#automatic micropipette

Explore tagged Tumblr posts

Text

Step-by-Step Guide to Achieving Consistent Pipetting Results

Pipetting is one of the important techniques in laboratories in many fields of study, ranging from molecular biology to chemistry, clinical research, and diagnostics. Every lab technician looks towards getting consistent pipetting results to obtain accurate data, reproducibility, and successful experiments.

At times throughout the experiment, they experience significant pipette failure, which affects the experiment. Along with this, they could see themselves in the middle of nowhere, and may also need to restart the experiment.

This could lead to affecting time management in the experiment procedures. It will also affect the quality of solutions involved in the experiment, as they will be exposed to the open air through the failed experiment.

This blog has discussed the various steps that can be followed for consistent pipetting results which can prevent various concerns through experiments. Below are step-by-step instructions to assist you in maximizing your pipetting technique and achieving consistent results every time.

Steps to Achieve Consistent Pipetting Results

Choose the Correct Pipette and Tip

Starting with the experiment procedures, before this selecting the right pipette and tip is critical to precision and accuracy. A pipette used should be within the volume range of your liquid transfer. If you are eager to buy one, you can first compare micropipette price between brands and find the right one for you.

Pipetting at the maximum or minimum limit of a pipette's capacity can be inexact. In addition, high-quality tips that are compatible with the pipette model guarantee a snug fit and do not leak or contain air pockets. If you work with volatile or sensitive samples, filtered tips may prevent contamination and preserve sample integrity.

Calibrate Your Pipette Periodically

Other than choosing the right pipette, calibration is important as it guarantees your pipette is dispensing the right volume. Following the pipette calibration guidelines is vital to ensure accuracy and compliance with laboratory regulations.

It can be useful to look for the manufacturer's instructions and calibrate pipettes at least every 3-6 months, depending on how often they are used. Further, it may provide you with enhanced pipetting standards.

Regular testing for inconsistency can be achieved through gravimetric testing, where water is pipetted and weighed to check for accuracy. Pipettes must also be treated gently—dropping them or subjecting them to extreme temperatures can influence their calibration and result in inaccurate results.

Optimize Your Pipetting Technique

Using a uniform pipetting method may reduce errors and enhance accuracy. Among all the helpful methods, it is pre-wetting the tip by aspirating and dispensing the liquid once before actual pipetting. This prevents volume irregularities due to evaporation.

Pipetting at a uniform angle is also essential; so hold the pipette vertically when aspirating and slightly angled around 10°-20° when dispensing. Aspirate with the tip 2-3 mm below the liquid level to prevent air bubbles. Besides, using continuous pressure when pressing the plunger and maintaining a rhythm constant for aspiration and dispensing provides consistent outcomes.

A quick pause before dispensing is used to make the liquid steady, minimizing inaccuracy. When dealing with thicker liquids such as glycerol, reverse pipetting can also be used to facilitate thorough dispensing without being retained in the tip.

Avoid Common Pipetting Errors

Even old hands get pipetting wrong. Certain prevalent mistakes involve utilizing the incorrect pipette or tip, which could result in leakage and incorrect volumes. Failure to pre-wet the tip might also cause variation in volumes, particularly when aspirating volatile solutions.

Excessive speed when pipetting might introduce air bubbles or foam into the liquid, which can eventually affect accuracy. Through this, improper pipetting, where the pipette is held off-centre while aspirating, may lead to differences in volumes. Additionally, temperature variations can impact precision, so it is important to allow cold or warm liquids to acclimate before pipetting.

Maintain and Store Your Pipette Properly

Proper maintenance extends the life of your pipette and can also play a major role in providing the required accuracy you crave. Investing in an automatic micropipette can also help improve precision and reduce manual errors. Regular cleaning with 70% ethanol and internal component checks can prevent contamination and mechanical failure.

Storage is another important part of keeping your pipettes working. So pipette should be stored vertically on a pipette stand to avoid internal contamination and mechanical wear. When using high-throughput pipetting, switching between several pipettes can distribute the stress among multiple instruments. An easy method to test for leaks is to hold the pipette tip against the lab bench after aspirating and see whether liquid leaks out.

Standardize and Train Pipetting Techniques in Your Lab

Following best practices by all technicians of the lab ensures uniformity in experiments. Most laboratories rely on the best micropipette brand in India, Microlit, to provide high-quality and dependable pipetting equipment.

Regular training sessions ensure that even seasoned scientists use proper pipetting techniques. Using Standard Operating Procedures (SOPs) ensures a standard approach, minimizing user variability. Furthermore, proficiency testing enables individuals to evaluate their pipetting skills and make improvements for improved reproducibility.

Conclusion

Consistent pipetting results are important for the required precision, reproducibility, and experiment success in laboratory settings. Utilizing a systematized protocol, lab personnel can avoid errors and optimize accuracy. Using a proper pipette and corresponding tips is the key to dependable liquid handling. Consistent calibration by the manufacturer is ensured to provide accurate measurements and rule out any disparity in the volumes measured.

Improving pipetting methods, including pre-wetting the tip, holding at a consistent angle, and applying steady plunger pressure, improves accuracy. Eliminating frequent errors like pipetting too rapidly, employing the wrong tips, and ignoring temperature equilibration increases precision. Maintaining pipettes properly and correctly storing them, such as frequent cleaning and leak testing, increases their lifespan and avoids mechanical breakdowns.

Apart from equipment maintenance, pipetting technique standardization throughout the lab via training sessions and following Standard Operating Procedures (SOPs) provides consistency in results. Spending money on quality pipettes and accessories, including those from well-known companies like Microlit, also aids in precise and reproducible pipetting.

By adopting these best practices, laboratories can provide consistent results, minimize experimental errors, and increase overall efficiency, resulting in more trustworthy scientific results.

#micropipette price#pipette calibration guidelines#automatic micropipette#micropipette brand in India#micropipette#pipettes

0 notes

Text

I really need people to understand that the things scientists do in their spooky, scary, mysterious labs full of strange and unnatural chemicals are the exact same things you do every day at home.

When I'm working with organic solvents, I use a ventilated fumehood so I don't breathe in toxic vapours, just like when you cook on a gas stove, you turn on the fan on your range hood so you don't breathe in toxic carbon monoxide (you'd better be doing this if you have a gas stove). When I need to add a specific amount of reagent, I'll use measuring instruments like a micropipette, just like when you need to add a specific amount of baking soda, you use measuring instruments like a teaspoon. When I want to analyze the chemicals in an environmental samples, I soak it in solvent so the chemicals leach out, just like when you want a coffee, you soak coffee grounds in hot water so the chemicals leach out (because yes, caffeine and all the other chemicals that make coffee, coffee, are chemicals). We are doing the exact same things, the difference is just what tools and ingredients we're working with.

But that's the same difference between you and a Michelin star chef. There are restaurants out there equipped with cutting-edge cooking equipment, things I don't know enough about to even give examples of just like you might not know enough about lab work to give examples of things I use. There are probably ingredients in dishes I've never even heard of because they're so far beyond what I can afford and just not necessary for the kind of food I make. But at most, people just scoff at how much money someone is willing to pay for a tiny plate of deconstructed fruit. Nobody pictures Gordon Ramsay the same way they picture scary chemical labs making scary chemical things.

You can also do science at home, and lots of people do! Not even just as cooking, kids especially like to do fun experiments like baking soda and vinegar explosions or separating the colours in a Sharpie or even extracting DNA from strawberries, which you can do with dish soap and rubbing alcohol. People even do the "fancier" experiments in garage labs, synthesizing organic molecules and such. Actual labs are just higher-tech for the same reason high end restaurants are higher-tech; you can't cure cancer in a garage, and you can't make chocolate sculptures in my tiny, student house kitchen without the proper molds and thermometers and supplies.

Obviously yes, scientists usually work with chemicals that are significantly more dangerous than what you find around your house, although your home is more dangerous than you think. People get food poisoning all the time, and I'd bet that more people die from eating spoiled food than from exposure to chemicals in a lab. And just because something starts out dangerous doesn't mean it stays that way. Raw chicken can make you sick or kill you, but cooked chicken is a delicious and healthy meal (as long as you season it, not seasoning your chicken automatically sends you to mega hell). Similarly, a lot of organic molecules are dangerous if you were to just chug them, but taken in correct dosages at appropriate times, the drugs that get made from those chemicals are completely safe.

I think there's this tendency to hold science as this separate, scary, complicated thing that only a few people are capable of doing and that anything coming out of a lab is unnatural and dangerous, and I think that scientists are responsible for that in a lot of ways. But with how significant anti-intellectualism is right now and how crucial that has been to the rise of fascism lately, I think it's just so important to understand that the only thing that makes science special is that my tools are just really expensive and when scientists make something that goes in your body, it's usually not food, because you don't need $2 000 measuring cups to make yourself some cookies.

Science is not special, labs are not unnatural, and this is so important to understand.

16 notes

·

View notes

Text

hq + what they’d be like as lab partners

───✱*.。:。✱*.:。✧*.。✰*.:。✧*.。:。*.。✱ ───

the good, the bad, and the ugly when it comes to lab partners. honestly, your partner will either make or break the lab experience for you... so choose wisely! based off my time wasted away in a well ventilated lab.

───✱*.。:。✱*.:。✧*.。✰*.:。✧*.。:。*.。✱ ───

atsumu ➝ a walking nightmare in the lab. always goes “the lab doesn’t seem that bad” to his friends and then gets stuck on the first five steps. is the one that gets a 348% error after decanting and drying underneath the hood and then makes up a random number for the results just to get out on time. for the remainder of the semester, YOU’RE the one doing the lab and atsumu’s just an errand boy gathering the necessary supplies. always forgets to label his beakers and will mix up the water and the acid because of this... the TA despises him and will rip the glassware out of his hands and label it for him before going back to the bench. since you’re his lab partner, you get your lab graded harder by association

kita ➝ the lab saint. he actually knows what he’s doing because he read the lab the day before, made multiple notes and diagrams, and will ask questions during initial procedure breakdown. the professors love him and ask if he would be willing to share his lab notes as a sample for the next semester. keeps his bench incredibly clean and does a 50/50 split of the work to keep things fair (also tells you that it’s the best way to learn). if you’re confused with the process, he takes over and shows you how to properly do it, making sure to go slowly and asks you if you understand. never gets frustrated when things don’t work out, instead traces back his steps to see where he went wrong. his percent yield is always in the 90′s (a walking god amongst men). people are constantly telling you how lucky you are to have him as a lab partner as if you don’t already know

akaashi ➝ the smart lab partner who doesn’t care what you do as long as you two get the right data. he’s a pretty chill guy, but if you tend to be on the clumsier side, he’ll take note and be like “...maybe I should do this part” to be nice. kind of burnt out and it shows in lab when he puts on his lab coat backwards or when he grips his micropipette a little too tight. sighs a lot when heating up or cooling solvents (he despises how most of lab is just a waiting game). funniest in the driest way possible, and if you reciprocate his sense of humor, then he’ll hold you to a higher regard. you two meet up every week to finish writing up the lab reports because it’s easier to check calculations and create your reasonings together this way (won’t admit that he enjoys your company aloud)

osamu ➝ didn’t show up to the first lab because he switched majors right beforehand. said he gave up on pre-med. it’s only the second week of classes, osamu...

suna ➝ has his lab partner do all the work and goes “Ooooh neat” when recording the reactions (straight up writes “turned yellow” as an answer... like okay? at what temperature? did it bubble? was a visible gas released? how long did it take? he does the bare minimum). kind of never knows what’s going on in lab because he reads the procedure right before class, so he’s heavily reliant on his partner. if YOU don’t know what’s going on... then you’re both screwed. always forgets his lab coat and you have to text him 30 minutes before class to go get it. has a nice circle of friends who share their data with him, so he’ll copy it and show it to you when you’re stuck. honestly, the only reason why you guys are passing lab is because of the sheer generosity of others

futakuchi ➝ the smart asshole in lab. gets the job done, but he’s horrible to work with. makes sure he does everything as fast as possible because he wants to get out within the next hour... if the directions call for medium heat, he has the hot plate dialed to the highest setting; will shake up the test tubes himself if the centrifuge is busy; doesn’t care about cross contamination and uses the same wooden stirring stick throughout the lab (just leaves it lying on the bench... the bench he never sterilizes). always pressuring you to hurry the hell up when grabbing solvents from the TA. bosses you around all the time and will straight up do the lab by himself when he’s in a rush (says “I have plans after this” as if you dont?!). you two get a nice grade... but was it worth it?

kuroo ➝ great partner, the only flaw he has is that he cares way too much about every little detail. follows lab instructions to the T. handbook says to stir for ten minutes? you’re standing there with that stirring rod for exactly ten minutes. doing titrations and the professor says the color should be a pale pink? he’s watching every single drip and is questioning if the pink should be more vibrant or not. need 7mL of water? he’s checking the meniscus of the graduated cylinder, dumping and refilling until it’s a perfect 7mL. sweats whenever he uses the pastor pipettes. makes you nervous sometimes because his lab anxiety rubs off you. by the time you two are halfway done, the rest of the class already left. you guys are always the last to leave lab, but he makes up for this by buying you lunch

matsukawa ➝ poured water into sulfuric acid. did it in front of the TA, was automatically failed for the lab that week, and kicked out for the day. now you have to do the lab by yourself

hanamaki ➝ was the one who told matsukawa to pour water into sulfuric acid as a joke. felt so bad about it that he went after him. you end up doing the lab by yourself and you don’t share the data with him out of pettiness. he failed the lab that week

sugawara ➝ he’s a fun lab partner, but he plays too much. like no, stop, please keep that petri dish away from your mouth; that agar may look like jelly, but we just streaked it with e. coli... will act like a model student whenever the TA walks by, but as soon as they’re out of sight... he’s treating the lab like it’s a cooking mama mini game. pretends that the inoculating loop put over the bunsen burner is a stick with a marshmallow at the end. even though he messes around a lot, he still gets his work done. texts you cheesy lab jokes. at the end of the semester, he stole a couple pH strips as a souvenir for surviving lab together and will occasionally use them to test on the water from the school fountains (spoiler: he no longer drinks from the water fountains on campus)

shirabu ➝ the TA. he was incredibly standoffish when he first introduced himself to the class, but really he’s just kind of awkward. knows when students copy data off of other people, but at this point he’s too tired to even care (he’s an undergrad TA, so he doesn’t get paid for being in the lab). can be kind of terrifying at points; he’ll be walking around to monitor students and will straight up ask “why are your hands shaking?” and “did you not read the lab before coming today?” when he sees you do something wrong, he’ll instantly correct you (you need to trash the micropipette tip RIGHT after you use it) in a stern manner. don’t cross him or else he’ll start grading your papers extra hard. someone wrote their phone number for him in their lab report once and he took points off for it

───✱*.。:。✱*.:。✧*.。✰*.:。✧*.。:。*.。✱ ───

#haikyuu#hq#haikyuu headcanons#no these lab partners really exist I'm not making this up#I pity you if you get stuck with atsumu or suna lmao#atsumu#kita#akaashi#osamu#suna#futakuchi#kuroo#matsukawa#hanamaki#sugawara#shirabu#moosh headcanons#this is so random my bad I just thought it would be so funny#also idk if it's just my lab but if you pour water into acid and the TA/professor catches you#then u get kicked out Lmao#build up those good habits#this is a mix of chem bio and molcell lab sorry I initially just wanted it to be chem lab lmao#I would say futakuchi's the worst lab partner but at least you don't have to worry about ur grade lol#q

167 notes

·

View notes

Photo

7.26.18 // 10:00am // things no one ever tells you about research

so you just landed a position as a "research assistant" huh? whether you're padding your resume, gpa, or you're one of those people who's just super driven and passionate, you might want to read this.. ;)

this isn't super back to school relevant, but i had an epiphany while i was at lab today (waiting for shit as usual) and wanted to make this. this advice is definitely a bit more tailored to biology/medical labs, but def includes some stuff that applies to a bunch of fields! you know the drill, more under the cut! xoxo, m

1. it's not as glamorous as you think it'll be. you're prob thinking “oh yeah i’m mature and i know how the world works. obviously you don’t cure cancer in 3 days.” that is true. (i’m not making fun i actually had a similar mindset). but it will take a *long* time. i’m talking months and years. you might do a a bunch of different experiments and try to get them to work and they never do. i literally worked in a lab for 6 months and didn’t produce a single useful result. it’s also possible it might start feeling like a mindless task or chore. what i’m trying to say is, don’t expect to feel like you’re changing the world. or even that you’re on the road to changing the world. you might have to go through a lot of failure and repetition to get even a little close

2. there’s a lot of waiting. this is definitely more specific to biology/chemistry type labs. but you will be sitting around waiting for reactions. a lot. bring something to do with you.

3. everything takes longer than you think it will. i’m serious. estimate how long something will take if you go slow, take your time, and account for something going wrong. now add at least 15 minutes to that. trust me.

4. you’ll screw up. a lot. you’ll pipette the wrong thing into the tube. you’ll drop glassware. you’ll forget to refrigerate something. maybe you’ll mislabel. don’t beat yourself up too much. be mindful and learn from mistakes, but know that everyone makes them. pi’s (principal investigators aka your boss/the researcher you work for) are generally pretty forgiving, especially in the first bit.

5. don’t mix bleach with anything but water. please don’t do it. take it from someone who has. it was terrifying.

6. you need a schedule. i don’t mean that you have hours and work 9-5. both of the labs i’ve worked in couldn’t care less when i came in. however, you need to plan things. if you’re working with cells, they’re a pain in the ass. once you get familiar with them, you’ll need to map out what/when you want to run experiments so you can make sure they’re ready at that time. or if you need to work with someone else to run experiments. for example, i work with a technician for certain assays and need to make appointments with her. or some processes are time sensitive and once you start them, you can’t stop until they’re over. don’t try to cram too much into one day or you’ll never go home.

7. weekends aren’t really a thing. ok this depends on how you structure your time/if things cooperate (hint: they never do)/what sort of research you’re doing. but i go into lab at least once every weekend pretty much. honestly having the whole lab to myself is kinda relaxing lol

8. bring headphones. otherwise you might go crazy from not being able to talk to anyone. also they can help you concentrate.

9. go slow. i mean this advice comes up in relation to everything. but it is *so important* for lab work. if you’re rushed or nervous or both, you’re way more prone to making mistakes. and lab reagents are expensive as all hell. seriously. look up the price of some sybr green.

10. ask questions. the other people in your lab/shared lab space are great resources. generally they’re pretty nice. obviously, senior members know a lot more than you do. but also other undergrads. someone else might be an expert in something you’re just learning. it’ll make sure you don’t break/waste anything and give you peace of mind. at the very least, you can share some accountability if you screw up lol.

11. check everything. if you’ve done an experiment a bunch of times and it still doesn’t work even though you fixed everything you thought you were doing wrong and asked a bunch of questions, you’re probably missing something. ideally, have someone watch you do the process. if not, go over your protocol with them. every single step. and every detail. i literally thought i was doing something wrong for months because i was using human dna primers and not mouse ones. i had checked everything else, but it never occurred to me to verify that.

12. document everything. as you learn, you’ll get more familiar and figure out what works best. you remember it now, but if you haven’t done something in 3 weeks and need to remember that one trick you figured out, you’ll be kicking yourself if you don’t write it down.

>> similar to documenting, label everything. know *exactly* what’s in a bottle because you’ll remember 3 days after you made it but in 3 months? might land you in trouble.

lightning round! mostly bio/chem/wet lab stuff!

- check the volume your micropipette is set to uptake. just because you grabbed the p1000 doesn’t mean it will automatically be sucking up 1mL

- accidentally sucked liquid up into the body of your automatic pipette? now it doesn’t work? you didn’t break the whole thing, it just needs a new filter. they’re about $5.

- always label your damn tubes. before you put stuff in them.

- a quick spin in the centrifuge is your best friend. especially if there was supposed to be 5 uL in that tube but you’re only getting 3.5

- put your agarose gel in the fridge until really hard before removing the comb. also remove the comb once the gel is submerged in buffer.

- it’s ok to use your other hand to brace the pipette if you’re shaky. it’ll save you a lot of grief.

- use old pipette boxes as racks for smaller tubes

- cells wait for nothing. not even new year’s day.

- use a timer. i’ve forgotten about things so many times, especially when i’m multitasking

- make note of any prep work that needs to be done before an experiment. (ex: set the centrifuge to 4 degrees) now you’ll know to do it beforehand and save yourself time.

- make sure equipment is available. before starting anything, make sure the stuff you’ll need to use will be ready when you need it. put a post it on the machine if you have to.

- keep a jacket in lab. i guarantee it will be cold. if you work in lab during the school year, you might want to keep some closed toed shoes and long pants there too depending on the “dress code”.

- learn basic lab maintenance/where stuff is asap. it sucks to be the only one in lab when you run out of something and don’t know how to fix that.

hope this was useful and let me know if you want to know more on this subject! or on anything. you know i love suggestions. xoxo, m

#pennyfynotes#pfynguides#masterpost#tips#stem#research#school#stuudy#study#studyblr#university#college#lab#advice#hufflepuffwannabe#stillstudies#castillos-co#universi-tea#noodledesk#thestudyfeels#jiyeonstudies#themedtimes

503 notes

·

View notes

Text

Biomed Grid | Automatic Generation of Drug Concentration Gradient by a Modified Ink-jet Printer and its Application in Drug Screening

Abstract

Manual preparation of drug concentration gradient is labor-intensive and limits the efficiency of a drug screening to some extent, especially at large scale. In this study, we reported an automatic method to generate drug concentration gradient in 24-well plate. We loaded drug solution in a modified hot ink-jet printer, designed printing pattern in the WORD software, customized the concentration gradient in the WORD software by RGB coding, and finally printed the drug concentration gradient in the 24-well plate. A drug concentration gradient can be automatically generated within 5s in arbitrary pattern. Based on this flexible technology, we developed an ink-jet printer-based drug screening assay. Concentration gradient of 5-fluorouracil, as well as Mcf-7 cells, were printed in the 24-well plate, and the inhibition rate of Mcf-7 cells was measured by MTT method. This was the first time that hot inkjet printing technology was used in drug screening.

Keywords: Bioprinting; Drug screening; Concentration gradient; Ink-jet printer; RGB

Introduction

Preparation of a concentration gradient of drug candidate is a prerequisite to study cell-drug interaction quantitatively. Currently, this step is manually operated in the laboratory, which is labor intensive and annoying. Automation is desirable in practice. Derringer et al. developed an automatic method to generate concentration gradient [1], and Ye et al. [2] used this method in drug screening [2,3], however, this method was only applicable in microfluidic device, not in 96-well or 24-well plate, thus its applications were limited. Previously, we established drug screening device based on biomedical engineering methods [4]. In this study, we developed a method to generate concentration gradient in plate automatically, using normal commercial ink-jet printer and WORD software. We also used the same printer to print the cell suspension, thus we finally developed a drug screening assay based on hot ink-jet printing. Hot ink-jet printing technique is useful for printing cells in biomedical engineering. It works by the principle in which the heating element turns the “biological inks” into bubbles at bottom of the nozzle instantly and the pressure generated makes a certain amount of inks free from the surface tension there and pushed from the nozzle. As an approach for cell printing, hot ink-jet printer has been used in tissue engineering [5], biological microarray construction [6], stem cell research [7] and gene transcription [8]. However, there are few reports in its application in drug screening at cellular level

In this paper, a hot ink-jet printer was custom-modified as an automatic dispensing tool for the engineering of cell arrays and generation of concentration gradient of drugs in a 24-well plate. By means of this apparatus, cell/drug composite arrays can be automatically generated for drug screening. RGB value was used as the output gauge of drug concentrations for the first time. A Mcf-7 cell/5-fluorouracil composite array was engineered to demonstrate the applicability of the hot ink-jet printer in the drug screening.

Experimental

Materials

Hoechst 33342 fluorescence dye and 3-(4,5-dimethylthiazol-2- yl)-2,5-diphenyltetrazolium bromide (MTT) were purchased from Kubolai inc. Beijing. Propidium iodide was obtained from Jingchun technology inc. Shanghai. 5-fluorouracil was purchased from Sigma- Aldrich, United Kingdom. Phosphorate buffer saline (pH7.4) was prepared and sterilized in lab. DMEM cell culture medium and fetal bovine serum from HyClone, New Zealand, was used in this study. Methanol of HPLC grade from local company was used. Ultrapure water was obtained with Millipore water purification system.

Instruments

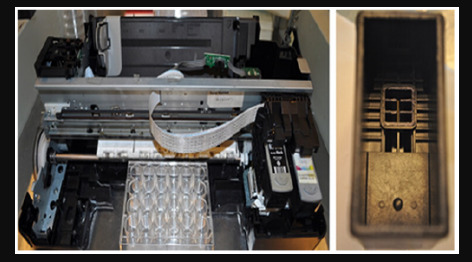

Canon PIXMA ip 1980 ink-jet printer with PG830 ink box from Canon, Japan, was modified in this study. Inverted fluorescence microscope IX71 from Olympus, Japan, was used. Agilent 1200 HPLC was from Agilent, USA. Synergy H1 microplate reader was from BioTek, USA (Figure 1). A Canon PIXMA ip 1980 printer and a Canon PG830 ink box for biological printing after modification. The white plate was a 24-well plate used as “paper”.

Modification of the Printer and the Cartridge

A Canon PIXMA ip 1980 hot-injet printer was modified as follows the front cover, paper support, rear tray, paper thickness lever and paper guide were dissembled sequentially while cartridge holder and paper sensor being kept intact. The printer after modification was shown as in Figure 1 (left part). Before use, the body of the printer was sterilized and kept inside an ultraviolet-lighted laminar hood overnight. A Canon PG830 ink box was modified as follows: after the top cover of the ink box was ripped from the main body of the box, the sponge inside the ink box was discarded and the metal filter at the bottom of the box was dismantled with the ink reservoir exposed, followed by a thorough cleanup. The ink box after modification was shown as in Figure 1 (right part). Prior to use, the box was emerged in 75% ethanol and air dried in a laminar airflow, followed by being exposed with ultraviolet light for at least 30 mins.

Figure 1: A Canon PIXMA Ip 1980 Printer and a Canon PG830 Ink Box.

Printing Concentration Gradient of 5-Fluorouracil in the 24-Well Plate

10ml 8mg/ml 5-fluorouracil solution was precisely obtained when 0.08g 5-fluorouracil was dissolved in PBS solution in a 10 ml volumetric flask and filtered through a 0.22 μm diameter membrane to remove possible bacteria. This working solution was loaded in the ink box. The printing pattern was designed in the WORD software with designated RGB values. Clicked the “print” button in the WORD software and the concentration gradient of 5-fluorouracil was automated created in the 24-well plate within 5s. We collected the drug solution printed in each well and analyzed their concentrations with HPLC. In a typical setup, a SB-C18 HPLC column (4.6mm diameter, 250mm long) was used and the sample was detected by ultraviolet absorption with a single wavelength of 265 nm. The temperature of the column was set at 35℃. The volume of each sample was 10 μl and the mobile phase was made of methanol and water (5:95) with a flow rate of 1.0ml/min.

Preparation and Printing of Cell Suspension

Mcf-7 cells of the third generation with a high viability was chosen as the main raw material for preparation of the cell suspension. Prior to being loaded into the ink box, a Mcf-7 cell suspension were prepared by pancreatic digestion, centrifuging, collection, counting and re-suspending. The Mcf-7 cell suspensions were prepared at four different concentrations, 3×106, 6×106, 9×106 and 1.2×107/ml. Following the pattern of a round spot with the diameter of 5 mm, the cell suspension with different densities were printed into a 24-well plate with the modified printer as above. Observation was made with an inverted microscope equipped with a X4 zoom objective.

Counting of Printed Cell Numbers and Viability Analysis

400 μl 10% NCBS culture media was added into the plate loaded with the printed Mcf-7 cells to keep their viability. And 10μl 0.4mg/ml Hoechst 33342 solution was added into the plate at 37℃ for 35mins in the dark, followed by the addition of 10 μl 0.2mg/ ml PI solution for another 10 mins. Then the cell suspension in the plate were collected and centrifuged. The cells from the bottom of centrifuge tube were collected and washed with PBS solution for 3 times. Then the cells washed were re-suspended in 1 ml cell culture medium to form a new cell suspension. 20μl new cell suspension was pipetted out and added dropwise onto a cell counter. Counting of cell number and observation of cells were conducted with an inverted fluorescence microscope with a X 10 zoom objective.

Procedure of Drug Screening

Mcf-7 cells with a high viability was selected for construction of cell/drug arrays. The Mcf-7 cell suspension were prepared by pancreatic digestion, centrifuging, collection, counting, and resuspension with a concentration of 9×106/ml. The Mcf-7 cell suspension was loaded into sterilized a PG830 ink box and printed into 5-mm-diameter round spots in a 24-well plate to form a Mcf-7 cell array. 400μl 10% NCBS culture media was immediately loaded into the plate. After being cultured at 37℃ under 5% CO2 for 24hrs, 8 mg/ml 5-fluorouracil solution were printed into the plate which were already loaded with Mcf-7 cells, with different RGB codes. As a result, cell/drug composite arrays (n=3) were formed. After being at 37℃, 5% CO2 for another 48 hrs, 40μl 5mg/ml MTT solution were loaded into the plate and incubated at 37℃ for 4hrs. Then the supernatant was discarded and 500 μl DMSO was added. The plate was shaken for 15mins to achieve DMSO thoroughly dissolved. Then 200 μl supernatant was collected and transferred into a 96-well plate and the adsorption under 490 nm wavelength was recorded.

Results

Printed Concentration Gradient of 5-Fluorouracil

The printing pattern was designed in WORD software, as shown in Figure 2. Each round spot, corresponding to a well in 24-well plate in location, was 5mm in diameter. These round spots varied in RGB values. We printed drugs following the pattern in Figure 2 and measured the concentration of drug in each well. We plotted the drug concentration in each well, as shown in Figure 3. This technology has five advantages compared to manual method

a) It is automatic;

b) We can obtain arbitrary concentration gradient by customizing the RGB values (Figure 3 A-D);

c) The RGB code value was linearly related to the concentration of printed 5-fluorouracil. This can be expressed as Y = -0.7691X+53.975 with R2 being equal to 0.9878 (Figure 3A);

d) It is fast, and a concentration gradient can be generated within 5s;

e) THE hot inkjet printer was cheaper than a micropipette which is used for manual preparation. (Figure 2)

Figure 2: The Printing Pattern Designed in The WORD Software.

Figure 3: Different Types of Drug Concentration Gradient Printed in the 24-Well Plate.

The printing pattern designed in the WORD software. Each row was designed for generation a specific drug concentration gradient. In the first row, the RGB values from left to right were (20,20,20), (30,30,30), (40,40,40), (50,50,50), (60,60,60), (70,70,70). In the second row, the RGB values from left to right were (70,70,70), (20,20,20), (70,70,70), (70,70,70), (20,20,20), (70,70,70). In the third row, the RGB values from left to right were (20,20,20), (20,20,20), (50,50,50), (50,50,50), (70,70,70), (70,70,70). In the fourth row, the RGB values from left to right were (70,70,70), (70,70,70), (50,50,50), (50,50,50), (20,20,20), (20,20,20). (Figure 3) On the top of each plot was the printing pattern designed in the WORD software, and the number below was RGB value. (Figure 4) (from left to right: 3×106/ml, 6×106 /ml,9×106 /ml), scale bar: 500 μm.

Printing of Mcf-7 Cell Suspension

Figure 4: The Bright Field Images of Printed Round Spots of Mcf-7 Cells with Varied Cell Concentration.

Figure 4 shows the printed pattern of Mcf-7 cells, with different concentration of Mcf-7 suspension loaded in the printer. When the concentrations were 3×106 /ml and 6×106 /ml, the printed round spots were incompletely constructed with sparse distributions of cells. It might be caused by the low concentration of cell suspension. When the concentration was 1.2×107/ml, few inks were injected from the nozzle and the printed round spot was hard to be identified. It might be attributed to the high concentration of the cell suspension which jammed the nozzle. However, when the concentration was 9×106/ml, the printed round spot was full of well-distributed cells. It showed that the cell suspension with a concentration of 9×106/ml is the best-performed one and should be adopted in the experiment.

After counting, the average number of cells in each round spot in the cell array was 3×104. After printing, the viability of the cells was the main gauge which reflects the validity of the cell printing process. Hot ink-jet printing was suspected to cause heat damage or mechanical damage on cells [8]. Hoechst33342 is a membrane permissive dye and emits blue fluorescence under 350 nm excitation after combining with DNA in cells. And PI is only capable of penetrating into dead cells. After PI combines with DNA in cells and emits red fluorescence under 543 nm excitation. Therefore, we can investigate the viability of cells when coupling Hoechst33342 and PI dyes after cell printing. As seen in Figure 5, the number of dead cells which emit red fluorescence is negligible and it supports that the negative effect of our cell printing technique on the viability of printed cells can be ignored (Figure 5).

Figure 5: Microscopic observations of printed cells dyed by Hoechst33342(left) and PI (right), under excitations of 350 nm and 543 nm wavelengths, respectively. Scale bar: 500 μm.

Drug Screening Assay Based on Printing

Table 1: Absorbance by MTT and relative inhibition rate (n = 3).

The concentration of the printed 5-fluorouracil can be pretuned with the RGB code setup from the WORD software. A Mcf-7 cell/5-fluorouracil composite array was formed after incubation for 48 hrs. And the inhibition rate of the experimental group at varied concentrations and the control group were tested with MTT method. And the statistics of their optical absorbance at different RGB values and the relative inhibition rates were listed in Table 1. It can be seen from Table 1 that within the range we investigated, the biological viability of the cells in the composite array increased as the RGB value ramped up. In our experimental setup in which RGB code value was kept between 20 and 70, the concentration of the printed 5-fluorouracil increased as the RGB value dropped. In another word, a low RGB value yielded a cell/drug composite array with a relatively high concentration and dose of 5-fluorouracil. Therefore, as the RGB value was lowered, a stronger interaction between Mcf-7 and 5-fluorouracil was achieved, and a higher inhibition phenomenon occurred. This suggested that the Mcf-7 cell/5-fluorouracil composite array established by our method can be used for the inhibition study of 5-fluorouracil at different concentrations and it possessed the potential of evaluating in vitro cellular viability.

Discussion

Cell printing technique has demonstrated remarkable advantages as following :

a) High precision, cells can be precisely localized and distributed in three dimensions [9];

b) Rapid speed, tissue samples with biological viability can be constructed in a short time;

c) High automation grade, it has the possibility to be industrialized at a large scale [10];

d) Simple to be established and operated, it is straightforward to be modified or upgraded [11].

In our experiment, RGB tuning was used for controlling the output doses of 5-fluorouracil and the hot inkjet technique was adopted to build cell/drug composite arrays. And the viability of the cells in the composite arrays were evaluated. Inspired by the model from Boland ‘s group [11,12], a Canon hot inkjet printer and an ink box were successfully modified into a biological printer. And a Mcf- 7 cell suspension with a concentration of 9×106 cells/ml showed the best printing performance in cell distribution and density on the array. The printed cell array demonstrated patterns with the most complete morphology. By testing the concentration of drug solutions with HPLC, we were able to identify the concentration of 5-fluorouracil on the printed matrix produced from different RGB code value. The results show that high-definition Mcf-7 cell arrays can be constructed with our modified printer and ink box. And moreover, the concentration of 5-fluorouracil arrays can be tuned by changing the RGB color code value. The viability of cells by printing is the major indicator for the feasibility of the printing operation. We used Hoechst33342 and PI to dye the printed cells and applied excitations of 350 nm and 543 nm, respectively. The results showed that hot inkjet printing has little damage on the Mcf-7 cells, and they are in consistency with the literatures [13,14]. Also, we used MTT method to identify the inhibition rate of 5-fluorouracil on Mcf- 7 in the cell/drug array. When RGB code value was 30, the dose of the 5-fluorouracil was 30.09±2.69 μg/ml with a relative inhibition rate of 49.02%. These results supported the feasibility of applying the cell/drug printing method in investigating in vitro cellular viability and it provides new possibility of drug screening based on biological printing.

Conclusion

In this study, we developed an automatic method to generate drug concentration gradient in 24-well plate based on hot inkjet printer. The total time was less than 5s. Arbitrary concentration gradient can be easily generated by RGB coding. The cost of printing equipment was very low. This method is expected to make drug screening experiment more user-friendly.

Read More About this Article: https://biomedgrid.com/fulltext/volume5/automatic-generation-of-drug-concentration-gradient-by-a-modified-ink-jet-printer-and-its-application-in-drug-screening.000876.php

For more about: Journals on Biomedical Science :Biomed Grid | Current Issue

#biomedgrid#american journal of biomedical science & research#Journals on vaccination#Health science Journal of Open access

0 notes

Photo

Micro-Angelo Scientists 3D Print Microscopic Copper Version of David StatueResearchers at ETH Zurich have 3D printed a microscale version of Michelangelo’s David using a special 3D printing technique. Michelangelo’s original statue of David is among the world’s most famous pieces of art. Now, researchers have created two tiny copper versions of the – originally 5.17 m tall – marble sculpture — a 1 mm tall David and a second one, which is even ten times smaller (0.1 mm). Both statues were created using a 3D-printing technique developed by ETH Zurich Professor Tomaso Zambelli, together with a team lead by Giorgio Ercolano from Exaddon, using the company’s CERES additive micro-manufacturing system, which is capable of printing complex and pure metal objects at the micrometer scale and with submicrometer resolution.The core component of the method is a micropipette coupled to a cantilever, allowing to monitor the force with which the point of the pipette touches the substrate. The dissolved metals are electrochemically deposited on a conductive substrate with extreme precision. With the help of optical force measurements, 3D objects can be automatically built up layer-by-layer. The tiny statue was printed in one go, with no supports or templates, and without requiring any firing or tempering.“The process allows us to print structures or geometries of all levels of complexity,” Ercolano explained in a recent press release. The electronics industry is primarily interested in the newly discovered printing process that would allow precisely repairing microelectronic systems. Zambelli is delighted with the result. “We’re thrilled that technology from our research lab has made its way into practical application,” the ETH professor says. (Source: ETH Zurich) https://www.instagram.com/p/B7PeaFKH5kw/?igshid=1g7bs6fo60xl8

0 notes

Text

Micromanipulator Market Global Trends, Market Share, Industry Size, Growth, Opportunities, and Market Forecast 2019 to 2026

Micromanipulator market is predicted to value over US$ 460 million by the end of 2026 and growing at a CAGR of over 22% during the forecast period, 2019 to 2026.

Micromanipulator is used to connect and wield a sample. Micromanipulators are employed in the situations in which the flow requires to be accurate on a submicron scale. Such movements are impossible to do by hand. It is used to study the metal particles and colloids of the industrial environment. Micromanipulation can be done using inverted microscopes and upright microscopes. Various instruments such as micropipette pullers, microinjection systems, bevellers and microinjection systems are used in micromanipulation. It permits a lab to produce its own micropipettes. Micromanipulators are used for various applications like life sciences, optics, circuit engineering and scientific disciplines.

Request a Sample Report @ https://www.futurewiseresearch.com/request-sample.aspx?id=205&page=requestsample

Increasing demand for micromanipulators in life science applications like microsurgical, chemical and physiological operation led to the robust growth of the market. Other applications like cell manipulation, transgenics, microinjection of adherent cells and others fuelled the growth of the market. Along with this, they have huge application in clinical research for the advancement of molecule development and contributed potential growth. Further, the rapid advancement of technologies led to the evolution of complete automatic equipment with superior optical performance and precision. The market is expected to witness huge capital investments in R&D during the forecast period and it is expected to boost the growth of the market. The market is majorly dominated by top manufacturers and it is expected to witness new players during the forecast period. The growing need to display the precise movement of the specimen is resulting in the growth of micromanipulators like injectors pipettes and cutting tools. Developing advanced methods and procedures and affordable rates have further fuelled the growth of the market. The global market is dominated by North America due to high capital investments and high adoption. It expected to remain dominant throughout the forecast period due to a high concentration of top manufacturers. It is followed by Europe due to high penetration among the end user segment. The Asia Pacific and Latin America is the most opportunistic space for manufacturers due to increasing adoption of micromanipulators among the end user segment during the forecast period. Rest of the world is expected to account a small fraction of market share due to less adoption. However, the lack of skilled workers is proving to be a restraint for the market.

Micromanipulator market players include Nikon Healthcare, Micro Control Instruments, Leica Microsystems, GmbH, Micromanipulators Company, Meyer Instruments Inc., Singer Instruments, Imina Technologies SA, Zeiss, Unisense and others.

Micromanipulator Market Restraints: • Lack of skilled professionals

Purchase a Copy of this Premium Research Report At & Ask for Discount: https://www.futurewiseresearch.com/request-sample.aspx?id=205&page=askfordiscount

Micromanipulator Market Segmentation: By Product Type • Electrical Micromanipulator • Hydraulic Micromanipulator • Manual Micromanipulator

By End User • Hospitals • Semiconductor manufacturers • Electronic manufacturers • Fertility centres • Specialty Clinics By Region • North America • Latin America • Europe • Asia Pacific • Rest of the World

Competitive Landscape: • Tier 1 players- established companies in the market with a major market share • Tier 2 players • Emerging players which are growing rapidly • New Entrants

FutureWise Key Takeaways • Growth prospects • SWOT analysis • Key trends • Key data-points affecting market growth

Objectives of the Study: • To provide with an exhaustive analysis on the global micromanipulator market by product type, by end-user, and by region • To cater comprehensive information on factors impacting market growth (drivers, restraints, opportunities, and industry-specific restraints) • To evaluate and forecast micro-markets and the overall market • To predict the market size, in key regions (along with countries)—North America, Europe, Asia Pacific, Latin America, and the Middle East • To record evaluate and competitive landscape mapping- product launches, technological advancements, mergers and expansions • Profiling of companies to evaluate their market share

Table of Contents

1.1. Introduction

1.1.1.1. Scope and Objective

1.1.1.2. Assumptions and Acronyms

1.1.1.3. Forecast Factors

1.1.1.4. Research Methodology

1.2. Executive Summary

1.2.1.1. Industry Cluster Analysis

1.2.1.2. Competition Matrix

1.2.1.3. Strategies Recommendations

1.3. Market Definition

1.3.1.1. Report Scope (Inclusions & Exclusions)

1.3.1.2. Market Segmentation

1.4. Global Micromanipulator Market Overview

1.4.1.1. Global Micromanipulator Market Revenue (USD Mn)

1.5. Key Inclusions

1.5.1.1. Porter’s Five Force analysis

1.5.1.2. Market Dynamics

1.5.1.3. Industry Trends

1.5.1.4. Regulatory Guidelines

1.5.1.5. Opportunities in Micromanipulator

1.6. Competition Dynamics

1.6.1.1. Company Share Analysis (2018)

1.6.1.2. Top 10 Product Pricing by Region

1.7. Global Micromanipulator Market Revenue (USD Mn), 2018-2026 by Product Type

1.7.1.1. Key Market Findings

1.7.1.2. Long Term ROI Segments

1.7.1.3. Revenue Opportunity Influencing Factors

1.7.1.4. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.7.1.4.1.1. Electrical Micromanipulator

1.7.1.4.1.2. Hydraulic Micromanipulator

1.7.1.4.1.3. Manual Micromanipulator

1.8. Global Micromanipulator Market Revenue (USD Mn), 2018-2026 by End User

1.8.1.1. Key Market Findings

1.8.1.2. Long Term ROI Segments

1.8.1.3. Revenue Opportunity Influencing Factors

1.8.1.4. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.8.1.4.1.1. Hospitals

1.8.1.4.1.2. Semiconductor manufacturers

1.8.1.4.1.3. Electronic manufacturers

1.8.1.4.1.4. Fertility centres

1.8.1.4.1.5. Specialty Clinics

1.9. Global Micromanipulator Market Revenue (USD Mn), 2018-2026 by Region

1.9.1.1. Key Market Findings

1.9.1.2. Long Term ROI Segments

1.9.1.3. Revenue Opportunity Influencing Factors

1.9.1.4. Market Revenue (USD Mn) Assessment and Forecast by Region,2026

1.9.1.4.1.1. North America

1.9.1.4.1.2. Latin America

1.9.1.4.1.3. Europe

1.9.1.4.1.4. Asia Pacific

1.9.1.4.1.5. Rest of world

1.10. North America Micromanipulator Market Revenue (US$ Mn), 2018-2026

1.10.1.1. Key Market Findings

1.10.1.2. Long Term ROI Segments

1.10.1.3. Revenue Opportunity Influencing Factors

1.10.1.4. Market Revenue (USD Mn) Assessment and Forecast by Country, 2018-2026

1.10.1.4.1.1. US

1.10.1.4.1.2. Canada

1.10.1.5. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.10.1.5.1.1. Electrical Micromanipulator

1.10.1.5.1.2. Hydraulic Micromanipulator

1.10.1.5.1.3. Manual Micromanipulator

1.10.1.6. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.10.1.6.1.1. Hospitals

1.10.1.6.1.2. Semiconductor manufacturers

1.10.1.6.1.3. Electronic manufacturers

1.10.1.6.1.4. Fertility centres

1.10.1.6.1.5. Specialty Clinics

1.11. Latin America Micromanipulator Market Revenue (US$ Mn), 2018-2026

1.11.1.1. Key Market Findings

1.11.1.2. Long Term ROI Segments

1.11.1.3. Revenue Opportunity Influencing Factors

1.11.1.4. Market Revenue (USD Mn) Assessment and Forecast by Country, 2018-2026

1.11.1.4.1.1. Brazil

1.11.1.4.1.2. Mexico

1.11.1.4.1.3. Argentina

1.11.1.4.1.4. Rest of Latin America

1.11.1.5. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.11.1.5.1.1. Electrical Micromanipulator

1.11.1.5.1.2. Hydraulic Micromanipulator

1.11.1.5.1.3. Manual Micromanipulator

1.11.1.6. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.11.1.6.1.1. Hospitals

1.11.1.6.1.2. Semiconductor manufacturers

1.11.1.6.1.2.1. Electronic manufacturers

1.11.1.6.1.2.2. Fertility centres

1.11.1.6.1.2.3. Specialty Clinics

1.12. Europe America Micromanipulator Market Revenue (US$ Mn), 2018-2026

1.12.1.1. Key Market Findings

1.12.1.2. Long Term ROI Segments

1.12.1.3. Revenue Opportunity Influencing Factors

1.12.1.4. Market Revenue (USD Mn) Assessment and Forecast by Country, 2018-2026

1.12.1.4.1.1. Germany

1.12.1.4.1.2. France

1.12.1.4.1.3. Spain

1.12.1.4.1.4. UK

1.12.1.4.1.5. Russia

1.12.1.4.1.6. Poland

1.12.1.4.1.7. Rest of Europe

1.12.1.5. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.12.1.5.1.1. Electrical Micromanipulator

1.12.1.5.1.2. Hydraulic Micromanipulator

1.12.1.5.1.2.1. Manual Micromanipulator

1.12.1.6. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.12.1.6.1.1.1. Hospitals

1.12.1.6.1.1.2. Semiconductor manufacturers

1.12.1.6.1.1.3. Electronic manufacturers

1.12.1.6.1.1.4. Fertility centres

1.12.1.6.1.1.5. Specialty Clinics

1.13. Asia Pacific America Micromanipulator Market Revenue (US$ Mn), 2018-2026

1.13.1.1. Key Market Findings

1.13.1.2. Long Term ROI Segments

1.13.1.3. Revenue Opportunity Influencing Factors

1.13.1.4. Market Revenue (USD Mn) Assessment and Forecast by Country, 2018-2026

1.13.1.4.1.1. Emerging Asia

1.13.1.4.1.1.1.1. China

1.13.1.4.1.1.1.2. India

1.13.1.4.1.1.1.3. ASEAN-5

1.13.1.4.1.1.1.4. Rest of Emerging Asia

1.13.1.4.1.2. Japan

1.13.1.5. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.13.1.5.1.1. Electrical Micromanipulator

1.13.1.5.1.2. Hydraulic Micromanipulator

1.13.1.5.1.3. Manual Micromanipulator

1.13.1.6. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.13.1.6.1.1. Hospitals

1.13.1.6.1.2. Semiconductor manufacturers

1.13.1.6.1.3. Electronic manufacturers

1.13.1.6.1.4. Fertility centres

1.13.1.6.1.4.1. Specialty Clinics

1.14. Rest of World America Micromanipulator Market Revenue (US$ Mn), 2018-2026

1.14.1.1. Key Market Findings

1.14.1.2. Long Term ROI Segments

1.14.1.3. Revenue Opportunity Influencing Factors

1.14.1.4. Market Revenue (USD Mn) Assessment and Forecast by Country, 2018-2026

1.14.1.4.1.1. Middle East

1.14.1.4.1.2. South Africa

1.14.1.4.1.3. North Africa

1.14.1.4.1.4. Rest of World

1.14.1.5. Market Revenue (USD Mn) Assessment and Forecast by Product Type, 2018-2026

1.14.1.5.1.1. Electrical Micromanipulator

1.14.1.5.1.2. Hydraulic Micromanipulator

1.14.1.5.1.3. Manual Micromanipulator

1.14.1.6. Market Revenue (USD Mn) Assessment and Forecast by End User, 2018-2026

1.14.1.6.1.1. Hospitals

1.14.1.6.1.2. Semiconductor manufacturers

1.14.1.6.1.2.1. Electronic manufacturers

1.14.1.6.1.2.2. Fertility centres

1.14.1.6.1.2.3. Specialty Clinics

1.15. Company Profiles

1.15.1.1. Competition Landscape

1.15.1.2. Global Company Share (USD Mn) Overview, 2018

1.15.1.3. Company Profiles

1.15.1.3.1.1. Nikon Healthcare

1.15.1.3.1.1.1.1. Corporate Overview

1.15.1.3.1.1.1.2. Financial Performance

1.15.1.3.1.1.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.1.1.4. Company Strategy & Channel Management

1.15.1.3.1.2. Micro Control Instruments

1.15.1.3.1.2.1.1. Corporate Overview

1.15.1.3.1.2.1.2. Financial Performance

1.15.1.3.1.2.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.2.1.4. Company Strategy & Channel Management

1.15.1.3.1.3. Leica Microsystems, GmbH

1.15.1.3.1.3.1.1. Corporate Overview

1.15.1.3.1.3.1.2. Financial Performance

1.15.1.3.1.3.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.3.1.4. Company Strategy & Channel Management

1.15.1.3.1.4. Micromanipulators Company

1.15.1.3.1.4.1.1. Corporate Overview

1.15.1.3.1.4.1.2. Financial Performance

1.15.1.3.1.4.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.4.1.4. Company Strategy & Channel Management

1.15.1.3.1.5. Meyer Instruments Inc.

1.15.1.3.1.5.1.1. Corporate Overview

1.15.1.3.1.5.1.2. Financial Performance

1.15.1.3.1.5.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.5.1.4. Company Strategy & Channel Management

1.15.1.3.1.6. Singer Instruments

1.15.1.3.1.6.1.1. Corporate Overview

1.15.1.3.1.6.1.2. Financial Performance

1.15.1.3.1.6.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.6.1.4. Company Strategy & Channel Management

1.15.1.3.1.6.2. Imina Technologies SA

1.15.1.3.1.6.2.1. Corporate Overview

1.15.1.3.1.6.2.2. Financial Performance

1.15.1.3.1.6.2.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.6.2.4. Company Strategy & Channel Management

1.15.1.3.1.7. Zeiss

1.15.1.3.1.7.1.1. Corporate Overview

1.15.1.3.1.7.1.2. Financial Performance

1.15.1.3.1.7.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.7.1.4. Company Strategy & Channel Management

1.15.1.3.1.8. Unisense

1.15.1.3.1.8.1.1. Corporate Overview

1.15.1.3.1.8.1.2. Financial Performance

1.15.1.3.1.8.1.3. Peer Comparison & 3C marketing equation

1.15.1.3.1.8.1.4. Company Strategy & Channel Management

1.16. Research Sources & Primary Verbatim

Inquire further details about this report at: [email protected]

About FutureWise Research:

We specialise in high-growth niche markets, assuring flexibility, agility and customised solutions for our clients. Through in-depth market insights and consultancy, we present our clients with the tools they need to be at the forefront of their industry – a position secured for far more than the near future.

Contact Us:

Company Name: FutureWise Research

Contact Person: Vinay Thaploo

Email:

Phone: +44 141 628 9353 / +1 970 279 4295

City: Leeds

Country: United Kingdom

Website:

www.futurewiseresearch.com

0 notes

Text

Powerful Desktop And Mobile Machines

Workstation

Engineered and built in Germany and Japan, CELSIUS workstations from Fujitsu help creativity, simulation, calculation and visualization at the highest specialist level. YOU WILL Require IVF Equipment AND IVF Consumables like,MAKLER COUNTING CHAMBER,AUTOMATIC SPERM ANALYSERS,Sperm Class Analyser,Coda Inline and Xtra Inline Filters,IVF Workstation,IVF Chamber,CO2 Mini Incubator,Portable CO2 Incubator,Craft Suction Pump,CO2 Incubator,IVF Controlled Price Freezer,micromanipulator firm,micromanipulator,Laser for PGD and Embryo Biopsy,Oocyte and Embryo Analysis Application,Oosight Imaging Program,glass Heating device for Microscopes,Heating Systems for microscopes,Anti-vibration Platform and Table,Modular Incubator Chamber,IUI Catheters,Embryo Transfer Catheters,Oocyte Collection Sets,Micropipettes for ICSI,ivf Pipettes,IVF Media for Assisted Reproduction,Seminal Collection Device,IVF Plasticware,Centrifuge and Spermfuge,Warming Plate and tray,Water Bath,Block Heater,Dry Bath,Transportable Test Tube Warmer,Mixer or Shaker,Adjustable Volume Pipettor and Tips,Pipette Pump,Cryogenic Equipment,Cord Blood,Stem Cell,Lab High quality Management etc.

youtube

HP and SOLIDWORKS announce the Ultimate SOLIDWORKS Bundle: SOLIDWORKS Premium + Z2 Mini, Big Efficiency at a modest value. Created for the most demanding workstation and server-class applications. The much more basic of the new HP Z Workstations is the only one to not support dual CPUs and its RAM caps at 256GB, though it nonetheless offers dual M.two slots for HP Z Turbo Drive PCIe SSDs and a decent performance increase from the earlier Z440. Researching laptop and desktop computers and software is essential to obtaining just the appropriate one for you and your family members. Nonetheless, the critical thing is that it is a fairly modern day Computer. Digital Audio Workstations usually don’t call for too a lot processing power, but do contemplate receiving a faster computer if achievable.

In short it can be mentioned that computer workstations are practically an essentiality for every office. Scan 3XS Pro Graphics workstations are created to provide the ultimate in overall performance, responsiveness and reliability. Nice post Scott, i may possibly just add the fact that you can use the gaming graphics card with the workstation video driver to get the best of both worlds. To update this series, HP now gives the ZBook 14 G2 These two new mobile workstations consist of newer dual core two.4 GHz Intel Core i7 Broadwell CPUs, 16GB of non-ECC 1600 RAM, and AMD FirePro M4150 GPUs with 1GB of committed RAM. Then along came the 32-bit NT Workstation editions – such as Windows NT Workstation 4. launched in 1996 The term Workstation fell away as Microsoft labelled its operating systems Server, Home, Pro, Enterprise, and so on.

But, if you need to have to check lots of disks on a regular basis and your time is useful then an option is a Difficult Drive Docking Station These comparatively new items are generally permanently connected to your Pc or Mac through USB and you then basically slot” or dock” the challenging drive into the docking station”. In an era of limitless world wide web access and smartphones, the mobile application is the easiest way to search for a holiday location. The security processor reported that the entry key is too big to fit in the trusted information shop. Keys for student offices can be picked up from John Baker , at the front desk in CERAS. If you can afford it, VMware Workstation is a single of the greatest virtualization applications out there.

Brooke M. Perry is an ardent technician related with Qresolve on the web tech assistance , with wide knowledge of fixing problems with PCs, laptops, tablets and smartphones. The new revised HP Z Series has a 2nd Generation Xeon Processor that permits for up to 16 cores in a single method. I am certainly honored to have had a part in the conservation of such a potent and magnificent species…but equally effective and magnificent has been the influence this project has had on so numerous folks more than the years, all more than the globe. Lenovo hails this model as the world’s initial multi-mode workstation, a single that manages to combine energy and creativity thanks to a 360-degree hinge that has, to some extent, set the common when it comes to convertible or 2-in-1 styles.

This model also has some configurations accessible with an larger efficiency GeForce GTX 965M which can be valuable if you are hunting into operating programs that demand a greater GPU such as Photoshop and Autocad. Moreover, a company overview, income share, and SWOT analysis of the top players in the Docking Station market place is obtainable in the report. We suggest employing a specialist graphics card from the NVIDIA Quadro variety. Mr. Coupal’s in depth knowledge and expertise enables him to fully analyze client systems to advocate the most efficient technologies and options that will both optimize their organization processes and fulfill instant and future ambitions. Evetech’s variety of Intel Core i9 Workstation PCs possesses the extraordinary energy of Intel’s most dominant enthusiast CPUs ever released.

With the HP Z238 Workstation, you will achieve peace of mind from our intense test and validation processes created for mission-vital environments. A lot of of these workplace cubicle setups consist of modular computer desks, modular desk walls, and desktop hutches. The B132L (introduced 1996 19 ), B160L, B132L+, B180L, C132L, C160L and C180L workstations are based on the PA-7300LC processor, a improvement of the PA-7100LC with integrated cache and GSC bus controller. As such, even though most processors come complete with a graphics unit, a separate graphics card is nevertheless the way to go. This allows for a fantastic FPS price, enabling for smooth transitions when rotating, panning, or zooming. I use a custom made workstation boasting dual six core Intel Xeon X5660, Sata 3 primary difficult drive 24 GB RAM and Nvidia Quadro 4000 graphic card plus 8TB hard drive mixture in Raid array.

On this page, we will only discuss the troubles with regards to some postures and ergonomically made computer components. Several professions that use engineering, animation, rendering of graphics, and mathematical plotting benefit drastically from a potent workstation. Configure with NVIDIA® Quadro® cards and accelerate your creativity with the world’s most potent workstation graphics. The 1st laptop mouse plan was conceived decades prior to folks began making use of their computers every single day at work and on the web when operate. After we have already reviewed 3 modern day ZBooks from HP ( 15u G3 , 15 G3 and Studio G3 ), we now have a closer look at the most significant model of the series, the ZBook 17 G3. You do not have to worry about the overall performance of this workstation, simply because the manufacturer has a clear focus on the functionality and not the thinnest building.

By picking Workstation Specialists you can be assured of a personal experience with ongoing right after sales support to assist you attain your organization prospective. With a Dual Core Xeon processor and up to 48GB RAM you can see why this machine became popular inside the inventive industry……However, the new HP Z Series offered in April is set to leading this. It’s equipped with dual Intel Xeon Bronze, Silver, Gold. The new point is the reality that these radio stations are stepping up their efforts and listeners look to be, nicely, listening. The zoom hardware allows the displayed video and graphics to be independently magnified in x and y by an integer value in between 1 and 16. Hardware zoom replicates pixels to acquire the preferred magnification and, as opposed to interpolated zoom, it can be supported in genuine time.

1. HP Remote Graphics Software program requires Windows and an net connection. The Workstation Refresh System is an Information Technology Baseline service for all state-funded and self-support units. Pc desks are often taken up by a lot of pieces of gear that you use and this can get in your way particularly at school. Keyboard workstations offer you with a higher palette for making original sounds and effects than other sorts of skilled keyboards. Workplace workstations are critical simply because they allow businesses to be a lot more effective in their usage of the workplace and have helped to reduce fees when leasing or buying the space necessary for their employees to perform. These days with much more and a lot more men and women are discovering the benefits of ergonomics.

Share CAD associated news, ask queries about CAD software, ask how to get into the business or show of your latest 3D model. This add-on is very useful, if you want to run a number of operating systems at the identical time on your laptop such as Windows 7, Chrome OS or the most current Linux. When it really is time to upgrade your method, be confident you happen to be up to speed on CPU, GPU, and RAM technologies. There are standard ones that just have a prime and an open storage space beneath while much more versatile ones have a surface area on leading, plus open or closed storage beneath, like some that have doors, drawers or both for keeping your items out of view. As opposed to the installation of industrial panel PCs, which can lead to key upheaval and disruption to supply chains, computer workstations for use in industrial settings do not require drastic alterations to computer software, processes and infrastructure.

The flagship Dell Precision 17 comes with a 4K UHD show, can tote 4TB of storage, and is offered with either i5, i7, or Xeon 7th generation processors and up to 64GB of memory. Access Intelligent gives distinctive, high-good quality, integrated hardware and software program packages that securely manage crucial data over wired and wireless networks, computer systems, Point-of-Sale devices, kiosks, and any other device that can accept and communicate through that guy smartcard technologies. Bottom Line: The Dell OptiPlex 7440 AIO is an excellent enterprise all-in-a single desktop with great overall performance, a lot of ports, and a 4K screen that gives you far more space to work. Still, if this device had been to have hit the market, it would have likely had the greatest camera of any tablet at the time.

from KelsusIT.com – Refurbished laptops, desktop computers , servers http://bit.ly/2vyDzrl via IFTTT

0 notes

Photo

While beer is fermenting in barrels, manual testing methods are often ineffective at determining if bacteria have contaminated the beer. For his senior thesis project, bioengineering concentrator Eloi Le Roux developed an automatic system to conduct catalase testing, which measures the oxygen level present in a substance to determine if bacteria are present. He created a micropipette controller that can automatically draw a sample of beer; the micropipette then injects a small amount of hydrochloric acid and uses a microphone to provide auditory feedback on the presence of bacteria. A tiny microphone inside the pipette enables brewers to listen for the sound of popping bubbles, a sign that bacteria are present. “The concept hearkens back to popping bubbles when you were a kid. You know that bubbles make sound and you know when you open a Coke bottle that sound is produced. The sound is very clear if you isolate it correctly and analyze it correctly,” he said. “Sound ended up being the best method, even though it may not be the first thing that comes to mind when you are detecting for these oxygen bubbles.”⠀ #Harvard #HarvardSEAS #LifeatSEAS #student #project #thesis #engineering #beer #fermentation #brewer #bacteria (at Harvard John A. Paulson School of Engineering and Applied Sciences)

#lifeatseas#harvard#bacteria#project#student#beer#brewer#harvardseas#thesis#fermentation#engineering

0 notes

Text

What are the fundamental mechanics of micropipettes, and how are they utilized in laboratory settings?

In the intricate world of laboratory equipment, micropipettes stand as indispensable tools for precise liquid handling. These marvels of technology play a pivotal role in various scientific experiments, enabling researchers to measure and transfer tiny volumes of liquids with unparalleled accuracy. Let's delve into the fundamental mechanics of micropipettes and their crucial utilization in laboratory settings.

Understanding Micropipettes:

At the heart of every micropipette lies a sophisticated mechanism designed to accurately dispense liquid volumes ranging from microliters to milliliters. The micropipettes price may vary depending on their features and specifications, but their significance in laboratory workflows remains unmatched.

Types of Micropipettes:

Micropipettes come in different types to cater to diverse laboratory needs. One common distinction lies in their operation mode, with manual and automatic micropipettes being the two primary categories. Manual micropipettes require manual adjustment of volume, while automatic micropipettes offer electronic control, enhancing precision and efficiency.

The Mechanics Behind Micropipettes:

The functionality of micropipettes revolves around a few key components. A piston mechanism, housed within the pipette, creates a vacuum or positive pressure to draw in or expel liquids. The pipette tip, typically made of plastic, serves as a vessel for liquid transfer. A volume adjustment knob allows users to set the desired volume accurately.

Utilization in Laboratory Settings:

Micropipettes find extensive application across various laboratory settings, from research laboratories to clinical diagnostics and beyond. Their precise liquid handling capabilities make them indispensable tools in fields such as molecular biology, biochemistry, microbiology, and pharmaceuticals.

Molecular Biology:

In molecular biology, micropipettes are used for tasks such as DNA amplification (PCR), DNA sequencing, and nucleic acid purification. Accurate dispensing of reagents and samples is crucial for the success of these experiments, making micropipettes invaluable assets.

Biochemistry:

Biochemists rely on micropipettes for protein assays, enzyme kinetics studies, and protein purification processes. The ability to handle small volumes of liquids with precision is essential for maintaining the integrity of biochemical samples and reagents.

Microbiology:

In microbiology laboratories, micropipettes are indispensable for culture preparation, microbial identification, and antimicrobial susceptibility testing. Accurate dispensing of culture media, antibiotics, and microbial suspensions is critical for obtaining reliable results.

Pharmaceuticals:

Pharmaceutical companies utilize micropipettes for drug formulation, quality control, and drug discovery processes. Precise dispensing of active pharmaceutical ingredients (APIs), excipients, and solvent solutions is essential for ensuring the efficacy and safety of pharmaceutical products.

Conclusion:

Now, it won’t be wrong to say that Micropipettes serve as the backbone of laboratory operations. It enables researchers to handle liquids with precision and accuracy. Whether in molecular biology, biochemistry, microbiology, or pharmaceuticals, these versatile instruments play a crucial role in advancing scientific research and discovery. While the micropipette price may vary, their value in laboratory workflows remains unparalleled. As technology continues to advance, we can expect further innovations in micropipette design and functionality, further enhancing their utility in laboratory settings.

0 notes

Text

Microlit Introduces Cost-Effective Liquid Handling Solutions for Small Labs

Meeting the Needs of Small Labs Small laboratories play a crucial role in scientific research, education, and clinical diagnostics. However, they often struggle with budget constraints that limit their ability to invest in advanced equipment. Recognizing this, Microlit has developed a line of affordable, yet high-quality liquid handling instruments that do not compromise on precision or durability. Our new range is specifically designed to empower small labs by providing them with the tools they need to achieve accurate and reliable results, without exceeding their financial limitations.

Innovative Solutions for Every ApplicationOur new range includes a variety of liquid handling instruments tailored to meet diverse laboratory needs:

Microlit NERO: A premium line of micropipettes offering ergonomic design and high accuracy. Available in single-channel and multi-channel models, NERO micropipette are perfect for applications requiring precision and reproducibility. The user-friendly calibration mechanism ensures consistent performance, making it an ideal choice for small labs with diverse pipetting needs. With NERO, labs can ensure that their liquid handling processes are both efficient and accurate, leading to reliable outcomes in every experiment.

Microlit E-BURETTE: An electronic burette designed to simplify titration processes. With its intuitive controls and electronic dispensing, the E-BURETTE reduces user fatigue and minimizes errors, ensuring reliable results every time. Its affordability makes it a great addition to small labs that require precise titration capabilities. Our automatic burette is not only cost-effective but also minimizes waste by delivering precise volumes, making it an eco-friendly choice for conscientious labs.

Microlit BEATUS Bottle Top Dispensers: These dispensers are designed to ensure safe and accurate dispensing of liquids directly from reagent bottles. The chemical compatibility of BEATUS with a wide range of liquids makes it a versatile tool for small labs that handle various chemicals and reagents. This versatility allows labs to reduce the number of different dispensers they need to purchase, further maximizing their budget.