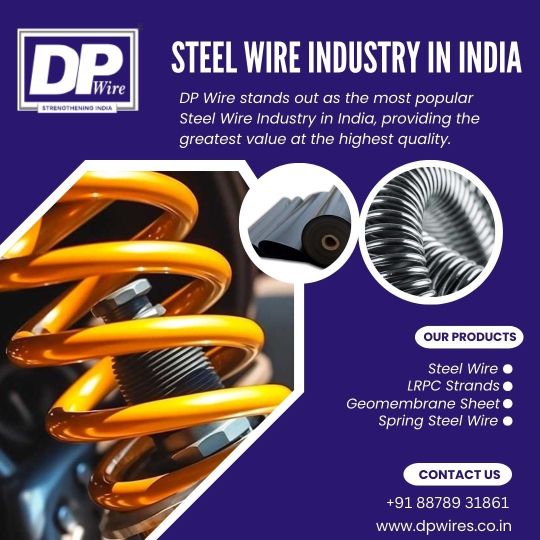

#Steel Wire Industry in India

Text

Top Steel Wire Manufacturers and Suppliers in India - Dp Wires

Dp Wires proudly stands as one of the top Steel Wire Manufacturers and suppliers in India, renowned for setting industry standards for reliability and quality. We not only lead the industry in the production of steel wires, but we also excel at providing a large selection of single-strand stainless steel wires.

Our products, which are carefully packaged in bundles or drums weighing 20 to 250 kg, are used in a wide range of industries, including the chemical, oil and gas, textile, machinery and pumping industries. Dp Wires guarantees excellent quality with finishes ranging from dull to bright drawn and shiny, making us the go-to option among those looking for dependable steel wire solutions in India.

For more information, Visit our site - Https://www.dpwires.co.in

#Steel Wire Manufacturers#Steel Wire Industry in India#Lrpc Strands#Geomembrane Sheet#Spring Steel Wire

2 notes

·

View notes

Text

Best MS Wire Mesh Manufacturer, Supplier, and Exporter in India - Mcneil Instrument

The best MS wire mesh manufacturer in India is Mcneil Instrument. A wide variety of MS Wire Mesh is available thanks in large part to us. These are highly praised by customers for their durable design, precise dimensional measurements, and great functional effectiveness. With excellent strength and corrosion resistance, MS wire mesh ensures long-lasting performance. Its affordability and easy maintenance further enhance its appeal for both industrial and residential projects. It provided a sturdy, long-lasting framework that could tolerate harsh external circumstances and was expertly welded from junction. McNeil Instrument ensures precision in every step of the production process. Our modern machinery and skilled workforce collaborate seamlessly to create mild steel wire mesh that meets the stringent requirements of diverse industries.

" https://www.mcneilinstrument.com/ms-wire-mesh.html "

0 notes

Text

#Steel wire ropes industry india#wire rope manufacturing company#Steel Wire Ropes manufacturer#Global wire rope manufacture#wire rope supplier in Germany#Netherlands#UK#Turkey#USA#Singapore#Dubai#Steel wire ropes manufacture#steel wire rope

0 notes

Photo

"Hatelloy Wires Manufacturer & Exporter."

Bhansali Enterprise sells a lot of products made of Hastelloy. One of them is Hastelloy C22 wire, which is made from the best raw materials. C22 alloy, a very versatile alloy, is used to make Hastelloy C22 wire. It is made up of chromium, nickel, tungsten, molybdenum, and other elements. Components made of material grade C22 have increased resistance to corrosion and a variety of industrial chemicals as a result of these elements. Bhansali Enterprise offers Hastelloy C276 Wire in various size shapes and details according to the prerequisite. These Hastelloy C276 Wires are made out of a super-compound that is appropriate in high-temperature applications. It is made up of chromium, nickel, and molybdenum alloy, which has excellent resistance to corrosion in an oxidizing environment. It is a corrosion-resistant alloy made of nickel, chromium, and molybdenum. Stress corrosion cracking, crevice corrosion, and pitting are all prevented by this alloy. These Hastelloy C276 Wires shows the capacity to limit the carbide precipitation while welding. Additionally, it exhibits excellent resistance to minimizing or preventing grain boundary precipitates during welding. HASTELLOY X WIRE is Bhansali Enterprise’ highest-grade wire and is widely used in a wide range of applications. Our wire is shaped in the ways that are needed in a variety of industries. These wires are held to specified standards, and dimensional changes define various specifications. With a higher Hastelloy grade, these wires are easier to form and more ductile. It has a higher tensile strength and is made specifically for use in applications at higher temperatures. HASTELLOY X, also known as a superalloy, is a high-performance alloy that keeps features like super strength, resistance to creep and cracking, and sustainability under high temperatures and corrosion.

#stainless steel wire#wire manufacturers#stainless steel wire manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#hastelloy composition#hastelloy c276 chemical composition#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

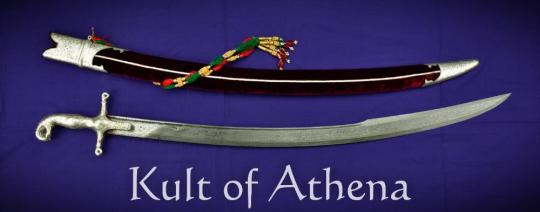

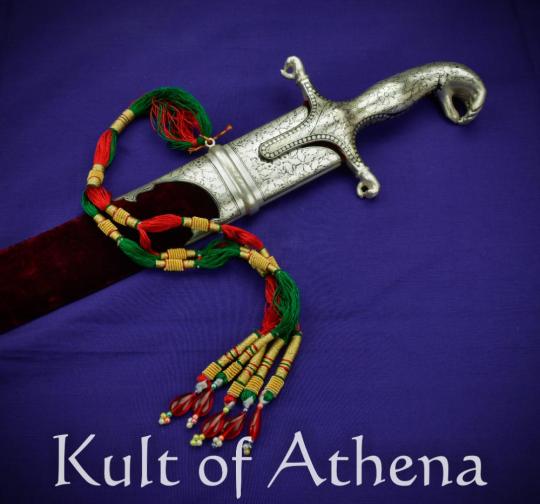

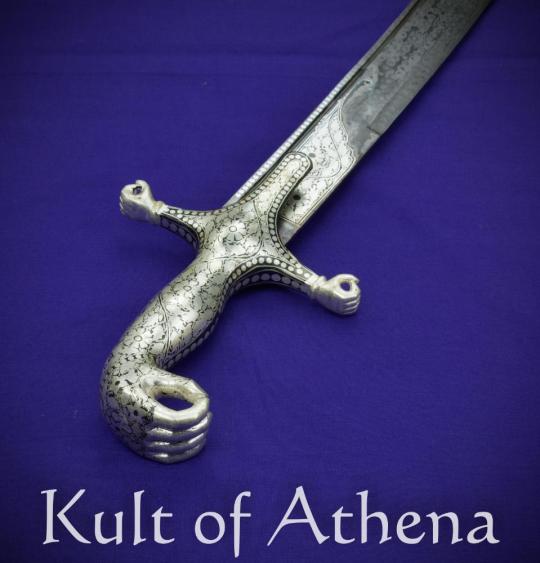

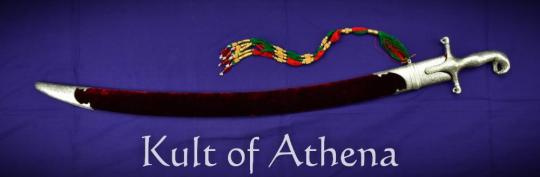

Damascus and Silver Koftgari Indian Saber with Hand design – Universal Swords

This ornate and entirely handcrafted saber from India with its damascus blade and koftgari-inlay embellishment is in itself a display of the traditional swordsmithing arts of India. The damascus steel blade features panels of silver inlay on both sides of the blade. The blade tang is secured by filling the hollow hilt and grip with a hardened resin to solidly anchor it into the hilt. This method of sword construction is a traditional technique in India.

The sword is paired with a wood-core scabbard overlaid in vibrant velvet. Its steel components were decorated with silver koftgari to match the sword. The Damascus steel blade is crafted from the melding of two different steels into a single billet from which the smith forges the blade; the mixed steel leaves a vibrantly visible rippled patterning on the blade surface. Traditionally this was a technique done to merge harder and softer steels into a single blade to impart it with both a hardness for durability and edge retention and a degree of flexibility to prevent the blade from becoming brittle.

This was done to get good results from the quality of iron available for smithing. Damascus is now technically inferior to pure steel made from modern industrial-scale methods, but it is still desired as the beauty of Damascus is instantly notable and is a testament to the skill of the smith who forged it with the traditional methods and the blade was further embellished with silver inlay at the base of the blade. The elegant and intricate design and patterning on the hilt was created with the laborious Koftgari technique; a traditional process exemplified by Indian smiths whereby a design is etched and chiseled and then strands of silver wire is carefully hammered into the etched design. The hilt is then heated in a kiln and the silver wire is then permanently annealed into a permanent design.

The patterning of the damascus blade varies with each blade in much the same manner as all fingerprints differ. Also the Koftgari designs are made to the individual design and artistry of the smith. Therefore every one of the swords of this type are uniquely crafted and are a testament to the traditional swordsmithing techniques of India.

Please Note: Unique Item – Only One Available!

#Kult of Athena#KultOfAthena#New Item Wednesday#Koftgari Indian Saber#Damascus and Silver Koftgari Indian Saber with Hand design#Universal Swords#Middle Eastern Indian & N. African Swords#sword#swords#weapon#weapons#blade#blades#sabers#Damascus Steel#Battle Ready#Indian Swords#Indian Weapons#Middle Eastern Swords#Middle Eastern Weapons

2 notes

·

View notes

Text

Supplier of Industrial Valve in Tamil Nadu

Meghmani Metal:

Meghmani Metal is an ISO 9001:2015 certified supplier of industrial valves based in Tamil Nadu, India.

The company offers a diverse range of stainless steel products, including steel flanges, SS fasteners, steel butt welding, steel pipe fittings, steel rods, wires, coils, and flats.

Meghmani Metal crafts industrial valves from various material grades, including stainless steel and high nickel alloys.

Their warehouse stocks a variety of valves such as ball valves, gate valves, control valves, needle valves, globe valves, butterfly valves, check valves, safety valves, and more.

Specifications:

Standard: ASTM A240, JIS4304-2005, ASTM A167, EN10088-2-2005, GB/T3280-2007, etc.

Specifications: ASTM A240 / ASME SA240

Sizes: Ranging from 1000mm x 2000mm, 1220mm x 2440mm, 4′ x 8′, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, and 2000mm x 4000mm to 6000mm.

Length: Options include 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc.

Thickness: Varying from 0.3mm to 100mm.

Range: Extending from 5mm to 150mm.

Surface Finishes: Various surface finishes are available, including hot rolled plate (HR), cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sandblast, brush, etching, SATIN (met with plastic coated), and more.

Service Coverage:

Meghmani Metal serves as a prominent supplier of industrial valves in Tamil Nadu, covering areas such as Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Pudukkottai, Rajapalayam, Ramanathapuram, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, and Vellore.

For further inquiries and information, interested parties are encouraged to contact Meghmani Metal.

Read the full article

#Arcot#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#IndustrialValve#Kanchipuram#Kanniyakumari#Kodaikanal#Kumbakonam#Madurai#Mamallapuram#Manufacturer#Nagappattinam#Nagercoil#Palayamkottai#Pudukkottai#Rajapalayam#Ramanathapuram#Salem#supplier#Thanjavur#Thoothukudi#Tiruchchirappalli

3 notes

·

View notes

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

Discover the Best steel wire manufacturers - DP Wire

Discover unparalleled quality and reliability with DP Wire, one of the leading steel wire manufacturers in the industry. With a commitment to excellence and innovation, DP Wire stands out as a trusted name in providing high-quality steel wire products for a diverse range of applications. As one of the best steel wire manufacturers, DP Wire employs cutting-edge technology and stringent quality control measures to ensure that every product meets the highest standards of performance and durability. For more information, click on the given link - https://www.dpwires.co.in/understanding-lrpc-strands-a-comprehensive-overview-with-dp-wires/

#steel wire manufacturers#steel wires#spring steel wire#steel wire industry in india#spring wire#wire manufacturer#wire supplier#wire products#industrial wires#lrpc strands

0 notes

Text

#strands#Earth Wire Strand Manufacturer India#structural Wire Strands Manufacturer#stay wire strands#structural strands Manufacturer#Earth Wire Rope Strands#strands for electrical industry#Steel Wire Strands Online#galvanised steel wire strands#wireropestrands

0 notes

Text

Square Bright Bar Manufacturer in Haryana

Steel and steel products contribute to a significant percentage of country’s economy. One of the products that find immense use in every other type of industry is bright bar, which is made out of steel as raw materials. The entire developing process of bright bars is complicated and carried out in different stages. There are various shapes, dimensions and sizes of bright bars available today and they have varied applications as well. Steel, as we all know has high durability and high tensile strength which makes it a core material for various construction purposes.

All about SS Engineering works

The company came into existence in 1968 and it is an ISO certified agency that is into developing various raw materials for industries and construction purpose. It is a reliable source manufacturing and exporting high quality bright steel bars of different types. The team has a well experience of over 54 years and that makes it an authentic Square Bright Bar Manufacturer in Haryana. The team has been able to cater to the varied needs of their clients all these years and the end result has always been 100 percent satisfactory. Quality and timely delivery as two main focuses for the company. Some of the widely accepted and appreciated list of products includes the likes of HB wires, bright bar, polished wire, square bright bar, hex bright bar, steel round bar among others. All these products are manufactured in different grades. Some of the clients in the list includes land rover, Honda, hero, designco, etc.

Production of Bright Bars

SS Engineering Works is one of the leading Square Bright Bar Supplier and manufacturer in India. The entire development process is very crucial and time consuming that needs utmost perfection and expertise. It is manufactured in the factory, where the raw material i.e. steel undergoes various processes to get different dimensions and sizes of the bright bars. The main raw material is called black bars which undergoes different processes namely drawing, peeling, grinding, polishing and col rolling to get the desired out.

Complete Manufacturing process of Bright Steel Bars

Be it round, square or any other shape of bright steel bars, the basic manufacturing process is more or less same. The actual material used in the process is called black bars, which is entirely different from black steel bars. This black bar is passed through dyes in very cold conditions or by using a peeling machine where there are turned. Before the final cold finishing, the material undergoes heat treatment for added strength. In order to get different sizes, different processes are used as follows:

Drawing – The black bar is drawn through different dyes to get desired shape which will reduce surface imperfection and provide tensile strength as well

Peeling – Here also surface imperfection is reduce but internal ones are pulled out

Grinding – The finished product is then moved towards grinding that enhance tolerance level and enhance surface finish

Polishing is a process of enhancing the finish of the surface of the product

Cold rolling – It is the final process that is majorly used to develop complex shapes

#Bright Bar manufacturer In Punjab#Bright Bar Manufacturers In Punjab#Bright Steel Bar suppliers In Delhi#Bright Bar manufacturer In Delhi#Bright Bar Manufacturing In Punjab

0 notes

Photo

"Steel Manufacturers In India."

The quality assurance system is guided by principles that support our unique working culture which incorporates respect. We ensure that finest quality material is used for our products. Our team of experts maintain a vigil on the quality of the products. Every single piece is attached with test certificates and reports. We are continually improving our quality to serve our clients better. We help customers develop their energy resources; bringing world class capability and delivering it locally. Providing sources to customers for growing their business at their locality We are values your needs and help to grow in industry. We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of our products. we are believing to give the delivery of products within time assign by us and quick delivery as per the customers requirement.

#stainless steel round bar#stainless steel wire#manufacturer of stainless steel in india#duplex stainless steel#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributor#steel manufacturers in india#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

Ceramic Band Heater Manufacturers

Hindon Electricals is one of the most popular ceramic band heater manufacturers and suppliers in India. Our heaters are used in commercial heating processes. We use nickel-chromium (NiCr) wire and a stainless steel sheath in the manufacturing of ceramic band heaters. Our top priority is the quality of our heaters and customer satisfaction. If you want to buy or learn more about our heaters, you can visit our website.

Add : A-1/274 Swadeshi Compound Kavi Nagar Industrial Area Ghaziabad -201001

Email : [email protected]

Ph : +91-9811098334, +91-7292031858

Visit : https://www.hindonheater.com/ceramic-band-heater/

0 notes

Text

Supplier of Stainless Steel Hexagonal Bar in Odisha

Arisa Impex is a Top Supplier of Stainless Steel Hexagonal Bar in Odisha.

Our manufacturing unit is located in Ahmedabad, Gujarat, India.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel.

We offer a premium range of high-grade quality series, including 200, 300, 400, and 600.

Stainless Steel Hexagonal bar is a solid piece of stainless steel shaped into a hexagonal cross-section.

This type of bar is known for its excellent corrosion resistance, strength, and versatility, making it ideal for various industrial and commercial applications.

Why Choose Us?

Effective Service: Our dedicated team ensures timely support and assistance to meet all customer needs efficiently.

Wide Product Range: We provide an extensive selection of products to cater to diverse industry requirements and applications.

Customization: Tailored solutions are available to meet specific client needs, ensuring optimal performance and satisfaction.

Cost Effective: We design our products and services to deliver high quality at competitive prices, maximizing value.

Specification:

SS Hexagonal Bar Grades: 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51, ASTM A276, ASTM A484

Size: 16mm to 55mm

Length: 4 to 6meters, or as customer’s requirements

Tolerances: K11, K10, K12, H8, H10, K9, H9, H11, H13, H12

Packing: Standard packing

Specifications: EN 10272, EN 10088-3 Grade 1.4301 (304), 1.4306 (304L), 1.4401 (316), 1.4404 (316L)

Finish: Black, Peeled, Polished, Smooth Turned, Rough Turned, Centreless Ground, Grinding, Cold Drawn Turned, Bright Drawn, Bright, Annealed

Usage in

Manufacturing and Fabrication

Automotive and Aerospace

Construction and Architecture

Marine and Coastal Applications

Arisa Impex is a Top Supplier of Stainless Steel Hexagonal Bar in Odisha including locations like Bhubaneswar, Cuttack, Rourkela, Berhampur, Sambalpur, Puri, Balasore, Bhadrak, Baripada.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#andAlloySteel#Angles#Annealed#ArisaImpex#Balasore#Baripada#Berhampur#Bhadrak#Bhubaneswar#Black#Bright#BrightDrawn#CentrelessGround#Coils#ColdDrawnTurned#Cuttack#Exporter#Flanges#FlatBars#Grinding#Gujarat#HexagonalBars#India#Manufacturer#manufacturingunitislocatedinAhmedabad#Odisha#Peeled#Pipes#Polished#Puri

0 notes

Photo

How to Choose the Right HB Wire Supplier for Your Needs

When it comes to construction, agriculture, fencing, and various other industries, HB wire is an essential material that is used for a wide range of applications. Choosing the right HB wire supplier is crucial to ensure that you get high-quality materials that meet your specific needs and requirements. With so many suppliers in the market, it can be overwhelming to make the right choice. In this blog post, we will discuss some key factors to consider when selecting an HB wire supplier to help you make an informed decision.

One of the most important factors to consider when choosing an HB wire supplier is the quality of the materials they offer. Shree Ji Steel Private Limited is a leading supplier of mild steel materials, including HB wire, known for providing top-notch quality products that meet industry standards. With a reputation for delivering high-quality materials, Shree Ji Steel Private Limited is a trusted name in the industry. When selecting an HB wire supplier, it is essential to ensure that they offer materials that are durable, reliable, and of superior quality to ensure the success of your projects.

In addition to quality, it is also crucial to consider the range of products and services offered by the supplier. Shree Ji Steel Private Limited specializes in mild steel and hot rolled materials, providing a wide range of options to cater to various needs and specifications. Whether you require HB wire for construction, agriculture, or any other application, Shree Ji Steel Private Limited has you covered with a diverse range of products to choose from. By selecting a supplier that offers a comprehensive range of materials, you can easily find the right HB wire to meet your specific requirements.

Furthermore, when choosing an HB wire supplier, it is important to consider their reputation and reliability in the industry. Shree Ji Steel Private Limited is known for its commitment to customer satisfaction, timely delivery, and excellent service. With a PAN India presence, Shree Ji Steel Private Limited has established itself as a reputable and reliable supplier of mild steel materials, earning the trust and loyalty of customers across the country. By choosing a supplier with a solid reputation and track record of excellence, you can rest assured that you will receive top-quality materials and outstanding service for your projects.

In conclusion, selecting the right HB wire supplier is essential to the success of your projects. By considering factors such as quality, range of products, reputation, and reliability, you can make an informed decision and choose a supplier that meets your specific needs and requirements. Shree Ji Steel Private Limited stands out as a leading supplier of mild steel materials, including HB wire, offering high-quality products, a wide range of options, and exceptional service to customers nationwide. When you choose Shree Ji Steel Private Limited as your HB wire supplier, you can trust that you are getting the best materials for your projects.

Product Page: https://shreejisteelcorp.com/wire-rod/

Website: https://shreejisteelcorp.com/

0 notes

Text

Stainless Steel 316L Sheets Manufacturers in India

One of the top exporters, suppliers, and stockists of a variety of metal works is Shree Venktesh Wires and Steels Pvt Limited. We've been offering our services all around the world. SS 316L sheets are a part of our product line. In many different manufacturing industry divisions, this commodity is among the most sought-after steel grades. This product has an exceptional amount of nickel components, which offers remarkable corrosion-proofing characteristics. We collaborate with Jindal Stainless Limited to manufacture sheets made of stainless steel in grades 316 as well as additional stainless steel grades. To satisfy our customers' needs, we offer the best jindal ss sheet price and 316L sheets in a variety of sizes, dimensions, and thicknesses.

Characteristics of jindal ss 316L sheet:

Higher creep resistance

Excellent formability.

Rupture and tensile strength at high temperatures

Corrosion and pitting resistance

Standards of Jindal ss 316L sheets:

Standards: ASTM A240 / ASME SA240

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness: 4mm-100mm

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, hairline, sand blast, Brush, etching, Hot rolled coil (HR), Cold rolled coil (CR), SATIN (Met with Plastic Coated), etc

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Form: Coils, Foils, Rolls, Plain Coil, Shim Coil, strips, Flats, Blank (Circle), Ring (Flange), etc.

Applications of Jindal ss 316L sheets:

A wide range of applications and industries use jindal stainless steel 316 sheets.

Below are a few of them:

Petrochemical Industry

Oil and Gas Industry

Chemical Industry

Power Plant Industry

Energy Industry

Pharmaceuticals Industry

Pulp & Paper industry

Food Processing Industry

Aerospace Industry

Refining Industry and many more.

Uses and Purpose of Jindal ss 316L sheets:

Jindal ss 316L sheets have a high tolerance to corrosion, outstanding resistance to oxidation, and exceptional grade strength thanks to their high chromium and nickel content. The maximum melting point of stainless steel 316L sheets is 1399 degrees Celsius (or 2550 degrees Fahrenheit). They have incredible yield and tensile strength ranges. Its range of elongation is the widest, at 35%. They also contain the elements carbon, manganese, silicon, phosphorus, sulfur, chromium, molybdenum, nitrogen, and nickel because they are a member of one of the 300 families.

Jindal steel dealers provide perforated sheets made of Jindal ss 316L sheets that are extensively used in the welding, electrochemical, mechanical, and construction industries. Hot rolled sheets made of Jindal ss 316L sheets are specifically created to have features like unprecedentedly high withstanding resistance to corrosion brought on by liquids, hardness, and temperature fluctuation resistance.

#Stainless Steel 316L Sheets Manufacturers in India#Stainless Steel 316L Sheets Suppliers in India#Stainless Steel 316L Sheets Stockists in India#Stainless Steel 316L Sheets Exporters in India

0 notes

Text

Building Foundations with steel wire manufacturers - DP Wire

"DP Wire is dedicated to building strong foundations with their steel wire manufacturers expertise. As a leading manufacturer, they provide high-quality steel wire products essential for various construction projects. From reinforcing concrete structures to supporting infrastructure, DP Wire's products play a crucial role in ensuring durability and strength. With a commitment to excellence, DP Wire is your trusted partner in creating solid foundations for the buildings of tomorrow. "Get more information on https://www.dpwires.co.in/

#steel wire manufacturers#steel wires#spring steel wire#steel wire industry in india#spring wire#wire manufacturer#geomembrane sheet#wire products#industrial wires

0 notes