#automatic coating machines and many more.

Text

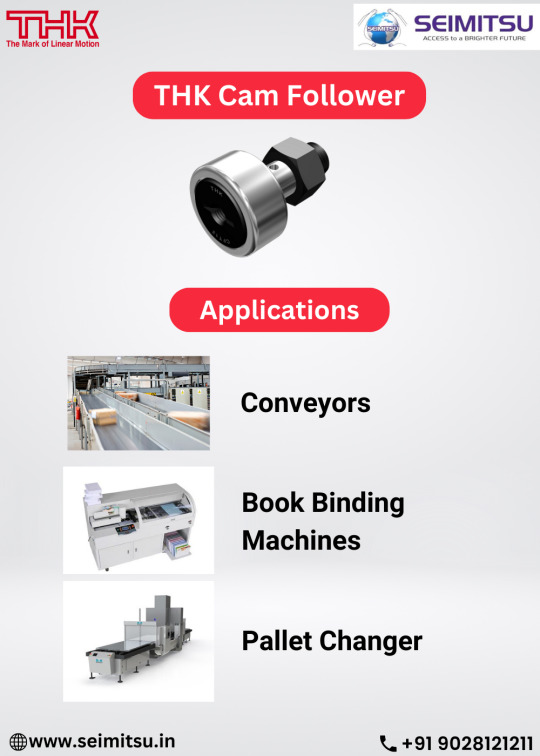

THK cam follower is a compact bearing with a high-rigidity shaft and needle bearing, it is used as a guide roller for linear motion. There are two types of outer rings spherical and cylindrical. The spherical outer ring absorbs a distortion of the shaft centre when the cam follower is installed and helps lighten a biased load. Cam followers are used in various applications like carrier systems, conveyors, bookbinding machines, pallet changers, automatic coating machines and many more.

SEIMITSU is an authorized distributor of THK

To know more: https://seimitsu.in/THK-rotation-Cam-Follower.html

Email Id: [email protected]

Call: +91 9028121211

#thk #camfollower #conveyors #sphericalbearing #carriersystem #seimitsu #seimitsufactoryautomation #robotics #distributors #bearing

#THK cam follower is a compact bearing with a high-rigidity shaft and needle bearing#it is used as a guide roller for linear motion. There are two types of outer rings spherical and cylindrical. The spherical outer ring abso#conveyors#bookbinding machines#pallet changers#automatic coating machines and many more.#SEIMITSU is an authorized distributor of THK#To know more: https://seimitsu.in/THK-rotation-Cam-Follower.html#Email Id: [email protected]#Call: +91 9028121211#thk#camfollower#sphericalbearing#carriersystem#seimitsu#seimitsufactoryautomation#robotics#distributors#bearing

0 notes

Note

hc V2 almost met Gabe in Gluttony but they heard the 'Machine, turn back now...' and decided that they had to obey the one authoritive human voice they heard in hell and backtracked to Limbo.

How do you think their friendship would develop when they do meet? V2 would probably be glad to talk to someone who is somewhat sane, and maybe they would appreciate Gabe's human form or would that be a source of awkwardness?

sjdhfgfg absolutely love the idea that for ONCE gabriel's whole little speech...works. like the only reason he does it is just a left over of his chivalric values even though it seems to have no meaning to the machines - give them the chance, he guesses, but it's become an automatic script of no consequence. until v2 is like "oh...ok. understood." it's glad in a way to get some direction while gabe is like ???????? IT LEFT?????? and he can sort of feel good for a bit that maybe his words mean something to somebody still. even some machine. at the very least, it was worth keeping it up until then.

i've talked about what i think their relationship would be like a little before, but i genuinely believe they have a lot they can relate on if given the chance - they are both based in violence yet are meant to act as protectors...and ultimately, they have both failed. however, this common ground hardly means they would get along at first - they see all of their flaws in the other, they see what they perceive as their own worthlessness, and that causes plenty of friction at first. what is v2 good for, still chasing after peace down in hell? humanity is gone and it has no one left to protect, yet it's still adhering to orders and programming that has absolutely no place in this world. it's small wonder v1 bested it twice. and what is gabriel good for? an angel without a god, still behaving like some kind of knight when heaven itself as rejected him and hell is being destroyed by machines. it's no wonder v1 bested him twice. they hate seeing themselves reflected back so plainly.

they wouldn't keep it up forever as they both come to terms with their realities, both taking one too many shots that just gets turned right back on them by the other. and gabriel would eventually see it's ridiculous, how he wants v1 to have a relationship with v2 yet he refuses to be civil; and v2 realizes how dumb it is to keep throwing insults at the one guy left in hell that might still appreciate the finer parts of its mind, the part that dreams, that has aesthetic senses no other machine does. And so they would slowly become more open to one another, the ice melting between them as they find more to share in than just their failure. yet there is something comforting in that foundation, one they don't touch for quite some time - they were both made for a singular purpose, and that purpose is now gone. they exist as beings never meant to be adrift, beings that should be discarded the minute they are no longer useful.

however, i think what proves to be most important for both of them is the far more human-like connection they find in one another - v2 was trained on human social models far more than any other machine and gabriel comes from the same creator as humanity. no, neither are an exact match as v2 is still very much ai, still a war machine with a coat of paint applied, while gabriel lacks much of humanity's creativity and power to fully self-direct, but it's a far closer approximation than either would have otherwise. v2 can finally talk about its imagination, about its dreams, with someone that understands (and even helps it interpret its more metaphorical simulations)...and honestly, i think v2 would like seeing gabriel's human face. he would apologize for its appearance now, knowing that the frostbite might be jarring - v2 doesn't really mind that either, though it does have protocols telling it how it should help him it has to keep ignoring lol it likes listening to the stories he tells it, describing all the humans this face knew and the simple things he would do with them even as an angel. over and over gabriel speaks on the kindness of the humans he met (of course, he was sent from god), how he was invited into their homes and shared food with them, how they always insisted he leave with a gift no matter how he refused. it's clear he misses them in a way many angels don't, but a way v2 does despite never really getting its chance to know them. so really their connection is one filled with a lot of mourning, a lot of grief for who they were and what they lost - it's outlet for feelings that had no other place before they met.

#they do also absolutely trade stories of their fights with v1 lol#though v2 does NOT understand how this made gabriel fall in love...weirdo!!!!!#but i just really like the idea that gabriel finds his future in v1 and finds his past with v2 if that makes sense#they are his emotional support machines#gabriel: are there any other....v-series-#v2: you will not have an entire team of v therapists no#cake answers#gabriel#v2

46 notes

·

View notes

Note

A lil scenario in my head, it's messy and eh, I just have no idea how to write war scenes as you can see, anyways, have my creation

Ramattra canonically woke up in New York, and watching genesis again, it gave me an idea.

You were one of many, but at the same one of not so many.

This war has been going on for years, and humanity was at a bring of exhaustion. Many children, women and men, died, their bodies never to be found. And soon, you will join them.

In a desperate move to make evacuation of children and wounded, any adult capable of walking and holding a weapon was ordered a suicide charge into the enemy forces to buy time for others, more important to flee. Overwatch forces and what was left of the army were too far away to help. You only had a few hundreds soldiers and around three thousand of volunteers willing to go. You were one of them, hoping silently to end your pain, and die in a fight. Useful.

You hid behind a piece of concrete rubble and sat down, your breath being ragged and uneven from the earlier run. Your hands trembling, yet not from fear, holding a rifle.

You got used to fear. To having to be afraid. You knew that the omnics that once took care of your child self were just machines after all. No matter how many funny backstories and meaningful names you gave them as a child. It was sad, really. To pity your now enemies. But now, you were just tired. You weren't sure if you wanted to see another day.

You turned your head to the right, and saw a ravager, who fell to the ground, aiming their weapon at you. Almost automatically you aimed your weapon at it, somehow faster, and...

You both stopped before pulling the trigger.

You watched shocked, as it's LEDs started blinking blue, as it's motion stopped.

You saw that it probably fell down, probably from the force of the explosion earlier, covered in mud and scratches. Part of its faceplate was broken, showing an optic that currently was widening and shrinking as if there were two sides fighting for dominance.

And then, it dropped the weapon, almost... Confused. Like suddenly this murder bit was a child, looking around in wonder. It touched its face, feeling around, and dropping it's weapon in the process. It slowly started standing up as well, it's LED's glowing soft blue instead of bloody red that you grew to hate.

You also got up, careful to not reveal yourself from behind your cover. You noticed that shots were quieter, almost at the standstill.

"I..." You looked down at it, as it spoke. To you. A human.

They never spoke out loud. They could, since they had a voice box that could mimic human speech, but R-7000, in your experience they never used the voice range that was mimicking human voice. They usually spoke commands in omnicode, humans being only able to hear a quiet hum.

"I am sorry..." His voice was surprisingly deep, yet still had this robotic echo to it, as all omnics did.

You did not say anything. You kept staring at him, flabbergasted. You never thought that whatever Overwatch planned in Nepal would actually work. Ever.

It was known to you that Overwatch was doing an operation meant to turn the tides of the war, something about making omnics able to disable their programming. But this... You felt that you witnessed something. Whenever good or bad, it was something.

You did not know to this day why you did what you did.

You slowly made your way to the sitting ravager until you were standing in front of him. You then tore material from your coat and tied it around omnics head, covering the damaged faceplate and optic. It just stared back at you, unmoving, as you finished it with a bow.

"You are... Not what you are" you said out loud, not really knowing what you meant at the time.

It titled it's head and raised its hand to touch the cloth. It looked like a child, scared, but curious.

This was the beginning of a new future that none ever expected to happen.

I read this in between the busy parts of my shift when it came through and I just stood there like :0

This is such a cool idea! Being there to fight and then witnessing the sentience-y of omnics… ooo boy I’d read this hands down-

13 notes

·

View notes

Text

CalmWriMo Day 23

[11/23/2023]

Update!

Firstly, happy Thanksgiving to those who celebrate! Enjoyed the day and foods with family and am thankful for that. (^.^) Also seriously feel like I have soooooo much time today!!! Had plenty of time to do all sorts of writing including below and a blurb I yeeted out earlier! Feels good. (^v^)

Progress:

2 Hour Writing Goal: ✅

Blurb: [see below]

Self Care:

Food: ✅

Hydration: ✅

Sleep: ✅

Reading: ✅

Blurb: All About the Food of Neocago!

In Neocago the majority of food is produced within massive vertical farming complexes known as agritowers. From them there are a number of common base products such as bioengineered mushrooms, ferns, algae, and single celled proteins. Meats, animal products, and more traditional crops are produced, but come with a higher price tag.

In the Undercity there are two main ways that people get food. The first is simply getting some cheap premade product from a vending machine or a grocer store (that is if there is one near enough). This often yields the most bland foods that is little more than the sum of it's ingredients crammed into a can or plastic bag. Things such as fernloaf, canned algae, and shroom patties. Enough to survive off of, but certainly not healthy nor particularly desirable. Some more creative folks have found ways to turn these into something closer to edible. This brings us to the second way food is procured in the Undercity. Street vendors and food stalls! Chefs experiment with these ingredients as well as some supplements (seasonings and vegetables) from small hidden gardens or Midcity grocery stores to make new dishes. This works, but cleanliness is often lacking leading to potential health problems. A major issue in the Undercity is growing food deserts, which occasionally causes some areas closer towards the edge of the city to become abandoned as food occasionally becomes completely unavailable.

The Midcity has decent grocery stores that provide traditional crops that are mostly unavailable in the Undercity. Many people in the Midcity often have a proper kitchen within their apartments and either cook their own food with available ingredients or simply eat premade packaged meals. Proper restaurants, with higher regard for health and safety, are dotted across the Midcity and provide many dishes as they would be before the Great Collapse. Of course there are also fast food restaurants in these parts of the city that quickly churn out cheap meals that are at the very least editable. Food shortages in the Midcity aren't unheard of, but a rarity in current times. In fact, much of the food that isn't sold within a couple days is often coated in bleach and thrown away. [I’ll leave you guessing why for now (o.o)]

The Uppercity is the center for fine dining and convenience. Real meats and animal products that are virtually unobtainable elsewhere are in abundance here. Every dish is only made with fresh high quality ingredients. Most apartments in the Uppercity have advanced vending machines that can be programmed to produce nearly any dish imaginable with ingredients automatically delivered directly to it. It is common for the hyper wealthy who have mansions to have their own personal in house chef. Even for them ingredients are often shipped directly to their door. An unavailable ingredient or dish isn’t simply unheard of here, but would be a great offense.

[What better a blurb for Thanksgiving than one about food!? (^v^) Anyways and always, hope that you had a lovely day, peace (^v^)v]

4 notes

·

View notes

Text

It’s PEBBLE TIME

-

She’s tracking a Stalker when the ruckus attracts her attention.

On her shoulder, Streak tenses, clacking his beak anxiously. His golden-white eyes roll toward her, as if asking what he should be doing next.

Talanah isn’t sure what to tell him; they’ve been tracing the Houndoom-like machine for the better part of the day, and, with the sun beginning to dip toward the horizon, they’re losing the light; the machine will be that much harder to track in the dark, and harder to fight without the telltale glimmer of light off of the armor plates that allow it to melt away into thin air.

The throaty warbles and stuttering growls wafting through the brush are also familiar; ones she’s heard many a time out here among the wilds of the Jewel.

“Couple of Liepards found something to scavenge, probably,” she murmurs, more to herself than to Streak, reaching up to give his head a reassuring stroke, “not like we can do much about that.”

As if the Sun itself is challenging her assessment, a pathetic little peeping noise starts up from the direction of the fracas, and the Liepards, excited by the prospect of fight in their prey, answer anew with a fresh round of battle cries.

It makes up Talanah’s mind in an instant.

“Streak,” she commands, and the Talonflame straightens automatically at the tone of her voice, “Aerial Ace.”

The Scorching Pokemon launches itself from her shoulder in a flurry of wings, and, snatching up her spear, she follows, crashing heedlessly though the brush.

The Stalker trophy will have to wait for another time.

One of the Liepards lets out a yowl from somewhere ahead as Streak’s attack connects, and, dodging past a low-hanging branch, Talanah lets out a smug little chuckle.

Never misses.

With Streak raising hell, the fight is easy to track; bursting through a thicket of whippy branches, she emerges into a clearing, taking a minute to get her bearings. Streak has one of the pair of Liepards backed against the trunk of a massive tree, swooping incessantly at its head as it snaps and snarls, leaping after him, always just a moment too slow.

The second one, this one an unfamiliar reddish-brown in color, is crouched over its hapless victim, something huddled in a shaking, green heap at its feet. As it raises a paw to strike, claws extended to their fullest and wreathed in shadowy flame, Talanah moves, throwing herself across the clearing and slamming the haft of her spear between the Leopard and its prey.

The Cruel Pokemon’s attack gouges deep, night-colored slices into the wood, and it snarls its fury, reaching over the spear shaft to slash at her arm. Undeterred by the threat of claws, Talanah puts her full weight behind her weapon and heaves, sending her opponent flying across the clearing and into its purple-coated fellow.

As the pair of them disentangle themselves, Streak lands on her shoulder, spreading his wings behind her head like a crown of sunbeams, embers scattering from between his feathers.

“Get out of here,” Talanah growls, brandishing the spear, “unless you want more.”

The Liepards consider it for a moment, the brown-coated one flexing its claws into the damp earth. But, finally, they think better of it; with a final ripping snarl, the pair turns, and vanishes into the brush. Neither of the hunters dares to move until the sound of their footsteps fades, and the ambient noise of the jungle picks back up again.

As Streak flutters into the branches above, keeping a stern eye on their surroundings, Talanah stows her spear, crouching beside the shivering heap on the ground. The little Pokemon flinches as her touch meets soft green feathers. Her fingers come away sticky with blood.

“Hey, hey,” she soothes, “you’re all right. Come here.”

Unwrapping the sash from around her waist, she scoops the little Pokemon into it, carefully swaddling it in the silk.

“Ligan will know what you are and how to help you. Just hang on until we get back to the Lodge.”

—

She returns from a contract three days later to find the little Pokemon staring at her intently from the little nest of rags she’s put together for it on the windowsill, in full sunlight, as Ligan had instructed.

“Natu like sunlight,” he’d said, when she’d brought the poor little creature into his quarters for advice, “and they’re shy around predators… you might want to have Streak keep his distance.”

Streak doesn’t need to be told that today; tired as he is, he flaps straight to his perch, beginning to preen the dust of the fight out of his feathers as she makes her way to the windowsill. This time, the TIny Bird Pokemon doesn’t flinch when she approaches.

“Hey. Glad to see you awake and feeling better.”

Crouching and extending a hand, she keeps her movements slow and measured. The Natu studies the offering for a moment, before carefully putting its tiny, bandaged wings out to clasp her finger between them. Its glimmering feathers are soft and sun-warmed, and Talanah can’t help but smile at the touch, and at its big, round, earnest eyes, staring up at her unblinkingly.

“Sorry. I just took you with me without thinking about it. But it’s better than being someone’s evening meal, right? I’ll take you back home to the Jewel once you’ve healed up.”

To her surprise, the little Natu climbs unsteadily onto her hand, clinging on with a weak, wobbly grip. Instinctively, Talanah cups her hands around the little Pokemon, and it nestles down into them as though perfectly at home. Raising a thumb, she gives the shimmering, downy feathers a stroke, and the Tiny Bird Pokemon leans into the touch with pleasure.

“You’re round and smooth… like a pebble. That’s what we’ll call you, until you’re ready to go home. Pebble.”

If Pebble likes the name, he doesn’t give her any indication, continuing to watch her from his position puddled in her palms. Streak casts them a curious look from beneath his wing as she stands and turns from the windowsill, but thinks better of it, ruffling his feathers and settling back down for a nap. Pebble gives him an intense stare as they pass, but quickly turns his eyes back to Talanah’s face as she carries him over the threshold.

“Ligan will want to have a look at you. And you should meet him, anyway, if you’re going to be staying at the Lodge for a while. You’ll need to know who you can trust. And who you should avoid.”

#Pebble is a Shiny Natu!#but Talanah does not know that... she just thinks 'He still looks a little pale... I think he can't go yet'#which suits Pebble fine; he was attached the moment she saved him haha#Horizon/Pokemon Stuff

8 notes

·

View notes

Text

https://baobikhangloi.com.vn/mang-phu-nong-nghiep-duc-lo-san

Perforated agricultural film products

Between the conventional coating and the perforated film, users often choose the non-perforated type because they are significantly cheaper. Pre-perforated coatings are more expensive not because the cost of the perforating equipment is too high, but because this perforation will slow down the overall system productivity considerably. However, in our opinion, the high price of these products is completely worth the performance they bring.

If you've ever used mulch for your growing work, you'll understand that punching holes for seeds or seedlings is a tedious and time-consuming task. Before the advent of perforated mulch, farmers around the world thought of many ways that this perforation could be done faster and easier.

On the smallest and simplest scale, they use knives, scissors or any other sharp object to make a cross in the membrane, then fold the excess plastic underneath to create holes shaped like square. This manual folding of 4 pieces of plastic takes a lot of time, the strength of the film is also weakened and it is easy to tear at the location of the cuts.

More advanced cutting tools for making circular holes in the coating have also been invented. Old milk cans are drilled with 2 small holes and inserted electrical wires to make handles, then hot coals are inserted. When the can of milk is hot enough, the farmer carries it away and places it on top of the mulch already spread in the garden, in the places where they want to drill holes. The plastic at this location will melt into the shape of the bottom of the box, and another farmer can go behind to collect the excess plastic. Plants or seeds can also be transplanted at this time.

In the same way as above, there are places where it is very popular to use wire mesh frames in old car air filters, especially those of light trucks and pickup trucks. The sharp edges on the mesh combined with the temperature of the coal inside will cut through the plastic film more easily. Instead of coal, one can also use kerosene or scrap plastic, or whatever as long as they are capable of burning for a long time.

Some people also use old PVC pipes, using a grinder to cut the pipe edges into a serrated shape to create a hole punching mold. When we forcefully press the water pipe into the covered ground, we will also get round holes like other methods. However, in hard areas, the plastic saw teeth will easily wear or break. Currently, metal punching tools with a similar design have also been sold a lot on e-commerce platforms. There are even variations that use electricity from the battery to heat.

However, no matter how creative these tools are, they are still manual, still consuming a lot of labor to perform on large agricultural lands. To cater for farming on such a scale, automatic agricultural film punching machines have been built. They are integrated right on the film production line, to produce pre-perforated agricultural films. Machined perforated agricultural film will have holes with uniform size and spacing according to pre-set parameters. These distances will be calculated to leave the most reasonable space for the growth of the plant's roots.

Currently, our Khang Loi company has invested in machinery system to produce perforated agricultural films, perforated on both transparent films and 2-layer films with one black side and one side. grey.

Although our large format plastic films or agricultural mulch can reach up to 8 meters wide, our mulch punching machine currently only works on films up to a maximum size of 8 feet. 3 meters. We will give you the option of 1 to 4 rows of holes. Each hole is 8cm in diameter and the distance between holes is customizable.

Our perforated agricultural film products use virgin resin as the main material, blended with special additive formulations to increase UV resistance and durability. Flexibility is also an advantage worth mentioning. This property makes our products resistant to the tension that occurs during installation, and is compatible with all mechanical punching operations, seeding operations, seedling without worrying about damage. membrane will be torn.

If you have a need or need more advice on the product, please contact us at 0902.732.168, or leave us a message in the contact section. Thank you very much!

2 notes

·

View notes

Text

Car Wash in Chandigarh: A Comprehensive Guide to Keeping Your Car Sparkling Clean

Owning a car in Chandigarh, a city known for its well-planned infrastructure and cleanliness, brings a sense of pride to many. However, maintaining that vehicle in pristine condition is essential to preserving its beauty and longevity. One of the most effective ways to achieve this is through regular car washes. In this article, we will explore everything you need to know about car wash in Chandigarh, the services available, and how you can ensure that your car remains in top-notch condition year-round.

Why is Regular Car Washing Important?

Keeping your car clean is about more than just aesthetics. Regular car washes offer several benefits:

Preserves the car's paint: Dust, dirt, bird droppings, and pollutants can erode your car’s paint if left untreated. Regular cleaning helps prevent this.

Improves resale value: A well-maintained car is much more appealing to potential buyers, and regular washing can ensure the exterior remains in good condition.

Enhances safety: Clean windows and mirrors improve visibility, while clean tires and undercarriages can prevent damage from debris.

Promotes hygiene: A clean interior, part of many car wash packages, reduces allergens and provides a more pleasant driving experience.

In a city like Chandigarh, where air quality can fluctuate, regular car washes can prevent dirt and pollutants from causing long-term damage to your vehicle. Now, let’s dive into the options for car wash in Chandigarh.

Types of Car Wash Services in Chandigarh

Chandigarh offers a wide range of car wash services tailored to meet the needs of all car owners, whether you're looking for a quick rinse or a detailed cleaning. Here are some of the popular options available:

1. Hand Car Wash

This traditional method involves manual cleaning by professionals using high-quality cleaning products. Hand washes are thorough and perfect for people who want to ensure that every inch of their car is cleaned with attention to detail. Hand car washes are especially useful for removing stubborn dirt, cleaning rims, and polishing surfaces to perfection.

2. Automatic Car Wash

For car owners on the go, automatic car washes provide a quick and convenient solution. These facilities use machines to clean the car’s exterior, saving time. Automatic washes typically involve a series of brushes, soapy water, and high-pressure jets to clean the car from all angles. While they are not as detailed as hand washes, they are perfect for routine maintenance.

3. Steam Car Wash

Steam car washing has gained popularity in recent years due to its environmentally friendly approach. This method uses minimal water and high-temperature steam to remove dirt, grime, and stains from both the exterior and interior of the car. The steam also disinfects, making it an excellent option for people concerned about germs. Additionally, steam car washes are gentle on the car’s paint and do not involve harsh chemicals, making them ideal for eco-conscious car owners in Chandigarh.

4. Mobile Car Wash

If you prefer the convenience of having your car cleaned at your home or workplace, a mobile car wash might be the right choice. Several companies in Chandigarh offer mobile car washing services, where trained professionals visit your location with all the necessary equipment to clean your vehicle on-site. This service saves time and ensures that your car gets the care it needs without requiring you to travel to a car wash center.

5. Car Detailing

For those who want their car to look like it just rolled out of the showroom, car detailing services are the best option. Detailing goes beyond the standard car wash, involving a deep clean of the interior and exterior, polishing, waxing, and sometimes ceramic coating. While it takes longer than a standard wash, detailing ensures your car is in pristine condition, which can be especially useful before long trips or special events.

Popular Car Wash Locations in Chandigarh

Chandigarh boasts several well-established car wash centers offering top-notch services. Here are some renowned car wash locations in the city:

Exppress Car Wash: A leading brand in Chandigarh, Exppress Car Wash is known for its state-of-the-art technology and eco-friendly cleaning solutions. They offer a range of services from basic exterior washes to full detailing packages.

The Detailing Mafia: Specializing in car detailing and premium washes, The Detailing Mafia offers steam washing, ceramic coating, and advanced detailing services. Their professional staff ensures a spotless finish for your car.

MyTVS: Known for providing reliable and affordable car wash services in Chandigarh, MyTVS offers a variety of wash packages to suit different budgets. They focus on providing quality services at pocket-friendly prices.

GoMechanic Car Washing Services: Offering both hand and automatic washes, GoMechanic is a popular choice for car owners looking for an affordable and efficient car wash in Chandigarh. They provide regular promotions and discounts, making their services highly accessible.

How to Choose the Best Car Wash in Chandigarh

With so many car wash options available, choosing the best one can feel overwhelming. Here are some factors to consider when selecting a car wash in Chandigarh:

Type of Service: Consider what your car needs. If you're looking for a quick clean, an automatic wash might be best. For a deep clean or detailing, choose a hand wash or detailing service.

Convenience: Mobile car wash services are perfect for busy individuals who want the convenience of getting their car cleaned at home or work.

Reputation: Look for car wash centers with positive reviews and a track record of satisfied customers.

Pricing: Compare the cost of services at different centers and choose one that fits your budget.

Eco-Friendliness: If sustainability is important to you, consider choosing a service that uses water-saving methods and environmentally friendly products, such as steam washing.

Conclusion

Maintaining the cleanliness of your car is essential, especially in a vibrant city like Chandigarh. With the variety of car wash in Chandigarh services available, from quick automatic washes to comprehensive detailing, there is something for every car owner. By regularly washing your car, you not only enhance its appearance but also extend its lifespan, ensuring that your vehicle remains a source of pride and enjoyment for years to come. Whether you’re looking for a basic wash or a full interior and exterior cleaning, Chandigarh has plenty of excellent options to choose from.

visit for more information

0 notes

Text

Tips and Tricks for Using a Coin Operated Car Wash

Maintaining your car’s appearance is an essential part of ownership, and using a coin operated car wash is one of the most convenient and affordable ways to do so. These self-service car washes allow you to control the cleaning process and customize it to meet your vehicle's specific needs. Whether you’re a regular user of coin operated car washes or just trying it for the first time, following a few tips and tricks can help you get the most out of your experience and achieve the best results.

Benefits of Using a Coin Operated Car Wash

Coin operated car washes offer several advantages over automatic or full-service car washes. First, they are often more cost-effective, allowing you to only pay for the time you use, typically charging by the minute. This flexibility is perfect for those who want a thorough clean without the higher costs of automatic washes. Another benefit is the level of control you have over the cleaning process. You can focus on specific areas of the car, adjust the water pressure, and even spend extra time on particularly dirty spots. This level of attention can help you achieve the best car wash results, leaving your car looking as good as new.

Tips and Tricks for Getting the Best Results

Preparation is Key

Before you arrive at the car wash, ensure you have enough coins or tokens to operate the machine. Many car washes now accept card payments, but it’s always good to have some change on hand just in case. Also, bring your own cleaning supplies, such as microfiber cloths, a bucket, and soap, if you prefer using your own products.

Pre-Rinse the Car

Start by using the high-pressure rinse setting to thoroughly wet the vehicle and loosen any dirt or debris. Focus on areas like the wheels, undercarriage, and grille, as these tend to collect the most dirt. Pre-rinsing is essential to ensure that dirt and grime don’t scratch the paint during the washing process.

Use the Soap Setting Wisely

After the pre-rinse, switch to the soap setting. Some coin operated car washes provide a foam brush for this step. Use the brush gently to avoid scratching the paint, and make sure to cover the entire surface of the car with soap. For stubborn areas, like bugs on the front bumper or bird droppings on the roof, spend a bit more time scrubbing.

Work in Sections

To avoid the soap drying on your car, it’s a good idea to wash the vehicle in sections. Start with the roof and work your way down. After soaping a section, immediately rinse it off with the high-pressure water to prevent soap spots.

Rinse Thoroughly

Once the entire car has been washed, use the high-pressure rinse again to remove all the soap. Pay extra attention to crevices around windows, mirrors, and door handles, where soap residue tends to linger. A thorough rinse ensures that no streaks or water spots are left behind.

Finish with a Wax or Spot-Free Rinse

Many coin operated car wash stations offer a wax or spot-free rinse option. The wax coating helps protect the paint, while the spot-free rinse uses deionized water to prevent water spots from forming on your car as it dries.

Best Car Wash Practices in Calgary

If you’re looking for the best car wash in Calgary, it’s important to take into account factors like location, the type of services offered, and user reviews. Many coin operated car washes in Calgary are known for their convenience and accessibility. They are ideal for drivers who prefer to handle the washing themselves but still want high-quality results. Choosing a car wash in Calgary that is well-maintained and offers up-to-date equipment will ensure you get the most value for your time and money.

Additionally, Calgary's changing weather conditions can cause significant dirt buildup on your vehicle. In winter, salt and grime from the roads can damage your car’s paint if not properly cleaned. Regular trips to a coin operated car wash during this season can prevent long-term wear and tear.

Conclusion

Using a coin operated car wash is an excellent way to keep your vehicle clean without spending a lot of money. By following these simple tips and tricks, you can make sure your car looks its best after every wash. Whether you’re looking for the best car wash or just want a quick and affordable solution, a car wash in Calgary can meet all your needs. With proper preparation, the right technique, and attention to detail, you’ll enjoy a spotless, shiny vehicle every time.

0 notes

Text

Recognizing the Raw Materials: Delhi's Wire Nail Production Process

In carpentry, building, and many other industries, wire nails are a need. Being one of the major centres for manufacturing, business owners and manufacturers may find it quite valuable to understand the raw materials used to make wire nails. This is the kind of information that is relevant to any person who is using or planning to buy a wire nail making machine, more so an automatic wire nail making machine in Delhi. This blog highlights the main raw materials employed in the wire nail making process and their significance in making sure the final product meets the standards both in quality and durability.

1. Steel wire rods are the core material.

Raw steel wire rods are used to make wire nails. The rods are pulled into slender wires, which are subsequently trimmed to length and formed into nails. The strength, durability, and corrosion resistance of the wire nails are directly influenced by the quality of the steel used in the wire rods. Higher quality steel results in these qualities. Since low-carbon steels offer both a fair degree of malleability and moderate strength, they are utilized in the production of wire rods and are hence appropriate for the nail industry.

Being based in Delhi, manufacturers always source high-quality steel wire rods from trustworthy vendors in the market to assure the quality standard of the end product. By choosing suitable steel wire rods, manufacturers can easily draw them according to the desired thickness with the help of an effective wire nail making machine and cut them to the size to take the shape of a base of a strong and reliable wire nail.

2. Coating Materials for Highly Durable Wire Nails

After the simple forming process for the nail is done, it is many times coated with various materials to give characteristics such as resistance to rusting and strength. The most commonly done ones include:

Zinc—galvanization: This offers a shield layer from corrosion and enables the nails to be used outdoors or indoors where the places are having a lot of moisture. In the places of manufacturing structures like buildings and roofing, the nails used are or require being galvanized to resist corrosion.

Phosphate: Most nails to be painted are coated with phosphate. It offers a rough texture to the nail so that the paint holds better inside.

Vinyl: A vinyl coat gives the drive smoothness to it; it also provides ease. It gives resilience to corrosion, similar to zinc.

The rich features that the automatic wire nail making machine acquires will ensure these coatings are applied efficiently in a manner that assures uniformity and high quality for each batch.

3. Lubricants for Smooth Manufacturing

Lubricants are quite essential today during the making of nails. Certainly, this is because, wire drawing and cutting, play a big role in the above processes in the reduction of wrestling, thus reducing the wear and tear of the equipment while at the same time ensuring a smooth finish according to the particular specifications. Now, this becomes quite important in those high-speed automatic wire nail making machines, where every operation that comes friction-reduced automatically enhances the efficiency and increases the life of the processors.

4. Other additives and Chemicals

Other wire nail machines in Delhi at times use another form of chemicals and additives to enhance the performance and look of the same. For example, the additives will either increase the bending resistance of the nails or provide a fine finish, as per the customer's specifications. The selection of these materials is based on nail application and customer specifications.

Procurement quality control for raw materials

For a wire nail maker to have high qualities in production, the choice of raw materials must be very critical. Many in Delhi follow strict adherence to maintaining quality provisions in choosing the right raw materials for every batch, be it impurities in steel wire rods, invariability in the coating, or maintaining the integrity of the wire nails by not letting lubricants and additives drizzle on them.

It is also the case that investment in reliable wire nail making machinery, such as that provided by Asvrmachine, is what goes into the final product's quality in a very big way. This is so since these machines are designed in a way that will ensure optimal performance with the handling of high-quality raw materials, therefore producing nails that are up to standard.

The Role of Machinery in Maximizing Raw Material Utilization

Today, the role of modern wire nail-making machines—particularly the automatic type—is significant for the best potential maximization of raw material use. These types of machines are fitted with advanced technology, which guarantees that all procedures are more exact and uniform, beginning with wire drawing to nail cutting and coating. By using a high-quality automatic machine for making wire nails in Delhi, manufacturers can decrease waste and optimally utilize given raw materials, hence lowering cost effects on business expenses.

Asvrmmachine is a top-of-the-range leader amongst the manufacturers of wire nail making machines, specially designed to meet the huge needs of manufacturers of wire nails in Delhi. Our machines are precision-engineered and made with efficiency; they promise super value for raw materials and good-quality wire nails, as expected in the industry.

Conclusion

Any manufacturer, who is interested in making quality nails, needs to understand that the basic raw materials that go into the making of wire nails are the choice of steel wire rods, the right coatings, and efficient lubricants, among other aspects at every stage of the process. The choice of steel wire rods, right coatings, efficient lubricants, and other things at every stage of the process go further down the line in keeping up the product's overall quality and durability. As a result, lending them the ability to make maximum use of the raw material to perfection while they have the right kind of machine in place—automatic wire nail making machine, for that matter. Considerate to partner with us—Asvrmachine.com, to know of our range of high-performance wire nail making machines that will increase your production capabilities in satisfying demand.

0 notes

Text

Unlocking the Secrets of SSD Chemical Solutions for Currency Cleaning

Are you searching for a reliable source to purchase SSD chemical solutions for cleaning stained and coated currency? Look no further! We provide top-notch SSD solutions for sale in Dubai, Sri Lanka, Iran, Thailand, Vietnam, and Senegal. Our cutting-edge products are designed to effectively clean anti-breeze banknotes, removing excess coated substances with remarkable efficiency.

Why Choose Our SSD Chemical Solutions?

Our SSD Solution is a powerful milky-white liquid compound specifically formulated for the cleaning of black-stained notes. Available in 1-liter, 1.5-liter, and two-liter metal insulated containers, this solution is a game-changer in the currency cleaning industry.

Key Features:

Activation Powder Synergy: Our solution works seamlessly when combined with activation powder, providing an unmatched cleaning experience.

Versatility: Suitable for various currencies, including Euro, USD, GBP, and many others.

Enhanced Cleaning: The chemical compound can be further enhanced by adding catalyst oxides and can be diluted with paste to expand its cleaning capabilities.

The SSD Solution Advantage

Our SSD Solution is renowned for its ability to clean all types of defaced notes, making it the preferred choice in the industry. With our Automatic Laser V-Q 375 Machines, we efficiently handle large-scale cleaning operations and deliver products to buyers worldwide.

Global Reach

We cater to customers across the globe, including the Americas, the United Kingdom, Europe, Africa, the Middle East, and more. Our automatic SSD, universal chemicals, and activating powders are trusted by technicians worldwide for cleaning black money.

Certified and Affordable

As a globally certified manufacturer of SSD solution chemicals, we pride ourselves on providing quality cleaning solutions at affordable prices. Our 100% pure SSD Solution is the go-to choice for those seeking effective black dollar cleaning chemicals.

How to Reach Us

Ready to experience the transformative power of our SSD chemical solutions? Contact us today!

Email: [email protected]

#price of ssd chemical solution#activation powder#clean black dollar with ssd#the ssd solution advantage#black money

0 notes

Text

Application of Acrylic Material in Thermoforming

With the demand for diversified designs and the wide application of new materials, plastic materials are favored by designers and users because of their unique characteristics. There are many types of plastic materials, with obvious characteristics and wide applications, acrylic materials are undoubtedly the ones.

Ⅰ. Thermoforming

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in the future manufacturing industry.

Thermoforming is divided into thin gauge thermoforming and heavy gauge thermoforming according to the thickness of the sheets.

Thermoforming is a plastic processing technology. The main principle is to heat a flat hard plastic sheet to soften it, then use vacuum to adsorb it to the surface of the mold, and then cool it into shape. It is widely used in plastic packaging, lighting, advertising, decoration and other industries.

Heavy gauge thermoforming refers to the use of materials with a thickness exceeding 2mm, which cannot be vacuum formed on fully automatic tools. A semi-automatic vacuum forming machine dedicated to thick gauge thermoforming must be used for processing and production.

To optimize the sheet forming process, it is crucial to consider various factors. Begin by carefully managing stress concentration heat sheet, ensuring that ambient air temperature is controlled. Achieve uniform temperature distribution across the sheet, paying particular attention to the sheet interior's cooling time. Use a proper mold covering to maintain forming temperature low. Employ a blowing mold consists of optical light sensors for precise monitoring. Alternatively, a jig or soft material can be utilized to enhance the cooling process. Implementing a horizontal heating system further contributes to the overall efficiency and effectiveness of the sheet forming operation.

Vacuum forming can be used for product design and manufacturing of rear-projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

The main advantage of pressure forming is that it can produce complex shapes and sizes, while also providing supporting services during the manufacturing process, such as printing and assembly, to meet vacuum forming requires of different customers.

Ⅱ. Acrylic Sheet

Acrylic

Acrylic (PMMA) particles are colorless or transparent material with a specific gravity of 1.19 g/cm3 and low surface hardness. They are easily scratched by hard objects and difficult to catch fire. The melting point of PMMA is about 130–140°C, which is much lower than the high temperature of glass, which is about 1000 degrees.

The panel is coated with a high concentration of ultraviolet absorber. Acrylic has high transparency, can be weathered for a long time, never fade, has a service life of 5 to 8 years, and has good light transmittance, up to 93%, with excellent light transmittance and light soft.

Acrylic sheet is a plexiglass processed through a special process. It has strong hardness, good material, radiation protection, and good light absorption effect. With the development and widespread application of optical technology, it has gradually been widely used in industrial manufacturing and modern home life. middle. Moreover, acrylic materials have large sales volume and high recognition in the market.

PMMA has the advantages of being light, cheap, and easy to form. Its forming methods include casting, injection molding, machining, vacuum forming, etc. Injection molding, in particular, can be produced in large quantities with simple process and low cost. Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

Why is Acrylic Sheet Suitable for Thermoforming?

Appearance

From the appearance point of view, acrylic sheets have the same transparency as crystal, with good light transmission effect, which can reach more than 93%. In the design and manufacturing process, many different colors can be customized according to requirements.

The dye effect is good. After a long period of There is no possibility of color fading after use. Only with good quality can it be widely promoted and used in the decoration process.

Good Processing Performance

It has excellent heat resistance. Generally speaking, the surface of its acrylic sheet has the advantage of very good resistance to high temperatures after encountering high temperatures. Of course, for different size ranges, they all need to be processed before they can be installed.

Its processing performance is relatively strong, and the quality and performance are the same as before processing. At the same time, it has good toughness and no defects will appear during the processing, the outdoor service life is about 5-10 years, and the color remains as new during use.

Production Process

In terms of the production process of acrylic sheets, there are mainly two types: casting type and extrusion type. The hardness and toughness of the sheet are improved through hot processing technology. This is why at the current stage, acrylic panels installed outdoors will not have any quality problems after a long period of weathering.

Therefore, the emergence of this new sheet material can have unique technical advantages from this process and form its own characteristics at the current stage.

Cast Plate: Higher molecular weight, excellent stiffness, strength and excellent chemical resistance. Therefore, it is more suitable for processing large-sized sign plaques, and the softening process takes a relatively long time.

This sheet is characterized by small batch processing, unmatched flexibility in color system and surface texture effects by other products, and complete product specifications, suitable for different needs.

Extruded plate: Compared with cast plate, extruded plate has lower molecular weight and weaker mechanical properties, but has higher flexibility, which is beneficial to bending and thermoforming processing, and its softening time is shorter. When processing larger-sized sheets, it is beneficial to various rapid vacuum forming.

At the same time, the thickness tolerance of extruded plates is smaller than that of cast plates. Since extruded boards are produced automatically in large batches, the colors and specifications are difficult to adjust, so the diversity of product specifications is subject to certain restrictions.

Translucency

In terms of appearance light transmission effect, there are mainly types such as transparent, translucent, milky white, etc. The colors are different, and the surface effects will also be different, and the visual impact is very strong.

Excellent Material

Acrylic sheet is a new green and environmentally friendly material in the 21st century. It has a high recycling rate and can be reused to make simple sheets. It has strong light transmittance. These characteristics make it play a key role in the decoration process.

Ⅲ. Application of Acrylic Thermoforming Products

In terms of engraving, decoration, handicraft production, advertising signs, light boxes, etc. PMMA has the advantages of being light, cheap, and easy to form.

Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

In construction, it is mainly used in lighting bodies, roofs, sheds, stairs and interior wall panels. The application of acrylic in lighting lampshades and automotive lamps on highways and high-end roads is also quite rapid.

With the construction of hotels, guesthouses and high-end residences in big cities, lighting bodies have developed rapidly. Lighting bodies made of extruded plexiglass panels have the characteristics of high overall structural strength, light weight, high light transmittance and good safety performance. Compared with inorganic glass lighting devices, it has great advantages.

In terms of sanitary ware, acrylic can be used to make bathtubs, washbasins, dressing tables and other products. Acrylic bathtubs have been widely used due to their luxurious appearance, depth, easy cleaning, high strength, light weight and comfortable use.

Acrylic is the best new material for manufacturing sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic also has the following advantages:

It has good toughness and is not easy to be damaged, it has strong repairability. Just use soft foam and a little toothpaste to wipe the sanitary ware as new.

The texture is soft and does not feel cold and biting in winter.

The colors are bright and can meet the individual pursuits of different tastes.

Using acrylic to make basins, bathtubs, and toilets is not only exquisite in style and durable, but also environmentally friendly. Its radiation is almost the same as the radiation of the human body's own bones.

Acrylic can be made into various fashionable products, such as leather bags, waist chains, watches, high heels, heels, hair accessories, brooches, bracelets, buttons, earrings, necklaces, rings, pendants, photo frames, etc. There are many types and unlimited development space for continuation.

At the same time, acrylic material has high processing plasticity and good surface hardness and transparent luster. It is often used by designers to match with various materials in the design of various exquisite containers to add texture and practicality to the containers, such as lipsticks and Delicate containers such as chemicals, and other daily necessities such as massagers, jewelry boxes, fans, etc.

Taking advantage of the cool feeling of acrylic material and combining it with creative design, acrylic material is perfectly presented in a variety of popular boutiques.

Acrylic thermoformed door panel series: European style, Chinese style doors, door frames, dado panels, ceilings, gussets, etc.

Acrylic thermoformed curtain boxes, window sill panels, window covers, etc.

Acrylic thermoformed furniture series: desktops, benches, countertops, shelves, kitchens (bookcases, wardrobes), etc.

Acrylic thermoformed series production of various speakers.

Processing and production of acrylic thermoformed vehicles and special-shaped decorative products for boats.

Ⅳ. Advantages of Thermoformed Acrylic Products

Transparency

Colorless and transparent organic glass sheet with a light transmittance of over 92%.

Excellent Weather Resistance

It has strong adaptability to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its performance will not change. It has good anti-aging performance and can be used outdoors with confidence.

Good Processing Performance

Suitable for both machining and vacuum forming, acrylic panels can be dyed, and the surface can be painted, screen-printed or vacuum coated.

Excellent Comprehensive Performance

Acrylic boards come in a wide variety of colors, and have extremely excellent comprehensive properties, providing designers with a variety of choices. Acrylic boards can be dyed, and the surface can be spray-painted, screen-printed or vacuum coated.

Non-toxic

It is harmless even if it comes into contact with people for a long time, and the gas generated when burned does not produce toxic gas.

Made of PMMA acrylic thermoforming, it has the characteristics of good light transmittance, bright and clean exterior and interior, environmental protection, and can be painted. The color can be changed to produce products of different specifications and shapes according to customer requirements.

Mainly used in plastic transparent covers of game consoles, lampshades, observation instrument covers, leisure furniture hammocks, organic handicrafts, bank signboards, advertising light boxes, etc.

Ⅴ. Precautions for Acrylic Thermoforming Production

General acrylic will undergo thermal deformation at about 100 degrees Celsius, so you must pay attention to this temperature when using it, and if it is to be used continuously, the temperature cannot be higher than 90 degrees.

When acrylic thermoformed products become blurry or unclean due to slight scratches or dust adsorption due to static electricity, you can use 1% soapy water to wipe them clean with a soft rag.

The hardness of the thermoformed surface is comparable to that of aluminum, so care should be taken to avoid scratching the surface when using or processing acrylic. If it is accidentally scratched, it will need to be restored by polishing.

When installing acrylic products, thermal expansion and contraction must be taken into consideration, and there must be a space for expansion and contraction during assembly.

If the preliminary processing work is not done well, the acrylic thermoformed product will also be deformed at the moment of demoulding, and the quality of the deformed product will inevitably be affected. In order to avoid similar problems from happening again, we must develop corresponding solutions to this problem.

In order to prevent deformation after pressure forming is demolded, the operator is first required to check the temperature of the cooling water, and at the same time adjust the water volume of the nozzle to meet the specified range. Secondly, the wind direction at each location must be adjusted to find the most suitable forming pressure for acrylic thermoforming production.

In addition, when demoulding, try to use the pressure of vibrating the upper mold to force smooth demoulding. If the air volume at the bottom can be appropriately increased, it will also be helpful to ensure the quality of acrylic thermoformed products. If these cannot solve the problem, the only way to overcome the deformation problem is to re-make the upper mold.

Conclusion

With the continuous advancement of social science and technology and the continuous improvement of process technology, acrylic thermoforming will have broader market prospects and application prospects in the future. Its future development trends include the following aspects:

1. Continuous improvement of creativity: As people pay more and more attention to personalization, acrylic thermoforming will use more creativity to create more unique products through different processes and materials.

2. More environmentally friendly and energy-saving: When making acrylic thermoforming products, low-carbon, environmentally friendly, and energy-saving methods will be increasingly used to achieve a greener production environment.

3. Upgrading of materials: As people pay more and more attention to health and environmental protection, acrylic blister materials will increasingly use healthy, environmentally friendly and safe materials, and improve the performance indicators of the materials through technical means.

0 notes

Text

Modern Kitchen Equipment: How to Choose the Best for Your Kitchen

In today's world, the kitchen is no longer just a place for cooking meals. It has become the heart of the home, a space for family gatherings, socializing with friends, and a zone for culinary experiments and creativity. To make this process as comfortable and efficient as possible, it's essential to choose the right kitchen equipment. In this blog post, we will explore several key aspects that will help you make an informed decision.

1. Kitchen Appliances

Multicookers and Pressure Cookers: These devices are lifesavers for busy individuals. A multicooker allows you to prepare a variety of dishes without needing to be present in the kitchen constantly, while a pressure cooker significantly reduces cooking time.

Blenders and Mixers: Indispensable tools for making smoothies, pureed soups, sauces, and desserts. Modern models come with numerous functions and attachments, making them versatile devices for any culinary task.

Coffee Machines: For coffee lovers, a coffee machine is not just a luxury but a necessity. Automatic models enable you to prepare complex coffee drinks, from espresso to cappuccino, with ease.

2. Kitchen Utensils

Knife Sets: A good set of knives is the cornerstone of any kitchen. When choosing knives, pay attention to the blade material and handle comfort. Stainless steel and ceramic are excellent options for long-lasting use.

Pots and Pans: Invest in high-quality pots and pans made of stainless steel, cast iron, or with non-stick coatings. They ensure even heat distribution and durability.

Kitchen Gadgets: Numerous small tools such as garlic presses, vegetable peelers, graters, and measuring cups make the cooking process much easier.

3. Storage and Organization

Storage Containers: Transparent containers of various sizes help keep food fresh and organize space in your fridge and cabinets.

Shelves and Racks: Additional shelves and racks create more storage space for dishes and kitchen utensils.

Drawer Organizers: These help keep cutlery, knives, and small kitchen gadgets organized and within reach.

4. Smart Kitchen Technology

With the advancement of technology, the kitchen is becoming increasingly smart. Today, you can find appliances that can be controlled via smartphone, programmable stoves and ovens, refrigerators with self-diagnosis functions, and many other smart features that make cooking even more straightforward and convenient.

In conclusion, the right choice of kitchen equipment not only makes the cooking process easier but also more enjoyable and productive. Invest in high-quality appliances and utensils that will serve you for many years and inspire culinary experiments. Let your kitchen become a true place of inspiration and comfort!

Kitchen Warehouse Trading LLC

Website: https://shop.kitchenwarehouse.ae

Phone: +971559997636

Address: Industrial Area 11, Industrial Area, Sharjah, UAE

Open hours: Mon-Sat 9 AM–8:30 PM; Sunday 10 AM–8:30 PM

#commercial kitchen equipment#restaurant equipment near me#restaurant kitchen equipment#kitchen equipment#restaurant equipment#commercial restaurant equipment#kitchen equipment in uae#kitchen equipment supplier in uae#kitchen supplies uae#commercial restaurant kitchen equipment#kitchen equipment supplier#kitchenware for restaurant#commercial kitchen suppliers#kitchen equipment and supplies#kitchen equipment supplies#restaurant equipment dubai#commercial kitchen equipment dubai#kitchen equipments in dubai#dubai kitchen equipment#kitchen equipment company in dubai#kitchen equipment supplier in dubai#kitchen equipments dubai#kitchen equipment suppliers in uae#commercial kitchen equipments#industrial kitchen equipment#commercial kitchen equipment suppliers in uae#kitchen equipment suppliers in dubai#kitchen equipment dubai#kitchen equipment suppliers uae#kitchen equipment companies in uae

0 notes

Text

Medical Sheet Metal Fabrication

In the modern medical industry, sheet metal products are an indispensable part. Medical device sheet metal product processing is an important manufacturing process that can provide high-quality medical equipment and appliances for hospitals and medical institutions, and provide better healthcare services for patients.

The application of medical device sheet metal processing is very wide, mainly involving medical equipment, medical devices, medical appliances and other fields. Sheet metal processing technology can manufacture medical devices of various shapes and sizes, such as operating tables, surgical lamps, surgical instrument racks, etc. These devices can help doctors perform surgeries and treatments more effectively. Medical sheet metal products can also be used to manufacture medical equipment, such as stretchers, wheelchairs, beds, etc. These tools can provide a more comfortable nursing environment and help patients recover.

Medical Metal Parts Manufacturing Capabilities

The advantage of medical sheet metal product processing is its precision and reliability. As an experienced sheet metal factory in China, we follow the strict quality control system, use well trained engineers and workers, use state of the art equipment to ensure our sheet metal parts have the best precision and accuracy.

We have decades of experience in manufacturing sheet metal parts for medical industry. Because of its complexity in design and aesthetics in appearance, medical device has high requirements on factories, and almost all processes will be involved, such as laser cutting, CNC bending, precision stamping, deep drawing, welding, surface treatment, etc. We already have a deep understanding of medical devices and can meet our customers' quality requirements.

How Yixing Technology Produce Medical Metal Parts

How to make medical device can be mainly divided into below four parts:

Part 1: Cutting Materials

Laser cutting is one of the most common cutting methods in sheet metal processing. Firstly, according to the size specifications of the finished sheet metal parts, stainless steel and other sheets are laser cut into the required dimensions for backup. This process is collectively referred to as cutting.

Part 2: Bending

Bending is the process of CNC bending the finished material according to the size specifications of the sheet metal workpiece. It will be prepared for the next step of sheet metal welding. Take patient transfer device as example, the main parts are square tubes. We use press brake or pipe bending machine to do the precise bending.

Part 3: Welding

Welding can be divided into two methods: manual welding or robot automatic welding. It is a process of welding finished materials based on the cut, bent or formed sheet metal parts. It is combining two or more types of the same or different types of sheets. Shanghai Yixing Technology can do TIG and MIG welding. Material selection and welding quality is the most important because it will influence the load bearing capacity and whether the machine can do straight line rolling. We pay attention on every detail.

Part 4: Surface Treatment

There are many surface treatment we can do such as sandblasting, anodization, polishing, powder coating, electrophoretic paint, hot-dip galvanizing, electroplating or others. For the patient transfer device, the main surface treatment is powder coating. The minimum coating thickness is more than 60um and we do 100 grid test and salt spray test to check the adhesion and corrosion resistance.

Patient transfer device is a complicated design and more process will be involved which is not listed above like riveting, threading, printing, heat treatment, assembly with motors and other plastic parts and hammock.

0 notes

Note

A garden sounds nice. {She still refuses to lift her head at him, but is now enjoying the warmth in the connection. He didn't pull away, so she supposes it's alright to stay, besides, she feels protected. But she's also trying not to think about his arms and how normal and breathtaking he looks without the white coat. He looks young and vibrant, albeit a little tired. She feels bad he's encouraging her, and is so nervous that he's making her heart swell in so many ways. She even wanted to laugh a little at his teases.}

Ok, no more cake box mix. I'll... if you send me your recipe... Maybe I'll try... {She hesitated but then presses a finger to the skin on his forearm, hoping it feels lighthearted to him.} You won't gatekeep it if I promise not to share?

{Her shoulder lifts off his arm as soon as they're outside, and she feels like she can breathe a little easier.} I'm- Thanks for walking with me, I'm glad you got to stretch. Please, um... I'd love to try those videos, if you want to share sometime. {She giggles, a little more relaxed.} Is that a private prescription, Doctor?

{She creates a bit of distance and goes to take in the greenery, admiring a bloom in front of her, but her eyes keep wandering back to him.}

~🏞️

(Not at all I just wish I wrote half as good!)

The new landscaping was finished a couple of weeks ago, so you're really in for a treat. We just have to make a quick stop at the vending machine by the entrance for a little gift for Clopidogrel. I have a feeling you two will really hit it off. His eyes flashed with a hint of mischievous energy as he tries to catch her gaze despite her hard fought avoidance.

He thinks that maybe his teasing and joking has pushed too hard when she keeps her head bowed, until he feels her finger reach out and poke the flesh of his forearm as she asks to try one of his recipes. Greyson can't help the thoughts that bloom in him- of how just that sliver of skin on skin contact sears and tightens the muscles around his lungs.

Instead, he laughs, happy enough to see her loosen up a bit. Gatekeep you dear lady? Perish the thought! Of course I'll send you my recipe. I'll even do you one better and teach you how to make it, you know, if you ever run into any trouble. But the recipe is pretty easy to follow.

After a quick stop at the snack machine for a packet of almonds that he slips into his pocket, the warm spring breeze finally greets them past the rush of the automatic doors. As Greyson feels the pressure of her shoulder lift off of him, there is a new sensation added to his heart- disappointment. She couldn't stay attached to him forever of course, that would be silly.

The lacking quickly dissolves, a puddle of forgotten setbacks as he hears it for the first time. The most adorable, carefree giggle he's ever heard from her before. Of course, yes. Absolutely. I have a few I can suggest- he's sure he sounds a bit too eager, too willing- but this is the most relaxed he's seen her, and he wants to keep pushing her towards this. To whatever this is.

Greyson is happy to let her walk in front of him, a few paces behind her as he watches her take in the garden and its many trees, flowers, and features. She looks radiant, resplendent even surrounded by all the sunlight, colours, and foliage, and he realized now why those old Grimm fairytales about men being lured off by beautiful forest spirits were written. He would surly follow.

He takes a few steps towards her when he notices her stop to admire the large cherry blossom in the central garden. Reaching up, he plucks one of the blooms, delicately holding it in his fingers as if it were one of his many surgical tools. Greyson takes a deep breath, exhaling to prep himself. He could do this. He could definitely do this.

Another step, and he was close behind her, head ducked low so his voice carried only as far as her ear, and careful to keep his tone from becoming too suggestive lest he come off totally inappropriate.

Is that something you'd like? A private prescription?

#greyson's appointments#answers#my favorite patient 🏞#lnds rp#(and i oop- 👀)#(also shhhshshhhshsh you're doing great oh my goodness !!!)

1 note

·

View note

Text

Carton industry continues to grow in India and globally

According to current research reports, the global carton industry is forecast to grow at a CAGR of 5% till 2033 to US$ 7.7 billion from the 2023 figure of US$ 4.7 billion. In India we see growth coming from eCommerce, food and beverages, FMCG, household products, and white goods. The variety of cartons keeps increasing from the simple monocarton, liquid packaging laminates, solid board luxury boxes, litho-laminated corrugated cartons and plain and white or bleached liner corrugated cartons. The litho-laminated e, f, and g-flute or micro-fluted cartons that incorporate recycled liners are seen as an economical solution providing a combination of better compression and protection while retaining their stand-out value on the shelf.

There is a perception that paper-based packaging or cartons are more sustainable than flexible packaging and there is some movement in this direction in the country too – although some of the special papers and coatings required to create barrier properties are not yet locally available as off-the-shelf inputs. Additionally, some of the uses of these cartons with barrier properties come from start-ups, niche and boutique products with volumes too low to justify the procurement and logistics costs of importing specialty papers.

Notably, Jitendra Rohilla of Komori India says, “Right now, many of our 6 and 7-color automated offset press installations are taking place at packaging converters as that industry is growing and will continue to grow. There are multiple factors for this growth including our small packaging consumption per capita, and the increasing wealth, young population, and the increasing focus on hygiene and shelf impact and shelf life.”

Venugopal Menon of Bobst India points out that the growth in packaging machinery is now driven by automation. He attributes the current growth to an increasing number of converters seeking automation solutions. Discussing Bobst Inda's performance in 2023, Menon noted that except for the corrugated segment, the company witnessed positive outcomes across the folding carton, flexible, and label segments. “We hope that the investment cycle in the corrugated board cycle will come back in 2024.”

In light of the changing needs of carton converters globally, Bobst has recently enhanced the automation and connectivity of its folder gluer portfolio by introducing a new generation of Expertfold, Visionfold, and Novafold machines.

TCPL, a packaging converter that produces both cartons and flexible packaging, recently entered the rigid box segment after acquiring a 100% stake in Creative Offset in late 2023. It commissioned three Zhongke automatic rigid box-making lines for manufacturing rigid and luxury boxes for mobile phones, smart watches, wearables, and the speciality gift packaging segment. Stating India has a lot of cell phone manufacturers and exporters, Pooja Rajpal, director of Zhongke India comments that business is good in India since the cellphone technology is changing fast, and everybody wants the latest phones – and the manufacturers need boxes for these.

One could see some of the impetus or energy in the local carton industry at Pamex 2024 in Mumbai, where companies like Komori, DGM, Bobst, and others announced several deals at the show. DGM India announced ten deals for its die-cutters, folder gluers, and flute laminators at Pamex. This businesslike optimism persists even in the face of currently flat top-line growth among converters because of the benign price of raw materials. While converted carton tonnage has increased in the past year, the soft prices of paperboard have led to modest increases in top-line revenues.

While research reports forecast a carton industry boom in the coming decade, the Asia Pacific region is emerging as a particularly lucrative market due to its high population, rapid industrialization and increasing consumer goods demand. Compact, modular and increasingly automated cartoning machines with quick changeover capabilities will gain traction with the need for flexibility and adaptability in handling diverse product lines.

0 notes

Text

The Working Principle and Function of the Coating Machine

Kerone is a leading provider of innovative thermal processing solutions, offering a range of machines and heating systems for use in many industries. Developing and producing heating systems that are especially tailored to meet the needs of particular customers is their specialty. Kerone provides coating machines that are intended to apply coatings onto different surfaces in addition to its heating solutions. These devices are essential in sectors where accurate coating application is critical to product performance and quality, such as the automotive, electronics, and pharmaceutical industries. Companies may improve the functioning and appearance of their goods by using Kerone's coating machines, which are designed to produce coatings that are uniform and consistent. Kerone, to put it simply, is a company that specializes in efficient heating of objects and provides the ideal coating application devices to improve their goods.