#Metal Core PCB

Explore tagged Tumblr posts

Text

High-Quality Metal Core PCB Solutions – Bestpcbs

Bestpcbs offers reliable Metal Core PCB manufacturing for superior thermal performance and durability. Ideal for high-power applications like LED lighting and automotive electronics, our PCBs ensure efficient heat dissipation and long-lasting functionality. With precise engineering, competitive pricing, and fast turnaround, Bestpcbs is your trusted partner for metal core PCB solutions that deliver performance and reliability every time.

0 notes

Text

A metal core PCB is a category of PCB that has a metal substrate. Metal Core PCB (MCPCB) can also come in different configurations such as single-layer, double-layer and multi-layer MCPCB.

0 notes

Text

Your Partner for Metal Core PCB Excellence

American Standard Circuits is your go-to metal core PCB supplier, offering expertly crafted metal backed PCBs and advanced PCB metal core technology. Contact us today to learn more about our tailored solutions!

0 notes

Text

Copper core PCB is a copper substrate + Insulated layer + copper

Copper core PCB is a copper substrate + Insulated layer + copper circuits layer PCB,also, it is called copper substrate pcb, copper based pcb,copper clad pcb.

A copper base PCB is a metal core PCB with a copper substrate. If a hybrid PCB whose substrate is a copper plate inlay in the FR4 board, it is also a copper base PCB.

Usually, copper-base PCBs have the same structure as aluminum PCBs - single-layer, double-layer with single component-mounting side, double-layer with dual component-mounting sides, and four-layer with dual component-mounting sides. Even they use the same prepreg material to insulate the copper layers. However, the copper substrate (398W/mK) has better thermal conductivity than the aluminum substrate (237W/mK).

#pcb#pcba#pcb manufacturer#aluminium pcb#ceramic pcb#pcb assembly#heavy copper pcb#mpcb#Metal core pcb#Copper core PCB#fpcb

0 notes

Text

Copper core PCB is a copper substrate + Insulated layer + copper circuits layer PCB,also, it is called copper substrate pcb, copper based pcb, copper clad pcb. https://www.htmpcb.com/metal-core-pcb-c-10.html

PCB PCB Manufacturer PCB Manufacturing Electronics

0 notes

Text

Explore the Applications of Ceramic Substrate PCBs in Electronics

Searching for high-quality Ceramic Substrate PCBs? Look no further than Hitech Circuits Co. Limited! Our advanced ceramic PCBs offer superior thermal conductivity and reliability for your electronic projects. With precise manufacturing and cutting-edge technology, we deliver top-notch ceramic substrates tailored to your specifications. Trust us for durable, efficient PCB solutions that meet your needs. Elevate your electronics with Ceramic PCBs from Hitech Circuits Co. Limited – your trusted partner for innovation and excellence.

1 note

·

View note

Text

It is called "2 Layers Aluminum Core PCB with White solder mask",if you just engage in or somehow need this product,welcome contact me to know more details

#2 Layers Aluminum Core#PCB with White solder mask#2 Layers with White solder mask#Aluminum Core with White solder mask#Aluminum Core PCB#metal core pcb

0 notes

Text

J-Cube Technologies Inc.

J-Cube Technologies Inc. is an organization that specializes in the production of printed circuit boards (PCBs).

Our company is based in Montreal, Canada, and has been active in the industry for over a decade. Through our success in Asian infrastructure development and the expansion of our engineering and technical manufacturing expertise, we have grown to be a world-class provider of comprehensive and reliable electronic solutions.

#jcubetech#jcubetechca#J-Cube Technologies Inc#metal pcb#metal core pcb manufacturer#metal core printed circuit board#aluminum core pcb#mcpcb#LED MPCB#Ceramic PCB#mcpcb manufacturer#Quick turn mpcb#pcb core#Printed Circuit Board#Analog circuit#Bare board#Blind via#Component#Dip Trace#Schematic Capture#Library Pane#Schematic Pane

2 notes

·

View notes

Text

Learn the Traits to Find the Best Mcpcb Manufacturer for Your Needs

Metal-core printed circuit boards are one of the most significant spare parts you need to operate and control electronic goods. The quality of this spare will affect the functioning of the entire device. Hence, the manufacturers and the suppliers of the product are some of the elemental stakeholders for electronic device-producing brands. Naturally, due to massive demand, you can find several makers and suppliers in the industry. In this article, we will discuss the traits to discern the best.

Years of experience

The first aspect which you must find out to work with the best mcpcb manufacturer is the number of years for which the company has been operational in the market. You must look for a brand which has been in the market for a minimum of one and a half decades.

Service Array

Services from the top manufacturers and suppliers can help patrons get the best value for their investment. Some of the vital services you can get from the market leaders is mcpcb assembly, mass production, product prototype and innovative designing. These brands are masters in customization and they can change and adapt their products as per the precise customer requirements.

Product Array

Apart from service variety these brands can also act as some of the best single window service providers for different products like single layer metal core pcb, double sided metal core pcb, two layer aluminum base pcb and multilayer aluminum base pcb. Hence irrespective of your requirement specifications you can turn to a single vendor to meet all your business needs.

Quality control certificate

Finally, before you select a vendor for your business one of the main things which you must check is quality assurance certifications for the products from the vendor. This is one of the parameters that give you assurance for the product quality into which you are investing and also for their internal procedures and organization culture. These are the vendors who can add much value to your business.

0 notes

Text

February 26 - March 1 2025 2010

A mother will do whatever is best for her children.

Now I dont like questioning the disembodied voices but...

The path through the mausoleum leads to a different part of the island where a dock can be found. Mom apparently rather than being forced away from Rose chose to leave of her own accord leaving only her martini glass behind.

WV is building a better Can Town, Exile Town, where '[a]ll expatriates are welcome, no matter what happened in the past, regardless of professional persuasion or metallurgical affiliation.' While this just at face value means the 'jobs' of each metal item, ie. can, mailbox, ammo, and type of metal, its really easy to think this is the future WV envisions for him and the others. Perhaps in this timeline, on this planet, he will do the same as Slick and make his own Town reality. AR is none too impressed, especially as this is WV's attempt at wooing PM, and yet, right outside of Exile Town hes got a militia started.

[A]ny town without a proper militia is as good as conquered.

As such he prepares one begrudgingly.

Sure~ Whatever you say AR. WV has his own moment of reflection admiring the sky 'oh my god a huge eggy looking thing just appeared in the sky.'

This is Daves fault. No really! we go back to Dave and Jade who have done most everything else to get the 'punch card eggy loking thign' which is immediately taken by the sprite crow to its 'nest made of shitty swords and soft puppet ass'. Obviously this makes Dave irate and he jokes about putting the egg in the microwave to hatch it which prompts Jade to dump his microwave off the skyscraper.

Not sure exploding the egg is what SBURB wants Dave.

We get to learn more about the differences in player entry and some new machines. Each time a player enters the amount of build grist is muliplied by 10. So John started with 20, Rose had 200 and Dave has 2,000. It seems like the later you enter the easier time you have building (and moving things, remember when 100 Grist was an insane amount to move the cruxtruder?). We can also see some new grist types have been unlocked from the get go though without enemies you cant really use them.

Then boy oh boy do I get to talk about computers again. Since Dave does not have any shale at his disposal hes kinda SOL on using the Punch Designix. This is terrible because we cant see what the JUMPER BLOCK EXTENSION and PUNCH CARD SHUNT actually do with the ALCHEMITER. However we can speculate.

So a Jumper is commonly used on Printed Circuit Boards (PCB) to create connections that modify circuit connections either for fixing electric connections or adapting a PCB for specific requirements. A Jumper Block is used to configure connections for different PCB options consisting of mulitple pins or sockets bridged by shunts to establish those connections. Shunts are used when you want to selectively make or break these connections easily, manually or automatically. Its noted that a card must be punched to affect the flow of current when insterted to the PUNCH CARD SHUNT. Given all this, it seems like this is an upgrade to alchemizing that can affect the core of the system and perhaps more easily automate the creation of new objects.

This is all well and good but that doesnt change the fact Dave does not have a way to punch said cards. So, all that done, Dave goes to install the mystery disk, which in any other circumstance I wouldnt do so casually. While doing so we get to see Rose fighting white Imps with more feline features on LOLAR and that Dave has 3 hours and 41 minutes to destruction.

The disk turns out to be gristTorrent, which is a version of BitTorrent, to leech some of Johns shale and build grist. Now Ive never used BitTorrent myself, though I have heard of it. It uses peer-to-peer (P2P) protocol to distribute data and files over the internet. Its mostly used for very large files and is faster than standard file downloads in this case. The 'seed', in this case John, hosts and sends the initial file while 'peers', in this case Dave, connect and download the file in parts and then in turn can become seeds for others. Dave initially has a decent download rate of 4 g/s (grist per second) that dips once he starts also leeching Build grist. This is because he is the only connection, as one of the downsides is time it takes to reach full download speed without enough peer connections to offset internet bandwith cost.

This concludes Sam's TEDtalk.

In all honesty, Ive tried to make as much of this as consumable as possible and I hope it helps anyone who is lost on the tech side of things. (im gonna need a tag of this too huh)

#homestuck#homestuck replay#hsrp liveblog#hsrp theories#TC's tech TEDtalks#<- there we go new tag. with bonus alliteration!#chrono

15 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

Top Reasons to Use Metal Core PCBs in High-Power Electronics

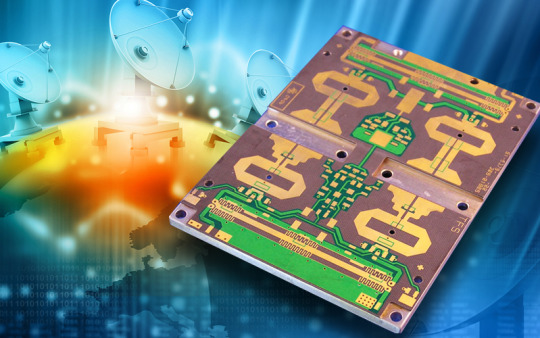

When it comes to high-power electronics, metal core PCBs (Printed Circuit Boards) offer an unmatched solution for efficient heat management and enhanced durability. Designed with a metal substrate, typically aluminum or copper, metal core PCBs outperform standard boards by effectively dissipating heat, which is crucial for maintaining the longevity and performance of high-power devices. Here’s why metal core PCBs are a top choice for high-power electronics and the benefits they bring to demanding applications.

1. Superior Thermal Management

One of the main reasons metal core PCBs are essential in high-power electronics is their superior thermal conductivity. Unlike traditional PCBs, which may struggle with heat buildup, metal core PCBs are designed to pull heat away from heat-generating components, reducing the risk of damage. This makes them ideal for applications like LED lighting, power supplies, and automotive electronics, where components are subjected to high temperatures.

2. Enhanced Durability and Stability

The metal layer in metal core PCBs provides additional strength and stability, making them more robust than standard PCBs. This added durability allows the board to withstand mechanical stress, vibrations, and thermal cycling. For high-power electronics, where devices may be exposed to extreme conditions, this durability ensures reliable performance over time.

3. Improved Efficiency for High-Power Applications

High-power electronics need to operate at optimal efficiency, and metal core PCBs play a critical role in achieving this. By effectively managing heat, metal core PCBs allow components to operate within their safe temperature range, reducing power loss and boosting efficiency. This is especially beneficial for applications like RF amplifiers and motor drives, where consistent power delivery is crucial.

4. Compact and Lightweight Designs

Despite their strength, metal core PCBs can be manufactured in compact, lightweight designs, making them ideal for modern electronic devices. The metal core allows for thinner boards without compromising thermal management capabilities, which is advantageous in applications where space is limited.

Discover High-Quality Metal Core PCBs

For high-performance metal core PCBs designed to meet the demands of high-power electronics, explore American Standard Circuits. Their RF metal-backed PCB solutions offer the reliability and efficiency required in demanding applications, from LED lighting to power electronics, ensuring your devices run cooler and last longer. Choose American Standard Circuits to experience the full benefits of advanced metal core PCB technology.

0 notes

Text

PCB Manufacturers in India: Powering the Future of Electronics

India is steadily emerging as a key global player in the electronics industry, with Printed Circuit Board (PCB) manufacturing at its core. PCBs form the essential backbone of every electronic device, from smartphones and laptops to advanced defense systems and electric vehicles.

As the electronics sector in India continues to thrive, PCB manufacturers in India are expanding their capabilities, delivering high-quality, cost-effective solutions to meet both domestic and global demands. This article explores India’s PCB manufacturing ecosystem and highlights some of the leading companies driving this growth.

Why PCB Manufacturers in India Are in High Demand

The growth of PCB manufacturing company in India is driven by several significant factors:

Government Initiatives

Government programs such as Make in India and the Production Linked Incentive (PLI) Scheme have provided a major boost to the electronics manufacturing sector, encouraging domestic PCB production and reducing dependency on imports.

Rising Electronics Consumption

The increasing use of electronics in industries such as automotive, telecom, defense, consumer appliances, and renewable energy has created a surging demand for quality PCB fabrication.

Competitive Advantage

Indian PCB manufacturers combine cost-effectiveness, skilled engineering, and adherence to international quality standards, making them competitive not just in India but also in international markets.

Export Capabilities

Many Indian PCB companies now actively export to global markets, particularly in Europe, the United States, and Southeast Asia, expanding India’s presence in the international supply chain.

Leading PCB Manufacturers in India

Below is a curated list of some of the top PCB manufacturers in India, known for their expertise, innovation, and commitment to quality:

AT&S India Pvt. Ltd.

Location: Nanjangud, Karnataka AT&S India, a subsidiary of Austria-based AT&S Group, specializes in advanced high-density interconnect (HDI) and multilayer PCBs, catering to automotive, industrial, and medical device industries.

Shogini Technoarts Pvt. Ltd.

Location: Pune, Maharashtra With over four decades of experience, Shogini Technoarts focuses on single-sided and double-sided PCBs, supplying sectors like automotive, telecom, and lighting.

Genus Electrotech Ltd.

Location: Gandhidham, Gujarat Genus Electrotech is a leading fully integrated electronics manufacturer producing PCBs alongside complete electronics assemblies, widely used in energy meters, LED lighting, and automotive electronics.

Circuit Systems India Ltd. (CSIL)

Location: Gandhinagar, Gujarat CSIL manufactures multilayer PCBs for industries such as telecommunications, aerospace, automotive, and consumer electronics, known for precision and high reliability.

Anand Electronics

Location: Bengaluru, Karnataka Anand Electronics produces single, double, and multilayer PCBs, catering to customers in automation, LED lighting, power electronics, and industrial systems.

Meena Circuits Pvt. Ltd.

Location: Gandhinagar, Gujarat Meena Circuits specializes in multilayer PCBs and metal core PCBs (MCPCBs), supporting power electronics, automotive components, and LED applications.

Hi-Q Electronics Pvt. Ltd.

Location: Mumbai, Maharashtra Hi-Q Electronics offers customized PCB solutions, including flexible and rigid-flex PCBs, for sectors such as aerospace, defense, medical devices, and industrial machinery.

Epitome Components Ltd.

Location: Aurangabad, Maharashtra One of India’s largest producers of single-sided PCBs, Epitome Components supplies to major OEMs in the consumer electronics and lighting sectors both domestically and internationally.

Fine-Line Circuits Ltd.

Location: Mumbai, Maharashtra Fine-Line specializes in prototype and production PCBs, especially multilayer rigid PCBs, for demanding applications in defense, aerospace, and telecommunications.

SFO Technologies (NeST Group)

Location: Kochi, Kerala Part of the global NeST Group, SFO Technologies provides advanced PCB fabrication services, serving high-end industries such as aerospace, defense, medical, and industrial electronics worldwide.

Benefits of Choosing PCB Manufacturers in India

Selecting PCB manufacturers in India offers businesses several clear advantages:

International Certifications: Most Indian manufacturers are certified with ISO, UL, IPC, and RoHS standards.

Wide Range of Capabilities: From single-sided to multilayer, flexible, and HDI PCBs.

Engineering Support: Many manufacturers provide design support, prototyping, and customization.

Global Reach: Indian manufacturers export to several developed markets, showcasing reliability and trustworthiness.

The Road Ahead for PCB Manufacturing in India

As India continues to strengthen its electronics manufacturing ecosystem, the PCB industry will play a vital role in achieving self-reliance and reducing imports of critical components. With investments in automation, advanced machinery, and sustainable manufacturing practices, Indian PCB manufacturers are well-positioned to meet global demand.

Conclusion: Partner with the Best PCB Manufacturers in India

Whether you are designing innovative IoT solutions, building critical EV systems, or developing specialized equipment for aerospace or defense, India’s PCB manufacturers can provide world-class solutions tailored to your needs.

If you’re searching for reliable and experienced PCB manufacturing partners, explore the top suppliers on FindingMFG. Connect with trusted PCB fabrication companies and accelerate your product development journey.

Visit FindingMFG.com today to discover the leading PCB manufacturers in India for your next project

0 notes

Text

Copper core PCB is a copper substrate + Insulated layer + copper circuits layer PCB,also, it is called copper substrate pcb, copper based pcb, copper clad pcb. For more information, you can visit our website https://www.htmpcb.com/metal-core-pcb-c-10.html

0 notes

Text

Maximize Performance with Ceramic PCB Technology

Experience the unmatched reliability and performance with Hitech Circuits Co. Limited's Ceramic PCB solutions. With over 10 years of experience designing and fabricating ceramic substrates, we are an industry-leading supplier in China committed to quality, service, and technical expertise. Our meticulously crafted Ceramic PCBs are extremely versatile and can replace a complete traditional PCB with a less complex design and enhanced performance. Designed with expertise, our Ceramic PCBs offer exceptional thermal conductivity and electrical insulation, making them ideal for demanding applications. Hitech Circuits Co. Limited also offers Ceramic Substrate PCB for your printed circuit board’s needs. For more details about Ceramic PCBs, contact us today!

1 note

·

View note