#Production Monitoring

Explore tagged Tumblr posts

Text

Key Benefits of Production Monitoring Services

In the relentless pursuit of manufacturing excellence, visibility is power. Knowing precisely what's happening on your factory floor at any given moment, understanding bottlenecks, and identifying quality deviations in real-time can be the difference between merely surviving and truly thriving. While an in-house Production Monitoring System (PMS) is a powerful tool, many businesses, particularly those with geographically dispersed operations, complex supply chains, or limited internal resources, find immense value in leveraging Production Monitoring Services from a specialized third-party provider like RAQC Services.

Think of it: you've designed a fantastic product, secured a reliable supplier, and even implemented rigorous pre-production inspections. But what happens during the production run, especially when manufacturing is thousands of miles away or across multiple facilities? This is where Production Monitoring Services become the externalized, unblinking eye, offering critical oversight, real-time insights, and proactive problem-solving that directly translates into superior product quality, enhanced efficiency, and a fortified brand reputation.

This blog post will delve into the profound benefits of engaging a professional Production Monitoring Service, highlighting how it empowers businesses to navigate the complexities of modern manufacturing with confidence and control.

What are Production Monitoring Services?

Production Monitoring Services involve a third-party expert (like RAQC Services) deploying personnel and, often, technology to continuously or periodically monitor the manufacturing process at a factory or production facility. Unlike a single, end-of-line inspection, these services provide ongoing oversight, collecting data on:

✅ Production Progress: Tracking actual output against planned schedules.

✅ Machine Performance: Monitoring uptime, downtime, cycle times, and identifying bottlenecks.

✅ Quality Adherence: Verifying that production steps are followed correctly and identifying quality issues as they emerge.

✅ Process Compliance: Ensuring adherence to Standard Operating Procedures (SOPs) and quality protocols.

✅ Material Usage: Monitoring material consumption and identifying potential waste.

✅ Workmanship: Observing the skill and consistency of operators.

The goal is to provide real-time or near real-time intelligence and proactive intervention capabilities, ensuring that production stays on track, quality standards are maintained, and potential issues are addressed before they escalate.

Key Benefits of Engaging Production Monitoring Services

The advantages of a well-executed Production Monitoring Service are multifaceted, impacting operational efficiency, cost control, quality assurance, and overall business strategy.

1. Real-Time Visibility into Remote Operations

Perhaps the most compelling benefit for businesses with overseas or distributed manufacturing.

✅ Bridging the Geographic Gap: You gain eyes and ears on the ground, providing transparent, objective data from factories you might not be able to visit frequently.

✅ Proactive Issue Detection: Instead of discovering production delays or quality issues weeks later, you receive immediate alerts and updates, allowing for timely intervention.

✅ Reduced Uncertainty: Replaces guesswork with concrete data, fostering confidence in your production schedule and product quality.

2. Enhanced Quality Control and Defect Prevention

Moving beyond reactive inspection to proactive quality assurance.

✅ Early Detection of Deviations: Inspectors monitor production processes in real-time, identifying when critical parameters (e.g., temperature, pressure, speeds, material ratios) drift out of spec, preventing batches of defective products.

✅ Identification of Root Causes: By observing the process, inspectors can help pinpoint the underlying causes of recurring defects (e.g., operator error, machine malfunction, material inconsistency), rather than just identifying the symptom.

✅ Reduced Rework and Scrap: Catching quality issues as they occur means fewer units need to be reworked or scrapped, leading to significant cost savings and reduced material waste.

✅ Consistent Product Quality: Ensures that quality standards are consistently applied throughout the entire production run, not just at the beginning or end.

3. Improved Production Efficiency and Throughput

A keen eye on the production line uncovers inefficiencies that can be immediately addressed.

✅ Bottleneck Identification: Experienced monitors can quickly identify areas where production flow is impeded – whether it’s a slow machine, an inefficient workstation, or a material handling issue.

✅ Minimizing Downtime: By monitoring machine status and operator activities, potential stoppages can be anticipated or quickly resolved, maximizing uptime.

✅ Optimizing Cycle Times: Observing actual production cycles helps identify opportunities to streamline processes and reduce non-value-added steps.

✅ Waste Reduction: Directly identifies and reports on material waste, idle time, and other non-value-added activities, leading to more lean operations.

4. Stronger Supplier Accountability and Performance

A third-party monitoring presence fosters greater discipline and transparency.

✅ Objective Reporting: An independent service provides unbiased data on supplier performance, free from internal factory biases.

✅ Driving Compliance: Knowing that an external monitor is present encourages factories to adhere strictly to agreed-upon specifications, SOPs, and production schedules.

✅ Performance Benchmarking: Data collected over time can be used to evaluate and compare supplier performance, aiding in future sourcing decisions and supplier relationship management.

✅ Facilitating Corrective Actions: When issues are identified, the monitoring service can help communicate findings clearly, ensuring factories understand the problems and implement effective corrective and preventive actions (CAPA).

5. Cost Savings and Risk Mitigation

The proactive nature of production monitoring directly impacts your bottom line and reduces potential liabilities.

✅ Reduced Returns and Rework: By preventing the mass production of defective goods, you significantly cut down on costly returns, warranty claims, and rework expenses.

✅ Lower Shipping Costs for Rejects: Avoids shipping defective products that will eventually be rejected by the customer.

✅ Protection Against Production Delays: Early detection of issues allows for timely adjustments, preventing costly delays in product launch or delivery schedules.

✅ Brand Reputation Safeguard: Delivering consistent, high-quality products builds customer trust and protects your brand from negative publicity associated with product failures or recalls.

✅ Insurance and Liability Reduction: Proactive quality control and detailed documentation can support insurance claims or mitigate liability in case of product incidents.

6. Support for Continuous Improvement and Lean Initiatives

Production monitoring generates the granular data necessary to fuel ongoing operational excellence.

✅ Data-Driven Decisions: Provides the factual basis for identifying areas for improvement, implementing changes, and measuring their impact.

✅ Root Cause Analysis: Real-time data and observations are invaluable for conducting thorough root cause analysis of production or quality issues.

✅ Validation of Improvements: Allows you to objectively verify whether process changes, new equipment, or training initiatives have achieved the desired improvements.

✅ Identifying Best Practices: Highlighting successful production lines or operator practices that can be replicated across the organization.

7. Focus on Core Competencies

By outsourcing production monitoring, businesses can reallocate their internal resources.

✅ Free Up Internal Teams: Allows your own quality and engineering teams to focus on design, innovation, and strategic development rather than day-to-day factory oversight.

✅ Access to Expertise: Leverages the specialized knowledge and experience of dedicated quality control professionals who understand international manufacturing standards and best practices.

✅ Scalability: Easily scale monitoring efforts up or down based on production volumes or project needs without incurring the overhead of hiring permanent staff.

Conclusion

At RAQC Services, we understand that effective production monitoring requires more than just a presence; it demands expertise, meticulous methodology, and clear communication. Our Production Monitoring Services are designed to provide you with:

✅ Experienced, Local Inspectors: Our teams on the ground are skilled in identifying nuances, understanding production processes, and communicating effectively with factory personnel.

✅ Customized Monitoring Plans: We work with you to develop monitoring protocols tailored to your specific product, industry, and quality requirements.

✅ Real-time Reporting and Dashboards: We provide transparent, detailed reports, often with photographic evidence and real-time updates, giving you immediate insights.

✅ Proactive Issue Resolution: Our inspectors act as your advocates, collaborating with factory management to address issues promptly and effectively.

✅ Comprehensive Data Analysis: We help you interpret the data from monitoring activities to drive continuous improvement and strategic decision-making.

In today's complex supply chains, managing production quality from afar is a significant challenge. Production Monitoring Services are no longer a luxury but a strategic necessity, providing the necessary oversight to ensure your products meet the highest standards, your operations run efficiently, and your brand reputation remains unblemished. Partner with RAQC Services to gain the confidence and control you need over your global manufacturing endeavors.

0 notes

Text

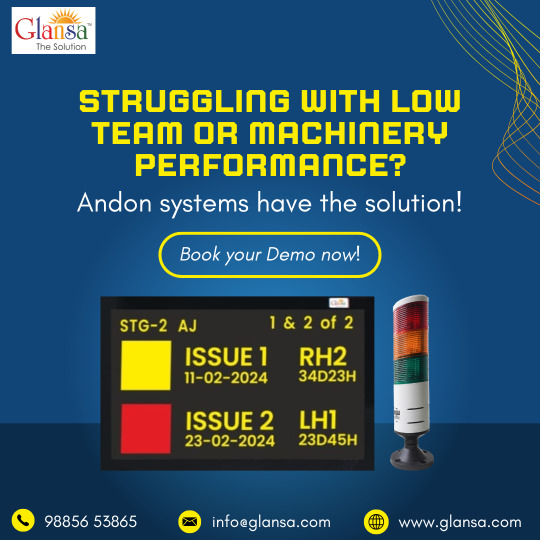

How Andon Devices Improve Manufacturing Efficiency – A Smart Factory Essential

Introduction

In today’s competitive manufacturing landscape, operational efficiency and real-time communication are critical. As factories move toward Industry 4.0, tools like the Andon device are becoming essential for lean production environments. An Andon system serves as an immediate visual and/or audible alert mechanism that highlights issues on the shop floor, enabling faster response times and reducing costly downtimes.

What is an Andon Device?

An Andon device is a signal system used in industrial settings to alert operators, supervisors, or maintenance teams about problems or abnormalities in real time. Traditionally, Andon systems were simple light signals. However, modern solutions—like those offered by Glansa Solutions—come with digital displays, IoT integration, and real-time data tracking.

Why Use an Andon Device?

Real-Time Communication: Operators can immediately alert others to issues without leaving their station.

Reduced Downtime: Early detection allows teams to resolve problems faster.

Increased Accountability: Tracks how long issues persist and who responded.

Better Decision Making: Collected data helps in analyzing production trends and implementing continuous improvements.

Key Features of Glansa’s Andon System

✔️ Visual and audible alerting

✔️ Custom-configurable signals

✔️ Web-based dashboard for real-time monitoring

✔️ Seamless integration with ERP and MES systems

✔️ IoT-enabled for smart factory use

Use Cases in Manufacturing

Glansa’s Andon devices are used in various sectors including automotive, electronics, textiles, and FMCG industries. Whether it’s to notify quality checks, machine breakdowns, or material shortages, Andon devices ensure faster responses and increased production visibility.

Why Choose Glansa Solutions?

Glansa Solutions is a trusted name in industrial automation and smart factory tools. With years of experience, we deliver scalable and intelligent Andon systems that help manufacturers meet their production goals while embracing digital transformation.

Conclusion

Investing in a robust Andon device is a smart move for manufacturers aiming to boost shop floor transparency and operational efficiency. With solutions like those from Glansa, businesses can stay ahead in the era of smart manufacturing.

📍 Learn more: https://glansa.com

#Andon Device#Manufacturing Technology#Glansa Solutions#Lean Manufacturing#Production Monitoring#Smart Factory#Industrial Automation#Shop Floor Management

0 notes

Text

What is production monitoring?

Introduction

Production monitoring allows buyers to pay attention to each manufacturing process to ensure that the factory production is running as expected. Third-party inspection companies ensure that products meet quality requirements by inspecting every link in the supply chain. Product inspectors use the internationally recognized ANSI/ASQC Z1.4 standard to test samples/semi-finished products/finished products to meet buyers' needs.

Details

What is production monitoring?

Production monitoring is a special on-site inspection that is mainly used to monitor production status and raw material inventory.

The inspector checks your supplier and verifies the quantity of raw materials required for the product before production. Weproving will provide a detailed report on the entire production cycle of your product.

Why is production monitoring necessary? 1. Make your suppliers responsible from the beginning to the end of the production process

2. Take control of the entire production process

3. Avoid any possibility of subcontracting

4. Timely discover factory production capacity/delays

5. Discover poor internal quality/production environment of the factory

By continuously tracking the inspection during the planned time period, you can keep abreast of the production status for a more accurate schedule and better quality control.

Nanjing Weproving Inspection supply professional inspection service. One stop solution for your business, factory audit, production inspection, amazon fba inspection and container loading check.

#production monitoring#production inspection#quality control#factory audit#supplier audit#production inspection company

0 notes

Text

Production monitoring involves the use of technology to continuously track, analyze, and optimize various aspects of the manufacturing process. This includes real-time data collection from machines, equipment, and production lines, as well as the analysis of this data to provide actionable insights. Production monitoring systems help manufacturers identify inefficiencies, detect anomalies, and make data-driven decisions to improve overall production performance and quality.

0 notes

Text

Elevate your operational efficiency with Mavarick AI’s cutting-edge Machine Monitoring solution. Designed to provide real-time insights into your machinery’s performance, our advanced platform enables you to track, analyze, and optimize equipment usage with precision. By leveraging sophisticated sensors and data analytics, Mavarick AI’s Machine Monitoring solution helps you anticipate maintenance needs, reduce downtime, and improve overall productivity. Our user-friendly interface offers actionable insights and comprehensive reports, allowing you to make informed decisions and enhance the reliability of your operations. Transform your approach to equipment management with Mavarick AI, and ensure your machines operate at peak performance.

0 notes

Text

Mavarick offers AI-Driven Carbon Reporting technology to accurately monitor and report manufacturing carbon emissions at corporate, organizational and product levels. Our comprehensive solutions include Carbon Accounting Software, Carbon Reporting Software, and Carbon Management Systems to provide carbon emissions analysis, audit-ready carbon footprint reports, and actionrecommendations for carbon emission reduction. Track – Track your carbon emissions with accurate data capture using our advanced Carbon Accounting Software. Analyse – Gain automated insights into your carbon emissions with our Carbon Reporting Software. Report – Generate audit-ready reports compliant with CSRD, CBAM, and ESRS standards using our Carbon Reporting Software.

0 notes

Text

At Mavarick our mission is simple to help manufacturers become more efficient and sustainable.as second-generation manufacturers our journey began on the shop-floor with a simple realisation – existing digital tools in the market were overly complex, created more inaccessible data silos and required too much of the operator. with Mavarick, accessing and using data in your day-to-day becomes effortless. our technology automatically captures and analyses your data, providing actionable recommendations for smarter decision-making.

0 notes

Text

bouquet for the boy 💐

#yes this was for valentine’s day#no im not late its still feb 💖#mp100#mob psycho 100#mp100 fanart#shigeo kageyama#my art#psykoe100art#this whole month i was distracted by rearranging my desk#as if a change of scenery will help me be more productive#so far i just removed a monitor and agonized over what monitor stand i should buy#theres so many and they’re not cute :(#i think once my keyboard arrives i can go back to wanting to draw#but until then im going to be haunted with cozy desk inspo boards

1K notes

·

View notes

Note

I need you to know that I too don't know how to move on from my life until the next chapter. I binged the entire thing in one sitting omg

YAYYY! happy to hear that <3 trust me i am glued to this computer determined to bring out the next chapter as soon as possible, in a way i cant move on either hahahhah

273 notes

·

View notes

Text

Ministry Office Tech Roundup

Oh boy! Oh boy!! New filming location means new set dressing and new technology to identify!! All of the following is from Chapter 20: Arrival of a Secret Agent.

For starters, the phones on the desk are the NEC DT330 in the 32-button layout option, sold c. 2010

(I cannot find photos of the 32 button DT330 in woodgrain but they sold it! Trust me! I found the 2010 BTB sales catalogue!)

Our dedicated clergy member has her papers stacked on top of an HP Pavilion DV7-6163CL, sold c. 2012

Judith's desk has a Casio Memory B-1 calculator, produced c. 1978

Frater's absurd battlestation consists of:

NEC Cromaclear P500 Monitor, c. 1996

Perix Perimice-209 Mouse, c. 2017

Generic RGB Gaming Keyboard, c. 2020

(I think it gets rebadged under multiple brand names -- the reference photo is from "KUIYN" and the the keyboard has used different keycaps over the years.)

Of course a monitor is useless without a computer, so everything is powered by a laptop under the table. It appears to be an HP laptop, something along the lines of a 14inch HP Stream c. 2020 onwards.

#listen i understand logistic filming reasons for why this set up is the way it is but it's still really funny to me#i like to imagine he broke the laptop hinge and the screen stopped working#frater!! turn on the keyboard rgb lights!!#stuff in ghost videos#ghost#ghost bc#ghost the band#ghost chapters#cardinal copia#papa emeritus iv#frater imperator#ghost lore#fieldghoul makes gifs#me @ the production crew: covering all the logos on the monitor with stickers cannot and will not stop me from finding it!!

125 notes

·

View notes

Text

SpongeBob running animation cels from Hall Monitor.

#spongebob squarepants#spongebob production art#spongebob#animation cel#painting#background#spongebob season one#hall monitor

228 notes

·

View notes

Text

Production Monitoring Service

The Production Monitoring Service from RAQC Services, a comprehensive solution designed to optimize and streamline your production processes.

With our advanced monitoring tools and expertise, we ensure real-time visibility into your production line, allowing you to identify bottlenecks, track performance, and make data-driven decisions.

Our service offers detailed analytics and customizable reports, enabling you to monitor key metrics such as production efficiency, downtime, and quality control.

By leveraging our Production Monitoring Service, you can enhance productivity, reduce costs, and improve overall operational efficiency.

Trust RAQC Services to provide you with the insights and support you need to achieve manufacturing excellence.

https://www.raqcservices.com/production-monitoring/

0 notes

Text

Improve Production Efficiency with Glansa’s Andon Device

Looking to reduce downtime and improve real-time visibility in your manufacturing process? Glansa offers intelligent Andon device solutions that provide instant visual and audio alerts for production line issues. Enhance your shop floor communication and accelerate response times with our customizable and reliable Andon systems.

#Andon Device#Manufacturing Technology#Glansa Solutions#Lean Manufacturing#Production Monitoring#Smart Factory#Industrial Automation#Shop Floor Management

0 notes

Text

Transparent Source / Supply.Family / Apple Pro Display HDR / Mockup / 2024

Download

#transparent source#supply.family#apple pro display hdr#mockup#2024#device#digital#graphics#monitor#product#shopsystem

34 notes

·

View notes

Text

Barrage of YouTube ads relentless, send help. Categories are diet pills, betterhelp, clothing sites I already buy from, bastard fast fashion and AI productivity, which is already HORRIFYING ENOUGH but a lot of these damn ads include fucking Slack notification sounds, which DISTURB MY PEACE.

#Like#Oooh my boss might be messaging me#NOPE BASTARD ADVERT#Also I will never want AI to run my life#They're trying to shame me for watching youtube instead of being PrODuctIVe#Meanwhile I am working hard on my other monitor#but I NEED something dumb in the backgroud to stop me losing my mind while I place walls one section at a time#over the entirety of Roman Southwark#With editor lag#I have been released from graveyard duty for now#ANYWAY maybe I could be more organised but if someone gives me a deadline I will make it work#most of my job is of the it's done when it's done variety at the moment#Sometimes it's hard to stay focused#hence need for background noise#to stop my brain wanting to go out seeking happy chemicals

4 notes

·

View notes

Text

Production monitoring refers to the continuous observation and analysis of manufacturing processes to ensure optimal performance and quality. It involves tracking various metrics and parameters in real time to identify inefficiencies, detect issues, and make data-driven decisions.

0 notes