#casting and moulding software

Explore tagged Tumblr posts

Text

Industries | Foundry CastingAluminium Die Casting

Roadmap IT Solutions pioneers in providing ERP Software for Aluminium Die Casting to digitize the workflow and to empower the businesses to attain global progress

#foundryerpsystem#casting and moulding software#erpsoftwareforfoundrymanagement#erpfoundrysoftware#castingindustry#deicasting#erpsoftwarecompany#erpsoftwareinpondicherry#erpsoftwareinchennai#erpsoftwareinbangalore#erpsoftwareincoimbatore

0 notes

Text

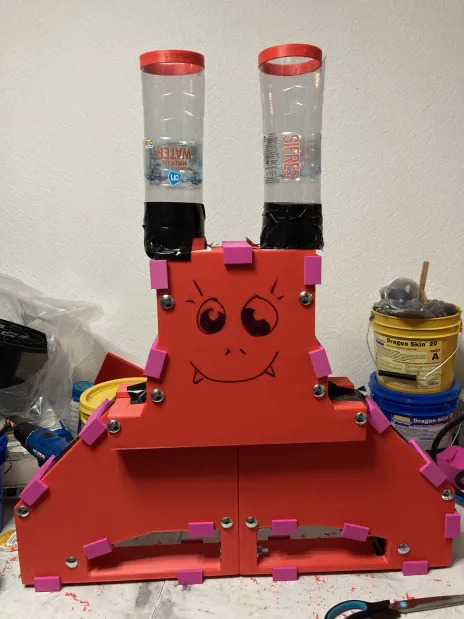

Fin V5 - V7: Utter Failure

I have for the last three or so weeks been sprinting ahead on new designs of fins which reduce the size but increase the thickness to create a stiffer fin.

This entire process has been an utter disaster again and again. My printer has been acting up terribly and it took me eleven days to print three days worth of parts. My parts are still warped and some had terrible stringing. I was also having an extremely difficult time with my CNC to make it behave and I still have not gotten a good pathing software yet set up.

I still did try to cast a fin, there were some noticable gaps but I hoped I could seal them. Getting the cast set up was four hours because I had to keep drilling out holes because nothing would align and nor would the poorly sized bolts actually fit. I had hoped I could use the bolts as alignment pins though in hindsight that was a fool's errand and the availability of specialty bolts seems fairly obscure in NL, and even DE or UK suppliers were not much better. The nice thing is the bolts did create a strong seal where they were positioned to be able to, the downside is that could really only happen because the two halves of the clamshell and not between the parts themselves as my printer and CNC can only make so large of parts.

Still I did forge ahead with the cast, which honestly I probably should have not with how many difficulties I had so far had. The process is messy, and disorganised, but still the casting part itself did not take long. I added two hopper tubes into the mould so I could store more silicone in it and these actually worked really well. Unfortunately the cast did not go well. It eventually started leaking and it did not fully fill. I did try adding more but after adding an extra 600mL on top of the early 900mL extra which represents around a 33% additional wastage I called it.

(I drew a face on it because it needed a face)

Unfortunately the next day the leaking was very bad, and despite my best efforts I was entirely unable to even remove the bolts to separate the clamshell and see even vaguely what it looks or feels like.

I think what I need to do is take a few weeks and really refine my process. I need to make it so my moulds are water tight so they do not leak. I also need to make it so I do not get silicone everywhere nor have to use nearly as many paper towels or clean nearly as many buckets.

I have a few ideas how to achieve this, but all of these will take some time to sort out. I am certainly not giving up, and though these setbacks are frustrating, I am feeling still plenty motivated to move forward.

Tuesday I will begin again with renewed plan and vigor. Doeg!

33 notes

·

View notes

Text

[Review] Sekiro: Shadows Die Twice (PS4)

Dark Souls But I Can Only Parry

Continuing my very sporadic playthrough of From Software's games, it's Sekiro! I knew going in that it's deliberately breaking the Souls mould in certain ways, but I didn't always get on with its choices and experiments. It's a narrower, more focused experience, which works both for it and against it.

The setting is Japan—yes, the country on Earth—late in the Sengoku period. It's not exactly historically accurate though, as you encounter phantasms, fishmen, strangely intelligent animals, supernatural ninja powers, and forces divine and demonic; and yet it's more grounded than some "fantasy Japan" games I've played. The part of me that loves to make connections between From's games was a tad disappointed that this takes place on The Earth when it didn't necessarily need to be, but that's a nitpick.

Having a strong sense of place and tone was a part of what endeared Bloodborne to me, and that applies here too. I have come to appreciate Elden Ring's complex and layered lore more over time, but both approaches have merit. In the case of Sekiro, it's a personal story with a small cast of connected characters. I struggled at times to grasp the precise political situation and how they fit into it but the themes of how various people and factions struggled for immortality and how it corrupted them in turn resonated.

The story and themes come together in the person of the player character Wolf, a ninja sworn to loyalty and protection of Kuro, a golden child who inherited the powers of a godly dragon. Many seek to exploit his gift but he bestows on Wolf the power of resurrection, which serves as a gameplay mechanic to help you bounce back from defeats (which will be many). Their ultimate goal is to rid Kuro of this tainted gift, which is done through a series of convoluted steps that take you to the corners of the isolated Ashina fiefdom and beyond to the divine realm.

Wolf's nature as a specified character ties into the removal of many RPG elements, relative to other Soulslike games. His ninja skills and prosthetic arm open the door to many new gameplay features: acrobatic grappling, various limited-use combat tools, and stealth takedowns. I enjoyed engaging with the sneaking to pick off enemies, and combat while risky is ultimately satisfying, but I felt restricted by the emphasis on consumable items and what I saw as prescriptions on how the game is to be played.

I spoke about a narrow focus: Sekiro's combat is all about the back and forth of parrying. More important than an enemy or boss's health bar is their posture meter, which is worn down by your attacks or by blocking theirs with precise timing. The lack of a stamina mechanic and speed of your attacks rewards aggressive play, but you can't just go all-out; you absolutely must read cues that suggest counterattacks, and on top of this learn the timing and behaviours of the various enemies. I particularly struggled with the more difficult attacks: grabs, thrusts, and sweeps are denoted by a warning kanji and have totally different responses, but in the heat of the moment I could never distinguish between three complex characters. They could have at least made them different colours!

More than any other From game, I got mightily upset with certain encounters and sequences. I was walled hard by difficulty spikes in the early game, with little recourse but to push through by repeated attempts. My chief nemesis: a simple one-armed ninja in a cramped well who becomes a regular mook later in the game! The midgame was more to my liking when things opened up and I got more of a grip on the mechanics and flow, but lategame bosses and the final fight completely stomped my arse again. Looking up tricks and strategies online helped, but you still have to build muscle memory yourself.

Sekiro doesn't seem to want to help you develop it though. FromSoft has implemented needlessly player-hostile mechanics before, but death in Sekiro is especially punishing. You'll instantly lose half your money and experience towards your latest skill point, unless a percentage chance happens to save you, and this chance goes down the more you die! It's actually not too bad if you go out of your way to farm XP and spend your dosh when you know there's a boss coming, but death can happen at any time, and the in-game economy felt out of wack while the skill trees are bloated with dubious abilities.

Overall I think Sekiro is a success. It builds on a Souls skeleton but with new flavours (to mix some metaphors), and delivers a cool ninja fantasy with some powerful imagery and setpieces. I just can't decide if its action-adventure mechanics make it more accessible than other From games, or if the prescriptive parry playstyle and lack of levelling make it a harder sell. My feelings are mixed; I'm glad I played it but also relieved to have beaten it... it can't hurt me anymore!

9 notes

·

View notes

Text

A specialised casting technique has emerged as a trusted solution, particularly for reinforcing high-stress areas like structural corners. This article explores how this process supports various industries—from construction to logistics—by improving strength, ensuring consistency, and enhancing performance while aligning with sustainability and cost-efficiency goals.

Strength at the Core of Structural Design

In structural engineering and heavy manufacturing, the integrity of joint areas plays a pivotal role in determining overall durability. These connection points are regularly exposed to mechanical pressure, vibrations, and environmental elements. Strengthening these areas ensures the long-term performance of equipment, buildings, or containers. Corner Casting is widely used in such applications, as it provides a reinforced solution specifically designed to handle concentrated stress. By incorporating Corner Casting in high-load zones, manufacturers can deliver structures with a stronger core, especially where failure is least tolerated.

Why Moulded Reinforcement Makes a Difference

Precision casting enables manufacturers to create solid, seamless parts that outperform traditionally welded or fabricated joints. The absence of seams reduces the risk of stress fractures, and the uniform density of the material provides excellent load-bearing capacity. These reinforcements offer peace of mind in critical applications such as building supports, lifting frames, or marine platforms, where absolute reliability is essential.

Selecting the right material is crucial. Cast steel remains a popular choice due to its strength, resistance to deformation, and ability to withstand harsh elements. For industries that demand peak mechanical performance, such as marine construction, oil rigs, or shipping containers, steel provides a trusted foundation. In addition, its compatibility with post-processing techniques like welding, painting, and machining makes it a versatile option.

Meeting Industrial Standards and Safety

The transportation and construction industries are governed by strict global standards. Shipping containers, for instance, must safely endure stacking, lifting, and shifting in unpredictable conditions. Their support structures are often produced using cast components that conform to these standards, ensuring durability during loading and unloading. In construction, these parts serve as dependable links between beams and panels, particularly in multistory frameworks.

Shaping Performance Through Design Precision

Modern design tools allow engineers to simulate real-world stress before production even begins. Using CAD software, manufacturers can predict the performance of a component under pressure, adjusting mould dimensions to improve strength or reduce weight. The result is a balance of structural integrity and efficient resource use, giving companies a competitive edge in performance and cost management.

Long-Term Durability in Harsh Conditions

Industrial environments are unforgiving. Components used in outdoor or high-pressure applications must endure continuous exposure to water, chemicals, UV light, and extreme temperatures. Precision-cast components offer enhanced resistance to these factors, maintaining shape and function for years. This makes them indispensable in projects where structural failure is not an option, such as coastal bridges, offshore platforms, or power facilities.

Consistency and Quality You Can Count On

Mass production demands consistency. Each unit must meet the same specifications, especially in industries where parts are installed interchangeably. The casting process allows for reliable repetition without quality degradation, thanks to reusable moulds and strict controls. Advanced inspection techniques like X-ray imaging or ultrasonic testing verify structural integrity before distribution, ensuring every piece is ready for performance. One of the most appealing aspects of this manufacturing method is its long service life. By minimising wear and tear in high-stress areas, companies benefit from fewer maintenance interventions and less frequent part replacements. This not only enhances operational uptime but also contributes to reduced lifetime costs—a major benefit for industries operating under tight margins or continuous production cycles.

Sustainability in Modern Manufacturing

Environmental responsibility is a growing concern in heavy industry. Today’s foundries incorporate eco-conscious practices like recycling excess materials, using energy-efficient furnaces, and adopting closed-loop cooling systems. Because these components last longer and require fewer replacements, they help reduce industrial waste. The combination of durability and low environmental impact adds significant value to any sustainable engineering project. From construction to aerospace, this production technique supports a wide range of industries. It is vital in the logistics industry, where containers must maintain their integrity during global transport. It supports mining equipment subjected to constant movement and impact. It also plays a key role in architectural structures that combine aesthetic appeal with strength. This wide range of applications highlights the process’s adaptability and importance in modern manufacturing.

Conclusion As engineering evolves, so do the methods that define precision and durability. Casting processes designed for structural enhancement remain at the forefront of reliable component manufacturing. Their ability to withstand pressure, maintain shape, and deliver consistent results across countless applications has made them a cornerstone of modern production. In particular, Corner Casting continues to be a preferred solution in industries that prioritise safety, efficiency, and performance, helping build the strong, sustainable structures of tomorrow. The increasing demand for high-performance infrastructure has placed a spotlight on components that provide structural integrity without compromising on design. From shipping containers and trailers to architectural frameworks and machinery, the corners often bear the brunt of stress. By incorporating robust casting techniques at these pressure points, manufacturers enhance both safety and longevity. This focus not only reduces repair costs but also ensures that structures remain reliable over decades of use. As materials and methods continue to improve, the reliance on expertly cast parts, especially at crucial joints, will become even more pronounced in the global industrial landscape.

0 notes

Text

NOVA Formwork Is Ready To Construct Smarter With AI

The construction building sector is being revolutionized, and it is also including new technologies such as Artificial Intelligence (AI) faster. Being a leader in the adoption of AI, Nova Formwork is undertaking a massive evolution of its processes. They also take pride in leading such a massive transformation with innovative and high-quality formwork systems.

In embracing AI in its operations, Nova Formworks aims to revolutionize the construction industry to make it efficient, sustainable, and safe. Let us see more about formworks and the use of AI as a significant progress in construction.

What is the Need for Formworks?

Formwork in construction is an important component that helps develop temporary moulds where the concrete is cast to achieve the desired shape. Good formwork ensures precision, reduces project time, and increases building strength.

Traditionally, formwork has been time and labour-intensive, and the entire process is sure to face issues like delays and high costs. All this is being reversed with the usage of AI technology, and the issues are resolved efficiently. Ultimately, AI is streamlining processes, saving material, and eradicating human errors for Nova Formworks.

How is Nova Formworks Applying AI Technology?

Nova Formwork is at the forefront of the application of AI technology in formwork systems to improve construction further through innovation. Nova Formworks uses AI-planning and design software to plan for all possible construction scenarios, chart out possible mistakes that can occur, and decide on the optimal solution. Such information improves project accuracy, reducing rework to a bare minimum.

Besides this, AI-based analytics also offer real-time tracking of the performance of the formwork, as well as useful details regarding load-carrying capacity, alignment, and structural behavior of the formwork. Thus, the use of formwork in construction with AI not only enhances safety but also ensures that every project is of higher quality.

Advantages of AI-Based Formwork Construction

The application of AI in formwork construction benefits in several ways, such as:

Cost Advantage: Smart utilization of material and lesser reworks results in enormous cost reduction in construction operations.

Enhanced Safety: Predictive maintenance and continuous monitoring provide enhanced construction site safety.

Sustainability: AI results in less wastage of material, paving the way for eco-friendly construction practices.

Future of Construction with AI

With AI technology advancing day by day, the formwork system will be further enhanced for any kind of construction needs. Nova Formworks invests in research and development (R&D) to make such AI-based advancements. Fully mechanised formwork installation, robot installations through AI, and smart sensors with real-time input are some of the probable means to evolve in the future.

The vision of the company is to evolve intelligent formwork solutions that are dynamic with real-time data capabilities. The cutting-edge technology positions Nova Formworks as a leadership brand for modern construction practices.

Conclusion

AI-based construction formwork systems are the new direction for the future, and this would be massively helpful for firms. Nova Formworks embraces innovative technologies that indicate their quality, innovation, and customer focus.

With its AI integration, Nova Formworks is not just diversifying its product portfolio but also providing opportunities for the construction sector. With the demand for smart building solutions growing day by day, the company is ready to lead the way with its smart, AI-driven formwork systems.

#nova formwork#plastic formworks#formworks in india manufacturer and supplier#construction#construction materials#formwork#construction material

0 notes

Text

The Impact of New Tech on Aluminum Casting Production and Design

Adding new technologies like automation, modelling software, and advanced sensors has had a big effect on aluminium casting, which is an important part of making things. Automation speeds up output, lowers the cost of labour, and improves consistency. Engineers can use simulation software to make mould designs better and predict problems before they happen. This cuts down on waste and raises the quality of the casting. Advanced sensors keep an eye on important parameters, ensuring exact control over temperature and pressure. This makes the castings stronger. These improvements will have big effects on the business.

Historical Context of Aluminum Casting

Aluminium casting has been around for a long time, and it uses both old-fashioned ways and new technology. At first, methods like sand casting and die casting were done by hand. New techniques, such as investment casting and solid mould casting, have been added to these methods over time to make them better. Technology has changed the business world by making it easier to make things with complicated shapes and patterns.

Impact on Production Efficiency

New technologies in casting, like 3D printing and additive production, have changed the business by making it possible to make prototypes quickly and custom parts. Automation and robotics have sped up output by reducing mistakes made by humans and streamlining processes. Computer-aided design (CAD) and simulation apps are now necessary to make designs better and reduce errors.

Enhancements in Design Capabilities

Improvements in aluminium casting have made production much more efficient by cutting down on wait times and increasing production rates. These technologies cut down on waste, energy use, and labour costs, which makes the business more competitive. They also help make production more sustainable and eco-friendly, which makes it easier for businesses to meet the needs of growing customers.

Quality Control and Assurance

New technologies like computed tomography and ultrasonic testing have completely changed modern checking methods. Real-time tracking and data analytics allow for quick changes, which reduces defects and raises the consistency and dependability of the product, making sure that aluminium castings meet strict performance standards.

Sustainability and Environmental Considerations

Every Aluminium casting production company is now focusing on sustainability and the environment. They are using energy-efficient furnaces, melting metal more efficiently, and reducing waste through process control, closed-loop systems, recycling programs, and circular economy practices. All of these things help make the future more sustainable.

Challenges and Limitations of New Technologies

New technologies come with problems, like high costs and large beginning investments, which can hurt smaller businesses. To get the most out of technology, it's important to fill in skill gaps and train workers, and integrating new technologies into current systems needs careful planning.

Future Trends in Aluminum Casting Technology

New technologies, such as additive manufacturing and advanced simulation tools, are expected to change the aluminium casting industry. These technologies will likely increase automation, improve efficiency, and raise product quality, giving businesses chances to grow and come up with new ideas.

Final Thoughts

New technology has had a big effect on metal casting, making it more efficient, better quality, and cheaper. To stay competitive in a market that is changing quickly, manufacturers must use new technologies. Performance and sustainability will get even better as new ideas are brought to the production and creation of aluminium castings in the future.

0 notes

Text

How Aluminum Foundry Services Can Cut Down Production Costs

In the manufacturing industry, aluminium foundry services are essential because they make it possible to supply a spread of aluminium components using casting, melting, and finishing techniques. These services, which are crucial in sectors including consumer products, automotive, and aerospace, are customized to satisfy certain design specifications. Cutting costs has a significant impact on manufacturing's sustainability and profitability. By streamlining manufacturing procedures, lowering material waste, and improving product quality, using aluminium foundry services will result in considerable cost savings. Complex geometries and lightweight designs could also be produced, which reduces material costs and increases energy efficiency during usage and transit. These services' scalability enables companies to switch production levels in response to plug demands, reducing excess inventory and related expenses.

Understanding Aluminum Foundry Services

The manufacturing of aluminium castings for the buyer goods, automotive, and aerospace sectors is a component of Aluminium foundry service. Aluminium is melted and then poured into moulds to harden into acceptable forms. The scope includes design advice, tooling, and finishing processes, as well as casting. Sand casting, die casting, and investment casting are common methods for casting aluminium. Die casting is quicker and more accurate, while sand casting is cheaper and versatile. Investment casting provides excellent dimensional precision and surface polish. Large manufacturers and specialized foundries that extensively invest in cutting-edge technology to enhance production capabilities define the world. Casting quality has increased, and labour expenses have decreased because of advanced technology and automation. Operations are streamlined by software, which boosts productivity and reduces waste. For material efficiency, premium aluminium alloys are necessary, and efficient machining and recycling techniques facilitate a circular economy.

The Role of Technology in Cost Reduction

Technology is important for cutting costs since it increases accuracy and reduces manual work. Software solutions also make effective planning and resource allocation possible. By boosting throughput and reducing material waste, technology also improves efficiency and waste reduction.

Material Efficiency and Waste Management

Superior aluminium alloys are essential for performance and longevity, which lowers the necessity for replacements and repairs. Just-in-time production and lean manufacturing reduce waste and maximize material use. Reusing scrap and excess materials, as well as recycling and reusing materials in foundry processes, lowers costs and features a positive environmental impact.

Labor Cost Savings

By redistributing workers to skilled jobs, boosting their capacities, and increasing their capacity to adapt to new technology, automation lowers labour costs. Additionally, it reduces redundancies and simplifies processes by fixing effective procedures in place, which lowers labour costs overall. This leads to cost savings in foundry operations.

Economies of Scale

The benefits of large-scale production, including enhanced efficiency, better negotiating power with suppliers, cost advantages, lower costs per unit due to volume discounts, lower transportation and handling costs, and therefore the effect of production volume on unit costs, are mentioned as economies of scale.

Customization and adaptability

Prototyping plays a key role in cost-effective production, early design flaw detection, and client feedback. This text emphasizes the benefits of customization and adaptability in development, emphasizing the power to adapt products to specific needs, improve customer satisfaction, reduce costs through efficient design modifications, streamline change implementation processes, minimize waste, and more.

Quality Control and Assurance

While abiding by industry norms, upholding high standards of quality improves consumer trust and brand reputation. Defects and rework, however, will end in higher costs and even a loss of revenue. Staff training, the implementation of continuous improvement procedures, and continuous improvement processes themselves are all samples of effective quality management techniques.

Case Studies and Real-World Examples

Successful applications of aluminium foundry services are demonstrated through case studies and real-world examples, demonstrating creativity and efficiency. Testimonials from customers attest to the standard of the services provided, and businesses see measurable cost reductions. Pre- and post-implementation cost comparisons offer valuable insights into resolving typical production issues. Best practices and lessons learned from industry leaders are also covered.

Conclusion

Numerous benefits, including cost-effectiveness, design freedom, and improved product performance, are offered by aluminium foundry services. Businesses should consider these services because the manufacturing sector develops to satisfy production demands and keep a competitive advantage. Long-term financial advantages and increased operational efficiency are possible outcomes of those services.

0 notes

Text

Diamond Jewellery Manufacturer: Crafting Timeless Elegance

Since diamonds have enthralled people for millennia, diamond jewellery has come to represent wealth, status, and classic beauty. The secret behind every gorgeous diamond piece is the skill of a diamond jewellery manufacturer, whose skill and attention to detail turn uncut stones into magnificent decorations. Jewellery manufacturing companies are essential to establishing market trends and guaranteeing that customers obtain the best jewellery in today's cutthroat marketplace.

The Role of a Diamond Jewellery Manufacturer

The task of designing, creating, and supplying diamond jewellery to merchants and customers falls to a diamond jewellery manufacturer. From tiny artisanal workshops to massive jewellery manufacturing companies that supply global brands, these producers work on a variety of scales. They are skilled in metalworking, gemstone setting, diamond procurement, jewellery design, and quality assurance.

Sourcing High-Quality Diamonds

The choice of premium diamonds is the first step towards creating a remarkable diamond jewelry piece. Diamond jewellery manufacturers may source their raw diamonds ethically or from mines. When choosing diamonds, the following important variables are taken into account:

Cut: A diamond's cut determines its brilliance and shine.

Clarity: Describes if there are any inclusions or flaws.

Color: Ranging from bright yellow or brown to colorless.

Carat Weight: The diamond's dimensions and mass.

Manufacturers frequently collaborate with diamond jewellery suppliers to ensure they have conflict-free, ethically sourced diamonds that adhere to the Kimberley Process Certification Scheme.

Jewellery Design and Prototyping

A diamond jewellery manufacturer employs skilled designers who conceptualize and create unique jewellery pieces. The design process typically includes:

Sketching and CAD Design – Digital software is used to create detailed 3D models of jewellery designs.

Prototyping – A wax or resin prototype is created to visualize the final piece before production.

Material Selection – Choosing the right metal (gold, platinum, silver) and additional gemstones to complement the diamonds.

Advanced Methods for Making Jewellery

To create high-quality jewellery, contemporary Jewellery manufacturing companies combine traditional artistry with cutting-edge technologies. Among the methods employed are:

Casting: To make Jewellery components, melted metal is poured into moulds.

Handcrafting: Jewellery is painstakingly shaped and polished by talented craftspeople.

3D Printing: Jewellery designs that are accurate and complex are made using 3D printing.

Stone Setting: Skilled setters carefully insert diamonds into Jewellery settings.

The Importance of Ethical and Sustainable Practices

To comply with environmental and ethical requirements, the jewellery industry is changing. Prominent diamond jewellery manufacturer follow eco-friendly procedures like:

Utilizing lab-grown diamonds, which are more ecologically benign than diamonds that are mined.

Ensuring craftspeople receive fair compensation and secure working conditions.

Using recovered metals and cutting trash to lessen the impact on the environment

Leading Jewellery Manufacturing Companies in the Sector

The global market is dominated by a few jewellery manufacturing companies that provide luxury brands and merchants with premium diamond jewellery. Among the most well-known producers are:

Aarna Jewels: Aarna Jewels is one of the best diamond jewellery manufacturer in India for every occasion.

Tiffany & Co.: Tiffany & Co. is well-known for its classic designs and exquisite craftsmanship.

Cartier: Cartier is a well-known brand in the production of fine jewellery.

Graff Diamonds: Graff Diamonds specializes in jewellery made of rare and valuable diamonds.

Signet Jewelers: One of the biggest jewellery makers and merchants in the world is Signet Jewelers.

Pandora: Pandora is a well-known brand of modern, reasonably priced diamond jewellery.

In the jewellery industry, these businesses set the standard for creativity, quality, and design.

How to Choose the Right Diamond Jewellery Manufacturer

If you are a retailer, business, or individual looking to collaborate with a diamond jewellery manufacturer, consider the following factors:

Reputation and Experience – Choose manufacturers with a proven track record of quality and reliability.

Certifications and Compliance – Ensure they adhere to ethical sourcing and industry standards.

Customization Capabilities – Look for manufacturers who offer bespoke jewellery solutions.

Technology and Craftsmanship – Evaluate their use of modern technology and skilled artisans.

Pricing and Production Capacity – Consider competitive pricing and their ability to meet demand.

In conclusion

The foundation of the jewellery industry is a diamond jewellery manufacturer, who creates classic items by fusing technology, craftsmanship, and ethical sourcing. The future of diamond jewellery is bright as long as jewellery manufacturers keep coming up with new ideas that give customers countless options for sustainability, quality, and style. Knowing the nuances of jewellery manufacture can help you appreciate the expertise behind every brilliant diamond item, whether you're a retailer, designer, or jewellery aficionado.

Article source: https://medium.com/@kirtihd99solutions/diamond-jewellery-manufacturer-crafting-timeless-elegance-0ff75e679c49?postPublishedType=initial

0 notes

Text

The Future of Jewellery Manufacturing with Advanced Jewellery Casting Machines

The jewellery industry has always been one of the most intricate and creative sectors in manufacturing, combining artistry with precision. As the demand for custom, high-quality jewellery pieces continues to grow, manufacturers are increasingly turning to innovative technologies to improve their production processes. One such breakthrough is the advanced jewellery casting machine, which is transforming the way jewellery is made. These machines have ushered in a new era of efficiency, accuracy, and design possibilities. But what does the future hold for jewellery manufacturing with the continued evolution of jewellery casting machines?

Revolutionizing Design Precision

In the past, creating fine jewellery often involved labor-intensive manual processes, with a significant degree of human error. While traditional casting methods such as lost wax casting are still used, advanced jewellery casting machines have taken precision to a whole new level. The machines now utilize state-of-the-art technology, such as computer numerical control (CNC) and 3D printing, to ensure that every detail of a design is captured with unmatched accuracy.

With these advanced casting machines, manufacturers can reproduce the most intricate and delicate designs with ease, ensuring flawless results. Complex patterns, fine engravings, and delicate textures that once required hours of manual work can now be produced in a fraction of the time. This revolution allows jewellery makers to expand their creativity, pushing the boundaries of design while maintaining the highest standards of quality.

Speeding Up the Production Process

The introduction of advanced jewellery casting machines has greatly improved the efficiency of jewellery production. Traditional casting methods often involved multiple stages of handcrafting, including mould making, pouring, and polishing, which could take a considerable amount of time. In contrast, modern jewellery casting machines streamline this process, allowing for faster production without compromising on quality.

Jewellery casting machines automate several key stages, such as wax injection, casting, and even some aspects of finishing, which results in significant time savings. Manufacturers can now produce large volumes of jewellery at a much faster rate, making them more competitive in the market. Additionally, these machines reduce the amount of waste, as the casting process is highly precise, which results in fewer defects and material losses.

Customization and Personalization

As customers increasingly seek personalised and one-of-a-kind jewellery pieces, the demand for customization has grown. Advanced jewellery casting machines are making it easier than ever for manufacturers to meet this demand. With the ability to create highly detailed and intricate designs through 3D modelling software, jewellers can now offer customized pieces with ease.

These machines can quickly adapt to a variety of designs, whether it's a unique engagement ring, a custom pendant, or an intricate bracelet. Through the use of digital technology, customers can now collaborate with jewellery designers to create a piece that reflects their personal style, preferences, and significance. This customization ability is not only a game-changer for the consumer market but also helps manufacturers stand out by offering truly bespoke services.

Sustainability and Material Efficiency

The jewellery industry is no stranger to the growing demand for sustainability, and advanced jewellery casting machines are helping meet these expectations. These machines are designed to use materials more efficiently, reducing waste during the casting process. In traditional jewellery casting, the process can produce a significant amount of scrap material, especially with precious metals like gold and platinum. However, modern casting machines are highly precise, ensuring that the exact amount of material is used for each cast, resulting in less waste.

Moreover, many advanced jewellery casting machines are now designed to work with recycled materials, which supports the move toward more sustainable jewellery production. This is an important step towards reducing the environmental impact of the jewellery industry, as it allows manufacturers to reuse valuable metals rather than relying on new, mined materials. These practices not only contribute to environmental conservation but also help jewellery businesses reduce costs and maintain ethical sourcing standards.

The Integration of Artificial Intelligence and Automation

Looking further ahead, the future of jewellery manufacturing will likely see even more integration of artificial intelligence (AI) and automation. AI can be used to optimize the casting process by learning from past production data, predicting potential issues, and adjusting parameters for optimal results. These advanced systems could also enable jewellery casting machines to become more autonomous, requiring less human intervention during production.

Additionally, AI could help improve quality control by analyzing each piece as it is being cast, ensuring that any imperfections are caught early in the process. This level of automation will reduce the need for manual oversight, allowing manufacturers to focus on innovation and creativity.

Conclusion

The future of jewellery manufacturing is undeniably intertwined with the continued development of advanced jewellery casting machines. These machines have already revolutionized the industry by offering faster, more precise, and sustainable methods of production. As technology continues to evolve, we can expect even more breakthroughs in design, efficiency, and sustainability, making jewellery creation faster, more customizable, and more environmentally friendly.

For manufacturers, investing in an advanced jewellery casting machine is no longer just an option��it is a necessity for staying competitive in a rapidly changing market. As the demand for unique, high-quality pieces continues to rise, these machines will play a pivotal role in shaping the future of jewellery manufacturing, driving innovation and transforming the industry for years to come.

0 notes

Text

How Rotational Moulds Are Made: Materials, Techniques, and Processes

Rotational moulding, or rotomolding, has gained immense popularity in the manufacturing industry due to its versatility and efficiency in producing durable, hollow plastic products. At the heart of this process lies the rotational mould, which plays a critical role in determining the quality and functionality of the final product. In this blog, we’ll explore how rotational moulds are made, including the materials, techniques, and processes involved, and how rotomolding experts ensure optimal results.

The Importance of Rotational Moulds in the Rotomolding Process

Rotational moulds are the foundation of the rotomolding process. They determine the shape, size, and texture of the final product, making their quality and design crucial for success. Unlike other moulding methods, rotational moulds must withstand high temperatures and continuous rotation during the manufacturing process, requiring careful material selection and precision engineering.

Materials Used in Rotational Moulds

The choice of material for rotational moulds depends on factors such as product requirements, production volume, and budget. Here are the most commonly used materials:

1. Aluminum

Advantages: Lightweight, excellent thermal conductivity, and corrosion resistance.

Applications: Ideal for complex mould designs, large moulds, and projects requiring quick heat transfer.

Techniques Used: CNC machining and casting.

2. Steel

Advantages: High strength, durability, and resistance to wear and deformation.

Applications: Suitable for high-volume production and products requiring precise dimensions.

Techniques Used: Fabrication and machining.

3. Hybrid Materials

Advantages: Combines the benefits of aluminum and steel for specific applications.

Applications: Used when cost-efficiency and performance must be balanced.

The selection of mould material directly impacts the product’s quality, the mould’s lifespan, and overall production costs, making it a critical decision in the rotomolding process.

Techniques for Manufacturing Rotational Moulds

Creating high-quality rotational moulds requires advanced manufacturing techniques and expertise. Here are the primary techniques used:

1. CNC Machining

Overview: CNC (Computer Numerical Control) machining is a precise method for shaping aluminium or steel moulds. It uses computer-controlled tools to cut and shape the material with high accuracy.

Benefits: Ensures tight tolerances, smooth surfaces, and complex geometries.

Applications: Used for detailed mould designs and prototypes.

2. Casting

Overview: This involves pouring molten metal, usually aluminum, into a mould cavity to create the desired shape. After cooling and solidifying, the mould is polished and finished.

Benefits: Cost-effective for large moulds and simple designs.

Applications: Ideal for bulk production where precision is less critical.

3. Fabrication

Overview: Fabrication involves welding and assembling steel plates to create the mould. This technique is often used for large or simple moulds.

Benefits: Durable and cost-efficient for straightforward designs.

Applications: Suitable for heavy-duty applications and high-volume production.

4. Electroforming

Overview: This process involves depositing metal onto a model using electrochemical plating. The model is then removed, leaving a thin but detailed metal mould.

Benefits: Excellent for highly detailed and intricate mould designs.

Applications: Used for small-scale production or products requiring fine details.

Key Processes in Rotational Mould Making

The process of making rotational moulds involves several critical steps. Here’s a breakdown:

1. Design and Prototyping

Conceptualization: Rotomolding experts collaborate with clients to understand product specifications, such as size, shape, and functionality.

Prototyping: A prototype or model is created using CAD software to ensure the mould design meets requirements.

Testing: Prototypes may be tested for functionality and accuracy before proceeding to full-scale mould production.

2. Mould Manufacturing

Material Preparation: The chosen material (aluminum, steel, etc.) is prepared for machining, casting, or fabrication.

Shaping and Assembly: The material is shaped using one of the techniques mentioned above. For complex designs, multiple components may be assembled into a single mould.

Surface Treatment: The mould is polished, textured, or coated to achieve the desired surface finish. This step ensures the final product’s aesthetic and functional qualities.

3. Quality Control

Inspection: Every mould undergoes rigorous quality checks to ensure dimensional accuracy, structural integrity, and thermal performance.

Testing: Some moulds are tested in trial runs to verify their compatibility with the rotomolding process.

4. Finalization and Delivery

Finishing Touches: Any final adjustments are made, such as adding vents, flanges, or inserts.

Delivery: The completed mould is delivered to the production facility, ready for use in the rotomolding process.

Why Rotomolding Experts Are Essential for Mould Manufacturing

Collaborating with rotomolding experts ensures that your rotational moulds meet the highest standards of quality and performance. Here’s why their expertise matters:

1. Precision and Accuracy

Rotomolding experts leverage advanced tools and techniques to produce moulds with tight tolerances and intricate details, ensuring optimal product quality.

2. Customization

Whether you need a mould for a unique product or a high-volume production run, experts can tailor the design and manufacturing process to your specific requirements.

3. Material Knowledge

With in-depth knowledge of materials, rotomolding experts can recommend the best options for your project, balancing cost, durability, and performance.

4. End-to-End Support

From initial design to final production, rotomolding experts provide comprehensive support, ensuring a seamless and efficient process.

Conclusion

The creation of high-quality rotational moulds is a meticulous and technically demanding process. From selecting the right materials to employing advanced manufacturing techniques, every step is crucial in ensuring the success of the rotomolding process. By partnering with rotomolding experts, manufacturers can access the expertise and precision needed to create exceptional moulds that meet their unique requirements. Whether you’re developing custom products or scaling up production, investing in quality rotational moulds is the foundation for achieving superior results.

0 notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

Industries | Foundry Casting

Roadmap IT Solutions pioneers in providing ERP Software for Aluminium Die Casting to digitize the workflow and to empower the businesses to attain global progress

#Foundry erp system#casting and moulding software#erp foundry software#erp software for foundry management#casting#erpsoftwareinchennai#erpsoftwareinpondicherry#erpsoftware#erpsoftwareinbangalore

0 notes

Text

How a Company Can Improve Production with an Aluminum casting supplier

Utilized in a sort of sectors, including consumer products, automotive, and aerospace, aluminum casting is an important part of the manufacturing industry. It's perfect for improving product performance and lowering weight due to its lightweight and corrosion-resistant qualities. Its accuracy and adaptability leave the assembly of intricate patterns and forms that satisfy contemporary technical specifications. By offering premium raw materials and cutting-edge casting technology, suppliers of aluminum casting materials increase production efficiency. Working with reliable suppliers shortens lead times, cuts waste, and improves internal control, which results in a more efficient manufacturing process and lower prices.

Understanding Aluminum Casting

Melted metal is poured into a mould during the aluminum casting manufacturing process to supply particular components and shapes. Sand casting, die casting, or permanent mould casting are often used, counting on the value, manufacturing volume, and required qualities. Due to its exceptional strength-to-weight ratio, resistance to corrosion, and thermal conductivity, aluminum could also be utilized in a good range of applications. Additionally, it reduces assembly procedures by enabling complicated geometries and elaborate designs. Because aluminum is so recyclable, it helps to scale back environmental impact and promote sustainability. It's frequently utilized in consumer products, automotive, and aerospace to enhance durability, performance, and fuel economy. Aluminum is a popular material in several industries due to its flexibility.

Selecting the proper Aluminum Casting Supplier

It is essential to carefully consider manufacturing capacity, industry standards, and financial stability when choosing an Aluminum casting supplier. By evaluating a supplier's technological prowess and expertise, you'll confirm they will satisfy project requirements, comprehend the method, and produce high-quality products while also adapting to changing industry expectations.

Establishing Strong Communication Channels

Clear communication, frequent meetings, and real-time feedback are all necessary for productive supplier collaboration. A collaborative atmosphere is promoted by putting tactics like frequent meetings and updates into practice. A simpler collaboration results from using technology to supply real-time information, which improves transparency and expedites problem-solving.

Implementing internal control Measures

Strict internal control procedures are necessary for the aluminum casting industry to ensure product quality and preserve supply chain integrity. Working alongside suppliers to determine precise quality standards and completing frequent audits and inspections strengthens adherence, lowers faults, and improves product dependability. To ensure customer satisfaction and build lasting partnerships with suppliers, this proactive approach is important.

Streamlining the availability Chain

By simplifying its supply chain, the aluminum casting sector will increase operating efficiency. Businesses will save lead times and inventory costs by identifying bottlenecks and inefficiencies through a radical study. Ensuring timely delivery of supplies and components entails streamlining order processing and building a solid logistical structure with suppliers.

Investing in Technology and Innovation

Modernizing aluminum casting procedures requires significant investments in innovation and technology. Cutting-edge tools like CAD and simulation software increase accuracy and hamper waste. Continuous improvement is promoted by supporting suppliers' adoption of creative approaches. Production efficiency is improved by integrating automation and digital technologies, which raises output and lowers operating expenses.

Training and Development

In order to take care of high standards in aluminum casting operations, worker growth and training are essential. It gives workers the know-how to handle cutting-edge equipment and uphold quality standards. A competent workforce is produced by working with suppliers on skill development projects, which benefits the entire supply chain. Innovation and excellence are fostered by continuous improvement for sustained industrial success.

Measuring Performance and Outcomes

Key performance indicators (KPIs) are essential for tracking the results of production improvement. They evaluate output rates, quality, and efficiency statistically. Frequent evaluation of supplier performance guarantees that suppliers fulfil requirements and make valuable contributions to the manufacturing process. Operational effectiveness is improved, and tactics are modified to address production and supplier contribution inadequacies in response to performance data.

Conclusion

There are several advantages to working with an aluminum casting supplier, including having access to top-notch materials and knowledge, which will enhance operational processes and production efficiency. For increased productivity and success in their production processes, companies should evaluate their existing supplier connections and take steps to make or strengthen alliances with suppliers of aluminum casting.

0 notes

Text

Mastering Manufacturing Sourcing Services and Moldflow And Casting Analysis

Maintaining a lead in the always-changing field of manufacturing depends on this. Imagine launching a product only to find that the sourcing of materials and the quality of the mold flow are subpar. This can result in significant losses and setbacks. Fortunately, advancements in manufacturing sourcing services and moldflow and casting analysis have provided manufacturers with robust tools to ensure quality and efficiency.

The Importance of Manufacturing Sourcing Services

The Manufacturing sourcing services are the backbone of the production process. These services involve the identification and procurement of raw materials, components, and other necessary elements from reliable suppliers. Efficient sourcing can significantly impact the cost, quality, and time-to-market of a product. For example, a company that sources high-quality materials at competitive prices can pass these savings onto customers, gaining a competitive edge.

How Sourcing Services Drive Efficiency

One of the primary benefits of manufacturing sourcing services is the streamlined supply chain they create. By working with trusted suppliers, manufacturers can ensure a consistent flow of materials, reducing the risk of production delays. Additionally, these services often include rigorous vetting processes, ensuring that all sourced components meet stringent quality standards. This not only enhances product reliability but also builds customer trust.

The Role of Technology in Sourcing Services

Technology has revolutionized manufacturing sourcing services. Advanced software solutions now allow manufacturers to track and manage their supply chains with unprecedented accuracy. Real-time data analytics can identify potential disruptions before they occur, enabling proactive problem-solving. Moreover, digital platforms facilitate better communication between manufacturers and suppliers, ensuring that all parties are aligned and any issues are promptly addressed.

Understanding Moldflow And Casting Analysis

Moldflow and casting analysis are critical processes in manufacturing, particularly in industries reliant on plastic and metal components. These analyses use sophisticated simulation software to predict how materials will behave during the molding and casting processes. By understanding these behaviours, manufacturers can optimize their designs, reducing the risk of defects and improving overall product quality.

Benefits of Moldflow and Casting Analysis

Implementing moldflow and casting analysis offers several advantages. Firstly, it helps in identifying potential issues such as air traps, weld lines, and sink marks before actual production begins. This pre-emptive approach saves time and resources that would otherwise be spent on troubleshooting post-production problems. Secondly, these analyses enable manufacturers to refine their designs, ensuring that the final product meets all specifications and performance requirements.

Technological Advancements in Moldflow and Casting

The field of moldflow and casting analysis has seen significant technological advancements. Modern simulation software provides highly accurate predictions, allowing for detailed analysis of material flow and solidification. This level of precision helps in optimizing the entire manufacturing process, from mould design to production parameters. Furthermore, continuous advancements in computational power mean that these analyses can be performed faster and more accurately than ever before.

Integration of Sourcing Services with Moldflow and Casting Analysis

The synergy between manufacturing sourcing services and moldflow and casting analysis is undeniable. Effective sourcing ensures that high-quality materials are used in production, which is critical for the success of moldflow and casting processes. Conversely, insights gained from moldflow and casting analyses can inform sourcing decisions, ensuring that the selected materials are best suited for the intended applications.

Conclusion

In conclusion, mastering manufacturing sourcing services and moldflow and casting analysis is crucial for achieving excellence in manufacturing. These processes not only ensure high-quality products but also enhance efficiency and cost-effectiveness. For businesses looking to stay competitive in the fast-paced manufacturing landscape, leveraging these tools is essential. To explore more about these innovative solutions, visit feamax.com.

Blog Source Url: -

0 notes

Text

Die Casting Molds: Precision & Durable Solutions - Topwellmoulding.com

Die casting is a critical manufacturing process for producing intricate metal parts with high precision and durability. At Topwell Moulding, we specialize in creating high-quality die casting molds that meet the stringent demands of various industries, including automotive, electronics, and consumer goods. Our expertise ensures that every mold we manufacture offers superior performance, long-lasting durability, and exceptional accuracy.

The Importance of Precision in Die Casting Molds

Die casting molds play a pivotal role in the production of complex metal components. These molds must be designed with extreme accuracy to ensure that the final products meet exact specifications. Whether it's producing components for automotive engines or housing for electronic devices, precision is crucial in achieving a flawless outcome.

At Topwell Moulding, we use advanced CNC machining and cutting-edge design software to ensure that every mold is crafted with meticulous detail. Our focus on precision results in:

Consistent quality: Each part produced is identical, ensuring uniformity and reliability in mass production.

High efficiency: Accurate molds reduce material waste and manufacturing errors, streamlining the production process.

Superior fit and finish: Die casting molds designed with precision yield parts with smooth surfaces and fine details, eliminating the need for extensive post-production work.

Durability: Built to Last

The longevity of die casting molds is critical for maintaining production efficiency and reducing downtime. Molds subjected to repeated casting cycles must withstand high temperatures and intense pressure, making durability essential.

Topwell Moulding ensures that our molds are built to last by:

Using premium-grade materials: Our molds are made from robust alloys that resist wear and corrosion, ensuring extended life even under rigorous production conditions.

Rigorous testing and quality control: Every mold undergoes thorough testing to ensure it can withstand the mechanical stress and thermal cycling of the die casting process.

Custom solutions: We offer tailored mold designs that meet the specific needs of your industry, optimizing durability for high-volume production runs.

Why Choose Topwell Moulding?

Experienced Team: Our engineers bring years of experience in die casting mold design and manufacturing, ensuring top-tier solutions for any project.

Advanced Technology: We leverage the latest technology and equipment to produce molds with precision, speed, and efficiency.

Industry Expertise: We serve a wide range of industries, including automotive, aerospace, and consumer electronics, providing specialized solutions that meet industry-specific requirements.

Customer-Centric Approach: At Topwell Moulding, we work closely with our clients to develop customized mold designs that align with their production goals.

Applications of Die Casting Molds

Die casting molds are indispensable in industries that require the production of durable metal parts with tight tolerances and complex geometries. Some common applications include:

Automotive components: Engine blocks, transmission housings, and heat sinks.

Electronics: Housings for devices, connectors, and intricate components.

Consumer goods: Handles, locks, and decorative metal fittings.

Conclusion

Die casting molds are essential for manufacturing high-quality metal parts with precision and durability. At Topwell Moulding, we are committed to delivering molds that meet the highest industry standards, ensuring your production processes run smoothly and efficiently. With a focus on precision engineering and long-lasting durability, our die casting molds are the ideal solution for your manufacturing needs.

Explore our full range of die casting mold solutions at Topwellmoulding.com and contact us to discuss how we can support your next project.

1 note

·

View note

Text

Mastering Composite Mold Casting: A Comprehensive Guide with a Composite Mold Making Kit

Composite materials have become essential in various industries, thanks to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. From aerospace to automotive, the demand for lightweight, durable, and high-performance components has driven the evolution of composite mold casting techniques. To meet these industry needs, the use of a composite mold making kit has become increasingly popular, offering an all-in-one solution for creating high-quality molds.

What is Composite Mold Casting?

Composite mold casting is a process used to create complex shapes and forms from composite materials. These materials typically include reinforced plastics such as carbon fiber, fiberglass, or BMC (Bulk Molding Compound) used in BMC molding and BMC moulding. The mold defines the shape of the final product and is critical for the success of the compression molding process.

The Composite Mold Casting Process

Mold Design and Fabrication: The first step is designing the mold, often using CAD software to create a precise model. Molds can be made from materials such as aluminum, steel, or even composites.

Surface Preparation: The mold surface must be prepared to ensure a smooth finish on the final product, often involving the application of a release agent to prevent the composite material from sticking.

Lay-Up Process: Layers of composite material, such as those used in SMC molds and composite molds, are placed into the mold to optimize the strength and stiffness of the final product.

Curing: The mold is placed in an oven or autoclave to cure, solidifying the resin matrix and forming a rigid structure. This step is critical in composite molding and thermoforming mold processes.

Demolding and Finishing: After curing, the part is carefully removed from the mold. Additional processes such as trimming, sanding, and painting may be applied to achieve the desired finish.

The Role of a Composite Mold Making Kit

A composite mold making kit is an invaluable resource, especially for professionals working with compression molds, thermoforming tools, or composite molds. These kits include all necessary materials and tools to create high-quality molds, streamlining the process and minimizing errors.

What's Included in a Composite Mold Making Kit?

Resins and Hardeners: Essential for creating the mold itself, these components ensure proper curing and durability, vital in thermoset molding.

Reinforcing Fibers: Some kits include fibers like fiberglass to strengthen the mold, particularly in high-stress areas.

Release Agents: These agents prevent the composite material from sticking to the mold during casting, ensuring easy demolding.

Mixing Tools: Brushes, mixing cups, and stir sticks are included to help apply the resin and hardener accurately.

Instructional Guides: Many kits provide detailed instructions or access to tutorials, making it easier for beginners to understand the mold-making process.

Benefits of Using a Composite Mold Making Kit

Using a composite mold making kit offers several advantages, particularly for those working in thermoforming tool and composite molding:

Convenience: Kits offer a convenient solution by providing all necessary materials in one package.

Cost-Effective: Purchasing a kit can be more affordable than buying each material individually, and it reduces the risk of buying incompatible products.

Quality Assurance: Kits are typically designed by professionals, ensuring high-quality materials and compatibility.

Time-Saving: The mold-making process is expedited with all materials readily available, reducing preparation time.

Applications of Composite Mold Casting

Composite mold casting has a wide range of applications across various industries:

Aerospace: Used to create lightweight, strong components like aircraft wings and fuselage sections.

Automotive: Essential for producing parts like bumpers and dashboards, where weight reduction is crucial.

Marine: Composite materials are used to create boat hulls and decks, offering excellent corrosion resistance.

Sports Equipment: Composite materials are favored for their strength and lightweight properties in products like tennis rackets and bicycle frames.

Conclusion

Composite mold casting is a sophisticated process vital to manufacturing high-performance components across various industries. Utilizing a composite mold making kit streamlines the process, offering a comprehensive solution that saves time, reduces costs, and ensures the production of top-tier molds. Whether you're working with SMC molds, thermoforming molds, or thermoset molds, mastering the art of composite mold casting with the right tools is essential for success.

0 notes