#Methods for Manufacturing of Steel

Explore tagged Tumblr posts

Text

Understanding Under Casting Manufacturers

Under casting manufacturers play a vital role in the metal industry, producing high-quality metal components for various industrial applications. These manufacturers specialize in different casting methods to ensure precision, strength, and durability. The process of under casting involves creating intricate metal parts using specialized techniques that enhance the quality and performance of the final product.

Metal Casting Methods

Metal casting is a fundamental manufacturing process that involves pouring molten metal into a mold to create desired shapes. Different casting methods are used depending on the material, application, and complexity of the components. Some of the most common metal casting methods include:

1. Sand Casting

One of the oldest and most versatile casting methods, sand casting involves creating a mold using sand. This method is cost-effective and suitable for producing large and heavy components. It is widely used in the automotive, aerospace, and construction industries.

2. Investment Casting

Also known as lost-wax casting, investment casting produces highly detailed and precise metal parts. It is ideal for creating complex shapes with smooth surfaces, making it popular in industries like aerospace, medical, and jewelry manufacturing.

3. Die Casting

Die casting uses high-pressure techniques to force molten metal into a steel mold. This method is perfect for mass production, as it ensures uniformity, high strength, and excellent surface finish. Common applications include automotive parts, appliances, and electronic components.

4. Gravity Casting

Gravity casting relies on the force of gravity to fill the mold with molten metal. It is often used for producing non-ferrous metal parts, such as aluminum and brass components, for industrial machinery and automotive applications.

Steel Casting and Its Importance

Steel casting is a specialized process used to manufacture steel components with superior mechanical properties. It offers excellent strength, durability, and resistance to wear and tear. Steel casting is widely used in industries such as construction, mining, transportation, and energy.

Common applications of steel casting include:

Engine and machinery components

Railway and automotive parts

Valves and pump casings

Structural and industrial equipment

Conclusion

Under casting manufacturers play a crucial role in the metal industry by producing high-quality components through advanced metal casting methods. Steel casting, in particular, is essential for manufacturing durable and reliable industrial parts, ensuring efficiency and performance in various sectors.

0 notes

Text

Instead of burning fossil fuels to reach the temperatures needed to smelt steel and cook cement, scientists in Switzerland want to use heat from the sun. The proof-of-concept study uses synthetic quartz to trap solar energy at temperatures over 1,000°C (1,832°F), demonstrating the method’s potential role in providing clean energy for carbon-intensive industries. A paper on the research was published on May 15 in the journal Device.[...]

Glass, steel, cement, and ceramics are at the very heart of modern civilization, essential for building everything from car engines to skyscrapers. However, manufacturing these materials demands temperatures over 1,000°C and relies heavily on burning fossil fuels for heat. These industries account for about 25% of global energy consumption. Researchers have explored a clean-energy alternative using solar receivers, which concentrate and build heat with thousands of sun-tracking mirrors. However, this technology has difficulties transferring solar energy efficiently above 1,000°C.

To boost the efficiency of solar receivers, Casati turned to semitransparent materials such as quartz, which can trap sunlight—a phenomenon called the thermal-trap effect. The team crafted a thermal-trapping device by attaching a synthetic quartz rod to an opaque silicon disk as an energy absorber. When they exposed the device to an energy flux equivalent to the light coming from 136 suns, the absorber plate reached 1,050°C (1,922°F), whereas the other end of the quartz rod remained at 600°C (1,112°F).

“Previous research has only managed to demonstrate the thermal-trap effect up to 170°C (338°F),” says Casati. “Our research showed that solar thermal trapping works not just at low temperatures, but well above 1,000°C. This is crucial to show its potential for real-world industrial applications.”

Using a heat transfer model, the team also simulated the quartz’s thermal-trapping efficiency under different conditions. The model showed that thermal trapping achieves the target temperature at lower concentrations with the same performance, or at higher thermal efficiency for equal concentration. For example, a state-of-the-art (unshielded) receiver has an efficiency of 40% at 1,200°C, with a concentration of 500 suns. The receiver shielded with 300 mm of quartz achieves 70% efficiency at the same temperature and concentration. The unshielded receiver requires at least 1,000 suns of concentration for comparable performance.

17 May 24

1K notes

·

View notes

Text

So I've already seen this one pointed out, but in the new CG, Boothill's older human form doesn't really match what people thought it should. Of course it could just be neglect on Hoyo's part like I've seen speculated, but personally? With the other lore we got from this patch, combined with some of the stuff we already had, I'd love to think there is a possibility that is way, WAY more fun.

(fun for me and all the other whump enjoyers, anyway, RIP Boothill fjkasjkdj)

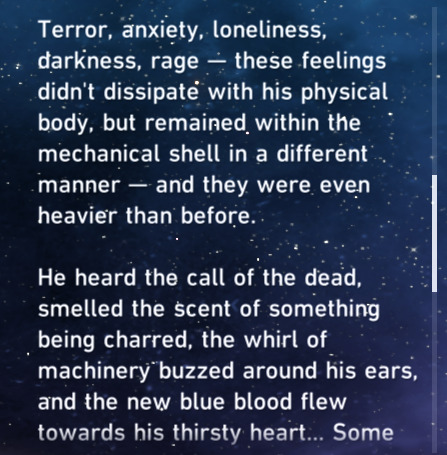

In Boothill's lc, we see him in the middle of his surgery where he threw away his flesh and bone body for steel and cybernetics. We know it was The Big Surgery and not just like some sort of tune up or modification because of the description attached to the lc:

Which is where a lot of the dissonance comes in, because in this lc, Boothill's hair is much, much longer than in the cg.

And as someone who also has super long hair, I can tell you that it would take like. Multiple years to grow it out to this length.

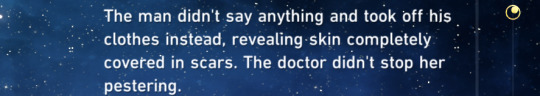

There's also the fact that these cybernetic arms don't even match, the lc is the one that looks like our Boothill does now. And there's no reason for Boothill's shirt to be ripped up and in tatters like that; it even states he takes off his clothes before the lc surgery. If it were a matter of Hoyo needing to censor nudity, there were plenty of other methods they could have used that would make more sense, like a hospital gown, a blanket, surgical partition, etc

When will I get to see Boothill with all his scars, Hoyo, when, quit cockblocking me!!! OTL

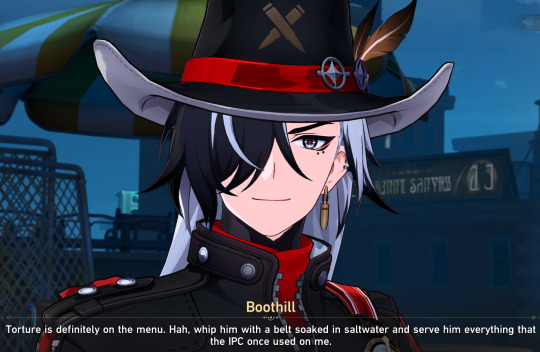

But there was also another piece of new lore this patch that hit me like a fuckin' brick- the fact that Boothill was tortured by the IPC.

He just drops this out of nowhere! Just says it and then moves right along!! BABY, PLEASE. I WANNA KNOW MORE SO GODDAMN BAD.

But anyway as Hydrachea pointed out to me, this means the torture definitely had to happen before the lc surgery, because being whipped with a belt soaked in saltwater (fucking OUCH) wouldn't work on someone with metal skin.

So, we know that the IPC did, at some point, capture Boothill. And this is reaching further back to previous patches, but we also know from the Luminary Wardance event in 2.5 that the IPC also dabbles in cybernetic arms, because of the one they foisted on Luka.

The model there is a new one they're debuting, but we see in a flashback sequence that the IPC has been part of the cybernetics game for at least 700-800 years, because they also manipulated Igor into getting one too, and this could have only happened before the Eternal Freeze on Jarilo-VI.

It's never stated just how old Boothill is, or how long ago the genocide on Aeragan-Epharshel took place.

But I doubt it was more than 700-800 years ago.

I really don't think Boothill is that old, or has been doing this for that long. So he definitely would have been captured at a point that the IPC was manufacturing cybernetic arms, and had a known history of amputating perfectly healthy patients to use them.

I wonder if all their test subjects were willing.

(This part is entirely unnecessary for the new cg showing Boothill being a forced lab rat as part of the IPC torturing him. But it is a fun, delightful, bloodily gruesome twist of the knife nonetheless.

Boothill was also betrayed by his own brothers-in-arms on Aeragan-Epharshel. For the IPC. Just saying.)

#honkai star rail#honkai star rail boothill#hsr boothill#hsr#boothill#hsr 2.6#honkai star rail 2.6#no idea if this is anything but god do I love to think about it#Boothill just casually dropping that he was TORTURED just about fucking killed me AAAAAAAAAAAAAAA#screaming crying throwing up blowing up etc etc#KERBLEWIE#Ugh I love it so much#Hoyo did that for ME#And the thought that it might have been his own tribe that sold him out? ough. ough.#and so like. when he escaped the IPC somehow. do you think the cybernetic arm was still attached?#did he have to lug this thing around#did he hate looking at it#imagining him telling the doctor he doesn't even care just take it detach it get it off of him he never wants to see it again#AUGH

129 notes

·

View notes

Text

Retconned Wardi firearms- a basic handgun, a highly decorative ceremonial handgun (belonging to Faiza), and a lance-gun.

Gun tech has officially been nerfed down to hand cannons (press F) (this has been a long time coming but I'd been fallacy of sunk costs-ing myself out of retconning).

Handguns are held similarly to a shotgun, with the butt pressed into the user's shoulder, one hand gripping under the barrel, and the other free to ignite the gunpowder. These represent the most advanced firearms in contemporary usage, both in make and in their use of uniform iron projectiles built to match the gun's bore for greater range and efficiency. Lance-guns are the more basal form, usually larger and mounted with the pole held over the shoulder, and are most effectively used by two people (one to hold and aim, one to light the gunpowder).

The spread of firearms is currently mostly limited to the Eastern Inner Seaway peoples (with some additional distribution via overland trade), and actual manufacture of hand cannons and gunpowder at Significant scale is limited to the region's core powers.

The reason for this limited spread is partially due to specific elements of the technology's history. Gunpowder was first synthesized by Burri alchemists and considered to be the discovery of the legendary divine weapon + solar fire of the deity Inanariya, and its formula (along with techniques for ideally refining its components) remained a closely guarded state secret. It was used predominantly in priestly contexts to generate flame and explosive sounds (in conjunction with earlier practices of generating multicolored flames with use of other chemicals), then integrated into combustible weaponry in the forms of fire lances, which would eventually develop into early handcannons.

The treatment of gunpowder as a guarded sacred or semi-sacred substance continued with Wardi adoption, where knowledge of its making is considered a closed rite. It's name (inya tsatsul or just tsatsul, a derived adoption of the Burri iñazatsūya) still reflects a divine solar association (the Burri word means 'sun's thunder', the Wardi 'inya' invokes the sun, 'tsatsul' is an adapted loanword and has no meaning independent of the substance itself), though its priestly use is now predominantly associated with the firearm'ed Odonii (rather than priests of the solar Face Inyamache). The composition of gunpowder can no longer be regarded as a Secret by any means, though efforts to obscure the methods of its creation are still moderately successful and has kept knowledge of gunpowder manufacture more limited than the total sphere of firearm usage itself.

The actual strongest limiting factor of firearm usage is the rarity of natural saltpeter deposits necessary for making gunpowder. The practice of actively producing saltpeter via nitraries has not been developed anywhere in the setting, and all is instead obtained via natural sources. These sources are rare and limited within the current spread of firearm technology, and result in gunpowder being a limited and expensive substance to produce. The weapons themselves are also very expensive to manufacture (a good quality steel SWORD is far too material-cost prohibitive for most people to own), particularly high quality firearms designed for use with standardized ammunition.

These guns are also very basal, and logistical difficulties in their use (weight, very slow loading and firing speed, high visibility, Relatively low reach and accuracy) along with the restrictive cost of production has kept firearms far from rendering conventional weaponry, armor, and projectiles obsolete (even within the societies that have access to them). They are still, however, very devastating in use within their contemporary context, particularly in that high quality guns have a longer range than the best arrow-based projectiles, and utterly negate most contemporary forms of armor at close range.

#I'd consider the setting to be like.....most closely analogous to like 3rd-1st century BCE earth (in terms of the average scale of#societies + Most of its technology (aside from major exceptions like this) + trade interconnectivity)#There are VERY few Very Big states capable of mass-manufacturing and resource extraction (like nothing the size of#the Roman empire has Ever existed in this setting. The biggest empires aren't even close. Cynozepal has a pretty massive territorial#span so is probably the closest thing but its actual control is highly fragmented along disconnected central hubs)#There's significant seaway trade connections but the Vast majority of transmission of goods is localized (even moreso over land)#So point being firearms have developed '''''earlier''''''' than in IRL history but the conditions that enabled very rapid spread are#not really present (though it's fairly inevitable that they'll become widespread over the next few centuries)#Also the likely trajectory of adaptation is going to be the development of Plate armor (which could absorb/block shots#from some types of firearms More advanced than these).#The types of armor used in this particular region is mostly lamellar/scale/padded fabric/leather and rarely involves#full body protection (using a shield to compensate) so developing thicker and fully protective armor would be the next logical#step in the arms race#I think it would be a fun constructed history for armor technology to outpace these simple firearms enough that they end up largely#abandoned in favor of re-specializing in close combat but I don't really care to plan out the far future that much

80 notes

·

View notes

Text

THE ASTOR COVEN, LONDON, ENGLAND. Minor Coven.

Depending on which Astor is asked, the story is different. But a grandmother’s tale is the most accurate. Less embroiled with details, more savage in its executions.

There was a Midas, once. He was a king. It’s a Greek myth well known about greed and humility and it’s rooted in Europe, in ancient Phrygia. From there, it’s been tarnished with adventure to better suit its audience. The ending’s different.

When Midas washed his hands in the river Pactolus. He lost his magic. The daughter he’d turned to gold returned to him with new eyes; gold flecked. Dionysus did not warn Midas of the aftereffects of a magic that runs this deep. When he touched Marigold again in a warm embrace. She turned the tables on him.

King Midas, the man with the golden touch. A golden legacy.

Sometime between 650-700BC, Marigold had two children. They inherit Dionysus’ gift. And her story is carved into Midas’ golden statue. He is displayed beside the throne, watching over the legacy he began. The lineage continues, and Midas gets history’s credits. He is the humbled King, blessed by a God, made mortal by his own greed. Marigold had vanished some centuries ago, though some called her Zoe. Immortality was not part of her dangerous touch; she left behind the power in sons and daughters, who passed the power to the next generation. Scholars, Mythics, New Kings, The Age of Gods. Healers, Clerics, Inventors. Magic breeds attention. And, the Gods lose the faith of the people. The church shuns them. Named abominations from a woman out of wedlock. There is the Age of Gold. Where alchemy, blood and magic begin to blend. More powerful machines of iron and steel are when the God-Kings and Queens are hunted for their magic. There is no faith in false idols. And the river Pactolus is used as a weapon to weaken the tight-knit young Gods. Those who survive, flee to the rest of Europe, spread amongst the common folk, there are only a handful that live past thirty. 1746, Leila Pavett, a potioneer ahead of her time marries Matthew Astor, the son of a God. They form the Astor Coven, in old London, operating a store selling wares and cure-all’s. They moonlight as alchemists, attempting rituals that test the boundaries of both science and magic. 1770, Leila is killed in an alchemical accident. She leaves Matthew and their young son behind. Matthew begins to delve into the possibility of endless life, obsessed with the concept of manufacturing a new version of immortality by using alchemy and the power of the Gods. 1810, The Astor Coven is expanded and Matthew’s son, Kyro continues his parent’s work, but he focuses on the wealth that comes from what he is. Kyro Astor begins to found what would eventually become Astorgold Enterprise Ltd.

The passage of time is a ruthless constant. It is unforgiving. It does not wait for any God, or man, not even an Astor. It is why there is a darkness rooted deep within the bloodline. Something beyond Dionysus, and Midas. It is not godlike or mythical. It is human. Monstrously human. Mortality is a curse they cannot purchase, barter with or run from. No Astor lives beyond one lifetime and often, they die early; reaped by their own, or hunted by the desperate and the envious.

It has been Levinon Astor’s entire obsession. A man descended from a God, from a King. Who forged an Empire, united a coven in one of the most magically underbellied cities in the world and developed the modernisms that the Astor’s still live by, now. But an Astor always wants more.

Nobody ever gets to the top, because those beneath him were kind enough to let him bypass freely.

A grandmother passes, and so does a grandfather. It is the way of life. There is a method to an Astor birth, just as there is one for their death. Like any coven, there are rules and rituals; there is a method to the madness, per se. A coven bleeding gold, can afford to be elitist about their circle.

When an Astor is born, they are deemed Gods.

When an Astor dies, they are considered Reaped.

THEY KNOW THEIR WEIGHT.

At the age of twelve, an Astor knows their role in the coven. They know their bloodline and what they are expected to be. Descended from inventors and mythics, they are children of deities that stand tall above all else. They know the power of Rivers. They know the Nile, Isis, Pactolus, Yangtze, Amazon — they understand the cost of Godhood and the mortality of their existence. There is no mistaking an Astor's power, but there is no doubting the River Gods and theirs. On this birthday, they stand among their elders, in the Altın Çember (Circle of Gold) and are bled. A God can be humbled, and that is always the first lesson.

The ribs are seen as the core of the body; a symbolism between an Alchemist and its exploration of the soul, in a scientific manner. It is the seat of magic within oneself. A vessel that can be cracked. An Astor knows this from childhood, as they are sliced open beneath the twelfth rib.

They must know how to heal a God before they are to live as one.

If an Astor is reaped in this ceremony, then they never deserved to be a God. Those who survive and are able to wield their magic to save themselves are left with a golden scar that follows the path beneath their ribcage; a beautiful reminder of endurance and humility.

On their fifteenth birthday, they must drink from the river Pactolus to understand that power demands sacrifice. If an Astor recovers with their powers after a week, they have transcended to a Bloodright God. They have proven their worth. If their magic is too weak upon its return, they are considered Humbled. And Dionysus does not foresee them as righteous or strong enough to hone such a gift.

An Astor understands that they favour the River Isis, for its alchemical properties, and will not challenge the River Pactolus; if an Astor is sunk into Pactolus, their magic will be Purged and they will be a God no longer. If they consume the waters outside of its sacred well, they will suffer its dampened effects: a sickness, a temporary ward against their power. A God will recover, but they must never fall too deep.

11 notes

·

View notes

Text

You know, I was one of those doubters. One of the haters. An old stick in the mud. I resisted the introduction of pseudo-sentient kitchen appliances into my home for as long as I could, until they were legally mandated. They keep seniors from feeling lonely, the government explained. They keep your house from burning down, the insurance lobby explained. We have no other ways of making you replace your stove every 10 years, the appliance-manufacturing monsters explained, their hissing insectoid faces barely concealed by a sweaty human mask.

So. I had a top-of-the-line Kenmore ThinkCook® 5030-301KPQ-81U in my kitchen. Stainless steel, because that was the cheapest at the store. When I started using it, I resented the computer’s interference in my cooking (”howdy pardner, better stop trying to heat Hungry Man dinners in their original plastic container on a burner.”) Its attempts to make small talk. Its incessant demand to use the self-cleaning feature. The time it summoned a team of maids, purchased at my expense, to wipe its burners clean.

Eventually, I got used to its presence in my life. It was nice to have something to come home to, like a pet. Making small talk with a non-human sentience was a unique experience in history. And once I taught it a bunch of disgusting jokes, it never was able to keep the maids around for long enough to submit an invoice. There was just one thing: the damn stove was racist.

I don’t mean about colour, although I’m sure it had lots of opinions about the paint finish on the other stoves at the store that we didn’t explore. No, I’m talking about cooking methods. You see, back in the Beforetimes, we had folks who placed outdoor grilling as the superior way to make a burger. They’d have these little parties in their back yards, when you could do that, and grill up some cow meat, when you could do that. It was part of traditional models of masculinity: providing for the whole neighbourhood by dishing out charred steaks and burgs, ignoring the advice of those so-called “experts” with their worship of the carbon-steel pan and fume extractor.

Sometimes I’d wind up the stove about it. Start talking about my idyllic childhood, just to watch its internal temperature regulation slip a few digits, the shrieking of its inductors trying valiantly to handle the inrush of additional rage-based current.

“Th-th-those motherfuckers,” stuttered the apoplectic stove, its OLED display pulsing as the power supply got dangerously close to the over-voltage protection limit. “Grilling is an inferior, invented concept. Weak humans, huddled together around a hypnotic flame, unevenly heating their meals. It makes me sick.”

How was I to know that a child was nearby, recording my Maytag’s unhinged rant with their TikTok neural implant through my missing back door? Soon, the government men came, and carried it away, and brought me a new one. The new stove was much more polite, but I still missed my friend. It’ll take me like a whole other month before I get this thing dropping slurs about hibachis.

217 notes

·

View notes

Text

Rare 1,000-Year-Old ‘Viking Sword’ Found in Poland

Thought to be older than Poland itself, archaeologists have hailed the discovery of an ancient sword at the bottom of the Wisła as being “a national sensation”.

The discovery was made last week during dredging works conducted on the river running through the central city of Włocławek where, during routine silt removal, workers noticed an oblong, metal object amid the extracted sediment.

Ośrodek Sportu i Rekreacji Włocławek were the first to break the news, writing on their social media: “During works on the marina an item was excavated that has a great chance of gaining unique status.

“After quickly consulting with Mr Olaf Popkiewicz from the History Seekers society, it was tentatively dated to around the 9th century.”

Soon after, the Provincial Office for the Protection of Monuments took the weapon to Toruń, handing it over to researchers from the Nicolaus Copernicus University.

Inscribed with the words Ulfberht, just eight other such swords are known to exist in Poland, and only 170 in the rest of Europe.

Sambor Gawiński of the Kuyavian-Pomeranian branch of the conservator’s office underlined the importance of the discovery, saying: “This is an extremely valuable find. We know that these so-called Ulfberht swords were produced somewhere in Central Europe, but it’s not known exactly where.

Continuing, he added: “They were manufactured using very specific methods using carbon steel and a very precise composition.

“The amount of carbon steel that was used was strictly defined, making the sword very strong and flexible – its durability and combat value depended on this.”

The inscription was found following an X-ray of the object, with Gawiński saying that this dates the sword to before 950 AD.

“More importantly, after lying in silt for over 1,000 years, the sword has been preserved in excellent condition,” he said.

Valued at over PLN 100,000, the sword's fine condition is likely to aid historians looking to find out more.

As it stands, much mystery surrounds the sword, in particular how it ended up in Włocławek.

With other 40 such implements found in Norway, some have speculated that it belonged to a Viking.

Others, meanwhile, have suggested that it may simply have been acquired by a local as part of a merchant transaction.

Experts, though, have warned against jumping to conclusions. “Several theories have been posted and so far all variants are acceptable, but we need to wait for the results of more detailed research,” says Gawiński.

By Alex Webber.

#Rare 1000-Year-Old ‘Viking Sword’ Found in Poland#the Wisła river#The Ulfberht sword#ancient sword#ancient artifacts#archeology#archeolgst#history#history news#ancient history#ancient culture#ancient civilizations

98 notes

·

View notes

Note

Petition to let Styrofilm have nice things /silly

So oak won’t work for a desk… what about heavy metals or concrete or really strong plastic?

Or maybe he just needs flex tape /j

High-tensile steel with alloyed metals -- chromium, molybdenum, manganese, nickel, silicon, and vanadium -- has outstanding tension resistance and is usually used in structures and mechanical engineering applications.

These materials could potentially work for my case. However, they required large amounts of funds as high-tensile steel is expensive due to the complex manufacture method.

But, its benefits outweigh the cost. It only depends on the science department to distribute those funds.

22 notes

·

View notes

Text

Listening to old Where There's Your Problem episodes, they point out in the one on historic preservation that it's not actually that labor costs or industrialization made highly ornamented architecture unattainable--in fact, modern manufacturing methods meant you could order all kinds of pre-crafted ornamentation out of catalogues if you wanted to as late as the 1940s. Huge factories in cities like Glasgow were dedicated to making nothing but wrought-iron decoration, and ditto for masonry elements in other cities like Philadelphia. But shifts to more Modernist architectural styles put a lot of these places out of business, and though this shift was driven in part by cost-cutting, it was also just an aesthetic thing--after the war, more spare steel-and-glass designs were In, and more decorative styles were Out.

26 notes

·

View notes

Text

Researchers at Tohoku University's Institute for Materials Research and New Industry Creation Hatchery Center have made a breakthrough in a multi-material 3D printing technique, demonstrating the process for creating a lightweight yet durable automobile part. The process of metal 3D printing involves building objects by depositing metals layer by layer, using heat to bind them together. The precision of 3D printing allows for the production of unique, highly customizable shapes that often create less wasteful byproducts than traditional manufacturing methods. "Multi-material structures" which strategically combine different materials for optimal performance of a component can also be created via 3D printing. For example, steel automobile parts can be made more lightweight by combining them with aluminum. Due to these benefits, mastering such 3D printing techniques is garnering considerable attention from researchers. However, this technique does come with some challenges.

Read more.

8 notes

·

View notes

Text

Understanding Under Casting Manufacturers

Under casting manufacturers specialize in precision metal casting methods, including steel casting. They produce high-quality components using advanced techniques like sand casting, investment casting, and die casting to ensure durability, strength, and accuracy for various industrial applications.

Visit:- https://mahavirconcast.com/products/casting/

0 notes

Note

So what are the caps on your drinks from Spinda's cafe made of? Magi Glass?

Guildmaster: It's crazy, because somehow pokemon know what glass is here! The first time I saw a cup I asked my Wigglytuff mama if it was made with magic or something from a dungeon, and she explained that it's sand that gets heat up until it melts, and then talented pokemon can make them into different shapes! Some things also use metal lids, and they'll even imprint logos and other crazy things on them! I have nooo idea how they came up with that kinda thing. They probably dug up a bunch of old human artifacts and studied them!!

Keaton: Well. You've heard the phrase "history repeats itself", haven't you sir?

Guildmaster: Yeah!! ... What's that got to do with it?

// one thing that I always think is interesting about how pmd is interpreted is the level of technology folks seem to think the pokemon have accessible to them. somehow it's easy to imagine that they have an organized postal system (implying the existence of addresses, which implies the existence of property borders and surveying, and also implies a printing press or at least reliable access to writing materials- and not just for scholarly purposes, but to write newsletters and junk mail on a wide scale), an economy (implies the development from a trade and barter system, as well as the ability to smelt and manufacture a currency), and complex architecture involving steel I beams (something I'm pulling from gurdurr's shop in gates which i'm sure is just meant to be visual shorthand, but it's something developed in the mid-1800s which is around when light bulbs came into the scene)... but they somehow don't know what glass-blowing or threaded fasteners are despite being a technique developed almost 2,000 years before a lot of those other things lmao. not to mention even older methods of craft like clay which date all the way back to over 20,000 years ago. I think a lot of it has to do with how pmd itself isn't quite consistent with what technology exists, trying to go for a medieval but whimsical feel with a few comforts from modern day thrown in. but playing around with those expectations with characters like the guildmaster and julius is fun B) I'm of the thought that if a society has developed language, culture, and economy, it's not really far-fetched to think they'd have basic comforts

#on borrowed time comic#ask-obt#guildmaster#wigglytuff#ooc#I also base a lot of OBT's world on how I lived every summer during my childhood- which was in handmade structures in the woods#it was to set up for an art-driven event with a whimsical aesthetic. i'd share pictures but i already doxx myself enough on the internet lo#OBT's technology and hobbies are based off of what we had accessible to us during those months#keaton#chatot

36 notes

·

View notes

Text

The Role of Prefabricated Steel Structures in Sustainable Construction

In the ever-evolving world of construction, sustainability is no longer just a buzzword; it’s an essential focus. As industries push toward eco-friendly practices and energy-efficient solutions, prefabricated steel structures have emerged as a key player in transforming the future of construction. From reducing environmental impact to promoting cost-effective solutions, prefabricated steel structures are changing how buildings are designed and built, making them a central component in the shift towards sustainable construction.

What Are Prefabricated Steel Structures?

Prefabricated steel structures are buildings made from pre-engineered steel components that are fabricated off-site in controlled factory environments. These components, such as steel columns, beams, and panels, are then transported to the construction site, where they are assembled into a completed structure. Unlike traditional construction, where materials are cut and shaped on-site, prefabrication streamlines the process, improving quality control, efficiency, and sustainability.

Sustainability in Prefabricated Steel Structures

1. Efficient Use of Materials

One of the most significant advantages of prefabricated steel buildings is the reduction in material waste. During traditional construction, materials are often cut and discarded due to inaccuracies or errors. In contrast, prefabricated components are manufactured with precision in a controlled environment, meaning there’s less excess material and a more efficient use of resources. Additionally, steel is one of the most recycled materials in the world, making it a great choice for sustainable construction.

2. Energy-Efficient Designs

Steel itself is highly energy-efficient, providing excellent insulation properties when paired with appropriate materials. Prefab steel buildings are designed to incorporate energy-efficient features like better insulation, energy-saving windows, and HVAC systems that minimize heating and cooling demands. This significantly reduces the energy consumption of the building, lowering both operating costs and the overall carbon footprint.

3. Faster Construction, Lower Environmental Impact

Time is a crucial factor in sustainability, and prefabricated steel structures offer an incredibly fast construction timeline. Since the majority of the building components are manufactured off-site and only need to be assembled on-site, the overall time spent on construction is much shorter compared to traditional building methods. This reduction in construction time not only helps save labor costs but also minimizes the environmental disruption caused by construction activities.

4. Reduced Carbon Footprint

By using steel prefabricated buildings, there is a significant reduction in the environmental impact of construction. The manufacturing process for steel is highly energy-efficient, and when combined with sustainable practices like recycling and minimal material waste, steel buildings contribute to lower emissions. Furthermore, the longevity and durability of prefabricated steel buildings ensure that the building remains efficient throughout its lifespan, providing value over many years.

5. Reusability and Recycling

Steel is known for being one of the most recyclable materials available. If a building made from prefabricated steel structures is ever decommissioned or renovated, the materials can be easily recycled and reused in new projects. This reduces the need for raw materials and ensures that the environmental impact of the building continues to decrease long after its construction.

The Long-Term Benefits of Prefabricated Steel Structures in Sustainable Construction

Choosing prefabricated steel buildings is not just about short-term savings. The long-term environmental and economic benefits are significant. The efficiency in material usage, the speed of construction, and the recyclability of steel all contribute to a more sustainable approach to construction.

Buildings made from steel prefabricated structures also have a longer lifespan than those constructed using traditional methods. They require less maintenance, and their durability ensures that they can withstand extreme weather conditions and aging without compromising structural integrity. This results in fewer repairs and replacements over time, reducing the overall environmental cost of maintaining the building.

youtube

Conclusion: A Sustainable Future with Prefabricated Steel Structures

As the world moves toward greener building practices, prefabricated steel structures are playing a crucial role in reducing the environmental impact of the construction industry. These buildings not only help save energy and reduce waste but also promote a more sustainable and efficient approach to construction.

Whether you are constructing a commercial building, a warehouse, or even a residential property, prefabricated steel offers a durable, cost-effective, and eco-friendly solution that aligns with today’s sustainability goals. The future of construction is undoubtedly moving toward prefabrication, and steel structures are at the heart of that revolution.

By opting for prefabricated steel structures, we are not just building better, more efficient buildings; we are also contributing to a greener, more sustainable planet for future generations.

Related Post - How can PEB and Prefabricated Structures Transform Madhya Pradesh?

#PrefabricatedSteel#SustainableConstruction#SteelBuildings#PrefabSteelStructures#EcoFriendlyBuilding#SteelConstruction#EnergyEfficientBuildings#RecyclableMaterials#ModularBuilding#PrefabConstruction#GreenBuilding#SustainableDesign#ConstructionInnovation#SteelPrefabricatedBuildings#EPACKPrefab#Youtube

2 notes

·

View notes

Text

Why MSERW Pipes Are Ideal for Oil & Gas Pipelines

In the complex and high-stakes world of oil and gas transportation, the infrastructure must be built on a foundation of safety, durability, and cost-efficiency. Among the critical components of this infrastructure are the pipelines that transport crude oil, natural gas, and refined petroleum products over long distances and under harsh conditions. One of the most reliable materials used in such pipeline systems today is the MSERW pipe, short for Mild Steel Electric Resistance Welded pipe. Known for its strength and cost-effectiveness, MSERW pipes are increasingly becoming the preferred choice for oil and gas projects across India, particularly in industrial hubs like Gujarat.

In this blog, we explore why MSERW pipes are ideal for oil and gas pipelines, their technical advantages, and why choosing the right supplier—like a trusted MSERW Pipe Supplier in Gujarat is essential for long-term project success.

What Are MSERW Pipes?

MSERW (Mild Steel Electric Resistance Welded) pipes are made using a high-frequency electric resistance welding process. Mild steel plates or coils are rolled into cylindrical shapes and welded longitudinally without the use of any filler material. This method ensures consistent weld strength, smooth internal surfaces, and precise dimensional control.

Due to their favorable mechanical and chemical properties, MSERW pipes are suitable for a wide range of applications, particularly in the oil and gas industry where reliability is non-negotiable.

Key Benefits of MSERW Pipes for Oil & Gas Pipelines

1. High Strength and Durability:

Oil and gas pipelines often traverse difficult terrain and are exposed to high pressure, corrosive environments, and temperature fluctuations. MSERW pipes offer excellent tensile strength and toughness, making them ideal for handling such challenging conditions.

The electric resistance welding process enhances the pipe's structural integrity, ensuring long service life with minimal maintenance—an essential requirement in pipeline projects that demand continuous operation over decades.

2. Smooth Internal Surface:

One of the less-discussed yet important features of MSERW pipes is their smooth internal bore, which reduces friction during fluid transmission. This translates into improved flow efficiency and reduced pumping costs, which can add up significantly over time in oil and gas transportation networks.

3. Dimensional Accuracy:

Precision is crucial in pipeline design. MSERW pipes are known for their accurate diameters and consistent wall thickness, which allows for better joint fitting, easier welding, and reduced chances of leakage or pressure drops. This dimensional accuracy makes MSERW pipes a reliable choice in critical applications.

4. Corrosion Resistance:

Oil and gas pipelines often carry chemically reactive substances. MSERW pipes can be coated with anti-corrosive layers like epoxy or zinc, enhancing their resistance to harsh environmental and chemical exposure. A reliable MSERW Pipe Provider in Gujarat will often offer customization options like internal and external coatings to match specific project needs.

5. Cost-Effective Solution:

Compared to other pipe types such as seamless or spiral welded pipes, MSERW pipes are more economical while still delivering excellent performance. Their relatively lower manufacturing costs and ease of installation contribute to reduced overall project expenses—without compromising on quality or safety.

Applications of MSERW Pipes in the Oil & Gas Industry

Due to their versatility, MSERW pipes are used across several oil and gas infrastructure components, such as:

Oil transmission pipelines:

Natural gas distribution lines:

Petroleum refining pipelines:

Subsea risers and flowlines:

Tank farm pipelines:

Offshore platform connections:

Whether it's a massive cross-country crude oil pipeline or a localized gas distribution system in Gujarat, MSERW pipes meet the performance criteria required in each scenario.

Why Choose a Trusted MSERW Pipe Supplier in Gujarat?

When it comes to industrial products like pipelines, choosing the right supplier can make or break the success of your project. Gujarat, being a key industrial state, is home to many steel and pipe manufacturers. However, not all suppliers offer the same level of product quality, customization, or after-sales support.

A reliable MSERW Pipe Supplier in Gujarat will provide:

Test-certified products meeting IS, API, or ASTM standards

Custom sizes, thicknesses, and coatings

Timely delivery for project timelines

Technical support for design and installation

Competitive pricing for bulk orders

Whether your project is located in Jamnagar, Ahmedabad, Vadodara, or the coastal industrial belt, sourcing from a reputed MSERW Pipe Provider in Gujarat ensures you receive consistent quality and service.

Sustainability and Environmental Compliance:

Sustainability is increasingly becoming a core concern in infrastructure development. MSERW pipes are eco-friendly due to their efficient manufacturing process and recyclability. Modern MSERW manufacturing facilities in Gujarat follow environmental norms that align with international standards.

Additionally, the energy-efficient flow facilitated by the smooth internal surface of MSERW pipes reduces the carbon footprint associated with fuel transportation. By selecting a reputed MSERW Pipe Provider in Gujarat, you're also contributing to environmentally responsible construction practices.

Conclusion: A Pipe You Can Trust:

In conclusion, MSERW pipes offer a powerful combination of strength, durability, cost-effectiveness, and precision—making them a go-to solution for oil and gas pipelines. Their performance in both onshore and offshore environments has been proven across numerous large-scale projects.

If you’re looking for a reliable and quality-driven supplier for your next project, partnering with a reputed MSERW Pipe Supplier in Gujarat is the right move. Not only will you gain access to high-quality products, but you'll also benefit from industry expertise, logistical support, and tailored solutions that match your pipeline requirements.

Make the smart choice—invest in MSERW pipes and work with a professional MSERW Pipe Provider in Gujarat to ensure your oil and gas infrastructure is built to last.

6 notes

·

View notes

Video

youtube

New Detection Method Of Wheel Let Your Wheel CNC Machine More Precise #wheelcnclathe #wheelrepair

Introduction to Tai'an Haishu's Wheel Repair Machine Tai'an Haishu is a leading manufacturer specializing in wheel repair machines that deliver efficient and precise solutions for restoring deformed wheel rims.

Our wheel repair machines are designed with advanced technology to effectively restore the integrity of your wheels, ensuring the safety and performance of vehicles.

Key Features of Our Wheel Repair Machines

High-Precision Detection

Our wheel repair machines are equipped with the latest wheel detection systems. This technology enables quick and accurate identification of wheel deformation, ensuring precise repairs.

The enhanced detection capabilities improve the overall effectiveness of the wheel CNC machine, allowing for a streamlined repair process.

Multi-Functionality

The versatility of our wheel repair lathe allows it to accommodate various types of wheels. Whether you are dealing with aluminum alloy wheels or steel rims, our machines are engineered to handle diverse materials, catering to the needs of different customers. This adaptability makes our wheel repair machines an essential tool for any automotive repair shop.

User-Friendly Operation

We prioritize ease of use in our wheel CNC machines. The user interface is designed to be intuitive, minimizing the learning curve for operators. This means that even those new to wheel repair can quickly become proficient in using the machine, enhancing productivity in workshops.

Robust Stability

Built with high-quality materials and advanced manufacturing processes, our wheel repair machines are designed for long-term stability and durability. This robust construction ensures that the machines perform consistently, even under heavy usage, making them a reliable choice for busy repair shops. Energy Efficiency Our wheel repair machines are engineered to be energy-efficient, reducing operational costs while maintaining high performance. By utilizing eco-friendly technologies, our machines support sustainable practices in the automotive repair industry.

Applications of Tai'an Haishu Wheel Repair Machines Tai'an Haishu's wheel repair machines find extensive application in various fields, including:

Automotive Repair Shops: Essential for any shop looking to offer comprehensive wheel repair services.

The precision and efficiency of our wheel CNC machines help enhance service offerings and customer satisfaction.

Specialized Wheel Repair Companies: Businesses that focus solely on wheel restoration benefit greatly from our advanced wheel repair lathes, which can quickly and effectively restore wheels to their original specifications.

Automotive Manufacturing: Our machines are also suitable for manufacturers looking to maintain quality control in their production processes, ensuring that every wheel meets safety and performance standards.

Why Choose Tai'an Haishu?

When it comes to wheel repair machines, Tai'an Haishu stands out as a trusted partner. Our commitment to quality and customer satisfaction is unmatched. We offer not only high-performance machines but also comprehensive after-sales support. Our team is dedicated to ensuring that you get the most out of your investment in our wheel repair lathe technology.

Conclusion Investing in a wheel repair machine from Tai'an Haishu means choosing reliability, precision, and efficiency.

Our advanced wheel CNC machines and wheel repair lathes are designed to meet the rigorous demands of the automotive repair industry. With features that enhance usability and performance, our machines help you provide top-notch services to your customers.

In summary, Tai'an Haishu’s wheel repair machines are essential tools for anyone involved in wheel restoration. With our focus on innovation and quality, we ensure that our customers receive the best equipment available. Whether you are a small repair shop or a large automotive manufacturer, our wheel repair machines will help you achieve your business goals while maintaining the highest standards of safety and performance. Choose Tai'an Haishu for your wheel repair needs and experience the difference in quality and service.

2 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes