#Winder Machine Price

Text

<3 to watch professional tailoring videos -- I may or may not get an answer to my sewing question, but I'm guaranteed to discover many little machines, tools, and haberdashery items that immediately seem essential to my continued success as a seamstress.

#TIL I learned that there are bobbin winders that just sit there on the table#ie are not part of your sewing machine & do not require you to unthread the machine to wind a bobbin#now I must acquire one#fortunately they seem to be reasonably priced#unlike my tailor's board which was the last item thrust upon my consciousness by a tailoring video#that thing was like £60#although I must concede that it is extremely useful & has massively improved my collars

27 notes

·

View notes

Text

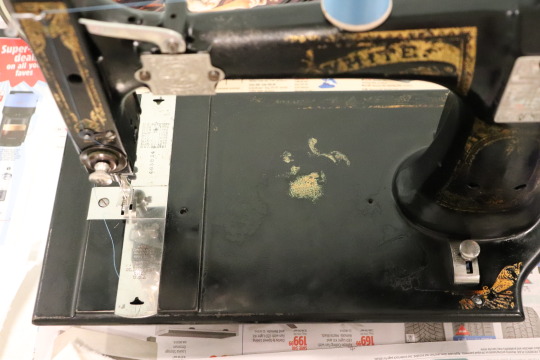

@once-a-polecat replied to your post “My uncle's friend asked if I wanted this machine...”:

So do Whites have the same parts availability as Singers? I see them around for a fraction of the price, I’ve just been holding out for a Singer because the parts are relatively easy to source. I’ve seen some really lovely White machines tho! I bet yours is going to look stunning when it’s cleaned up. That cabinet is {chefs kiss}

I don't know, I haven't looked into it because mine's not missing any pieces and still has all 6 bobbins.

I think that as long as you can verify that it has all the parts, and at least one or two bobbins, it probably won't need any new ones.. ever? The little rubber ring on the bobbin winder and the treadle drive belt degrade after a few decades and need replacing, but you can easily buy those, and everything else is highly unlikely to break from regular use.

The one thing I was worried about was accidentally stripping the screws while taking it apart for cleaning, and there was one screw that I didn't quite have the right size of screwdriver for and it started to look a bit ehhhh so I just didn't take that part off. It wasn't one of the really gunky ones anyways, and I did my best to clean around it, and may try again someday if I get more sizes of screwdriver.

So I'd advise making sure you have all the right tools before starting and slathering all the stuck bits well in kroil (what the guy in a video I watched yesterday used) or wd-40 (what I used) or some such loosening thing.

It seems like it's very hard to find new bobbins, especially since there are different styles of shuttle and the bobbins are not interchangeable. Mine's a boat style and my bobbins wouldn't work in a bullet style from a couple years later.

While cleaning this thing it hasn't even crossed my mind to wonder where I'd find replacement parts because, well, what could possibly break?

Nearly every single piece is cast iron or steel, and it's already been used SO much that the decals on the bottom are almost completely gone just from the amount of fabric that's run over it.

As mentioned in the previous post it's about 140 years old, was owned by a woman who made her living sewing on it for many decades, and it still works just fine!

I haven't got the bobbin winder cleaned up yet and it's still off the cabinet, but I couldn't resist trying it out with just the hand wheel (using one of the bobbins that was wound long before I was born) once I got all the bits back on and yeah! Perfect stitches right away!

As long as it's kept well oiled it's just gonna keep on chugging along indefinitely.

Are you seeing these White machines in person at secondhand stores and such? If you can check to make sure they have bobbins and that no pieces are missing, I'd say grab one!

Maybe keep some reference pics of working ones so you can look and see, or even better see if you can make a stitch with it before buying it, and presumably if it can do that even slowly and gunkily then it'll just need cleaning like this one did.

By all accounts they're REALLY good machines! I'm super excited to try mine out properly, and to post more about all the features.

It has a lip around the bottom of the needle bar so that if some oil drips down it won't get on your needle! Genius!! Why doesn't every machine ever have that?!

It's also fairly quiet AND you can adjust the bobbin tension right in the middle of a seam without disturbing the sewing or taking the shuttle out. Incredible.

The manual for mine says "The Best in the World" on it, and while that's just a normal Victorian thing to say about a product, I'm not about to argue with them. There are a few little things that I like better on Singers, such as the quality of the hinges that hold the machine to the cabinet, and the way the presser foot attaches, but all in all this White VSII is extremely goddamn good so far and I have no doubt that once I get the bobbin winder cleaned up it'll also work perfectly!

So yeah, GET ONE!

254 notes

·

View notes

Text

This is the sewing machine I need in order to use my Cutie quilting frame. It's on sale for $879, and is normally $1049. It has the original price on my Throne list, which is irritating, but if anyone wants a quilt valued at $879 or less, please purchase this for me while it's on sale.

The quilt can be something listed in my shop or a custom piece!

This machine will make it possible for me to turn my quilt tops into finished quilts. It will also save my hands and make it easier for them to heal.

Here's my Throne list:

Here's my work:

6 notes

·

View notes

Text

Manufacturer of Exporter Metal Expander Roller Standard Quality at Best Price – CON-PAP-TEX

We are a “CON-PAP-TEX” manufacturer and exporter of metal Expander Roll Metal Expander Roller Manufacturer is most suitable in high-speed pulp & paper & Textile Applications it is also known as Wrinkle Removers, Bow Rollers & Banana Rollers. Metal expander roll has a hard Chrome surface which is suitable for high-speed and high-tension applications for paper industries, particularly for slitter re-winder, Calendars, Poop Reels, and M.G cylinders. On high-speed machines, it does not wear & tear so it is commonly used in place of Rubber Bow Roll. Metal Bow Roll with individual Rotating Segments. Carbon Steel Designed Bow Rollers. For more information:

Website: conpaptex.co.uk

Email id: [email protected]

Mobile No: +91-7940085305

#Metal Expander Roller Manufacturer#Metal Expander Roller#Metal Expander Rollers#Metal Expander Roll

2 notes

·

View notes

Text

Top Factors Influencing Wooden Watch Box Prices in Pakistan

Introduction

In the realm of luxury and practicality, wooden watch boxes stand out as a quintessential accessory for watch enthusiasts. These elegant storage solutions not only keep timepieces organized but also enhance their presentation. However, the price of Wooden Watch Boxes In Pakistan can vary significantly based on several factors. This article delves into the key factors influencing these prices and offers insights into finding the perfect wooden watch box that suits both your style and budget.

1. Material Quality

The quality of the wood used in crafting a watch box plays a pivotal role in determining its price. High-quality, solid wood such as mahogany, walnut, or oak typically costs more than plywood or cheaper alternatives. Premium woods are favored for their durability, rich grain, and sophisticated appearance. For instance, a wooden watch box made from solid mahogany will generally be more expensive than one crafted from lesser-grade wood.

Key Considerations:

Type of Wood: Exotic or premium woods drive up the price.

Finish and Treatment: High-quality finishes and treatments enhance the wood's appearance and longevity but can also increase the cost.

2. Craftsmanship and Design

The level of craftsmanship involved in making a wooden watch box is another significant factor affecting its price. Intricate designs, detailed carvings, and complex joinery require skilled artisans and additional time, thus raising the cost. Handcrafted wooden watch boxes, which showcase exceptional craftsmanship and unique designs, often come at a premium compared to machine-made counterparts.

Key Considerations:

Handcrafted vs. Machine-Made: Handcrafted boxes generally cost more due to the artistry and effort involved.

Design Complexity: More elaborate designs and customizations can increase the price.

3. Size and Capacity

The size and capacity of a wooden watch box directly impact its price. Boxes with larger capacities, which can hold multiple watches, are usually more expensive. A wooden watch box with a higher number of partitions or additional features like a glass lid or drawer will cost more than a simpler design.

Key Considerations:

Number of Partitions: More partitions mean higher costs.

Size Dimensions: Larger boxes will generally be more expensive due to the increased material and labor involved.

4. Interior Lining and Features

The interior lining and additional features of a wooden watch box also influence its price. High-quality linings made from materials such as velvet, leather, or suede add to the overall cost. Features like built-in winders, compartments for other accessories, and customization options also contribute to the price.

Key Considerations:

Type of Lining: Premium linings add to the cost.

Additional Features: Extra features like winders or compartments can increase the price.

5. Brand and Origin

The brand and origin of a wooden watch box can affect its price. Renowned brands known for their quality and design often charge more for their products. Additionally, wooden watch boxes imported from countries known for high-quality craftsmanship, such as Pakistan, may come at a higher price point due to shipping and import duties.

Key Considerations:

Brand Reputation: Well-known brands often have higher price tags.

Import Costs: Imported boxes may be more expensive due to additional costs.

6. Customization and Personalization

Customization and personalization options can significantly impact the price of a wooden watch box. Custom engravings, bespoke designs, and personalized compartments add uniqueness to the watch box but can also raise the cost. Many consumers are willing to pay extra for a personalized touch that makes their watch box truly one-of-a-kind.

Key Considerations:

Engravings and Personalization: Custom details can increase the price.

Bespoke Designs: Unique designs tailored to individual preferences are typically more expensive.

7. Market Trends and Demand

Market trends and demand also play a role in determining the price of wooden watch boxes. Trends in interior design, changes in consumer preferences, and fluctuations in material costs can all impact prices. For example, during periods of high demand or shortages of certain materials, prices may increase.

Key Considerations:

Current Trends: Popular styles and materials can affect pricing.

Supply and Demand: High demand or low supply can drive up prices.

Popular Wooden Watch Boxes in Pakistan

To provide a practical understanding, here are some examples of wooden watch boxes available in Pakistan, highlighting their features and prices:

Wooden Watch Boxes with Glass Lid - 10 PartitionsThis elegant watch box features a glass lid and ten partitions, offering both style and functionality. The use of high-quality wood and a sophisticated design make it a popular choice for those seeking a blend of luxury and practicality.

Customized Wooden Watch BoxesMany artisans in Pakistan offer customizable wooden watch boxes that cater to specific preferences and needs. These boxes can be tailored with custom engravings, unique designs, and personalized features, adding a touch of individuality.

Conclusion

When purchasing a wooden watch box in Pakistan, understanding the factors that influence its price is essential for making an informed decision. From material quality and craftsmanship to size, features, and brand, each element contributes to the overall cost of the watch box. By considering these factors, you can select a wooden watch box that not only fits your budget but also enhances your collection with elegance and functionality.

For those interested in exploring premium wooden watch boxes and other exquisite Pakistani Handicrafts, visit Crafts Emporium. Whether you’re looking for a luxurious Wooden Watch Box or a unique piece to complement your collection, Crafts Emporium offers a diverse range of handcrafted items that reflect exceptional quality and artistry.

0 notes

Text

Custom Slew Ring Bearing Fit for Your Demands

In the world of heavy-duty machinery, precision and reliability are paramount. Slew ring bearings, also known as turntable bearings or Slew ring Bearings, play a crucial role in ensuring smooth and controlled rotation in various industrial applications. Slew ring Bearing actions, or turntable addresses, are ball or comber- style behaviors composed of double-barreled concentric rings, either of which may include a gear. This feather of bearing enhances draft support and power transmission in all directions, and they’re commonly employed to support heavy loads for slow processes and large accoutrements alike as earth excavators and construction cranes. The exclusive power and elasticity of Slew ring bearing comportments have made them progressively valued in a wide collection of businesses, counting construction, manufacturing, robotics, machine tooling, and medical uses.

Slew Ring Bearing Usages:

Slew ring Bearing actions are again and again trusted upon to support loads in actually large, heavy- duty accoutrements. Their exceptional combination of weighty burden support and mobility improvement makes them useful in a variety of diligence and operations, including

Heavy- Duty Machinery. Slew ring Bearing conducts are current in heavy- duty outfit like cranes, excavators, and additional ministry that bear considerable cargo- bearing capacities and smooth pirouette. They offer the necessary strength and constancy to grip the extreme pressures and forces encountered throughout swinging, rotating, and lifting operations.

Wind Turbines. Wind turbines count on rotating nacelles to efficiently capture wind energy. Slew ring Bearing conducts support the nacelle and allow for smooth gyration, indeed under harsh thundershower conditions.

Mining Equipment. Slew ring Bearing behaviors are used in colored types of mining accoutrements, including conveyors, shovels, excavators, and mound declaimers.

Aerospace. Slewing comportments support movements in critical aerospace outfit, including satellite antennas, space delving ministry, and aircraft dock gear.

Crawlway- Borers. Slewing bearings are the main guard comportments in lair- borers and serve as the connective part of the knife head to insure that it rotates.

Water Treatment complexes. Slew ring Bearing conducts are normally used in wastewater treatment systems, suchlike as circuitous scraper purifiers.

Robotics Equipment. Robotic joints and arms depend on slewing actions to ease precise movement and positioning.

Medical Diagnostic Equipment. Slewing speeches are used in CT scanners and other advanced medical imaging accoutrements.

Other Applications of Slew Ring Bearing Actions Include

Pay- Off Reels

High- Speed Capstans

Large, Precision, and Index Turntables

Purities, Thickeners, and Rotary Distributors

float Buoys

Bottling Equipment

Fifth Wheels on campers and Farm Vehicles

Cranes & Excavators

Machining Tools

Radar Antennas

Log DE barkers

Coil Winders

Slew Ring Bearing Bearings from Kavistu Bearing

Kavitsu Slew ring Bearing comportments represent a technological caution in the fields of Mechanical power transmission systems. Kavitsu is a colonist in manufacturing and supplying of planetary gear systems and associated products for last 31 cycles. This field is a completely disparate field thank what Kavitsu was doing afore.We serve huge assiduousness requisite for construction ministry, palace cranes, truck mounted cranes, smash cranes, robotics and so on; the operations are endless. We’re proud to be one of India’s some Slew ring bearing manufacturers who have developed these products indigenously. We can guarantee that our Slew ring bearing comportments match global norms and are competitively priced.

Kavitsu Bearing is the best Slew ring bearing supplier, Manufacturer, Exporter, Dealer inABU DHABI, Algeria, Australia, Bhutan, Canada, Czech Republic, Egypt, Germany, Indonesia, Italy,Netherland, New Jersey, Saudi Arabia, Singapore, Spain, Thailand, Turkey, UAE, UK, USA, Vietnam,Port de Bejaia Algerie, Melbourne, Phuentsholing, Toronto, Ontario, Montreal, Joliette, Port ofPRAGUE, Cairo, HAMBURG, Eschweiler, SURABAYA, Milano, Genoa, Amsterdam, Rotterdam,Riyad,Dammam, Barcelona, Bangkok, Istanbul, Heathrow, Cleveland, Oklahoma, Houston,Pittsburgh, NEWYork, Hare Apt, Seattle, Minneapolis, HCMC Port.

Interested in learning other about our Slew ring Bearing comportments or other perfection- composed products? Request a citation or address us to speak with an expert directly for other information about kavistu bearing, appertain to kavistu bearing.

0 notes

Text

Buy Usha Tailor Deluxe Sewing Machine at Murthy Sewing Machines in Chennai

Introduction

Sewing machines are essential tools for both professional tailors and hobbyists. Among the plethora of brands available in the market, Usha stands out for its reliability, durability, and innovative features. For those in Chennai looking to purchase a high-quality sewing machine, Murthy Sewing Machines offers an exceptional selection, particularly the Usha Tailor Deluxe model. This article will delve into the features of the Usha Tailor Deluxe sewing machine, the benefits of purchasing from Murthy Sewing Machines, and why this combination is the perfect choice for your sewing needs.

Why Choose the Usha Tailor Deluxe Sewing Machine?

The Usha Tailor Deluxe sewing machine is renowned for its durability and versatile features. It is designed to meet the needs of both beginners and experienced sewers, making it a versatile choice for any sewing project.

Key Features of the Usha Tailor Deluxe

Certified Quality and Safety: The machine is ISI-marked and certified by the Bureau of Indian Standards (BIS), ensuring that it meets high standards of quality and safety.

Durable Components: The machine includes forged steel components for critical parts like the Connecting Rod, Feed Fork, Feed Dog Holder, Oscillating Rock Shaft, and Needle Bar Link, ensuring long-lasting performance.

Automatic Pressure Adjuster: This feature allows the machine to adapt to different fabric types, from light to heavy, ensuring consistent stitch quality.

Fabric Selector Knob: Easily choose the appropriate settings for various fabrics, enhancing the versatility of your sewing projects.

Lever-Type Stitch Regulator: Provides precise control over stitch length, enabling fine-tuned adjustments for different sewing tasks.

Auto Tripping Spring-Loaded Bobbin Winder: Simplifies the bobbin winding process, saving time and effort.

Hinged-Type Needle Plate: Makes it easier to insert and remove the bobbin and bobbin case, facilitating smoother operations and maintenance.

Versatile Operation: The machine can be operated by hand or with a motor, offering flexibility to suit different preferences and needs.

Foot Variants: Includes options like the zipper foot and buttonhole foot, broadening the range of possible sewing applications.

Warranty: Comes with a 2-year carry-in service warranty, providing peace of mind and ensuring support for any issues that may arise.

Why Buy from Murthy Sewing Machines?

Located in Chennai, Murthy Sewing Machines has established itself as a trusted name in the sewing machine industry. Our showroom offers a comprehensive range of Usha sewing machines, including the highly sought-after Usha Tailor Deluxe model.

Benefits of Purchasing from Murthy Sewing Machines

Competitive Pricing: While the standard price for the Usha Tailor Deluxe is around Rs 7500, Murthy Sewing Machines offers it at a special price of Rs 6500. This competitive pricing ensures you get the best value for your money.

Authentic Products: We guarantee genuine Usha products, so you can be confident in the authenticity and quality of your purchase.

Expert Staff: Our knowledgeable and friendly staff are always available to help you choose the right machine for your needs, offering personalized advice and guidance.

Comprehensive Range: In addition to the Usha Tailor Deluxe, we stock a wide variety of Usha sewing machines to cater to different requirements and budgets.

Service and Maintenance: As an authorized Usha Sewing Machine Service Center, we provide excellent after-sales service and maintenance. Our skilled technicians are available for repairs and servicing, ensuring your machine remains in top condition.

Convenient Location: Situated in Chennai, our showroom is easily accessible. We also offer online shopping options with doorstep delivery for added convenience.

Reputation and Trust: Murthy Sewing Machines is recognized by the local community for our reliable service, quality products, and customer-focused approach.

The Buying Experience at Murthy Sewing Machines

When you visit Murthy Sewing Machines, you are not just purchasing a product; you are investing in a comprehensive service experience. Our showroom is designed to provide a comfortable and informative shopping environment. You can see and test various models, including the Usha Tailor Deluxe, to make an informed decision.

Step-by-Step Buying Process

Consultation: Our staff will discuss your sewing needs and recommend the best models to consider.

Demonstration: See the Usha Tailor Deluxe in action. Our team will demonstrate its features and functionalities, answering any questions you may have.

Comparison: Compare different models side by side to evaluate which one best meets your needs.

Purchase: Once you’ve made your decision, we will facilitate a smooth and efficient purchase process.

After-Sales Support: Our relationship doesn’t end with the sale. We provide ongoing support, including maintenance services and technical assistance.

Conclusion

For those in Chennai looking to buy a reliable, high-quality sewing machine, the Usha Tailor Deluxe from Murthy Sewing Machines is an excellent choice. With its robust features and the support of a trusted retailer like Murthy Sewing Machines, you can embark on your sewing projects with confidence. Visit our showroom today to explore our range and take advantage of our competitive pricing and exceptional service. Whether you are a professional tailor or a sewing enthusiast, the Usha Tailor Deluxe will meet and exceed your expectations, ensuring a delightful sewing experience.

0 notes

Text

tips for buying your embroidery machine

Embroidery Machine Essentials: 10 Tips for Navigating the Market and Choosing the Perfect Machine

Embroidery machines have revolutionized the crafting world, allowing individuals to add intricate designs and personal touches to their creations. Whether you're a seasoned sewist or a curious newcomer, investing in an embroidery machine can open up a world of possibilities. However, with a vast array of options available, selecting the right machine can be a daunting task. To help you navigate the market and make an informed decision, here are 10 essential tips for buying your embroidery machine:

1. Define Your Needs and Goals

Before embarking on your machine search, take a moment to reflect on your embroidery aspirations. Will you be primarily embroidering clothing, home décor items, or wearable crafts? Do you envision creating intricate designs or simple embellishments? Identifying your priorities will help narrow down your options and ensure you choose a machine that aligns with your specific needs.

2. Set a Realistic Budget

Embroidery machines range in price from affordable entry-level models to high-end professional machines. Determine how much you can comfortably spend and factor in additional costs, such as software, supplies, and maintenance. Setting a budget will prevent you from overspending and ensure you prioritize the features that matter most.

3. Consider Hoop Size and Stitch Capacity

Hoop size determines the maximum embroidery area you can create. If you plan to embroider large items like blankets or jackets, prioritize a machine with a larger hoop. Similarly, stitch capacity refers to the number of stitches the machine can execute per minute. For intricate designs, consider a machine with a higher stitch capacity to ensure smooth and efficient embroidery.

4. Evaluate Operating System and Software

Embroidery machines typically use a proprietary software platform that enables you to upload, edit, and transfer designs. Familiarize yourself with the software's features and ease of use. Some machines offer compatible software suites for enhanced functionality, while others rely on USB connections or other methods for design transfer.

5. Assess Needle Placement and Thread Tension

The placement of needles can significantly impact the quality of your embroidery. Machines with multiple needles allow for faster stitching and more complex designs. Thread tension plays a crucial role in creating consistent and professional-looking embroidery. Check the machine's needle arrangement and tension adjustment mechanisms to ensure they align with your desired level of craftsmanship.

6. Explore Embroidering Features and Applications

Some machines offer advanced features like automatic thread cutting, bobbin-winders, and lettering tools, while others focus on basic embroidery functions. Consider the features that are most important to you, such as automatic thread color changes, automatic thread trimming, and the ability to embroider over multiple layers of fabric.

7. Research and Read User Reviews

Once you've narrowed down your options, extensively research the specific models you're considering. Read user reviews, watch online demonstrations, and consult with experienced embroidery enthusiasts to gain insights into the machines' performance, strengths, and limitations.

8. Consider Local Service and Support

Ensure the embroidery machine you choose is backed by a reputable brand with a strong customer service network. Check for local dealers or authorized service centers in your area to ensure prompt support in case of any technical issues or warranty claims.

9. Test Drive Potential Machines

If possible, visit a local sewing or embroidery store and test drive the machines that interest you. This will provide you with hands-on experience, allowing you to gauge the machine's ease of use, operation, and overall performance.

10. Seek Expert Advice

Don't hesitate to seek guidance from experienced sewers, embroidery enthusiasts, or qualified professionals at sewing or craft stores. Their insights and recommendations can be invaluable in making an informed decision that aligns with your skills, goals, and budget.

Embroidery machines can be an investment, but with careful consideration and informed decisions, you can find the perfect machine to enhance your creative endeavors and bring your embroidery dreams to life. By following these essential tips, you'll be well-equipped to navigate the market, select the right machine for your needs, and embark on a rewarding journey of personal expression and artistic exploration.

More tips

- Determine Your Needs: Before purchasing an embroidery machine, it's important to determine what you'll be using it for. Are you a professional embroiderer or will you be using it for personal projects? Will you be embroidering on a variety of materials or just one type? Answering these questions will help you narrow down your options and ensure that you purchase a machine that will meet your needs.

Research Different Brands and Models: There are many different brands and models of embroidery machines on the market. Take the time to research different options and compare features. Look for machines with a good reputation for reliability and durability.

Consider the Size of the Embroidery Area: The size of the embroidery area is another important factor to consider. If you plan on embroidering large projects, you'll want to look for a machine with a larger embroidery area. On the other hand, if you'll mostly be working on smaller projects, a smaller embroidery area may be sufficient.

Look for a Machine with a Large Embroidery Field: A large embroidery field will allow you to work on larger projects, and also give you more flexibility when it comes to placement of your designs. This also means that you can do larger designs, or do more than one designs at a time.

Check for Built-in Patterns and Designs: Many embroidery machines come with a variety of built-in patterns and designs. This can be a great feature if you're just starting out, as it will give you a good selection of designs to work with. If you're more experienced, you may prefer a machine that allows you to create and edit your own designs.

Consider the Number of Needles: The number of needles on an embroidery machine can have a big impact on the quality of your finished projects. Look for a machine with at least two needles, as this will allow you to change thread colors more easily.

Check for a Good Lighting System: Good lighting is essential for precision embroidery. Look for a machine with a bright, adjustable light that will illuminate your work area and make it easier to see your designs.

Consider the Price: Embroidery machines can be quite expensive, so it's important to consider the price when making your decision. Look for a machine that offers the features you need at a price you can afford.

Look for a Good Warranty: A good warranty can provide peace of mind and protect your investment in case something goes wrong with your machine. Look for a machine with a warranty of at least one year.

Consider the Brand Reputation: Research the brand reputation of the machine you are buying. This will give you an idea of the customer support you can expect, as well as the quality of the machine you are buying.

In conclusion, when it comes to buying an embroidery machine, it's important to consider your needs, research different brands and models, and look for a machine with a large embroidery area, built-in patterns and designs, a good number of needles, a good lighting system, a good warranty, and a good brand reputation. By following these tips, you'll be well on your way to finding the perfect embroidery machine for your needs.

Read the full article

0 notes

Text

youtube

Installing the inner panel- for C series

Xtelary watch winders will help to save and prolong your watch life. We provide customers with the best quality watch winding machine at the most favorable price. With powerful technological innovations such as Japanese motor, LCD or touch screen control, LED lighting and automatic start/stop system, Xtelary watch winders provides a unique combination of quality and function. All Xtelary watch spools are packaged separately in a strong cardboard package, including manuals and adapters. Find visit us: https://xtelary.com/pages/about-us

For more information visit us: https://www.youtube.com/watch?v=adKaU5k6t9s

0 notes

Text

The production line of three-layer co-extrusion Film Blowing Machine has advanced automation functions, such as centralized feeding, batching, weight control, IBC internal cooling, automatic thickness control, and automatic central winding. All functions are integrated on the touch screen, thus simplifying operations and increasing productivity. Besides reducing a significant amount of raw material used in the formula, another advantage of the ABC machine is that the 3 layer film that it produces is 30% stronger than film produced by a mono layer extruder.

FEATURES

FEATURES OF THREE LAYER ABC BLOWN FILM MACHINE

30% Stronger Film

50% Cost Saving

100% Recycled Material Used

Application: T-shirt bags, shopping bags, garbage bags etc.

Suitable Material: HDPE, LDPE, LLDPE

Film Width from 500~2000mm

Extruder Dia: 40mm, 45mm, 55mm, 65mm, 80mm

Output: 45~200 kg/hr

SPECIFICATION

SPECIFICATION OF THREE LAYER ABC BLOWN FILM MACHINE

Model Name

ABC 3layer Blown Film Machine

Final Product

HDPE, LDPE, LLDPE Plastic Film

Application

Flexible packaging bags, T-shirt bag, garbage bag, shopping bag

Material used

HDPE, LDPE, LLDPE virgin raw material, recycled material, biodegradable material,

Output range

45~200kg/hr (depends on extruder size)

Film Layer

Multilayer - ABA Three layer

Screw Diameter

40, 45, 55, 65, 80mm (customized)

Screw L/D

28/1, 30/1, 32/1(customized)

Screw Material

38 CRMOALA

Width

500~2000mm

Thickness

0.01~0.1mm (customized)

Optional Devices

Auto loader, rotary die head, corona treater, automatic winder, double winder, EPC, mixing machine, automatic gravimetric device

Delivery Time

30days

Warranty

1 year

Technical Assistance

Engineers available to service machinery overseas

0 notes

Text

The machine can sew light materials as well

Janome HD3000 vs HD1000 Not all the threads have been tested. T-40 is reliable. When used with the appropriate topstitching needle, topstitching threads are also suitable. Reduce the top tension when using heavier threads; if utilizing in the bobbin, it could also need to be adjusted. One bobbin box is normally reserved for T-50, and the other is for specialty or stronger threads. Only straight stitching or travel are done on this machine. Indeed, I do! Many videos on YouTube show people removing the eight layers of denim. When I make bags, it glides effortlessly over cork, vinyl, eight layers of fabric with interfacing, and four layers of fabric for home décor. It's a wonderful small device! On denim, this machine performs amazingly. This device is amazing! It is a workhorse despite being compact, straightforward to set up, and easy to use. I also appreciate how that makes me feel. I am 5'2" tall, so using this machine to hem jeans is a delight. I purchased mine for its heavy-duty capabilities, and I use my old New Home 6000 for all other needs.

I just have grown accustomed to the simplicity of using my old computer, which I've had for around 30 years. The machine can sew light materials as well, but, for no apparent reason. It should be simple to use the correct needle size for lighter fabrics because the presser foot tension fluctuates. With to the presser foot pressure that is simply adjustable with only a simple turn of the dial, you can sew with a wide range of fabric thicknesses. Freedom of the Arms Sew shirt sleeves and pant legs with ease with the Free-Arm.

Hard Case/Cover, 1/4" Seam Foot, 2 Packs of Leather Needles, 1 Pack of Universal Needles, 1 Pack of Bobbins, Blind Hem "G" Foot, Overedge "C" Foot, Rolled Hem "D" Foot, Zipper "E" Foot, and Buttonhole "B" Foot are among the accessories that are included. Also comprises Button automatically Choose a simple stitch: The stitch you want to use will appear in red when you adjust the dial to that setting. You can quickly view each of the 18 built-in stitches thanks to the Flip-Up Stitch Panel. The Janome HD1000 has many of the useful features you'd expect on a machine with a higher price tag.

A built-in buttonhole, 13 of the most practical stitches, and dependably dependable performance on a range of fabrics are all features of the Janome HD1000. For regular stitching, the HD1000 Janome sewing machine is a wonderful value. Even better, the Janome HD1000 includes an automatic needle threader that makes it simple to thread needles without putting too much pressure on your eyes. A trustworthy and enjoyable stitching experience is provided by the Janome HD-1000's user-friendly features and exceptionally sturdy design. the arm's freedom Horizontal Complete Rotary Hook, Painted Aluminum Body, 860 SPM 18 stitch maximum per minute The maximum stitch width and length are 6.5 mm and 4 mm, respectively. Adjusting Foot Pressure in Three Steps Extremely High Presser Foot Lift, Snap-On Presser Feet, Built-In Needle Threader, Built-In Thread Cutter, Horizontal Spool Pin, 7-Piece Feed Dog, Heavy Durability Frame, Lay-In Thread Tension Control, Drop Feed, Reverse Stitch Lever, Push/Pull Bobbin Winder Stitch Selection Dial,

0 notes

Text

Price: [price_with_discount]

(as of [price_update_date] - Details)

[ad_1]

The Newest design for Cord Organizer Upgrade Made of high grade Silicone material, durable in use. Self-adhesive effect can mount on most smooth surface, like glass, wood, wall, etc. You will never lose your cable at the floor or behind the desk when you own a cable organizer like this. Desktop wall wire fixed self-adhesive abs wire clip network cable finishing buckle cable wire organizer. It can keep all your cables within arms reach while in use and also remain in place while disconnected. This cable organizer is designed for a single cable wire fixing, to make your desk and office tidy and organized. 3M Heat-resistant Strong Adhesive we have chosen the bottom glue of 3M high-quality heat-resistant adhesive, which can be safely applied to heating appliances such as pressure cookers, toasters, etc. Wider Sticking Area The entire back of our product is the bonding area, the glue has a larger contact area with the machine, so that the wire winder of the kitchen appliance sticks firmly to the appliance and will not fall off. Wider Storage Space Cord Organizer is 1 inch high and 1.8 inch long with Butterfly wing design, so there is enough space to completely wrap wires of different lengths and thicknesses without scattering. Curved Surfaces Available Softer flexible rubber material makes it perfectly fit the curved surface of the appliance. Larger contact area and better fit, so it is stronger and more durable.

* HIGH QUALITY MATERIALS: This power cord organizer stand is made of sturdy and durable, high quality silicone material, not easy to deform, so you can use it with confidence.

* This power cord organizer can be securely attached to small devices using double-sided tape. The tape used on the bottom is tested many times and is hard to fall off.

* COMPATIBLE WITH MULTI CABLES: This cable holder is compatible with a variety of cables, allowing you to properly organize and organize various cables and create a tidy home space.

* Kitchen appliance cord holder can be used to organize the power cord of various kitchen appliances such as stand mixers, pressure cookers, toasters, coffee machines, mixers and more. It can also be placed horizontally in the living room. Place more route mobile codes.

[ad_2]

0 notes

Text

Need Blown Film Extrusion Machine? All India Machinery Is The Destination!

The packaging industry is massive, and it helps in packing goods precisely so that they can reach the end-consumer safely. The Mini Model Blown Film Extrusion Machine Manufacturers In India are engaged in making excellent quality machines with the help of the latest technology and knowledge. Today, in this article, we are going to shed some light on Extrusion Blown Film, so, if you want to know about it, then keep on reading the paragraphs below.

What Is Extrusion Blown Film?

It is a common process for the production of continuous films, which are used primarily for packaging.

Steps Included In The Making Blown Film

The first and foremost step in this process is to melt the plastic in the extruder.

After melting it in the extruder, the molten polymer enters an annular die head where it is formed into a tube of plastic material.

After exiting the die of the film tube, the plastic is pulled upwards by nip rollers, during this, compressed air is blown into the film to get the desired film thickness and width, and then chilled air is blown on and outside the tube.

Once it's cooled down, the film approaches the nip rollers, and there the bubble of the film is gradually flattened.

After this, the nip rollers transport the film to the in-line slitters and roll winders.

If you or anyone you know is searching for a blown film extruder machine, then you don’t have to look for it any further, as the best manufacturer is here at your service. All India Machinery is also known as the Blown Film Extruders For Garbage Bags Manufacturers In India, as they are making the best machines as per the technology. So, if you need anyone blown film extruders, then you don’t have to worry about it anymore, because the best manufacturers are here at your service.

About All India Machinery

All India Machinery is one of the leading names in the country for making a wide range of machinery. The success rate of the company is very high, because for them the overall satisfaction of the client is essential, and they assure that proper guidelines are followed. It is a promise that you will get all types of machinery right under one roof at competitive market prices. For more information regarding various machinery and their prices, you can scroll through the website as their you will get all the information.

Credit:- https://penzu.com/p/39d33354

#Mini Model Blown Film Extrusion Machine Manufacturers In India#Blown Film Extruders For Garbage Bags Manufacturers In India

0 notes

Link

KEW ENGG & MFG. PVT. LTD. is biggest manufacturer, exporter & supplier of all types of Winding Unwinding Machine. Winder Unwinder Machine with high performance winding quality with an integral part of winding technology depending on stretch wrap film, cling film and many more. We are Winder Rewinder Machine offering premium quality range of Winding Unwinding Machine. Used in textile as well as various allied industries, offered unwinding machine is manufactured by our proficient professionals in line with industry norms by using the best quality components and sophisticated technology. We offer this unwinding machine in varied specifications and designs for our prestigious clients. For more information:

Website: kew.net.in

Email: [email protected]

Contact Us: +91-7940085305

YouTube: https://www.youtube.com/watch?v=E_XuuJvF0jM

#Winder Unwinder Machine#Winder Machine Price#Winding Machine#Winding Machine For Sale#Winding Machine For USA#Winding Rewinding Machines#Winding Rewinding Machine In USA Price#Winding Unwinding Machine#Winding Rewinding Machine

1 note

·

View note

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

Krishna Engineering Works we have been manufacturing, exporting, and supplier of all types of Doctor Re Reeling Machine, Doctoring Rewinding Machine, Inspection Rewinding Manufacturer, Winding Rewinding Machine. We have designed and built for accuracy for doctoring use with air brake with reel diameter, Edge Guide with actuator for the Unwind reel, Air shafts for Doctoring Re Reeling Machine units. It is used to salvage badly rewound coils produced on the Slitting and Rewinding Machine.

#Doctoring Re Reeling Machine#Doctoring Slitting Machine#Winding Unwinding Machine#Unwinding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Rewinding Machine#Fabric Winding Machine#Inspection Rewinding#Automatic Reeling Machine Price#Textile Reeling Machine#Industrial Slitting#Winding Rewinding Machine#Film Winder Rewinder Machine#Doctoring Inspection Machine

5 notes

·

View notes