#automation conveyors

Explore tagged Tumblr posts

Text

Chain Conveyor Manufacturer in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry is a leading chain conveyor manufacturer in Faridabad, offering rugged and reliable solutions for heavy-duty material handling across manufacturing and assembly lines. Our chain conveyors are built for strength, durability, and smooth operation, ideal for industrial automation and large-scale production setups.

#Chain conveyor Faridabad#conveyor manufacturer Faridabad#Vashnavi Conveyor#industrial chain conveyor#heavy-duty conveyor#material handling systems#automation conveyors

0 notes

Text

Been playing stupid amounts of Plate Up lately, and the Tetris effect of this one is constantly having the urge to optimize/automate my kitchen in ways that are tragically impossible.

Listen if the dishes could just automatically move back to the cabinet once they completed drying—

#Once I get conveyors in my blueprint pool we'll be in business#In game I automated cakes the other night and I was so proud#We don't need to talk about how much sleep I got#Vee life

3 notes

·

View notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

0 notes

Text

Automated Order Picking System Manufacturer | Conveline Rollers

Conveline Systems Pvt Ltd, based in Ahmedabad since 2014, excels as a manufacturer of automated order-picking conveyor systems and intralogistics solutions. Their expert team designs modular belt, roller, pallet and motorised-roller conveyors engineered for seamless integration with robotics and manual operations. Deployed across food, pharmaceuticals, warehousing, logistics and general manufacturing, Conveline’s precision systems optimize material flow, boost productivity, and cut handling costs. With global exports and a robust support network, they deliver custom, high-efficiency automation tailored to diverse industry needs. Visit us: https://www.convelinerollers.com/order-picking-system

0 notes

Text

Truck Loading Conveyor Manufacturers in Faridabad: Leaders in Innovation

Looking for cutting-edge truck loading conveyor solutions? Discover why Faridabad is the heart of conveyor manufacturing in India. Home to industry-leading companies, Faridabad-based manufacturers are known for their technological innovation, customized designs, and cost-effective solutions for modern logistics and warehousing.

From telescopic conveyors to hydraulic truck loaders, these manufacturers are empowering India’s supply chains with faster, safer, and more efficient material handling systems. Whether you're in e-commerce, FMCG, agriculture, or manufacturing, these conveyors are engineered to deliver unmatched performance.

#truck loading conveyor#Faridabad manufacturers#conveyor systems India#telescopic conveyor#hydraulic loading conveyor#material handling India#warehouse automation#belt conveyor#loading solutions India

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

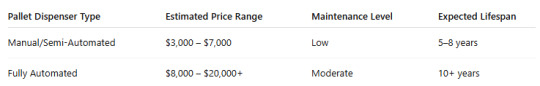

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Rugged Variable Frequency Drives (VFDs)

When the job gets hot, the Optidrive E3 steps up. Designed for extreme environments like hot manufacturing plants, dusty workshops, and washdown areas, this NEMA 4X outdoor rated VFD is rugged, dust-tight, and resistant to UV, oils, greases, and acids—all while delivering smooth, efficient motor control.

With NEMA 4X sealed enclosure, it's ideal for splash zones and harsh industrial areas. Setup is simple with application macros for fans, pumps, and general machinery, plus a built-in and lockable power disconnect, potentiometer, and 3 position switch for fast and easy local control. Contact us today if you need a rugged, high performance VFD built for harsh environments.

The VFD Exchange

#invertek#vfd#electrical#industrial#automation#torque#speed#frequency#voltage#current#engineering#hvac#pumps#fan#mixer#compressor#conveyor#nema4x

0 notes

Text

How to Choose the Right Conveyor System for Your Industry

Conveyor systems play a huge role in the spread of productivity, safety issues minimization, and material handling optimization in most industries. Whether it is manufacturing, packaging, food processing, or logistics, the appropriate conveyor system is of prime importance while maximizing business processes. Having such a long list to pick from, the crucial thing to determine is which among these fields will influence your choice. Below are the rules for selecting the best conveyor system for your line of business.

1. Understand Your Industry’s Needs

Start by defining the specific requirements of your business. Different businesses have diverse types of conveyors and material handling, and your conveyor must be able to accommodate these requirements for peak performance.

Conveyors used in manufacturing must be heavy-duty to handle bulky, heavy materials.

Conveyors used in food processing must be sanitary.

E-commerce shipping conveyors must be automated and speedy to handle volumes of packages.

Consider factors like:

Weight and size of the items

Production throughout (how much material needs moving per hour)

Operating environment (hygienic, temperature-controlled, or heavy-duty)

Space available for system integration

2. Evaluate Different Types of Conveyor Systems

Once you know your requirements, it’s time to explore the different types of conveyor systems. Some common options include:

Belt Conveyors: Best suited for light-weight to medium-weight materials. Used most in food processing, electronics assembly, and packaging.

Roller Conveyors: Perfectly suited for bulkier loads such as pallets, usually deployed in warehouses.

Chain Conveyors: Suitable for hard-core items such as metal shavings or car parts. Most robust and most resilient.

Decline and Incline Conveyors: Utilized to transfer goods from one plane to another throughout a factory floor or warehouse complex and remove manpower.

Automated Guided Vehicles (AGVs): Sophisticated, automated machines that are inexpensive and multi-functional.

3. Automation and Advanced Features

When it comes to efficiency, automated conveyors will be your lifesavers. Smart conveyors track real-time movement, decrease downtime, and optimize product flow with Programmable Logic Controllers (PLCs) and IoT sensors. For example, for conveyors and material handling in warehouses, smart conveyors with sensors streamline sorting and routing. Completely automated material handling systems even use robotic arms for pick-and-place operation to ensure improved speed and accuracy of packing.

4. Industry-Specific Conveyor Solutions

Every industry has unique needs. Some industrial conveyor solutions are designed specifically to meet these requirements. For example:

Manufacturing: Heavy-duty conveyors like chain-driven live rollers (CDLR) or high-speed pallet conveyors transport heavy and bulky loads and so they are the best conveyor system for manufacturing.

Packaging: Wondering how to choose a conveyor for packaging? Accumulation conveyors or drag chain conveyors offer excellent good movement with machinery.

Food and Drink: Sanitary conveyors easy to clean and corrosion-resistant are required for food processing to ensure hygiene and keep away contaminants.

5. Consider Maintenance and Durability

Reliability is the top priority. Select a conveyor system which requires less maintenance and is easy to repair. Modularity is best, since they can be re-configured easily to accommodate evolving needs. This provides long-term value and minimum possible disruption to your business.

6. Initial Cost and Return on Investment (ROI)

Consider the initial expense and long-term cost savings. An effectively designed conveyor system saves labor, saves time, and eliminates mistakes. Ultimately, the correct conveyor system will earn its money back in the form of enhanced efficiency and reduced operational expenses.

0 notes

Text

Belt Conveyor Manufacturing in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry is a prominent name in belt conveyor manufacturing in Faridabad. We design and produce a wide range of belt conveyors tailored for various industries, including packaging, logistics, food processing, and assembly lines. Our conveyors ensure seamless material flow, high durability, and low maintenance.

#Belt conveyor manufacturing Faridabad#belt conveyor suppliers#Vashnavi Conveyor#industrial belt conveyors#conveyor manufacturers in Faridabad#material handling equipment#automated conveyor systems

0 notes

Text

#PneumaticConveying#IndustrialFabrication#ConveyingSystems#FabricationExperts#HighQualityManufacturing#EngineeringSolutions#MaterialHandling#PneumaticSolutions#Automation#IndustrialInnovation#pneumatic conveyor systems#lump breaker#bulk materials handling#macawberindia#bulkmaterialhandling#dense phase pneumatic conveying system#macawber engineering

0 notes

Text

Streamlining Industrial Success With Reliable Spare Parts Supply

The industrial sector relies on the effectiveness of its processes and machinery; hence, spare parts suppliers are the backbone of this success. These suppliers provide key parts that keep production lines rolling without any form of delay. Their main priority is to deliver high-quality parts that meet industrial standards while focusing on timeliness. This way, industries can continue without being interrupted, minimize downtime, and maintain operational integrity. With a well-established network, a Spare Parts Supplier for the Industrial Sector helps to streamline procurement and logistics for industries worldwide.

Their solutions cater to diverse operational challenges, from filtration systems to specialized machinery components. Suppliers are a vital part of operational success, combining experience, efficiency, and technological knowledge. Businesses rely on their expertise to quickly access the right spare parts when needed, empowering industries to thrive even in unforeseen disruptions. Through trusted supply chains and industry partnerships, they provide strategic solutions that sustain industries’ global demand.

#Control and automation systems Offenburg#VBN Hydraulic equipment#Conveyor equipment Offenburg#spare parts Supplier for industrial sector#industrial automation service providers#flexible export solutions offenburg#industrial spare parts

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

0 notes

Text

Hanging System Painting Line

The Hanging System Painting Line is an automated production line for spraying the surface of central air-conditioning shells and tubes. The hanging system ensures that the workpiece can move smoothly during the spraying process, ensuring the uniformity and quality of the spraying. The automated hanging spraying line can operate continuously, greatly improving production efficiency. It is widely used in central air-conditioning manufacturers, refrigeration equipment manufacturers and other fields. #factory #oem #odm #fyp #coatingline #paintingline #sprayingline #homeappliance coating line

#factory#oem#odm#fyp#coatingline#paintingline#sprayingline#homeappliance coating line#Metal Spraying Line#metal painting line#automated painting line#automatic spraying equipment#overhead conveyor system#Home appliance coating line

0 notes

Text

Best Truck Loading Conveyor Solutions by Indian Manufacturers

Looking for efficient and durable truck loading conveyors? Explore the best solutions from leading Indian manufacturers offering telescopic, flexible, and belt conveyors tailored to your industrial needs. Improve loading speed, reduce manual effort, and ensure workplace safety — all at competitive prices. Ideal for warehouses, logistics hubs, e-commerce, and manufacturing units. ✅ Custom designs

✅ Quick delivery

✅ Low maintenance Get in touch with trusted Indian conveyor suppliers today!

#Truck Loading Conveyor#Indian Conveyor Manufacturers#Telescopic Conveyor#Material Handling#Warehouse Equipment#Logistics Automation#India Manufacturing

0 notes