quiet security and also changed control

Supply chain management upgraded

The showcase is available to all consumers and regulators.

Better documentation and transparency

Increased competitiveness in the private and public healthcare sectors

ISO 13485 and Kenyan Administrative Compliance

Affiliating your QMS to ISO 13485 auditor in Kenya makes a difference in ensuring that your QMS complies with local laws. By:

Pharmacy and Harms Board (PPB)

Kenya Bureau of Guidelines (KEBS)

Ministry of Wellbeing (MOH)

It will also prepare your store to be eligible for CE Checking (EU) or FDA endorsement (USA), which often requires ISO 13485 auditor in Kenya compliance.

Why Factocert for ISO 13485 Certification in Kenya?

We provide the best ISO Consultants in Kenya who are knowledgeable and provide the best solutions. Kindly contact us at [email protected]. ISO Certification consultants in Kenya and ISO auditors in Kenya work according to ISO standards and help organizations implement ISO Certification with proper documentation.

For more information, visit ISO 13485 certification in Kenya

0 notes

Text

Comprehensive Medical Device Testing and Compliance Solutions with Microchem Laboratory

The path to launching a safe, effective medical device is complex, requiring rigorous testing, validation, and compliance with strict regulatory standards. Microchem Laboratory stands as a trusted partner in this journey, offering a full range of medical device testing services to support manufacturers through every stage of product development and regulatory approval.

Whether you need efficacy assessments, cleaning validation, or regulatory compliance support, Microchem’s state-of-the-art facilities and scientific expertise ensure your devices meet the highest standards of safety and performance.

Reliable Medical Device Testing Services

When developing a new medical device, ensuring its safety and functionality is not optional — it’s mandatory. Microchem Laboratory’s comprehensive medical device testing services are designed to help manufacturers meet stringent FDA and ISO standards. Their expertise spans antimicrobial efficacy evaluations, sterility assurance, biocompatibility assessments, and material compatibility testing.

Through a data-driven and GLP-compliant approach, Microchem delivers reliable and precise results. Services such as microbial ingress testing and biocompatibility assessments provide critical insights into your product’s performance, helping to ensure that the device will perform safely under real-world conditions. With Microchem as your partner, you can move forward confidently toward regulatory submission and market launch.

Thorough Medical Device Cleaning Validation

Medical devices that are reused must be free from contaminants to ensure patient safety. Cleaning validation is an essential part of the regulatory process for such devices. Microchem Laboratory specializes in medical device cleaning validation, using rigorous, science-based methods to evaluate the effectiveness of reprocessing procedures.

Their studies simulate actual clinical conditions and utilize artificial soil loads that mimic blood, proteins, and other organic materials typically encountered during device use. By assessing hard-to-clean areas and worst-case scenarios, Microchem ensures a thorough examination of cleaning efficacy.

Detailed, FDA-compliant reports provide robust evidence that your cleaning procedures are effective, helping support your regulatory submissions and bolstering confidence in your product's safety. Trust Microchem to deliver meticulous cleaning validation solutions that protect patients and advance your business objectives.

Ensuring Medical Device Efficacy Testing

In an increasingly competitive healthcare market, proving the effectiveness of your medical device is crucial. Microchem Laboratory offers tailored medical device efficacy testing to demonstrate that your product performs as intended, especially when antimicrobial properties are involved.

Their services include antimicrobial efficacy evaluations using standards like ISO 22196, as well as microbial ingress testing to ensure that bacteria and other microorganisms cannot penetrate or compromise your device. They specialize in efficacy testing for a wide range of products, including wound dressings, surgical instruments, and catheters.

Using GLP-compliant methodologies and a robust scientific framework, Microchem provides actionable, reliable results that facilitate regulatory approval and enhance market confidence. By leveraging Microchem’s expertise in efficacy testing, you can be sure that your medical devices meet — and exceed — industry expectations.

Expertise in Medical Device Regulatory Compliance

Achieving medical device regulatory compliance is one of the most challenging and critical milestones for manufacturers. Non-compliance can result in delays, additional costs, and even product recalls. Microchem Laboratory offers comprehensive testing services specifically designed to ensure that your devices align with FDA, ISO, and other global regulatory standards.

Their team assists with a wide range of compliance needs, from cleaning validations and sterilization efficacy to disinfection validations and material compatibility studies. Their GLP-compliant processes and meticulous attention to detail result in clear, comprehensive reports that strengthen your regulatory submissions.

By partnering with Microchem Laboratory, you gain access to a team that understands the nuances of the approval process and is committed to supporting your journey to market success.

Why Choose Microchem Laboratory?

Choosing the right laboratory partner can make the difference between a smooth regulatory pathway and costly setbacks. Microchem Laboratory offers several key advantages:

Comprehensive Capabilities: From antimicrobial efficacy to sterility assurance and cleaning validation, they cover all major testing needs.

Regulatory Expertise: Their studies are designed to meet or exceed FDA and ISO requirements, reducing risks during submission.

GLP Compliance: Their Good Laboratory Practice-compliant methods ensure reliable, repeatable, and defendable data.

Timely Results: Microchem understands the importance of timelines and delivers precise results quickly to keep your project on track.

Client-Centered Service: With customized study designs and personal support, they help you navigate the complexities of product testing and compliance.

At every step, Microchem Laboratory combines scientific excellence with a commitment to quality and customer satisfaction, making them a trusted ally for medical device manufacturers worldwide.

Conclusion

Bringing a medical device to market demands rigorous validation and regulatory compliance. With Microchem Laboratory’s wide range of medical device testing services, medical device cleaning validation, medical device efficacy testing, and medical device regulatory compliance expertise, you can trust that your product will meet the highest standards of safety, performance, and reliability.

Don't leave your device’s success to chance. Partner with Microchem Laboratory — your ally in achieving excellence in medical device development, testing, and compliance.

Contact Microchem Laboratory today to learn more about how they can support your medical device testing and regulatory needs.

0 notes

Text

Clean & Critical: Endoscope Reprocessing Market Reaches $4.8B Goal 🔁🧼

As hospitals and clinics strive to reduce the risk of healthcare-associated infections (HAIs), the need for reliable endoscope reprocessing systems — ranging from automated reprocessors and disinfectants to drying cabinets and tracking solutions — has intensified. The goal is clear: prevent contamination, ensure compliance, and boost patient trust in clinical environments.

Market Dynamics

The surge in demand for endoscope reprocessing is being powered by several intertwined dynamics. First, the increasing prevalence of chronic gastrointestinal disorders and cancers is fueling endoscopic procedure volumes. In parallel, global infection control standards are becoming more rigorous, compelling healthcare providers to invest in high-quality reprocessing solutions.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS10277

Among the product categories, automated endoscope reprocessors (AERs) are leading the charge due to their efficiency and consistency, helping reduce human error. The trend toward automation is transforming the market, ensuring standardization and compliance across facilities. Complementary technologies like UV-C disinfection and hydrogen peroxide vaporization are also gaining traction.

On the flip side, challenges like high equipment costs, skilled labor shortages, and regulatory complexities pose hurdles. Additionally, the rise of single-use endoscopes could potentially disrupt the market by reducing the need for reprocessing altogether. Nevertheless, the drive toward sustainable and eco-friendly solutions presents fresh opportunities, with companies innovating to meet environmental and economic goals.

Key Players Analysis

The competitive landscape is vibrant, with leading firms like Olympus Corporation, Steris PLC, and Cantel Medical Corporation dominating the market. These companies continue to invest in advanced technologies, R&D, and strategic partnerships to stay ahead. Innovations in endoscope tracking, energy-efficient devices, and smart integration with hospital systems have set them apart.

In addition to established giants, emerging players such as Medi Clean Innovations, Scope Care Systems, and Endo Pure Solutions are making waves with cost-effective, specialized, and eco-conscious offerings. This diversity of players contributes to a dynamic marketplace brimming with innovation and adaptability.

Regional Analysis

North America leads the global market, underpinned by robust healthcare infrastructure, high awareness levels, and strict regulatory oversight. The United States is a standout performer, investing heavily in infection control technologies.

Europe follows closely, with countries like Germany and the UK playing key roles due to their emphasis on healthcare quality and technological innovation. The continent benefits from harmonized standards that support consistent market growth.

Browse Full Report : https://www.globalinsightservices.com/reports/endoscope-reprocessing-market/

Meanwhile, Asia-Pacific is emerging as a powerhouse. Nations like China and India are investing in healthcare modernization, driven by a growing middle class and medical tourism. With improved accessibility and infrastructure, this region is likely to witness exponential growth.

Latin America and the Middle East & Africa show moderate but steady development. While challenges remain in terms of economic and logistical constraints, the growing awareness of infection risks is pushing healthcare providers to upgrade their reprocessing practices.

Recent News & Developments

The past year has seen a flurry of activity in the endoscope reprocessing market. Pricing dynamics are shifting, influenced by the integration of smart features, energy-efficient systems, and compliance-focused design. Costs for AERs now range from $10,000 to $50,000, depending on their capabilities and sophistication.

Regulatory frameworks from agencies like the FDA and EU MDR have become more stringent, demanding robust compliance and spurring innovation in sterilization protocols. Key players are aligning with these regulations by enhancing automation, traceability, and sustainability in their products.

Additionally, strategic mergers and acquisitions are reshaping the landscape. Companies are joining forces to expand global footprints, strengthen product portfolios, and explore untapped regional markets. This consolidation trend is expected to intensify as the market matures.

Scope of the Report

This report offers an in-depth exploration of the endoscope reprocessing market, analyzing trends across product types, technologies, services, applications, and end-users. It maps out the historical journey and provides accurate forecasts from 2025 to 2034, highlighting growth drivers, restraints, competitive strategies, and technological innovations.

The report evaluates key development strategies, including product launches, partnerships, and acquisitions. It provides actionable insights into market segmentation, regional performance, and regulatory landscapes. Stakeholders can leverage this information to navigate challenges, identify growth hotspots, and capitalize on emerging trends.

Whether you’re a manufacturer, healthcare provider, or investor, this comprehensive outlook equips you with the knowledge to make informed decisions in an increasingly complex and competitive market.

Discover Additional Market Insights from Global Insight Services:

Outpatient Oncology Infusion Market : https://www.globalinsightservices.com/reports/outpatient-oncology-infusion-market/

Neurorehabilitation Devices Market : https://www.globalinsightservices.com/reports/neurorehabilitation-devices-market/

Aquaculture Vaccines Market : https://www.globalinsightservices.com/reports/aquaculture-vaccines-market/

Bioanalytical Testing Services Market : https://www.globalinsightservices.com/reports/bioanalytical-testing-services-market/

Biodegradable Implant Devices Market : https://www.globalinsightservices.com/reports/biodegradable-implant-devices-market/

#endoscopereprocessing #healthtech #infectioncontrol #patientcare #medicaldevices #hospitaltech #disinfectiontech #aers #uvdisinfection #hydrogenperoxide #healthcareinfrastructure #automatedreprocessing #cleaningprotocols #gastrotech #pulmonologycare #urologytech #medicalstandards #hospitalequipment #diagnostictech #surgicalsafety #globalhealth #medinnovation #sterileprocessing #regulatorycompliance #healthtechinnovation #medicaltourism #asiahealthcare #northamericahealth #europehealthcare #latamhealth #middleeasthealthcare #reprocessingtech #singleusevsreusable #biomedicaldevices #greenhealthcare #sustainablehospitals #ecofriendlytech #medtechstartups #infectionprevention #endoscopytech #futureofhealthcare

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

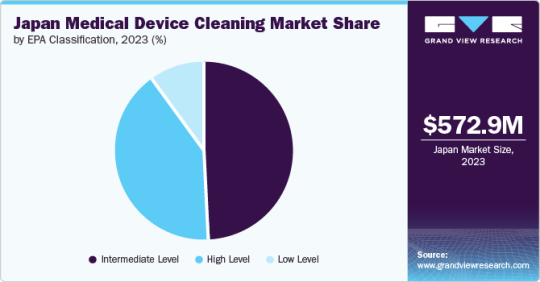

The Clean Sweep: A Report on the Japan Medical Device Cleaning Market

Japan Medical Device Cleaning Market Growth & Trends

The Japan Medical Device Cleaning Market size is anticipated to reach USD 1,169.49 million by 2030 and is projected to grow at a CAGR of 10.83% over the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to the increasing competition among the market players and the growing efforts to reduce hospital-acquired infections.

Several studies are being published focusing on the increasing number of infections acquired in hospitals and the measures that can prevent them. For instance, a study published by the National Library of Medicine in May 2020 found that nosocomial infections, also known as healthcare-acquired infections, are a significant burden on hospitalized patients in Japan. This study analyzed the Japanese claims database and found that out of 73,962,409 inpatients registered in the database, 9.7% had community-acquired infections (CAI), and 4.7% had nosocomial infections (NI). As a result, the growing burden of hospital-acquired infections is expected to increase the demand for medical device cleaning products in Japan.

Moreover, the growing use of single-use devices and the rising manufacturing of medical devices are anticipated to propel the Japanese medical device cleaning market. Industry stakeholders are focusing on increasing the development of medical devices in the country. For instance, in May 2023, Terumo Corporation, a medical device company, invested around USD 360 million to construct a new manufacturing facility for the Medical Care Solutions Company in Japan.

In addition, in January 2022, Kaneka Corporation invested around USD 69 million to build a new medical device plant in the Tomatoh Industrial Area in the northern area of Japan. Companies are expanding their manufacturing facilities. These expanding manufacturing facilities will require medical device cleaning solutions for sterilization, reprocessing, and cleaning in the future. Thus, the rise in investments in medical device manufacturing and development in Japan is projected to increase the demand for medical device cleaning products in the coming years.

Curious about the Japan Medical Device Cleaning Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Japan Medical Device Cleaning Market Report Highlights

Based on device type, the semi-critical segment dominated the market in 2023 and accounted for 46.02% of revenue share. However, the critical segment is anticipated to grow fastest over the forecast period due to the increasing infection control awareness and growing aging population.

Based on technique, the disinfection segment dominated the market in 2023 and accounted for 49.53% of the revenue share. However, the sterilization segment is anticipated to grow fastest from 2024 to 2030. Advancements in sterilization technologies are expected to boost segment growth in the coming years.

Based on EPA classification, the intermediate-level segment dominated the Japan market and accounted for the largest revenue share, 48.84%, in 2023. In contrast, the high-level segment is expected to grow fastest, with the fastest CAGR over the forecast period.

Japan Medical Device Cleaning Market Segmentation

Grand View Research has segmented the Japan Medical device cleaning market based on the device type, technique, and EPA classification:

Japan Medical Device Cleaning Device Type Outlook (Revenue, USD Million, 2018 - 2030)

Non-Critical

Semi-Critical

Critical

Japan Medical Device Cleaning Technique Outlook (Revenue, USD Million, 2018 - 2030)

Cleaning

Detergents

Buffers

Chelators

Enzymes

Others

Disinfection

Chemical

Alcohol

Chlorine & Chorine Compounds

Aldehydes

Others

Metal

Ultraviolet

Others

Sterilization

Heat Sterilization

Ethylene Dioxide (ETO) Sterilization

Radiation Sterilization

Japan Medical Device Cleaning EPA Classification Outlook (Revenue, USD Million, 2018 - 2030)

High Level

Intermediate Level

Low Level

Download your FREE sample PDF copy of the Japan Medical Device Cleaning Market today and explore key data and trends.

0 notes

Text

Medical Device Reprocessing Market: Market Trends and Competitive Analysis 2024-2032

The Medical Device Reprocessing Market was estimated at USD 2.69 billion in 2023 and is projected to reach USD 9.63 billion by 2032, growing at a compound annual growth rate (CAGR) of 15.29% during the forecast period of 2024-2032. Get Free Sample Report @ https://www.snsinsider.com/sample-request/3485 Regional Analysis North America: Dominates the market due to advanced healthcare infrastructure and stringent regulatory standards promoting reprocessing practices. Europe: Exhibits significant growth driven by cost-containment measures in healthcare and increasing adoption of reprocessed devices. Asia-Pacific: Anticipated to witness rapid expansion owing to rising healthcare expenditures, growing awareness about reprocessing benefits, and the presence of a large patient pool. Market Segmentation By Type: Reprocessing Support & Services Reprocessed Medical Devices By Device Category: Critical Devices Semi-Critical Devices Non-Critical Devices By Application: Surgical Instruments Endoscopy Equipment Respiratory Care Devices Others Key Players The major key players are Stryker, Innovative Health, NEScientific, Inc., Medline Industries, LP, Arjo, Vanguard AG, Cardinal Health, SureTek Medical, Soma Tech Intl, Johnson & Johnson MedTech and other players. Key Points Reusable medical devices, such as surgical forceps and endoscopes, are essential in healthcare for their cost-effectiveness and utility across multiple patients. Proper reprocessing of these devices is crucial to eliminate contaminants and prevent infections, thereby ensuring patient safety. The increasing prevalence of chronic diseases, like asthma and COPD, underscores the importance of reprocessed surgical instruments in managing healthcare costs and sustainability efforts. Adherence to industry standards and best practices in medical device reprocessing significantly reduces infection risks and enhances patient outcomes. Supply chain challenges, including material shortages and manufacturing complexities, can impact the availability and cost of reprocessed devices. Future Scope The future of the medical device reprocessing market appears promising, with technological advancements enhancing the efficiency and safety of reprocessing methods. Innovations in sterilization technologies and the development of more durable medical devices suitable for multiple reprocessing cycles are expected to drive market growth. Additionally, increasing environmental concerns and the push for sustainable healthcare practices will likely encourage the adoption of reprocessed devices, further propelling the market forward. Conclusion The medical device reprocessing market is set for substantial growth, driven by the need for cost-effective healthcare solutions, environmental sustainability, and stringent infection control measures. As healthcare systems worldwide strive to balance quality patient care with economic and environmental considerations, the role of medical device reprocessing becomes increasingly vital. Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK) Other Related Reports: Fertility Services Market Medical Power Supply Market Post Traumatic Stress Disorder Treatment Market MRI Guided Neurosurgical Ablation Market

#Medical Device Reprocessing Market#Medical Device Reprocessing Market Share#Medical Device Reprocessing Market Trends#Medical Device Reprocessing Market Size

0 notes

Text

Automated Endoscope Reprocessing Market: Trends and Growth Opportunities

Introduction

The automated endoscope reprocessing market has been experiencing significant growth in recent years, driven by increasing concerns about infection control, advancements in reprocessing technologies, and the rising number of endoscopic procedures worldwide. The market is expected to witness steady expansion as healthcare facilities prioritize efficiency, safety, and regulatory compliance in endoscope reprocessing.

Market Trends

1. Rising Demand for Infection Control Solutions

Hospital-acquired infections (HAIs) have become a critical issue, leading to stringent sterilization guidelines. Automated endoscope reprocessors (AERs) ensure thorough and standardized cleaning, minimizing contamination risks. The shift from manual to automated endoscope reprocessing is accelerating due to growing awareness and compliance requirements.

2. Technological Advancements in AERs

Manufacturers are integrating smart technologies, such as automated tracking systems and real-time monitoring, to enhance efficiency and traceability in endoscope reprocessing. Innovations in chemical disinfectants and high-level disinfection (HLD) techniques are further improving the reliability of reprocessing systems.

3. Stringent Regulatory Standards

Regulatory bodies, including the FDA and CDC, have established strict guidelines for reprocessing reusable medical devices. Compliance with these standards is fueling the adoption of automated endoscope reprocessors, as healthcare providers seek to meet safety and hygiene protocols.

Growth Opportunities

1. Expansion in Emerging Markets

Developing regions, such as Asia-Pacific and Latin America, present lucrative growth opportunities due to increasing healthcare infrastructure investments. The rising prevalence of gastrointestinal and respiratory diseases is boosting the demand for endoscopic procedures, further driving the need for efficient reprocessing solutions.

2. Adoption of Single-Use Endoscopes

While the focus remains on automated endoscope reprocessing, the industry is also witnessing a surge in single-use endoscopes to reduce cross-contamination risks. This shift could lead to hybrid market trends where both automated reprocessing and disposable options co-exist.

3. Integration of Artificial Intelligence (AI) and IoT

The incorporation of AI-powered monitoring systems and IoT-enabled devices in automated reprocessors is revolutionizing infection control. Predictive maintenance, data analytics, and cloud-based reporting systems enhance efficiency and reduce operational costs, making AERs more attractive to healthcare providers.

Conclusion

The automated endoscope reprocessing market is poised for substantial growth, fueled by stringent regulatory mandates, technological advancements, and the need for effective infection control solutions. Companies investing in innovation and expanding into emerging regions will likely gain a competitive edge in this evolving landscape. As healthcare systems continue to prioritize patient safety, the demand for efficient, automated reprocessing solutions will remain strong.

0 notes

Text

Ortho Phthalaldehyde Market Size, Share, and Competitive Landscape

Rising Demand for High-Efficiency Disinfectants Drives Growth in the Ortho Phthalaldehyde Market

The Ortho Phthalaldehyde Market size was valued at USD 5.83 billion in 2023. It is expected to grow to USD 9.25 billion by 2032 and grow at a CAGR of 5.26% over the forecast period of 2024-2032.

The Ortho Phthalaldehyde (OPA) Market is driven by increasing demand for high-performance disinfectants in healthcare, pharmaceuticals, and industrial applications. OPA is widely recognized for its superior antimicrobial properties, making it a preferred alternative to traditional disinfectants like glutaraldehyde. The rising need for effective sterilization solutions, coupled with stringent hygiene regulations in hospitals and medical facilities, is fueling the market expansion. Additionally, its applications in chemical synthesis and water treatment contribute to the growing global demand.

Key Players in the Market

The Ortho Phthalaldehyde market features a competitive landscape, with key industry players focusing on product innovation, regulatory compliance, and sustainability. Leading companies in the sector include:

AK Scientific Inc.

Alfa Aesar

MP Biomedicals

DPX Fine Chemicals

Virox

Thermo Fisher Scientific Inc.

Parchem Fine & Specialty Chemicals

TCI America

Merck Millipore Corporation

Sigma-Aldrich Co. LLC

These companies are investing in advanced formulations and expanding their production capacities to cater to the growing demand for OPA-based disinfectants.

Future Scope and Emerging Trends

The future of the Ortho Phthalaldehyde Market looks promising as healthcare facilities worldwide prioritize infection control and patient safety. The shift toward non-toxic and biodegradable disinfectants is driving research into environmentally friendly OPA formulations. Moreover, the rising adoption of automated disinfection systems in hospitals and laboratories is increasing the use of OPA-based solutions. Additionally, innovations in high-purity OPA for pharmaceutical and biotechnology applications are expanding its market potential. With growing concerns over hospital-acquired infections (HAIs), the demand for OPA in sterilization and medical device reprocessing is expected to surge.

Key Market Points:

✅ Rising Healthcare Demand: Increased usage of OPA-based disinfectants in medical facilities. ✅ Superior Antimicrobial Properties: Preferred over glutaraldehyde for sterilization due to enhanced safety and efficacy. ✅ Growth in Water Treatment Applications: Expanding use in industrial and municipal water treatment processes. ✅ Regulatory Compliance: Companies focusing on meeting stringent safety and environmental standards. ✅ Advancements in Chemical Research: Ongoing R&D to develop safer and more sustainable OPA formulations.

Conclusion

The Ortho Phthalaldehyde Market is set for continued growth, driven by increasing hygiene awareness, advancements in disinfection technologies, and expanding industrial applications. As industries and healthcare providers seek safer and more effective sterilization solutions, OPA is emerging as a key component in infection control. Companies investing in sustainable production methods and innovative applications will be well-positioned to capitalize on this growing market.

Read Full Report: https://www.snsinsider.com/reports/ortho-phthalaldehyde-market-3861

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Ortho Phthalaldehyde Market#Ortho Phthalaldehyde Market Size#Ortho Phthalaldehyde Market Share#Ortho Phthalaldehyde Market Report#Ortho Phthalaldehyde Market Forecast

0 notes

Text

Automated Endoscope Reprocessing Market Analysis: Growth Opportunities and Challenges in 2024 and Beyond

The automated endoscope reprocessing (AER) market is experiencing significant growth as healthcare institutions seek more efficient and effective methods for cleaning and disinfecting endoscopic equipment. With increasing concerns over infection control, technological advancements, and regulatory pressures, the market is poised to grow substantially in 2024. However, several challenges and constraints remain that could impact the pace of this growth.

Growth Drivers

Increased Demand for Endoscopic Procedures The rising number of minimally invasive surgeries, driven by an aging population and advancements in diagnostic techniques, has created an increased demand for endoscopes. Proper cleaning and disinfection of these instruments is pivotal in preventing healthcare-associated infections (HAIs), further driving the need for automated reprocessing systems.

Technological Advancements Innovation in AER technologies has made these systems more efficient, user-friendly, and capable of providing better outcomes regarding time-saving, quality control, and reducing human error. Smart features such as automated tracking, integrated reporting, and sterilization protocols are boosting the demand for these systems in hospitals and clinics worldwide.

Stringent Regulatory Guidelines As healthcare facilities face mounting pressure to adhere to infection control standards, regulatory bodies like the FDA and CDC have implemented stricter guidelines for the reprocessing of endoscopic equipment. Automated systems offer a more reliable and consistent way to comply with these regulations, further driving the market growth.

Focus on Patient Safety Patient safety remains a priority in healthcare settings, and automated endoscope reprocessing systems help minimize the risk of cross-contamination and infection transmission. This increased focus on infection control has made AER systems a vital component in healthcare institutions.

Challenges and Restraints

High Initial Investment Costs One of the primary barriers to the widespread adoption of automated endoscope reprocessing systems is the high upfront costs associated with purchasing and installing these machines. This can be a significant obstacle for smaller healthcare providers or facilities operating on tight budgets.

Technical Limitations Although advancements in AER technology are notable, certain technical limitations still persist. These include challenges related to the reprocessing of complex or delicate endoscopes and the need for ongoing maintenance and calibration to ensure the systems remain efficient and reliable.

Shortage of Skilled Workforce Despite the automation of reprocessing systems, skilled personnel are still required to operate and maintain these devices. The shortage of trained professionals in healthcare settings poses a challenge, particularly in regions with a limited workforce in the medical device field.

Regulatory Compliance and Standards Variability The lack of uniform global standards for automated endoscope reprocessing can create confusion and difficulties for manufacturers, healthcare providers, and end-users. Variability in regulatory requirements across different regions complicates market entry for some companies and may limit the growth of the market in certain areas.

Opportunities

Emerging Markets The market for automated endoscope reprocessing systems is expanding rapidly in emerging economies, particularly in Asia-Pacific and Latin America. These regions are experiencing growing healthcare infrastructure and an increasing demand for better infection control measures, presenting significant growth opportunities for AER manufacturers.

Integration with Hospital Information Systems (HIS) The integration of automated endoscope reprocessing systems with hospital information systems offers a tremendous opportunity for improving workflow efficiency, ensuring better data tracking, and providing a holistic approach to infection control and patient safety.

Sustainability and Eco-Friendly Innovations There is increasing demand for environmentally friendly products in the healthcare industry. Manufacturers are working towards developing automated reprocessing systems that use less water, energy, and chemicals, thereby promoting sustainability while still ensuring effective sterilization.

Post-Pandemic Surge in Healthcare Investment The COVID-19 pandemic has underscored the importance of infection control measures in healthcare. As a result, hospitals and healthcare institutions are expected to increase investment in automated reprocessing systems to improve patient safety and prevent the spread of infections.

Future Outlook

The future of the automated endoscope reprocessing market looks promising as the healthcare sector continues to prioritize patient safety and infection control. The growing emphasis on minimally invasive procedures, technological advancements, and stricter regulatory requirements will drive demand for AER systems. However, challenges such as high costs, workforce shortages, and regulatory variability must be addressed to fully realize the market's potential.

The market is expected to witness significant growth, with key players focusing on innovations to overcome existing barriers and capitalize on emerging opportunities. The integration of AI and machine learning into AER systems, as well as the continued expansion into emerging markets, will be key factors that shape the future landscape of the market.

Conclusion

The automated endoscope reprocessing market is poised for substantial growth in 2024 and beyond, driven by technological advancements, a focus on patient safety, and increasing regulatory pressures. While challenges such as cost, technical limitations, and workforce shortages persist, the market presents significant opportunities for growth and innovation. Manufacturers and healthcare providers must work together to overcome these barriers and unlock the full potential of automated reprocessing systems, paving the way for a safer and more efficient healthcare system.

Request Sample PDF Report: https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NjE2&RD=Automated-Endoscope-Reprocessing-Market-Report

#AutomatedEndoscopeReprocessingMarket#AutomatedEndoscopeReprocessingMarketGrowth#AutomatedEndoscopeReprocessingMarketInsights#AutomatedEndoscopeReprocessingMarketOpportunities#AutomatedEndoscopeReprocessingMarketAnalysis#AutomatedEndoscopeReprocessingMarketDynamics

0 notes

Text

What role does risk management play in ISO 13485 Certification in Kenya?

What is ISO 13485 Certification?

ISO 13485 certification in Kenya is a worldwide standard for quality-management structures in the therapeutic gadget business. It provides the essentials for businesses, including the developing, designing introduction, adjusting and dispersing restorative devices and services.

Certification confirms that your business:

Keeps the consistency of the item and quality

Meets the requirements of the administrative department.

Uses a security approach based on risk and performance

Why is ISO 13485 Certification Imperative in Kenya?

Kenya The Drug Store and Harms Board (PPB) controls restorative devices in Kenya. In compliance with ISO 13485 consultant in Kenya:

Encourages the enrollment of items and endorsement by the PPB

Validity upgrades in contract tenders as well as open segment agreements.

Underpins will send instructions to markets like the EU and the ISO 13485 consultant in Kenya

Shows its commitment to quiet security and item dependability

Reduces the risk of product reviews and non-compliance

Who Ought to Get ISO 13485 Certified in Kenya?

ISO 13485 is perfect for:

Medical device manufacturers

The importers and exporters who deal in equipment for therapeutic use

Wholesalers and distributors

Sterilization benefit providers

Companies are creating software for the use of restorative technology.

Health offices are part of the item Reprocessing.

Steps to Get ISO 13485 Certification in Kenya

1. Hole Analysis

Find any gaps between your frameworks currently in use and ISO 13485 requirements.

2. Documentation

Create required documents such as a quality guide, chance management record, and strategies.

3. Framework Implementation

Implement the standards’ requirements for operations, starting from acquisition up to the generation stage and distribution.

4. Inner Audit

Conduct internal reviews to determine the framework’s suitability and to ensure compliance.

5. Administration Review

Senior management assesses the results of reviews and validates preparation for external certification.

6. Certification Audit

A certified certification body performs a two-stage audit to ensure the certification complies.

7. Certification Issuance

After a successful test, Your company will be granted ISO 13485 consultant services in Kenya certification, which is typically large for 3 years.

Documents Required for ISO 13485 Certification

Quality method and manual

Risk administration procedures

Plan of product development and advanced files

Traceability records, as well as item labeling

Complaint handling, as well as an input system

Control and assessment of suppliers’ records

Internal Review and Remediation Activity ISO 13485 consultant services in Kenya Reports

Cost of ISO 13485 Certification in Kenya

The shiftings that are fetched are based on these factors:

Company size

Numerous facilities and products

Operation complexity

Certification body chosen

On average, ISO 13485 certification in Kenya costs between KES 200,000 to KES 800,000, which includes discussions, documentation, preparation, and audit.

Benefits of ISO 13485 Certification in Kenya

Made strides in quiet security and also changed control

Supply chain management upgraded

The showcase is available to all consumers and regulators.

Better documentation and transparency

Increased competitiveness in the private and public healthcare sectors

ISO 13485 and Kenyan Administrative Compliance

Affiliating your QMS to ISO 13485 auditor in Kenya makes a difference in ensuring that your QMS complies with local laws. By:

Pharmacy and Harms Board (PPB)

Kenya Bureau of Guidelines (KEBS)

Ministry of Wellbeing (MOH)

It will also prepare your store to be eligible for CE Checking (EU) or FDA endorsement (USA), which often requires ISO 13485 auditor in Kenya compliance.

Why Factocert for ISO 13485 Certification in Kenya?

We provide the best ISO Consultants in Kenya who are knowledgeable and provide the best solutions. Kindly contact us at [email protected]. ISO Certification consultants in Kenya and ISO auditors in Kenya work according to ISO standards and help organizations implement ISO Certification with proper documentation.

For more information, visit ISO 13485 certification in Kenya

0 notes