#Predictive Maintenance Of FAB

Text

In the fast-paced world of semiconductor manufacturing, staying ahead of technology while managing costs is a constant challenge. Einnosys, a company dedicated to innovative industrial solutions, introduced EIGEMbox—a simple yet powerful device that can transform existing semiconductor equipment by adding modern automation capabilities. This case study explores how EIGEMbox helped semiconductor fabs save a massive $3 million in equipment upgrade costs and enhance their operational efficiency.

#EIGEMBox#SECS/GEM#secs gem software#gem300#secs/gem software#fab automation#predictive maintenance for pumps

0 notes

Text

like the grand innovation of ros is that actually now 1) you don't have to rewrite your MESSAGING FRAMEWORK from scratch every time and you get a bunch of debug tools for free and 2) theres a bunch of prototype grade components you can probably plug together to get a demo if you know what you're doing

it's great but it's not like. whatever's going on in webservices world. and the webservices people and vcs who are used to it HATE this!!! i interned for a really crappy startup once whose entire concept was "hey, why is robotics not like webservices? clearly we need to reimplement ros but worse and dockerized lol what's hard realtime" and it so clearly had only survived as long as it had because it was The Baby of this VC guy who tried to sell me on javascript like it was an abusive boyfriend i should give ~another chance~, and right after i left they hired a new ceo and pivoted to having an actual product. theres ALLLL these guys coming from webservices land who want to pretend really hard that a malfunctioning robot is exactly as disposable as a malfunctioning docker container, and that gluing together preexisting robotics components (largely research-grade code developed on a completely different robot from whatever your product is) is exactly as easy as gluing together APIs, and it ends so badly for them every time. it's adorable.

relatedly my dad has this theory, which i think has a lot of predictive power, about how a company Makes It Big doing one thing (SAAS, or online ads, or B2B software, or like. making computer chips) and then that product cycle cadence/approach is baked into the company culture so hard that they completely flub it when they try to make something that necessitates a different approach. intel fucking sucks at making software because they inevitably drop support after 18 months because when you make a chip you design it and you send it to the fab and then it's out of your hands and there's no real way to "fix bugs" (you just maintain an errata sheet and add more tests so you can catch the bugs in the next chip you design). webservices companies who do continuous deployment or bust are often really really bad at coping with the sales and maintenance cycles of Big Businesses that a lot of b2b software is for. and software people in full generality have a ridiculously hard time with the concept that you can't exactly continuously deploy improved suspension for your robot chassis, because you have to actually crack the robot open on a workbench and swap it out.

in microservices world one of the baked-in cultural attitudes is "cattle not pets" -- your herd of docker containers is like a herd of cattle; when one of them malfunctions you take it out back and shoot it and spin up a new one, you don't waste energy on failure recovery. when you bring this approach to robotics land it inevitably fails! you have spent 4 or 5 figures minimum on a robot, that thing's a fucking pet! and also, when it malfunctions, it's flailing around potentially doing damage out here in the real world, which is... generally considered to be bad. there have to be layers and layers and layers of safety systems and fallbacks and failure recovery logic and everything needs to be designed to fail into a state that won't maim anyone, or it inevitably will fail, and maim someone. even just "if something goes wrong stop moving immediately" has some complexity to it.

webservices people are also big on "eventual consistency" and almost nothing in robotics is physically safe to do on an eventual consistency basis or else your robot will eventually (but consistently!) destroy itself and/or anything around it. the closer you get to low level control the more important it is to have hard timing guarantees and that's generally sort of antithetical to the philosophy that hardware should be as abstracted away as possible

#vc guy cornered me in an otherwise empty room with no windows for this speech too it was . bad#the trashcan speaks#robotics

75 notes

·

View notes

Photo

Because of the storm that rolled over my house and because @katblu42 mentioned it :D

-o-o-o-

The hatch creaked as the hydraulics let it down to the dry hard packed dirt. A small puff of dust billowed up around the hot cahelium and it caught in his nose, tickling in the heat.

The horizon was flat and the earth iron red as it disappeared into the ominous grey of the cloud blocking the sky.

Virgil’s boots made their own puffs of dust as he stepped off the hatch and emerged from under the shadow of Two. The puffs followed him as he walked the length of his ‘bird. The dirt gritted under his specialised soles as he avoided the heat of her cooling VTOL and the scorch of her now quiet thrusters.

His landing was precautionary. A warning light had come on during the flight home and dumping himself in the middle of the Outback for a mechanical check was preferable to taking a swan dive in the middle of the Tasman.

Outside appearances gave no clue to the issue and unfortunately, he would have to wait for her engines to cool off before attempting to access the thruster that was the problem.

A sigh and he turned back to look at the horizon.

He truly was in the middle of nowhere.

“Thunderbird Two, status report.”

Typical Scott. His brother was hip deep in a rescue on the other side of the planet, but his brother radar still managed the range.

“Status a-okay, Thunderbird One. Just taking a moment to gaze at the scenery.”

“John says you have a mechanical fault.”

“Quite possibly. Fine for the moment. Just need a little cooling time. I’ll keep you updated.”

“FAB, Thunderbird Two.”

And then it was back to the silence.

True silence.

There was no wind.

No water.

No birds.

Just the heat of a dying day leaching out of the sand, the creak of his cooling ‘bird, and the potential energy in the air.

It was going to rain.

The Kansas farm boy could tell that much. Even in another country and an entirely different environment, he could feel it.

He didn’t need fancy instrumentation to predict that.

The impending storm raised the hair on his arms under his uniform. It itched at his skin and spoke of change.

Ants crawled across his boots, winged queens and drones launching to join a cloud of them off to his right.

It was eerie.

He shifted where he stood, unsure of what to do next. He wasn’t one for killing time. Time was a valuable thing and needed to be used to its upmost. But this stop was unplanned and there was little he could do while waiting.

Sure, there were tasks. There were always tasks, nitty gritty maintenance jobs. He was never short of work.

But the air was still. The sense of building atmospheric release buzzed across his senses.

It was tantalising.

He shivered.

There were still a couple of hours before sunset, but the air was dark due to the heavy cloudbank looming over the landscape.

A thought.

A flash of guilt followed by stubborn determination.

He turned and climbed back on to the hatch and retracted it, only to lower it again a few moments later with a folded chair and a box in his hands.

He parked it in the sand.

The silence was a physical presence.

He opened the box to reveal a portable watercolour kit – a neat palette of half pans, a fine brush and a small block of high-quality paper.

It was an indulgence he kept aboard his ‘bird. One he had yet to use, so this was definitely an opportune moment. A tiny amount of time to throw down some colour and capture this red-on-blue-grey intensity.

It didn’t take him long to realise he had forgotten a couple of things. A muttering step back into his ‘bird and he returned with a small table and a cup full of water.

He finally managed to settle himself. Painting while wearing his uniform wasn’t the most comfortable. It was bulky and in the way. He did shed his gloves, which meant he had to take off his wrist controller. Scott would frown enough to dent his nose, but he couldn’t paint with his gloves on.

There was heavy lifting, but there was also sensitive and tactile manipulation. He liked to think he was capable of both.

A dip of his brush into clear water, a dab of cadmium red, and colour spilled onto the paper.

Payne’s grey filled the sky in soft billows with just a hint of ultramarine. He tried to keep his touch gentle. Watercolour was so unforgiving. Fast and delicate, the colours could easily be overdone and unlike acrylic or oils, could not be undone satisfactorily.

It took all his concentration to sketch out the worn landscape.

The parched air dried the colours quickly and it wasn’t long before he was flicking strands of yellow ochre spinifex in the foreground, the little painting almost done.

In the distance, the clouds rumbled warning.

He dabbed in a second layer to bring up the contrast, the greys echoing the thunder on the horizon. Just a touch of green brought out the red of the iron in the sand.

“I really don’t know how you do that.”

Virgil nearly fell out of his chair.

“Scott!” His heart thudded in his ears and he clutched the drying painting in his hands as it tried to slip from his fingers. “What the hell?! How did you…?” He shot to his feet and turned to find his brother standing behind him. Beyond, at a respectable distance, sat Thunderbird One.

Scott held up both hands, taking a step back. “Hey, I saw you were painting, so I parked back a ways. Figured you wouldn’t want VTOL messing with your paints.” But then his brother was smothering a grin. “You were kinda zoned out there, Virg.”

“You were in Prague! How did you get here so fast?” It was a stupid question. He was Scott Tracy. Fast was part of his genome.

But his brother frowned. “It’s been over an hour since I last contacted you. The situation is resolved. I was on my way back and thought I’d check in. John said he hadn’t had an update.”

Virgil stared at his brother. An hour? He brought his wrist up to check the time, but his controller was on the little table beside his chair with his discarded gloves.

Oh.

Scott arched an eyebrow at him.

Virgil grunted before putting the painting down carefully and retrieving his equipment. A moment later, his gloves were on and his wrist controller back in place.

It was indeed over an hour later.

Thunderbird Two would have cooled down enough forty-odd minutes ago.

“You were lost in your painting, weren’t you.” It wasn’t a question. His brother sighed, walked over to the table and picked up the piece of art. Blue eyes scrutinised it. “Nope. I don’t have a clue how you do that. It’s great, Virg.” He handed it over and somewhat numbly, Virgil took it.

He stared at the strokes in which he had been so absorbed earlier. The landscape stretched into the paper, reds bouncing off blues, the stillness captured in pigments.

Okay, so he had to admit, it was working quite well. He had muddied the colour a little in one corner and there was a patch where he’d left more white paper than was probably necessary because he was too worried about over doing the paint, but overall it mostly did what he wanted it to do. Oh, his wash hadn’t quite worked in that bit. Damn.

But…

He could get away with it.

“Earth to Virgil? You okay in there?”

Scott was smirking.

Virgil glared at him before cradling the watercolour block in one hand, picking up the palette with the other and packing it away. He stomped his way back to his ‘bird.

He ignored the laugh behind him.

He was stashing the paints in their locker when Scott joined him in Two, both the table and chair folded up in his hands. “Where do you stash these?”

Virgil gestured in the direction of the utility store and his brother put the equipment away.

Back in the cockpit, Virgil pulled up the suspect control and found the red light still glaring accusingly as Scott entered behind him.

“Give me ten. I need to inspect her starboard thruster.” He grabbed a safety line and threw back the overhead hatch. The gloomy atmosphere crept into the cockpit, but he ignored it and elevated the himself up so he could climb onto the top of his ‘bird.

“Virgil, you do know there is a storm coming in. You’re standing on the highest point for miles.”

“I’ll only be a minute.” Keep your pants on.

But his brother was right. His dawdling with his paints had cost him time and the weather was moving in.

He hurried across the back of his Thunderbird sliding carefully onto her starboard intake, and making his way down to the access hatch. He hooked in his safety line, prodded his controller to release the security, and hauled the hatch open.

Five minutes later, with several profane words that had Scott even more concerned, he yanked an obstruction out of her secondary intake valve.

It was a bright yellow, now somewhat grimy, Thunderbird Four.

No more than four inches long.

“I’m going to kill him.”

“Virg? What? Who?”

“Gordon.” He didn’t elaborate. The sky was well and truly rumbling now and he needed to get inside.

Tightening the valve, he gave it a good once over to check for damage. Another poke at his controller and the dash confirmed the issue resolved.

Access secured, he unhooked his line and made a run for the main hatch just as the landscape lit up white with lightning.

He leapt into his ‘bird as if he had that lightning on his tail.

His boots hit deck plates. Virgil reached up and threw the hatch closed and sealed away the angry sky.

Scott was staring at him.

Virgil met that gaze before walking past his brother towards his pilot seat. He casually chucked the little Thunderbird Four to his brother like the grenade it was.

Scott caught it. “What the hell?”

Gordon was dead twice over and he didn’t even know it.

“You better get back to your ‘bird. The sky’s going to open up any minute and we should probably be above it rather than below it.” Virgil poked at the weather read out. It was only a weather front, nothing compared to the cyclone forces the Thunderbirds were capable of tackling. “You might get wet.”

Scott was still glaring at the model in his hand. A distracted grunt.

Gordon was definitely dead.

Possibly more than twice.

“Okay, less imaginary brother murders and more getting back to your ‘bird.”

“Huh?”

Yeah, so now who was zoning out?

Virgil nudged his brother onto the hatch platform and stepped on himself, lowering it onto the red dust again.

He stepped off the deck plates just as the first fat rain drops started to hit the dust.

Damn. “Too late.” And as if he had given the sky permission, it really opened up.

Water hit dry earth in big splats, puffs of red rose only to be taken down by more rain. The stipple of water fast became patches and then the land deepened in colour. The bright iron red darkened almost to a burgundy. The spinifex he had so finely painted not half an hour earlier, shifted from a yellow ochre to a gold that almost glowed in the remnant light.

As Scott stepped up beside him, secure under the protection of Two’s nose, the landscape bleached suddenly and the sky grumbled and cracked. The air smelt of ozone and the sharp evaporation of precipitation in the heat. But there was more water than the air or the earth could take and it puddled in the indents between the rocks.

Some kind of thorny lizard darted out from a tuft of spinifex and hurried under the shelter of Two beside the brothers. At the lack of the rain on its back, it looked up as if surprised. Two reptilian eyes stared at them before darting back out into the rain.

Scott took another step forward and Virgil put a hand on his arm.

“You’re not going to try to run through that.”

“I’ve got to get back to One.”

“Why?”

“Because…” His brother trailed off.

Virgil squeezed his arm gently. “Take a minute. This is a desert storm. It will be short lived. We can wait.”

Blue eyes stared at him.

Okay, so waiting wasn’t part of Scott Tracy’s genome.

“Take a minute. Watch.” Virgil turned back to the storm and revelled in the release of the tension that had been building for the last couple of hours. He watched the rain hit the earth, the patterns, the dance of spinifex leaves. He listened to the roar, the wet splat against cahelium, the sigh as the water disappeared into the grass and the grumbles in the clouds.

Scott eventually turned to look and, for a short while there, they were just a couple of brothers staring out at the storm.

The fact they were sheltering underneath one of the most advanced technological creations on the planet was unimportant.

“This is all your fault, you know.” Scott’s voice was soft.

A grunt. “I think Gordon’s is the more likely culprit.”

“If you hadn’t stopped to paint, we’d be home by now.”

Virgil didn’t answer immediately. He took a breath. “But then we would have missed this.”

At that moment the sun finally hit the horizon and slipped through a gap in the clouds to light up the wet landscape in gold. Rain still fell, but it was as if it was liquid sunlight failing from the sky. Water glistened on everything and the clouds lit up from underneath.

Thunder rumbled in clouds turning pink in the east.

“Yeah, we would.” But the acknowledgement was distracted as Scott stared at the spectacle.

Perhaps they had something for which to thank Gordon. It was a moment that they would never have experienced if Virgil hadn’t had to stop.

He breathed in the freshened air and let it out with a relaxing sigh.

No.

Gordon was still dead.

-o-o-o-

32 notes

·

View notes

Text

Austria: F-35 to replace the Eurofighters

Fernando Valduga By Fernando Valduga 11/10/2022 - 22:09em Military

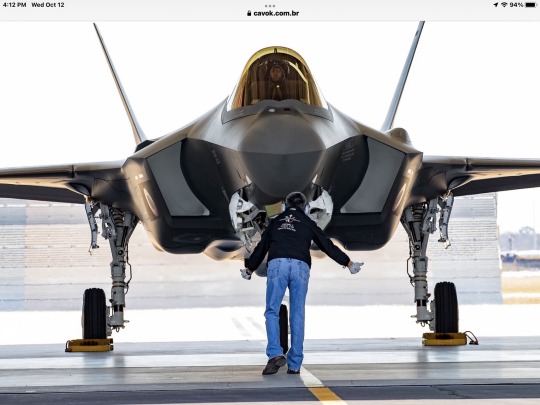

Austria is considering the fifth-generation F-35 Lightning II stealth game as a potential replacement for its Eurofighter Typhoon fleet after 2030.

The information was revealed on October 7 by the American website specialized in defense Jane's. With a defense budget of €16 billion (US$ 15.5 billion) by 2027, Jane's reveals that the arms management of the Austrian Ministry of Defense (MoD) was tasked with collecting information, allowing a value assessment of a possible acquisition of the fifth generation "stealth fighter" in the next decade.

The Eurofighter flight hour cost is expensive. In addition, the lack of coordination between customer countries, as well as in the method of assembling the devices (their elements are built by each of the parts) poses problems, especially in the supply of spare parts. Having become complicated for a dignified modernization, the T1 standard is simply no longer popular. And to make matters more difficult, the Austrians do not find a buyer country.

In addition, the current 15 Typhoons jets are insufficient to ensure 24/7 air policing. Only a few hours a day (6 to 8) are possible, when the availability of the fleet allows it.

The Armaments Directorate of the Austrian Ministry of Defense has been working on the future aircraft for several years. But this time, a commission was created to study the possibilities offered by Lockheed Martin's F-35. This is just a first step. If the latter is validated, the country will carry out a new evaluation with a possible request for an official offer.

The new Austrian federal government has set the goal to allow the armed forces to effectively and efficiently perform their constitutional tasks of maintaining neutrality and ensuring security in airspace.

It would be the latest European country to choose the American plane manufactured by Lockheed Martin. Last week, the Czech Republic began negotiations for the possible purchase of 24 F-35 stealthmen. Before that, Greece sent an official request to the United States for the purchase of 20 F-35 fighters last July. Spain is considering the acquisition of the F-35, as well as Portugal.

Austria is very interested in a future collaboration with its neighboring Italy, which is producing it, Switzerland, which has just ordered it, and the Czech Republic and Germany, which are heading towards the American plane. The possibilities of training, sharing experiences and maintenance are therefore numerous. There is no doubt that all these options will weigh a lot on the final decision.

In addition, the company said it could deliver the first F-35 fighters to Germany in 2026. Berlin will also acquire the F-35 multifunction fighters, as announced by the German Ministry of Defense last March. In 2030, the F-35s will replace the Tornado fighter fighters, supplied to the Air Force (Luftwaffe) since 1980.

But with regard to Austria, time will reveal whether Jane's report is a concrete hypothesis.

Meanwhile, last February, at the Singapore Airshow, the American defense giant revealed its production goal of the F-35 for 2022, Shepardmedia reported. Lockheed Martin said it expects to produce between 148 and 153 F-35 fighters this year, an increase over the 142 aircraft produced in 2021.

At the end of June, the American defense contractor had declared that she expected an increase in orders in Europe for her fifth-generation fighter.

Lockheed Martin predicted in June 2022 that more than 550 F-35 fighters will be operating in Europe by 2035, above 128 in June 2022.

Tags: Military AviationEurofighter TyphoonF-35 Lightning IIAustrian Air Force

Previous news

VIDEO: Boeing 747 Dreamlifter loses wheel of the main landing gear during takeoff

Next news

IMAGES: FAB's KC-30 performs first operational mission

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

HENSOLDT is equipping DA62MPP aircraft with its mission system "MissionGrid" (pod EO/IR under the nose of the aircraft) on behalf of QinetiQ (Photo: Diamond Aircraft)

MILITARY

Hensoldt mission system for reconnaissance flights is put into operation

12/10/2022 - 15:56

HELICOPTERS

South Korean Coast Guard receives third Sikorsky S-92

12/10/2022 - 15:01

AIR ACCIDENTS

Accident with Indian Navy MiG-29K on the coast of Goa

12/10/2022 - 12:52

HELICOPTERS

Boeing presents the Modernized Apache

12/10/2022 - 09:29

BRAZILIAN AIR FORCE

IMAGES: FAB's KC-30 performs first operational mission

12/10/2022 - 08:33

MILITARY

Kaman will develop logistics UAS prototype for the U.S. Marine Corps

11/10/2022 - 17:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

7 notes

·

View notes

Text

Industrial pre-drying and heating solutions for fabrics, yarns, and non-woven materials.

Kerone is a leading provider of industrial pre-drying and heating solutions for fabrics, yarns, and non-woven materials. Their advanced equipment effectively removes excess moisture and evenly heats up materials to ensure they are ready for further processing. By utilizing Kerone's specialized solutions, manufacturers can prevent issues like shrinkage and color bleeding, resulting in higher quality end products. With a focus on efficiency and quality, Kerone's pre-drying and heating solutions play a crucial role in optimizing production processes for the textile industry, ultimately leading to improved productivity and product reliability.

Industrial pre-drying and heating solutions are crucial for fabrics, yarns, and non-woven materials to ensure they are ready for further processing. These solutions involve using specialized equipment to remove excess moisture and heat up the materials efficiently. By pre-drying and heating these materials, it helps prevent issues such as shrinkage, color bleeding, and uneven drying during the manufacturing process. This ensures that the materials are in optimal condition for the next steps in production, leading to higher quality end products. Implementing industrial pre-drying and heating solutions can improve production efficiency and product quality in the textile industry.

Advantages

Moisture Control: Pre-drying reduces moisture content, preventing mold growth and enhancing product durability.

Improved Dye Uptake: Drier materials absorb dye more evenly, ensuring vibrant and consistent colors.

Reduced Energy Consumption: Pre-dried materials require less energy for subsequent drying processes, lowering overall energy costs.

Enhanced Strength: Removing excess moisture increases the tensile strength of fabrics, making them more resilient during handling and processing.

Better Process Efficiency: Pre-drying stabilizes material properties, improving consistency and efficiency in manufacturing processes.

Application

Shrinkage Control: Pre-drying helps minimize shrinkage by stabilizing fibers before final processing, ensuring consistent dimensions in the finished fabric.

Enhanced Dye Absorption: Dry fabrics absorb dyes more uniformly, leading to vibrant and even coloring without patchiness or streaks.

Improved Finishing: Pre-dried fabrics accept finishing agents better, enhancing properties like softness, water repellency, and wrinkle resistance.

Reduced Energy Consumption: By pre-drying, the main drying phase requires less energy, reducing overall production costs and environmental impact.

Mold Prevention: Removing moisture from fabrics helps prevent mold growth during storage and transportation, maintaining material integrity.

Futures

Energy Efficiency: Pre-drying technologies will increasingly focus on reducing energy consumption, utilizing renewable energy sources, and improving thermal management to lower the overall carbon footprint of textile production.

Advanced Materials: The development of materials with inherent quick-drying properties, such as nano-coatings and hydrophobic treatments, will enhance drying efficiency and reduce the need for energy-intensive processes.

Smart Drying Systems: Integration of IoT and AI in drying systems will enable real-time monitoring and optimization, leading to significant improvements in efficiency, quality control, and predictive maintenance.

Microwave and Infrared Drying: Adoption of microwave and infrared technologies will provide rapid and uniform drying, minimizing fabric damage and preserving the physical properties of yarns and non-woven materials.

Sustainable Practices: Emphasis on sustainability will drive the use of eco-friendly pre-drying methods, such as air-drying, solar drying, and other low-impact techniques that align with green manufacturing goals.

Conclusion

Implementing industrial pre-drying and heating solutions is essential for preparing fabrics, yarns, and non-woven materials for subsequent processing stages. These solutions effectively remove excess moisture and ensure uniform heating, preventing common issues like shrinkage, color bleeding, and uneven drying. By maintaining optimal material conditions, these technologies enhance production efficiency and product quality, ultimately leading to superior end products. Adopting advanced pre-drying and heating systems not only streamlines the manufacturing process but also supports sustainability goals through energy-efficient practices, positioning the textile industry for a more productive and environmentally conscious future.

0 notes

Text

Recent Innovations and Trends in Semiconductor Manufacturing Equipment

The semiconductor industry is continuously evolving, driven by technological advancements and innovations in semiconductor manufacturing equipment. This research article explores the latest trends and innovations in semiconductor manufacturing equipment, supported by qualitative and quantitative data analysis.

Market Size:

The semiconductor manufacturing equipment market has witnessed significant growth in recent years, fueled by the increasing demand for semiconductor chips across various industries such as consumer electronics, automotive, and telecommunications. According to recent market reports, the global semiconductor manufacturing equipment market was valued at approximately USD 91.2 billion in 2023. Projections indicate robust growth, with the market of semiconductor manufacturing equipment to reach USD 149.8 billion by 2028, representing a CAGR of 10.4% during the forecast period.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=263678841

Market Trends:

Advanced Process Technologies: The semiconductor industry is transitioning towards advanced process nodes such as 7nm, 5nm, and beyond, driving the demand for cutting-edge manufacturing equipment capable of delivering higher precision and efficiency.

Lithography Innovation: Lithography remains a critical process in semiconductor manufacturing, and recent innovations in extreme ultraviolet (EUV) lithography technology have enabled manufacturers to achieve finer feature sizes and higher yields.

3D Packaging and Integration: With the increasing complexity of semiconductor devices, there is a growing trend towards 3D packaging and integration techniques. Advanced equipment for wafer bonding, through-silicon via (TSV) formation, and die stacking are essential for enabling these advanced packaging technologies.

Industry 4.0 and Smart Manufacturing: The adoption of Industry 4.0 principles and smart manufacturing solutions is revolutionizing semiconductor fabs. Equipment with integrated sensors, connectivity, and data analytics capabilities are enhancing operational efficiency, predictive maintenance, and overall productivity.

Environmental Sustainability: There is a growing emphasis on sustainability in semiconductor manufacturing, driving the development of equipment with lower energy consumption, reduced chemical usage, and improved waste management systems.

Semiconductor Manufacturing Equipment

Innovations:

Next-Generation Etching Systems: Advanced etching systems with atomic layer etching (ALE) capabilities are enabling precise and uniform etching processes, essential for the fabrication of advanced semiconductor devices.

Metrology and Inspection Solutions: Innovations in metrology and inspection equipment, such as optical and scanning electron microscopes (SEM), are enhancing defect detection and process control at nanoscale resolutions.

Materials Deposition Technologies: Novel deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), are facilitating the deposition of thin films with exceptional uniformity and conformality, crucial for advanced device manufacturing.

Robotic Automation: Robotic automation solutions are increasingly being integrated into semiconductor manufacturing equipment to improve throughput, reduce human error, and enable lights-out manufacturing operations.

AI-Enabled Process Optimization: Artificial intelligence (AI) and machine learning (ML) algorithms are being deployed to optimize semiconductor manufacturing processes, leading to improved yield, reduced cycle times, and enhanced product quality.

The semiconductor manufacturing equipment industry is undergoing rapid transformation driven by technological innovations and emerging trends. Manufacturers must embrace these advancements to stay competitive in an increasingly dynamic market landscape. By leveraging cutting-edge equipment and adopting innovative manufacturing strategies, semiconductor companies can enhance productivity, accelerate time-to-market, and drive sustainable growth in the semiconductor industry.

0 notes

Text

Supporting the renaissance of the 200mm fabs

Earlier this year, Intel revived its construction of the 450mm factory in Chandler, Arizona. While that grabbed a lot of media attention, equally of significance is a quiet renaissance in the demand for 200mm fabrication happening across the world. Interest in IoT and automotive sector has particularly contributed a surge in demand for MEMS, power, analog and discrete semiconductors, much of which can be manufactured in 200mm wafer fabs.

According to SEMI, by 2019, installed capacity of 200mm will reach close to 5.4 million wafer starts per month. This will be almost as high as capacity in 2006, adding a net capacity of more than 600k wpm in 5 years. Of the 19 new fabs that started construction in 2016-17, 4 are 200mm.

Despite the healthy growth in this installed capacity, the industry is experiencing an acute shortage of 200mm fab capacity. And, should the IoT and EV and various other changes in automotive markets take off as expected, the surge in demand could make the capacity shortage even more acute over the next few years.

Many of the existing 200mm semiconductor fabs operating in US and Europe were expected to close soon a few years back. However, now there is a much stronger rationale to extend their lives, and continue to operate them for longer, given the expected demand growth.

To continue to run these fabs profitably, there needs to be a renewed focus on improving fab cost efficiencies, and increasing yields. For this, there are a number of levers that could be deployed. To do so, it is important to understand the economics and operating models of these fabs. They are very different from the 300mm fabs, which are highly automated. 200mm fabs have much higher labor intensity per square-unit of silicon. They are typically used with smaller production runs. They use old equipment, much of which is difficult to maintain, and cost of replacement parts has surged in the last few years.

There are a number of emerging levers that can be used to improve the efficiency and yields, and especially have the potential to address these operating specifics of the 200mm fabs. Four of these are particularly important:

Improving downtime prediction and station utilization: Old fab equipment understandably tends to have more downtime. Unfortunately, 200mm equipment parts are in scarce supply, and are getting increasingly expensive. Latest machine learning techniques can reduce downtime and improve maintenance planning significantly by better predicting out of control parameters of the equipment and process. These go well beyond control charts that apply rules such as Nelson rules. Furthermore, they can predict using large number of parameters and the interplay between those parameters. Alarms for timely intervention can also be dynamically triggered based on cost and impact functions.

Improving factory traceability and real-time information visibility: Production costs can be reduced by improving feedback loops with upstream activities. Manufacturing production orders can be prioritized based on demand criticality, for example by allowing putting some orders on hold to let the important orders progress. The most important capability to build here is a granular lot traceability. It also provides more manufacturing flexibility by allowing lot splits and merges. Furthermore, a building a central data bus can allow real-time reaction to any events across the factory, allowing faster response to potential downtimes and wastages.

Improving low-hanging operations automation: 200mm fabs have a heavier load of direct and indirect labor costs. These fabs were built in 1990s, when semiconductor manufacturers hadn't yet developed the automated tools to handle hundreds of steps required in die manufacturing, and manual activities were needed, especially since the processes varied significantly. Although automation in these fabs improved with time, there are many fabs where surprisingly large amount of low-hanging automation opportunities still exist. Techniques, such as extensive use of RFID to track all movable parts, can improve automation significantly. Updating old IT systems, for example for maintenance management can further reduce operating costs significantly.

Left shift of quality predictions: Yield improvement is the most critical goal of all semiconductor operations. Yield has become even more important in 200mm factories given the capacity constraints. Unfortunately probe testing, post-assembly testing and customer defect tracking provide the feedback too late. Having better quality interventions earlier can make a significant difference in yield improvements. There are two parts to the shift-left of quality interventions. First, supervised or unsupervised modelling to help detect failures throughout the manufacturing process, as the wafer goes through hundreds of steps. Second, linking failures during probe testing to the exact cause of failure can help eliminate the root cause. Given the complexity of semiconductor manufacturing process and the volumes of data that gets generated, these techniques are not easy to apply. Data science and information technology have evolved significantly. The first part is much easier to apply, and small investments in the direction can make a big difference.

Semiconductor companies with 200mm fabs have a reason to be excited. They are certainly in demand. And opportunities have emerged to improve their efficiency and yield further, so that they can continue to meaningfully contribute to the companies’ bottom-line for possibly even a decade more than was earlier thought!

1 note

·

View note

Text

We Predict These Kitchen Trends Will Be Everywhere in 2021@|what is new in kitchen design@|https://ift.tt/3h75BTp

DANA GALLAGHER

While the all-white kitchen will probably never go out of style, there are lots of new design trends for 2021 that will make you equally happy. Think: natural elements with some pops of color as well as a visit to the dark side with colors you might never expect. We know, we know. You’ve already carefully chosen every appliance, picked out each piece of hardware, and planned your kitchen design to a T, but there are ways to dip your toes into the world of color without messing up your rustic farmhouse kitchen aesthetic. On the color front, why not try painting your ceiling a fun color, like Haint Blue? How about hauling in some colorful appliances?

[external_link_head]

Join the Country Club today and enjoy exclusive access to home tours, seasonal craft projects, recipes and, more!

If you’ve been wanting to layer in more natural elements, try “sustainable” and “eco-friendly” items. These are words that are popping up more and more, with many companies offering green solutions for cabinets and shelving. You can also think about bringing in handmade tiles in materials like terra-cotta and cement—a great solution for adding a little more soul to your space, regardless of whether or not you opt to completely switch over to a farmhouse style vibe.

When it comes to countertops, quartz is quickly becoming an affordable and low maintenance alternative to our beloved marble. There are even new trends for accessorizing your countertops, like vintage plate racks made to display your grandmother’s china. Hardware and metal finishes continue to push the envelope—think brass, nickel, and matte black. Removable wallpaper companies are making it even easier to experiment with pattern on walls and backsplashes. Consider 2021 as the year of the kitchen!

1 of 39

Kitchens with Curves

You’ve probably seen it trending in furniture design and we love how it is translated into this beautiful designed by Tiffany Leigh Design. Head over to her blog to read more about this space. It is packed with fun ideas!

2 of 39

Integrated Range Hood

Designer Stefani Stein created a seamless look in this kitchen where the range blends right in to the subway tile walls.

3 of 39

Colorful Kitchen Islands

Try painting your kitchen island a striking color like Alison Giese Interiors did on this project. We love how it stands out and contrasts the other white cabinets.

4 of 39

Bright Colored Cabinets

Because we all need a little more sunshine in our lives after 2020, am I right?! Pair them with a fun backsplash, and you will smile every time you walk into your happy kitchen!

5 of 39

Modern Black

As suggested by Semihandmade, “If you’re going for a trendy look, start with black cabinets and really commit to the modern approach by nixing those upper cabinets in favor of sleek natural wood open shelving.” Just like Yellow Brick Home did with this space, using cabinet doors by Semihandmade.

6 of 39

New Rustic

We know the rustic look has been around for a long time now, but if you pair it with a pop of fresh paint like Designer Hadley Wiggins-Marin did here, you can really and modernize redefine that rustic look.

7 of 39

Terra Cotta Tiles

When you think of terra cotta you probably have warm and earthy thoughts of potted plants and garden shops. Pair that material with soapstone countertops and classic brass hardware, and you have a unique yet traditional and beautiful kitchen. We love everything happening in this space, especially those terra cotta floors!

[external_link offset=1]

8 of 39

Marble Kitchen Countertops

Carrara marble like that shown here will always be in style, but if you’re a red wine drinker, quartz could be a much better fit for you and your kitchen. While it looks like a natural stone, engineered quartz is more affordable and less prone to stains.

SHOP WHITE SHELVES

9 of 39

Kitchen Larders

Originally a room in the home used for storing and preserving foods (think: the refrigerator before the refrigerator was invented), the kitchen larder has transformed into a stand-alone cupboard or pantry. They can be large enough to house the majority of your dry goods but small enough to keep things organized while taking up a minimal amount of valuable space. Forget a walk-in and sub in counter-top cabinet or add doors to enclose pre-existing shelving.

SHOP PANTRY STORAGE

10 of 39

Handmade Kitchen Tiles

Bring texture and nuance to your kitchen walls with handmade tiles. The possibilities are vast—try terra-cotta or cement in colors that range the rainbow—although we lean toward more neutral hues.

SHOP LIGHTING FIXTURES

11 of 39

The 5th Wall (The Kitchen Ceiling)

Don’t forget about your kitchen ceiling! Add a fun hit of color, wallpaper, or wood paneling to add dramatic flair to your space.

SHOP BLACK WALL PAINT

12 of 39

Reclaimed Wood Kitchen Cabinetry

If you’re installing custom cabinets, opt for a rough-hewn, reclaimed wood. And good news if you’re going pre-fab, companies such as IKEA are moving to more natural, eco-friendly materials for their kitchen cabinets. From bamboo to even recycled plastic bottles, cabinet companies are taking this revival of reduce and reuse very seriously.

SHOP KITCHEN STOOLS

13 of 39

Kitchen Wallpaper

While wallpaper has become less scary to the general population over the last five years or so, folks are still reluctant to hang it in the kitchen. If you’re scared about the permanency of wallpaper, try something less, well, permanent. There are plenty of peel-and-stick papers in trendy designs that are incredibly easy to install and remove. Hot tip: Opt for a graphic design that mimics the look of tile.

SHOP PEEL AND STICK WALLPAPER

14 of 39

Kitchen Plate Racks

Vintage plate racks are coming back in a big way in 2021. Whether displayed on countertops or mounted on walls, they add a ton of soul to a space and give you an actual place to store and display your dishware instead of hiding it away in a hutch or cupboard.

SHOP BLUE GINGHAM NAPKINS

15 of 39

Mix-and-Match Kitchen Metals

The year 2021 is not about being matchy-matchy—and that goes double for your heavy metals. Choose a nice nickel for your knobs and then go with a cool brass or matte white for your faucet. Choose a whole different metal for your lighting fixtures.

SHOP KITCHEN RUGS

16 of 39

Hidden Kitchen Appliances

Not a fan of stainless steel facades? Try adding fronts to your appliances that mimic your cabinetry. Refrigerators and dishwashers disappear when clad to match their cabinet cohorts. Even your massive oven hood can get in on the action.

SHOP KITCHEN STOOLS

17 of 39

Open Shelving

Open shelves allow you to showcase your beautiful kitchenwares among other heirlooms and antiques. The ability to see through your storage also means everything is easy to find. Just don’t forget to clean your items often since they will be open to the elements that might be floating through your kitchen. It’s also helpful to keep every day items on the lowest, most accessible shelf.

SHOP SHELVING

18 of 39

Standout Sinks

You don’t have to go nuts to achieve an on-trend kitchen. While an apron-front sink in a farmhouse kitchen isn’t exactly unexpected, a farmhouse sink in soapstone with brass hardware is a showstopper—especially when it’s set against white walls, wood cabinets, and stainless steel countertops.

[external_link offset=2]

SHOP BRASS HARDWARE

19 of 39

Natural Wood Tones in the Kitchen

While we’re still seeing stained and painted woods, we’re also seeing it in its natural state. Try adding a kitchen island—or just the topper—in a pretty, grainy wood. Brown wooden shelves that feel original to the house are another way to test the waters with wood. It will bring a warmth to any kitchen space, especially those trending bright white ones!

SHOP SWIVEL STOOLS

20 of 39

Tons of Texture

For those who fear color, focus on mixing up the finishes. Designer Cathy Chapman chose white beadboard on the ceiling and shiplap for the walls. She used unlacquered brass strap hinges and latches on the cabinets, black marble on the island countertop, and tons of warm woods on the floors, backsplash, and remaining countertops.

SHOP SHIPLAP

21 of 39

Swoon-Worthy Ceilings

When you want to maintain neutrality but still have some fun in the kitchen, shoot for the stars—or in this case, the ceiling. Here, the Madcap Cottage team chose to paint the ceiling a Southern porch-inspired blue (Blue Ground by Farrow & Ball) and added an elaborate antique lantern.

SHOP BLUE PAINT

22 of 39

Hints of Color

You don’t have to scrap an all-white kitchen to stay on trend. Dip your toe in the color pool instead, whether you store colorful pottery in glass-front cabinets, bring in colorful furniture, or paint a large piece like this kitchen island in Tropical Moss by Dunn-Edwards Paints.

SHOP YELLOW PAINT

23 of 39

Open Kitchen and Living Areas

Maximize living space by making the family room and kitchen one large room. A mix of lighting helps differentiate the areas, while a uniform wall color keeps everything cohesive.

SHOP LIGHTING FIXTURES

24 of 39

Pretty Pantries

Gone are the days of having a dark little pantry to house dry goods hidden away from prying eyes. Today’s kitchens boast roomy pantries with shelving aplenty for your cereals and collectibles. Proud of your organizational skills and want to show off? Finish the pantry space with a screened porch door painted in an eye-catching color, like this bright green hue.

SHOP GREEN PAINT

25 of 39

Range of Colors

Appliance makers like Lacanche, Big Chill, and Smeg offer up a host of practical pieces in a number of colors and finishes, which will definitely liven up your range.

SHOP SMEG APPLIANCES

28 of 39

Butcher Block Countertops

In this Massachusetts beach house, a savvy couple replaced linoleum with warm wood for a durable upgrade. Butcher block is virtually maintenance-free—it just needs an occasional coating of mineral oil—and the natural material is the perfect neutral to break up the sterility of an all-white palette.

SHOP MINERAL OIL

[external_footer]

source https://livingcorner.com.au/we-predict-these-kitchen-trends-will-be-everywhere-in-2021what-is-new-in-kitchen-designhttps-hips-hearstapps-com-hmg-prod-s3-amazonaws-com-images-sustainablekitchen-1570570383-jpgcrop1-00/

1 note

·

View note

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance

SECS/GEM compliance offers several significant benefits for semiconductor manufacturing:

Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings.

How to Get Started with EIGEMBox

Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today!

Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Photo

The hatch creaked as the hydraulics let it down to the dry hard packed dirt. A small puff of dust billowed up around the hot cahelium and it caught in his nose, tickling in the heat.

The horizon was flat and the earth iron red as it disappeared into the ominous grey of the cloud blocking the sky.

Virgil’s boots made their own puffs of dust as he stepped off the hatch and emerged from under the shadow of Two. The puffs followed him as he walked the length of his ‘bird. The dirt gritted under his specialised soles as he avoided the heat of her cooling VTOL and the scorch of her now quiet thrusters.

His landing was precautionary. A warning light had come on during the flight home and dumping himself in the middle of the Outback for a mechanical check was preferable to taking a swan dive in the middle of the Tasman.

Outside appearances gave no clue to the issue and unfortunately, he would have to wait for her engines to cool off before attempting to access the thruster that was the problem.

A sigh and he turned back to look at the horizon.

He truly was in the middle of nowhere.

“Thunderbird Two, status report.”

Typical Scott. His brother was hip deep in a rescue on the other side of the planet, but his brother radar still managed the range.

“Status a-okay, Thunderbird One. Just taking a moment to gaze at the scenery.”

“John says you have a mechanical fault.”

“Quite possibly. Fine for the moment. Just need a little cooling time. I’ll keep you updated.”

“FAB, Thunderbird Two.”

And then it was back to the silence.

True silence.

There was no wind.

No water.

No birds.

Just the heat of a dying day leaching out of the sand, the creak of his cooling ‘bird, and the potential energy in the air.

It was going to rain.

The Kansas farm boy could tell that much. Even in another country and an entirely different environment, he could feel it.

He didn’t need fancy instrumentation to predict that.

The impending storm raised the hair on his arms under his uniform. It itched at his skin and spoke of change.

Ants crawled across his boots, winged queens and drones launching to join a cloud of them off to his right.

It was eerie.

He shifted where he stood, unsure of what to do next. He wasn’t one for killing time. Time was a valuable thing and needed to be used to its upmost. But this stop was unplanned and there was little he could do while waiting.

Sure, there were tasks. There were always tasks, nitty gritty maintenance jobs. He was never short of work.

But the air was still. The sense of building atmospheric release buzzed across his senses.

It was tantalising.

He shivered.

There were still a couple of hours before sunset, but the air was dark due to the heavy cloudbank looming over the landscape.

A thought.

A flash of guilt followed by stubborn determination.

He turned and climbed back on to the hatch and retracted it, only to lower it again a few moments later with a folded chair and a box in his hands.

He parked it in the sand.

The silence was a physical presence.

He opened the box to reveal a portable watercolour kit – a neat palette of half pans, a fine brush and a small block of high-quality paper.

It was an indulgence he kept aboard his ‘bird. One he had yet to use, so this was definitely an opportune moment. A tiny amount of time to throw down some colour and capture this red-on-blue-grey intensity.

It didn’t take him long to realise he had forgotten a couple of things. A muttering step back into his ‘bird and he returned with a small table and a cup full of water.

He finally managed to settle himself. Painting while wearing his uniform wasn’t the most comfortable. It was bulky and in the way. He did shed his gloves, which meant he had to take off his wrist controller. Scott would frown enough to dent his nose, but he couldn’t paint with his gloves on.

There was heavy lifting, but there was also sensitive and tactile manipulation. He liked to think he was capable of both.

A dip of his brush into clear water, a dab of cadmium red, and colour spilled onto the paper.

Payne’s grey filled the sky in soft billows with just a hint of ultramarine. He tried to keep his touch gentle. Watercolour was so unforgiving. Fast and delicate, the colours could easily be overdone and unlike acrylic or oils, could not be undone satisfactorily.

It took all his concentration to sketch out the worn landscape.

The parched air dried the colours quickly and it wasn’t long before he was flicking strands of yellow ochre spinifex in the foreground, the little painting almost done.

In the distance, the clouds rumbled warning.

He dabbed in a second layer to bring up the contrast, the greys echoing the thunder on the horizon. Just a touch of green brought out the red of the iron in the sand.

“I really don’t know how you do that.”

Virgil nearly fell out of his chair.

“Scott!” His heart thudded in his ears and he clutched the drying painting in his hands as it tried to slip from his fingers. “What the hell?! How did you…?” He shot to his feet and turned to find his brother standing behind him. Beyond, at a respectable distance, sat Thunderbird One.

Scott held up both hands, taking a step back. “Hey, I saw you were painting, so I parked back a ways. Figured you wouldn’t want VTOL messing with your paints.” But then his brother was smothering a grin. “You were kinda zoned out there, Virg.”

“You were in Prague! How did you get here so fast?” It was a stupid question. He was Scott Tracy. Fast was part of his genome.

But his brother frowned. “It’s been over an hour since I last contacted you. The situation is resolved. I was on my way back and thought I’d check in. John said he hadn’t had an update.”

Virgil stared at his brother. An hour? He brought his wrist up to check the time, but his controller was on the little table beside his chair with his discarded gloves.

Oh.

Scott arched an eyebrow at him.

Virgil grunted before putting the painting down carefully and retrieving his equipment. A moment later, his gloves were on and his wrist controller back in place.

It was indeed over an hour later.

Thunderbird Two would have cooled down enough forty-odd minutes ago.

“You were lost in your painting, weren’t you.” It wasn’t a question. His brother sighed, walked over to the table and picked up the piece of art. Blue eyes scrutinised it. “Nope. I don’t have a clue how you do that. It’s great, Virg.” He handed it over and somewhat numbly, Virgil took it.

He stared at the strokes in which he had been so absorbed earlier. The landscape stretched into the paper, reds bouncing off blues, the stillness captured in pigments.

Okay, so he had to admit, it was working quite well. He had muddied the colour a little in one corner and there was a patch where he’d left more white paper than was probably necessary because he was too worried about over doing the paint, but overall it mostly did what he wanted it to do. Oh, his wash hadn’t quite worked in that bit. Damn.

But…

He could get away with it.

“Earth to Virgil? You okay in there?”

Scott was smirking.

Virgil glared at him before cradling the watercolour block in one hand, picking up the palette with the other and packing it away. He stomped his way back to his ‘bird.

He ignored the laugh behind him.

He was stashing the paints in their locker when Scott joined him in Two, both the table and chair folded up in his hands. “Where do you stash these?”

Virgil gestured in the direction of the utility store and his brother put the equipment away.

Back in the cockpit, Virgil pulled up the suspect control and found the red light still glaring accusingly as Scott entered behind him.

“Give me ten. I need to inspect her starboard thruster.” He grabbed a safety line and threw back the overhead hatch. The gloomy atmosphere crept into the cockpit, but he ignored it and elevated the himself up so he could climb onto the top of his ‘bird.

“Virgil, you do know there is a storm coming in. You’re standing on the highest point for miles.”

“I’ll only be a minute.” Keep your pants on.

But his brother was right. His dawdling with his paints had cost him time and the weather was moving in.

He hurried across the back of his Thunderbird sliding carefully onto her starboard intake, and making his way down to the access hatch. He hooked in his safety line, prodded his controller to release the security, and hauled the hatch open.

Five minutes later, with several profane words that had Scott even more concerned, he yanked an obstruction out of her secondary intake valve.

It was a bright yellow, now somewhat grimy, Thunderbird Four.

No more than four inches long.

“I’m going to kill him.”

“Virg? What? Who?”

“Gordon.” He didn’t elaborate. The sky was well and truly rumbling now and he needed to get inside.

Tightening the valve, he gave it a good once over to check for damage. Another poke at his controller and the dash confirmed the issue resolved.

Access secured, he unhooked his line and made a run for the main hatch just as the landscape lit up white with lightning.

He leapt into his ‘bird as if he had that lightning on his tail.

His boots hit deck plates. Virgil reached up and threw the hatch closed and sealed away the angry sky.

Scott was staring at him.

Virgil met that gaze before walking past his brother towards his pilot seat. He casually chucked the little Thunderbird Four to his brother like the grenade it was.

Scott caught it. “What the hell?”

Gordon was dead twice over and he didn’t even know it.

“You better get back to your ‘bird. The sky’s going to open up any minute and we should probably be above it rather than below it.” Virgil poked at the weather read out. It was only a weather front, nothing compared to the cyclone forces the Thunderbirds were capable of tackling. “You might get wet.”

Scott was still glaring at the model in his hand. A distracted grunt.

Gordon was definitely dead.

Possibly more than twice.

“Okay, less imaginary brother murders and more getting back to your ‘bird.”

“Huh?”

Yeah, so now who was zoning out?

Virgil nudged his brother onto the hatch platform and stepped on himself, lowering it onto the red dust again.

He stepped off the deck plates just as the first fat rain drops started to hit the dust.

Damn. “Too late.” And as if he had given the sky permission, it really opened up.

Water hit dry earth in big splats, puffs of red rose only to be taken down by more rain. The stipple of water fast became patches and then the land deepened in colour. The bright iron red darkened almost to a burgundy. The spinifex he had so finely painted not half an hour earlier, shifted from a yellow ochre to a gold that almost glowed in the remnant light.

As Scott stepped up beside him, secure under the protection of Two’s nose, the landscape bleached suddenly and the sky grumbled and cracked. The air smelt of ozone and the sharp evaporation of precipitation in the heat. But there was more water than the air or the earth could take and it puddled in the indents between the rocks.

Some kind of thorny lizard darted out from a tuft of spinifex and hurried under the shelter of Two beside the brothers. At the lack of the rain on its back, it looked up as if surprised. Two reptilian eyes stared at them before darting back out into the rain.

Scott took another step forward and Virgil put a hand on his arm.

“You’re not going to try to run through that.”

“I’ve got to get back to One.”

“Why?”

“Because…” His brother trailed off.

Virgil squeezed his arm gently. “Take a minute. This is a desert storm. It will be short lived. We can wait.”

Blue eyes stared at him.

Okay, so waiting wasn’t part of Scott Tracy’s genome.

“Take a minute. Watch.” Virgil turned back to the storm and revelled in the release of the tension that had been building for the last couple of hours. He watched the rain hit the earth, the patterns, the dance of spinifex leaves. He listened to the roar, the wet splat against cahelium, the sigh as the water disappeared into the grass and the grumbles in the clouds.

Scott eventually turned to look and, for a short while there, they were just a couple of brothers staring out at the storm.

The fact they were sheltering underneath one of the most advanced technological creations on the planet was unimportant.

“This is all your fault, you know.” Scott’s voice was soft.

A grunt. “I think Gordon’s is the more likely culprit.”

“If you hadn’t stopped to paint, we’d be home by now.”

Virgil didn’t answer immediately. He took a breath. “But then we would have missed this.”

At that moment the sun finally hit the horizon and slipped through a gap in the clouds to light up the wet landscape in gold. Rain still fell, but it was as if it was liquid sunlight failing from the sky. Water glistened on everything and the clouds lit up from underneath.

Thunder rumbled in clouds turning pink in the east.

“Yeah, we would.” But the acknowledgement was distracted as Scott stared at the spectacle.

Perhaps they had something for which to thank Gordon. It was a moment that they would never have experienced if Virgil hadn’t had to stop.

He breathed in the freshened air and let it out with a relaxing sigh.

No.

Gordon was still dead.

-o-o-o-

#thunderbirds are go#thunderbirds fanfiction#thunderbirds#Virgil Tracy#Scott Tracy#earth and sky#nuttyfic reblog#I will write something new at some point#muse mangled a bit by circumstances#working on it

46 notes

·

View notes

Text

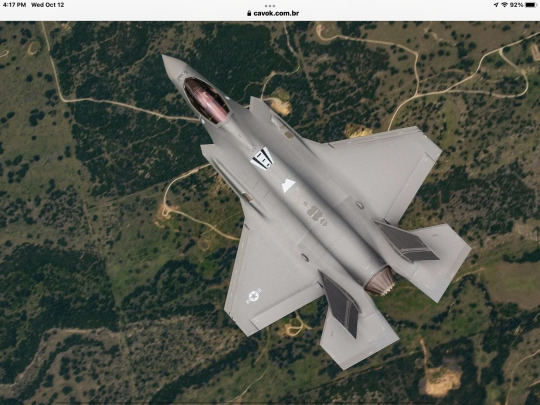

Lockheed will be able to deliver the F-35s to Germany from 2026 and see more orders in Europe

Fernando Valduga By Fernando Valduga 06/23/2022 - 12:00 PM in Air Shows, ILA Berlin, Military

Lockheed Martin said on Wednesday (06/22) that it can deliver the first F-35 fighters to Germany in 2026 and expects more orders for the aircraft in Europe, as Greece and the Czech Republic have expressed significant interest.

"You will hear more about it soon," said J.R. McDonald, vice president of business development of Lockheed Martin's F-35, to journalists at a press conference at the ILA Berlin Air Show.

The Lockheed executive pointed out that Germany's request was for the standard configuration of block 4 of the aircraft and part of the reason was the need for speed, mainly because the F-35 will replace the country's aged fleet of Tornados.

At the same time, the first F-35 aircraft that Germany ordered to replace its Tornado fleet aged in 2025-2030 can be delivered from 2026, depending on the outcome of negotiations with the government in Berlin, said McDonald, a former USAF F-15 driver.

F-35.

German companies, including engine manufacturer MTU, are currently analyzing how they can get involved in the program by providing parts or maintenance, McDonald added.

Lockheed intends to deliver 148-153 aircraft this year and is producing at a rate of 12-13 fighters per month, McDonald said. So far, about 810 F-35 fighters have been delivered in total. He noted that last year alone, four countries selected 223 F35 fighters.

McDonald also predicted that more than 550 F-35 fighters will be operating in Europe by 2035, up from the current 128. He said he was aware of the debate on European autonomy, but emphasized that 25% of the aircraft parts came from Europe and any European customer can request the delivery of the aircraft on the final assembly line and check-out (FACO) in Italy.

Source: Reuters

Tags: Military AviationF-35 Lightning IIILA Berlin Air ShowLockheed MartinLuftwaffe - German Air Force

Previous news

BRAZIL: Air Force Commander receives CEO of Saab to deal with the purchase of 26 more Gripen fighters

Next news

Australia receives two more Chinook helicopters from the USA

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in a specialized aviation magazine in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

AIR SHOWS

Spain officially acquires 20 Typhoon fighters within the Halcón project

06/23/2022 - 6:13 PM

MILITARY

IMAGES: RAF Typhoons conduct bilateral training with the Turkish Air Force

06/23/2022 - 4:00 PM

AIR SHOWS

First helicopter flight powered exclusively by sustainable aviation fuel

06/23/2022 - 3:00 PM

HELICOPTERS

Australia receives two more Chinook helicopters from the USA

06/23/2022 - 2:00 PM

One of the first two Gripens fighters integrated into the FAB. (Photo: Isac Nobrega / Air Force Agency)

BRAZILIAN AIR FORCE

BRAZIL: Air Force Commander receives CEO of Saab to deal with the purchase of 26 more Gripen fighters

06/23/2022 - 11:00 AM

MILITARY

Taiwan claims that 29 Chinese aircraft have entered its air defense zone

06/23/2022 - 09:00 AM

HOME Main Page Editorials Information Events Collaborate SPECIALS Advertise About

Cavok Brasil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

History

Military

Brazilian Air Force

Space

SPECIALS

Cavok Brasil - Digital Tchê Web Creation

2 notes

·

View notes

Text

How IoT is Making Heavy Equipment Safer and More Efficient

In today’s challenging world, it has become very difficult to grow against the competition for heavy equipment manufacturers. Though the digital world seems to be ubiquitous yet certainly the global digital developments have not bypassed the traditional heavy equipment manufacturing sector. The modern heavy equipment sector has to be agile, forward-thinking, and innovative in order to keep up with the pace of other sectors. Heavy equipment manufacturers need to deliver robust and powerful solutions that support the current requirements to hasten future innovations. With accelerating business transformation, competitive landscape, and digitizing solutions, there is a need for heavy equipment manufacturers to capitalize on these opportunities to deliver game-changing equipment.

Heavy equipment companies are faced with a competitive global market along with its varied dynamism. Heavy equipment equipment design manufacturers serve industries such as aerospace, defense, agriculture, construction, mining, semiconductor fabs, and various distribution centers, etc. As the business challenges involved with these sectors are highly complex and diverse, the heavy equipment manufacturers have to leverage technology to reduce costs, innovate, and thrive in complex environments. It is essential for the heavy equipment manufacturers to ensure profitable growth along with the better quality of the products. They have the responsibility to deliver enhanced operational performance and reliability as per the productivity metrics. With the evolving and dynamic regional scenarios, safety, and health, they have to ensure compliance with each of the regulations for trusted partnerships with end-users. And, at the same time, they have to meet the demand for higher product throughput along with lower lifecycle costs.

Internet of Things (IoT), is a connection of devices through the internet that has allowed heavy equipment manufacturers to keep track of their production, costs, and delivery effectively. It has enabled data insights and innovation at heavy equipment businesses. It has enhanced real-time access to equipment data leading to new revenue opportunities for the manufacturers. IoT has allowed predictive maintenance of heavy equipment by detecting and communicating maintenance requirements. It has allowed the companies to cut down on preventive maintenance strategies. Predictive maintenance enables reduce control costs, minimum downtime, enhanced equipment life, and reliability. Modern heavy equipment is equipped with various sensors to monitor the parameters like torque, pressure, temperature, and cylinder movement, etc. IoT has allowed to keep track of asset movement and preventing assets from getting stolen or lost. It has allowed companies to gain real-time visibility by monitoring routine productivity via tablet and handheld devices, which has given rise to a new generation of solutions for companies.

It is crucial for companies to cut down on project costs through optimum utilization of the equipment to compete in a low margin industry. The reduction of the total number of equipment deployed at the site due to the enhanced utilization of the equipment enhances the profit of the companies. The presence of sensors IoT devices on the heavy equipment helps in monitoring the real-time utilization of the equipment by the authorities and take decisions based on the workload of the equipment over the period. By connecting existing industrial equipment, sensors, and machines with various applications enables a highly integrated and smart decision-making value chain.