#PCB Design Software Market price

Explore tagged Tumblr posts

Text

Global Polyurethane Foam Mattress Market Forecast (2025–2031): Growth, Trends & Strategic Insights

"

The Global Polyurethane Foam Mattress Market is projected to grow steadily from 2025 through 2031. This report offers critical insights into market dynamics, regional trends, competitive strategies, and upcoming opportunities. It's designed to guide companies, investors, and industry stakeholders in making smart, strategic decisions based on data and trend analysis.

Report Highlights:

Breakthroughs in Polyurethane Foam Mattress product innovation

The role of synthetic sourcing in transforming production models

Emphasis on cost-reduction techniques and new product applications

Market Developments:

Advancing R&D and new product pipelines in the Polyurethane Foam Mattress sector

Transition toward synthetic material use across production lines

Success stories from top players adopting cost-effective manufacturing

Featured Companies:

Tempur Sealy International

Serta Simmons Bedding

Sinomax

Sleemon

Recticel

Corsicana

MLILY

Sleep Number

Hilding Anders

Ashley

Pikolin

Derucci

King Koil

Get detailed profiles of major industry players, including their growth strategies, product updates, and competitive positioning. This section helps you stay informed on key market leaders and their direction.

Download the Full Report Today https://marketsglob.com/report/polyurethane-foam-mattress-market/1007/

Coverage by Segment:

Product Types Covered:

King Size

Queen Size

Single Size

Applications Covered:

Private Households

Hotels

Hospitals

Others

Sales Channels Covered:

Direct Channel

Distribution Channel

Regional Breakdown:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

Key Insights:

Forecasts for market size, CAGR, and share through 2031

Analysis of growth potential in emerging and developed regions

Demand trends for generic vs. premium product offerings

Pricing models, company revenues, and financial outlook

Licensing deals, co-development initiatives, and strategic partnerships

This Global Polyurethane Foam Mattress Market report is a complete guide to understanding where the industry stands and how it's expected to evolve. Whether you're launching a new product or expanding into new regions, this report will support your planning with actionable insights.

" Exclusion Chromatography (SEC) HPLC Columns Cell-Site Simulators Ship Dismantling CAD/CAM Software for Sheet Metal Ship Management and Crew Management Rebar Coupler Modular Office Furniture Consumer Goods (CPG)ing Software and Platforms Energy-as-a-Service (EaaS) Glass-Melting Furnaces Vacuum Plasma Machine for Bare PCB Manufacturing Direct to Garment Printers Under Eye Gel

0 notes

Text

Rain Sensor: Advanced Automotive Safety Technology

What is a Rain Sensor?

A rain sensor is an electro-optical system that uses infrared technology to detect the presence and intensity of precipitation on the windshield. This system is designed according to ISO 11452-9 standards and operates as part of the automatic wiper system.

What is a Rain Sensor in Cars?

The rain sensor is installed behind the central rearview mirror and consists of three key components:

Infrared Light Source: LED with wavelength of 880-940 nanometers

Photodiode Receiver: Detects light reflection from the glass surface

Signal Processing Unit: Analyzes data at a rate of 100 samples/second

The most important capability of the rain and light sensor is its ability to detect raindrops as small as 0.5 millimeters.

How Does a Rain Sensor Work?

The rain sensor operates in four stages:

Emission of light pulses to the external glass surface

Measurement of reflection coefficient with photodiode

Calculation of precipitation intensity based on reflection changes

Sending commands to ECU for wiper speed adjustment

The rain sensor system can distinguish between rain, snow, and water spray from other vehicles.

Benefits of Rain Sensors

Key advantages of rain sensors in cars include:

40% reduction in accident probability during rainy conditions

Automatic wiper speed adjustment from 1 to 6 levels

15% savings in windshield washer fluid consumption

Increased lifespan of wiper blades

Rain Sensor Construction

Rain sensor construction is based on advanced optical and electronic principles. The sensor consists of a light-emitting diode (LED) for projecting infrared light onto the windshield surface and an optical sensor for measuring the amount of reflected light.

Under normal, dry conditions, infrared light is completely reflected from the glass surface. However, when water droplets are present, the light becomes scattered and the amount of reflected light decreases.

These changes are detected by the optical sensor and converted into electronic signals. These signals are then sent to the vehicle's Electronic Control Unit (ECU), which issues commands to activate the wipers.

Modern rain sensors are constructed from these materials:

Lens: Polycarbonate with anti-reflective coating

PCB: Printed circuit fiber with gold plating

Optical Adhesive: UV-Curable epoxy with refractive index of 1.52

Housing: ABS with IP69K protection rating

Rain Sensor Price

The cost of a rain sensor depends on various factors:

Number of optical channels (1 to 3 channels)

Operating temperature range (typically -40 to +85°C)

CAN Bus compatibility

Manufacturer brand (Bosch vs. Valeo)

The current price range for car rain sensors in the Iranian market in 2024 is between 1.2 to 5 million tomans.

Rain Sensor Installation

To install a car rain sensor, the installation location on the windshield is first determined, usually behind the center mirror. The glass surface in this area is then completely cleaned and dried to ensure proper sensor adhesion.

The rain sensor, which includes an electronic module and an optical gel layer, is attached to the glass using special adhesive. After installation, the sensor cables are connected to the vehicle's electronic system, and necessary software settings are performed through diagnostic equipment to properly synchronize the sensor with the wiper systems.

Finally, the sensor's performance is tested under various weather conditions to ensure its proper operation.

Rain Sensor Repair

Rain sensor repair typically involves checking and fixing problems related to its optical and electronic components. If the sensor doesn't work properly, electrical connections and related cables should first be examined.

Additionally, the windshield surface at the sensor installation location must be cleaned of any contamination and scratches. If there are problems with optical components, such as LED or optical sensor, replacement of these parts by experienced specialists is recommended.

In some cases, reprogramming the sensor software or vehicle ECU can resolve operational issues.

Rain Sensor: Integration of Optics and Electronics for Safety

Modern rain sensors with 99% accuracy and 50-millisecond response time have created new standards in active safety systems. Development of this technology is moving toward integration with more advanced systems such as fog detection and automatic headlight adjustment.

Proper maintenance, including periodic lens cleaning and connection inspection, can extend the system's useful life up to 10 years.

Source: http://galaxyturbo.co/blog/car-accessories/what-is-rain-sensor/

0 notes

Text

Madox Technologie: Leading Engineering Service Provider in Bangalore

Bangalore, often referred to as the Silicon Valley of India, is a thriving hub for technology and innovation. Among the many businesses that contribute to its industrial and technological growth, Madox Technologie stands out as a premier Engineering Service provider in Bangalore. With a strong commitment to quality, innovation, and customer satisfaction, Madox Technologie has carved a niche for itself in the engineering services industry.

About Madox Technologie

Madox Technologie is a renowned name in the field of engineering services, offering comprehensive solutions across multiple industries. The company specializes in product design, mechanical engineering, electrical and electronics engineering, software development, and prototyping. With a highly skilled team of professionals and state-of-the-art technology, Madox Technologie provides customized engineering solutions that meet global standards.

Why Choose Madox Technologie?

As a trusted Engineering Service provider in Bangalore, Madox Technologie brings several advantages to its clients:

Expertise and Experience – With years of experience in the industry, Madox Technologie has successfully executed complex engineering projects for a diverse clientele.

Cutting-edge Technology – The company leverages the latest tools and technologies to provide innovative and efficient solutions.

Customer-Centric Approach – Madox Technologie focuses on understanding client requirements and delivering tailored solutions that enhance business performance.

Cost-Effective Services – Offering competitive pricing without compromising on quality makes Madox Technologie a preferred choice.

End-to-End Solutions – From concept development to final implementation, the company provides complete engineering support.

Services Offered by Madox Technologie

Madox Technologie offers a wide range of engineering services, including:

1. Mechanical Engineering Services

Madox Technologie specializes in mechanical product design, CAD modeling, analysis, and prototyping. The team ensures that all designs meet industry standards while optimizing for efficiency and performance.

2. Electrical & Electronics Engineering

The company provides innovative solutions for electrical and electronic product development, including PCB design, circuit analysis, embedded systems, and automation solutions.

3. Product Design and Development

With expertise in industrial design, 3D modeling, and prototyping, Madox Technologie helps clients turn ideas into market-ready products.

4. Software Development

Madox Technologie also offers software solutions for engineering applications, including simulation software, IoT integration, and customized engineering software development.

5. Prototyping and Testing

To ensure product reliability and performance, Madox Technologie provides advanced prototyping and testing services, reducing the time to market.

6. Welding Robot Solutions

As a leading Welding Robot solution provider in Bangalore, Madox Technologie delivers automated welding solutions designed for efficiency, precision, and consistency. Their advanced robotic welding systems help industries streamline their production processes, ensuring high-quality welds with minimal downtime.

Industries Served

Madox Technologie caters to a variety of industries, including:

Automotive – Designing and developing automotive components and systems.

Aerospace – Engineering solutions for aircraft components and structures.

Healthcare & Medical Devices – Developing precision-engineered medical equipment.

Industrial Manufacturing – Providing automation and process optimization solutions.

Consumer Electronics – Assisting in the development of electronic gadgets and devices.

Commitment to Quality and Innovation

Quality and innovation are at the core of Madox Technologie's operations. The company follows stringent quality control processes and adheres to international engineering standards. With a focus on continuous improvement, Madox Technologie invests in research and development to stay ahead in the competitive market.

Client Testimonials

Many clients have benefited from Madox Technologie's expertise and professionalism. Here’s what some of them have to say:

"Madox Technologie transformed our product idea into a functional prototype with precision and efficiency. Their team is highly skilled and professional." – Automotive Client

"The engineering solutions provided by Madox Technologie helped us streamline our manufacturing process, reducing costs and improving productivity." – Industrial Manufacturing Client

0 notes

Text

A Guide About Understanding EMS in Electronics Manufacturing

Electronics Manufacturing Services (EMS) play a vital role in the production of electronic components or sub assemblies. EMS providers offer a range of services such as PCB assembly, Box Build, Supply Chain Management, Engineering, Product Management, and after sales support, ensuring that businesses receive high-quality, reliable electronic products without the need for in-house manufacturing capabilities.

At Arrival Electronics Limited, EMS solutions are designed to support businesses in various industries, including automotive, aerospace, medical, industrial, and consumer electronics. By partnering with a reliable EMS provider, companies can focus on innovation and product development while benefiting from expert manufacturing processes.

The Role of EMS in Modern Electronics Production

EMS providers take on various responsibilities to assist businesses in bringing their products to market. These include:

1. Design and Prototyping

EMS providers collaborate with businesses in the early stages of product development. This includes design assistance, prototyping, and testing to ensure functionality and compliance with industry standards.

2. Component Sourcing and Procurement

Finding the right components at competitive prices is essential in electronics manufacturing. EMS providers leverage their supply chain relationships to source components efficiently while ensuring authenticity and quality control.

3. PCB Assembly (PCBA)

Printed Circuit Board Assembly (PCBA) is a core service in EMS. This involves surface-mount technology (SMT) and through-hole assembly, ensuring the electronic components are securely placed and soldered onto circuit boards.

4. Testing and Quality Control

Quality assurance is critical in electronics manufacturing. EMS providers perform rigorous testing, including in-circuit (ICT), functional, and environmental stress testing, to ensure products meet performance standards and reliability expectations.

5. Final Product Assembly and Integration

Beyond assembling circuit boards, EMS providers also manage full product integration, including enclosure assembly, software installation, and final testing.

6. Logistics and Aftermarket Services

Once the product is manufactured, EMS providers handle logistics, warehousing, and distribution. Additionally, they may offer repair and refurbishment services to extend product life cycles.

Comprehensive Turnkey Manufacturing Solutions for Every Stage of Production

Experience full turnkey manufacturing services designed for precision and efficiency. Our expertise includes:

Complex SMT assemblies

High-density PCBs

Rapid-turn prototypes

Serial production

Box build solutions

Complete product assembly & testing

Custom cable assemblies

Aftermarket service support

Our advanced facilities ensure top-tier quality and innovation at every stage of production.

Benefits of Partnering with an EMS Provider

Choosing a trusted EMS provider like Arrival Electronics Limited brings several advantages to businesses looking to produce high-quality electronic products efficiently.

Cost Efficiency

By outsourcing electronics manufacturing, businesses can reduce operational costs, including labor, equipment, and infrastructure investments. EMS providers streamline production processes, minimising waste and maximising efficiency.

Access to Advanced Technologies

EMS providers stay current with the latest manufacturing technologies, ensuring that businesses benefit from state-of-the-art production methods without the need for continuous investment in new equipment and training.

Scalability and Flexibility

Whether a business needs low-volume prototyping or high-volume production, EMS providers offer the flexibility to adapt to varying demands. This particularly benefits startups and growing companies that need adaptable manufacturing solutions.

Improved Product Quality

Strict quality control measures in EMS manufacturing ensure that each product meets industry and regulatory standards. This reduces defects, enhances reliability, and leads to greater customer satisfaction.

Faster Time-to-Market

EMS providers help accelerate product development timelines by handling the complexities of manufacturing. With efficient production processes, businesses can bring their products to market faster while maintaining high quality.

Key Industries Benefiting from EMS

Various industries rely on EMS providers to develop and produce electronic products efficiently. Some of the key sectors include:

Automotive Electronics: The automotive industry depends on EMS providers to produce advanced driver-assistance systems (ADAS), infotainment systems, and power management solutions. Precision manufacturing is essential to ensure safety and performance in vehicles.

Medical Devices: Medical electronics, including diagnostic equipment, wearable health monitors, and imaging devices, require strict compliance with regulatory standards. EMS providers ensure medical devices meet these standards while maintaining reliability and accuracy.

Aerospace and Defense: In aerospace and defense applications, reliability is paramount. EMS providers manufacture high-performance electronic components for avionics, radar systems, and communication equipment that withstand extreme conditions.

Industrial Automation: EMS supports the development of industrial control systems, sensors, and automation solutions that optimize manufacturing and operational efficiency in industrial settings.

Consumer Electronics: EMS providers manufacture various consumer electronics, from smartphones to smart home devices, ensuring high-quality production while maintaining cost-effectiveness.

Choosing the Right EMS Provider

When selecting an EMS provider, businesses should consider the following factors:

Industry Experience and Expertise

A provider with extensive experience in a specific industry understands the challenges and requirements unique to that sector. Arrival Electronics Limited has decades of experience delivering quality EMS solutions across multiple industries.

Quality Certifications and Compliance

Certifications such as ISO 9001, ISO 13485 (for medical devices), and AS9120B (for aerospace) indicate a provider’s commitment to quality and compliance with industry standards.

Technological Capabilities

An EMS provider should have access to modern manufacturing technologies, including automated assembly lines, advanced testing equipment, and robust supply chain management systems.

Supply Chain and Component Sourcing

A strong supply chain network ensures access to high-quality components while mitigating risks such as shortages and counterfeit parts.

Customer Support and Communication

Clear communication and reliable customer support are essential for successful collaboration. A responsive EMS provider keeps businesses informed throughout the manufacturing process.

Experience Efficiency & Cost Savings with Our Tailored Manufacturing Solutions

We provide efficient, cost-effective manufacturing services designed to meet your unique needs. By leveraging proven lean manufacturing techniques, we help you maximise value with:

Minimal inventory requirements

Lower overall acquisition costs

Risk mitigation through multiple inventory locations

Enhanced quality assurance

Guaranteed on-time delivery

Why Arrival Electronics Limited?

Arrival Electronics Limited is a trusted partner for businesses seeking comprehensive EMS solutions. With a strong commitment to quality, reliability, and industry expertise, the company provides end-to-end support for electronics manufacturing, from design to final product assembly.

With extensive experience in sourcing, assembling, and testing electronic components, Arrival Electronics Limited ensures businesses receive products that meet performance expectations and regulatory standards. Whether you require small-batch prototyping or large-scale production, their team is ready to assist with your EMS needs.

Conclusion

EMS plays a vital role in modern electronics manufacturing, offering businesses a way to produce high reliability products efficiently and cost-effectively. By working with an experienced EMS provider like Arrival Electronics Limited, companies can streamline their production processes, maintain strict quality control, and confidently bring their electronic products to market.

For more information about EMS solutions, visit www.arrivalelectronics.co.uk.

0 notes

Text

GOOD EVENING, NAUGHTY CHILDREN. IT'S ENGINEERING STORY TIME.

Today I might have gotten someone in India written up and also gave several engineers and a program manager heart palpitations

Context: The primary program I support has 9 different circuit cards, one of which is called the Processor card. As you might imagine, it has the processor, the memory that our software is loaded on and runs from, etc. Processors, memory chips, data registers, etc. are hellishly proprietary. If I design a board to use the TX38Q processor from Semiconductors R Us, I cannot swap in something similar from MacroCircuits Inc without redesigning half the board.

In 2018, we updated the processor card to use a new Flash memory chip, because the old one was obsolete and we could not get more for love or money. The pre-2018 memory chip will be called AML, because that's the beginning of its part number and the only part of that number I can be bothered to remember. The post-2018 memory chip will be called WHE-T, because that's the end of its part number and also the only part I can be bothered to remember. Every six months or so, program leadership will request an obsolescence scrub from an engineering team based out of India. They use the documented parts list, a private database of part numbers, and several tools to determine if parts are still available on the market or if we're skating close to the edge.

Today, the program manager was suddenly up in arms because we couldn't buy more AMLs. The general response from the engineering team was "yeah, and?" but because I am thorough, I went ahead and checked to see what we were using on the current design. WHE-Ts. Cool. Pulled up a side-by-side comparison to see if we could maybe just… swap them? No. Not just no, but hell no. They're completely different sizes, both physically and in terms of memory allocation and organization. Can't be done. The software engineers would riot and the PCB designers would murder me.

But while I was checking to see whether WHE-Ts were interchangeable with AMLs, I discovered that WHE-Ts are marked as obsolete. That's funny. I don't remember them coming up in a scrub before, but I'm sure they must have and our very responsible program leadership would have done the responsible thing and ordered a butt ton of them, to tide us over on production until the next redesign. Right?

Right??

No.

Over the summer, the company that makes WHE-Ts lost the capacity to manufacture the core of the part. I don't know if there was a horrible accident at their chip manufacturer and all the dies were shattered or what, but they can't make them anymore. Industry standard for announcing end of life for a part is to give 6 months notice. August 1st, they announced that the part should be listed as End Of Life effective immediately, last purchase orders were due by September 15th, and last shipments would be completed by December 31st. The entire product line is finito.

Also over the summer, my site's obsolescence manager quit, so no one was watching the Change Notices as closely as they should have been. We missed the deadline to order more parts.

If that was the end of the story, the engineer and project manager heart palpitations would be explained, and no one in India would be getting in trouble.

In mid-January, one of the chief engineers requested an obsolescence scrub. On January 27th, someone in India said that they had talked to the manufacturer of WHE-Ts, and they'd said the part was active with no plans to obsolete it.

A part that hadn't been available anywhere, for any price, for four weeks.

So now, with zero warning and a looming contract, we get to redesign the most complex circuit card.

7 notes

·

View notes

Text

Key Factors to Consider When Choosing an X-Ray Inspection System

X-ray inspection systems have become indispensable in industries like manufacturing, electronics, food processing, and aerospace, offering unparalleled accuracy in detecting defects and ensuring quality control. However, selecting the right X-ray inspection system can be a challenging task, given the variety of options available in the market. Choosing the wrong system can lead to inefficiencies, higher costs, and potential risks to your production process. To help you make an informed decision, this article outlines the key factors to consider when selecting an X-ray inspection system for your needs.

1. Industry-Specific Requirements

Different industries have unique demands when it comes to X-ray inspection. The system you choose should be tailored to the specific requirements of your sector.

Food Industry: Systems must detect foreign objects like metal, glass, and bone while meeting strict regulatory standards.

Electronics: High-resolution systems are essential for inspecting solder joints, PCBs, and micro-components.

Aerospace and Automotive: Systems need to detect internal cracks or voids in critical components to ensure safety.

Understanding your industry’s specific requirements will help you narrow down options and select the most suitable system.

2. Inspection Resolution and Sensitivity

The resolution and sensitivity of an X-ray inspection system determine its ability to detect small or subtle defects. High-resolution systems are crucial for industries like electronics and aerospace, where even minute defects can have significant consequences.

Key Considerations:

Check the resolution of the detector and the size of defects the system can identify.

Ensure the system provides consistent sensitivity across varying materials and densities.

Higher resolution often comes with a higher price tag, so balance your needs with your budget.

3. System Throughput and Speed

For industries with high production volumes, the speed and throughput of the X-ray system are critical. A slower system can create bottlenecks, impacting overall efficiency.

Key Considerations:

Evaluate the inspection speed and whether it aligns with your production line’s output.

Check if the system can handle batch or continuous inspections without compromising accuracy.

Some systems are designed for high-speed applications, making them ideal for industries like food processing and packaging.

4. Ease of Integration and Scalability

The X-ray inspection system should integrate seamlessly into your existing production line or workflow. Additionally, it should offer scalability to accommodate future growth or changes in production demands.

Key Considerations:

Ensure the system supports easy integration with current conveyor belts, robotic arms, or other automated systems.

Look for modular designs that allow upgrades or expansion without replacing the entire system.

Seamless integration reduces downtime and ensures smooth operations.

5. Software Capabilities

Modern X-ray systems are equipped with advanced software for analysis, reporting, and automation. The right software can enhance functionality and usability.

Key Features to Look For:

User-friendly interface and intuitive controls.

Automated defect detection using AI or machine learning.

Real-time monitoring and data analysis capabilities.

Compatibility with your existing quality management systems.

Advanced software can significantly reduce human error and improve inspection accuracy.

6. Regulatory Compliance

In industries like food and pharmaceuticals, compliance with regulatory standards is non-negotiable. The X-ray system you choose must meet these standards.

Key Considerations:

Verify that the system adheres to industry-specific regulations such as FDA, HACCP, or ISO certifications.

Ensure it has features like contaminant detection or radiation shielding to meet safety requirements.

Compliance ensures smooth audits and avoids potential legal issues.

7. Maintenance and Support

An X-ray inspection system is a long-term investment that requires regular maintenance and support to perform optimally.

Key Considerations:

Evaluate the manufacturer’s service offerings, including maintenance contracts and warranty terms.

Check for the availability of spare parts and the ease of replacing them.

Ensure the system comes with robust technical support and training resources.

Reliable maintenance and support minimize downtime and extend the system’s lifespan.

8. Cost and Return on Investment (ROI)

While cost is a significant factor, it’s essential to assess the value the system brings to your operations rather than focusing solely on the initial price.

Key Considerations:

Compare the system’s cost with the benefits it offers, such as improved accuracy, reduced waste, and enhanced quality control.

Calculate the potential ROI by factoring in productivity gains, reduced defect rates, and customer satisfaction.

Investing in a high-quality system may involve higher upfront costs but can lead to substantial savings over time.

9. Radiation Safety

X-ray systems emit radiation, which can pose risks if not properly contained. Ensuring the system meets safety standards is vital for protecting operators and complying with regulations.

Key Considerations:

Check for shielding features that minimize radiation exposure.

Ensure the system complies with radiation safety standards such as ANSI or CE certifications.

Proper safety measures create a secure working environment and build trust with employees.

Conclusion

Choosing the right X-ray inspection system is critical for ensuring the efficiency and safety of your production processes. By considering factors such as industry requirements, resolution, throughput, integration, software capabilities, compliance, and cost, you can make an informed decision that aligns with your business needs. Investing in the right system not only improves product quality but also enhances your brand reputation and operational efficiency. Take the time to evaluate your options, and you’ll find an X-ray inspection system that delivers long-term value.

0 notes

Text

Affordable PCB Design Services for High-Quality Prototypes

Looking for affordable PCB design services without compromising on quality? Bay Area Circuits offers expert solutions for high-quality PCB prototypes that meet your specific needs. Whether you're developing a simple single-layer board or a complex multi-layer design, our experienced team ensures precision and efficiency in every project.

Our services extend beyond just design. We provide printed circuit board fabrication, delivering fast, reliable, and cost-effective solutions. With cutting-edge equipment and years of experience, we create prototypes that meet industry standards, ensuring your product performs optimally from the start.

We also offer advanced printed circuit board design software like InstantDFM to streamline your design process. This tool allows you to check for manufacturability, reduce errors, and optimize your design, saving you time and money. InstantDFM provides automated feedback and pricing within minutes, ensuring a smooth transition from design to production.

Choose Bay Area Circuits for affordable PCB design services and high-quality prototypes. With our expertise, you can bring your electronic products to market faster and with confidence. Contact us today! To know more, Visit - https://bayareacircuits.com/

0 notes

Text

Full Turnkey PCB Services: Streamlining Your Electronics Production

In the rapidly evolving world of electronics, having a reliable and efficient partner for your printed circuit board (PCB) needs is crucial. Full turnkey PCB services offer a comprehensive solution that covers every aspect of PCB development and manufacturing, from design to final assembly. This all-inclusive approach ensures a seamless process, minimizing the complexity and risk associated with managing multiple suppliers. Let’s explore how full turnkey PCB services can enhance your project’s success.

What Are Full Turnkey PCB Services?

Full turnkey PCB services provide a complete solution for PCB production, encompassing design, prototyping, manufacturing, assembly, and testing. This means that you only need to work with one provider for the entire process, streamlining communication and reducing the risk of errors. The turnkey approach covers several key stages:

Design and Engineering: This initial phase involves collaborating with your team to create a detailed PCB design. Experts use advanced software tools to develop schematic diagrams and layout designs that meet your specifications. The design phase includes reviewing the project requirements, optimizing for manufacturability, and ensuring compliance with industry standards.

Prototyping: Once the design is finalized, a prototype is produced to test and validate the PCB. This step is critical for identifying any design issues or performance concerns before moving to full-scale production. Prototyping allows for iterative testing and adjustments, ensuring that the final product meets all functional requirements.

Manufacturing: With the prototype approved, the manufacturing process begins. This includes fabricating the PCBs using high-quality materials and advanced manufacturing techniques. The process involves etching, plating, and drilling to create the circuit board layers. Manufacturing also ensures that the PCBs meet rigorous quality standards and are produced efficiently.

Assembly: PCB assembly involves mounting and soldering electronic components onto the PCB. This can be done using surface-mount technology (SMT), through-hole technology, or a combination of both. The assembly process requires precision and attention to detail to ensure that all components are correctly placed and soldered.

Testing and Quality Assurance: After assembly, the PCBs undergo thorough testing to ensure they function correctly and meet quality standards. This may include electrical testing, functional testing, and reliability testing. Quality assurance helps identify and resolve any issues before the PCBs are shipped to the client.

Logistics and Delivery: The final step involves packaging and delivering the completed PCBs to the client. Full turnkey services often include inventory management and logistics support to ensure timely and accurate delivery.

Benefits of Full Turnkey PCB Services

Streamlined Communication: Working with a single provider simplifies communication, reducing the chances of miscommunication and project delays. You have a single point of contact for all aspects of the PCB production process.

Cost Efficiency: Full turnkey services can be more cost-effective than managing multiple suppliers. By consolidating design, manufacturing, and assembly, you can take advantage of bulk pricing and reduce overhead costs.

Reduced Risk: A turnkey approach minimizes the risk of errors and compatibility issues that can arise when working with different suppliers. Integrated processes ensure that each stage of production is aligned and optimized.

Faster Time-to-Market: With a streamlined process, projects can move from design to production more quickly. Faster turnaround times help you bring your product to market sooner, gaining a competitive edge.

High-Quality Results: Turnkey providers typically have extensive experience and expertise in PCB production, ensuring that the final product meets high-quality standards and performs reliably.

Conclusion

Full turnkey PCB services offer a comprehensive and efficient solution for electronics production, handling everything from design to delivery. By partnering with a provider that offers turnkey solutions, you can streamline your project, reduce risks, and achieve high-quality results. Whether you’re developing a new product or scaling up production, full turnkey services can help you navigate the complexities of PCB manufacturing and bring your vision to life. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Key Reasons for Hiring Skilled & Trained Electronic Circuit Board Design Professionals!

To get efficient and superior results, experienced engineers for electronic circuit board design can construct electronic circuits and advanced electronic devices.

Reputable electronic design companies hire skilled and qualified circuit designers who can build a great circuit or product design for a wide range of industries.

Key Reasons for Hiring Skilled and Trained Electronic Design Professionals?

Industries such as electronics and technology, healthcare and medical devices, automotive and transportation, aerospace and defense, energy and utilities, manufacturing and industrial, and others can reduce additional labour costs by hiring professional designers and receiving cost-effective designs at a competitive rate.

These expert designers are often trusted partners with years of experience in Australia, particularly in a competitive industry where innovation is critical.

They achieve superior product and client service quality through their highly skilled personnel and the use of cutting-edge electrical circuit design software.

From the initial concept to the final design management, their experience helps clients through the entire process, providing peerless services at cheap prices.

Because of their wide network of local and overseas assemblers and component suppliers, they can easily manage any issues or impediments associated with assembly technologies and procedures. This assures timely and cost-effective production while retaining the quality and consistency of their output.

To meet project objectives and generate prototypes quickly enough to please clients and gain their trust across multiple decades, they use a holistic approach to product development that incorporates modern technologies.

Their success in component selection, schematic design, prototype, and PCB assembly process management is certain.

Find a Reliable Design Engineering Company for Circuit Design:

Select a renowned design engineering company to receive ensured reliable and high-quality electrical design and components.

Find organizations with a strong track record of completed projects, extensive circuit design experience, and a highly qualified engineering staff.

Verify their qualifications, certificates, and customer evaluations to determine their legitimacy.

Assess their problem-solving abilities and whether they can accomplish the design within the budget and timelines.

Finally, compare their overall market services and choose a reputable design engineering firm to assist you in developing effective electronic circuits and competing in the market.

Source: https://extrondesignservice.blogspot.com/2024/08/key-reasons-for-hiring-skilled-trained.html

0 notes

Text

Today’s world is moving rapidly towards Industry 4.0, which requires a strong collaboration of electronics, software, and manufacturing. PCBs are the game changer in this aspect. As per market forecast, the PCB market will grow from 86.76 billion USD in 2024 to 152.46 billion USD by 2033, marking a CAGR of 5.8% [1]. By reducing the manufacturing cost, you can be more market competitive. This blog will discuss the specifics of cost-effective PCB assembly, which will help you make wise decisions. Knowing PCB Assembly Costs

Let’s understand the factors that affect PCB assembly costs. Below are some important considerations:

Board complexity and design: The cost of your PCB can be determined by the number of layer counts. Though they cost more than simpler, single-layer, or double-layer boards, multilayer boards give more design freedom. The board size is also equally important. Larger boards are capable of handling more components, which can translate to more material and fabrication expenses. Furthermore, higher component density and complicated circuit designs will increase assembly time and drive up costs. Types of Components Used: Through-hole technology calls for human or semi-automated assembly of components, which costs more than surface-mount technology (SMT). In SMT, automation is used to assemble components at a fast pace. Often requiring specialist handling, ball grid arrays (BGAs) and other sophisticated components increase the assembly cost. Technology Used in Assemblies: Your board design and component type will determine which type of technology, among SMT, through-hole, or mixed assembly approaches, is to be used. Every technique has financial implications; however, working with a reputed and experienced PCB assembly company can help you choose the most affordable solution for your requirements. Order Quantity: PCB assembly works through economies of scale. Usually, you can negotiate better in case of higher volume orders and reduce per-unit costs. Lead time constraints: Tighter deadlines and expedited assembly result in extra costs. To mitigate the short project schedule, you need to buy components at a higher price and modify the manufacturing schedule. Optimizing Profit and Cost Knowing the cost drivers now will help you investigate ways to simplify your PCB manufacturing process and maintain control of expenses: Design for Manufacturability (DFM): Incorporate DFM ideas from the very beginning. It helps reduce the number of layers as much as possible, using standard parts and ensuring that the spacing between parts is right for automated placement.

Strategic Component Selection: Whenever possible, standardize component packages to simplify the assembly. Look at easily available, reasonably priced components that meet your PCB performance needs. Leverage Technology: Most advanced PCB assembly companies use modern automated inspection systems to guarantee quality and eliminate human error. This increases efficiency as well as the quality of products, which helps to save money. Strong Communication and Collaboration: Always keep the lines of communication open with your PCB assembly partner. Communicate your design objectives and financial limitations at the outset. You can benefit from their knowledge and insight as they point out ways to cut costs and propose new strategies. PCB Power is one of the leading PCB assembly companies, with strong knowledge and commitment. For any type of assistance, you can always approach our experts. Do Market Analysis Do in-depth market analysis on component pricing and assembly cost and ask for estimates from several reliable PCB manufacturers. This lets you evaluate pricing schemes and, depending on cost, capacity, and lead times, determine which best fits your project. Smart Tips: Consider prototyping: Invest in low-volume prototypes to validate your idea before deciding on a high-volume manufacturing run. Long-term partnerships: Strong relationships with a trustworthy PCB assembly partner can be quite advantageous over the long run. Final Thoughts: Increasing selling costs is not the right approach to making profits. You must think of reducing production costs and avoid rework and rejections. These strategic techniques can help you reduce PCB assembly expenses and improve general project efficiency. To learn more about the efficient PCB assembly process and other insights, connect with PCB Power. Email us at [email protected] or call us at +1(818) 886 8900.

Read More:- The Definitive Guide to Reducing PCB Assembly Costs and Enhancing Efficiency

0 notes

Text

Bonanza Wealth Management Research Recommends Apollo Micro Systems Ltd. as a 'Buy'

In a detailed research report, Bonanza Wealth Management has identified Apollo Micro Systems Ltd. (AMSL) as a strong 'Buy' candidate. The report highlights AMSL’s significant experience, robust financial performance, and strategic growth initiatives, positioning it favorably within the defense and electronic manufacturing sectors.

Company Overview - Apollo Micro Systems Ltd. (AMSL) brings over 38 years of expertise in designing, developing, and assembling custom-built electronic and electromechanical solutions. The company’s extensive portfolio includes electronic manufacturing services, PCB fabrication, embedded software design and development, circuit board assembly, hardware design services, and custom-built electronic systems. AMSL serves critical sectors such as defense, space, and homeland security, providing high-performance and mission-critical solutions to both public and private sectors.

AMSL initially focused on offering design services to the Indian Space Research Organisation (ISRO). Over time, it expanded to develop systems and subsystems for electronic hardware and software, serving esteemed clients like the Defence Research and Development Organisation (DRDO) and various Defence Public Sector Undertakings (DPSUs). The company’s vision is to evolve into a platform-level development and supply provider, offering end-to-end solutions from concept to production.

Financial Performance and Projections - AMSL has demonstrated impressive financial growth, with revenue and profit after tax (PAT) growing at a compound annual growth rate (CAGR) of 22.3% and 44.8%, respectively, during the fiscal years 2021 to 2024. Key financial highlights from Bonanza Wealth Management’s report include:

Revenue: Increased from INR 1,354 million in Q4 FY23 to INR 1,354 million in Q4 FY24, marking a year-over-year growth of 26.8%.

EBITDA: Grew by 25.6% year-over-year to INR 287 million in Q4 FY24, driven by increased scale of operations and cost-efficient execution. The EBITDA margin slightly declined by 19 basis points to 21.2% in Q4 FY24.

PAT: Experienced a substantial year-over-year growth of 79.3% in Q4 FY24, reaching INR 129 million compared to INR 72 million in Q4 FY23.

Strategic Expansion Plans

AMSL is expanding its manufacturing capabilities significantly. The company operates a 55,000 square feet facility in Hyderabad and plans to add two new facilities measuring 40,000 and 350,000 square feet. This expansion, involving a capital expenditure of INR 1,500 million, is expected to be operational within the next 12 months, enhancing AMSL’s production capacity and enabling it to meet the growing demand.

The company’s strategic expansion aligns with its participation in over 150 indigenous programs and 60 Development cum Production Partner (DcPP) programs as a sub-system partner, boasting more than 700 onboard technologies.

Market Position and Opportunities - AMSL is a key player in India’s electronic, electromechanical, and engineering design sector, specializing in critical mission and time-sensitive solutions. Its products serve various industries, including aerospace systems, ground defense, space, avionics systems, homeland security, and transportation.

The company’s involvement in significant defense projects, including missiles, naval torpedoes, and underwater mines, underscores its strong market position. AMSL’s participation in indigenous missile programs like AGNI, PINAKA, AKASH-NG, VLSRSAM, VARUNASTRA, TAL, NIRBHAY, and ATAGS further solidifies its role as a major supplier in the defense sector.

Valuation and Recommendations - Bonanza Wealth Management values AMSL at 84.0 times the FY26 estimated earnings per share (EPS) of INR 1.53, resulting in a target price of INR 129.00, indicating an upside potential of approximately 20.0%. This valuation reflects AMSL’s strong order execution visibility, capacity expansion plans, and growth opportunities in the defense sector.

Risks and Concerns - While AMSL’s expansion plans are promising, any delays in adding new facilities could impact future growth prospects. Additionally, changes in defense manufacturing policies by the Ministry of Defence could negatively affect the company.

Analyst Insight - Rajesh Sinha, Senior Research Analyst at Bonanza Wealth Management, emphasizes AMSL’s robust financial performance, strategic expansion plans, and strong market position as key drivers for its recommendation. The report assures investors of the research's objectivity and independence, with no conflicts of interest.

Conclusion - With a proven track record and strategic growth initiatives, Apollo Micro Systems Ltd. is well-positioned to capitalize on emerging opportunities in the defense and electronic manufacturing sectors. Bonanza Wealth Management’s 'Buy' recommendation highlights the company’s potential for long-term growth and value creation for investors.

0 notes

Text

Beyond Borders: Vancouver's Leading Edge in PCB Assembly Services

Efficiency and Economy are Optimized with Vancouver PCB Assembly

Are you trying to find trustworthy and reasonably priced PCB assembly services in Vancouver? It's here for you! In this blog post, we'll discuss electrical manufacturing services in more detail as well as the benefits of choosing Vancouver first for any PCB assembly needs. Whether your company is new or well-established, cutting costs and improving productivity should always come first. Let's get going now and see how Vancouver can help you accomplish that!

An Overview of PCB Assembly Services in Vancouver

In Vancouver, which is well-known for its thriving tech sector, there are numerous companies that offer top-notch PCB assembly services. But what exactly goes into assembling a PCB? In short, it's the process of creating printed circuit boards by mounting and soldering electrical components onto them.

The first stage in PCB assembly is designing the board's layout and circuits using specialized software. This ensures that each component is linked and positioned correctly. When the design is finished, it is sent to the manufacturing process.

The next step is to purchase the components. Strong supplier relationships have made it possible for Vancouver-based PCB assembly businesses to get premium parts at competitive costs. This not only saves time but also ensures that your items meet high quality requirements.

Sophisticated pick-and-place machines are utilized to carefully arrange each component on the board after it has been bought. These devices accurately align each component with the specifications of the design. In order to securely bind the components to the board at the proper positions, soldering is done after installation.

As the final step in PCB assembly, each board needs to go through a thorough inspection and testing procedure before being delivered. This ensures that the functionality is free from errors or malfunctions. Throughout this crucial phase, accuracy and consistency are guaranteed by the use of automated testing equipment.

Now that you have a clear understanding of the process of PCB assembly in Vancouver, let's look at the numerous advantages that choosing this city as your ideal location can provide you in terms of efficiency and cost!

Why Vancouver Is the Best Location for PCB Assembly

Choosing the best location for PCB assembly can make a big difference in terms of increasing output and cutting costs. One location that stands out from the others is Vancouver. These are the principal advantages of selecting Vancouver for your PCB assembly needs.

In Vancouver, the electronic manufacturing services industry is flourishing. This suggests that you have access to cutting edge equipment and a wide range of skilled staff members. There are many top-notch PCB assembly companies in the region that offer complete services, from design and prototype to manufacturing and testing.

Lower lead times and transportation costs can be attributed in large part to Vancouver's excellent geographic location. Due to its west coast position in Canada, it enjoys easy access to both domestic and international markets. This implies that you will be able to meet deadlines without compromising quality because your assembled PCBs will come faster.

Vancouver also has reliable local component providers and a robust supply chain network. This proximity eliminates the need for delays caused by shipping components from far away and reduces the possibility of damage occurring during transit.

Choosing Vancouver for your PCB assembly needs also ensures that strict environmental regulations are followed. Electronics manufacturers view the city as an environmentally favorable choice due to its strong emphasis on sustainability initiatives. You can reduce your carbon footprint without compromising high production standards by working with local companies that adhere to environmental requirements.

In conclusion (as instructed), picking Vancouver as the location for your PCB assembly offers a number of advantages, such as quick access to professionals and state-of-the-art equipment in a bustling commercial district! Its ideal location allows for quick market reach and reduces transportation expenses! Furthermore, its strong supply chain network ensures timely procurement—and this is never the "in conclusion"! It's an environmentally friendly choice, last but not least (never say "overall" or "finally"), if you abide by stringent environmental laws!

A Look at a Few Items for Cost-effective and Efficient PCB Assembly

When attempting to optimize the cost-effectiveness and efficiency of PCB assembly, there are a few factors to consider. If you properly consider these factors, you can ensure a streamlined manufacturing process while keeping costs under control. The following are important points to keep in mind:

Select a Vancouver PCB assembly company with a plethora of industry experience based on experience and expertise. Look for companies who have a history of offering top-notch products and services. Experienced technicians will know how to put things together quickly and effectively, saving you time.

Check the PCB assembly company's quality control methods to make sure they are working effectively. Extensive testing at various stages of the production process is necessary to identify any defects or issues early on. Tight quality control procedures cut down on rework and waste, which decreases costs.

Advanced Equipment: Select a company with state-of-the-art machinery and tools designed specifically for efficient PCB assembly processes. Modern equipment not only speeds up production but also ensures accuracy and precision when installing components.

Supply Chain Management: Effective supply chain management is essential for low-cost PCB assembly. Look for companies that have established relationships with reputable component suppliers who offer competitive pricing without compromising quality.

Design Optimization: Throughout the design phase, collaborate closely with the PCB manufacturer of your choice to optimize layouts, reduce complexity, and increase manufacturability efficiency without sacrificing functionality or performance.

Cost analysis: Perform a comprehensive cost analysis before selecting a Vancouver PCB assembly service supplier.

Consider all of the expenses, such as labor, overhead, and shipping fees.

Obtain quotes from several different providers before selecting one.

By striking the right mix between the value and price offered by each potential vendor, you may prevent choosing an affordable solution at the expense of quality.

0 notes

Text

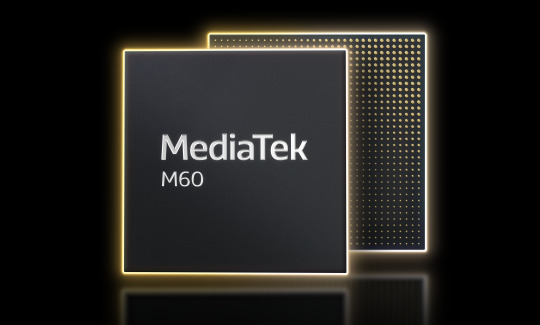

New MediaTek 5G RedCap technology transforms connectivity

MediaTek 5G RedCap technology

MediaTek, which makes has introduced its The company solutions, which will allow them to provide 5G technology download speeds as well as impressive power efficiency to a wide variety of Internet of Things equipment.

The previously the RedCap software modem technology and chipset family have been introduced by MediaTek as part of the company’s efforts to accelerate the migration to 5G-NR for consumer, corporate, and industrial IoT applications.

MediaTek T300 chipset series

MediaTek has announced that it would be extending its line of modems and chipsets to enable 5G RedCap. This announcement was made possible by MediaTek’s industry experience in 5G connection. The new solutions, the M60 modem IP and the MediaTek T300 chipset series, will make it simple for MediaTek to ease the transition to 5G-NR for a wide variety of applications. These applications include things like wearables, lightweight augmented reality devices, IoT modules, and devices built with edge artificial intelligence in mind.

RedCap, an abbreviation that stands for “reduced capability,” is an initiative that aims to bring the advantages of 5G to non-traditional radio (NR) consumer, corporate, and industrial devices. RedCap promises to bring dependability for devices that have minimal bandwidth needs by fully using the movement of 5G networks to the Standalone (SA) network architecture. This will offer many of the advantages of 5G without the expense and complexity of standard 5G solutions. RedCap will take full use of the evolution of 5G networks to the SA network design.

As stated by JC Hsu, Technical Senior Vice President at MediaTek, “Our 5G RedCap solutions constitute an important aspect of our objective to make accessible 5G, allowing consumers with the ability to maximize the efficiency of component while delivering devices capable of supporting 5G spanning a range of purposes and a range of price points.” “Our customers now have the ability to deliver 5G-enabled devices from a range of applications and a range of price points,” he said.

“The migration to 5G RedCap will replace legacy 4G/LTE solutions, offering significantly better power efficiency and more reliable user experiences when compared to leading edge 5G eMMB modem solutions and legacy 4G LTE Cat 4 and Cat 6 devices.”

The MediaTek T300 series is pioneering new territory in the 5G RedCap area since it is the world’s first single die solution for 5G RedCap that utilizes a 6nm Radio Frequency System-On-Chip (RFSOC) architecture. This RFSOC will enable marketers to build creative designs for corporate, industrial, consumer, augmented reality (AR), and data-card applications, allowing them to profit on the burgeoning RedCap market.

The MediaTek T300 series incorporates a single-core Arm Cortex-A35 in a substantially more compact PCB area. This is made possible by the extremely efficient TSMC 6nm process, which was used to build the series. The MediaTek T300 series is capable of supporting data transfer speeds of up to 122 Mbps in the uplink direction and 227 Mbps in the downlink direction.

The T300 series and the M60 5G modem IP both satisfy the 3GPP R17 standard and combine MediaTek’s industry-leading power efficiency with coverage upgrades and exceptionally low latency. Furthermore, the two of these products have been compatible using 5G networks. The The substance M60 is able to give users up to 70 percent reduction in energy consumption in compared to competitive 5G eMBB technologies and as much as seventy-five percent power savings in comparing to 4G LTE network solutions. This is possible via the incorporation of MediaTek’s UltraSave 4.0 semiconductor and the minimization of needless paging receptions.

To continue to address the constantly evolving relationship needs and standards, MediaTek’s The company solution are bringing about an exciting new era of efficiency, stability, and savings in expenses for devices with 5G RedCap capabilities across the consumer, businesslike, and industrial markets. Samples of devices included in the Broadcom T300 category will be accessible throughout the first half of 2024, and commercial samples will be available in the second half of the same year.

Read more on Govindhtech.com

1 note

·

View note

Text

Get Top-notch Schematic Electronics Design, Development, & Repair Services!

In this period of technology, schematic electronics design is one of the most important parts of developing and building any electronic product. When a product design is developed by experts in electronic engineering, ensure the reliability of the product in addition to its functionality, and cost-effectiveness.

In the competitive landscape of electronic circuit board design, a recognised firm can deliver flawless circuit design and electronic repair services. These companies are experts in manufacturing, comprehensive support, leveraging decades of experience and cutting-edge software.

Their essential contributions help conserve resources and promote sustainability in an increasingly throwaway consumer electronics market.

Importance of Electronics Design, Development, and Repair Services:

Usually, skilled electronic experts provide clear and well-documented schematic capture and PCB design processes that reduce downstream errors, and costly recalls, and increase production efficiency. They are experts in component selection and forethought to avoid product shortages and maintain long-term viability.

Experienced circuit designers provide crucial help, from initial design to prototype and final product, in addition to delivering new solutions to stay ahead of the competition.

Their experience not only improves product quality, optimises manufacturing processes, and aids in competitive advantages in the fast-paced electronics business.

In addition to design and development, these professionals guarantee the longevity and functionality of electronic gadgets with a thorough understanding of circuits and components.

They can swiftly detect faulty PCBs or any other electronic issues promptly, and resolve them within minimal downtime and also help in extending product life to eliminate waste or resources.

Their understanding of schematic electronics design allows them to explore complex systems, discover root issues, and execute successful solutions.

How to Find a Trusted Design and Repair Service for Electronic Products?

Search online to find trusted electronic product design and development services.

Read their customer reviews and check successful project portfolios.

Contact them directly by email or calls to discuss your needs, execution period, and pricing; it also helps to gauge their customer response and service quality.

Finally, compare overall services in the market and select a trusted design and repair service suitable for your needs and benefit from improved performance, less downtime, and cost-effective upkeep.

Source: https://extrondesignservice.blogspot.com/2024/08/get-top-notch-schematic-electronics.html

0 notes

Text

MediaTek Expands its Product Portfolio for 5G RedCap Support

The arrival of 5G RedCap tech has certainly given rise to new tech innovations in the way of software and hardware, and a lot of manufacturers have deemed it wise to invest in research and development towards adoption and support for modern 5G solutions. With that being said, MediaTek recently announced that it was expanding its portfolio of modems and chipsets to include 5G RedCap support, in the form of the M60 modem IP and MediaTek T300 chip series. With these new hardware advancements, MediaTek hopes that it will be easier to facilitate the transition to 5G-NR for different applications for require long-lasting and efficient battery life, such as wearable devices, light-weight AR hardware, IoT modules, and devices built with edge AI in mind. JC Hsu, Corporate Senior Vice President at MediaTek states: “Our RedCap solutions are a significant part of our mission to democratize 5G, providing our customersthe ability to optimize components and deliver 5G-enabled devices from a range of applications and arange of price points. The migration to 5G RedCap will replace legacy 4G/LTE solutions, offering significantly better power efficiency and more reliable user experiences compared to leading edge 5G eMMB modem solutions and legacy 4G LTE Cat 4 and Cat 6 devices.” For those unfamiliar with the term, RedCap is short for "reduced capability," and is designed to give NR consumers the benefits of 5G, such as enterprise solutions and industrial devices. RedCap makes use of more modern 5G networks and is developed to be optimized for devices with low bandwidth requirements, with lesser costs and complexities involved. MediaTek says that its T300 series is the world's first 6nm Radio Frequency System-on-chip solution that's designed to work with RedCap, and will allow brands to fully utilize the advantages of the growing RedCap adoption within different industries and such. It's built on TSMC's 6nm process and integrates a single-core Arm Cortex-A35 in a more compact PCB area. Additionally, the T300 is capable of supporting up to 227 Mbps downlink and 122 Mbps uplink data rates. With that in mind, MediaTek adds that both the T300 series and M60 will support with 3GPP R17 standard, and are developed to be power efficient with low latency. They're also equipped with MediaTek’s UltraSave 4.0 technology; the M60 in particular offers up to a 70% reduction in power consumption compared to similar 5G eMBB solutions, and up to 75% power savings compared to 4G LTE solutions. In terms of market availability, MediaTek says that T300 series devices will be sampled in the first half of 2024, with commercial samples in the second half of 2024. Read the full article

1 note

·

View note

Text

Renesas Electronics Selects Altium to Unify PCB Development Tools and Accelerate Solution Design for Partners and Customers

【Lansheng Technology Information】 Renesas Electronics announced today that it has cooperated with Altium, LLC, a global software manufacturer in San Diego, California, USA, to standardize the development of all printed circuit board (PCB) designs on the cloud platform Altium 365.

Renesas currently employs multiple PCB design tools company-wide, in part because the different businesses it has acquired over the past few years have all brought their own legacy software into the company. As Renesas integrates components from different product groups into system solutions as "Winning Portfolios," a unified PCB design tool will simplify board design for demonstration and evaluation of these "Winning Portfolios" and all other product suites , thereby reducing design complexity, improving system cost structure, and speeding up time to market.

Renesas' "Winning Portfolio" is an engineering-proven solution that integrates embedded processing, analog, power and connectivity products, allowing customers to leverage this high-level platform to realize design concepts, shorten product development cycles and reduce design-in costs. Overall risk to market. Renesas has launched more than 400 "successful product portfolios" to a wide range of customers and markets.

Altium 365 is the ideal cloud-based PCB design platform. With Altium 365, users are able to collaborate with design stakeholders and other participants while keeping IP secure and designs under version control. Users can organize designs, libraries, and contributors in one place, while sharing links to designs for real-time collaboration. With unique CAD intelligence functions, data can be stored and accessed online. Renesas will publish the ECAD library of all its products to the Altium Public Vault, and through features such as the manufacturer's component search on Altium 365, customers can select Renesas components directly from the Altium library to reduce time to market.

Lansheng Technology Limited, which is a spot stock distributor of many well-known brands, we have price advantage of the first-hand spot channel, and have technical supports.

Our main brands: STMicroelectronics, Toshiba, Microchip, Vishay, Marvell, ON Semiconductor, AOS, DIODES, Murata, Samsung, Hyundai/Hynix, Xilinx, Micron, Infinone, Texas Instruments, ADI, Maxim Integrated, NXP, etc

To learn more about our products, services, and capabilities, please visit our website at http://www.lanshengic.com

0 notes