#Power monitoring system

Explore tagged Tumblr posts

Text

The Global Impact of High-Quality Current Transformer Bases

In the ever-evolving landscape of energy distribution and management, current transformers play a pivotal role in ensuring accurate measurement and monitoring of electrical currents in power systems. A critical component within these transformers is the current transformer base, which serves as the foundation for the safe and efficient operation of transformers. As global demand for energy continues to surge, the significance of high-quality current transformer bases in modern power infrastructures cannot be overstated.

Current transformer bases are instrumental in energy distribution networks, helping to measure current accurately and protect electrical systems from faults and overloading. This blog will delve into the global impact of high-quality current transformer bases and highlight the importance of reliable manufacturers and exporters in India, the growing role of air-insulated switchgear companies, and the increasing need for advanced power monitoring systems.

The Role of Current Transformer Bases in Power Systems

Current transformers (CTs) are essential in the measurement and control of electrical currents in various applications, from power generation and transmission to industrial automation and energy metering. The current transformer base acts as the structural platform on which the transformer operates, ensuring the stability and insulation of the CT during operation.

High-quality current transformer bases provide enhanced accuracy in current measurement, which is critical for maintaining the efficiency and safety of power systems. These bases also ensure proper insulation and protection of the transformer, preventing short circuits, arcing, and other potential hazards.

For industries where power quality and reliability are paramount, such as manufacturing, utilities, and data centers, the performance of the current transformer base directly impacts the effectiveness of power monitoring and control systems.

India: A Global Hub for Current Transformer Base Manufacturing

India has emerged as a key player in the global energy sector, and its manufacturers are becoming increasingly prominent in the production of critical power components. As a leading current transformer base manufacturer and exporter in India, Radiant Enterprises and other companies have made significant strides in meeting global demand for high-quality products. Indian manufacturers are known for their technical expertise, innovative solutions, and adherence to international standards, making them a trusted source for current transformer bases.

The rise of India as a global manufacturing hub has been driven by several factors:

Cost-Effective Production: Indian manufacturers offer competitive pricing without compromising on quality, making their products attractive to global markets.

Skilled Workforce: India boasts a highly skilled workforce with expertise in the design, production, and testing of electrical components, including current transformer bases.

Adherence to International Standards: Indian manufacturers comply with global quality standards such as ISO, IEC, and other industry certifications, ensuring that their products meet the stringent requirements of international clients.

Growing Export Market: India’s export market for electrical components has seen steady growth, with manufacturers catering to the needs of clients across Europe, North America, Africa, and Asia.

As the global demand for energy continues to rise, the role of Indian manufacturers and exporters in meeting the need for high-quality current transformer bases becomes even more significant.

Impact on Power Monitoring Systems

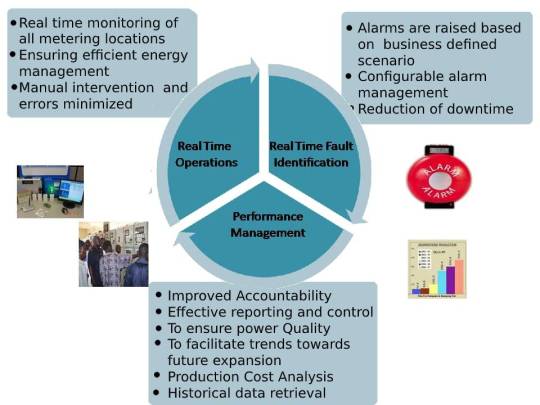

Power monitoring systems are essential tools in modern electrical infrastructure, providing real-time data on the performance of power distribution networks. These systems help monitor energy usage, detect faults, and optimize the efficiency of electrical systems, thereby ensuring the reliability and safety of power networks.

The accuracy of power monitoring systems depends heavily on the precision of current transformers and, by extension, the quality of the current transformer bases. High-quality current transformer bases ensure that the transformers can operate effectively, delivering accurate data to power monitoring systems.

Some of the key benefits of power monitoring systems include:

Real-Time Data: Power monitoring systems provide instant data on power usage, current levels, and potential faults, allowing for immediate corrective action.

Improved Energy Efficiency: By analyzing data from power monitoring systems, businesses can optimize their energy usage, reduce waste, and lower operational costs.

Enhanced Safety: Power monitoring systems can detect anomalies in current flow, such as overloads or short circuits, and alert operators to potential safety hazards before they escalate.

Preventive Maintenance: With accurate data on system performance, companies can implement preventive maintenance strategies, reducing downtime and preventing costly repairs.

Given the growing emphasis on energy efficiency and sustainability, the demand for high-quality power monitoring systems continues to rise globally. In turn, the importance of reliable current transformer bases in supporting these systems cannot be overstated.

The Role of Air Insulated Switchgear Companies in India

Switchgear is a vital component of power distribution systems, used to control, protect, and isolate electrical equipment. Air-insulated switchgear (AIS) is one of the most widely used types of switchgear in medium- and high-voltage power distribution applications. These systems use air as the primary insulating medium and are designed to protect electrical circuits from faults while ensuring the continuity of power supply.

Air-insulated switchgear companies in India are playing a key role in modernizing electrical infrastructure across the country and globally. India has become a prominent player in manufacturing air-insulated switchgear due to its expertise in power distribution equipment, favorable production costs, and adherence to international quality standards.

Air-insulated switchgear companies in India contribute to the global power industry in several ways:

Innovative Solutions: Indian manufacturers are continually developing advanced air-insulated switchgear solutions to meet the evolving demands of modern power systems. These innovations include more compact designs, improved insulation technologies, and enhanced safety features.

Cost Efficiency: Indian air-insulated switchgear companies offer competitive pricing compared to manufacturers in other parts of the world, making them a cost-effective solution for global clients.

Environmental Considerations: As the world shifts toward greener energy solutions, air-insulated switchgear offers an environmentally friendly alternative to gas-insulated switchgear, which uses greenhouse gases such as SF6 for insulation.

The Global Impact of High-Quality Electrical Components

The global energy landscape is undergoing a profound transformation driven by the increasing demand for electricity, the transition to renewable energy sources, and the need for improved energy efficiency. As a result, the demand for high-quality electrical components, including current transformer bases and air-insulated switchgear, is growing at an unprecedented rate.

High-quality current transformer bases are crucial for ensuring the accuracy and reliability of electrical measurements, which in turn supports the effective operation of power monitoring systems. These systems are essential for optimizing energy usage, improving safety, and ensuring the reliability of electrical infrastructure.

The growing role of current transformer base manufacturers and exporters in India in meeting global demand highlights the country's importance in the global energy sector. Indian manufacturers are supplying high-quality products that meet international standards, helping to improve power distribution networks around the world.

Similarly, air-insulated switchgear companies in India are contributing to the modernization of electrical infrastructure, both domestically and internationally. Their innovations are helping to improve the efficiency and reliability of power systems, while also offering environmentally friendly solutions.

Conclusion: Powering the Future with Quality

As the world moves toward a more connected and energy-efficient future, the importance of high-quality electrical components, such as current transformer bases, air-insulated switchgear, and advanced power monitoring systems, will continue to grow. These components are critical to ensuring the safe, reliable, and efficient operation of power distribution networks, which are essential to the global economy.

Manufacturers and exporters in India, including current transformer base manufacturers, are playing a vital role in meeting global demand for high-quality electrical products. Their commitment to innovation, quality, and sustainability is helping to shape the future of the global energy landscape, ensuring that power systems are equipped to handle the challenges of tomorrow.

With the rise of renewable energy, the expansion of smart grids, and the increasing focus on energy efficiency, the demand for reliable and accurate electrical components will only continue to grow. By investing in high-quality current transformer bases and partnering with reputable air-insulated switchgear companies in India, businesses can ensure that they are prepared for the future of energy.

#Power monitoring system#Current transformer base manufacturer and exporter in India#Air insulated switchgear companies in India

4 notes

·

View notes

Text

Power Monitoring System Market Set to Soar Amid Energy Efficiency Focus

Global Power Monitoring System Market is estimated to be valued at USD 5.07 Bn in 2025 and is expected to exhibit a CAGR of 7.1% over the forecast period 2025 to 2032.

The Power Monitoring System market encompasses hardware and software solutions designed to track, record, and manage electrical parameters within industrial, commercial, and utility environments. These systems enable real-time monitoring of voltage, current, power factor, and energy consumption, delivering actionable market insights that optimize operational efficiency and reduce downtime. By integrating advanced analytics and intuitive dashboards, power monitoring solutions help facility managers identify abnormal power events, support preventive maintenance, and enforce energy-saving measures. Power Monitoring System Market Insights as businesses prioritize sustainability and cost control, the demand for seamless data visualization and automated alerts has grown, driving market trends toward cloud-based platforms and IoT integration. The robust architecture of modern power monitoring systems also enhances safety by flagging overloading conditions and mitigating fire risks. These advantages underscore the critical need for comprehensive energy management in manufacturing plants, data centers, and smart infrastructure projects. Get more insights on,Power Monitoring System Market

#Coherent Market Insights#Power Monitoring System#Power Monitoring System Market#Power Monitoring System Market Insights#Hardware#Software

0 notes

Text

https://poweramr.in/energy-management-system

Discover the power of an energy monitoring system for efficient energy management. Our solutions provide real-time data, insights, and control to optimize energy consumption and reduce costs.

0 notes

Text

youtube

first episode is up!! :0 i heard people here are kinda crazy for this story, but this is the first time ive ever seen it!!

#the dark eye#inscape#the cask of amontillado#ostuber#vtuber#shōko onishi#onishi shōko#mac os#mac os 7#system 7#happymac#classic macintosh#crt monitor#power mac#Youtube

9 notes

·

View notes

Text

I just looked at newish video cards prices and god lord these things are like, 2-3 years of my full salary

#rambling#my videocard is still good but its getting there#i have nvidea geforce gts 1070ti#*gtx i mean#even tho its an old one its still good (cope)#also to upgrade my videocard (even if we imagine ill be able to buy one lmao) i also need new motherboard new processor new cooling system a#nd new power module#basically everything lmao#i have new ssd and memory tho got em not so long ago#although main problem is that i have an unnesessary huge monitor my dad bought to play world of tanks on lmao#if i had smaller one it would be better#maybe ill buy smaller monitor but at the same time this one is awesome and i dont want it to go to waste

2 notes

·

View notes

Text

🏥 AI in Healthcare: How Artificial Intelligence Is Revolutionizing Medical Treatment

🤖 What Is AI in Healthcare? AI in healthcare refers to using machine learning, neural networks, and big data to improve medical care. It helps doctors diagnose faster, treat smarter, and monitor patients remotely. Applications include: Disease prediction Robot-assisted surgeries AI chatbots for symptom checking Automated image analysis (X-rays, MRIs, CT scans) 🧬 Faster and More Accurate…

#AI health innovation#AI hospital tools#AI in drug discovery#AI in healthcare#AI in hospitals#AI in medical research#AI patient monitoring#AI-powered diagnosis#artificial intelligence in medicine#future of medicine#health chatbots#healthcare automation#healthcare technology#medical AI#medical data security#next-gen healthcare#personalized treatment AI#predictive medicine#remote patient tracking#robotic surgery#smart diagnosis#smart health AI#smart healthcare system#virtual health assistant#wearable health tech

0 notes

Text

Vishay launches new high-CMTI isolation amplifiers for EV and industrial power applications

June 5, 2025 /SemiMedia/ — Vishay Intertechnology has introduced a new line of high-reliability isolation amplifiers — VIA0050DD, VIA0250DD, and VIA2000SD — targeting precision current and voltage sensing in industrial, energy, and electric vehicle (EV) systems. The VIA series delivers industry-leading common-mode transient immunity (CMTI) up to 150 kV/μs and offers tight gain accuracy of ±0.05%…

#electronic components news#Electronic components supplier#Electronic parts supplier#EV current sensing#GaN system monitoring#high CMTI amplifier#industrial motor control#isolation amplifier#power inverter monitoring#Vishay VIA series

0 notes

Text

About Certivo | Intelligent Compliance Solutions for Global Regulatory Needs

Certivo delivers intelligent compliance solutions designed to simplify and automate regulatory management for modern businesses in the USA, UK, and EU. Our AI-driven compliance platform helps enterprises navigate complex requirements with ease, offering real-time automated compliance monitoring and powerful product compliance software. At Certivo, we’re driven by a mission to transform how companies handle compliance, reducing risk and boosting operational efficiency. Discover our core values, vision, and innovation behind our trusted compliance management solutions. Whether you're in life sciences, automotive, or tech, Certivo helps you simplify regulatory compliance and scale faster with confidence.

#AI-powered compliance management software#intelligent compliance solutions for enterprises#automated regulatory compliance tools#best compliance software for B2B companies#compliance management solutions for global businesses#regulatory compliance automation platform#AI-driven product compliance software#compliance monitoring system for EU and US regulations#scalable compliance platform for regulated industries#digital compliance solutions for multinational companies

0 notes

Text

"In un giorno come questo, il sole è un insulto alla tua assenza."

"In a day like this, the sun is an insult to your absence."

- Any Other

#the northern wind's blog#the northern wind#blogs on tumblr#tumblr blogs#text posts#italian lyrics#Italian#lyrics#quotes#any other#that happens when you unfortunately come into contact with people with a black soul and some power#power: the ability to impact to another person's life#doctors have too much power#and im not talking about the power that comes with the territory#waaaaaay too much power#way more than any other person/category in this world#they can do the most horrible things to a person and never have to respond for that to anyone#It is necessary to reform the health system by introducing a system of continuous control and monitoring#of their work and their mental conditions#plus psychological and psychiatric tests during university#and they must be a discriminating factor regarding the possibility of becoming a doctor#*to impact another person's life (sorry)#impact other people's lives

1 note

·

View note

Text

MG Cooling Solutions offers the best IoT-based HVAC monitoring system, providing real-time insights, predictive maintenance, and energy optimization. With smart sensors and cloud connectivity, it ensures efficient HVAC performance, reduced downtime, and cost savings. Ideal for commercial spaces, it enhances comfort and sustainability through advanced automation and remote monitoring.

#best IoT-based HVAC monitoring system#IoT Building Automation System#IoT-powered HVAC automation#IoT Energy Management Solution#IoT-based HVAC monitoring Solution#IoT-based HVAC#system

0 notes

Text

Innovative Solar Power for Supermarkets: PVB's Bright Future

In the ever-evolving landscape of renewable energy, PVB stands out as a leader in the photovoltaic inverter industry, particularly with their innovative solar power solutions tailored for supermarkets.

Supermarkets are increasingly recognizing the benefits of integrating solar power into their operations, not only to reduce energy costs but also to enhance their commitment to sustainability. PVB's cutting-edge inverters are designed to optimize energy efficiency, ensuring that supermarkets can harness the full potential of solar energy.

With features such as advanced grid management and real-time monitoring, PVB inverters empower supermarket operators to make informed decisions about their energy consumption. This not only leads to significant cost savings but also contributes positively to the environment by reducing carbon footprints.

Moreover, PVB is dedicated to continuous innovation, ensuring that their products remain at the forefront of technology. Their commitment to quality and performance means that supermarkets can rely on PVB inverters for a seamless integration of solar power into their energy systems.

In conclusion, PVB's innovative solar power solutions are paving the way for a brighter, more sustainable future for supermarkets everywhere. Embrace the change and join the solar revolution with PVB!

#real-time monitoring#photovoltaic inverter#solar power#energy systems#sustainability#innovation#renewable energy

0 notes

Text

IoT in Action: Transforming Industries with Intelligent Connectivity

The Power of Connectivity

The Internet of Things (IoT) has become a cornerstone of innovation, as it reimagines industries and redefines the way business is conducted. In bridging the physical and digital worlds, IoT enables seamless connectivity, smarter decision-making, and unprecedented efficiency. Today, in the competitive landscape, intelligent connectivity is no longer just a technology advancement; for businesses wanting to be relevant and continue to thrive, it is now a strategic imperative.

IoT is not simply about connecting devices; it’s about creating ecosystems that work collaboratively to drive value. With industries relying heavily on real-time data and actionable insights, IoT-powered connectivity has become the backbone of operational excellence and growth. Let’s explore how this transformative technology is revolutionizing key sectors, with a focus on how businesses can leverage it effectively.

Applications of IoT in Key Industries

1.Smart Manufacturing: Efficiency Through Connectivity

Manufacturing has embraced IoT as a tool to streamline operations and boost productivity. By embedding sensors in machinery and integrating real-time monitoring systems, manufacturers can:

Predict and Prevent Downtime: IoT-enabled predictive maintenance reduces unplanned outages, saving time and money.

Optimize Resource Allocation: Smart systems track inventory, raw materials, and energy consumption, ensuring optimal usage.

Enhance Quality Control: Real-time data from production lines helps identify defects early, maintaining high-quality standards.

Example: A global automotive manufacturer integrated IoT sensors into its assembly lines, reducing equipment downtime by 25% and improving production efficiency by 30%. The ability to monitor machinery health in real time transformed their operations, delivering significant cost savings.

2.Healthcare: Improve Patient Outcomes

In healthcare, IoT has been a game-changer in enabling connected medical devices and systems that enhance patient care and operational efficiency. The main applications include:

Remote Patient Monitoring: Devices track vital signs in real time, allowing healthcare providers to offer timely interventions.

Smart Hospital Systems: IoT-enabled equipment and sensors optimize resource utilization, from patient beds to medical supplies.

Data-Driven Decisions: IoT integrates patient data across systems, providing actionable insights for personalized treatment plans.

Example: A major hospital has put into operation IoT-enabled wearables for chronic disease management. This solution reduced the number of readmissions to hospitals by 20% and empowered patients to take an active role in their health.

3.Retail: Revolutionizing Customer Experiences

IoT is revolutionizing retail through increased customer interaction and streamlined operations. Connected devices and smart analytics allow retailers to:

Personalize Shopping Experiences: IoT systems track customer preferences, offering tailored recommendations in real time.

Improve Inventory Management: Smart shelves and sensors keep stock levels optimal, reducing wastage and improving availability.

Enable Smooth Transactions: IoT-driven payment systems make checkout easier and much faster, increasing customers’ convenience

Example: A retail chain leveraged IoT to integrate smart shelves that automatically update inventory data. This reduced out-of-stock situations by 40%, improving customer satisfaction and driving higher sales.

Role of Intelligent Connectivity in Business Transformation

Intelligent connectivity lies at the heart of IoT’s transformative potential. By connecting devices, systems, and processes, businesses can:

Accelerate Decision-Making: Real-time data sharing enables faster, more informed decisions, giving companies a competitive edge.

It increases collaboration by allowing smooth communication between departments and teams, making the entire system more efficient.

Adapt to Market Dynamics: IoT enables companies to respond quickly to changes in demand, supply chain disruptions, or operational challenges.

Intelligent connectivity is not just about technology; it’s about creating value by aligning IoT solutions with business objectives. This strategic approach guarantees that IoT investments will deliver measurable outcomes, from cost savings to improved customer loyalty.

How Tudip Technologies Powers Intelligent Connectivity

Tudip Technologies specializes in designing and implementing IoT solutions that drive meaningful transformation for businesses. With a focus on innovation and collaboration, Tudip ensures that its clients achieve operational excellence through intelligent connectivity.

Tailored Solution for Every Business Industry

Tudip understands that no two businesses are alike. By customizing IoT strategies to address specific challenges, Tudip helps clients unlock the full potential of connectivity. Examples include:

Smart Supply Chains: Implementing IoT systems that provide real-time visibility into inventory and logistics, reducing delays and improving efficiency.

Energy Management: Developing IoT frameworks to monitor and optimize energy usage, driving sustainability and cost savings.

Healthcare Innovations: Designing networked medical devices that allow remote patient monitoring and data integration without a hitch.

The Future of Connected Systems

The demand for intelligent connectivity will keep increasing as the industries continue to evolve. Emerging trends in IoT include edge computing, 5G networks, and AI-powered analytics, which promise to redefine possibilities for connected ecosystems.

Businesses that embrace these advancements stand to gain:

Greater Resilience: IoT enables adaptive systems that can withstand market fluctuations and operational challenges.

Enhanced Innovation: Connected technologies open doors to new business models, revenue streams, and customer experiences.

Sustainable Growth: IoT optimizes resources and processes, contributing to long-term environmental and economic sustainability.

The future belongs to those who see connectivity not just as a technological tool but as a strategic enabler of transformation. The right partner will help businesses transform IoT from a concept into a competitive advantage.

Conclusion: Embracing Intelligent Connectivity with Tudip

IoT is not just changing the way businesses operate—it’s redefining what’s possible. From manufacturing and healthcare to retail and beyond, intelligent connectivity is driving innovation, efficiency, and growth across industries.

Tudip Technologies is at the forefront of this transformation, offering customized IoT solutions that deliver real results. By prioritizing collaboration, adaptability, and measurable outcomes, Tudip ensures that its clients stay ahead in an increasingly connected world.

Now is the time to embrace the power of IoT and unlock its potential for your business. With Tudip as your partner, the journey to intelligent connectivity is not just achievable—it’s inevitable.

Click the link below to learn more about the blog IoT in Action: Transforming Industries with Intelligent Connectivity https://tudip.com/blog-post/iot-in-action-transforming-industries-with-intelligent-connectivity/

#Tudip#IoT#intelligent connectivity#real-time data#predictive maintenance#smart manufacturing#remote patient monitoring#healthcare IoT#retail IoT#smart shelves#supply chain optimization#edge computing#AI-powered analytics#5G networks#industrial IoT#connected devices#digital transformation#operational efficiency#business intelligence#automation#data-driven decision-making#IoT solutions#smart systems#enterprise IoT#IoT-powered connectivity#sustainable growth#technology innovation#machine learning#cloud computing#smart sensors

0 notes

Text

Unveiling the Power: Exploring the Importance of Transformer Oil Testing

Introduction

Importance of Oil Testing in Transformers

Oil testing serves as a diagnostic tool to evaluate the condition of the insulating oil used in transformers. By analyzing the oil’s composition and properties, experts can detect potential issues such as contamination, oxidation, or degradation. This enables early detection of problems, facilitating timely preventive maintenance or repairs.

Regular oil testing provides multiple advantages:Early Problem Detection:It helps identify abnormal conditions that might otherwise go unnoticed, reducing the risk of unexpected failures and costly downtime.Enhanced Decision-Making: It offers valuable insights into the overall health of the transformer, aiding in informed decision-making regarding maintenance and replacement strategies.

In conclusion, oil testing is an indispensable practice for ensuring the reliability and longevity of transformers. By leveraging oil analysis, companies can proactively address potential problems, optimize performance, and ultimately save significant costs in the long run.

Why is Oil Testing Important for Transformers?

Transformers are the backbone of modern electrical power systems, playing a crucial role in the efficient transmission and distribution of electricity. These vital components rely on insulating oil to maintain performance and longevity. The insulating oil not only acts as an electrical insulator but also helps dissipate heat generated during the transformer's operation. Over time, this oil can become contaminated, oxidized, or degraded, leading to issues that compromise the transformer’s functionality and may result in catastrophic failures.

Oil testing provides a comprehensive evaluation of the oil's condition, allowing for the early detection of potential issues. By analyzing the oil’s physical, chemical, and electrical properties, experts can identify abnormalities or changes that may indicate underlying problems within the transformer. This proactive approach enables timely preventive maintenance, repairs, or replacements, ultimately enhancing the transformer’s reliability and extending its service life.

Furthermore, oil testing is a critical component of a transformer’s health monitoring and maintenance program. By regularly assessing the oil’s condition, operators can make informed decisions about the transformer’s operational status and maintenance requirements. This helps minimize the risk of unexpected failures and ensures the reliable delivery of electricity to end-users.

Types of Tests Conducted in Oil Testing

Oil testing includes a variety of analytical procedures designed to evaluate the condition and properties of insulating oil in transformers. These tests can be categorized into the following key areas:

Physical Tests:Focus on the oil’s physical characteristics, such as color, appearance, viscosity, and dielectric strength. These parameters can indicate contamination, oxidation, or degradation of the oil.

Chemical Tests:Chemical analysis provides insights into the oil’s composition and the presence of contaminants or byproducts. Tests such as dissolved gas analysis (DGA), acid number measurement, and water content determination can help identify issues like overheating, partial discharges, or moisture presence.

Electrical Tests:Evaluate the oil’s electrical properties, such as dielectric breakdown voltage, power factor, and resistivity. These tests determine the oil’s ability to withstand electrical stress and provide early warning signs of potential insulation failures.

Understanding BDV Testing

The BDV test uses a specialized apparatus that gradually increases the voltage applied to the oil sample until breakdown occurs. A low BDV value indicates reduced insulating capacity due to contamination or deterioration. Regular BDV testing ensures that the oil maintains its dielectric strength, allowing the transformer to operate safely under various electrical loads. Maintaining a high BDV value allows transformers to operate more reliably and efficiently, minimizing the risk of insulation failure and unexpected downtime. As part of a comprehensive oil testing program, BDV testing provides a clear indication of the oil’s health and supports informed maintenance decisions.

Benefits of Regular Oil Testing

Regular oil testing offers a multitude of benefits for transformer owners and operators, making it an essential component of a comprehensive asset management strategy:

Early Problem Detection:Regular monitoring allows for early identification of potential issues like contamination, oxidation, or degradation, enabling timely preventive maintenance or corrective actions.

Optimization of Maintenance Strategies:Oil testing provides data that can be used to optimize the transformer’s maintenance schedule, ensuring efficient resource allocation and peak performance.

Improved Reliability and Lifespan:Addressing issues identified through oil testing helps extend the equipment’s lifespan and enhance its overall reliability, reducing the need for costly replacements.

Cost Savings:Regular oil testing can lead to significant cost savings by proactively addressing problems before they escalate, avoiding high expenses associated with emergency repairs, unplanned downtime, and premature equipment replacement.

Common Issues Detected Through Oil Testing

Oil testing is a powerful tool for identifying a wide range of issues that can affect the performance and longevity of transformers. Some common problems detected through oil analysis include:

Contamination: Foreign particles, such as dirt, moisture, or metal particles, can compromise the oil’s insulating properties, leading to increased electrical stress.

Oxidation:Over time, insulating oil can oxidize, forming sludge, varnish, and other byproducts that impair cooling and insulating capabilities.

Thermal Degradation:Excessive heat can break down the oil, forming gases and byproducts that indicate overheating or insulation failure.

Partial Discharges: Localized electrical discharges can be detected through oil testing, indicating insulation issues or maintenance needs.

Frequency of Oil Testing

The frequency of oil testing depends on the transformer’s size, age, and operating conditions. For smaller transformers, testing may be conducted annually or every two years. However, for larger, more critical transformers, more frequent testing, semi-annually or quarterly is typically recommended. Factors such as operating environment, load conditions, and any known issues can also influence testing frequency. For example, transformers in harsh environments or under high-stress conditions may require more frequent testing to ensure reliable performance.

Oil Testing Methods and Equipment

Oil testing for transformers involves various analytical techniques and specialized equipment, including:

Dissolved Gas Analysis (DGA):Measures dissolved gas concentrations in the oil, providing insights into potential issues like overheating, partial discharges, or arcing.

Dielectric Breakdown Voltage Testing: Assesses the oil’s ability to withstand electrical stress, a key indicator of its insulating performance.

Interfacial Tension (IFT) Measurement:Evaluates the oil’s stability at the water interface, with changes indicating contamination or oxidation.

Fourier Transform Infrared (FTIR) Spectroscopy: Identifies the chemical composition of transformer oil, including the presence of additives, contaminants, and degradation by-products.

How to Interpret Oil Testing Results

Interpreting oil testing results is critical for understanding the transformer’s condition and determining appropriate actions. Experienced professionals evaluate various parameters, comparing them to industry standards and historical data to identify abnormalities or trends that may indicate underlying issues. For example, increased concentrations of dissolved gases like hydrogen or acetylene may suggest partial discharges or overheating. Similarly, a decrease in dielectric breakdown voltage or an increase in acid number may indicate the need for oil filtration or replacement. By taking a holistic approach to interpreting oil testing data, professionals provide informed recommendations for maintenance, repairs, or replacement, ensuring reliable transformer operation.

Importance of Professional Oil Testing Services

Entrusting oil testing to professional service providers ensures the accuracy and reliability of results, as well as the effective implementation of maintenance strategies. Professional services offered:

Accurate and Reliable Results:Calibrated equipment and strict quality control protocols ensure accurate and reliable oil testing results.

Comprehensive Analysis and Interpretation:In-depth analysis and interpretation of data, identifying potential issues, and recommending corrective actions.

Compliance with Industry Standards:Adherence to ASTM (American Society for Testing and Materials) standards ensures quality testing procedures and reporting.

Customized Maintenance Strategies:Tailored maintenance strategies based on the specific needs and conditions of the transformer.

Conclusion

In the world of electrical power systems, the importance of oil testing for transformers cannot be overstated. As the backbone of modern power grids, transformers play a crucial role in delivering reliable electricity. Oil testing provides invaluable insights into the condition of a transformer’s insulating oil, enabling early detection of potential issues and facilitating timely maintenance actions. The benefits of regular oil testing include improved reliability, extended lifespan, and significant cost savings. By embracing this essential practice, companies can unlock the power of their transformers, ensuring they remain resilient, efficient, and ready to meet the evolving energy needs of the future.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#lube oil#oil analysis#lvdh#transformer oil#transformers#transformer oil cleaning#oil condition monitoring#flushing#chemcial cleaning#oil testing#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power industry#steel#metal#mining#oil#lube oil flushing

0 notes

Text

Wire rope electric hoist: a powerful assistant for efficient lifting.

#Wire rope electric hoist#Efficient lifting equipment#Industrial construction hoist#Powerful lifting capacity#Multiple lifting heights available#Stable operating speed#Compact structure design#Sturdy and durable materials#Advanced transmission system#Intelligent safety protection#Overload protection device#Travel limiter#Reliable braking system#Intelligent monitoring function#Industrial manufacturing application#Construction application#Logistics and warehousing application#Electric power maintenance application

1 note

·

View note

Text

AI-POWERED FLEET MANAGEMENT

🚗 Fleetblox Cloud Garage is compatible with 43 car makes, seamlessly connecting to over 177 million vehicles through a single platform. 🌍 With global coverage across North America and Europe, our advanced AI-driven solution 🤖 optimizes fleet management, ensuring maximum operational efficiency ⚙️ and streamlined performance—all in …

#AI powered fleet solution#Cloud-based fleet tracking#No hardware fleet management#Electric vehicle fleet integration#Remote fleet monitoring#Vehicle tracking system#Virtual parking management#Real-time fleet analytics#GPS-free fleet solution

0 notes

Text

The global Switchgear Monitoring System Market is projected to reach USD 2.7 billion by 2028 from an estimated USD 1.8 billion in 2023, at a CAGR of 8.4% during the forecast period. The demand to secure electrical distribution systems is the need for the continuous monitoring of switchgear, and growing investments in renewable energy offer high-growth opportunities for the market.

#switchgears#switchgear#switchgear monitoring system market#switchgear monitoring system#switchgear monitoring#switchgear industry#switchgear market#air insulated switchgear#gas insulated switchgear#gas insulated switchgear industry#energy#energia#power generation#utilities#power#utility#electricity

0 notes