#cnc tooling

Text

Tools to Succeed in High-Speed Machining

In the rapidly evolving world of manufacturing and machining, where innovation and technological advancements have revolutionized the industry, speed still remains a game-changer.

High-speed machining (HSM) is a cutting-edge technique that enables faster material removal rates, increased productivity, and improved surface finishes. However, it also presents unique challenges that require the right tools and strategies for success.

In this article, we'll explore the essential tools and techniques that you must know to excel in high-speed machining.

1. Robust Cutting Tools:

The foundation of any successful high-speed machining operation is the selection of robust cutting tools. Tools specifically designed for HSM are engineered to handle the increased speeds and feeds while maintaining stability and precision. Carbide end mills with advanced coatings, such as TiAlN or TiCN, are excellent choices for high-speed applications. These coatings enhance tool life and reduce friction, allowing for faster cutting without compromising tool integrity.

2. High-Quality Tool Holders:

The role of tool holders in HSM cannot be understated. They must provide secure clamping, minimal runout, and excellent vibration damping to maintain tool stability. High-quality tool holders, such as shrink-fit or hydraulic chucks, are designed to excel in high-speed applications. They minimize the chances of tool deflection, resulting in superior machining accuracy and extended tool life.

3. Rigorous Tool Assembly Balancing:

High-speed machining places immense demands on cutting tools, and even a slight imbalance can lead to catastrophic consequences. To avoid tool chatter, poor surface finishes, and tool breakage, it’s crucial to ensure the proper balance of the tool holder and cutting tool assembly. Since most machine shops do not have a balancing machine, it is critical to ensure the balance of the tool holder, which generally represents the greatest source of mass in the tooling assembly, exceeds the RPM requirements of the application. This way, as additional components are added to the tooling assembly such as the cutting tool, collets, and/or retention knobs, the overall balance of the tooling assembly still meets the ROM requirement of the application.

4. Advanced Cutting Strategies:

High-speed machining requires more than just pushing the spindle's RPM to the max. Employing advanced cutting strategies is essential for optimizing tool engagement and reducing heat generation. Techniques like trochoidal milling, adaptive roughing, and high-efficiency machining (HEM) distribute the cutting load evenly and maintain consistent chip evacuation. These strategies not only enhance tool life but also improve machining efficiency.

5. Coolant and Lubrication Systems:

Coolant and lubrication play a critical role in high-speed machining. Effective cooling helps dissipate heat generated during cutting, preventing tool wear and thermal deformation. Minimal lubrication systems (MQL) are gaining popularity in HSM because they deliver a fine mist of lubricant directly to the cutting zone, reducing friction and heat buildup. Proper coolant and lubrication systems are essential for maximizing tool life in high-speed applications.

6. CNC Machine with High Dynamics:

The choice of CNC machine is a pivotal factor in HSM success. Machines with high dynamics, rapid acceleration, and precise control are ideal for achieving optimal results. These machines can quickly respond to changes in cutting conditions and maintain stability at high speeds. Investing in a state-of-the-art CNC machine designed for high-speed applications can significantly boost productivity.

7. Monitoring and Control Systems:

To succeed in high-speed machining, real-time monitoring and control systems are indispensable. These systems track critical parameters such as spindle speed, tool wear, and temperature. By continuously monitoring the machining process, operators can make timely adjustments, ensuring tool integrity and consistent performance.

8. Training and Expertise:

Last but not least, having skilled operators and engineers who understand the intricacies of high-speed machining is vital. Training programs and ongoing education ensure that the team can optimize tool selection, cutting strategies, and machine parameters. Experienced personnel can troubleshoot issues, maximize tool life, and adapt to the challenges presented by HSM.

9. Material Selection and Toolpath Optimization:

Choosing the right material for your machining project is crucial when it comes to high-speed machining. Some materials are better suited for HSM than others due to their machinability and thermal conductivity. Additionally, optimizing toolpaths is essential for minimizing tool wear and maximizing tool life. Using CAM (Computer-Aided Manufacturing) software to generate efficient toolpaths that reduce sharp turns and sudden directional changes can significantly extend the lifespan of your cutting tools in high-speed machining operations.

Conclusion

It cannot be overstated that high-speed machining offers incredible potential for increased productivity and efficiency in manufacturing. However, it requires careful consideration of the tools and strategies employed. By investing in robust cutting tools, high-quality tool holders, rigorous tool balancing, advanced cutting strategies, effective coolant and lubrication systems, high-dynamics CNC machines, monitoring and control systems, workpiece, tool holder balancing, and skilled personnel, you can unlock the full benefits of high-speed machining. With the right tools and expertise, you'll be well-equipped to thrive in the fast-paced realm of high-speed machining, attaining outstanding outcomes and maintaining a competitive edge.

1 note

·

View note

Text

Jr. Design Engineer Position Opening

Jr. Design Engineer Position Opening

Job Title: Jr. Design Engineer

Job Description:

N.J. Sullivan Company, a leading manufacturer of electrical products for the construction and utility markets, is looking to add to our engineering team. The ideal candidate will have an accredited associates’s degree/certificate in CAD, modeling/drafting. Motivated self-starter able to work individually and in a team…

View On WordPress

#Autodesk#CAD#CAD models#CNC fabrication#CNC tooling#DXF flies#Jobs#Jr. Engineer#position opening#solidworks

0 notes

Text

Instead of any sex toys, I want someone to tie me up and bring out a tool box. Use vice grips to squash my tits. Clamp my nipples and skin with pliers, stick a screwdriver in my ass. Use a drill against my skin. Shove a hammer in my cunt and make me stand up until it falls out of me, and punish me for it. Use a wrench and hammer to bruise my body. Stick as many allen keys in my cunt as you can and watch them all fall out. Shove all the little drill bits in my cunt and ass and punish me if i cant push out every single one. Make me fuck every handle of every tool and then lick them clean for you. Keep me in your garage and make sure i intimately know every tool you own..

#r@petoy#cnc roleplay#use me use me use me#r@pe kink#bd/sm slave#mas0chist#object insertion.#hard k1nk#bd/sm dynamic#bd/sm blog#this is why i love older men hehe#also i have fucked tool handles before their shape is so good omg#literally perfect for fucking#this is kinda the only fantasy i cant even do to myself...

889 notes

·

View notes

Text

My sugar daddy fantasy is to have my own little bimbo cottage that I live in. Covered cutesy items for me to spend all day there however I like.

The catch? I can either wear slutty clothes or walk around naked and there are rigs in every room.

My daddy will give the house key to his friends as a gift and they can pop in and use me whenever they like. Fill me up with their cum and leave me a slutty drooling mess. Doesn't matter where I am or what I'm doing. I'm daddy's free use whore and I'm there to be used. Day in and day out by daddy and his friends. Waking up every morning in handcuffs or with a cock in my mouth. And I can never leave because daddy has livestream cameras everywhere showing the world how much of a slut I am. My perfect little bimbo life x

#rough cnc#g@ng r@pe#bunny suit#fox girl#cat girl#bunny girl#cvm bunni#dumb bunny#cnc stalking#degredation kink#free use slvt#cnc free use#sex tool#r4p3b4it#rapedoll#rap3toy#rapekink#cnc fr33use#cnc brat#cnc kidnapping

69 notes

·

View notes

Text

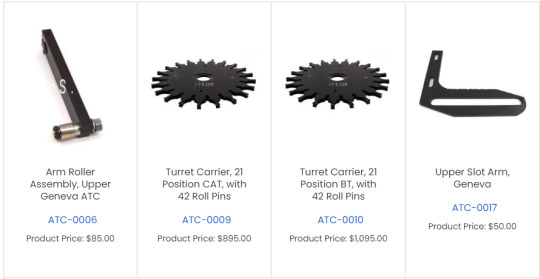

Fadal Tool Changer - Overview

About Fadal Tool Changer Parts

When it comes to Fadal tool changer parts, quality and reliability are paramount. At ITSCNC, we understand the importance of keeping your CNC machines operating at peak performance, which is why we offer a comprehensive selection of tool changer parts backed by a 90-day warranty. Whether you need carousel arms, grippers, or other components, we have you…

View On WordPress

#CNC Tool Changer Parts#Fadal Arbor Shim#Fadal Arm Roller Assembly#Fadal ATC Roller Assembly#Fadal ATC Slide Motor#Fadal ATC Tool Changer#Fadal BT Tool Clip#Fadal CAT40 Tool Clip#Fadal CNC Machines#Fadal cnc parts#Fadal Dual Arm Tool Changer#fadal machine parts#Fadal parts#Fadal Parts For CNC Machine#fadal parts online#Fadal Reman Servo Turret Amplifier#Fadal Roller Bearing#Fadal Servo Turret Power Supply#fadal tool changer#Fadal Tool Orientation Key#Fadal Turret Carrier#Fadal Turret Spindle#Fadal Turret Worm Gear

3 notes

·

View notes

Text

Examining the Knowledge of Manufacturers of Deep Hole Drilling Equipment

Precision is essential in machining, and sophisticated equipment and tools are the foundation of precision machining. Prominent contributors to this domain of precision are companies that specialize in deep hole drilling equipment.

When it comes to precision engineering, WIDMA is a brand that epitomizes innovation and excellence. With a history that dates back to 1984, it has continuously raised the bar for accuracy in machining operations. WIDMA is a leader in developing innovative solutions. It has seamlessly incorporated its unmatched knowledge to create and refine. Excellence in precision engineering begins here.

In order to achieve the required levels of accuracy, deep hole drilling machines, tool grinding machines, and fine boring machines are essential. Let's examine these manufacturers' contributions to the machining industry and their depth of experience.

Manufacturers of Deep Hole Drilling Equipment: Masters of Precision

Deep hole drilling is a specialized machining process. It requires a very high degree of accuracy and skill. The creators of these machines, which redefine accuracy in boring holes of different depths, are the deep hole drilling machine manufacturers.

Innovation in Technology

Top producers consistently make investments in cutting-edge technology, expanding the capabilities of deep hole drilling machines. These machines are equipped with advanced features like automated tool changers and high-pressure coolant systems. Precise control systems also improve their accuracy and performance. Because of their dedication to innovation, manufacturers are able to keep up with the changing needs of industries that need complex drilling solutions.

Tailored Solutions

The capacity to offer customized solutions is a distinguishing feature of the best deep hole drilling machine manufacturers. These manufacturers are aware that every industry has different needs when it comes to drilling. Because of this, they design machines that can be tailored to fit particular requirements.Because of its adaptability, deep hole drilling solutions can be found by manufacturers in a wide range of industries that precisely match their machining requirements.

Comprehensive Support

Prominent producers provide state-of-the-art machinery along with extensive support. This includes knowledgeable application engineers and educational initiatives. It also includes attentive customer support.

Manufacturers can assist their clients in maximizing efficiency. Further they can help in attaining the required degree of precision in their operations. It also helps to optimize the performance of deep hole drilling machines by having a thorough understanding of the nuances of their machines and applications.

Tool Grinding Machines: Sharpening the Edge of Precision Machining

Tool grinding machines play a critical role in maintaining the sharpness and accuracy of cutting tools. These machines are essential for reshaping and sharpening tools. It helps in ensuring that they perform optimally and contribute to the precision of machining processes.

Precision Grinding Technology

Tool grinding machine manufacturers are at the forefront of precision grinding technology. They employ advanced grinding techniques and cutting-edge materials to manufacture machines that can achieve micron-level precision. This level of precision is vital for industries where even the slightest deviation can impact the quality and accuracy of the final product.

Flexibility in Sharpening Tools

Tool grinder manufacturers are aware that various tools call for various methods of sharpening. They consequently create machines with a wide range of functions. They also aid in accommodating different materials and tool geometries. A wide variety of tools used in precision machining can be handled by these machines.

Integration of Automation

Leading tool grinding machine manufacturers incorporate automation into their machines to improve efficiency and repeatability. Automated features that aid in their functionality include tool loading and unloading. In-process measurement and wheel dressing help create a smooth and effective tool grinding process. This automation guarantees accurate and consistent tool sharpening in addition to increasing productivity.

Fine Boring Machine Manufacturers: Crafting Sublime Precision

Fine boring machines play a crucial role in achieving precise and accurate bores in various components. Manufacturers specializing in fine boring machines bring forth engineering excellence to meet the demanding requirements of industries where tight tolerances are non-negotiable.

Advanced Control Systems

Fine boring machine manufacturers incorporate advanced control systems to ensure precision and repeatability in boring operations. These control systems enable operators to program and monitor the machining process, making adjustments in real-time for optimal results. The integration of advanced controls contributes to the overall efficiency and accuracy of fine boring machines.

Pioneers of Precision Engineering

Manufacturers are forging ahead in precision engineering by creating machines that are precision instruments precisely calibrated to satisfy the demanding standards of contemporary manufacturing. When it comes to creating creative solutions, WIDMA leads the way. It has developed and improved with ease, fusing its unparalleled expertise. This is where precision engineering excellence starts.

2 notes

·

View notes

Note

what are ur thoughts on the winners room trope?

ooooo okay surface level analysis: i like winner’s room fics :)

etwas tieferes: i think it’s cool that it’s (afaik) unique to hockey fandom and i enjoy the way it integrates a lot of unspoken rules in hockey with desire/makes them a physical/tangible reality… also the narrative potentials/world-building it opens up can be fun because there’s not really a set of rules for the “winner’s room” trope. are there in-universe rules? who gets chosen? who’s exempt? who gets to pick? where’s it going down? is it the entire room or one guy? what if your (ex)boyfriend is on another team? does somebody need to be taught a lesson or do you need to remind someone who got traded you still love them? also, most important, winner’s room gives you the chance to put two random-ass guys you saw interact for 0.002 seconds and went “hmmm. interesting” about into a Situation and i love that

#yeah buddy!! i love answering questions!!! unironically i have so many opinions!!!!#refraining from putting this in the main text but had to go: yeah who doesn’t love a good g*ngb*ng#it also doesn’t just have to be a bunch of dudes fucking though per always: i think winner’s room fics can bring up interesting dialogues#about the idea of bodily autonomy and self-sacrifice or sacrifice in sports#every fic can utilize a trope their own way so you might have lighter versions or heavier versions and#tw: sa#dub-con/CNC elements which. given the truth of SA and abuse in hockey it’s valuable to have tools to explore and i feel like i need to#address that when i talk about this? obvi dead dove do not eat for some fics re:winner’s room but i think a lot of them do talk about#control and power to some extent if you were to do a deep literary analysis. which we don’t need to. sometimes it’s enough to read a fic one#time because you liked the main pairing and didn’t know SHIT about the flyers and then come back to it years later and absolutely lose your#goddamn mind about the fact that actually you DID know about travis konecny before you thought you did and at one point there were all these#guys that you now know and love who were just like. random fuckers in the sides of the fic. i tend to do that a lot bc i will read for#nearly everything (if i love u. i will read your works even if i don’t know anything about the fandom and also i am always willing to jump#on new ships) so also tangentially i think winner’s room fics are a lot of fun because you can see a lot of different interactions between a#lot of guys like not only is it this guy and this guy but also this guy and that guy and these two interacting around the sacrifice etc etc#tangled web many layers und so weiter. not sure if any of that makes sense but also i’m gonna tag for mentions of sa/wjc/hockey canada stuff#i don’t even really know if winner’s room functions as well even in other sports bc of the Team Identity in hockey & cultural context#liv in the replies#winner’s room can be layered with SO many other kinks and tropes and aus and also just like. i like it & that’s probably all i needed to say#also obvi re: rules for trope there aren’t ever any there’s just some popular variations and we can kinda see some of those forming#but i’m not even sure if winner’s room has its own tag on the archive? i’d have to check i know i have a few saved in my bookmarks at least#OH also if you made it this far. wasn’t sure if this was like a ‘do u got recs’ or a ‘what’s your moral stance’ or ‘hey is this something ur#into’ so. good faith good vibes y’all and if this wasn’t what u meant please elaborate the question i do love answering things#ty for the ask!!!!#for the record i do watch hockey like the leonardo dicaprio pointing meme finding milliseconds of interaction to go HAHA GAY NARRATIVE about

4 notes

·

View notes

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

5 notes

·

View notes

Text

Want a daddy to make me a sex toy collection and watch me use every single one the second it arrives. Have him facetime me at random times to tell me to use certain toys on myself till I cum on my phone x. Makes me wet just thinking about it ❤️

#sugarbaby#sex tool#free use slvt#use me pls#spoilt#cnc brat#r4p3b4it#cnc kidnapping#attention wh0r3#needy wh0re#spicy content#sexy content

26 notes

·

View notes

Text

#CNC spoilboard cutter#cnc insert router tooling#cnc insert v groove bit#cnc helical planing cutter#solid carbide router bit for wood#ball nose solid carbide bit#compression solid carbide bit#upcut solid carbide bit#down cut solid carbide bit#solid carbide router bit for plastics#dowel drill bits#v point drill bits for wood#hinge drill bits#solid carbide dowel bit#solid carbide through point bit#panel saw blade

2 notes

·

View notes

Text

Copper mold sample test made by CNC milling machine. #copper #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

4 notes

·

View notes

Text

Myway Fabrication work is done on a large scale, in factories or industrial settings. However, it can also be done on a smaller scale, in shops or even at home. Fabrication work often requires specialised equipment and skills.

Visit Here: https://www.mywayfabrication.com/

#Metal Fabrication#Forming#Punching#Shearing#Rolling#Welding#Laser Cutting#Custom Tool & Die#CNC Machining

2 notes

·

View notes

Text

Enhance precision with our specialized CNC tool offerings.

In the area of CNC machining, precision reigns ideally suited. Every reduce, each contour, each elaborate element hinges at the accuracy and satisfactory of the equipment hired. Birla Precision Technologies Limited stands as a beacon of excellence on this area, providing specialized CNC Precision Tooling that raise machining operations to remarkable ranges of precision and efficiency.

CNC Precision Tooling: The Backbone of Machining Excellence

At the heart of every CNC Precision Tooling operation lies the precision tooling that shapes raw substances into finished products with meticulous accuracy. Birla Precision Technologies Limited is aware the essential function that tooling performs in the machining procedure and has dedicated itself to crafting tools that surpass industry requirements. From high-velocity steel slicing equipment to superior carbide inserts, Precision's product lineup includes a various range of answers tailored to meet the exacting needs of modern-day manufacturing.

Precision Redefined:

What units Precision aside is its unwavering dedication to precision engineering. Each device bearing their call undergoes rigorous checking out and excellent guarantee protocols to make certain remarkable performance and reliability. Whether it is reaching micron-degree tolerances or retaining consistency across big production runs, Precision equipment deliver consequences that exceed expectancies over and over.

Moreover, Precision's full-size revel in in each home and worldwide markets positions it as a relied on companion for manufacturers looking for precision tooling answers. With a robust recognition on innovation and continuous development, Precision stays ahead of the curve, watching for enterprise traits and growing current technologies that push the limits of what's feasible in CNC Precision Tooling.

Enhancing Precision:

Precision is not only a buzzword for Precision—it is a way of life. By leveraging brand new manufacturing strategies and leveraging the cutting-edge improvements in device design, Precision tools empower machinists to acquire ranges of precision that have been once notion unattainable. Whether it's aerospace components requiring uncompromising accuracy or problematic scientific devices traumatic ideal surface finishes, Precision tools upward push to the venture, delivering consequences that talk for themselves.

Furthermore, Precision's dedication to patron delight extends past just presenting one of the best tooling merchandise. The employer takes a holistic approach to customer support, imparting comprehensive technical help, education packages, and ongoing upkeep offerings to ensure that its clients get the most out of their investment in precision tooling.

Conclusion:

In conclusion, when it comes to enhancing precision in CNC Precision Tooling, Precision Technologies Limited stands head and shoulders above the competition. With a wealthy legacy of engineering excellence and a continuing pursuit of perfection, Precision maintains to set the benchmark for precision tooling answers within the industry.

So, whether or not you're a seasoned machinist trying to take your operations to the following stage or a budding producer aiming for precision-driven success, appearance no further than them. Visit their website these days to explore their complete variety of CNC precision tooling offerings and revel in the their Advantage firsthand. Contact Birla Precision Technologies Limited now to elevate your machining capabilities to new heights.

0 notes

Text

Unlocking the Power of the Fanuc Test Simulator: Your Gateway to Testing Fanuc Robots and Components

In the world of industrial automation, precision and reliability are paramount. For businesses that rely on Fanuc robots, ensuring that every component functions flawlessly is crucial. This is where the Fanuc Test Simulator comes into play. In this blog post, we'll dive into how this indispensable tool enables comprehensive testing of Fanuc robots, robot servo amplifiers, spare parts, and teach pendants, ensuring your operations run smoothly and efficiently.

What is the Fanuc Test Simulator?

The Fanuc Test Simulator is a state-of-the-art testing platform designed specifically for Fanuc robotic systems. It provides a controlled environment where you can thoroughly test and diagnose various components of Fanuc robots. This includes everything from the robots themselves to their servo amplifiers, spare parts, and teach pendants.

Comprehensive Testing for Fanuc Robots

One of the standout features of the Fanuc Test Simulator is its ability to test all models of Fanuc robots. This includes:

Articulated Robots: From small, precise models to large, heavy-duty robots, the simulator can handle them all.

Delta Robots: Known for their speed and precision in pick-and-place operations, delta robots can also be tested for optimal performance.

Collaborative Robots (Cobots): Ensuring safety and efficiency in collaborative environments is critical, and the simulator helps verify these aspects.

By simulating real-world conditions, the Fanuc Test Simulator allows you to identify and rectify issues before they impact your production line.

Testing Robot Servo Amplifiers by Cnc-shopping engineers

Servo amplifiers are the heart of any robotic system, controlling the motors that drive the robot's movements. The Fanuc Test Simulator enables you to test these amplifiers thoroughly with dedicated Fanuc Servo motors, ensuring they deliver precise and consistent performance. This is vital for maintaining the accuracy and reliability of your robotic operations. (Such as FANUC A06B-6100, 6102, 6104, 6107 and well know models such as FANUC A06B-6107-H001 which is fully tested on the FANUC Robot Test bench)

Ensuring the Quality of Fanuc Robot Spare Parts

Spare parts are essential for minimizing downtime and maintaining the longevity of your robots. With the Fanuc Test Simulator, you can test these parts before they are integrated into your system. This proactive approach helps prevent potential failures and ensures that every component meets Fanuc's high standards.

Verifying Fanuc Teach Pendants

Teach pendants are the interface between the operator and the robot, making their reliability crucial. The Fanuc Test Simulator allows you to test teach pendants for functionality and durability, ensuring that they provide accurate control and feedback.

Why Choose the Fanuc Test Simulator?

Accuracy: The simulator replicates real-world conditions, providing accurate test results.

Efficiency: Quickly diagnose and address issues, minimizing downtime.

Versatility: Test a wide range of Fanuc robots and components.

Reliability: Ensure all parts meet Fanuc's stringent quality standards.

Linking to Our E-Store

Ready to enhance your testing capabilities with the Fanuc Test Simulator? Visit our e-store at CNC-Shopping.us to explore our range of Fanuc robots, servo amplifiers, spare parts, and teach pendants. Our products are designed to work seamlessly with the Fanuc Test Simulator, ensuring you get the most out of your investment.

Conclusion

The Fanuc Test Simulator is an invaluable tool for any business that relies on Fanuc robotic systems. By enabling comprehensive testing of robots, servo amplifiers, spare parts, and Fanuc teach pendants, it ensures your operations remain efficient and reliable. Don't wait until a problem arises—invest in the Fanuc Test Simulator and keep your production line running smoothly.

Visit CNC-Shopping.us today to learn more and make your purchase.

#cnc-shopping#fanuc robotic#fanuc#Fanuc teach pendant#Fanuc servo amplifiers#machine-tools#industry#automation#A06B-6107-H001

0 notes

Text

#cnc free use#popularblog#release#guide#free stuff#tools#free use kink#free use slvt#free palestine#free gaza#motivational#motivating quotes#motivating myself#motivat#get motivated#motivationalquotes

0 notes

Text

CNC Metal Cutting Machine Tools Market to Exhibit 6.7% CAGR by 2027 - Report by Market Research Future (MRFR)

CNC Metal Cutting Machine Tools Market Overview: According to a comprehensive research report by Market Research Future (MRFR), “CNC Metal Cutting Machine Tools Market Research Report, Product Type, By Application and By Region - Forecast Till 2027” the market is expected to expand at a CAGR of 6.7% from 2020 to 2027 (forecast period).

Market Analysis

CNC metal cutting machining is a manufacturing process that uses computer software that has been pre-programmed to control the movement of factory machines and equipment. The approach is used to control a wide range of complex devices, including metal cutting, broaching, grinders, lathes, and others. These machines are frequently used in metal cutting operations to obtain the desired cutting of the metal workpiece. Metal cutting machines currently on the market include plasma cutters, laser cutting devices, and fiber cutters.

0 notes