#Rotary Printing Machine

Explore tagged Tumblr posts

Text

Enhance Textile Production with ATE's Advanced Rotary Printing Machines

ATE stands as a leader in the textile engineering sector. It offers an array of machinery and accessories that cover the entire textile value chain. ATE types of machinery include conventional and technical textiles and encompass everything from spinning, weaving, and knitting.

It also includes dry and wet finishing, printing, home textiles, and specialized textiles like synthetic fibres, filaments, and non-wovens. You will find utilities such as air engineering, water treatment, and laboratory equipment, which makes ATE a one-stop solution provider for the textile industry.

Textile Printing technology by ATE

ATE has established itself as the go-to source for end-to-end textile processing technology. It boasts of long-standing partnerships with the world's leading manufacturers. In the realm of wet and dry processing, ATE provides state-of-the-art technology for knit fabrics, including advanced finishing equipment and continuous processing solutions for bleaching, mercerizing, and dyeing in open-width form.

For textile printing, ATE brings the latest technology, from engraving shop equipment to print washers, all sourced from renowned manufacturers worldwide.

About Rotary Printing Machines by ATE

Rotascreen Rotary Printing Machines stand out as versatile solutions for a wide range of textile printing applications. These machines ensure precision and efficiency across entry-level digital printing with Colaris Infiniti Digital Printing Machine or high-capacity rotary printing.

The Colaris 3 Digital Printing Machine represents the pinnacle of high-performance, high-quality digital printing technology. Designed for precision and efficiency, it meets the demanding needs of modern textile production with exceptional output and reliability. The Modus Loop Steamer offers advanced fabric steaming capabilities, integrating saturated and superheated steam along with hot air. This ensures uniform treatment of textiles for superior results. JetScreen DX is an innovative, cost-effective direct exposure system for rotary screen printing, delivering fast and accurate results. It stands out for its competitive edge in both speed and economy, making it an ideal choice for high-volume production environments. Rotascreen Rotary Printing Machines excel in continuous fabric printing. It utilizes a perforated cylindrical screen that applies colourants with precision. The Rotascreen machines, developed by J. Zimmer Maschinenbau GmbH, Austria, are versatile, offering both open and closed bearing systems to suit various applications. The original Zimmer Magnet System Plus enhances colour application, accommodating repeat sizes from 640 mm to 1020 mm, ensuring high-quality prints for home textiles, fashion, flags, technical textiles, and even wallpapers. Features of Rotary Printing Machines by ATE

The Rotascreen's V-Type print head with its open bearing system provides a compact and robust design. This allows adjustment of repeat sizes from 64 to 120 cm. The machine's digital synchronization between screens and the printing blanket drive ensures impeccable accuracy, even at speeds of up to 120 meters per minute.

This precision makes the Rotascreen adaptable to a wide range of textile materials, from woven fabrics to delicate knits, terry towels, and blankets.

Key features It has customizable features such as adjustable magnet power, roll rod diameter, and screen installation. The Rotascreen Rotary Printing Machines offer unparalleled versatility and efficiency for textile printing operations. The Rotascreen Printing Machine is engineered for high-speed precision, with a robust and integrated computer control system. This advanced system uses top-quality electronic components in air-conditioned cabinets to eliminate any potential heat-related issues. The drying process is crucial to achieving superior print quality, and the Rotascreen machine excels in this area with its modular, high-efficiency hot air nozzle dryer. This powerful drying system comes with heating options that include central steam, thermal oil, hot water, or direct gas burners. For colour application, the Rotascreen machine combines the benefits of the magnet system with the traditional blade squeegee system. The modular design allows for easy replacement of components such as colour pipes, the main body, magnet holding ledges, and side limiters, all constructed from durable materials like stainless steel, aluminium, and carbon fibre. Key Benefits of Rotary Printing Machines by ATE

Here are some operational benefits of the rotary printing machine by ATE:

The Original Zimmer Magnet System Plus is used for precise colour application. It comes with automatic pre-repeat adjustment and design memory for efficiency There is an option for single or dual-sided screen drive, and it has a compact, solid construction for durability These machines enable high-precision printing at speeds up to 120 m/min You get the benefit of optimized visibility of printed fabric between individual printing stations Conclusion

The Rotascreen Rotary Printing Machine represents innovation in textile printing technology. It combines advanced engineering with user-friendly controls to deliver exceptional performance and reliability.

The machine's exceptional drying systems and renowned colour application technology ensure consistently high-quality results, which can be customized according to the specific needs of each production line. This machine by ATE enhances operational efficiency and empowers businesses to push the boundaries of textile innovation.

0 notes

Text

"Empowering Excellence with Innovation in Flexographic Printing." 🔥

Exciting News from Webtech! 📣

We are thrilled to announce the finalization of yet another significant order—a 10-color Fully Servo Flexographic Printing Machine in 350 mm working width, custom-designed for lamitube substrates, for our esteemed client in Maharashtra. This client stands as a leader in the Indian market for printing lamitube substrates, and it’s an honor for us to collaborate with such a distinguished company.

This project promises to be exceptional, featuring cutting-edge advancements in our latest generation LABELTECH S4 SERIES. We are excited to bring these innovations to life and look forward to sharing more updates on our products and services. ✨

Stay tuned for more exciting news! 📺

#label printing#flexo innovation#flexo printing machine#flexo#packaging labels#webtech#lamitube Printing#10 Colors press#label#rotary Label Printing Machine#Labeltech S4 SERIES#Fully Servo Flexo Press

0 notes

Photo

Top 10 Inventions of the Industrial Revolution

The British Industrial Revolution transformed life at work and at home for practically everyone. Noise, pollution, social upheaval, and repetitive jobs were the price to pay for labour-saving machines, cheap and comfortable transportation, more affordable consumer goods, better lighting and heating, and faster ways of communication.

Any shortlist of inventions is bound to be far from complete, but the following have been chosen not only for what they could do but also for how they permitted other inventions to become possible and how they transformed working life and everyday living for millions of people. The period under consideration is also important and here is taken as 1750 to 1860. With these criteria in mind, the top 10 inventions of the Industrial Revolution were:

The Watt Steam Engine (1778)

The Power Loom (1785)

The Cotton Gin (1794)

Gas Street Lighting (1807)

The Electromagnet (1825)

The First Photograph (c. 1826)

Stephenson's Rocket (1829)

The Electrical Telegraph (1837)

The Steam Hammer (1839)

Mass Steel Production (1856)

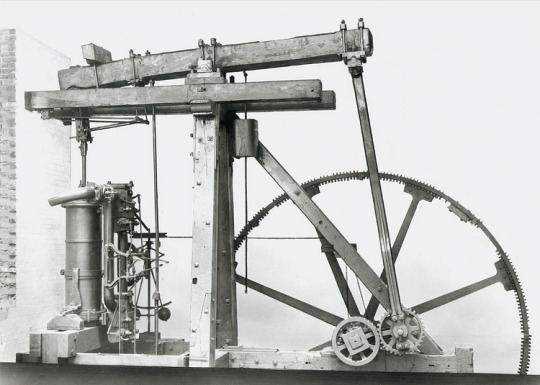

The Watt Steam Engine

The steam engine, which harnessed power from the expansion of heated water, is often cited as the single most important invention of the Industrial Revolution, principally because so many other important subsequent inventions used it as their power source. The steam engine was born from the necessity to pump out flooded mine shafts and enable deeper mining. The first steam pump was invented by Thomas Savery (c. 1650-1715) in 1698. In 1712, Thomas Newcomen (1664-1729) perfected his more powerful steam pump to drain coal mines of water in Dudley in the Midlands.

To make the steam engine more useful for other purposes, it had to be made more efficient both in terms of fuel consumption and power. The Scottish instrument maker James Watt (1736-1819) and Matthew Boulton (1728-1809) kept tinkering with the workings of the steam engine until, in 1778, they had perfected a separate condenser to vastly increase the engine's efficiency. Power was also increased by the steam powering the piston down not just up (hence its name, a double-acting engine), increasing the 'horsepower', a term coined by Watt. The engine also had its power converted to a more versatile rotary motion using a flywheel. Using just one-quarter of the fuel of Newcomen's engine, Watt's engine was cheap enough to use almost anywhere. Steam engines kept on evolving, notably with the expansion steam engine, and they benefitted from ever-better tool machinery that could make stronger and better-fitting parts.

By 1800, Britain boasted over 2,500 steam engines, most of them used in mines, cotton mills, and manufacturing factories. 500 of these engines were made by the Watt and Boulton factory in Birmingham. Every walk of life was affected. Steam now powered fountains, threshing machines, sewage pumps, and printing presses. Essentially, any work that required pushing, pulling, lifting, or pressing could be made much more efficient using steam-powered machines. Steam engines were harnessed for trains and steamships, and, aptly, all these uses caused a boom in the coal mining industry, which had been the origin of the machine in the first place.

Continue reading...

35 notes

·

View notes

Text

1. Essential Sewing Techniques

Basting: Temporary long stitches to hold fabric before final sewing.

Backstitch: Strong hand stitch for seams that need durability.

French Seam: Elegant finish that hides raw edges inside a folded seam (common in high-end garments).

Gathering: Creates controlled fullness (e.g., ruffles on sleeves or skirts).

Zigzag Stitch: Prevents fabric fraying on raw edges; used in stretch fabrics.

Quilting: Combines piecing (sewing fabric patches) and stitching through layers for texture.

2. Cultural & Historical Significance

Ancient Egypt: Linen garments were hand-sewn with flax thread; some stitches survive today.

Japan: Sashiko embroidery (functional decorative stitching) reinforced workwear.

Europe: The 18th-century mantua dress required intricate draping and sewing skills.

Industrial Revolution: Sewing machines (like Singer’s 1851 model) democratized fashion but also fueled sweatshop labor debates.

3. Must-Have Sewing Tools

Fabric Shears: Sharp scissors reserved only for fabric.

Seam Ripper: Fixes mistakes without damaging material.

Tailor’s Chalk/Marking Pens: For tracing patterns.

Thimble: Protects fingers when hand-sewing thick fabrics.

Bobbins: Hold thread in sewing machines.

Rotary Cutter & Mat: Precision cutting for quilters.

4. Modern Sewing Innovations

Computerized Machines: Auto-threading, embroidery designs via USB, and touchscreen controls.

3D Printing: Custom buttons, accessories, or even fabric-like materials.

Smart Fabrics: Sewable LED circuits, conductive thread for wearable tech.

Sustainable Stitches: Growing use of upcycled materials and zero-waste pattern design.

5. Famous Figures in Sewing

Coco Chanel: Started as a seamstress; revolutionized women’s fashion.

Elizabeth Keckley: Former enslaved woman who became Mary Todd Lincoln’s dressmaker.

Yves Saint Laurent: Master of precision tailoring.

Contemporary Makers: Blogs like Tilly and the Buttons and YouTube sewists inspire DIY fashion.

6. Sewing’s Psychological & Social Benefits

Mindfulness: Repetitive stitching can reduce stress (like "textile therapy").

Community: Quilting bees, online sewing forums, and #SewingTwitter foster connection.

Empowerment: Self-sufficiency in making/modifying clothes challenges fast fashion.

8 notes

·

View notes

Text

It all started with a reddit post.

No it didn’t. It started when I was 5 and my mom handed me fabric and thread and buttons to keep me busy while she sewed. It started with the Christmas and Easter dresses my grandmother turned out every year without fail. It started with holding tapestries my other grandmother wove. It started with listening to my great-grandmother talk about the quilts city women paid her to finish for them and the rugs she wove on her floor.

I’ve always said that I had textiles in the blood, as a genetic legacy. While only one of the women who came before me called herself an artist (my maternal grandmother) they all chose textiles as their medium.

I made my first quilt in middle school, I think. My grandmother spent decades as purely a garment seamstress, working in a suit store and altering prom dresses on the side, sewing for herself and her loved one. She loved clothes and her huge basement was packed with everything she had made herself. She found herself seeking a new challenge. She’d avoided quilting (possibly because her mother was a quilter and they had a complex relationship) but she decided to give it a go. Her first quilt was a pinwheel, pieced by machine and then hand quilted while she recovered from a knee surgery. She let me quilt a block. I decided I’d make a quilt too, pinwheels the same as her. I didn’t have a book, or a pattern, or the internet and she wasn’t there when I started. I cut my triangles mostly by eye, with scissors, on the living room floor. They were big, maybe 10 inches. I sewed them up and wonky is the kindest word I could give them now, but I felt like a genius. I didn’t know you were supposed to quilt it before binding so I bound it, and pinned the layers together. I even quilted some of the squares. And then I slept with it, pinned together for roughly a decade. It was never fully quilted. It wasn’t long enough to cover both my shoulders and feet, but it was the perfect weight for a summer quilt. I wish I knew what had happened to it.

My second quilt was a whole cloth quilt. I was in grad school. I had the internet, but I didn’t use it. I wanted something the same weight as the first quilt, but long enough to cover my feet. I bound it with satin blanket binding, and quilted a cross, one row up the length through the middle, and one row across the width. I did not read the directions on the batting about how far apart the quilting lines should be. It is now my son’s favorite blanket. It hasn’t fallen apart.

I did a lot more learning (but not enough) and a lot of growing before I tried quilting again. By this time I was a parent and I had learned the value of measuring and rotary cutting. Again I’d make a pinwheel quilt. I learned how to make half square triangles four at a time. My grandmother passed either shortly before or after I started it and I think of her when I work on it. It took me a long time to make the blocks, it took me even longer to put them together. I thread basted it on the floor. I knew enough not to bind before quilting, but I hadn’t yet learned to start in the center of quilt. I worked around the edges and learned even more. I learned that if I quilt too much my hands hurt, I learned that my spouse will sleep under a quilt left on the couch even if it isn’t finished or bound. I eventually learned I should have started in the middle. I started it in 2019, its 2024 and I’m still slowly quilting the blocks. I bound it eventually because the edges were showing a lot of wear (because my spouse has been sleeping under it). Someday it will be done, but it makes me laugh to know that it is serving its purpose regardless, and has been for years.

Another chapter in my quilting story. It was roughly 4am and I was sick. Hopped up on every medication known to humankind and scrolling through my phone. I stumbled across a video of someone stitching fabric wrapped around hexagons together by hand. Half a dozen videos later I was sitting at a computer printing out templates onto cardstock paper and digging through the remains of pandemic mask making fabric. I made a coaster, and then I made a pillow. Before I even made it past the fog of flu I started a hexagon quilt. I didn’t plan, but I kept a somewhat cohesive color story. 900+ hexagons later I had a finished quilt top, it took me about a year, and eventually I chose a backing and used my sewing machine to quilt it together, starting from the center working out, binding at the end. And that is the moment that I finally felt like a quilter.

Its been a while since that night scrolling. I’ve made more quilts, large and small. Not a lot, but enough. I spend a lot of my down time thinking about quilts. When I’m quilting I think about those who came before me, I think about my grandmother’s hands. I think about how intrinsic quilting is to the place I grew up, all the hands that came before my grandmother, and her mother, and the lineage going back through the largely unrecorded history of poor women in rural Appalachia.

Getting back to reddit. The other day I was scrolling through and was struck by this quilt posted on reddit by u/karenosmile.

Classic and yet it is also intrinsically modern.Chaotic and random, but also a repeated pattern of the same simple block. It brought to mind quilts I’d seen while looking through museum collections online (which is a delightful activity for slow afternoons). I went back through my links and the collections again, looking at other examples of quilts that feature that classic ageless block - the half square triangle, also known as the HST. I wanted to know what made that quilt on reddit feel so modern.

The oldest quilt I found in my brief review that felt like it had the same feel as the reddit quilt was this quilt from the 1840s. It is orderly, but combining different sizes of half square triangles. I would not see this as old fashioned if I saw this quilt posted online tomorrow.

The next quilt has been printed out and taped to my wall for months. It was made in 1898 by one Lura, for another Lura. Another lineage. This quilt only has one size of HST and they are orderly arranged to create strong diagonal lines of color across the quilt.

Coming to the 20th century we have another quilt* that uses half square triangles of different sizes, however this one uses blocks of HSTs arranged and combined with large white triangles to form yet another larger HST.

Ultimately I think the thing that sets the original reddit quilt apart is the scattered variety of block sizes and the seemingly random placement of the blocks. The varying size abandons the strict repetition of the museum pieces while maintaining the simple geometry of the block itself.

*Link may not work as it is from Jstor

#quilting#hand quilting#historical quilt#quilt history#half square triangles#hst#classic quilt blocks

16 notes

·

View notes

Text

Final Moments

I've had this one sitting in docs for a good half year. The aftermath of the Spamton Neo boss fight has always interested me and I decided to expand on that.

---

He had given it all he possibly had.

Snap, pop.

So had they.

His joints wracked with exhaustion, his porcelain skin scuffed with two decades of desperation. The puppet raised his tired eyes up to his lenses, they were clouded and foggy with prints and things lost to memory. It was with a solemn sort of defeat he acknowledged the ivy wire around his body, his wrists, his willpower.

*Footsteps struck the ground in the distant darkness.

What was once the phantom sound of a rotary phone, was now the ticking clock on an old friend’s wristwatch. He was being held ruthlessly in the hand of something fated. It smelled of dust and cobwebs, of murk and… muck. It felt hollow and dark, very dark, it has always been his only companion. Oh, how he craved company.

*There was a soft murmur of armor clinking.

His life rolled like an old film in his mind, for he had done everything he possibly could, but he was, and always would be, thrown away. He tried to deal himself another hand of cards, to barter with his sixth sense, and to argue with his aching gears and circuits. One more time, get up again. It’s all about luck, it’s all about hard work, life is a ladder you climb, he used to muse. There’s nowhere I must go but up.

*The breeze whistled something like sympathy.

The motor in his mechanical heart thumped, shook, and whirred. He smelled of burning electrical, of rust and rotted glass. He was a machine with no checklight, a walking technical malfunction, that no one bothered to help repair. Tell me, how is a broken machine to fix itself?

*The basement walls closed their eyes, and looked away.

The man reared his tired head with an ugly pop, and stared at nothing in particular. No, indeed, he needn't get back up on his feet again, if even he could. For he knew somewhere deep in his wretched gut, that if there wasn’t him to throw away, then there was no one. To try and be big when you are fated to be small, is to watch in hopeless agony as you are hammered down time and time again. He would always be Spamton G. Spamton, the email guy.

It is your fate.

A gentle smile crept onto his face, because oh but, maybe, someone valued him. Maybe, just maybe, in his last moments, he could impart what little about him was useful onto the Lightners. The only people who'd shown him kindness, with no strings attached. He inhaled a shaky breath, and looked on as his only friends walked toward him.

“It seems after all I couldn’t be more than a simple puppet.”

His voice was dry and hoarse, but soft, bracketless. There was no salesman left.

“But you three, you’re strong.”

The smell of burning wires could make a stomach ache.

“With a power like that… Maybe you three can break your own strings.”

His jaw clacked lifelessly with each syllable. The end was nearer, nearer, yet nearer.

But even still.

“Let me be your strength.”

#spamton#deltarune#deltarune chapter 2#spamton g spamton#utdr#writing#is this a fic#fic#angst#walt vault#this drabble is meant to double as poetry in a way i was kinda having some poetic fun#spamton fic#i do a drabble sometimes as a treat#important to keep in mind I don’t write often#runs away

22 notes

·

View notes

Note

Puppy print soles…😵💫😵💫😵💫 that sounds absolutely pawsome…

Puppy’s other favorite that she hasn’t gotten to do in a long time is a spa day, where she has her partner sit and watch a movie while puppy washes and scrubs(like a sugar scrub) and moisturizes her feet. Something very emotionally fufilling about servicing and being so close to soft soles…

Puppy hasn’t taken good care of her skin and has no tattoos, but wants some. Problem is money and time and puppy isn’t very good with pain.

-puppy visiting family for Easter

Oooh that sounds delightful! I'd love to try that. I like giving foot massages (massages in general tbh) but so far they've not been in a kink setting but that would be really nice ☺️

I've recently been trying to develop some skincare routines and I'm doing well enough but it's hard to maintain them when I'm around others for some reason, same with most of my routines 😕

For a little while we were a tattoo apprentice so Nikki and Lami decided to get a tattoo kit when we wanted more tattoos and couldn't afford them, I've not got as much of a drive to get tattoos apart from the paws. Plus before I got a rotary machine we were using a coil machine which is a loud sensory hell for me.

I hope your visit with the family goes well puppy xx

2 notes

·

View notes

Text

Nickel Rotary Screen & Nickel Screen Engraving Chemical Manufacturer, Supplier & Export in India

Welcome to Roopa Screen Private Limited. We are one of the most recognized and leading manufacturers, suppliers and exporters of various engraving products, rotary screen printing machine, nickel rotary screen, textile spares.

We are technically advanced and well equipped with manufacturing facilities, we are competent of fabricating and offering a wide range of engraving products, rotary screen printing machine, nickel rotary screen, textile spares and nickel screen engraving chemicals like photo emulsion for rotary screens. Our range of machines are known for their durability, efficiency, precision, technical superiority and are also easy to operate.

2 notes

·

View notes

Text

Your First Quilt: A Step-By-Step Guide

Pattern

Select your pattern. For beginners, it’s best to start with a simple charm square pattern that doesn’t require complicated techniques. Check my beginner pattern but make it smaller, free charm square quilt patterns.

Select Fabric

Choose your fabric. Cotton is generally the easiest to work with and is available in a wide range of colors and prints. You can also grab any fabric bundle on sale at the local craft store to get you started. After all, you just want fabric you can practice with. If you have friends or family members that sew, why not ask for some of their scrap fabric or older fabrics they no longer want.

Cutting Fabric

Cut your fabric pieces according to the pattern instructions. Be sure to measure twice and cut once! Use 5″ squares for your first quilt. Buy one or two Pre-Cut Charm Packs. If you are cutting the fabric yourself, be careful using the rotary cutter for the first time. Invest in cutting gloves to protect your hand and fingers so you don’t cut them off! The best ruler for beginners is the 5″ x 24″ straight acrylic quilting ruler. It’s long enough to cover your WOF (width of fabric and it’s 5″, the same size you want your charm squares to be for your first quilt.

Sewing Squares

Use the floor, bed, sofa, or any other flat surface to layout your 5″ squares before sewing. Once you like the layout, sew your fabric pieces together. Start by sewing individual pieces together into rows, then sew the rows together to form the quilt top. Match up your inner corners, pinning in place until you have the full row pinned. Don’t worry if the outer edges don’t match up perfectly, they can be trimmed later if needed.

Basting and Machine Quilting

Add batting (the middle layer of the quilt) and backing fabric, then sew all three layers together. This is known as “basting” and “quilting.” Here are several tutorials on basting, machine quilting with walking foot and straight line quilting.

Binding

Finish your quilt by adding a binding around the edges. This gives your quilt a clean, finished look and protects the edges from wear and tear. Please check out these quilt binding tutorials that include how wide to make your binding, single fold or double fold and how to join the binding ends. Use the top tool bar, search for binding for all posts on this topic.

Congratulations, you’ve just completed your first quilt! Remember, practice makes perfect, so don’t be discouraged if your first few quilts aren’t perfect. The most important thing is that you’re learning and having fun.

#crafts#gifts#decor#sewing#quilting#briar rose quilts#bedding#shopping#quilters of tumblr#holiday#first quilt#quilt#quilt pattern#how to quilt#learn quilting

5 notes

·

View notes

Text

tagged by @littencloud9 !!!

no pressure tags: @itsyaboyredacted @spliqi @rotary-supercollider

3 notes

·

View notes

Text

Superior Print Protection with UV Coating Technology

UV coating machines are redefining the boldness in terms of finishing and protecting printed products. This liquid coating is immediately cured under ultraviolet light to yield a satin or glossy finish that is a definite plus in visual appeal. Apart from premium appearance, UV coatings enhance the durability of prints by rendering them immune to moisture, scratches, and fading, an ideal solution for labels, brochures, packages, and marketing materials.

At UV Graphic, we manufacture best-in-class UV coating machines with precision and efficiency. These machines can easily coat different materials, such as paper, cardboard to specialty substrates, because they are versatile. Advanced features would typically ensure high performance, uniform coating quality, and less downtime in operations.

The UV coating machine supplied by UV Graphics truly provides prints with lively and professional finishes, all the while prolonging the lifespan of printed products. With our trustworthy technology, it suits modern printing needs to meet the consumer's expectations. Opt for superior UV coating solutions being as modern, quality, and efficient as possible.

#uv curing systems#curing machine manufacturer#rotary hot foil stamping#flexo printing machines manufacturer#UV Coating Machines Manufacturer

0 notes

Text

15 Inventors Who Were Killed By Their Own Inventions

Marie Curie - Marie Curie, popularly known as Madame Curie, invented the process to isolate radium after co-discovering the radioactive elements radium and polonium. She died of aplastic anemia as a result of prolonged exposure to ionizing radiation emanating from her research materials. The dangers of radiation were not well understood at the time.

William Nelson - a General Electric employee, invented a new way to motorize bicycles. He then fell off his prototype bike during a test run and died.

William Bullock - he invented the web rotary printing press. Several years after its invention, his foot was crushed during the installation of the new machine in Philadelphia. The crushed foot developed gangrene and Bullock died during the amputation.

Horace Lawson Hunley - he was a marine engineer and was the inventor of the first war submarine. During a routine test, Hunley, along with a 7-member crew, sunk to death in a previously damaged submarine H. L. Hunley (named after Hunley’s death) on October 15, 1963.

Francis Edgar Stanley - Francis crashed into a woodpile while driving a Stanley Steamer. It was a steam engine-based car developed by Stanley Motor Carriage Company, founded by Francis E. Stanley and his twin Freelan O. Stanley.

Thomas Andrews - he was an Irish businessman and shipbuilder. As the naval architect in charge of the plans for the ocean liner RMS Titanic, he was travelling on board that vessel during her maiden voyage when the ship hit an iceberg on 14 April 1912. He perished along with more than 1,500 others. His body was never recovered.

Thomas Midgley Jr. - he was an American engineer and chemist who contracted polio at age 51, leaving him severely disabled. He devised an elaborate system of ropes and pulleys to help others lift him from the bed. He was accidentally entangled in the ropes of the device and died of strangulation at the age of 55.

Alexander Bogdanov - he was a Russian physician and philosopher who was one of the first people to experiment with blood transfusion. He died when he used the blood of malaria and TB victim on himself.

Michael Dacre - died after testing his flying taxi device designed to permit fast, affordable travel between regional cities.

Max Valier - invented liquid-fuelled rocket engines as a member of the 1920s German rocket society. On May 17, 1930, an alcohol-fuelled engine exploded on his test bench in Berlin that killed him instantly.

Mike Hughes - was killed when the parachute failed to deploy during a crash landing while piloting his homemade steam-powered rocket.

Harry K. Daghlian Jr. and Louis Slotin - The two physicists were running experiments on plutonium for The Manhattan Project, and both died due to lethal doses of radiation a year apart (1945 and 1946, respectively).

Karel Soucek - The professional stuntman developed a shock-absorbent barrel in which he would go over the Niagara Falls. He did so successfully, but when performing a similar stunt in the Astrodome, the barrel was released too early and Soucek plummeted 180 feet, hitting the rim of the water tank designed to cushion the blow.

Hammad al-Jawhari - he was a prominent scholar in early 11th century Iraq and he was also sort of an inventor, who was particularly obsessed with flight. He strapped on a pair of wooden wings with feathers stuck on them and tried to impress the local Imam. He jumped off from the roof of a mosque and consequently died.

Jean-Francoise Pilatre de Rozier - Rozier was a French teacher who taught chemistry and physics. He was also a pioneer of aviation, having made the first manned free balloon flight in 1783. He died when his balloon crashed near Wimereux in the Pas-de-Calais during an attempt to fly across the English Channel. Pilâtre de Rozier was the first known fatalities in an air crash when his Roziere balloon crashed on June 15, 1785.

15 notes

·

View notes

Text

Some additions regarding quilt making

Quilting cotton and batik won't fray/thread in the wash, unless it's very low quality

If you wash one fabric you'll be using for a project, you must wash all thr fabric for that project. Why? Because when you finish the quilt, it'll watp and the stitches may even tear.

If the edges you're cutting are looking gnarled, the blade is dull. Change your rotary blade and sharpen your scissors.

Get a scissor sharpener. They are very inexpensive. Mine cost $3, and I use if for all the scissors in the house. Rotary blade sharpeners, in my experience, make the blades duller.

Clean your sewing machine(s) between projects!!! This will prevent skipped stitches, threads won't get tangled, and the machine will work significantly better. Do not use one of those cans with pressurized air. Those will only shove lint and thread I to the gears. I use tiny fluffy tools and paintbrushes used for painting tiny things. There are vacuum cleaners made for this work as well. Doing this between every project is imperative for a healthy machine and fewer mistakes.

Use the correct thread. Threads come in a variety of thickness and material. Low quality makes a lot of lint, but it's ideal for a tight budget. High quality makes virtually no lint, but coats a small fortune.

Change your needles!!! They get very dull, and this results in things looking messy. Also, use the correct needles. Needles for denim/jeans are ideal for foundation paper piecing, btw.

Shorten or lengthen stitches as needed. Foundation paper pieces should be 1.4-1.6mm, whereas general pieces is 2mm. You want to be able to fit a seam ripper in there.

Get a quarter inch foot. They rarely come with sewing machines, so you'll likely need to purchase it separately. The seam allowance for quilts is a quarter inch. I've seen them as cheap as $1 and as expensive as $10. Get them cheap.

If you're interested in foundation paper piecing, get a transparent foot with a guiding line mark on it. I also recommend a half each seam allowance because it helps things lay flatter.

For the paper, cheap printing paper. It's strong enough to not fall apart while working, but weak enough to rear off without tearing stitches. You don't need special paper. Also, keep a master copy of all your patterns, and save the files on an external hard drive if you can. If something happens to your computer, you won't lose everything.

Use a plastic container to store used blades, dull or broken needles, and busted pins. You can contact someone about disposing these safely, like a company that handles the sharps boxes hospitals and diabetics put used needles/syringes in. I use an empty bubblegum container for the pins and needles and for blades it's the case they came in.

You don't have to use name brand blades, btw.

Rotary cutters with a bearing/ball bearing in them are your friend. The cutter moves much more easily and doesn't require as much effort to use. They're more expensive, yes, but if your hands are a wreck or your joints aren't so steady (I have hEDS), these things will be a life changer.

Things I wish I had read in "beginner" sewing tutorials/people had told me before I started getting into sewing

You have to hem *everything* eventually. Hemming isn't optional. (If you don't hem your cloth, it will start to fray. There are exceptions to this, like felt, but most cloth will.)

The type of cloth you choose for your project matters very much. Your clothing won't "fall right" if it's not the kind of stretchy/heavy/stiff as the one the tutorial assumes you will use.

Some types of cloth are very chill about fraying, some are very much not. Linen doesn't really give a fuck as long as you don't, like, throw it into the washing machine unhemmed (see below), whereas brocade yearns for entropy so, so much.

On that note: if you get new cloth: 1. hem its borders (or use a ripple stitch) 2. throw it in the washing machine on the setting that you plan to wash it going forward 3. iron it. You'll regret it, if you don't do it. If you don't hem, it'll thread. If you don't wash beforehand, the finished piece might warp in the first wash. If you don't iron it, it won't be nice and flat and all of your measuring and sewing will be off.

Sewing's first virtue is diligence, followed closely by patience. Measure three times before cutting. Check the symmetry every once in a while. If you can't concentrate anymore, stop. Yes, even if you're almost done.

The order in which you sew your garment's parts matters very much. Stick to the plan, but think ahead.

You'll probably be fine if you sew something on wrong - you can undo it with a seam ripper (get a seam ripper, they're cheap!)

You can use chalk to draw and write on the cloth.

Pick something made out of rectangles for your first project.

I recommend making something out of linen as a beginner project. It's nearly indestructible, barely threads and folds very neatly.

Collars are going to suck.

The sewing machine can't hurt you (probably). There is a guard for a reason and while the needle is very scary at first, if you do it right, your hands will be away from it at least 5 cm at any given time. Also the spoils of learning machine sewing are not to be underestimated. You will be SO fast.

I believe that's all - feel free to add unto it.

39K notes

·

View notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Text

Volumetric Pumps Market Size [2025] Industry Share, Growth, Scope, Revenue

Global “Volumetric Pumps Market” research report is a comprehensive analysis of the current status of the Volumetric Pumps industry worldwide. The report categorizes the global Volumetric Pumps market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Volumetric Pumps market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Volumetric Pumps Market?

By Company

Alaris

Baxter International

BD

BPL Medical Technologies

Cameron Sino

CHOSEN SUPPLIES

Codan

Core Lab

Feit

Hanna Instruments

Hteco

Italtecno Srl.

KMG

Mighty Max Battery

Mindray

Nuova Simonelli

PCM

SigmasTek

SPS

Vermont Flexi Pumps

Winequip

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Volumetric Pumps

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Volumetric Pumps Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Volumetric Pumps Market report answers the following questions:

What are the main drivers of the global Volumetric Pumps market? How big will the Volumetric Pumps market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Volumetric Pumps market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Volumetric Pumps market?

What are the market opportunities and threats to which players are exposed in the global Volumetric Pumps market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/volumetric-pumps-market-104442

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Antiperspirant and Deodorant Market

Microfilm and Microfiche Equipment & Supplies Market

Oil Quality Analyzer Market

Outdoors Advertising Market

Sleeping Pod Market

Tapping Machine Market

Diamantane Market

Laser Soldering Machine Market

Tablet Rotary Presses Market

Night Runners Running Lights Market

Other Reports Here:

Manicure Service Market

Photo Printing Kiosk Market

Computer Based Training Software Market

Luminous Keyboard Market

Long Nose Pliers Market

Photography Services Market

Frozen Spring Roll Market

Corporate Leadership Training Market

Reflow Oven Market

Commercial Aircraft Airframe Materials Market

0 notes

Video

youtube

rotary table insoles printing machine trademark label printing machine

0 notes