#Pharmaceutical Processing Machine Exporter

Explore tagged Tumblr posts

Note

Theitsa, what is the attitude towards weed in Greece? I went along with my friend to visit a guy he knew in a village in Syros last summer. I was suprised when we walked through the gate to his garden and it was full of weed. Like just out there growing in the open for everyone to see. The guy was baked too. I thought it was illegal?

What he did is illegal but our culture is kinda lax, and it's known that in the islands many cultivate weed in remote fields 😅 Usually it is allowed to be sold under specific circumstances. Also in the last few months I've seen more and more stores dedicated to cannabis products and cannabis products vending machines, even in towns. Not all towns, but I mean it doesn't have to be Thessaloniki or Athens for such a vending machine to exist. A few tens of thousands of people will do.

Now, the longer legal answer:

With the Joint Ministerial Decision (JMD) No. G5g oik. 49690/2017 (Government Gazette 2238/B/29-6-2017), cannabis (and its resin) was reclassified from Table A of Law 3459/2006 on "Narcotics"—which includes completely prohibited substances—to Table B, which pertains to pharmaceutical substances. This legislative change effectively recognized cannabis as a medicinal substance with therapeutic benefits rather than merely a psychoactive substance with harmful health effects. Medical cannabis refers to medication in which the only active ingredient (i.e., the active substance) comes from varieties of the Cannabis Sativa L species with a tetrahydrocannabinol (THC) content greater than 2% (THC > 0.2%). Since then, the circulation of pharmaceutical preparations or proprietary medicinal products containing more than 0.2% THC has been permitted, provided they have a drug circulation license and are accompanied by a special (double-lined red) prescription. The medicinal properties of tetrahydrocannabinol (THC) include anti-inflammatory, analgesic, antimicrobial, and neuroprotective effects. It also acts as an appetite stimulant, has anti-nausea and antiemetic properties, and reduces the intensity of muscle spasms. Additionally, it appears to contribute to apoptosis, particularly in cancer cells. Cannabis administration is justified only in the following cases: a) In cases of acute and objectively excessive pain. b) In cases of oncological diseases. c) In cases of rheumatoid arthritis. With Law 4523/2018, the unified regulation of the production, possession, transport, storage, and supply of raw materials and substances derived from Cannabis Sativa L with a THC content greater than 0.2% (THC > 0.2%) was approved. This law also allowed for the establishment and operation of processing units for the production of final medical cannabis products, exclusively for either supplying the state monopoly for medical use or for export. The distribution of the product follows an integrated system, meaning that the same entity (whether a natural or legal person): Produces the substance. Possesses it. Transports it. Stores it. Finally supplies/sells it as a finished product to buyers. Any license or approval granted by the relevant authorities is non-transferable. There are numerous restrictions and criteria that must be met for license approval. While Law 3459/2006 classified cannabis as a prohibited narcotic substance, Law 4139/2013 on "addictive substances" clarified that narcotic substances do not include raw harvested products from the cultivation of low-THC cannabis varieties (Cannabis Sativa L) with a THC content of up to 0.2%. According to this decision, only contract-based industrial hemp cultivation is now legal in Greece, and only for varieties listed in the relevant European catalog. All preparations and CBD cannabis flowers are freely available on the market, as cannabidiol (CBD) is not classified as a narcotic substance (Law 3459/2006 – Government Gazette A’/103/25.5.2006) and does not contain the controlled substance tetrahydrocannabinol (Δ9-THC) above the legal limit of 0.2% (Law 4139/2013 – Government Gazette 74/A’/20-03-2013).

source

2 notes

·

View notes

Text

Export Import Products List

Exporting and importing products is a major part of the global economy. In 2022, the value of global merchandise trade was over $28 trillion. This means that businesses and consumers all over the world are exchanging goods and services on a massive scale.

There are a wide variety of products that are exported and imported, but some of the most common include:

Agricultural products: This category includes food crops, such as wheat, rice, and corn, as well as livestock and animal products, such as meat, dairy, and eggs.

Chemicals: This category includes a wide range of products, such as petrochemicals, pharmaceuticals, and fertilizers.

Electrical machinery and equipment: This category includes products such as generators, motors, and computers.

Food and beverages: This category includes processed foods and drinks, as well as fresh produce.

Machinery and equipment: This category includes products such as machine tools, engines, and construction equipment.

Manufactured goods: This category includes a wide range of products, such as textiles, clothing, and electronics.

Minerals and fuels: This category includes products such as crude oil, natural gas, and coal.

Other goods: This category includes products that do not fall into any of the other categories, such as furniture and toys.

Textiles and clothing: This category includes products such as yarn, fabric, and garments.

Transport equipment: This category includes products such as cars, trucks, and airplanes.

The specific products that are exported and imported vary from country to country. For example, the United States is a major exporter of agricultural products, machinery, and equipment, while China is a major exporter of manufactured goods and electronics.

Factors to Consider When Choosing Export Import Products

There are a number of factors that businesses should consider when choosing which products to export or import. These factors include:

Demand: Is there a strong demand for the product in the target market?

Competition: How much competition is there for the product in the target market?

Profitability: Is the product profitable to export or import?

Regulations: Are there any regulations that restrict the export or import of the product?

Logistics: How will the product be transported to and from the target market?

Benefits of Exporting and Importing Products

There are a number of benefits to exporting and importing products. For businesses, exporting can help to increase sales and profits, and it can also help to diversify the business's customer base. Importing can help businesses to access products that are not available domestically, and it can also help businesses to reduce costs.

For consumers, exporting and importing can help to lower prices and increase the availability of goods. For example, consumers in the United States can buy fresh produce from all over the world, and they can also buy electronics and other manufactured goods at lower prices because of imports.

Conclusion

Exporting and importing products is a vital part of the global economy. It helps businesses to grow and consumers to save money. If you are considering starting an export import business, there are a number of resources available to help you get started.

#Export Import Products List#export import products#export import data#exporter#bussiness#export#import#importers

2 notes

·

View notes

Text

How Indian Industrial Valve Manufacturers Are Shaping Global Supply Chains

Industrial valves play a critical role in controlling the flow of liquids, gases, and slurries in pipelines and machinery. They are used in almost every major industry—from oil and gas to water treatment, power plants, pharmaceuticals, chemicals, and food processing. Over the years, Industrial Valves Manufacturers in India have made a significant mark globally due to their consistent quality, competitive pricing, and technological improvements.

Let’s explore how India evolved from being a domestic supplier to becoming a global hub for industrial valve manufacturing.

1. Growing Demand from Indian Industries

India has seen rapid industrial development in the last two decades. Industries like oil & gas, petrochemicals, fertilizers, steel, power generation, and water treatment require a constant supply of industrial valves to manage pressure, flow, and safety within pipelines and systems.

This large-scale demand pushed Indian companies to start manufacturing a wide range of valves such as:

Gate valves

Globe valves

Check valves

Ball valves

Butterfly valves

Safety relief valves

Control valves

As a result, Indian manufacturers gained extensive knowledge and experience, allowing them to meet both domestic and international standards.

2. Skilled Workforce and Engineering Expertise

One of India's biggest strengths is its large pool of talented engineers and technicians. This skilled workforce enables Industrial Valves Manufacturers in India to:

Design technically accurate products

Maintain high quality control

Innovate with better materials and production techniques

Provide customized valve solutions

Many companies invest in training, research & development, and testing to improve the efficiency and durability of their valve products.

3. Cost-Effective Production and Competitive Pricing

Another major advantage India has is its cost-effective manufacturing ecosystem. The availability of:

Local raw materials

Affordable labor

Modern machining and foundry setups

...allows Indian manufacturers to offer top-quality valves at lower prices compared to European or American counterparts—without compromising on performance. This makes Indian valves highly attractive for international buyers.

4. Adoption of International Standards and Certifications

To compete globally, Indian manufacturers began adopting key certifications such as:

ISO (International Organization for Standardization)

API (American Petroleum Institute)

CE (European Conformity)

BIS (Bureau of Indian Standards)

These certifications assure customers that the products meet safety, quality, and environmental standards. Many Indian companies also conduct third-party inspections and rigorous in-house testing before shipping valves to overseas clients.

5. Government Support and Export Promotion

Government initiatives like ‘Make in India’ and Production-Linked Incentive (PLI) Schemes have played a major role in encouraging manufacturing growth. Financial assistance, simplified tax policies, and export incentives have helped valve manufacturers grow their operations and reach global customers.

Moreover, India’s participation in trade expos and industrial exhibitions worldwide has helped showcase the quality of Indian-made valves on international platforms.

6. Well-Developed Industrial Clusters and Supply Chains

Industrial valves are manufactured in key regions such as:

Pune and Mumbai (Maharashtra)

Ahmedabad and Vadodara (Gujarat)

Coimbatore and Chennai (Tamil Nadu)

Hyderabad (Telangana)

These clusters are equipped with foundries, fabrication shops, testing facilities, skilled labor, and logistics support. Proximity to seaports and airports allows easy and timely export to countries in the Middle East, Europe, Asia, and the Americas.

7. Ability to Provide Customized Valve Solutions

Not every project or application needs the same type of valve. Some require corrosion resistance, high-pressure handling, or compact sizes. Indian manufacturers are known for their flexibility and customization, which gives them an edge over bulk producers in other countries.

Whether it’s valves for marine use, cryogenic applications, or hazardous chemicals, Indian manufacturers can develop specialized solutions based on customer needs.

8. Focus on Innovation and Modern Technologies

Today’s Industrial Valves Manufacturers in India are not just focused on production but also on innovation. They use:

Computer-aided design (CAD)

CNC machining

Simulation software

Automated testing units

This helps improve precision, reduce product failure, and offer valves with better lifecycle performance. Some companies are also investing in smart and IoT-enabled valves for Industry 4.0 applications.

9. Strong Global Presence and Partnerships

Many Indian valve companies have expanded their footprint by:

Exporting to over 50+ countries

Partnering with EPC (Engineering, Procurement, and Construction) firms

Setting up offices or distributors abroad

Working with global oil & gas and power companies

These collaborations have helped Indian valve manufacturers better understand global market needs and improve their product offerings.

Conclusion

India's journey toward becoming a global hub for industrial valve manufacturing is the result of strategic growth, technical excellence, cost competitiveness, and government support. Today, Industrial Valves Manufacturers in India are known for their quality, reliability, and global standards.

Whether you are looking for standard valve solutions or custom-engineered products, Indian manufacturers have proven their ability to deliver with precision, performance, and professionalism.

1 note

·

View note

Text

How to Start a Caraway Oil Manufacturing Plant: A Complete Feasibility Report

The global demand for essential oils is booming, and among them, caraway oil is carving a niche for its wide applications in food flavoring, pharmaceuticals, aromatherapy, and personal care. Entrepreneurs looking to enter the essential oils industry may find caraway oil manufacturing both profitable and sustainable. If you're considering investing in this sector, understanding the full scope—from raw material procurement to market dynamics—is crucial. This article serves as a comprehensive guide for starting your own plant, backed by a Caraway Oil Manufacturing Plant Project Report that can guide your business strategy and investment decisions.

1. What is Caraway Oil?

Caraway oil is an essential oil extracted primarily from the seeds of the Carum carvi plant, also known as Persian cumin or meridian fennel. The oil is rich in compounds like carvone and limonene, which give it a spicy, sweet aroma and strong antimicrobial properties. It is widely used in digestive tonics, toothpastes, soaps, and as a natural flavoring agent in breads and cheeses.

2. Market Potential and Demand

The global essential oils market is projected to grow at a CAGR of over 8% between 2023 and 2030. Caraway oil is gaining prominence due to rising consumer demand for natural ingredients in wellness products. Regions such as Europe and North America dominate the consumption of caraway oil, while India, Egypt, and Hungary are major producers.

Key Market Drivers:

Rising use in food & beverage as a flavoring agent.

Increased interest in traditional and herbal medicines.

Growth in aromatherapy and natural cosmetics.

3. Business Feasibility: Is It Worth the Investment?

A Caraway Oil Manufacturing Plant is a moderate-to-high capital investment, but the profit margins are attractive due to the premium pricing of essential oils. A feasibility analysis reveals that initial investment typically ranges between $50,000 to $250,000, depending on the plant’s scale and location. Most businesses can expect a break-even period of 18 to 24 months. With efficient operations, the profit margins can be as high as 25% to 40%, offering a strong return on investment for those targeting both domestic and export markets.

4. Step-by-Step Guide to Starting the Plant

Step 1: Market Research and Project Planning

Start with detailed market research to:

Understand target demographics and customer needs.

Evaluate local and global competition.

Identify raw material sourcing locations.

Use this data to create a solid business plan, outlining production goals, budget estimates, marketing strategy, and risk analysis.

Step 2: Obtain Regulatory Approvals

Depending on your location, the following licenses and certifications may be required:

FSSAI (for food-grade oil)

GMP Certification

Pollution Control Board Clearance

Trade License and Factory License

Export-Import Code (IEC)

Step 3: Location and Infrastructure

Choose a location close to agricultural zones growing caraway seeds. This reduces logistics costs and ensures a steady supply.

Infrastructure Requirements:

Distillation units (preferably stainless steel)

Raw material storage area

Oil storage tanks

Laboratory and testing area

Packaging unit

Office and admin space

Step 4: Procurement of Machinery

The most common method of extraction is steam distillation, which requires the following machinery:

Steam boiler

Condenser

Separator

Storage vessels

Packaging machine (bottle filling, labeling)

Optional: Cold press or solvent extraction units for additional value-added products.

Step 5: Raw Material Sourcing

Caraway seeds are the main raw material. Ensure:

High purity (no moisture, free from fungal contamination)

Bulk purchase at harvest season to reduce costs

Reliable supply chain, possibly through contracts with farmers

Step 6: Production Process

The standard manufacturing process involves:

Cleaning and sorting of caraway seeds.

Steam distillation to extract oil.

Separation of oil and water.

Filtration and quality testing.

Packaging in UV-protected containers.

Step 7: Staffing and Training

You’ll need:

Trained machine operators

Quality control analyst

Packaging staff

Sales and marketing personnel

Managerial and administrative staff

Step 8: Quality Control and Certifications

Quality is key for customer retention and export eligibility. Test for:

Refractive index

Specific gravity

Purity and chemical profile

Microbial safety

Certifications like ISO 9001, HACCP, and USDA Organic can enhance your product credibility.

5. Marketing and Sales Strategy

A multi-pronged marketing approach is essential:

Online Channels:

Build an e-commerce website.

Leverage Amazon, Etsy, and other B2B platforms like Alibaba.

SEO & content marketing targeting keywords like natural caraway oil and essential oil suppliers.

Offline Channels:

Distributors in the FMCG and pharmaceutical sectors.

Participation in trade fairs and industry expos.

Cold pitching to herbal product manufacturers and wellness brands.

6. Budget Considerations

While actual expenses vary, a small to medium plant requires capital investment in land (if not leased), machinery, licenses, working capital, and marketing. For instance, machinery and setup can consume the bulk of the budget, followed by regulatory compliance costs and raw material procurement. Budget planning should allow for at least six months of operating expenses until the business starts generating consistent revenue.

Conclusion

Starting a Caraway Oil Manufacturing Plant is a promising business opportunity in the ever-expanding natural products sector. With careful planning, compliance with regulations, and strategic marketing, entrepreneurs can build a scalable, export-ready business with long-term viability. A detailed Caraway Oil Manufacturing Plant Project Report can further streamline the process by offering insights into cost analysis, plant layout, technical know-how, and market projections—serving as the blueprint for your venture.

0 notes

Text

Liquid Ring Vacuum Pumps in India: What’s New in 2025?

As industrial applications continue to evolve, liquid ring vacuum pumps remain a cornerstone of dependable and efficient vacuum generation. With their robust design, durability, and ability to handle wet and dirty gases, these pumps are widely used in industries such as pharmaceuticals, food processing, paper, chemical manufacturing, and power generation. In 2025, India’s liquid ring vacuum pump sector is witnessing significant transformations driven by innovation, sustainability, and global demand.

The Indian Market: Expanding Horizons

India has steadily emerged as a key player in the global vacuum pump market. Backed by strong engineering capabilities and cost-effective manufacturing, the country has become a preferred destination for sourcing these high-performance machines. Liquid Ring Vacuum Pump Manufacturers in India are increasingly catering not just to domestic needs but also to global demands from Southeast Asia, Europe, and Africa.

What makes Indian manufacturers stand out is their ability to combine international quality standards with competitive pricing. In 2025, this trend continues with a stronger emphasis on R&D, customized engineering solutions, and environmental compliance.

Key Trends Driving the Market in 2025

1. Energy Efficiency and Eco-Conscious Designs

Modern industries are moving toward greener technologies. Liquid ring vacuum pumps are now being designed with reduced energy consumption in mind. Indian manufacturers are adopting advanced impeller designs, variable frequency drives (VFDs), and smart monitoring systems that significantly improve the operational efficiency of these pumps.

2. Smart Integration and IoT Compatibility

With Industry 4.0 taking firm root, pumps are no longer just mechanical devices. IoT-enabled vacuum pumps can now monitor pressure levels, operating temperatures, and maintenance cycles in real-time. This predictive maintenance feature helps reduce downtime and boosts productivity, especially in critical process industries.

3. Compact and Modular Designs

Space-saving and modular construction have become a necessity for many industries. Liquid ring vacuum pumps manufactured in India are being redesigned to be more compact while maintaining or even enhancing performance. This shift is particularly beneficial for SMEs and export-focused industries with limited plant space.

4. Export Quality Compliance

Increased emphasis on compliance with international standards such as ISO, CE, and ATEX ensures that Indian-made pumps can meet global expectations. Many Liquid Ring Vacuum Pump Manufacturers in India are investing in certifications and quality systems to strengthen their global footprint.

5. Customized Engineering Solutions

2025 sees a rising demand for application-specific solutions. Whether it's corrosion-resistant materials for chemical plants or food-grade pumps for processing units, manufacturers are offering tailored designs that meet unique industrial requirements.

Future Outlook: Growth Through Innovation

The coming years hold immense promise for the Indian vacuum pump industry. With supportive government policies, increased industrialization, and growing international trust in Indian engineering, the market is projected to grow steadily.

Moreover, Indian manufacturers are expected to adopt more sustainable production techniques and integrate renewable energy into their operations. From better metallurgy to more intelligent controls, every aspect of liquid ring vacuum pump design and manufacture is undergoing transformation.

Conclusion

The year 2025 marks a new chapter for liquid ring vacuum pumps in India, one defined by smart technology, energy efficiency, and global competitiveness. With a strong focus on quality, customization, and innovation, Liquid Ring Vacuum Pump Manufacturers in India are not only meeting current industrial needs but also preparing for the future of smart manufacturing.

If you're looking to stay ahead in your industry with reliable vacuum solutions, now is the time to explore the latest advancements coming out of India’s thriving pump manufacturing ecosystem.

Request a free quote today and discover how advanced Indian-made vacuum pumps can enhance your operational efficiency.

Visit: https://www.kakatipumps.com/

0 notes

Text

The Golden Grain of Good Health: A Deep Dive into Sesame Seeds Manufacturers

In the evolving world of superfoods, sesame seeds have carved a niche for themselves as a nutritional powerhouse with immense global and cultural significance. Known for their tiny size yet massive health benefits, sesame seeds are not just culinary staples but also rich in history and industry. Today, the demand for quality sesame seeds is soaring—driven by the increasing popularity of plant-based and nutrient-dense diets. This surge has put the spotlight on Sesame Seeds Manufacturers, especially those operating in India, one of the largest producers and exporters of sesame seeds globally.

Let’s explore the sesame seed industry in-depth—from cultivation to processing, major players, export potential, and why Sesame Seeds Manufacturers in India are leading the global stage.

Understanding the Importance of Sesame Seeds

Before diving into the industrial aspects, let’s look at why sesame seeds are so sought-after:

Nutritional Value: High in healthy fats, proteins, calcium, iron, magnesium, and antioxidants.

Health Benefits: Supports heart health, reduces inflammation, strengthens bones, and improves skin and hair.

Versatile Usage: Widely used in cooking, confectionery, bakery products, cosmetics, and pharmaceuticals.

Due to these reasons, global consumers increasingly rely on Sesame Seeds Suppliers in India to ensure a consistent supply of premium-quality sesame seeds.

Types of Sesame Seeds in the Market

To understand what Sesame Seeds Manufacturers deal with, you must first know the main varieties:

White Sesame Seeds – Most commonly used in bakery and food products.

Black Sesame Seeds – Known for higher oil content and used in premium culinary dishes.

Brown Sesame Seeds – Often used in oil extraction and are slightly less expensive than black seeds.

Hulled and Unhulled – Hulled seeds have the outer shell removed, while unhulled seeds retain their natural covering.

India: The Powerhouse of Sesame Seeds Manufacturing

India is among the top producers, exporters, and Sesame Seeds Manufacturers globally. Here's why:

1. Ideal Climatic Conditions

The semi-arid and tropical climates in states like Gujarat, Rajasthan, Uttar Pradesh, Madhya Pradesh, and Maharashtra are perfect for sesame cultivation.

2. Government Support

Schemes like the “Mission on Oilseeds and Oil Palm” (MOOP) support farmers and Sesame Seeds Manufacturers in India through subsidies and modern equipment.

3. Organic Farming Initiatives

India leads in organic sesame farming, catering to international markets like the USA, EU, and Middle East, making it a preferred choice for Sesame Seeds Suppliers in India aiming for premium markets.

The Role of Sesame Seeds Manufacturers

From Farm to Factory

Sesame Seeds Manufacturers play a vital role in bridging the gap between farm harvest and market-ready product. Their responsibilities include:

Procurement: Sourcing raw sesame seeds directly from farmers or cooperatives.

Processing: Cleaning, hulling, drying, roasting, and packaging to meet quality standards.

Quality Control: Ensuring the product meets domestic and international safety regulations.

Distribution: Supplying to local markets, exporters, and direct clients.

What Makes the Best Sesame Seeds Brands in India Stand Out?

Not all manufacturers are created equal. The top Sesame Seeds Brands in India typically excel in the following areas:

1. Consistency in Quality

They invest in high-tech cleaning and hulling machines to ensure purity and maintain the natural oil content.

2. Certifications

Top Sesame Seeds Manufacturers in India hold international certifications like ISO, HACCP, FSSAI, and USDA Organic, enhancing trust in global markets.

3. Custom Packaging & Export Readiness

Customized packaging options, from vacuum packing to bulk containers, make it easier for buyers to choose based on need.

4. Traceability & Transparency

Many reliable Sesame Seeds Suppliers in India now provide full traceability from farm to pack—an important factor for quality-conscious consumers and companies.

Market Demand for Sesame Seeds Worldwide

The sesame seed market is growing steadily, with global demand driven by:

The rise in vegan and plant-based diets

Demand for cold-pressed oils and natural sweeteners like tahini

Popularity of Japanese, Korean, and Middle Eastern cuisine globally

India exports sesame seeds to over 50 countries. Some of the major importers include:

United States

Germany

Japan

South Korea

UAE

Turkey

This gives an edge to the top Sesame Seeds Manufacturers in India, especially those offering quality products at competitive prices.

Key Challenges Faced by Sesame Seeds Manufacturers

While India is flourishing in this sector, Sesame Seeds Manufacturers face several hurdles:

1. Price Volatility

Due to changing weather patterns and global commodity prices, sesame seeds often experience fluctuations.

2. Pest and Fungal Issues

Sesame crops are sensitive to fungal infections, making proper storage and handling a critical part of the processing chain.

3. Strict Export Regulations

Countries like Japan have zero-tolerance pesticide residue policies, requiring Sesame Seeds Suppliers in India to adhere to extremely strict standards.

Technological Advancements in Sesame Seed Processing

Innovation is transforming this age-old industry. Let’s look at how modern Sesame Seeds Manufacturers are improving productivity and quality:

Laser Sorters: Identify and remove foreign particles or discolored seeds.

Automated Roasting: Ensures uniform roasting to preserve nutrients and enhance taste.

Cold Press Technology: Used by premium Sesame Seeds Brands in India for oil extraction, preserving flavor and nutrients.

These advancements are helping Sesame Seeds Suppliers in India meet growing international demand while maintaining quality.

Tips to Choose the Best Sesame Seeds Suppliers in India

If you're a buyer, wholesaler, or business looking for reliable Sesame Seeds Manufacturers, here are a few tips:

Check Certifications: ISO, FSSAI, USDA Organic, etc.

Ask for Samples: Quality should be tested before committing to bulk.

Verify Source: Opt for manufacturers who directly source from farms.

Custom Packaging: Choose a manufacturer offering flexible packaging sizes.

Review Export Track Record: Look for companies with a strong export history.

Why Businesses Trust Indian Sesame Seeds Brands

From small businesses to multinational food chains, many buyers prefer Sesame Seeds Brands in India for:

Affordable pricing due to high local production

Organic and natural options

Strong after-sales and logistic support

Ability to meet urgent and large-volume orders

Spotlight: The Rise of Private Labeling in Sesame Seeds

An emerging trend in the sector is private labeling, where Sesame Seeds Manufacturers in India produce seeds under another company’s brand. This is particularly popular in:

Organic stores in the USA and Europe

Supermarket chains in the Middle East

Online sellers on Amazon, Flipkart, and other marketplaces

Private labeling helps retailers maintain brand identity while leveraging Indian manufacturing efficiency.

The Future of Sesame Seeds Manufacturers

The future looks promising for the sesame seed industry in India. Upcoming trends include:

Increased demand for value-added sesame products like tahini, sesame snacks, and sesame butter.

Growing interest in sustainable and organic agriculture.

Blockchain and AI in supply chain management for improved traceability.

As awareness around health and natural foods rises, Sesame Seeds Manufacturers are bound to play an even more pivotal role.

Final Thoughts

Sesame seeds may be small, but their impact on health, cuisine, and economy is monumental. Whether it’s nutrition-conscious households, gourmet chefs, or international wholesalers, all are seeking top-tier Sesame Seeds Suppliers in India. Thanks to advanced technology, robust infrastructure, and a deep-rooted agricultural culture, Sesame Seeds Manufacturers in India are equipped to meet this demand with excellence.

As the global appetite for superfoods grows, India’s Sesame Seeds Brands will continue to flourish—connecting tradition with technology and health with flavor. For More Information About Sesame Seeds Visit Here:- https://www.valencyagro.com/Sesame-Seeds

#Sesame Seeds Manufacturers#Sesame Seeds Manufacturers in India#Sesame Seeds Suppliers in India#Sesame Seeds Brands in India

0 notes

Text

Barcode Technology in India: Applications, Benefits, and Industry Use Cases

In today’s fast-paced digital landscape, barcode technology has become an integral part of business operations across the globe, and India is no exception. With the increasing emphasis on automation, traceability, and inventory management, barcode systems have found a firm foothold across diverse industries. From retail shelves in Mumbai to pharmaceutical warehouses in Hyderabad, the use of barcodes has transformed the way data is captured and managed. This article explores the applications, benefits, and key industry use cases of barcode technology in India, highlighting why this seemingly simple innovation is crucial to modern businesses.

What is Barcode Technology?

Barcode technology involves the use of visual, machine-readable representations of data. A barcode typically consists of a series of black and white lines of varying widths (linear barcodes) or patterns such as QR codes (2D barcodes). These codes can be scanned using optical scanners or camera-based devices to retrieve information instantly. The retrieved data can then be used for a variety of tasks such as product identification, inventory tracking, billing, and much more.

In the Indian context, barcode technology has been adopted extensively in the last decade, supported by government initiatives, growing e-commerce penetration, and the need for greater efficiency in logistics and retail. The Barcode India (BIND) initiative by GS1 India, a standards organization, has played a key role in promoting global standards for barcoding within the country.

Applications of Barcode Technology in India

The applications of barcode technology in India are vast and growing. Here are some of the key sectors and their specific implementations:

1. Retail and E-Commerce

One of the earliest adopters of barcode systems in India has been the retail industry. Barcodes simplify point-of-sale transactions by reducing manual entry and minimizing errors. Supermarkets, shopping malls, and small kirana stores use barcode scanners for billing, stock checking, and order placement. With the rise of e-commerce platforms such as Amazon and Flipkart, barcodes also help in tracking shipments, verifying product authenticity, and managing returns efficiently.

2. Healthcare and Pharmaceuticals

In the healthcare sector, barcodes are used to improve patient safety, streamline medical records, and manage inventory of drugs and equipment. Hospitals use barcode wristbands to track patient details and medication schedules, minimizing human errors. The Indian pharmaceutical industry has also made barcode labeling mandatory for export packaging to ensure track and trace capability, addressing concerns around counterfeit drugs.

3. Manufacturing and Logistics

The manufacturing industry uses barcode systems for asset tracking, inventory control, and production line management. In logistics, barcodes play a critical role in warehouse management, order fulfillment, and real-time shipment tracking. With India's growing emphasis on 'Make in India' and smart manufacturing, barcodes are essential in establishing efficient supply chains.

4. Government and Public Services

Governments in India have also embraced barcode technology for various public service initiatives. From tracking voter identity cards to managing public distribution systems (PDS), barcodes ensure transparency and efficiency. Indian Railways uses barcodes in ticketing and parcel tracking systems, contributing to better service and reduced fraud.

5. Education and Libraries

Several educational institutions across India use barcode systems for managing student records, library books, and attendance tracking. With digital campuses becoming more common, barcodes help automate processes and reduce paperwork.

6. Agriculture and Food Industry

In India’s vast agriculture and food sector, barcode technology is emerging as a tool to improve supply chain transparency. It enables traceability from farm to fork, which is crucial for food safety and quality control. Export-oriented businesses use barcodes to comply with international food safety standards and enhance their credibility in global markets.

7. Apparel and Textiles

Barcode usage in the Indian textile and apparel industry helps with SKU-level tracking, warehouse management, and inventory planning. With the rise of omnichannel retail, seamless integration of online and offline data through barcodes helps clothing brands optimize operations and customer experience.

Benefits of Barcode Technology

The benefits of adopting barcode systems are numerous and impactful across various scales of business. Here’s why Indian companies are increasingly integrating barcode technology into their operations:

1. Improved Accuracy

Manual data entry is error-prone, time-consuming, and inefficient. Barcodes reduce human error significantly, ensuring accurate data capture in real-time.

2. Operational Efficiency

From inventory management to point-of-sale processing, barcodes streamline operations. They enable quick access to data, reduce wait times for customers, and facilitate faster decision-making.

3. Cost Savings

Although setting up a barcode system requires an initial investment in hardware and software, it leads to long-term cost savings. Improved efficiency reduces labor costs and inventory shrinkage.

4. Better Inventory Control

Businesses can track stock levels with precision, avoiding overstocking or understocking. This is particularly beneficial in sectors like retail, where managing seasonal inventory is critical.

5. Enhanced Traceability

With barcodes, businesses can trace the lifecycle of a product from production to delivery. This is vital for sectors like food, pharma, and electronics, where quality and compliance are key.

6. Scalability

Barcode systems are scalable, meaning they can be expanded as a business grows. Whether it's a small retail store or a multi-location warehouse, the same technology can be adapted to fit.

7. Integration with Digital Systems

Barcodes can easily be integrated with ERP systems, warehouse management software (WMS), and point-of-sale (POS) platforms, enabling a centralized view of operations.

Challenges and the Road Ahead

Despite its many benefits, the adoption of barcode technology in India still faces challenges. These include lack of awareness among small businesses, cost of implementation, and inconsistent regulatory compliance. However, with increasing digital penetration, falling costs of scanners and printers, and government support through digital initiatives, these hurdles are slowly being overcome.

India is also witnessing a shift toward advanced barcode solutions, including QR codes and RFID (Radio Frequency Identification). While QR codes are commonly used in mobile payments and ticketing, RFID allows for non-line-of-sight data capture and is gaining popularity in logistics and asset tracking.

Conclusion

The rise of barcode technology in India reflects the country’s ongoing digital transformation across sectors. Whether in retail, pharmaceuticals, logistics, or public services, barcodes have become indispensable tools for ensuring efficiency, accuracy, and transparency. As Indian businesses continue to modernize, the role of barcode systems will only expand, supported by global standards, local innovation, and a growing demand for smart automation.

Investing in barcode technology is no longer optional—it’s a strategic necessity. Businesses that embrace this tool will gain a competitive edge, while those that lag behind risk inefficiencies and lost opportunities. With the right planning and implementation, barcode systems can be a powerful catalyst for business growth in the evolving Indian economy.

Contact Information

Interested in implementing barcode technology for your business in India? Our team of experts can help you choose the right solution, set up your systems, and train your staff for maximum efficiency. Whether you're a retailer, manufacturer, healthcare provider, or logistics operator, we offer tailored solutions that fit your needs.

#technology#barcode#asset management#rfid solutions#aidc technologies india#real time tracking#electronic devices#aidc#qr code#barcode printers

0 notes

Text

Where to Find the Best Industrial Talc Powder Manufacturers in India

India is a global leader in mineral resources, and one of the most desired industrial minerals that are produced here is talc. It finds extensive applications in the plastics, paints, paper, ceramics, cosmetics, rubber, and pharmaceuticals industries, for which the talc is suited because it is soft, chemically inert, more resistant to temperature, and absorbs moisture. For companies that are based on medical supplies and high-quality material, locating the best industrial talc powder manufacturers in India is a significant factor in the case of product quality as well as cost.

India has emerged as one of the leading producers and exporters of industrial talc powder globally for the past few decades. It is endowed with tremendous reserves, a highly educated human resource pool, and mineral processing technological breakthroughs that made it the number one choice destination to obtain products from for companies across the globe.

What Makes Indian Talc Powder Unique

Indian talc is renowned for its whiteness, low iron levels, and silky texture. These are paramount in delicate applications like cosmetics, pharma, and food-grade processing. The best industrial talc powder manufacturers in India operate with higher degrees of quality control, compliance certification, and R&D capacity to achieve domestic as well as overseas standards.

They generally offer quantities of talc products in various mesh sizes and chemical contents. Ultrafine polymer talc or coarse grades of ceramics—Indian firms can actually fulfill special orders.

Indian regions where talc is manufactured

When looking for the top industrial talc powder manufacturers in India, it is helpful to know where the largest producing clusters are. These areas provide easy access to superior raw materials and are hubs of some of the largest companies in the business:

Rajasthan: The hub of Indian talc manufacturing is largely in Udaipur and Bhilwara districts. The area provides high-purity quality talc and comprises skilled manufacturers.

Madhya Pradesh: Renowned for its abundant mineral content and growing units of talc processing.

Andhra Pradesh and Uttarakhand: Building major hubs of mining as well as processing operations.

These regions are adequately equipped with the presence of vast numbers of natural resources, road connectivity, and skilled manpower — all favorable to a prosperous talc-producing community.

Characteristics of Skilled Talc Powder Suppliers

Getting the right supplier is more than costs. The best industrial talc powder manufacturers in India possess some key characteristics:

Consistent Quality: Regular monitoring and control processes for uniform particle size, color, and composition.

Newer Technology: Precise grinding mills, jet pulverizers, and advanced sorting technology to provide precise specifications.

Certificates: Compliance with ISO, REACH, GMP, and other international standards of quality and sustainability.

Customization: Capacity to manufacture products according to the unique needs of industries such as plastics, paints, rubber, or pharmaceuticals.

International Reach: Sufficient logistics capacity and export permits to foreign purchasers.

These capacities achieve a stable, long-term supply chain, which enables innovation and excellence in your end products.

Chanda Minerals—A Reliable Name in the Industry

One of the new industrial talc powder manufacturers in India is Chanda Minerals. With headquarters in the hub of India and production facilities at the center of India, Chanda Minerals undertakes industrial-grade mining of talc, processing, and supplying. Its ultra-modern manufacturing facility is well equipped with hi-tech machines and a highly skilled staff that guarantees consistency, purity, and tailoring to each order.

Chanda Minerals is an industry solution provider serving diversified industries like plastics, paint, ceramics, and agriculture. With its stringent quality checks, eco-friendly mining, and guaranteed delivery, it has become a trusted partner for Indian consumers and international consumers. With expertise in the industry coupled with enthusiasm towards innovation, Chanda Minerals becomes a trusted supplier for the international talc market.

How to Choose the Perfect Manufacturer

Following are some tips that will assist you in locating the most appropriate industrial talc powder manufacturers in India for your company:

Request Samples: Always sample the product for your specific application before you buy a large quantity.

Visit Facilities: Wherever feasible, visit the plant in order to get an idea about the capacity of production and quality checks.

Check References: Request customer references or case studies and obtain information relating to reliability and performance.

Evaluate Logistics Support: Ensure your supplier is capable of furnishing you with packaging, warehousing, and shipping as per your specifications.

The correct manufacturer will reduce your cost of production, improve product quality, and allow you to compete favorably in your market.

The Future of Talc Manufacturing in India

While corporate leaders are inculcating performance and sustainability, Indian talc manufacturers are not only tackling this with upcoming processing technology and green technology. New applications in biopolymers, green paints, and food-grade packing are being driven by emerging opportunities for growth.

Indian industrial talc powder manufacturers are also stepping into research and development for value-added products with enhanced functional properties like fire retardancy, better dispersion, or antibacterial properties.

Final Thoughts

India's reputation in the talc industry rests on the solidity of natural resources, technological superiority, and business ethics. Be a global company or a local producer, top industrial talc powder manufacturers in India possess the professionalism, customization, and quality of service you need to survive in competitive industrial economies.

With companies like Chanda Minerals at the vanguard, the future of Indian talc manufacturing is rosy — both for innovation and for export."

0 notes

Text

Qingdao IPG Tech Co., LTD specializes in manufacturing pastillator machines and granulation equipment for industrial processing. Their systems transform molten materials, such as sulfur, wax, resin, and gum rosin, into uniform, dust-free pastilles or pellets, suitable for industries like adhesives, pharmaceuticals, food, and chemicals. The company offers complete conveyor belt production lines, handling materials with viscosities from 10 to 40,000 mPa.s and temperatures up to 300°C. Their equipment features advanced rotary distribution technology, steel belt cooling systems, and customizable solutions for precise pellet production. IPG exports to countries including Great Britain, India, Kazakhstan, Korea, and Russia, and provides automatic weighing and packaging systems to meet diverse customer needs.

Address: Jiaohe Economic Zone Management Committee, Liuwang Town, Huangdao District, Qingdao City, Shandong Province, China

Website: https://www.pastillatorsystem.com/

Phone Number: +86 19953217585

Business Email: [email protected]

Business Hours: 24/7

1 note

·

View note

Text

Hastelloy C22 Fasteners Manufacturer, Supplier & Exporter in India

Overview

Ananka Group is a leading manufacturer, supplier, and exporter of Hastelloy C22 Fasteners in India and globally. Designed to withstand the most aggressive environments, Hastelloy C22 fasteners offer excellent resistance to corrosion, stress, and oxidizing or reducing chemicals. We manufacture our fasteners in compliance with international standards such as ASTM, ASME, DIN, and ISO, guaranteeing exceptional quality and reliable performance across all applications.

What is Hastelloy C22?

Hastelloy C22, or Alloy C22, is a nickel-chromium-molybdenum-tungsten alloy that possesses high corrosion resistance in a broad spectrum of severe environments. It offers superior performance in oxidizing, reducing, and mixed acid environments, far exceeding that of standard stainless steels and many other corrosion-resistant alloys.

Types of Hastelloy C22 Fasteners We Offer

Hastelloy C22 Bolts

Hex Bolts

Heavy Hex Bolts

U-Bolts

Eye Bolts

J-Bolts

Socket Head Bolts

Hastelloy C22 Nuts

Hex Nuts

Heavy Hex Nuts

Nylock Nuts

Flange Nuts

Dome Nuts

Coupling Nuts

Hastelloy C22 Screws

Machine Screws

Socket Head Cap Screws

Self-Tapping Screws

Countersunk Screws

Hastelloy C22 Washers

Flat Washers

Spring Washers

Lock Washers

Fender Washers

Hastelloy C22 Threaded Rods

Fully Threaded Rods

Stud Bolts

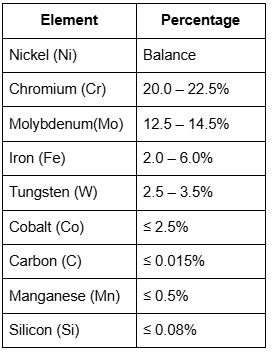

Chemical Composition of Hastelloy C22

Mechanical Properties

Key Features of Hastelloy C22 Fasteners

Reliable performance in both oxidizing and reducing conditions.

Suitable for wet chlorine gas, nitric acid, acetic acid, formic acid, and seawater

Superior thermal stability and mechanical strength

Weldable and formable for complex assemblies

Applications of Hastelloy C22 Fasteners

Chemical Processing Industries

Pulp and Paper Manufacturing

Waste Treatment Plants

Pharmaceutical & Biotech Equipment

Marine and Offshore Engineering

Pollution Control Systems

Nuclear Power Systems

Why Choose Ananka Group for Hastelloy C22 Fasteners?

State-of-the-Art Manufacturing – Precision CNC machining and rigorous quality control.

Worldwide Delivery Network – Catering to clients throughout the USA, Europe, the Middle East, and Asia.

Standards Compliance – ASTM B574, B564, B575, ASME, DIN, ISO, and more.

Custom Solutions – We manufacture as per client's drawings and specifications.

Bulk Stock Availability – Fast turnaround time with ready-to-ship inventory.

Available Standards & Grades

ASTM B574 / B564 / B575 / B622 / B619

ASME SB-574 / SB-564 / SB-575

ISO, DIN, EN, BS Standards on request

Packaging & Export

Our Hastelloy C22 fasteners are securely packed in:

Wooden crates

Bubble wraps

Waterproof packaging

Custom labeling for bulk orders

Exported to over 30 countries, including the USA, UK, Germany, UAE, Saudi Arabia, Australia, and Singapore.

FAQs

Q1. What are Hastelloy C22 fasteners used for?They are utilized in extremely corrosive environments such as chemical processing, marine, and nuclear industries.

Q2. Are Hastelloy C22 fasteners resistant to seawater?Yes, they offer excellent resistance to saltwater corrosion and pitting.

Q3. What makes Hastelloy C22 better than other alloys?It offers superior corrosion resistance in both oxidizing and reducing environments, making it versatile for complex applications.

Q4. Do you offer custom fastener manufacturing?Yes, we offer made-to-order solutions per drawings or sample requirements.

#Hastelloy#Hastelloyc22#B2B#b2bbusiness#Marketing#Manufacturing#Fasteners#Engineering#Grade#Material#Blog#Articles#Export#GlobalBusiness#Networking#Innovation#MadeInIndia#GlobalSupplyChain#BusinessGrowth#anankafasteners#ananka#manufacturer#supplier#tumblr#blog tumblr

0 notes

Text

Pharma Machine Manufacturer & Supplier in India | IRM Enterprise Pvt. Ltd – Trusted Pharma Machine

IRM Enterprise Pvt. Ltd stands as a prominent Pharma Machine Manufacturer in India, offering a comprehensive range of pharmaceutical machines that meet stringent industry standards and cater to the needs of pharmaceutical producers across the globe.

Leading the Way in Pharmaceutical Machines

IRM Enterprise Pvt. Ltd has carved a niche in the Indian pharmaceutical machinery industry through its innovative approach, superior engineering, and commitment to quality. As one of the most reputed Pharma Machine Suppliers, the company offers equipment that serves the full spectrum of pharma production – from formulation and granulation to tablet compression, capsule filling, liquid processing, and packaging.

The pharmaceutical industry demands precision machinery capable of handling complex formulations and high production volumes without compromising on hygiene and efficiency. IRM Enterprise delivers on all fronts, offering tailored solutions to both small-scale manufacturers and large-scale pharmaceutical corporations.

Wide Range of Pharma Machines Offered

IRM Enterprise Pvt. Ltd specializes in a vast portfolio of pharmaceutical machines engineered to optimize production, minimize downtime, and ensure regulatory compliance. Key offerings include:

Tablet Compression Machines: These machines are essential in compressing granulated powders into tablets of uniform size and weight. IRM’s tablet press machines are known for their robustness, user-friendly interface, and high output efficiency.

Capsule Filling Machines: Designed to accurately fill powder, granules, or pellets into capsules, these machines ensure dose consistency. Available in both semi-automatic and fully automatic variants, they serve diverse production needs.

Liquid Filling and Sealing Machines: Perfect for filling oral and injectable liquids, these machines guarantee precise fill volumes and sterile sealing – critical in maintaining drug efficacy.

Granulation Equipment: Including high shear mixers, fluid bed dryers, and oscillating granulators, these machines prepare the base material for tablet or capsule formation.

Powder Processing Machines: From blenders to mills and sifters, IRM Enterprise manufactures a full range of equipment that ensures uniform mixing and size reduction of pharmaceutical powders.

Packaging Solutions: IRM offers a variety of machines for blister packing, strip packing, labeling, and cartoning. These machines help maintain product integrity and extend shelf life.

Why Choose IRM Enterprise Pvt. Ltd as Your Pharma Machine Partner?

As a trusted Pharma Machine Manufacturer in India, IRM Enterprise Pvt. Ltd brings several advantages that set them apart:

✅ Unmatched Engineering Expertise

Backed by years of experience and a skilled R&D team, IRM Enterprise incorporates the latest technological advancements into every machine they produce.

✅ Compliance with International Standards

All machines are designed to comply with GMP (Good Manufacturing Practices), WHO, and other international standards, ensuring acceptance in global markets.

✅ Customization for Diverse Requirements

Every pharmaceutical production unit has unique needs. IRM provides customized machinery solutions that align perfectly with specific production goals and space constraints.

✅ Durability and Reliability

The machines are built with high-grade stainless steel and precision components to ensure long-lasting performance with minimal maintenance.

✅ After-Sales Support and Training

IRM Enterprise is not just a machine supplier but a long-term partner. They offer complete installation support, operator training, and prompt after-sales service to ensure smooth operation.

Serving the Indian and Global Market

IRM Enterprise Pvt. Ltd is not just a Pharma Machine Manufacturer for the Indian market but has extended its reach across international borders. With exports to Asia, Africa, the Middle East, and parts of Europe, the company has become a reliable name worldwide. Their commitment to delivering technologically advanced and cost-effective solutions makes them a preferred Pharma Machine Supplier in competitive international markets.

Future-Ready Manufacturing Solutions

The pharmaceutical sector is constantly evolving with the integration of automation, data tracking, and smart controls. IRM Enterprise is well-prepared to meet these future demands by offering machines embedded with Industry 4.0 features. With innovations like PLC-based automation, touchscreen interfaces, real-time data monitoring, and remote diagnostics, their pharmaceutical machines are designed for the future of smart manufacturing.

Industries Served

IRM Enterprise caters to a diverse clientele, including:

Pharmaceutical manufacturers

Nutraceutical companies

Biotech firms

Ayurvedic and herbal medicine producers

Research laboratories

Veterinary medicine manufacturers

Each sector requires high levels of hygiene, accuracy, and scalability—features IRM’s machines are specifically designed to deliver.

Commitment to Sustainability and Clean Manufacturing

IRM Enterprise is equally focused on sustainability, integrating energy-efficient designs and reducing waste in the manufacturing process. Their pharma machines are designed to reduce power consumption, optimize material usage, and promote eco-friendly operations—ensuring a greener footprint for your manufacturing unit.

Quality Assurance and Certifications

Every machine undergoes rigorous quality checks at every stage of production. IRM Enterprise is ISO-certified and adheres to strict QA/QC protocols. Their machines meet national and international compliance standards, giving clients peace of mind and assurance of consistent performance.

In a competitive and quality-driven industry like pharmaceuticals, the importance of reliable, high-performance machinery cannot be overstated. IRM Enterprise Pvt. Ltd, as a trusted Pharma Machine Manufacturer in India, stands as a beacon of quality, innovation, and customer satisfaction. Their comprehensive range of pharmaceutical machines is a testament to their dedication to excellence and their deep understanding of the industry's evolving needs.

Whether you're looking to set up a new pharmaceutical manufacturing unit or upgrade existing equipment, IRM Enterprise Pvt. Ltd is your ideal partner for world-class machinery and ongoing support.

Ready to Upgrade Your Pharmaceutical Production?

Get in touch with IRM Enterprise Pvt. Ltd, your trusted Pharma Machine Manufacturer and Supplier in India, for top-of-the-line pharmaceutical machines tailored to your needs.

Let’s build the future of pharmaceutical manufacturing—together.

For more info: https://www.karnavatiengineering.com/

Call Now: 7567876473

Email id: [email protected]

Location: S. No. 342, Nani Kadi, Taluka - Kadi, Dist - Mehsana, Gujarat - 382715, India

#Pharmaceutical Machines#Pharma Machine#Pharma Machine Manufacturer#Pharma Machine Manufacturer in India#Pharma Machine Suppliers

0 notes

Text

How Calcium Carbonate Is Extracted and Processed

Calcium carbonate is one of the most widely used minerals across the globe. It is a crucial raw material in industries such as construction, paper, plastics, paints, pharmaceuticals, and agriculture. Found naturally in limestone, chalk, and marble, calcium carbonate (CaCO₃) is prized for its whiteness, purity, and versatility. But how does it go from natural deposits to a fine, industrial-grade powder?

This article provides a comprehensive look into how calcium carbonate is extracted and processed—from quarry to final product. We’ll also highlight why working with a trusted Calcium Carbonate Manufacturer in India can ensure superior quality, cost efficiency, and supply chain reliability.

What Is Calcium Carbonate?

Calcium carbonate is a chemical compound made up of calcium, carbon, and oxygen. It naturally occurs in rocks such as limestone, marble, and chalk, and is also found in the shells of marine organisms and eggs. It is available in two primary forms:

Ground Calcium Carbonate (GCC): Produced by mechanical grinding of natural limestone or marble.

Precipitated Calcium Carbonate (PCC): Produced through a chemical precipitation process involving carbon dioxide and lime.

This article focuses on the extraction and processing of Ground Calcium Carbonate (GCC).

Step-by-Step: How Calcium Carbonate Is Extracted and Processed

1. Mining and Quarrying

The process begins with the identification of high-purity limestone or marble deposits. In India, states like Rajasthan, Gujarat, and Himachal Pradesh are known for their vast reserves of quality limestone.

The mining process includes:

Surveying and Mapping: Geologists assess the quality, thickness, and distribution of the deposit.

Overburden Removal: The top layer of soil and rock is removed to access the limestone.

Extraction: Limestone is extracted using drills, explosives, or mechanized equipment like excavators and bulldozers.

The extracted rocks are then transported to the processing plant for further refinement.

2. Primary Crushing

At the plant, the raw limestone is passed through crushers (usually jaw or cone crushers) that reduce large chunks into smaller, manageable pieces. This step is essential to prepare the material for grinding.

3. Grinding and Pulverization

The crushed limestone is fed into grinding machines such as ball mills, vertical roller mills, or Raymond mills. The goal here is to reduce the limestone into a fine powder.

The degree of fineness depends on the intended application:

Coarse particles (100-200 mesh) for agriculture and construction

Fine particles (300-500 mesh) for plastics, paints, and coatings

Ultra-fine particles (800 mesh or more) for specialty industries like cosmetics or pharmaceuticals

4. Air Classification

Once ground, the powder is passed through classifiers or sieves that separate particles based on size. Air classifiers are often used to ensure a uniform particle distribution. Finer grades may go through multiple stages of classification.

5. Surface Treatment (Optional)

In some industries—particularly plastics, rubber, and coatings—the calcium carbonate may undergo surface modification. This involves coating the particles with fatty acids like stearic acid to enhance compatibility with organic compounds and improve dispersion.

6. Quality Control and Testing

Before packaging, calcium carbonate undergoes stringent quality control tests, including:

Whiteness and brightness index

Particle size distribution (PSD)

Moisture content

Chemical purity (CaCO₃ content)

Specific gravity and oil absorption

These parameters ensure that the product meets industry-specific requirements.

7. Packaging and Distribution

Once the product passes quality checks, it is packed in moisture-proof bags or bulk containers (such as jumbo bags or tankers) depending on the client's requirements. It is then shipped locally or exported to global markets.

Applications of Calcium Carbonate

The versatility of calcium carbonate makes it essential in various industries:

Construction

Used as a key ingredient in cement, concrete, and mortar. It also serves as a base material in roads and as a filler in asphalt.

Paper and Pulp

Calcium carbonate is used as a filler and coating agent to enhance paper brightness, smoothness, and printability.

Plastic and Rubber

Acts as a functional filler to improve mechanical strength, reduce material costs, and increase thermal conductivity.

Paints and Coatings

Used as an extender and pigment, it improves opacity, brightness, and weather resistance.

Agriculture

Used to neutralize acidic soils and provide essential nutrients like calcium and magnesium.

Pharmaceuticals and Food

High-purity grades are used as dietary calcium supplements and food additives (E170).

Why Choose a Calcium Carbonate Manufacturer in India?

India is one of the largest producers of calcium carbonate in the world. Partnering with a reliable Calcium Carbonate Manufacturer in India offers several advantages:

1. Abundant and High-Quality Resources

India has vast limestone deposits known for their high purity, making it easier to produce premium-grade calcium carbonate at scale.

2. Cost-Efficient Production

Lower labor and production costs allow Indian manufacturers to offer highly competitive pricing without compromising on quality.

3. Technological Expertise

Modern Indian manufacturers use advanced machinery and quality control systems, ensuring consistent product specifications across batches.

4. Export Capabilities

Many Indian suppliers are well-established exporters, capable of meeting international demand with proper documentation, timely delivery, and global logistics support.

5. Customization and Technical Support

Top-tier manufacturers offer tailored solutions such as custom particle sizes, surface-treated grades, and technical consultations for specific industrial applications.

Conclusion

The production of calcium carbonate—from natural limestone to industrial-grade powder—is a well-defined, precision-driven process involving extraction, grinding, classification, and testing. Its widespread use across diverse industries makes it one of the most important industrial minerals today.

Choosing the right Calcium Carbonate Manufacturer in India is key to ensuring consistent quality, cost savings, and reliable supply. Whether you're in construction, plastics, pharmaceuticals, or agriculture, sourcing calcium carbonate from a trusted Indian manufacturer can significantly enhance your product performance and operational efficiency.

0 notes

Text

India's Rising Rubber Manufacturing Power

In today's fast-paced industrial environment, components that ensure safety, efficiency, and reliability are more critical than ever. Among these essential components are rubber seals, gaskets, and custom-moulded products—key to preventing leaks, managing pressure, and improving machine performance. India, with its growing manufacturing expertise, is now home to leading global suppliers in this space. Companies like GB Rubber Product and other custom rubber moulded products manufacturers are setting high standards in quality, innovation, and customization.

The Importance of Seals and Gaskets in Industrial Applications

Whether it's an automotive engine, hydraulic system, chemical plant, or food processing equipment, seals and gaskets are indispensable. They prevent the leakage of liquids and gases, withstand high pressures and temperatures, and extend the service life of machinery. That’s why choosing the right seals and gaskets suppliers is essential for industries across sectors.

Top seals and gaskets suppliers in India now offer a broad range of solutions—including rubber, silicone, PTFE, and graphite gaskets—that are resistant to oil, chemicals, and temperature fluctuations. They serve key sectors such as automotive, railways, aerospace, defense, oil & gas, and pharmaceuticals, delivering components that meet global standards.

GB Rubber Product: A Name Synonymous with Quality

One of the most trusted names in the Indian rubber industry is GB Rubber Product. Known for its commitment to quality and customer satisfaction, the company specializes in manufacturing rubber components that are used across diverse industries.

GB Rubber Product offers a comprehensive range of solutions including anti-vibration mounts, rubber-to-metal bonded parts, gaskets, seals, bellows, and custom-engineered rubber parts. With a strong focus on R&D and product testing, the company ensures all products meet stringent performance requirements and international certifications.

Thanks to its investment in modern infrastructure and highly skilled workforce, GB Rubber Product is not only serving the domestic market but is also exporting to clients across Europe, the Middle East, and North America. Their products are engineered to perform in the most demanding environments, offering reliability and long service life.

Custom Rubber Moulded Products Manufacturer: Tailored to Industry Needs

The industrial world is rapidly shifting toward customization, and that's where a Custom Rubber Moulded Products Manufacturer becomes crucial. These manufacturers specialize in designing and producing tailor-made rubber components to suit specific operational needs.

A custom rubber moulded products manufacturer can develop products in various shapes, hardness levels, and material types—whether it’s Nitrile, EPDM, Silicone, Neoprene, or Viton. These custom components are widely used in sealing, vibration isolation, damping, and load-bearing applications across industries.

By working closely with clients during the design and prototyping stages, these manufacturers ensure that the final product offers a perfect fit and optimal performance. From rubber grommets and bushings to engine mounts and diaphragms, the focus is always on delivering value through innovation and precision.

Conclusion

India's rubber manufacturing sector is evolving rapidly, offering both standard and customized components for industries across the globe. Reputed seals and gaskets suppliers, industry leaders like GB Rubber Product, and skilled custom rubber moulded products manufacturers are driving this change with their technical expertise, material knowledge, and commitment to quality.

As global demand grows for reliable and performance-focused rubber components, Indian manufacturers are perfectly positioned to deliver—backed by scalable production, competitive pricing, and strong engineering capabilities.

0 notes

Text

Trusted AODD Pump Manufacturers in India

In the dynamic landscape of industrial fluid handling, AODD Pump Manufacturers in India have emerged as pivotal players, delivering innovative and reliable solutions across various sectors. Among these, Ambica Machine Tools stands out as a premier AODD Pump Manufacturer in India, renowned for its commitment to quality, performance, and customer satisfaction.

Understanding AODD Pumps

Air Operated Double-Diaphragm Pumps (AODD pumps) are positive displacement pumps powered by compressed air. They are designed to handle a wide range of fluids, including corrosive, viscous, and abrasive substances, making them indispensable in industries such as chemicals, pharmaceuticals, food and beverage, and wastewater treatment.

Why Choose Ambica Machine Tools?

As a leading Air Operated Double-Diaphragm Pump Supplier, Ambica Machine Tools offers a diverse range of AODD pumps engineered for durability and efficiency. Their pumps are constructed from high-quality materials like SS316, PVDF, aluminum, and polypropylene, ensuring compatibility with various industrial applications.

Key features of their AODD pumps include:

Self-Priming Capability: Able to prime up to 5 meters, facilitating easy startup without manual priming.

Run-Dry Operation: Designed to operate safely without fluid, preventing damage during unintentional dry runs.

Explosion-Proof Design: Suitable for hazardous environments, as they operate without electricity, reducing the risk of sparks.

Low Maintenance: Simplified construction with fewer moving parts minimizes wear and tear, leading to reduced downtime.

These features position Ambica Machine Tools as a trusted Air Operated Double-Diaphragm Pump Exporter, catering to clients not only in India but also across the Middle East, Africa, Southeast Asia, and Europe.

Applications Across Industries

The versatility of AODD pumps makes them suitable for a multitude of applications:

Chemical Processing: Handling acids, solvents, and corrosive fluids with ease.

Pharmaceuticals: Transferring syrups, ointments, and other sensitive products while maintaining hygiene standards.

Food and Beverage: Moving products like milk, sauces, and juices without compromising quality.

Oil and Gas: Safely transferring fluids in explosive environments.

Water Treatment: Managing wastewater and sludge efficiently.

Ambica Machine Tools' commitment to delivering high-performance pumps tailored to specific industry needs underscores their reputation as a leading AODD Pump Manufacturer in India.

Commitment to Quality and Innovation

Ambica Machine Tools adheres to stringent quality standards, ensuring that each pump meets international certifications such as ISO, CE, and ATEX. Their focus on innovation and customer-centric design has solidified their position among the top AODD Pump Manufacturers globally.

By offering customized solutions and comprehensive technical support, they ensure that clients receive pumps that align perfectly with their operational requirements.

Conclusion

For industries seeking reliable and efficient fluid handling solutions, partnering with a reputable Air Operated Double-Diaphragm Pump Supplier is crucial. Ambica Machine Tools exemplifies excellence in this domain, providing high-quality AODD pumps that cater to diverse industrial needs.

Whether you're in the market for a dependable AODD Pump Manufacturer in India or an experienced Air Operated Double-Diaphragm Pump Exporter, Ambica Machine Tools offers the expertise and product quality to meet and exceed expectations.

0 notes

Text

Source Used Industrial Drying Equipment from The Largest Dealer in Southern Hemisphere!

Both new and established companies might benefit from investing in used industrial drying equipment. Used machinery is an affordable option for well-established businesses looking to increase production capacity, replace antiquated equipment, or test new product lines without having to make a sizable financial investment.

Purchasing used industrial equipment frees up funds for other important initiatives like marketing or research and development. Buying used equipment lowers startup costs and makes it simpler for businesses with tight finances to enter the market. Reliability and efficiency are ensured by high-quality used machinery, which frequently operates on par with new equipment.

Investing in Used Industrial Equipment from Reputable Dealers:

Purchasing used equipment promotes sustainability by cutting waste, making it an environmentally responsible decision. They supply the best machine with appropriate inspection and upkeep when sourcing from reputable dealers.

To make it a low-risk investment for their clients and encourage expansion and innovation for companies of all sizes, some dealers also offer a warranty at the time of purchase.

Companies looking to buy high-quality, dependable, and reasonably priced machinery without increasing their export expenditures can look for these top Southern Hemisphere merchants.

These details reduce the possibility of downtime and guarantee that every machine operates at its best, which has allowed them to gain the trust of their customers for more than ninety years.

They also provide a "try before you buy" service that lets clients test equipment in actual settings to make sure it suits their needs before making a purchase.

They ensure that businesses have access to the right, carefully examined, and reconditioned machinery to meet their unique demands by combining their significant industry expertise with a reputation for providing many businesses with great service.

They offer a diverse portfolio that includes companies in the food, pharmaceutical, and manufacturing industries. Their large workshop facilities and knowledgeable experts also guarantee that all machinery satisfies strict quality standards and is frequently rebuilt according to manufacturing specifications.

Buying used equipment from a reliable dealer helps start-ups save a lot of money on their initial capital outlay and free up funds for other essential areas like product development or marketing.

Expanding production capacity or modernising machinery can also be advantageous for established firms without incurring the high costs associated with purchasing new equipment.

Additionally, these top-used machine dealers streamline the acquisition process and reduce operational disruptions by providing value-added services like international shipping, equipment leasing, and machinery removals.

Thus, conduct thorough market research to choose a reputable used machine dealer and purchase the machine people need at a reasonable price.

Source

0 notes

Text

The Hidden Risks of Ignoring Flip-Off Cap Inspection in Pharma Packaging

In pharmaceutical manufacturing, every detail counts — from sterile filling to labeling. But one component often overlooked is the flip-off cap that seals injectable vials. It’s small, yes — but the consequences of not inspecting it are anything but.