#predictive maintenance software

Explore tagged Tumblr posts

Text

Construction software that integrates with Xero

Explore the construction software that integrates with Xero to streamline your payroll and financial management. Visit Prestartr for tailored solutions that simplify operations and ensure accuracy in payroll processing for construction businesses.

#prestartr#fleet management software#project cost tracking software#civil construction management software#construction software#predictive maintenance software

0 notes

Text

Predictive Maintenance: AI & IoT Revolutionizing Asset Management

For businesses that rely on machinery and equipment, ensuring optimal operations is essential. This is where predictive maintenance becomes a game-changer. Powered by AI and IoT, this proactive maintenance strategy helps monitor equipment conditions in real-time, predicting failures before they occur.

Predictive vs Preventive Maintenance

🔹 Preventive Maintenance follows a time-based servicing schedule, reducing unexpected breakdowns but leading to over-maintenance and higher costs. 🔹 Predictive Maintenance relies on real-time data to determine when servicing is truly needed, reducing downtime, maintenance costs, and extending equipment lifespan.

How IoT Enhances Predictive Maintenance

✔ Real-Time Monitoring – IoT sensors track temperature, vibration, and pressure. ✔ Data Integration – Machines and software communicate seamlessly for better analysis. ✔ Remote Diagnostics – Maintenance teams can monitor assets remotely, reducing manual inspections. ✔ Improved Decision-Making – Accurate data ensures optimized maintenance strategies.

AI’s Role in Predictive Maintenance

✅ Failure Prediction – AI predicts breakdowns in advance. ✅ Anomaly Detection – Identifies irregularities in equipment performance. ✅ Prescriptive Analytics – Provides actionable insights for preventing failures. ✅ Continuous Learning – AI systems improve over time, enhancing prediction accuracy.

0 notes

Text

XPump is a cutting-edge, AI/ML-based solution designed for real-time monitoring and predictive maintenance of pumps. It continuously tracks critical parameters like vibration, temperature, and voltage, providing early warnings to prevent failures and optimize performance. XPump integrates seamlessly with your existing systems, enhancing operational efficiency and reducing downtime and maintenance costs.

#Real Time Pump Monitoring System#predictive maintenance software#predictive maintenance for pumps#best predictive maintenance software#predictive maintenance systems#predictive maintenance applications#predictive maintenance pumps#predictive maintenance software cost

0 notes

Text

Airline Predictive Analytics

Elevate your airline's operational efficiency with Zulu Airline Systems' cutting-edge airline predictive analytics. Our advanced analytics platform empowers airlines to forecast demand, optimize scheduling, and enhance customer satisfaction. By leveraging data-driven insights, you can make informed decisions that reduce costs and improve service delivery. Experience the future of airline management and transform your operations today. For more information, contact us at 678-641-6254.

#airline planning system#airline scheduling system#airline software platform#airline gating maintenance#airline predictive analytics

0 notes

Text

"Economy Redefined: Bridgera's Support Makes Predictive Maintenance Implementations Easier"

Suppose that each lost minute in your operations is costing thousands. "Predictive maintenance," fueled by "IoT" and "advanced analytics," is set to revolutionize asset management and operational effectiveness. However, the path ahead is not free of hurdles. With total assistance from Bridgera and the industry's top-of-the-line "IoT solutions," the implementation is as seamless as a drive to the future of "predictive maintenance" with the least trouble or disruption.

#iot#iot solutions#iot platform#iot integration#iot development#iot asset tracking#iot software development services#predictive maintenance#advanced analytics

0 notes

Text

AI-Powered Predictive Maintenance in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, keeping machines running smoothly is essential for producing high-quality medicines. Traditional maintenance methods, like fixing machines after they break or scheduling routine checkups, can lead to unexpected failures or unnecessary repairs. AI-powered predictive maintenance is changing this by helping manufacturers prevent problems before they happen, saving time and money.

#AI development company in Dallas#Artificial Intelligence#AI-powered predictive maintenance#Manufacturing efficiency#Preventive maintenance#AI-based software development

0 notes

Text

How to Improve Overall Equipment Effectiveness (OEE) in Asset Performance Management

Introduction

Overall Equipment Effectiveness (OEE) is a key metric for assessing how efficiently equipment is used within an organization. Improving OEE can significantly impact productivity and profitability. When combined with Asset Performance Management (APM), which includes the use of advanced technologies like predictive maintenance, organizations can achieve optimal equipment utilization. This article provides practical strategies for enhancing OEE using APM principles.

Strategies to Improve OEE with APM

Integrate Predictive Maintenance APM software offers predictive maintenance capabilities that use real-time data to anticipate potential equipment failures. By addressing issues before they result in downtime, equipment availability is maximized, boosting the OEE score.

Leverage Real-Time Monitoring APM software provides continuous monitoring of asset performance, enabling teams to respond swiftly to anomalies. This proactive approach enhances performance and prevents issues that could lower the OEE score.

Optimize Maintenance Schedules Traditional maintenance schedules can result in unnecessary downtime. APM software uses data analytics to suggest maintenance only when needed, ensuring equipment remains operational for as long as possible without compromising performance.

Utilize Data-Driven Insights APM solutions collect extensive data that can be analyzed to find trends, identify inefficiencies, and improve processes. Insights gained from data analytics can help refine operations to achieve better performance and product quality.

Employee Training and Engagement Even with advanced APM systems in place, employee training is essential for effective use. Ensuring staff are well-versed in interpreting data and making informed decisions can significantly contribute to higher overall equipment effectiveness.

Conclusion Improving OEE within an organization requires a combination of strategic approaches and advanced tools like APM software. By leveraging predictive maintenance, real-time monitoring, and data-driven insights, organizations can enhance equipment efficiency, reduce downtime, and achieve sustainable growth. Adopting these strategies ensures that assets operate at peak performance, benefiting overall operations and contributing to long-term success.

#apm#predictive maintenance#asset performance management#overallequipmenteffectiveness#apm software#ombrulla

0 notes

Text

Shoreline AI | Revolutionary APM & Methane Leak Detection

0 notes

Text

iDataOps our machine monitoring software fetches the data generated at an equipment level and monitors equipment with predictive maintenance, preventive maintenance and OEE.

#machine monitoring software#predictive machine maintenance#preventive maintenance#asset maintenance management

0 notes

Text

How to Calculate Production Efficiency?

When discussing manufacturing and production, achieving operational excellence requires a close analysis of key performance metrics, with production efficiency as the pivotal measure.

The concept encapsulates the complexities of resource allocation, process optimization, and output maximization, acting as a barometer for the performance of a manufacturing instrument. Rooted in mathematical precision, the calculation of production efficiency is a compass guiding enterprises through the complicated web of inputs and outputs, presenting a clear cut idea of the efficacy with which resources are transformed into tangible products.

What is Production Efficiency?

Production efficiency is a key performance indicator that assesses how well a manufacturing process converts inputs into outputs. It involves evaluating the utilization of resources, time, and materials to ensure maximum productivity.

Why is Production Efficiency so Important?

Production efficiency is a critical metric for several reasons. Let’s check it out quickly.

Cost Reduction: Efficient production processes lead to lower production costs, ensuring competitiveness in the market.

Resource Optimization: Maximizing efficiency allows businesses to make the most of their resources, minimizing waste and improving sustainability.

Timely Deliveries: Efficient production ensures timely delivery of products, enhancing customer satisfaction and maintaining a positive brand image.

Improved Profitability: Higher production efficiency directly correlates with increased profitability, making it a key focus for businesses aiming to thrive in a competitive environment.

How to Improve Production Efficiency with CMMS?

CMMS helps achieve production efficiency by introducing a systematic and proactive approach to maintenance. CMMS transforms production management into a streamlined, efficient, and future-ready process, ensuring organizations stay ahead in the competitive business world.

Predictive Maintenance

Asset Tracking

Work Order Management

Data Analytics

Inventory Management

Mobile Accessibility

Documentation and Compliance

Ending Note:

Maximizing production efficiency is essential for sustained success. Businesses can achieve optimal performance by understanding the concept, calculating efficiency, and addressing roadblocks. Implementing CMMS solutions further enhances the ability to proactively manage maintenance and improve overall production efficiency, ensuring long-term viability and profitability.

If you’re eager to explore how CMMS can revolutionize your production processes and drive success, contact us at [email protected]. Our experts are ready to guide you on the transformative journey toward enhanced efficiency and sustainable growth.

#Asset Management#CMMS Software#Inventory Management#Predictive Maintenance#Production Efficiency#Work Order Management

0 notes

Text

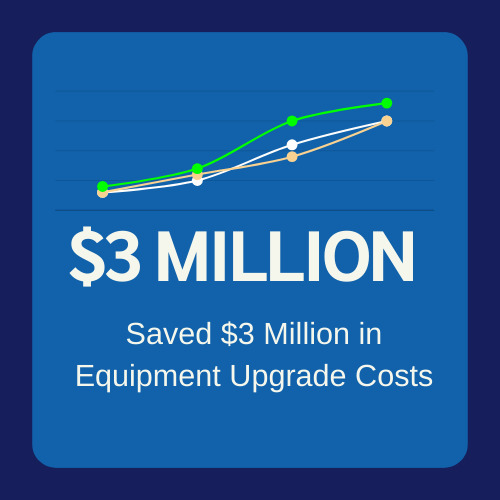

In the fast-paced world of semiconductor manufacturing, staying ahead of technology while managing costs is a constant challenge. Einnosys, a company dedicated to innovative industrial solutions, introduced EIGEMbox—a simple yet powerful device that can transform existing semiconductor equipment by adding modern automation capabilities. This case study explores how EIGEMbox helped semiconductor fabs save a massive $3 million in equipment upgrade costs and enhance their operational efficiency.

#EIGEMBox#SECS/GEM#secs gem software#gem300#secs/gem software#fab automation#predictive maintenance for pumps

0 notes

Text

Airline Scheduling Software Solutions Making Aviation Industry Profitable

Aviation sector stakeholders are greatly benefiting from the growth of airline scheduling software markets. This is because they eliminate the manual element and make planning and execution easier with real-time updates by optimizing available resources in all elements of aviation operations. For more information please visit : https://medium.com/@zuluairlinesystem/airline-scheduling-software-solutions-making-aviation-industry-profitable-c04fde2953a1

#airline planning system#airline software platform#airline scheduling system#airline gating maintenance#airline predictive analytics

0 notes

Text

Predictive Maintenance in the Manufacturing Industry

In the ever-evolving landscape of the manufacturing industry, where the downtime can easily translate to resulting in heavy financial losses, predictive maintenance has emerged and now become a groundbreaking solution with many industries including manufacturing industries that are seamlessly transitioning to embrace its significantly valuable advantages.

So, What is Predictive Maintenance?

Predictive Maintenance is a strategic and proactive approach to any equipment’s maintenance that uses advanced and high-end technologies as well as data analytics to predict when the testing machinery is likely to fail, therefore allowing for timely interventions and reducing the risk of disruptions in the production processes.

Why is Predictive Maintenance Important?

The importance of Predictive Maintenance lies in the valuable benefits that it offers starting with: -

1. Avoiding Unplanned Downtime

Predictive Maintenance helps in utilizing real-time data and condition monitoring to predict potential issues before they even escalate into critical and damaging failures. This anticipation helps manufacturers to schedule and plan maintenance during planned downtimes, avoiding any costly disruptions to occur during production processes.

2. Streamlining Asset Performance

With the continuous assessment and monitoring of the condition of the manufacturing equipment, predictive maintenance makes sure that the assets operate at their peak efficiency. This not only helps to extend the lifespan of the machinery but also fully maximizes the production output as well as reduces the unnecessary energy consumption.

3. Cost Efficiency

The ability to timely navigate and address issues before they result in major breakdowns drastically minimizes repair and replacement costs. This cost-effective and efficient approach to maintenance is one of the driving reasons for its widespread adoption, especially in the manufacturing sector.

4. Enhanced Quality Control

Predictive Maintenance plays an important role in enhancing quality control, especially within the textile industry by proactively managing the performance and health of the machinery. Fully utilizing the real-time data and advanced analytics, predictive maintenance helps in ensuring that the manufacturing equipment operates under the desired optimal conditions. This proactive approach makes sure that the corrective measures are taken well in advance, to avoid any escalation of problems and fully safeguard the overall quality of the manufactured textiles.

5. Data-Driven Decision Making

Textile Manufacturers can fully harness the valuable insights derived from predictive maintenance data to enhance overall productivity and efficiency. This obtained information can act as a strategic asset, empowering manufacturers to make better and well-informed decisions that can minimize downtime, optimize the overall operations, and elevate the productivity of manufacturing processes.

6. Ensuring Operational Safety

Predictive Maintenance also helps in ensuring operational safety as the machines operating at their highest performance levels are not only efficient but even less likely to malfunction unexpectedly. This optimization is important in creating a safe and sound working environment where the equipment behaves and functions predictably, thus reducing any chances of accidents that could be caused by unforeseen technical errors.

7. Achieving a Competitive Edge

Manufacturers that are leveraging the power of predictive maintenance also gain a strong strategic advantage over their competitors as this systematic approach helps in achieving efficient textile production at a much lower cost compared to their counterparts.

Essential Components in Predictive Maintenance

Presented below are the 3 Vital components that help in creating a robust framework for enabling industries to predict, prevent, monitor, assess, and optimize equipment performance.

a). Smart Sensing Solutions

The Advanced Sensor Technology integrated in the system allows to collect real-time data on various aspects of the machinery such as vibration, lubrication, and temperature to name a few. These sensors serve as integral components by providing important data inputs to enhance the observational capabilities of the predictive maintenance systems.

b). Advanced Analytics and Machine Learning

Cutting-edge algorithms assess and analyze the data collected by sensors to identify patterns that indicate any potential equipment failures. Machine learning models constantly work to improve predictive capabilities with more data, thus refining the accuracy and precision of maintenance predictions over time.

c). Condition Monitoring

Consistent Monitoring of the machine conditions allows the manufacturers to move from planned maintenance to condition-based maintenance. This shift minimizes unnecessary interventions making sure that the maintenance activities are performed accurately when required.

All in all, Predictive Maintenance holds significant importance in the Manufacturing industry as it reduces unnecessary costs, minimizes downtime, enhances the product quality, and helps in improving the overall operational efficiency. The use of data and technology in the predictive maintenance structure ensures that the manufacturing equipment runs smoothly, which is very important in a cutting-edge and competitive industry like the Textile industry as Product Quality and Efficiency are key factory for Success and providing the Right value to the Customers.

#paramountinstruments#qualitycontrol#qualityassurance#qualitycontrolassessment#iiot#predictive maintenance#technology#software#machine learning

0 notes

Text

What are the Most Utilized Maintenance Strategies?

Unveiling the secrets to machinery longevity and optimal performance! Dive into our latest infographic on the 'Most Utilized Maintenance Strategies' and discover the key approaches that top industries swear by. Equip yourself with the knowledge to enhance efficiency and reduce costs. Now, with Cryotos Maintenance Management Software, you can harness the power of the most utilized maintenance strategies right at your fingertips.

#cmms#cmms software#maintenance management#maintenance software#preventive maintenance#predictive maintenance#facility management software#work order

0 notes

Text

In today's fast-paced industries, optimizing asset performance is crucial for maintaining a competitive edge. Asset Performance Management (APM) focuses on maximizing the value of physical assets by leveraging data analytics and IoT technology. This proactive approach enables organizations to identify potential issues before they escalate, improve operational efficiency, and reduce downtime.

Key Benefits of APM:

Predictive Maintenance: Utilize data to anticipate failures and schedule maintenance, saving costs and extending asset lifespan.

Enhanced Decision-Making: Gain insights from real-time data to make informed operational decisions.

Increased Reliability: Boost asset reliability by monitoring performance and addressing issues promptly.

Incorporating APM strategies leads to not only improved asset management but also enhanced profitability and sustainability for organizations. 🌍✨

#asset performance management#predictive maintenance#overall equipment effectiveness#apm software#apm#asset lifecycle management

0 notes