#Rotary Printing Machine Spares

Explore tagged Tumblr posts

Text

Nickel Rotary Screen & Nickel Screen Engraving Chemical Manufacturer, Supplier & Export in India

Welcome to Roopa Screen Private Limited. We are one of the most recognized and leading manufacturers, suppliers and exporters of various engraving products, rotary screen printing machine, nickel rotary screen, textile spares.

We are technically advanced and well equipped with manufacturing facilities, we are competent of fabricating and offering a wide range of engraving products, rotary screen printing machine, nickel rotary screen, textile spares and nickel screen engraving chemicals like photo emulsion for rotary screens. Our range of machines are known for their durability, efficiency, precision, technical superiority and are also easy to operate.

2 notes

·

View notes

Text

Choosing the Right Digital Inkjet Printing Machine Supplier for Your Needs

Choosing the Right Digital Inkjet Printing Machine Supplier for Your Needs

Digital inkjet printing machines have completely transformed the printing sector by providing fast and flexible prints of high quality. They can print intricate pictures on different substrates thereby used in a variety of applications ranging from commercial printing to personalized gifts.Get more news about Printing Machine,you can vist our website!

Understanding Your Printing Needs

You must know what you need in terms of printing before choosing a supplier for digital inkjet printers machines. Find out about the types of materials, quality, volume, and pricing. These details will help minimize your options so that you can choose the right provider who is capable of meeting your specific requirements.

Digital Inkjet Printing Machine Supplier: PSI

PSI is a well-known digital inkjet printer supplies company. We have a wide range of products that meet the specific needs of consumers for printing. Some of these include rotary inkjet printers as well as cylindrical inkjet printers, flatbed inkjet printers, and many other products that effectively fulfill their respective roles.

Cylindrical Inkjet Printers S1 and S2

When it comes to printing on cylindrical materials such as bottles, cups, and tubes, PSI’s S1 and S2 cylindrical inkjet printers are perfect. These printers are known for their accurate image positioning capabilities and they can work with different types of inks to give bright long lasting pictures.

T4 Rotary Inkjet Printer for Tubes

The T4 rotary inkjet printer is a good choice for anyone looking forward to printing on tubes or other similar items. It consistently provides high-quality prints while still being able to handle different tube sizes hence making it suitable for use in various industries.

SPR10 Rotary Digital Inkjet Machine

PSI’s SPR10 rotary digital inkjet machine is one of the best products out there that has been designed specifically for high volume cylindrical printing. With its advanced features, it promises fast and efficient printing which makes it ideal for businesses that want to increase production rates.

SP55 One Pass Flat Inkjet Printer

The SP55 one pass flat inkjet printer is highly regarded by many when it comes to flat surface printing. It can print at high speeds without compromising picture quality; hence, this machine is applicable across various printing functions.

F600/900 Visual Positioning Flatbed Inkjet Printer with Conveyor

For firms that need exact positioning and high-throughput, F600/900 visual positioning flatbed inkjet printer with conveyor is the best. It has a conveyor system that enhances the efficiency of printing through continuous printing.

What to Consider When Choosing a Supplier

When choosing a supplier for digital inkjet printing machines several factors should be considered:

Quality and Reliability of Product

Make sure you buy from a reputable company that sells machines that are durable and work efficiently. PSI is known for making powerful and efficient printers, so you can trust us.

After-sales Support

It may also be worth considering whether there is after-sales support, such as maintenance services, spare parts supply, and technical guidance. PSI ensures that we will not only buy products for our customers, but also take good care of them.

Compatibility with Your Business Needs

Depending on whether it is for small scale customization or large scale production, go for a supplier whose machines match your business operations.

Therefore, selecting a good supplier of digital inkjet printing machines is an important decision that could affect the performance of your printing business. PSI has many high-quality printers to choose from and is committed to customer satisfaction, which makes us a reliable partner for companies looking to increase their printing capabilities. To make the best decision and benefit from cutting-edge printer technology, consider your unique needs in conjunction with these points.

0 notes

Text

Laser Engraving, Marking And Etching: An Overview Of Associated Aspects

The word Laser is an abbreviation which marks the process that is carried out by using a highly focused beam of light that is created by the stimulated emission, which is amplified to the desired extent where in the beam thus generated will leave a mark on the surface of a material. When this highly focused beam gets in contact with the material’s surface, it changes the material’s physical property and appearance.

While this focused beam aims at a specific area, a precise, contrasted mark is formed. Laser marking process makes it ideal for material surfaces which require accuracy and permanency. With the advancement of science and technology, the recent technically progressive cutting-edge fiber laser technology has been on the trend, belonging to the solid-state lasers category, they have a shorter wavelength due to which a smaller focal diameter beam is created or formed the point of impact on the material surface. In this case the intensity is many folds greater than the carbon di oxide laser technology. Owing to the high power beam and a considerably smaller wavelength, they are almost maintenance-free providing a service life of about 25000 hours.

Another category of lasers, the crystal lasers, too have their place in the same class, as of the solid state laser systems. In this type the diodes generate crystal laser beams, essentials present in these diodes are usually carrier crystals of neodymium. Even in this case the wavelength is quite convenient to mark on metals and plastics as well. But the main difference in this crystal lasers are the deterioration of the diodes over a period of time, rendering it not 100% maintenance free but requires some maintenance of the system, mainly the replacement of diodes.

These crystal lasers are efficient on coated metals, with an extended performance on other metals too. As mentioned crystal lasers can be used to mark and engrave on plastics, ceramics and other delicate and fragile material surfaces also. The topic of laser engraving and marking goes never ending, likewise the applications of these systems also is quite wide ranged. Lasers and its applications are applied in almost all the products ranging from an automobile spare part to laser printing on packing materials like wrappers, boxes and other similar containers.

Automobile engines and other critical parts are laser etched or laser marked or laser engraved for their unique and authentic engine and chassis numbers. These markings are permanent and deep so that they cannot be tampered easily. Organizations like Signvec, in Singapore manufacture, service and supply laser marking machine of supreme quality and performance. Specifically specialised in laser rotary engraving machine, laser cutting and laser marking machines, the organization delivers products ranging from the high end to the affordable range.

In Order To Find Out More Details On Laser Engravers Please Be Touch With Us Today Onwards..!

#laser engraving machine#fiber laser marking machine#fiber laser marker#laser engravers#engraving machine#engraving machines#laser engraver#engraver#engravers#laser engraving machines

0 notes

Text

How much is a hydraulic copper busbar machine

The topic I want to share with you today is how much a hydraulic copper bar busbar machine costs. I hope that through the following explanation, you can learn more about this aspect!

Single or double busbars or busbar sections plus bypass: the power supply reliability is high, and the operation is flexible and convenient, but the investment has increased and the economy is slightly poor. Especially when the bypass circuit breaker is used for this circuit, the operation is complicated and increases Opportunities for misoperation. At the same time, due to the installation of bypass circuit breakers, the corresponding protection and automation systems are complicated. The above are the advantages of Shandong Dalin Machinery CNC busbar processing machine.

Many printed circuit boards have some settings of switches or shorting bars to match the actual needs, so when replacing the spare parts board of the busbar machine, be sure to record the original switch position and setting status, and prepare the new board The same setting, otherwise it will generate an alarm and cannot work. The replacement of some printed circuit boards requires some specific operations after the replacement to complete the establishment of software and parameters. This requires careful reading of the instructions for use of the corresponding circuit board. How much is a hydraulic copper row processing machine

On the other hand, it has a long service life. Compared with other types of bus machines, the ring bus machine has a long service life. It is not only wear-resistant and corrosion-resistant, but also has strong impact resistance and waterproof. For the most part, the service life of ring bus machines is very long.

The turret busbar processing machine is an auxiliary equipment designed to improve work efficiency and ensure operation safety. Its special structure makes the turret busbar processing machine more efficient than the traditional busbar processing machine, no matter the type of busbar or The speed and turret busbar processing machine are all higher than ordinary busbar processing machines. The reason of the equipment itself also leads to a broad market prospect.

The busbar machine is equipped with three processing units: punching, cutting and folding. Through the operation panel or foot switch, the punching, cutting and folding of the busbar can be performed separately or simultaneously. The production efficiency of this machine is High and easy to use.

The output of the pulse coder is generally two pairs of differential signals, A and A, B and B, which can be used for position and speed measurement. The four square waves of A and A, B and B are introduced into the PG card, and the direction is identified and multiplied by the magnification. After that, it becomes a measurement pulse representing the displacement, which is introduced into the PLC high-speed counting terminal for position control. The system of the bus processing machine adopts the relative counting method for position measurement. Before running, program the various signals, such as the position of the speed change point, The number of pulses corresponding to the position of the leveling point and the position of the braking stop point are respectively stored in the corresponding memory unit. During the operation of the elevator, the following signals are detected by the rotary encoder and the software calculates in real time: the position of the floor where the elevator is located, Speed point position, leveling point position.

Busbar processing requires good casting and machinability calculation capabilities. It has strong corrosion resistance. The busbar processing and production process is quite cautious, so in the manufacturing process, we must pay attention to what we should do? How much is a hydraulic copper row processing machine

The software used is the special auxiliary design software (GJ3D) developed by our company, which can be used on the Internet to realize programming automation. This software is the first to apply 3D graphics technology to the busbar processing industry, and the advanced nature of this technology is world-class. The software is easy and quick to operate, intuitively and three-dimensionally displays the processing shape of the busbar, can accurately calculate the exact position of punching, cutting and folding workpieces, automatically generates machine codes, reduces the time for manual coding, and eliminates the possibility of errors in manual coding. This software can demonstrate the whole process of punching, cutting and folding, and prevent material waste caused by manual code input errors.

0 notes

Link

We have been successfully manufacturing, exporting & supplying all types of above Textile Machinery Spare Parts, Stenter Machine, Jigger Machine, Cloth Guider, Folding Machine Spares, Rubber Rollers and Rubber Fillet, Textile machinery spare parts, Textile Machinery Spares, Bowl Mangle & Drying Range Spares, Rotary Printing Machine Spares and many more. We always have Spares of Textile Processing Machinery readily available from Stock. Spares Textile Processing Machinery.

#Textile Machinery Spare Parts#Textile Machinery Spares#Textile Machinery Parts#Textile Processing Machinery#Textile machine spare part#Rubber Rollers#olding Machine Spares#Textile machinery spare parts Manufacturer#Bowl Mangle & Drying Range Spares#Rotary Printing Machine Spares#Stenter Machine#Jigger Machine#Cloth Guider

1 note

·

View note

Text

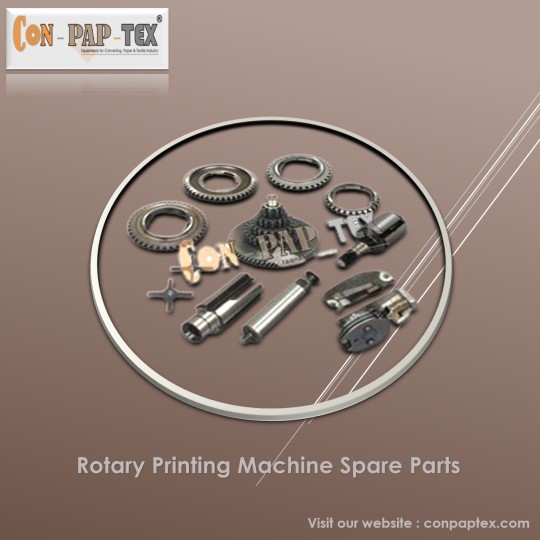

We are a leading manufacturer, exporter, and supplier of Spare Parts for Rotary Printing Machine international standards for the last 25 years from India. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS, etc. For more information:

Website: conpaptex.com

Email: [email protected]

Contact Us: +91-7940085305

2 notes

·

View notes

Link

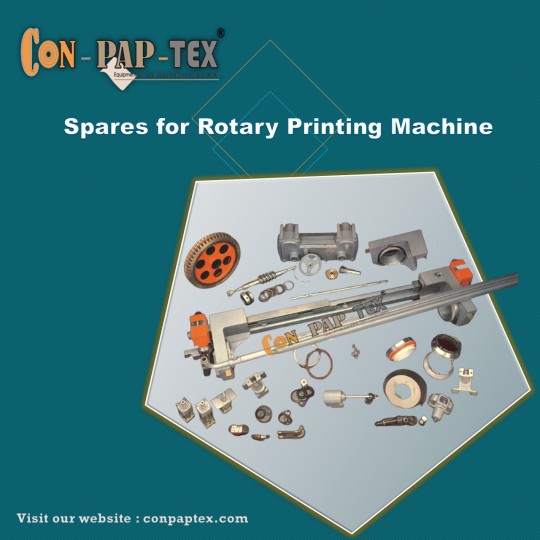

Con-Pap-Tex is a Company Promoted by Experts Technocrats having more than 25 Years of Experience in Rotary Printing Machine, and Rotary Printing Machine Part. Spare Parts for Rotary Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc.

#Spare Parts for Rotary Printing Machine#Rotary Printing Machine Part#Textile Machinery Parts#Rotary Printing Machine Spare Parts#Rotary Screen Printing Machine Parts

1 note

·

View note

Link

We are leading manufacturer, exporter and supplier of Spare parts for rotary printing machine international standard from last 25 years. Spares for Rotary Printing Machine, Rotary Printing Machine Parts are Hand Wheel, Screen Drive Gear Shaft, Washing Brush, textile machinery. For more information Visit Our Website: conpaptex.com

#Spare parts for rotary printing machine#rotary printing machine#rotary printing machine price#used rotary printing machine for sale#rotary textile printing machine#spares for rotary printing machine

0 notes

Link

Leading manufacturer of Stenter Machine Spare Parts like Chain Link, Bottom Parts, Stenter Machine Pin Bar, Stenter Clip, textile machinery in India. A Textile Machinery Spare Parts Manufacturer, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Mechanical Cloth Guiders, Folding Machine, Gear Sets, Nylon Gear Cuppling & Sleeve, Rubber Roller, Stenter Clip, Stenter Machine Pin Bar etc. Stenter Clips of Any Make like Artos, Dhall, Harish, Yamuna, Hi-Tech, S.M., Stenmech Lucy , Bharat Eng., Monfort, Montex, Swastik, Bruckner, Babros, Ambika, Famatex, etc. Chain Link & Bottom Parts (Pin Block, Loop Chain) of Any Make Stenter Machine. Pin Bars - Any make like Artos, Harish, Supra, Montex etc. Shaft (Main Drive, Driven Horizontal Shaft, etc.) Over Feed (Rubber Pulley Assembly, Drum Pulley Assembly, Post Pin Brush Assembly, Three Finger Uncurrler Assembly).

#Stenter Machine Spare Parts#Textile Machinery#Stenter Machine#Textile Machinery Spare Parts Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Mechanical Cloth Guiders#Folding Machine#Textile Machine Manufacturer#Textile Machine price#Textile Machinery Spare Parts#Textile Machinery Industry#Textile Machinery in India

0 notes

Link

Spares Textile Processing Machinery, Textile Machinery Spare Parts Manufacturer India, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine. Universal (Multi Repeat) Bridge Assembly Drive & Pump Side for 640,820,914. Single Repeat Bridge Assembly Drive & Pump Side for 640,820,914. Universal Screen Setting Assembly (RH / LH). Screen Setting Assembly (RH / LH). Screen Guide Bearing Bracket. Screen Guide Bearing & Pin. Stenter Machine Spare Parts like, Stenter Clips, Chain Link Bottom Parts, Pin Block, Loop Chain, Pin Bars, Gear Box Parts, Shaft, Over Feed and Chain Wheels. Cloth Guider Spare Parts, Bracket left & right, Base Plate Alluminium Left, Base Plate Alluminium Right, Tope Fiber Roller Laminated complete, and Fiber Roller Laminated only. Healed Frames and Healed Frame Accessories. Reeds, Heralds and Drop Pins. Spinning Weaving Machinery Spare Parts.

https://youtu.be/NqBr-6efPf8

#Stenter Machine#Textile Machinery Spare Parts#Textile Machinery#Textile Machine price#Textile Machine spare parts#Textile Machine Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Textile Machinery Spare Parts Manufacturer India#Spares Textile Processing Machinery#Spinning Weaving Machinery Spare Parts#Stenter Machine Spare Parts#Cloth Guider Spare Parts#Folding Machine Spare Parts

0 notes

Link

Textile Machinery Spare Parts Manufacturer like Stenter and Jigger Machine spare parts, Cloth Guider, Textile Rotary Printing Machine Spares form India. Over Feed for Stenter Machine. In the Textile Machinery, we manufacture, export & supply Stenter Machine, Chain Link Bottom Parts, Jigger Machine, Cloth Guider, Folding Machine, Rotary Printing Machine Parts, Bowl Mangle & Drying Range, Gear Set, Spinning & Weaving Machine, Rubber Rollers, and Rubber Fillet from India. We have been successfully manufacturing, exporting & supplying all types of above Textile machinery. We always have following Spares of Spinning & Weaving Machine readily available from Stock Heald Frames and Heald Frame Accessories, Reeds, Healds and Drop Pins, Temple Cylinder and Rings, Airjet. Rubber Roller, Wrinkle Removing Rolls, Banana Roller, Bow Roll, Metal Rolls, Metal Bow Expander Roll, Industrial Rollers, Hard Chrome Plated Rolls etc. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS.

#Textile Machinery Spares Manufacturer#Textile Spare parts#Textile Machinery Spare Parts#Spare Parts of Textile Machine#Stenter Machine#Over Feed for Stenter Machine#Textile Rotary Printing Machine#Spinning and Weaving Machine#Wrinkle Removing Rolls#Metal Bow Expander Roll#Industrial Rollers#Banana Roller#Textile Spare Parts Suppliers

0 notes

Link

Textile Machinery Spare Parts Manufacturer India, Rubber Roller, Rubber Fillet, Stenter Machine, Jigger Machine, Cloth Guider, Rotary Printing Machine Part. chain-link-bottom-parts, Jigger Machine, Cloth Guider, Folding Machine, Rotary Printing Machine Parts, Bowl Mangle & Drying Range, Gear Set, Spinning & Weaving Machine, Rubber Rolls, and Rubber Fillet from Ahmedabad, Gujarat, India. Continuous interaction with our customers & personal good relations with them is our work policy. All type of Bow Roll Manufacturer for Textile Processing Machinery. Textile Machinery Spare Parts, Textile Machinery Parts, Textile Machinery Part, Textile Machinery Spares, Textile Machinery.

#Textile Machinery Spare Parts#'#Textile Machinery Parts#Textile Machinery Part#Textile Machinery Spares#Textile Machinery#Rubber Roller#Chain Wheels#Pin Bars#Stenter Clips#Textile Machine#Textile Machinery price#Types Textile Machine#Machinery Spare Parts#Rubber Roll#Rubber Fillet#Bow roll#stenter machine#Jigger Machine#Cloth Guider#Rotary Printing Machine Part#Rotary Printing Machine Parts

1 note

·

View note

Text

How to choose dehumidifier heat pump air conditioner

Japan dehumidifier, dehumidifier, dehumidifier, dehumidifier, pipeline dehumidifier, industrial dehumidifier and temperature regulating dehumidifier series all adopt heat pump air conditioner, air to air heat pump supplier advanced high-efficiency rotary famous brand compressor, high gold plating heat exchange system, low noise and large air volume external rotor fan. Nikkei dehumidifier adopts the second generation motion control chip specially designed for dehumidifier by American IR company to realize sensorless vector control By running the control algorithm embedded in the chip, the control link of software programming is reduced, the performance of dehumidifier is stable and reliable, and the dehumidification effect of air dryer is in the leading level in the same industry. Japanese ultrasonic humidifier: using 2 million times per second of ultrasonic high-frequency vibration, water atomization into 1-5 micron ultrafine particles and negative oxygen ions, through the pneumatic device, the water mist diffuses into the air to increase the humidity of the surrounding air, so as to achieve the purpose of humidifying the air. Dehumidifier, industrial humidifier, constant temperature and humidity machine have passed the Sino German certification in February 2006, and have opened the integrity service. Dehumidifier, Shanghai dehumidifier, Hangzhou dehumidifier, dehumidifier, dehumidifier price, dehumidifier brand, humidifier price, humidifier brand, humidifier price, humidifier, Beijing humidifier, humidifier principle, Shanghai humidifier, ultrasonic humidifier won the title of 2008 Ali bid. The industrial air dehumidifier uses the principle of mechanical refrigeration and freeze-drying, sucks the moist air, drops it below the dew point temperature through the evaporator, condenses the water in the air into water droplets, and then condenses and heats up by the refrigeration compressor, and then turns into dry air to discharge, so as to achieve the purpose of drying airThis product can effectively remove the moisture in the air, thus reducing the relative humidity of the air, inhibiting the growth of mold, maintaining the humidity balance, and reducing the loss caused by moisture, corrosion and deterioration. The industrial air dehumidifier of Japan industry has an intelligent humidity constant control system, and the user can input the required humidity value into the microcomputer control system of the dehumidifier according to the production needs, Automatic control of dehumidifier work and shutdown, through automatic control to achieve the most effective dehumidification effect, reduce the operating cost of the whole machine. Technical authority, personalized product design, energy efficiency ratio higher than national standards. Careful follow-up service in the whole process of pre-sale and after-sale, To create air humidifier, dehumidifier, industrial dehumidifier, dehumidifier, dehumidifier, air dehumidifier, humidifier, constant temperature and humidity air conditioner and other air dehumidification equipment industry famous brands. Diurnal dehumidifier and humidifier are suitable for precision electronics, optical instruments, bioengineering, textile, medicine, packaging, food, printing industry, underground engineering and national defense, etc In our advanced laboratory, we strictly inspect all kinds of purchased raw materials to ensure that they meet the highest quality requirements of daily dehumidifiers and humidifiers. In the process of product development and production, we carry out strict tests on various spare parts and finished products to avoid possible weaknesses, and more time is spent on the operating conditions of products Due to the strict quality control system, the dehumidifier and humidifier can meet the requirements of ISO9001The highest requirement of international quality standards. The total quality management program creates the highest quality and best reputation of Nippon dehumidifier and mini split heat pump diurnal humidifier. Therefore, engineering authorities around the world (as well as some of our major customers) naturally recognize our model and recognize our production. Nippon dehumidifier and humidifier will continue to pay attention to the development of users, understand the real needs of users, and will continue to research and develop the latest and most cutting-edge technology, and adhere to the use of the most advanced and top-level materials to produce the most excellent and reliable products. To provide users with better solutions, until become a model in the industry. There is no factor that will change the quality of trump we offer to our customers.

1 note

·

View note

Link

We are Manufacturing, Exporting & Supplying Textile Machinery Spare Parts Manufacturer India, we make Stenter Machine, Chain Link Bottom Parts, Jigger Machine, Cloth Guider, Folding Machine Parts. In the Textile Machinery, we manufacture, export & supply Stenter Machine, Chain Link Bottom Parts, Jigger Machine, Cloth Guider, Folding Machine, Rotary Printing Machine Parts, Bowl Mangle & Drying Range, Gear Set, Spinning & Weaving Machine, Rubber Rolls, and Rubber Fillet. We are manufacturer of Air Shaft, Safety Chuck and Textile Machinery Spare Parts.

#Textile Machinery Spare Parts#Stenter Machine#Textile Machinery Parts#Spares Textile Processing Machinery#Machinery Spare Parts#Textile Machinery Spare Parts Manufacturer#Chain Link Bottom Parts#Cloth Guider

2 notes

·

View notes

Text

Doall 16 Lathe Manual

The Parts Manual naming convention is Model underscore first three digits of the Serial Number, i.e. You will return more results by using less in your search criteria. You may search by using “305” or the first part of the serial number “517”. Clausing-6900-Series-Lathes-Manualjp2.zip (View Contents) 27-Mar-2018 15:46. 14 1-2, 16, 16-24 CE3458 Parts Manual.pdf: 21-Mar-2018 14:08: 3.9M: Southbend 10, 13.

Do-ALL 17-inch Lathe. Late Model Machine (made by Harrison in the UK) Late-model with a very 'square-edged headstock', large sheet-aluminium covers embossed with 'speeds and feeds' and a screwcutting operated only by rotary lever controls (no sliding lever). Operator's Instruction Manual and Spare Parts Manual as detailed Sectional Drawings.

DoAll '16 ½” (Actually a Harrison M450/500) Operation and Maintenance Manual with Parts as Exploded component Drawings.

Do-ALL 17-inch lathe (by Harrison in the UK) : Early model with three downward-pointing spindle-speed controls levers. Operator's Instruction Manual and Spare Parts Manual as detailed Sectional Drawings. Includes a copy of the DoALL Technical Sales and Specification and Accessories Catalogue. £35

Print code: MD398B

DoAll ZW-3620 'Zephyr' BandSaw. Instruction Manual

Print code: MD398C

DoAll DZ-36 Saw. Instruction Manual and Parts as Sectional Drawings and Illustrations.

Print code: MD398D

DoAll 26-3 BandSaw: Operator's Instruction Manual and Parts Manual as Sectional Drawings.

Print code: MD398E

DoAll 1612-0 and 3613-0 BandSaw Models. Operator's Instruction and Maintenance Manual.

Print code: MD398F/US

DoAll 2612-0M BandSaw: Detailed 60 Page Operator's Instruction and Maintenance Manual.

Print code: MD398G/US

DoAll 2612-1M BandSaw: Detailed 60 Page Operator's Instruction and Maintenance Manual.

Print code: MD398H/US

DoAll 2613-20 BandSaw: Detailed 160 Page Operator's Instruction and Maintenance Manual.

Print code: MD398J-US

Who Made The Doall Lathes

DoAll BandSaw 2614-1: Detailed 150 Page Operator's Instruction and Maintenance Manual.

Print code: MD398K-US

DoAll BandSaw 3613-20 : Detailed 150 Page Operator's Instruction and Maintenance Manual.

Print code: MD398L

DoAll BandSaws V16, V26, V36 and ML . Operator's Instruction, Maintenance and Parts as Sectional drawings.

DoAll HC-35A and HC-35 Automatic and Manual Power Saws. Operator's Instruction, Maintenance and Lubrication Manual.

MD398MP Do-All HC-35A and HC-35 Automatic and Manual Power Saws. Parts Manual

Print code: MD398N

DoAll 26-3-60-3 Countourmatic Saw. Operator's Instruction Manual.

Doall 13 Lathe Parts List

Print code: MD398P

DoAll Servo-controlled Contour Sawing Attachment. Set-up and Operation Instructions.

Print code: MD398Q

DoAll Model 56250 Bandsaw. Parts Manual as Sectional Drawings.

Print code: MD398R

DoAll DBW-15 Butt Welder. Instruction and Illustrated Parts Manual.

Print code: MD398S

DoAll Lathe. Late-model Machine (made by Harrison in the UK) with a 'square-edged headstock', large sheet-aluminium covers embossed with 'speeds and feeds' and screwcutting operated by rotary lever controls (no sliding lever). Operator's Instruction Manual and Spare Parts Manual as detailed Sectional Drawings. Includes a copy of the DoAll Technical Sales, Specification and Accessories Catalogue.

Doall Lt13 Lathe Owners Manual

Print code: MD398SC

DoAll Model 8 Tool and Cutter Grinder (a re-badged Boxford G200). Instruction Manual and Parts Manual as Sectional Drawings.

Doall 17 Tailstock

Additional information

Swing over bedways

16'

Swing over cross slide

10'

Swing in gap

24'

Length of gap

13-1/2'

Distance between centers

60'

Spindle speeds (18)

40 – 2000 RPM

Spindle bore diameter

2-5/8'

Inch feeds

0.0016 to 0.028

Metric feeds

0.04 to 0.71

Inch threads (38)

Feb-72

Metric threads (35)

0.2 – 14

Cross slide travel

10'

Compound travel

3-13/16'

Bed width

14-3/16'

Bed length

83'

Leadscrew pitch

4 TPI

Leadscrew diameter

1-1/4'

Tailstock travel

5-1/2'

Motor

10 HP

Voltage

220 / 440

Phase

3

Cycles

60

Amps

27 / 13.5

Approxiimate dimensions

106' x 48' x 50-1/2' high

Approximate weight

4,000 lbs. Download vsdx file.

0 notes

Link

We “CON-PAP-TEX” are leading manufacturer, exporter and supplier of Rotary Spares, Spare Parts for Rotary Screen Printing Machine. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc. Also, we are leading manufacturer of Rubber Roller, Slitter Rewinding Machine, Web Guiding System and more.

0 notes