#Rotary Production System

Explore tagged Tumblr posts

Text

CNC Rotary Table: A Game-Changer for CNC VMC Machine Productivity

In the world of precision machining, the CNC Rotary Table stands out as a revolutionary upgrade for vertical machining centers (VMCs). Whether you're a job shop, OEM, or toolroom manager, integrating a rotary table into your setup can dramatically enhance productivity, accuracy, and flexibility. At Kuvam Technologies, we specialize in offering a comprehensive range of rotary solutions that meet the diverse needs of modern industries. This blog will guide you through everything you need to know about rotary tables for CNC machines, their types, advantages, and how they drive performance and profitability.

#Rotary Table#CNC Rotary Table#Rotary Production System#CNC 4th Axis Rotary Table#CNC Rotary Table Manufacturer

0 notes

Text

Rotary Production System are manufactured by Kuvam Technologies

On a VMC, HMC jobs can be completed for a fair machine hour cost.

Actually, the modular concept design of the rotary production system includes a drop-in rotary union for the power clamp.

For the machine shop working in high volume or bulk production, it offers an all-encompassing approach.

In a single setup, the Rotary Production System can machine three or all four sides of the component.

resulting in increased productivity.

comparable to an integrated system Faceplate, tailstock, base plate, brackets for installing the fixture, and fixture plate are included.

We offer you with best benefits including quick setup changes, adaptability, increased clamping torque because of breaks on the Rotary table and Faceplate tailstock sides for application.

We are specialists in CNC Rotary Tables, CNC Spindles, and Angle Head for VMC are our areas of expertise. We have installed 2155+ items, helped 595+ clients, prevented a loss of 25.5+ crore, and generated 255+ crore in revenue across 140 cities and 25 states.

Our Company Details:

Kuvam Technologies Pvt. Ltd.

Plant Add. - Block G-293, Sector - 63, Noida - 201301, U.P., India

Office: +91 120 457 1546

All India: +91 9311779331, 8448996970, 9319293895, 9319293896, 9311779331

Email id: [email protected]

Website: www.kuvamtechnologies.com

Facebook - https://www.facebook.com/kuvamtechnologiespvtltd/

Twitter - https://twitter.com/kuvamTechnology

Linkedin - https://www.linkedin.com/company/kuvam-technologies-pvt-ltd/

Instagram - https://www.instagram.com/kuvam_technologies

Youtube - https://www.youtube.com/channel/UC0bOksHQlNTJsg-FUFMiIIw

1 note

·

View note

Text

youtube

Egg Tray Making Machine | Paper Egg tray Making Machine

Laxmi Enterprises is the leading manufacturer, retailer,importer, macking machine, Egg tray machine, Paper plats machine etc.

#International Traders Channel | Fully Automatic Egg Tray Machine | Metal Multilayer Dryer | egg tray machine for sale | egg tray production#egg tray packing machine#egg tray manufacture#egg tray manufactures#Paper Pulp egg tray manufactures#ITC#International_Traders_Channel#laxmi_enterprises#Fully Automatic#Laxmi Enterprises#Manufacturer#Fully Automatic Egg Tray Machine Metal Multilayer Dryer#Eggs Trays Brick Dryer System#Semi Automatic Egg Tray Machine (Without Dryer)#Paper Pulp Egg Tray Making Machine#Rotary Egg Tray Making Machine#Egg Tray Forming Machine#Egg Tray machine with Brick Dryer#Automatic Egg Tray Plant Video how to make#egg tray making machine price in india#egg tray making machine for sale#egg tray making machine price in south africa#egg tray making machine south africa#egg tray making machine price in kolkata#egg tray making machine companies#egg carton making machine#paper egg tray making machine#small egg tray making machine#manual egg tray making machine#egg carton manufacturing machine

0 notes

Note

What's an automotive technology that you wish had made it that didn't?

NSU Trapeze, 1973, by Bertone. In the late 60s and early 70s it seemed likely the rotary engine, invented by Felix Wankel, was going to take over the auto industry. The advantages of compact design, smoothness, low weight, and fewer parts over piston internal combustion engines gave rotary power a bright future. NSU was the first car company to develop the Wankel motor into series production but from the late 60s all major automobile makers were working on rotary power, perhaps most famously General Motors and of course Mazda. Alas as is often the case physics got in the way, despite its remarkable power the Wankel system has lower thermal efficiency and higher emissions relative to a piston engine. So from the early 70s one by one everyone abandoned their rotary programs apart from the Volkswagen AG (by now owners of NSU), Citroën and Mazda. Not only was Bertone's Trapeze rotary-powered but it also presents another configuration concept that seemed to have potential in the 70s and early 80s. Mid-engined 4/5 seat cars. A number of concepts were presented with 2 and 4 doors that could seat multiple passengers with engines placed behind the rear seats (in the Trapeze it was in the middle of them). However no-one ever got around to putting a mid-engine 4-door saloon into production and the industry moved onto almost universal adoption of front transverse engines and front wheel drive.

Fun fact about Felix Wankel (1902-1988) inventor of the rotary engine, he was extremely nearsighted and never held a driver’s licence but had the same chauffeur for most of his life

rotary gif by Y_tambe

#NSU#NSU Trapeze#Bertone#Bertone Trapeze#concept#mid-engine#rotary engine#Wankel engine#twin rotor#dead brands#4-seater#question#answer

194 notes

·

View notes

Text

Here they are, the Davion Cav lance. This is an insanely weird box with mechs from a big mishmash of sources and eras, but it does have extremely strong Davion pedigree.

First up we have everyone's favorite barista guerilla-piloted shithead medium, the Legionaire. The LGN is a chassis with a very strong identity- it virtually always goes at some variation of 7/11 with reasonable armor and a single centerpiece fuckoff gun, generally a rotary autocannon. As a RAC mech it's pretty ok- it can stick that gun where it wants to with a concerning degree of accuracy and because it just has the one gun in the event of a jam it can peel off from a fight to go spin the round out without much FOMO on anything else. The mini does a good job of conveying thar this is a mech built around its primsry weapon system and I like the freakishly long monky arms, though the cockpit detailing is a bit doughy. The alternative barrel is a nice touch, allowing you to swap between the common RAC or I presume the large energy weapon seen on variants like the PPC-bearing 2K or the recent april fools RISC hyperlaser version. Shame we didn't get an Arrow-IV attachment

Next up we have our Mechwarrior machine, the Hellspawn. Affectionately, this thing is a piece of shit. Built to replace the Dervish, the HSN is another chassis with a strong identity- all Hellspawns have a ground speed of 6/9 with some number of jump jets between 5 and 8, most carry a payload of missiles and lasers to engage at a variety of ranges, and most carry some number of advanced electronics. Unfortunately due to the machinations of some Lyran spy at the production facility, it took until about the Jihad for GM to make a version of this thing that wasn't a germanium plated suicide booth with paper armor and a lot of unCASEed boom ready attempt to set an air speed record for fastest mechwarrior to reach the big mechbay in the sky.

Growsing about early teething troubles aside, I fucking *love* the way the Hellspawn looks. @laguzmage has brought up the idea of the 'Contraption' mech before and this thing is an alltime hall of fame doohickey. Asymmetrical, unbalanced, blocky, somehow simultaneously tall and short, it's the beautiful sort of ugly that only industrial equipment can be. There are a mid-double digit number of mechtechs and pilots who decided this thing was their wife in 3063 and spent a decade aggressively convincing GM to make a version that loved them as much as they loved it and they were right to do so.

At the exact opposite end of the industrial design spectrum, we have this Fast and Furious bastard. The Gunsmith is what happens when you put a limit on the size of a great power's army and they decide to compress an entire new chassis family's worth of R&D into exactly one fast idiot. The CH11-NG (there is only one model for this thing) moves as fast as a Dasher, is armed with more pulse lasers than a Wraith, and has enough reflective armor to approximate a Hunchback's belt when faced with the natural enemy of the Extremely Fast Dipshit, the pulse laser. As a light hunter and flanker it's murder par excellence, mostly kept in check by the completely unshielded engine that means a) it builds heat like a motherfucker and b) is mostly only allowed in games where you are committing crimes already because moving from standard tech to xtech is roughly the equivalent of getting drafted from your college basketball team into the fucking wizard wars.

Oh and did I mention the thing is unbearably cool? As a carryover from the good-ish years before grey monday, the Gunsmith is a thoroughly futuristic looking design with its sleak cockpit, downforce-inducing head, and angular limbs. It looks totally out of place next to the Mechwarrior IV brick mechs and the various mid-31st century TROs' chunky militarism. It looks like it managed to escape from an anime about racing mecha by breaking the light barrier with the help of a poorly understood particle. I have no clue how I'm gonna paint this thing

Oh, and the Enforcer is here too, I guess. As far as I can tell this is the same Enforcer we've seen in the Hansen's/Urban Lance boxes, albeit with a new pose and updated molding to match Liya's newer standards. Its... fine? All of the existing enforcers are basically visually identical because the interesting revisions to the design were all shunted off into its derivatives, namely the Enforcer III. We could've gotten a different head sculpt maybe idk.

#battletech#hobby#miniatures#battlemech#mechwarrior#medium mech#light mech#hellspawn#legionaire#gunsmith#enforcer#mech talk

43 notes

·

View notes

Text

I feel like no one is asking the important question ever since the pre-8x05 interview with Oliver came out...

Robinson R22

It's small, it's lightweight, it's fast, it's agile, the 2-seat Robinson R22 is the Cessna 152 of the rotary world, meaning it's by far the most popular model for basic pilot training.

Everything from its 2-bladed semi-rigid teetering rotor system, to its T-bar cyclic design keeps the production and maintenance costs of the R22 to a relatively affordable level, hence allowing more aspiring pilots to achieve their dream without breaking the bank. Due to its popularity, employment opportunities are also easier to come by. Once you've successfully gotten your flight instructor license, you can basically accumulate flight hours while earning money by instructing other students.

Please don't be mistaken, the R22 is popular among student pilots solely for its cost effectiveness. It's in no way an easy helicopter to fly. Because it's so light, the controls are extremely sensitive, some may even say twichy. The first 10 or so hours in the R22 can be quite a frustrating experience. Instead of you flying the chopper, it'll feel like it's flying you, that it has a mind of its own. Even the most experienced former military pilots who spent their entire career flying attack helicopters may feel like they're writing cursive in the sky for their first couple of hours in the R22 before slowly getting used to it. But if you manage to tame this beast, you can basically learn to fly anything.

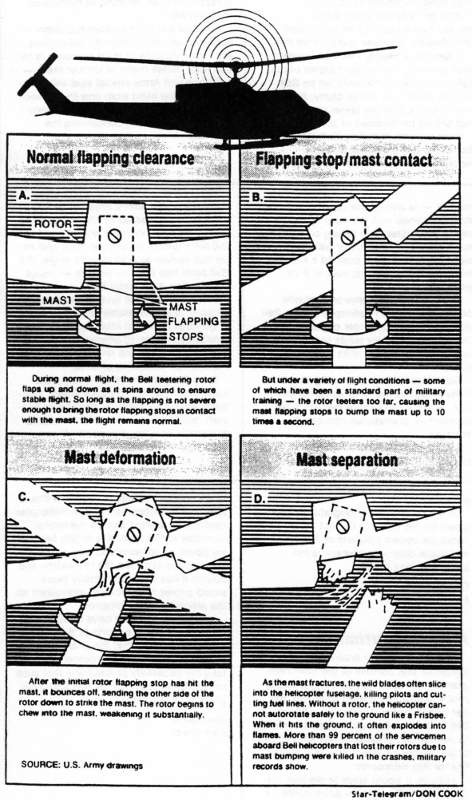

The Robinson rotor system design also makes it very susceptible to mast bumping. (Yes, even more so than other similar teetering rotor designs) While it can be prevented by adequate pilot training (to avoid instinctively overcontrolling the aircraft), once it happens and the rotor separates from the mast, it's basically always a death sentence.

But the most important factor that may disqualify the R22 as BuckTommy's training helicopter of choice, is its lack of cabin space and low weight limit. It has a maximum cabin width of 3.7 feet, which is cramped even for normal sized people, let alone our 2 human tanks. Not only will they be pressed flush against each other (kinda hot ngl), their shoulders will be squeezed tight by the doors, which makes the overall flying experience very uncomfortable, even a bit limiting. The maximum weight the R22 can carry, including fuel, luggage and occupants, is 490 lbs. If you want to have enough fuel to last for more than 30 minutes, that leaves you only 400 lbs to spare. I strongly suspect the combine weight of these beefcakes exceeds that number.

Robinson R44

The Robinson R44 is basically the bigger, 4 seat version of an R22. It has all the advantages of the R22 in terms of performance, cost effectiveness and abundance of employment opportunities (It's the most produced piston engine helicopter), with the added bonus of a more spacious cabin, a higher weight limit (it's designed for 4 occupants after all) and less sensitive controls as it's quite a bit heavier.

It still has the same heightened risk of mast bumping, and it's more expensive to rent and operate than the R22 (seeing that it's double the size).

A unique advantage of starting your pilot training in the R44 is that once you get your PPL (private pilot license), you've already had enough experience in a 4 seater and you can immediately take your friends and family to the sky with you, no transition or additional training needed. I think Buck will appreciate that.

Schweizer S300

Unlike the Robinsons, the Schweizer S300 was designed especially for training purposes, so it's much more forgiving to fly for student pilots.

It has a 3-bladed fully articulated high inertia rotor system, making it very stable in flight and eliminating the issue of mast bumping. Its conventional but clean cockpit design also makes the learning experience more straightforward. The cabin can be configured into a 2 pilot training setup, or a 1 pilot+2 passengers one, so naturally, the cabin is quite spacious as well.

It has a traditional cyclic in the middle for controls, instead of the T-bar in Robbies.

One possible downside of the S300 is the lack of an RPM governor, meaning pilots have to manually adjust the throttle to maintain rotor speed when maneuvering the helicopter. It adds a bit of workload, but it's not hard getting used to.

The major problem with this aircraft is the giant flat windshield in the front creating enormous amount of drag. It may be suitable for training, but absolutely not for any medium to long distance leisure flying. Its range is quite short, and if you run into strong headwind, it can be veeeerrrryyyyy slooooooooowwwwwww.

Guimbal Cabri G2

Watch out, she's the new hot chick kid on the block. She's young, she's smooth, she's cool and she's from France. (Cue gone girl cool girl speech) First introduced in 2008, this bird was designed to be the ultimate training helicopter, combining the sleek aerodynamic fuselage and lightweight 2 seat configuration of the R22, but with extra space for comfort, and the stability and controllability of the Schweizer S300, without the added drag. It's fast, agile, but at the same time safe and comfortable.

Designed by a former Eurocopter engineer, the Cabri G2 has many modern systems in place to ensure the safety of the inexperienced student pilot.

It has a glass cockpit with fully integrated flight computer system. Unlike flying the Robbies, where you only have a analog fuel gauge, the Cabri G2's system constantly calculates and shows you the estimated time you have left in the air with your current amount fuel.

It has a 3-bladed articulated main rotor just like the Schweizer, so mast bumping is not an issue either, but it also has the added protection of a shrouded tail rotor called a Fenestron, which is a trademark of Eurocopter (known as Airbus Helicopter now).

Instead of being exposed to the element like traditional tail rotors, the Fenestron type is housed in a sort of window in the tail to protect it from striking foreign object in flight, thus greatly enhancing its safety.

Like all aircrafts designed in the 21st century, it's largely made out of light composite material, so it can be spacious and sophisticated without compromising on weight.

The Cabri G2 was designed to be very crash resistant. According to the manufacturer, the seats can withstand shocks from a crash with as high as a 2000 fpm descent rate. Its fuel tank is also incorporated with resistant technology to prevent a fuel fire post crash.

With the Cabri G2, learning to fly a helicopter has never been safer, comfier and cooler.

I can't hide my bias to this hot chick beautiful bird, she's just that good, but she's also very hard to find and super expensive to rent. Over 6866 Robinson R44 were ever built, but the new girl Cabri G2? Just around 300. It's very expensive to rent, the hourly rate comparable to a 4 seat R44, simply due to its rarity. But Tommy works in the industry? I'm sure he can pull some strings for his boyfriend if the G2 is what he wants.

Turbine helicopters

The previous 4 models are all powered by piston engines. They're cheaper, easier to maintain, but not powerful enough for bigger utility helicopters operated by the military or authorities. If your goal is to work for those institutions, you'll eventually have to gain experience in a helicopter with turbine engines.

So why not start in a turbine helicopter, you asked? Well, they're super expensive to rent. The hourly rates for the above 4 models are all in the hundreds, but for a turbine one, like the AS350 (the one Tommy flew to the cruise ship and to Vegas with Eddie), it's in the thousands.

Although we're talking about Tommy "knows a guy" Kinard, who magicked a whole AS350 news helicopter for his personal trip to a fight in Vegas, and Evan "trust fund baby" Buckley here. I guess they can somehow get a giant turbine one without any problem like us commoners. They're easier and more fun to fly anyways. (Faster but more stable.)

#bucktommy#tommy kinard#evan buckley#911 meta#aviation realism#911 abc#tevan#kinley#I was inspired by the “which car Tommy drives” post months earlier#I'm trying to reclaim my joy for BuckTommy related aviation topics one step at a time#It's all just for fun

31 notes

·

View notes

Text

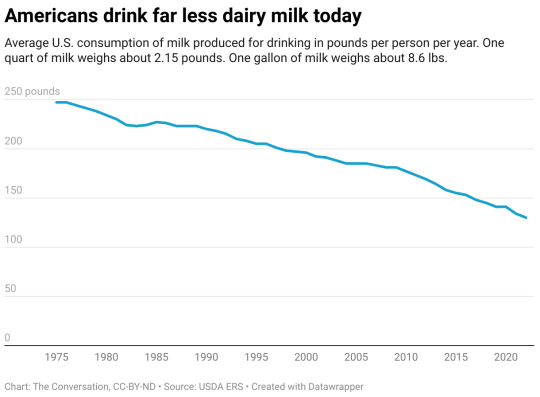

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

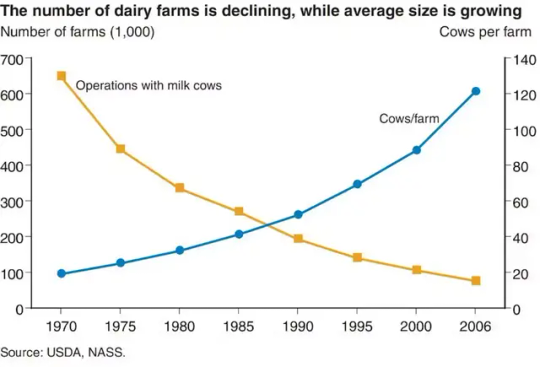

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

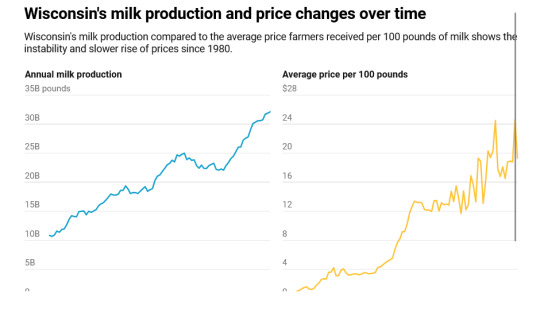

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

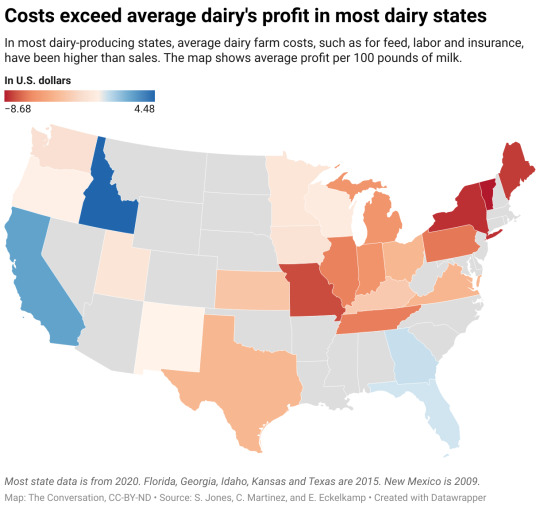

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

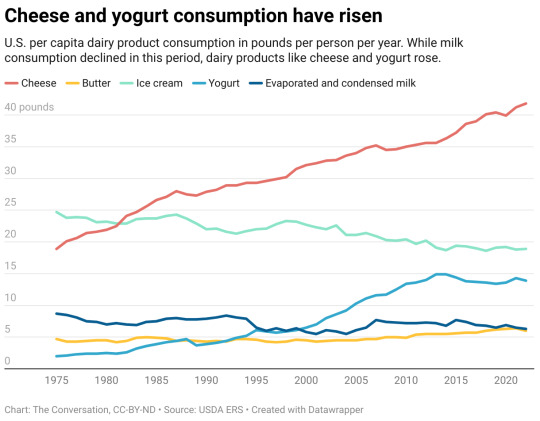

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Text

AKAI - SB1 - Deep Impact

"... for a lengthy spell, bassists that used pedals were given a side-eye.

But as synth pedals continue to be made, it’s hard to believe that some of its earliest heavy-hitters were released in the ‘80s and ‘90s, such as the Korg X-911 and the DigiTech XP300 Space Station. But while those faffed about with a more general kitchen-sink approach to the subject, it was Akai in 200X that came out with the most potent offering to date. This is the Akai SB1 Deep Impact.

Although some places claim the Deep Impact came out in the late ‘90s, nobody that I know is entirely sure when the Deep Impact was released. As far as I can tell, it was 2002. Prior to that, Akai’s “professional” website came out with guns blazing about its silver boxed series that included the VariWah and Intelliphase. However, a short time later, Akai Pro’s website appeared to go dark, resurfacing with pictures of gleaming mixers and MPCs. It’s too bad; the Head Rush, Unibass and Deep Impact were arguably the best pedals Akai ever produced.

When a pedal’s endorsee list contains players like Bootsy Collins, Chris Wolstenholme and Paul Turner of Jamiroquai, you pretty much know what to expect: throbbing, guttural filter sweeps with a funk chaser. And yeah, you get that. But you get a pretty bang-on stab at a host of synth patches, including fifths, warbling pads and much more. It’s not without its limitations, though.

The Unibass and Deep Impact were centered on the frequency range of the bass guitar; the Unibass generated a fat unison mode with an octave up and subtle thickening, which is easily adaptable to six strings. However, the Deep Impact in particular made no bones about its applications. When played with a guitar, notes outside of the bass frequency range cut through at a very distinct threshold, and not in a “hardware limitation” kind of way; there is a literal cut-off point. One note in a scale gets enveloped in the circuit, and the very next rings through as if there was no effect at all.

The way it’s used is deceptively complex. Like the old analog synths it seeks to replicate, dialing in a patch takes a little effort, and in the same way as many of them. Two of the unit’s three knobs are for input and output levels—the Input control is accented with a metering system and lets you set the clipping threshold of the unit before setting the output volume. While two-thirds of the knobs are standard fare, the money is in the program system.

On offer are nine programs with a blank parametric slate. The left footswitch cycles through these programs in ascending order, while an optional footswitch cycles in descending order, and the center control cycles through 10 different parameters (and one preset loading option), all of which are fully adjustable with the rotary encoder in the center of the unit. Most of them correspond to controls on real analog synths, such as (filter) Cutoff, Resonance, Attack and Decay. When you factor in this multi knob, the Deep Impact actually has 12 controls for your tweaking pleasure, far more than the competition. And the ends to which you can adjust the tone are relatively absurd.

While vintage synths of yore can oscillate and destroy your ears when the resonance is cranked, Akai thoughtfully keeps the extent of the parameters usable. With that being said, the Deep Impact will mercilessly punish any subwoofer placed before it. Akai promises a four-oscillator affair within the Deep Impact and while there’s no way to dial it in solely based on those merits, it certainly sounds gargantuan. It’s probably why they are worth so much.

The original designer of the Deep Impact, one Andras Szalay, revived the project well after Akai washed its hand of the line under the company name PandaMIDI and the product name Future Impact I. For a spell, it was tough even to get one of those, and prices encroached upon the original. Now on its third revision, readily available and with a new brand name, the Future Impact continues to carry the torch. There’s just something about that Akai unit, though..."

cred: catalinbread.com/blogs/kulas-cabinet/akai-db1-deep-impact

28 notes

·

View notes

Text

Launched a century ago, the Bugatti Type 35 didn’t just make a single impact—it revolutionized the racing world with its innovative design and engineering. The car became legendary not only for its initial capabilities when it debuted in 1924 but also for the continuous improvements Bugatti implemented throughout its production. Ettore Bugatti was one of the first automobile manufacturers to grasp the marketing potential of winning races on Europe’s renowned circuits and road tracks, which brought considerable publicity to his brand. Confident as he was in the capabilities of his new car, even Bugatti could not have predicted that the Type 35 would become the most successful race car in history, achieving 2,500 victories during its active racing career.

The first Type 35, released in 1924, was equipped with a 1,991cc eight-cylinder engine, delivering 90 PS in race trim. By early 1926, Bugatti had increased the engine size to 2,262cc for the Type 35T, named after the famous Targa Florio road race in Italy, which it won, with two smaller-engined Type 35s finishing close behind. Despite this success, Ettore Bugatti realized that to stay ahead of the competition, he needed more than just increased engine displacement. He knew that the future of performance lay in forced induction, even though he was initially not a fan of superchargers, which were seen as inefficient at the time.

“It’s no secret Ettore Bugatti preferred naturally aspirated engines and was not an early enthusiast of supercharging due to its perceived inefficiency,” says Luigi Galli, Specialist for Heritage and Certification at Bugatti. “However, what’s less well known is that Bugatti was forward-thinking about the potential of forced induction, experimenting with superchargers even before the Type 35 debuted at its first race in Lyon in August 1924. In fact, Bugatti applied for French patent number 576.182 on January 22, 1924, for a ‘Compresseur ou pompe à palettes,’ a rotary vane supercharger design that could provide extra power on demand by forcing pressurized air into the carburetor. If Bugatti was going to use a supercharger, he was determined to innovate in his own way.”

As a result, Ettore Bugatti, alongside the Italian engineer Edmond Moglia, developed a unique three-rotor Roots-type supercharger, differing from the common two-rotor designs of the time. This supercharger was strategically mounted on the engine’s offside, which allowed it to warm up more quickly and improve overall engine cooling—a principle that remains relevant in modern engine design. The Type 35TC, where “TC” stands for Targa Compressor, was introduced in late 1926. It evolved into the Type 35B in 1927, featuring a larger radiator and cowling, known as the ‘Miramas’ design, which enhanced cooling capabilities. This configuration enabled the Type 35B to produce up to 130 PS, achieving speeds over 205 km/h (150 mph).

By late 1930, further refinements led to what many consider the ultimate version of the Type 35B. This final iteration featured a twin-cam, two-valve-per-cylinder engine, a twin fuel filler cap, improved suspension, wheels, brakes, and tires, as well as a lower-mounted supercharger relief valve. Bugatti’s relentless pursuit of perfection extended to optimizing every element of the combustion system, from sculpted pistons and cylinder heads to the use of aviation-grade fuel, which boosted the output to 140 PS.

Today, at Bugatti’s atelier in Molsheim, each Bugatti model is hand-assembled with the same meticulous attention to detail that Ettore Bugatti applied to the Type 35. A century later, Bugatti’s engineers and designers continue to push the boundaries of automotive excellence, upholding a legacy of innovation and performance that began with the groundbreaking Type 35.

13 notes

·

View notes

Photo

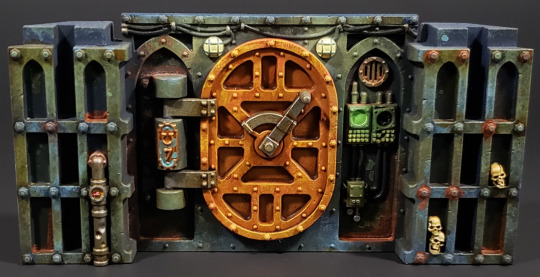

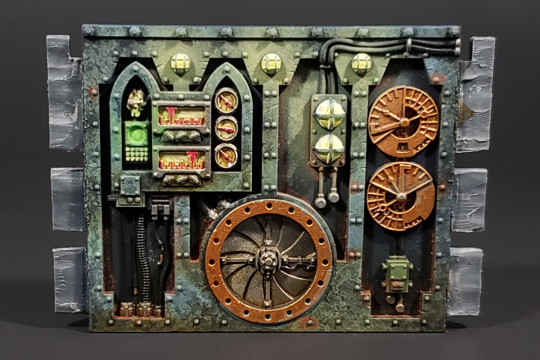

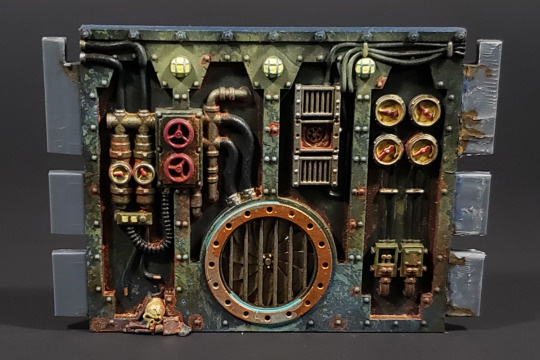

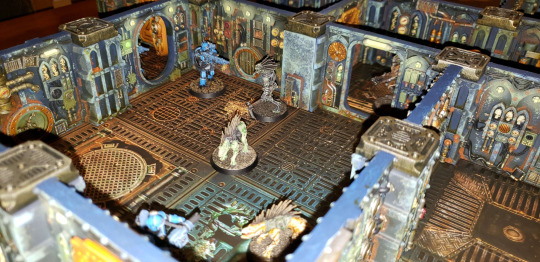

Killzone Gallowdark! It’s finally (almost) done!

Gallowdark terrain is assembled differently for each mission, using a system of slots and pegs. By default, the fitting is a bit tight in places, so I took a rotary tool and sanded off about a third of the width from each. The fitting is much looser now, maybe too loose, but with the connector caps keeping everything snug and the terrain not exactly moving once it's set up for play, I don't think it's an issue.

Despite how the finished product looks, the painting process for everything was pretty simple. Everything was primed with a dark blue primer, then I sponged two layers of heavily thinned light blue all over. This created a very random pattern of dots and larger splotches, along with different tones despite the single color used, as areas that went on heavier or lighter dried differently. The doors were painted orange, and the same sponging technique was used with a yellow on top.

Afterwards, detail was added with just 7 colors: silver for pipes, copper for tanks, green for panels and boxes and things like that, white for dial faces, red for handles and dial pointers, a charcoal gray for wires, and a khaki for the skulls. After that, each piece was given an all-over wash with a homemade light brown wash.

After letting it dry overnight, I spent some time adding rust to the corners, over certain bolts, along pipes, and anywhere else I thought looked appropriate with an effects paint. Additionally, a very thin pale turquoise was used to add oxidation effects to some parts of the copper areas. Finally, I went over all of the lights and keypad displays with white again before airbrushing a tiny bit of pale yellow and a midtone green onto them for a slight glowing effect. There are actually 2 of every wall piece, but one isn't radically different enough from the other to really need to be shown off.

Despite all of this, there are actually still a bunch of mission-specific scatter terrain pieces that I need to finish up, but that’ll come later.

Update, later is now! Check out the finished terrain collections for:

Into the Dark

Shadowvaults

Soulshackle

Gallowfall

102 notes

·

View notes

Text

The Evolution of DJ Controllers: From Analog Beginnings to Intelligent Performance Systems

The DJ controller has undergone a remarkable transformation—what began as a basic interface for beat matching has now evolved into a powerful centerpiece of live performance technology. Over the years, the convergence of hardware precision, software intelligence, and real-time connectivity has redefined how DJs mix, manipulate, and present music to audiences.

For professional audio engineers and system designers, understanding this technological evolution is more than a history lesson—it's essential knowledge that informs how modern DJ systems are integrated into complex live environments. From early MIDI-based setups to today's AI-driven, all-in-one ecosystems, this blog explores the innovations that have shaped DJ controllers into the versatile tools they are today.

The Analog Foundation: Where It All Began

The roots of DJing lie in vinyl turntables and analog mixers. These setups emphasized feel, timing, and technique. There were no screens, no sync buttons—just rotary EQs, crossfaders, and the unmistakable tactile response of a needle on wax.

For audio engineers, these analog rigs meant clean signal paths and minimal processing latency. However, flexibility was limited, and transporting crates of vinyl to every gig was logistically demanding.

The Rise of MIDI and Digital Integration

The early 2000s brought the integration of MIDI controllers into DJ performance, marking a shift toward digital workflows. Devices like the Vestax VCI-100 and Hercules DJ Console enabled control over software like Traktor, Serato, and VirtualDJ. This introduced features such as beat syncing, cue points, and FX without losing physical interaction.

From an engineering perspective, this era introduced complexities such as USB data latency, audio driver configurations, and software-to-hardware mapping. However, it also opened the door to more compact, modular systems with immense creative potential.

Controllerism and Creative Freedom

Between 2010 and 2015, the concept of controllerism took hold. DJs began customizing their setups with multiple MIDI controllers, pad grids, FX units, and audio interfaces to create dynamic, live remix environments. Brands like Native Instruments, Akai, and Novation responded with feature-rich units that merged performance hardware with production workflows.

Technical advancements during this period included:

High-resolution jog wheels and pitch faders

Multi-deck software integration

RGB velocity-sensitive pads

Onboard audio interfaces with 24-bit output

HID protocol for tighter software-hardware response

These tools enabled a new breed of DJs to blur the lines between DJing, live production, and performance art—all requiring more advanced routing, monitoring, and latency optimization from audio engineers.

All-in-One Systems: Power Without the Laptop

As processors became more compact and efficient, DJ controllers began to include embedded CPUs, allowing them to function independently from computers. Products like the Pioneer XDJ-RX, Denon Prime 4, and RANE ONE revolutionized the scene by delivering laptop-free performance with powerful internal architecture.

Key engineering features included:

Multi-core processing with low-latency audio paths

High-definition touch displays with waveform visualization

Dual USB and SD card support for redundancy

Built-in Wi-Fi and Ethernet for music streaming and cloud sync

Zone routing and balanced outputs for advanced venue integration

For engineers managing live venues or touring rigs, these systems offered fewer points of failure, reduced setup times, and greater reliability under high-demand conditions.

Embedded AI and Real-Time Stem Control

One of the most significant breakthroughs in recent years has been the integration of AI-driven tools. Systems now offer real-time stem separation, powered by machine learning models that can isolate vocals, drums, bass, or instruments on the fly. Solutions like Serato Stems and Engine DJ OS have embedded this functionality directly into hardware workflows.

This allows DJs to perform spontaneous remixes and mashups without needing pre-processed tracks. From a technical standpoint, it demands powerful onboard DSP or GPU acceleration and raises the bar for system bandwidth and real-time processing.

For engineers, this means preparing systems that can handle complex source isolation and downstream processing without signal degradation or sync loss.

Cloud Connectivity & Software Ecosystem Maturity

Today’s DJ controllers are not just performance tools—they are part of a broader ecosystem that includes cloud storage, mobile app control, and wireless synchronization. Platforms like rekordbox Cloud, Dropbox Sync, and Engine Cloud allow DJs to manage libraries remotely and update sets across devices instantly.

This shift benefits engineers and production teams in several ways:

Faster changeovers between performers using synced metadata

Simplified backline configurations with minimal drive swapping

Streamlined updates, firmware management, and analytics

Improved troubleshooting through centralized data logging

The era of USB sticks and manual track loading is giving way to seamless, cloud-based workflows that reduce risk and increase efficiency in high-pressure environments.

Hybrid & Modular Workflows: The Return of Customization

While all-in-one units dominate, many professional DJs are returning to hybrid setups—custom configurations that blend traditional turntables, modular FX units, MIDI controllers, and DAW integration. This modularity supports a more performance-oriented approach, especially in experimental and genre-pushing environments.

These setups often require:

MIDI-to-CV converters for synth and modular gear integration

Advanced routing and clock sync using tools like Ableton Link

OSC (Open Sound Control) communication for custom mapping

Expanded monitoring and cueing flexibility

This renewed complexity places greater demands on engineers, who must design systems that are flexible, fail-safe, and capable of supporting unconventional performance styles.

Looking Ahead: AI Mixing, Haptics & Gesture Control

As we look to the future, the next phase of DJ controllers is already taking shape. Innovations on the horizon include:

AI-assisted mixing that adapts in real time to crowd energy

Haptic feedback jog wheels that provide dynamic tactile response

Gesture-based FX triggering via infrared or wearable sensors

Augmented reality interfaces for 3D waveform manipulation

Deeper integration with lighting and visual systems through DMX and timecode sync

For engineers, this means staying ahead of emerging protocols and preparing venues for more immersive, synchronized, and responsive performances.

Final Thoughts

The modern DJ controller is no longer just a mixing tool—it's a self-contained creative engine, central to the live music experience. Understanding its capabilities and the technology driving it is critical for audio engineers who are expected to deliver seamless, high-impact performances in every environment.

Whether you’re building a club system, managing a tour rig, or outfitting a studio, choosing the right gear is key. Sourcing equipment from a trusted professional audio retailer—online or in-store—ensures not only access to cutting-edge products but also expert guidance, technical support, and long-term reliability.

As DJ technology continues to evolve, so too must the systems that support it. The future is fast, intelligent, and immersive—and it’s powered by the gear we choose today.

2 notes

·

View notes

Text

Northtown Maintenance-of-Way, part 3

For the final part of this mini-series, I'll be focusing on a few miscellaneous, specialized machines used in the track maintenance process. Each one's role can be done by other, less specialized machines, but it would be a good deal harder.

This is a Mineral Products Inc. Multi-Purpose Machine. It's a mechanical jack of all trades, used for everything from trenching to blowing snow off of tracks. Its most common use is as a 'yard cleaner': the big broom mounted to the front picks up material between the rails and loads it onto a conveyor belt, which can dump it off to the side or into a towed railcar. Another popular job is snow removal: the broom is exchanged for an auger system, and the rear-most conveyor can be replaced with an impeller fan and chute. MPI's website says the machine can move 2000 pounds of snow per hour, and the blower can fling it up to 150 feet away from the tracks. Because it's not limited to just the rails, it can also be used on yard roads & parking lots. Other attachments include a trencher, air blower, rotary broom, and a hydraulic arm which can be fitted with its own range of attachments. I'm starting to sound like a shill here... but it is a pretty cool piece of kit.

The next piece of machinery is Herzog's ACT, or Automated Conveyor Train. It's a special set of cars which uses a conveyor system and swinging boom to "precisely" drop ballast where it's needed. The yellow thing seen above is the train's main power unit. I don't know if it uses hydraulic or electric motors, but this car powers them. Each train set has up to 30 cars, which are just high-side gondolas with conveyors in the bottom. Each car has its own conveyor, which dumps into the next car's conveyor through a small hopper.

A closer look at the connection between cars. I don't know if the water is from recent rains or the train's dust suppression system.

And here's the 'front' of the train, which is really the end. It features the operator's cabin and the most important bit, the unloading arm. It can move ballast 50 feet from the center of the tracks, according to Herzog's website. Conveyor trains like this one are mostly used for filling in washed-out track beds, but can also strategically place piles of ballast for future projects. As of writing this post, the control car is still less than a year old. It really is the cutting edge of ballast-dropping technology!

The last machine is another Herzog product: the creatively-named Rail Unloading Machine. It looks complicated, but is actually quite simple. A crane arm feeds sticks of continuously-welded rail (CWR) into a roller system, which feeds it forward (backwards, really) through two clamps and onto the ground.

A view of the other side. Same deal, but all folded up. Check out the flex on that arm!

6 notes

·

View notes

Text

Protecting Your Electrical Systems: A Look into Al Taqwa’s Complete Range

In today’s fast-paced world, electrical systems power everything from homes and offices to factories and infrastructure. With increasing energy demands and the growing importance of uninterrupted power supply, having the right switchgear and protection systems is more important than ever. That’s where Al Taqwa United Enterprises LLC, one of Oman’s leading electrical suppliers, plays a crucial role.

In this blog, we’ll explore how Al Taqwa offers a complete range of electrical switchgear products that protect and power systems across the country — safely and efficiently.

Why Electrical Protection Is Critical

An electrical system without proper protection is like a car without brakes. From power surges to short circuits, the risks of equipment damage, data loss, and fire hazards are significant. High-quality electrical protection devices ensure:

· Safe power distribution

· Equipment longevity

· Compliance with safety standards

· Reduced downtime in case of faults

Al Taqwa addresses all of these needs with a comprehensive and reliable product portfolio.

Al Taqwa: A Trusted Name in Electrical Switchgear in Oman

Established in 20011, Al Taqwa United Enterprises LLC has grown into a respected electrical trading and switchgear assembly company in Oman, Qatar, the UAE, and India. Their focus on quality, innovation, and customer satisfaction makes them a preferred partner for engineers, contractors, and facility managers across sectors.

Complete Electrical Switchgear Range from Al Taqwa

Al Taqwa’s product line is designed to meet the needs of low-voltage electrical systems in residential, commercial, and industrial environments.

1. Electrical Panels and Distribution Boards

These serve as the central hub for electrical power distribution. Al Taqwa supplies and assembles:

· Main Distribution Boards (MDBs)

· Sub Main Distribution Boards (SMDBs)

· Final Distribution Boards (FDBs)

· Control Panels and Feeder Pillars

All panels are tailored to meet Omani electrical standards and international safety norms.

2. Circuit Protection Devices

The key to preventing electrical fires and damage is reliable overcurrent and earth fault protection. Al Taqwa offers:

· Miniature Circuit Breakers (MCBs)

· Molded Case Circuit Breakers (MCCBs)

· Residual Current Devices (RCDs)

· Earth Leakage Relays

These components ensure quick fault detection and automatic power cut-off during hazards.

3. Metering and Monitoring Devices

To optimize energy use and improve system performance, monitoring is essential. Al Taqwa provides:

· Analog and Digital Panel Meters

· Current Transformers (CTs)

· Voltage and Frequency Meters

· Energy Monitoring Units

These products give real-time data for smarter electrical management.

4. Electrical Accessories and Control Components

To support the full installation lifecycle, Al Taqwa stocks:

· Terminal blocks

· Cable ties and lugs

· Contactors and timers

· Rotary switches and power supplies

These ensure smooth installation, operation, and maintenance of electrical systems.

Top Electrical Brands Represented by Al Taqwa

Al Taqwa partners with internationally recognized electrical brands, including:

· Enza Electric — Quality switchgear products known across Europe and the Middle East

· Civaux Electric — Comprehensive panel systems and circuit protection components

· Stefan Electric — Trusted for metering solutions and industrial electrical accessories

· Salzer Electric — Renowned for rotary switches and control products

These collaborations ensure Al Taqwa can offer reliable, durable, and cost-effective solutions to its clients.

Beyond Products: Al Taqwa’s Expert Services

Al Taqwa goes beyond just supplying electrical components. Their team of experts offers:

Custom switchgear assembly tailored to project requirements

Site inspections and installation support

Annual maintenance contracts

Technical consultation and troubleshooting

This makes Al Taqwa a one-stop solution for all electrical needs in Oman.

Conclusion: Trust Al Taqwa for Complete Electrical Protection

When it comes to protecting your electrical systems, choosing a trusted provider like Al Taqwa ensures both peace of mind and long-term performance. From high-quality panels and circuit breakers to metering systems and expert service, Al Taqwa covers the full spectrum of electrical protection.

For engineers, project managers, or business owners looking to safeguard their infrastructure, Al Taqwa United Enterprises LLC stands out as the best source of electrical switchgear in Oman.

Explore More:

Visit https://altaqwaoman.com to view the full product catalog or request a quote tailored to your project needs.

#electrical#electrical equipment#electrical supplies#switchgear#oman#ElectricalSystems#ElectricalSafety#ElectricalSolutions#ElectricalProtection#SwitchgearSolutions#PowerDistribution#LowVoltageSystems#CircuitProtection#ElectricalPanels#ControlPanels

3 notes

·

View notes

Text

Enhance Your Farming Efficiency with Shaktiman Rotavator and Farming Equipment

In the modern agricultural landscape, efficiency and productivity are paramount. To achieve these goals, farmers need reliable, high-quality equipment that can handle the demands of contemporary farming. Shaktiman, a leading name in the agricultural machinery sector, offers a range of farming equipment designed to meet these needs. Among their impressive lineup, the Shaktiman rotavator stands out as a must-have tool for today's farmers.

The Shaktiman Advantage

Shaktiman is synonymous with innovation and durability. With a commitment to enhancing agricultural productivity, Shaktiman provides a wide array of farming equipment, each designed to streamline farming processes and improve yield. Their machinery is built to withstand the rigors of farming, ensuring longevity and consistent performance.

Understanding the Importance of Farming Equipment

Farming equipment plays a crucial role in modern agriculture. From preparing the soil to planting, cultivating, and harvesting, the right equipment can make each stage of farming more efficient and less labor-intensive. Investing in quality farming equipment like that offered by Shaktiman can significantly impact a farm's productivity and profitability.

The Versatile Shaktiman Rotavator

One of Shaktiman's flagship products is the rotavator, a versatile and efficient piece of equipment designed to prepare the soil for planting. A rotavator, also known as a rotary tiller, is used to break up, churn, and aerate the soil. This process is essential for creating a healthy soil structure, which promotes better root growth and nutrient absorption for crops.

Key Features of the Shaktiman Rotavator

Durable Construction: Shaktiman rotavators are built with high-quality materials, ensuring they can handle tough soil conditions and extended use without compromising on performance.

Efficient Soil Preparation: The rotavator's blades are designed to penetrate and churn the soil thoroughly, creating a fine tilth that is ideal for planting. This helps in better seedbed preparation and weed control.

Adjustable Settings: Shaktiman rotavators come with adjustable depth settings, allowing farmers to customize the tilling depth according to their specific needs. This flexibility makes the rotavator suitable for different types of crops and soil conditions.

Fuel Efficiency: Engineered for efficiency, Shaktiman rotavators are designed to consume less fuel, reducing operational costs for farmers.

Ease of Use: Shaktiman rotavators are designed with user-friendliness in mind. They are easy to attach to tractors and simple to operate, ensuring that even those new to using such equipment can do so effectively.

Benefits of Using a Shaktiman Rotavator

Investing in a Shaktiman rotavator offers numerous benefits for farmers:

Improved Soil Health: By aerating the soil and improving its structure, the rotavator promotes healthier root systems and better nutrient uptake, leading to more robust crop growth.

Time and Labor Savings: The rotavator significantly reduces the time and effort required for soil preparation, allowing farmers to cover larger areas more quickly and with less physical strain.

Cost-Effective: With its fuel-efficient design and durable construction, the Shaktiman rotavator offers long-term savings on fuel and maintenance costs.

Versatility: Whether you're preparing a seedbed for vegetables, cereals, or other crops, the adjustable settings and versatile design of the Shaktiman rotavator make it suitable for a wide range of agricultural applications.

Conclusion

In today's competitive agricultural market, efficiency and productivity are key to success. Shaktiman's range of farming equipment, particularly the rotavator, provides farmers with the tools they need to optimize their operations. With a Shaktiman rotavator, farmers can achieve better soil preparation, healthier crops, and improved overall productivity. Investing in Shaktiman equipment is a step towards a more efficient and profitable farming future.

Visit Shaktiman Agro to explore their full range of farming equipment and discover how their innovative solutions can benefit your farm.

2 notes

·

View notes

Text

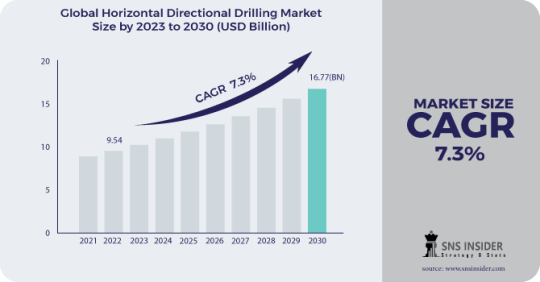

Horizontal Directional Drilling Market Analysis and Forecast 2031: Exploring Size, Share, and Scope Trends

The Horizontal Directional Drilling research report provides a quick analysis of market value, volume, return, factors, opportunity, competition, and current strategic behaviour. This includes forecasting demand, detailed explanations of assumptions and methodologies, as well as historical data and forecasts. This study examines the financial market environment to assess competition in local and global markets. The survey highlights the growth potential of the Horizontal Directional Drillingindustry over the forecast period.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1099

The report includes data on strategic alliances, new product launches, projects, transactions, collaborations, key market players, and drivers, constraints and opportunities. It provides the tools you need to assess the Horizontal Directional Drilling market for companies, customers, buyers, sellers, service providers, and distributors.

Market Segmentation

By Technique

Conventional

Rotary Steerable System

By Parts

Rigs

Pipes

Bits

Reamers

Others

By Application

On-shore

Off-shore

By End User

Oil and Gas Excavation

Utility

Telecommunication

By Company

American Augers, Inc.

Ditch Witch

Ellingson Companies

Vermeer Corporation

The Toro Company

Baker Hughes Incorporate

Halliburton Company

Schlumberger Limited

Weatherford International National Oilwell Varco, Inc.

Nabors Industries, Ltd.

The Application Management Services (AMS) market is divided into three categories: type, provider and application, allowing you to more accurately assess the size, climate, growth and development of the market. Charts, diagrams and records are used to represent the segments. Horizontal Directional Drillingmarket research also provides insights into the target market's product category and is based on a variety of organizational objectives such as product segmentation, production volume, product definition, and requirements, etc.

The market study thoroughly investigates the scope of the target market. Market innovation that has been stable in the past and is expected to stabilize again in the future is the subject of this study. Industry structure, definition, product characteristics, market penetration and maturity analysis are all included in the Horizontal Directional Drilling market report. Market size and growth rate are also analysed for forecast periods.

Regional Analysis

The report covers industry rankings and reported interpretations using regional surveys. Use of both primary and secondary sources to calculate market revenue for large industry organizations. Therefore, this study contains several important features. This Horizontal Directional Drillingmarket study explores the many factors that influence the growth of a region, including the financial, cultural, social, technical and political conditions of the region. This chapter describes the regional and global globalization of various term exchanges. Similarly, this study provides a reliable amount of country-by-country research and analysis of regional market share.

Buy This Report Here @ https://www.snsinsider.com/checkout/1099

Competitive Outlook

The size of the sector is also determined by the characteristics of the major players in the sector, according to the report. Major capabilities of major industry players are studied using secondary as well as primary sources and their revenue in the market is calculated in this study. This market research examines the top-down tactics of large companies. This section of the report provides contact details for the major vendors in the Horizontal Directional Drillingindustry. The survey also explores the market competition, market prices and channel characteristics among the major players.

0 notes

Text

Unleashing the Legend: The FD3S RX-7 and its Timeless Allure

Introduction In the pantheon of Japanese sports cars, few names stir the soul like the Mazda RX-7, specifically its third generation, the FD3S. Since its debut in the early 1990s, the FD3S RX-7 has captivated enthusiasts with its unique blend of style, performance, and technological innovation. This article dives into the heart of what makes the FD3S RX-7 a timeless icon in the JDM car scene.

Design and Style The FD3S RX-7 is a masterpiece of automotive design. Its sleek, flowing lines and aggressive stance make it instantly recognizable. The car's design was ahead of its time, featuring a lightweight, aerodynamic body that still looks modern today. The pop-up headlights, a nostalgic yet defining feature, add to its charm, embodying the spirit of the 90s sports car era.

Rotary Revolution: The Heart of the RX-7 At the core of the FD3S's allure is its unique rotary engine. The 13B-REW, a twin-turbocharged rotary engine, set the RX-7 apart from its peers. This compact yet powerful engine delivers a high power-to-weight ratio, providing an exhilarating driving experience. The rotary engine's smooth power delivery and high-revving nature make the RX-7 not just a car, but an experience to drive.

Performance and Handling The FD3S RX-7 is renowned for its exceptional handling characteristics. Thanks to its lightweight construction and well-balanced chassis, it offers a driving experience that is both engaging and accessible. The RX-7's handling is enhanced by its advanced suspension system and its low center of gravity, making it a favorite among track enthusiasts and casual drivers alike.

Cultural Impact and Legacy Beyond its technical prowess, the FD3S RX-7 holds a special place in automotive culture. It has been a staple in motorsports, drifting scenes, and popular media, contributing to its legendary status. The RX-7's appearances in movies, video games, and TV shows have cemented its image as a symbol of speed and style.

Modifications and the Enthusiast Community The FD3S RX-7 is not just a car; it's a canvas for personal expression. The enthusiast community has embraced this vehicle, leading to a wide range of modifications. From engine swaps to body kits, the possibilities are endless. This level of customization has kept the RX-7 alive and relevant, even decades after its production ended.

Conclusion: The Eternal Charm of the FD3S RX-7 The FD3S Mazda RX-7 is more than a car; it's a legend. Its combination of design, performance, and unique rotary engine technology makes it a standout in the JDM scene. Its influence extends beyond the automotive world, becoming a cultural icon. For car enthusiasts, the FD3S RX-7 is not just a memory of the past but a continuing source of inspiration and passion. In the world of JDM cars, the RX-7 remains an eternal favorite, a symbol of a bygone era that continues to excite and inspire.

2 notes

·

View notes