#Surface preparation for epoxy

Explore tagged Tumblr posts

Text

Introduction to Epoxy.com Flooring: What You Need to Know Before You Install

Epoxy.com flooring has become a popular choice for both residential and commercial spaces due to its durability, aesthetic appeal, and resistance to various elements. Whether you’re considering Epoxy.com flooring for your garage, basement, or commercial facility, understanding the basics is essential before embarking on the installation process. What Is Epoxy.com Flooring? Epoxy.com flooring…

#Chemical-resistant flooring#Commercial epoxy flooring#concrete surface preparation#Customizable epoxy floors#durable flooring#Epoxy coating benefits#Epoxy coatings for high-traffic areas#Epoxy floor application#Epoxy floor coating#Epoxy flooring installation#Epoxy flooring installation guide#Epoxy.com coatings#Epoxy.com flooring#epoxy.com Products#Epoxy.com resin#Floor maintenance#Floor protection#High-performance epoxy#Industrial Flooring#Low-maintenance flooring#Residential epoxy flooring#Surface preparation for epoxy

0 notes

Text

Flooring Installation Contractors in Poteau | ATF Oklahoma

When it comes to enhancing the look and feel of your home or business, flooring plays a crucial role. In Poteau, finding the right flooring installation contractors is essential to ensure high-quality results and long-lasting durability. Whether you’re interested in residential polished concrete floors, epoxy flooring, or need a flooring design consultant, Poteau offers a range of options to suit your needs. Here’s what you need to know about Flooring Installation Contractors in Poteau.

Residential Polished Concrete Floors in Poteau

Residential polished concrete floors are gaining popularity in Poteau due to their sleek, modern appearance and easy maintenance. Polished concrete floors are not only visually appealing but also durable and cost-effective. They are ideal for both residential and commercial spaces, providing a clean and contemporary look.

Benefits of Polished Concrete Floors

Durability: Polished concrete floors are incredibly durable and can withstand heavy foot traffic, making them ideal for high-traffic areas.

Low Maintenance: These floors are easy to clean and require minimal maintenance, saving you time and money.

Aesthetic Appeal: Polished concrete offers a modern, elegant look that can be customized with different finishes and colors.

Polished Concrete Floors Cost in Poteau

The polished concrete floors cost in Poteau can vary depending on several factors, including the size of the area, the level of polishing required, and any additional design elements. On average, you can expect to pay between $3 to $8 per square foot. It’s best to consult with local flooring installation contractors to get an accurate estimate for your specific project.

Epoxy Flooring Types in Poteau

Epoxy flooring is another excellent option for both residential and commercial properties. There are various epoxy flooring types in Poteau to choose from, each offering unique benefits and aesthetic appeal.

Popular Epoxy Flooring Types

Metallic Epoxy Floors: These floors provide a stunning, reflective surface that mimics the look of marble or other high-end materials.

Solid Color Epoxy Floors: Ideal for garages and industrial spaces, these floors are durable and easy to clean.

Quartz-Filled Epoxy Floors: This type of epoxy flooring incorporates colored quartz grains, offering both durability and a decorative finish.

Epoxy Concrete Floor in Poteau

Installing an epoxy concrete floor in Poteau can transform any space with its durable and attractive finish. Epoxy floors are resistant to stains, chemicals, and abrasions, making them perfect for garages, basements, and industrial environments. They also offer a non-slip surface, enhancing safety in high-traffic areas.

Flooring Design Consultant in Poteau

A flooring design consultant in Poteau can help you choose the best flooring options for your space, ensuring that the design complements your interior decor and meets your functional needs. Whether you’re renovating your home or designing a new commercial space, a flooring design consultant can provide expert advice and recommendations.

Epoxy in Poteau

Epoxy flooring in Poteau is a versatile and durable solution for various applications. From residential garages to commercial warehouses, epoxy flooring offers numerous benefits, including:

Durability: Epoxy floors can withstand heavy loads and high traffic, making them ideal for both residential and commercial use.

Aesthetic Flexibility: Available in a wide range of colors and finishes, epoxy floors can be customized to match any decor.

Safety: Epoxy floors provide a non-slip surface, reducing the risk of accidents in high-traffic areas.

Conclusion

Finding the right flooring installation contractors in Poteau is essential for ensuring high-quality results and long-lasting floors. Whether you’re interested in residential polished concrete floors, epoxy flooring, or need expert advice from a flooring design consultant, Poteau has a variety of options to meet your needs. For more information and to explore your flooring options, visit ATF Oklahoma serving Tahlequah and Tecumseh areas.

#Residential Flooring in Poteau#Epoxy Kitchen Floor Residential in Poteau#Commercial Flooring Contractors in Poteau#Flooring Installation Contractors in Poteau#Flooring Contractors in Poteau#Commercial Flooring in Poteau#Industrial Flooring in Poteau#Flooring Design Consultant in Skiatook#Flooring Installation Service in Skiatook#Demolition of All Flooring in Skiatook#Coating Floor in Skiatook#Concrete Polishing in Skiatook#Surface Preparation in Skiatook#Floor Coating in Skiatook#Epoxy Concrete Floor in Skiatook#Epoxy Flooring Types in Skiatook#Epoxy Floor Service in Skiatook#Epoxy Floor Installation in Skiatook#Epoxy Floor for Kitchen in Skiatook#Epoxy Floor Contractor in Skiatook#Epoxy Finish Floors in Skiatook#Epoxy Coated Flooring in Skiatook#Concrete Epoxy Floor in Skiatook#Commercial Flooring for Kitchen in Skiatook#Polished Concrete Floors Cost in Skiatook#Commercial Epoxy in Skiatook#Residential Polished Concrete Floors in Skiatook

0 notes

Text

EPOXYSHİNE - DRAGON+

Welcome to our comprehensive guide on "Epoxy Shine," where we delve into the transformative power of epoxy flooring solutions. In today’s design-driven world, achieving a polished and durable floor is essential for both residential and commercial spaces. Epoxy coatings not only elevate the aesthetic appeal but also provide long-lasting protection against wear and tear. Whether you’re considering a modern upgrade for your home or a robust flooring solution for a bustling business, epoxy shines as a versatile choice that meets a variety of needs. In the following sections, we’ll explore innovative flooring solutions, focusing on the benefits of epoxy flake flooring, which combines functionality with style for a stunning finish that can withstand the test of time.

Epoxy Shine

When it comes to achieving a brilliant and long-lasting finish, epoxy shine is the ideal solution for various flooring needs. Known for its incredible durability and aesthetic appeal, epoxy shine enhances the overall beauty of a space while providing a protective layer that withstands wear and tear.

The key to attaining that stunning epoxy shine lies in the application process. Proper surface preparation, quality materials, and skilled application techniques combine to create a glossy finish that can transform mundane concrete floors into vibrant, eye-catching surfaces. This shine doesn’t just elevate the design; it also reflects light, making spaces appear larger and more inviting.

Moreover, epoxy shine is not just about looks; it offers significant functional benefits too. The glossy surface is resistant to stains, chemicals, and moisture, making it an excellent choice for high-traffic areas such as garages, warehouses, and commercial spaces. Whether for aesthetic or practical purposes, ensuring your floors have that perfect epoxy shine can significantly enhance your property's value and appeal.

Floor Solutions

When it comes to choosing the right floor solutions, there are numerous options available that cater to various needs and preferences. Whether you are going for aesthetic appeal, durability, or maintenance ease, understanding the different types of flooring can significantly impact your choice.

One popular choice for many homeowners and businesses is epoxy flooring. This option provides a sleek and modern look while ensuring high durability and resistance to wear and tear. Epoxy shine not only enhances the floor's visual appeal but also makes it easier to clean and maintain over time.

Additionally, epoxy flake floors are gaining traction due to their unique aesthetic and customization options. They allow for a blend of colors and textures, giving homeowners the flexibility to create a more personalized look for their spaces. With such a wide array of flooring solutions, it's essential to consider factors like budget, usage, and design preferences before making a decision.

Flooring Solutions

When it comes to choosing the perfect flooring for your space, the options can be overwhelming. Flooring solutions are essential for both aesthetic and functional purposes, ensuring that your space not only looks great but also serves its intended function. From residential to commercial applications, the right flooring choice can make all the difference.

One popular choice in the realm of flooring solutions is epoxy flake floor systems. This type of flooring combines durability and design flexibility, making it a favorite among many homeowners and business owners. With a wide range of colors and patterns available, epoxy flake flooring can be customized to fit any space, providing a unique look that stands out.

For those seeking a brilliant shine, epoxy shine finishes can elevate your flooring game. These finishes not only provide a glossy look but also protect the flooring from wear and tear. Utilizing a performing solution like epoxy ensures that your floors can handle heavy foot traffic while maintaining their stunning appearance.

Epoxy Flake Floor

When it comes to durable and aesthetically pleasing flooring options, epoxy flake floors stand out as a superior choice. These floors are crafted using an epoxy resin mixed with decorative flakes, resulting in a unique finish that is both functional and visually appealing. The versatility of this flooring solution allows it to be used in various settings, from residential garages to commercial spaces.

The main advantage of epoxy flake floors is their resistance to impacts, chemicals, and stains, making them ideal for high-traffic areas. Their seamless nature prevents dirt and grime accumulation, offering a low-maintenance solution that is easy to clean. Furthermore, the aesthetic flexibility of the colored flakes lets homeowners and business owners customize their floors to match existing designs and personal preferences.

In addition to their durability and style, epoxy flake floors also contribute to improved safety. The texture of the flakes can enhance slip resistance, making them a practical choice for spaces where moisture is common. Whether you're looking to upgrade your garage or create a modern showroom, epoxy flake flooring provides an excellent combination of beauty, resilience, and safety.

510 notes

·

View notes

Note

Even with how technland decided to treat dl2, are you going to continue drawing art and doing little merch for dl2? I enjoy your art so much. I'm still hoping deep inside that techland just did an ultimate prank and will include aiden and everyone else in the story of the new game!!!

Yeah! I’m just pissed + busy rn but I will do more stuff, if not for the fandom then for the spite. They’ll see there is love for the game and I won’t let them forget about our characters. In fact I am preparing a new giveaway bundle which is going to include some of the following:

-DL animal epoxy glitter stickers (16 chars)

-holographic metallic postcard set of 2

-Hakon Aiden tsum tsum (the pic is the old batch I have a new design coming)

-10cm mini plush

-ripple surface mermaid acrylic keychain

-character dress up magnet with outfits and misc

-DL2 UI themed sticky note

-Adjustable clear cover notebook

-beer resin charms (which I don’t have a pic yet I submitted the order too late)

And 3 more items yet in the works. I will get everything done possibly by the end of next month, we’ll see then. So keep an interesting for whoever like to be able to acquire everything :33

#dying light#dying light 2#aiden caldwell#dying light hakon#🐙 dl art#i didn’t feel like tagging every character but nearly every character is here#sorry things are slow I’ve been really busy and sad lately#also for those who got the gift box of last year all items are different!!! they are entirely new merch designed this year#there will also be more stuff I promise but since it’s not done I won’t reveal it but I’ll give you a sneak peek if you message

24 notes

·

View notes

Text

The metal work on the 1965 Mini Cooper S is nearing completion, carried out on a Celette frame machine. The final tasks involve crafting a new drip rail, as well as preparing and applying epoxy primer to the exposed metal surfaces.

#celette#celettebench#framemachine#cars#car#accident repair#collision repair#collision tech#automotive#automobile#mini#vintage car#vintage cars#old cars#classic car#oldtimer#frame rack#mini cooper

23 notes

·

View notes

Text

More dye adventures with Zonda Journey, Zephyr Slip alt deco

Okay, this is going to be a bit text heavy and process oriented, and there's no snazzy new design to show off, just sharing my process a bit as it develops.

April wanted her copy of Zephyr Slip in custom colors, so following Transformers redeco tradition, Zephyr now has a sister, Zonda Journey. (The Zonda is a wind from the mountains in Argentina, though far to the west of the locale where Austroraptor was discovered.)

The build was a mixed success but a learning experience in my pursuit of a dying process that results in uniform, predictable, and durable color.

Aside from a more stable kickstand, Zonda's design didn't change much from Zephyr's. For ease of dying and painting, the scooter floor, wing insets, and nasal / maxilla area were all separate pieces this time and glued into place with two-part epoxy, but not much else has changed in the model.

The build does differ from Zephyr Slip in that several of Zonda's joints use clear polyurethane rods in place of ABS ones, most importantly in the feet and tail. These have to be threaded into place and cut, but they're compliant, so while posing is a little spongy, they support more weight with more stability and absorb some shock, making the figure less likely to tip over from bumping the shelf.

But back to the dyes. Details like the inside of Zonda's headlights and taillights, and her claw emblem, pinstripes, face details, and rims are painted, and as usual she has paper decals for her eyes and console. But the bulk of her color, everything magenta, purple, or black, is dyed. I'm going to work through those in reverse order here, black, purple, magenta.

Some of the black parts were printed in stock black resin, like the wheels, but I've had difficulty with failed prints using it, and elements like the black sections of the tail and head where I've used white resin and dyed it black end up with a uniform, more satin finish, so I think that I'm going to prefer that method from now on.

Using black ink for brushed-in details like the shoe treads works, but it's risky, because the ink can sometimes find the grain of the printed surface and wick away where I don't want it. Anywhere I intend to do this on future models will require a deep trench in the model to capture the ink, similar to the grooves used for Zonda's pinstriping seen on the part above.

Zonda's darker purple elements could have been more uniform with a couple more tries. Brushing the ink on with any color but black leaves a patchy, cloudy surface, and dying in a bath requires far too much ink. Workbenchmaniac suggested using an airbrush to apply the ink, and that seems to work very well, with a lot less waste than a bath and much more uniform results than brushing, so with a bit more practice, that might be my go-to method for dying parts, especially with a layer of clearcoat on top as here.

Zonda's magenta parts were simply printed in color, but I ran into a novel problem right away that I didn't solve at all: she was never intended to be magenta in the first place. The dyed liquid resin was lavender.

I already knew from working on Nova that dying liquid resin would really only work for pastel colors, and that the color after curing wouldn't quite match the liquid form. Nova's pink was also a little less punchy and fluorescent after printing. But I wasn't prepared for the wild swing around the color wheel this dye underwent with printing and curing.

I've read that alcohol dyes are ironically susceptible to UV photodegradation, but I'm not convinced that's what's at work here. In fact, all of Zonda's headlights and taillights have clear UV resin poured in and cured in place after painting, which means that areas of both the magenta and the surface-dyed purple have been exposed to much longer UV blasting with no visible effect.

So I've learned some things from this process. I think the most reliable tools in my kit in relation to dye are brushed black dye and airbrushed everything else. Airbrushing gives me bright and predictable colors, and with practice I can make them pretty uniform. Black dye, which is always uniform and can go over any other color, is a handy tool for detailing as long as the model is prepared with grooves to control the spread. And breaking elements down into parts that can be dyed separately continues to be a reliable and useful step that saves much more workbench time than it takes in Blender time.

As for Zonda Journey, I have a lot of things to improve on for next time, but I'm reasonably happy with the result for now, and April is happy with her, which is what counts.

7 notes

·

View notes

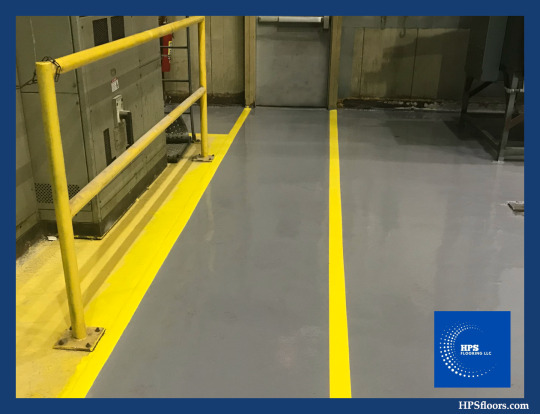

Text

Hand-grinding hard-to-reach areas is a vital step in the epoxy flooring preparation process. It ensures that these areas are properly prepared, free of contaminants, and have the necessary surface texture for the epoxy to adhere effectively. This meticulous attention to detail helps prevent future adhesion problems, enhances the durability and longevity of the flooring, and ensures a high-quality, professional finish.

#flooringcontractors#CommercialFlooring#floorcoating#EpoxyFlooring#epoxyfloorcoating#IndustrialFlooring#FlooringSolutions#FlooringExperts#epoxycoating#tbt#epoxy flooring#epoxy floor#facilitymaintenance#epoxy flooring contractors#epoxy flooring contractors nj#commercial flooring#epoxy floor contractors

3 notes

·

View notes

Text

youtube

In this video, I’ll guide you through creating a stunning diorama of a meteor impact on the moon’s surface. This detailed tutorial covers every step, from preparing the base to crafting the crater and embedding the meteor for a realistic effect. Using materials like epoxy resin, plexiglass, silicone mold-making rubber, and resin pigments, you’ll learn how to bring this cosmic scene to life.

#jedrek29t#resinart#epoxyresin#resin#epoxy#tutorial#diy#howto#making#craft#impact#meteor#diorama#lamp#nightlamp#fire#Youtube

6 notes

·

View notes

Text

"Manufacturing Processes Used by Mild Steel Dowel Bars Manufacturers in Sweden"

INTRODUCTION

Mild steel dowel bars are indispensable in the construction industry, especially for enhancing the durability and stability of concrete structures. Known for their exceptional strength and adaptability, these bars play a crucial role in ensuring efficient load transfer across joints in pavements, slabs, and other structural applications. This article explores the intricate manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden, focusing on precision, quality, and innovation.

1. Raw Material Selection

The manufacturing process begins with selecting high-quality mild steel, known for its optimal balance of strength and ductility. Manufacturers in Sweden adhere to stringent quality standards to ensure that the raw material meets the requirements for construction-grade dowel bars.

2. Cutting and Sizing

Once the raw mild steel is procured, it is cut into specific lengths based on the application requirements. Precision cutting ensures uniformity, which is essential for effective load transfer and durability in concrete structures. Advanced cutting tools, including laser and hydraulic cutters, are often used to achieve accuracy.

3. Surface Preparation

Surface preparation is a vital step in the manufacturing process. The steel is cleaned to remove impurities, such as rust, grease, or mill scale, that may affect its bonding with concrete or its durability. Abrasive blasting or chemical treatments are commonly used for thorough cleaning.

4. Heat Treatment for Strength Enhancement

To enhance the mechanical properties of mild steel, manufacturers employ heat treatment techniques. This process improves the tensile strength and resilience of the bars, making them suitable for high-stress applications. Controlled heating and cooling cycles ensure uniformity and consistent quality.

5. Corrosion-Resistance Coating

Mild steel is susceptible to corrosion, especially in harsh weather conditions or when exposed to moisture. To mitigate this, manufacturers in Sweden apply protective coatings, such as epoxy or galvanization. These coatings not only extend the lifespan of the dowel bars but also ensure compliance with environmental and safety standards.

6. Straightening and Finishing

After heat treatment and coating, the bars are straightened to ensure they meet precise alignment specifications. Advanced machinery is used for this step, eliminating any deformations and achieving a smooth, uniform surface.

7. Quality Inspection and Testing

Quality assurance is a cornerstone of the manufacturing process. Mild Steel Dowel Bars Manufacturers in Sweden conduct rigorous testing to ensure that the bars meet international construction standards. Key tests include tensile strength analysis, corrosion resistance evaluation, and dimensional accuracy checks.

8. Packaging and Distribution

Once the dowel bars pass all quality checks, they are packaged using materials that protect them during transportation and storage. Proper labeling and documentation ensure that the bars reach their destination with traceability and compliance intact.

Advantages of Swedish Manufacturing Processes

Precision Engineering: Swedish manufacturers utilize advanced machinery and technology to achieve unmatched precision in dowel bar production.

Sustainability Practices: The focus on eco-friendly methods, such as recycling and reducing waste, aligns with Sweden's commitment to sustainability.

Compliance with Global Standards: By adhering to stringent international construction norms, Swedish manufacturers ensure that their products are recognized worldwide for quality and reliability.

Conclusion

The meticulous manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden highlight their dedication to quality and innovation. From raw material selection to final packaging, each step ensures that the dowel bars are robust, durable, and suited for a wide range of construction applications. These processes set a benchmark for the global industry, making Sweden a leader in the production of high-quality mild steel dowel bars.

3 notes

·

View notes

Text

Warehouse Epoxy Flooring: Durable, Safe, and Efficient

When it comes to maintaining a warehouse, the flooring is often an overlooked yet crucial aspect of the facility's infrastructure. The floor must withstand heavy loads, constant foot traffic, and machinery movement while ensuring safety and efficiency. Epoxy flooring is a top choice for warehouses.

What is Epoxy Flooring?

Epoxy flooring is a surface coating created by mixing resin and hardener, forming a durable, seamless layer. This coating bonds exceptionally well to concrete floors, providing an even, resilient surface. The result is a floor that can endure the demanding environment of a warehouse while offering a professional appearance.

Why Choose Epoxy Flooring for Warehouses?

Durability: Warehouses experience high-impact activities, from forklifts carrying heavy loads to constant foot traffic. Epoxy flooring is highly resistant to abrasions, and impacts making it ideal for such environments. Its durability reduces the need for frequent repairs, saving time and costs.

Safety First: Epoxy flooring offers slip-resistant options that can be customized with visible markings for pathways, loading zones, and hazardous areas, improving navigation and reducing accidents.

Easy Maintenance: The seamless nature of epoxy floors makes cleaning and maintenance a breeze. Unlike traditional flooring, there are no cracks or crevices for dirt and debris to accumulate, ensuring a cleaner workspace with minimal effort.

Chemical Resistance: Many warehouses deal with chemicals or materials that can damage conventional flooring. Epoxy floors resist chemical spills, preventing stains and maintaining the floor’s integrity over time.

Cost-Effective: While the upfront cost of epoxy flooring may be higher than some alternatives, its longevity and minimal maintenance requirements make it a cost-effective investment for any warehouse.

Customization Options for Warehouse Needs

Epoxy flooring can be tailored to meet the specific needs of your warehouse. From anti-slip coatings to high-gloss finishes for better lighting, the options are vast. Additionally, color coding and line markings can help organize workflows and improve safety.

Installation and Maintenance

Professional installation is critical for ensuring the longevity of epoxy flooring. The process involves surface preparation, which may include cleaning, repairing cracks, and applying a primer. Once the epoxy is applied, it cures to form a hard, durable surface.

Regular maintenance involves simple sweeping and occasional mopping with mild detergents. For warehouses dealing with heavy traffic or chemical spills, periodic inspections can help ensure the floor remains in excellent condition.

#epoxyflooring#sherwinwilliams#warehousefloorpainting#epoxy floor contractor nj#epoxy flooring#epoxy warehouse flooring#epoxy contractor nj#warehouse floor painting#warehouse epoxy floor#chemical resistant floor#commercial flooring

3 notes

·

View notes

Text

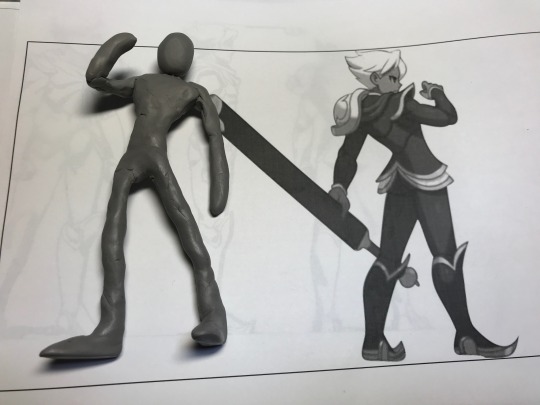

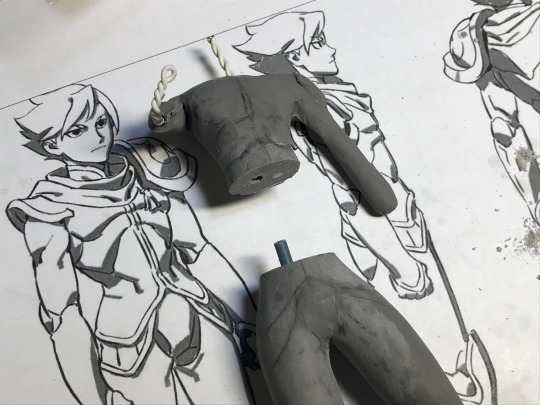

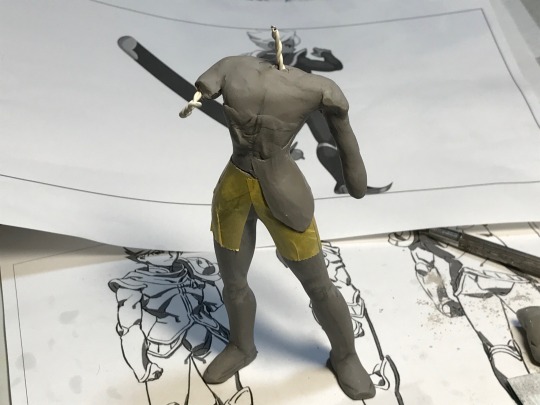

DHAR/indivisible #1

When I asked if there was anything my family wanted for their birthdays, they requested figurines of characters that they don't sell and don't think will ever come out.

So, I'm going to make a figure of the character "DHAR" from the game Indivisible.

When I first made my own figures about 10 years ago, I tried using fund and putty, but this time I decided to try using something called Sculpey, which I had been interested in for a while. Simply put, it is clay that can be baked in an oven.

I'm a complete beginner when it comes to figure making, so I'll just follow what I see on the internet. It looks like the core is made of wire, so I prepared the wire I had at home.

Since there are no detailed settings for the character, I decided to make him about 180cm tall, so if he was made into a 1/12 scale, he would be about 15cm, so I decided to make him around 15cm. Sculpey seems to bite better if the wire is twisted.

Add Sculpey to the wire that will become the core by posing it in a similar pose.

Once it had taken some shape, I baked it in the oven. Because Sculpey was surprisingly soft, when I was making the shape of the legs, the shape of the body part I was holding would be distorted, and my nails would hit it and make a dent, so I had to adjust the shape to a certain extent for each part I was working on. It seems better to bake it frequently when it becomes hard.

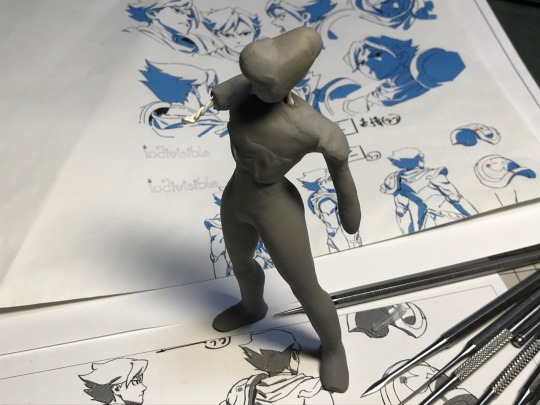

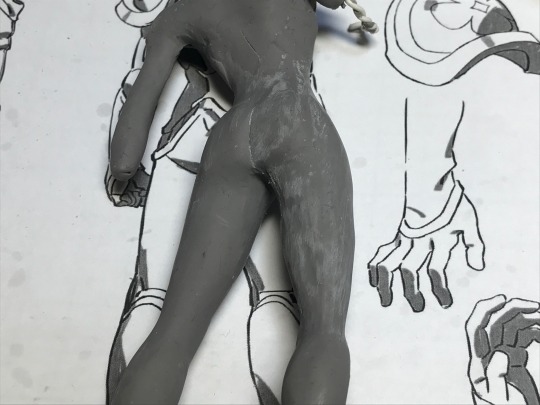

First, I finished the area from my waist to my knees.

I tried baking it in this state, applying sandpaper, and seeing if I could carve the streaks. It seemed like I could carve the sujibori with the chisel I always use without any problems. When you put sandpaper on it, it feels like epoxy putty, and even though it's hardened, it's a little sticky, and the sandpaper gets clogged quickly. No matter how smooth you intend to smooth it, you will notice that the surface is undulating when you sand it.

I split it around the waist and hit a 3mm shaft. From here, we will continue with surface processing and modeling for the lower body.

Once the lower body is adjusted to a certain extent, protect the lower body with masking tape and add additional parts to the upper body.

I will make time and progress little by little.

Well then.

to be continued.

Please support us in producing the kit.

・Patreon patreon.com/SMC9999

・Buy Me A Coffee https://www.buymeacoffee.com/smc9999

・Ko-fi https://ko-fi.com/smc9999

5 notes

·

View notes

Text

Acid Etching vs Mechanical Cleaning of Concrete

Acid etching is a common method for preparing concrete surfaces, but whether it is “okay” depends on the specific application and the level of surface preparation required. Below is a detailed comparison of acid etching vs. mechanical methods (sanding or grinding). Acid Etching for Surface Preparation How it Works: Acid etching uses diluted acids (typically muriatic or phosphoric acid) to…

#acid etching#acid etching vs mechanical cleaning concrete#concrete floor coating#concrete surface preparation#Epoxy#epoxy installation#epoxy novolac concrete surface preparation#epoxy resin#epoxy surface preparation#epoxy systems#mechanical cleaning

0 notes

Text

Flooring Installation Service in Skiatook | ATF Oklahoma

When it comes to enhancing the beauty and functionality of your home or business, the right flooring can make all the difference. If you're in Skiatook, Oklahoma, and looking for top-notch flooring installation services, ATF Oklahoma offers comprehensive solutions to meet your needs. From coating floors to concrete polishing and surface preparation, here’s how professional services can transform your space.

Coating Floor in Skiatook

Floor coating is a popular choice for both residential and commercial properties in Skiatook. Coating your floor not only improves its appearance but also adds a layer of protection against wear and tear. Whether you’re looking to coat your garage floor, basement, or commercial space, ATF Oklahoma provides high-quality floor coating services that ensure durability and easy maintenance. The benefits of floor coating include:

Enhanced Durability: Coated floors are more resistant to damage from heavy foot traffic, spills, and impacts.

Aesthetic Appeal: With various colors and finishes available, floor coatings can significantly improve the look of your space.

Easy Maintenance: Coated floors are easier to clean and maintain, making them ideal for busy areas.

Concrete Polishing in Skiatook

Concrete Polishing in Skiatook is an excellent way to upgrade the look and feel of your concrete floors. This process involves grinding down the surface to achieve a smooth, shiny finish. Polished concrete floors are not only visually appealing but also extremely durable and low-maintenance. ATF Oklahoma specializes in concrete polishing in Skiatook, providing a sleek and modern flooring solution that’s perfect for both homes and businesses. Key advantages of concrete polishing include:

Longevity: Polished concrete floors are highly durable and can last for many years with minimal maintenance.

Eco-Friendly: Polishing concrete is an environmentally friendly option as it makes use of existing materials without the need for additional coverings.

Cost-Effective: Compared to other flooring options, polished concrete is a cost-effective solution that offers excellent value for money.

Surface Preparation in Skiatook

Proper surface preparation is crucial for the success of any flooring installation. This process ensures that the surface is clean, smooth, and ready for the new flooring material. ATF Oklahoma offers comprehensive surface preparation services in Skiatook, including cleaning, leveling, and repairing any imperfections. By ensuring a well-prepared surface, you can achieve a flawless finish and extend the lifespan of your new floor.

Floor Coating in Skiatook

Floor coating services are essential for protecting and beautifying your floors. ATF Oklahoma provides expert floor coating in Skiatook, using high-quality materials and techniques to deliver exceptional results. Whether you need an epoxy coating for your garage or a decorative coating for your living room, their team has the expertise to handle it all. Floor coatings offer several benefits, such as:

Protection: Coatings protect against stains, scratches, and other forms of damage.

Customization: With a wide range of colors and finishes, you can customize your floor to match your style and preferences.

Improved Safety: Some coatings offer slip-resistant properties, making your floors safer for everyone.

Flooring Design Consultant in Shawnee

For those in Shawnee, Oklahoma, looking to design their dream floors, a flooring design consultant can provide invaluable assistance. A consultant can help you choose the right materials, colors, and finishes to achieve the look you desire. ATF Oklahoma offers expert advice and guidance to ensure your flooring project meets your aesthetic and functional goals.

Conclusion

Whether you need floor coating, concrete polishing, surface preparation, or design consultation, ATF Oklahoma provides top-quality Flooring Installation Services in Skiatook and Shawnee, Oklahoma. Their experienced team is dedicated to delivering outstanding results that enhance the beauty and durability of your floors. Contact them today to start your flooring project and transform your space with professional expertise and care.

#Flooring Design Consultant in Skiatook#Flooring Installation Service in Skiatook#Demolition of All Flooring in Skiatook#Coating Floor in Skiatook#Concrete Polishing in Skiatook#Surface Preparation in Skiatook#Floor Coating in Skiatook#Epoxy Concrete Floor in Skiatook#Epoxy Flooring Types in Skiatook#Epoxy Floor Service in Skiatook#Epoxy Floor Installation in Skiatook#Epoxy Floor for Kitchen in Skiatook#Epoxy Floor Contractor in Skiatook#Epoxy Finish Floors in Skiatook#Epoxy Coated Flooring in Skiatook#Concrete Epoxy Floor in Skiatook#Commercial Flooring for Kitchen in Skiatook#Polished Concrete Floors Cost in Skiatook#Commercial Epoxy in Skiatook#Residential Polished Concrete Floors in Skiatook#Epoxy Flooring Contractors in Skiatook#Flooring Contractor in Skiatook#Industrial Flooring for Kitchen in Skiatook#Industrial Flooring in Skiatook#Commercial Flooring in Skiatook#Flooring Contractors in Skiatook#Flooring Installation Contractors in Skiatook#Commercial Flooring Contractors in Skiatook#Epoxy Kitchen Floor Residential in Skiatook#Residential Flooring in Skiatook

0 notes

Text

EPOXYSHİNE - DRAGON+ (3)

Epoxy floor coating is not just a practical choice for enhancing the durability of your flooring; it's also a stylish solution that can transform any space. Whether you're a homeowner looking to revamp your garage or a business owner seeking reliable commercial flooring solutions, understanding the benefits of epoxy will help you make informed decisions. As you search for "floor polishing near me," consider how an expertly applied epoxy coating can elevate your interiors while providing a long-lasting finish.

Epoxy Floor Coating

Epoxy floor coating is a highly durable and resilient flooring solution that has gained popularity in both residential and commercial spaces. This type of coating is made from a combination of resin and hardener, creating a strong bond when applied to existing concrete surfaces. The result is a seamless surface that can withstand heavy foot traffic, chemicals, and abrasions.

One of the major benefits of epoxy floor coating is its versatility. It can be customized in various colors and finishes, including high-gloss and matte textures. This means that property owners can choose a look that complements their interior design while still providing the durability they require. Additionally, the smooth finish of epoxy makes it easy to clean and maintain, which is particularly advantageous in commercial settings.

Furthermore, the installation process for epoxy floor coating is relatively quick, often completed within a few days. However, it’s essential to hire professionals who have the expertise and equipment to ensure a flawless application. The right team will properly prepare the surface, allowing for optimal adhesion and longevity of the coating.

Floor Polishing Near Me

When searching for floor polishing near me, it's essential to find a service that not only meets your expectations but also understands the unique needs of your flooring. Professional floor polishing can revitalize old surfaces, restoring their shine and luster while protecting them from future wear and tear.

Many local companies offer specialized services in floor polishing that cater to various materials, including hardwood, tile, and concrete. A quick search in your area will yield numerous options, allowing you to compare prices, services, and customer reviews to find the best fit for your needs.

Additionally, hiring professionals for floor polishing ensures that the job is done correctly and efficiently. They use advanced equipment and high-quality products that not only enhance the appearance of your floors but also extend their lifespan. So, don't hesitate to reac

Commercial Flooring Solutions

Commercial flooring solutions are essential for businesses seeking to enhance their aesthetic appeal while also ensuring durability and functionality. The choice of flooring can greatly influence the overall atmosphere of a commercial space, leading to improved employee morale and customer satisfaction.

Among the various options available, epoxy floor coatings stand out due to their seamless finish and resistance to heavy foot traffic. These coatings not only provide a sleek look but also protect the underlying surface from wear and tear, making them ideal for warehouses, retail spaces, and industrial environments.

Moreover, businesses often explore additional options such as vinyl flooring, carpet tiles, and laminate surfaces to meet specific needs. Each of these materials offers unique advantages, allowing business owners to choose the most suitable flooring solution that aligns with their operational demands and aesthetic preferences.

Metallic Epoxy Floor

A metallic epoxy floor offers a stunning visual appeal that enhances the aesthetic of any space. The reflective properties of the metallic pigments create a unique look, resulting in a three-dimensional effect that can mimic a variety of surfaces, such as water, marble, or even molten metal. This type of flooring is especially popular in modern homes, showrooms, and commercial spaces, providing an eye-catching yet durable surface.

One of the significant advantages of a metallic epoxy floor is its durability. This flooring solution is resistant to stains, chemicals, and impacts, making it ideal for high-traffic areas. Additionally, it is easy to clean and maintain, which means that business owners and homeowners can save time and resources. The seamless nature of epoxy flooring also contributes to a hygienic environment, especially in spaces like hospitals or laboratories.

Installing a metallic epoxy floor can be a customized process, allowing property owners to choose their preferred colors and patterns. Whether you’re looking for a sleek, industrial look or a vibrant, artistic finish, this flooring solution can be tailored to meet your unique vision. By consulting with professionals, you can ensure that your metallic epoxy floor is installed correctly and maximizes its longevity and beauty.

598 notes

·

View notes

Text

Epoxy Floors in Oklahoma City: The Ultimate Flooring Solution

When it comes to durable, attractive, and long-lasting flooring options, epoxy floors in Oklahoma City are gaining popularity. Whether you're a homeowner looking to upgrade your garage or a business owner seeking a practical and aesthetically pleasing solution for your commercial space, epoxy flooring is a versatile choice that offers numerous benefits.

Epoxy Flooring Basics

Epoxy flooring is a type of surface coating that combines resin and hardener to create a strong, seamless, and highly resilient floor. It's a popular choice in various settings, from industrial facilities and warehouses to retail stores and homes. In Oklahoma City, epoxy floors are appreciated for their ability to withstand the city's variable weather conditions and heavy foot traffic.

Advantages of Epoxy Floors

Durability: Epoxy flooring is incredibly durable and can handle heavy loads without cracking or chipping. It can withstand the weight of vehicles, making it an ideal choice for garages and auto shops.

Easy Maintenance: Epoxy floors are effortless to clean and maintain. They are resistant to stains, chemicals, and moisture, making them perfect for areas prone to spills and accidents.

Aesthetically Pleasing: Epoxy floors are available in a wide range of colors and patterns, allowing you to customize your flooring to match your style and space. They can also be enhanced with decorative elements like flakes, metallic pigments, or quartz.

Longevity: When properly installed and maintained, epoxy floors can last for many years, making them a cost-effective investment.

Safety: Epoxy floors can be customized to include anti-slip additives, making them safer for areas where slip and fall accidents are a concern.

Applications of Epoxy Flooring in Oklahoma City

Residential Garages: Many homeowners in Oklahoma City are choosing epoxy flooring for their garages. It not only enhances the appearance of the space but also protects the concrete underneath from oil, grease, and other stains.

Commercial and Industrial Spaces: Epoxy flooring is a popular choice for commercial and industrial spaces in Oklahoma City. It can withstand heavy machinery, high foot traffic, and chemical exposure, making it suitable for manufacturing facilities, warehouses, and factories.

Retail Stores: Retailers appreciate the clean and polished look of epoxy floors, which can elevate the ambiance of their stores. The customizable design options allow for branding elements to be incorporated into the flooring.

Restaurants and Bars: Epoxy flooring's resistance to spills and easy cleaning make it a practical choice for the food and beverage industry. It also offers an opportunity for creative designs to enhance the dining experience.

Installation Process

Professional installation is crucial to achieving the full benefits of epoxy flooring. The process typically involves the following steps:

Surface Preparation: The existing concrete floor is thoroughly cleaned and prepared, which may include repairing cracks and imperfections.

Primer Application: A primer is applied to ensure proper adhesion between the epoxy coating and the concrete surface.

Epoxy Coating Application: The epoxy mixture is applied to the prepared surface, and it can be customized with various colors and patterns.

Additional Design Elements: If desired, decorative elements like flakes, metallic pigments, or quartz can be added during the epoxy application.

Topcoat Application: A clear topcoat is applied to provide additional protection and enhance the floor's shine.

Conclusion

Epoxy flooring installation offer a durable, attractive, and low-maintenance flooring solution for residential, commercial, and industrial spaces. With their customizable design options, resistance to stains and chemicals, and long lifespan, epoxy floors have become a top choice for those seeking a practical and aesthetically pleasing flooring solution in the vibrant city of Oklahoma. Whether you want to upgrade your garage or enhance your commercial space, epoxy flooring is a versatile option that can meet your needs and exceed your expectations.

https://mtcustomconcrete.com/epoxy/

2 notes

·

View notes

Text

Concrete Floor Coatings Near Me: Valence Coatings

If you're searching for high-quality concrete floor coatings near me, look no further than Valence Coatings—your trusted partner in durable, stylish, and protective flooring solutions. Whether you’re upgrading a residential garage, commercial workspace, or industrial facility, Valence Coatings delivers top-tier performance with aesthetic appeal.

Why Choose Concrete Floor Coatings?

Concrete is a tough material, but it’s not indestructible. Over time, it can suffer from:

Cracks and surface deterioration

Oil and chemical stains

Moisture damage

Abrasion from foot and vehicle traffic

Concrete floor coatings provide a resilient layer that extends the life of your floor, enhances safety, and offers a visually pleasing finish.

Valence Coatings: Your Local Experts

As a leading name in the industry, Valence Coatings specializes in advanced coating systems that are designed for longevity and performance. What sets them apart?

1. Tailored Solutions for Every Need

Valence Coatings offers a wide range of options including:

Epoxy floor coatings

Polyaspartic and polyurethane systems

Decorative flakes and metallic finishes

Slip-resistant and UV-stable coatings

Whether you're looking for a showroom-quality finish or heavy-duty protection, they’ll tailor the system to your specific environment.

2. Local Service, Trusted Results

Searching concrete floor coatings near me often leads to mixed results—but Valence Coatings stands out with local service teams that are responsive, experienced, and dedicated to quality. From consultation to completion, they work closely with you to ensure satisfaction.

3. Expert Installation Process

Proper preparation is key. Valence Coatings uses advanced techniques to grind, clean, and prime the concrete surface before applying the coating. Their multi-step installation ensures optimal adhesion and performance, minimizing future maintenance.

4. Durability Meets Design

Their coatings don’t just protect—they also enhance. Choose from a wide range of colors, textures, and finishes to match your brand, design aesthetic, or personal taste.

Ideal Applications

Valence Coatings is perfect for:

Garages and driveways

Basements

Warehouses and factories

Retail stores and showrooms

Restaurants and commercial kitchens

No matter the space, Valence Coatings provides a solution that adds value and long-term protection.

Ready to Upgrade Your Floors?

Stop searching for “concrete floor coatings near me” and trust the proven expertise of Valence Coatings. Their professional-grade products and commitment to excellence ensure your floor stands the test of time—with style.

Contact Valence Coatings today for a free consultation and see how they can transform your concrete surfaces into durable, beautiful floors built to last.

0 notes