#electronic vehicles

Text

China targets EU pork imports in response to tariffs on EVs

The Chinese government targeted European farmers by launching an investigation into EU pork imports, AP News reported.

This came just days after the EU said it planned to impose temporary tariffs on Chinese-made electric vehicles (EVs).

However, the Commerce Department did not mention tariffs on EVs when it announced on Monday that it was launching an anti-dumping investigation into pork from Europe. However, the move is widely seen as a response to the EU’s step on electric vehicles. It also gives China a bargaining chip in any trade negotiations.

China could impose a 25% duty on imports of gasoline cars with powerful engines in the name of fighting climate change. The move would have hit Mercedes and BMW hard. By deciding not to do so, the government may, however, be recognising the German car industry’s public opposition to the EU tariffs, as well as its significant production in China.

The Chinese market is an important one for German car manufacturers. President of the German Association of the Automotive Industry (VDA), Hildegard Müller, called the EU’s 12 June tariff announcement another step away from global co-operation.

The risk of a global trade conflict is rising further as a result of this measure.

Read more HERE

#world news#world politics#news#europe#european news#european union#eu politics#eu news#china#chinaeurope2024#china 2024#china news#chinese politics#pork#imports#electronic vehicles#ev

0 notes

Text

High-power wireless charging and precision circuits with YMIN Q MLCC.

YMIN Q series MLCC offers high-voltage endurance (1kV-3kV), ultra-low ESR, and superior temperature stability. Ideal for high-power wireless charging and precision circuits, it enhances integration and reliability while promoting miniaturization and lightweight design.

0 notes

Text

Charging Infrastructure for Electric Vehicles: Challenges and Solutions

The rapid rise of electric vehicles (EVs) represents a seismic shift in the automotive industry, promising a future of cleaner, greener transportation. However, the widespread adoption of EVs hinges on the availability and reliability of charging infrastructure. As the number of electric vehicles on the road continues to grow, addressing the challenges of EV charging infrastructure becomes increasingly critical. Here’s an in-depth look at the challenges and potential solutions in this pivotal area.

Challenges in EV Charging Infrastructure

1. Insufficient Charging Stations

One of the most significant hurdles for electric vehicles is the lack of sufficient charging stations. While the number of EVs is rising rapidly, the expansion of charging networks is lagging behind. This imbalance creates range anxiety among potential EV buyers, who worry about finding convenient charging points during long trips or in less populated areas. To foster greater adoption of electric vehicles, it’s essential to build a dense and widespread network of charging stations.

2. Slow Charging Speeds

Current charging technologies often struggle with slow charging speeds, particularly at standard public charging stations. Many EV owners must wait several hours to fully charge their vehicles, which is impractical for those who need quick turnarounds or are on long journeys. Faster charging solutions, such as DC fast chargers, are available but are not yet widespread. Enhancing charging speed is crucial for making electric vehicles more convenient and comparable to traditional gasoline refueling.

3. High Installation Costs

Installing charging infrastructure, especially fast chargers, comes with high costs. This includes the expense of the charging units themselves, electrical upgrades, permits, and labor. These costs can be a significant barrier for businesses and municipalities looking to install charging stations. The financial burden can deter the expansion of the necessary infrastructure, slowing the overall adoption of electric vehicles.

4. Grid Capacity and Stability

The increasing number of electric vehicles places additional demands on the electrical grid. High concentrations of EVs charging simultaneously can strain local power systems, leading to stability issues or even outages. Ensuring the grid can handle this increased load requires significant investment in upgrades and smart grid technologies to manage the demand efficiently.

Solutions to EV Charging Challenges

1. Expanding Charging Networks

To combat the issue of insufficient charging stations, governments and private companies must invest in expanding the charging network. Incentives such as grants, subsidies, and tax breaks can encourage businesses to install more charging points. Public-private partnerships can also play a vital role in funding and developing widespread charging infrastructure, particularly in underserved areas.

2. Advancing Fast Charging Technology

Investing in and advancing fast charging technology is essential for reducing charging times. Ultra-fast chargers, which can provide a significant amount of charge in just 15-30 minutes, should be deployed more widely. Research and development in battery technology, such as solid-state batteries, can also help improve charging speeds and efficiency, making electric vehicles more practical for everyday use.

3. Reducing Installation Costs

To lower the costs of installing charging infrastructure, standardization and economies of scale are crucial. Developing universal standards for charging equipment can reduce costs and simplify installations. Additionally, bulk purchasing and streamlined permitting processes can further decrease expenses, making it easier for businesses and municipalities to set up charging stations.

4. Enhancing Grid Management

Upgrading the electrical grid to handle the increased demand for electric vehicles is vital. Implementing smart grid technologies can help manage load distribution and prevent overloading. Energy storage solutions, such as battery storage systems, can also provide backup power during peak demand times. Moreover, integrating renewable energy sources, like solar and wind, can support a more sustainable and resilient grid.

Conclusion

The future of electric vehicles depends heavily on the development of robust and accessible charging infrastructure. Addressing the challenges of insufficient charging stations, slow charging speeds, high installation costs, and grid capacity is critical to support the widespread adoption of EVs. By expanding charging networks, advancing fast charging technology, reducing installation costs, and enhancing grid management, we can pave the way for a cleaner, more sustainable transportation future. The transition to electric vehicles is inevitable, but overcoming these hurdles will determine how quickly and smoothly it happens.

This Blog Is Originally Published At: https://aggressivegroupco.blogspot.com/2024/05/charging-infrastructure-for-electric.html

0 notes

Text

youtube

Toyota New Engine Will Destroy The Entire EV Industry | Caractics

This new engine from Toyota is set to revolutionize the EV industry. With improved performance and efficiency, Toyota's new engine is expected to revolutionize the way EVs are used and experienced. Get ready to experience a whole new level of driving. Watch the video Toyota's new engine will destroy the Entire EV Industry

#toyota new engine#electronic vehicle#electronic car#electronic vehicles#car electronic#toyota vehicle#toyota electric car#toyota electric#toyota plug in hybrid#toyota electric vehicles#toyota new electric car#toyota evs#toyota hybrid electric car#toyota electric cars 2023#toyota all electric car#toyota ev car#toyota new engine technology#ev industry#Youtube

0 notes

Text

youtube

Toyota New Engine Will Destroy The Entire EV Industry | Caractics

🌟This new engine from Toyota is set to revolutionize the EV industry. With improved performance and efficiency, Toyota's new engine is expected to revolutionize the way EVs are used and experienced. Get ready to experience a whole new level of driving. Watch the video Toyota's new engine will destroy the Entire EV Industry

#toyota new engine#electronic vehicle#electronic car#electronic vehicles#car electronic#toyota vehicle#toyota electric car#toyota electric#toyota plug in hybrid#toyota electric vehicles#toyota new electric car#toyota evs#toyota hybrid electric car#toyota electric cars 2023#toyota all electric car#toyota ev car#toyota new engine technology#toyota new engine will destroy the entire ev industry#ev industry#caractics#Youtube

0 notes

Text

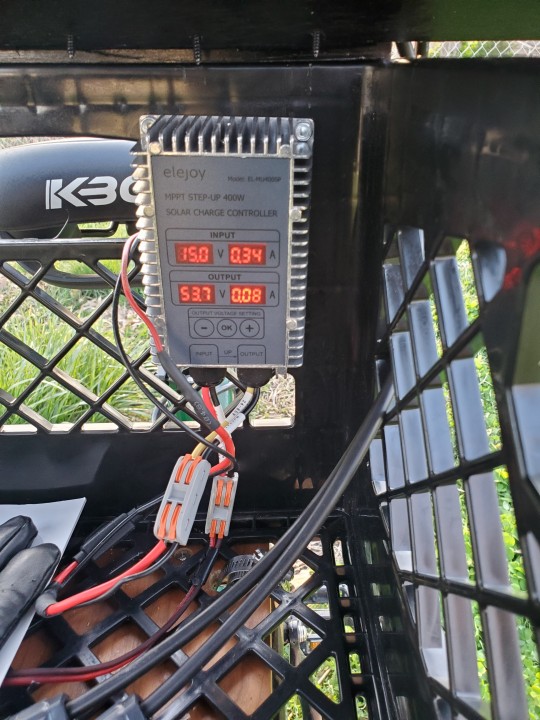

Day 5 or 6 of working on the solar bike. The main bike is effectivaly finished. Decided to go lightweight on everything and it was definantly the way to go. On the back is a 24qt milk crate big enough to hold another few bike batteries. That has a thin as possible sheet of hobby plywood above it that is ziptied to the 50w flexible solar panel. And mounted to the milkcrate with hobby screws. The panel recharges the bike through a mppt step up charge controller. The front panel charges just a simple 5v battery pack for my phone. All in all, I think it turned out well.

295 notes

·

View notes

Text

Dodge Viper SRT-E All Electric Supercar Concept

#autos#cars#automotive#coupe#luxury car#sports cars#dodge concept#dodge#muscle car#american muscle car#hemi#classic cars#classic car#dodge viper#electric cars#electronic#electric vehicles#elegant

149 notes

·

View notes

Text

Keep an eye on the sky...

#truck#trukk#radar#air defense#early warning radar#anti air#electronic warfare#ew#military#military vehicle

38 notes

·

View notes

Text

On Electric Cars (and their shortcomings)

#electric cars#electric vehicles#ev car brands#ev car goes up in flames & sets house on fire after driver put toaster under car to ‘warm up batteries’ in cold weather#ev cars#cars#car#vehicle#vehicle electronics#vehicles#pollution#pollutants#polluted water#polluted air#ecology#econotego#class war#eat the rich#eat the fucking rich#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government#video

10 notes

·

View notes

Text

Car companies demand a 20% price cut! What impact will it have on the SiC industry?

At the beginning of 2024, BYD launched a plug-in hybrid car for only about 70,000 yuan. Many car companies such as Nezha and Changan quickly followed suit and cut prices one after another. The price war continued throughout 2023 and became more and more intense.

As car prices drop, the pressure is also directly passed on to upstream parts suppliers. To borrow the recent words of Zhang Yong, CEO of Nezha Automobile, "pass the cold to everyone."

Recently, Xu Daquan, President of Bosch China, revealed in an interview that car companies will put more pressure on suppliers to reduce prices in 2024. "The requirements are all to reduce prices by 20%… In the past, the price reduction was usually 3%-5% per year." Under the extreme pressure, many auto parts suppliers were "sweating profusely" and shouted that they couldn't stand it. Bosch reluctantly said that the result of shutting down and not doing anything might be better than a 20% reduction; while Nidec and Freya made it clear that they would shift their focus from China to other markets.

However, it may not be a wise move to blindly ask suppliers to reduce prices. How can we not only reduce vehicle costs but also improve vehicle performance? I think there are 3 cost reduction paths:

Use new technologies to reduce the overall cost of the vehicle. For example, using 800V+SiC is expected to reduce the cost of the vehicle by 30,000 yuan;

Starting from other electronic control components, such as switching to film capacitor solutions, it is estimated that the cost of capacitors can be reduced by 4 times;

Actively introduce Chinese-made components from Yongming Electronics and other companies to further reduce vehicle manufacturing costs.

Below we will analyze them one by one so that you can see if they are reasonable.

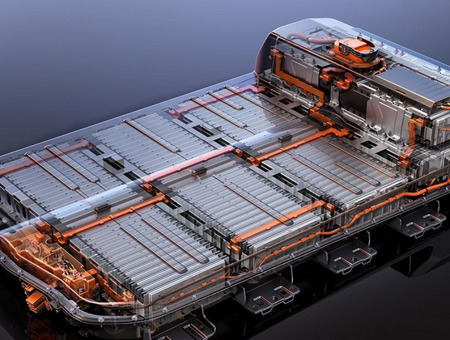

SiC is expected to turn the tide and reduce costs and increase efficiency for new energy vehicles

Under the wave of price cuts for new energy vehicles, SiC semiconductors, as a key component of the main drive inverter, are also under great pressure. However, SiC will have multiple benefits in the future, including:

Taking up most of the market share of automotive IGBT modules, the market growth is huge;

Upstream substrates, chip production capacity and yield rates continue to improve, and SiC modules have certain room for price reduction;

New technologies can be used to reduce the usage and cost of SiC chips for electric drives.

At present, many car companies have achieved optimization of SiC main drive costs. For example, Nissan's new generation SiC electric drive system cost has been reduced by 30%, Tesla's main drive SiC has been reduced by 75%, and Xpeng's new electric drive has reduced carbonization by 30%. Silicon cost reduced by 50%…

More importantly, even under the current high price situation, SiC technology can "decompress" automobile companies and significantly reduce the cost of car manufacturing.

The general consensus in the industry is that new energy vehicles using SiC as main drive can increase vehicle battery life by 3%-10%. According to Bloomberg data, the industry average price of automotive power batteries in 2023 will be US$139/kWh. Based on this calculation, a 98kWh 800V model can save US$681-1362 (approximately RMB 4898-9797) in battery cost alone.

Li Xiang, chairman and CEO of Li Auto, said at the 2023 spring media communication conference that medium and large SUVs usually require 100kWh battery capacity to achieve a cruising range of 600 kilometers, but Li Xiang achieves the same through "800V platform + SiC technology + drag coefficient optimization" The cruising range only requires 80kWh, and the cost of a bicycle can be reduced by about 30,000 to 40,000 yuan.

Therefore, in the context of a car price war, the SiC supply chain must speed up cost optimization, and car companies and Tier1 should also speed up the introduction of SiC technology.

Thin film capacitors help silicon carbide enter the car, further alleviating cost anxiety

The largest cost of electric vehicles is the power battery (accounting for about 38%), and electronic control accounts for about 6%. According to Infineon's estimates, power semiconductors (IGBT/SiC, etc.) account for about 40% of the cost of electronic control, followed by DC-Link capacitors, which account for about 16% of the cost.

Therefore, in addition to SiC modules, low-cost DC-Link capacitor solutions are also beneficial to reducing electric drive and electronic control costs, and can alleviate the cost anxiety of car companies to a certain extent.

According to Nrel and Myavnet reports1, in a 30KW, 650V DC link, only 4 film capacitors need to be used. If replaced by electrolytic capacitors, 10 devices are required. It is estimated that the price of 4 film capacitors is lower than 10 aluminum electrolytic capacitors. The capacitance is more than 4 times lower and the volume is 15 times smaller.

In addition, according to Yongming Electronics, to give full play to the advantages of SiC, it is also necessary to match suitable capacitors for electronic control.

This is because new energy vehicles require higher power density and smaller size of motor controllers, and power modules are gradually shifting from traditional silicon-based IGBT modules to SiC MOSFET modules. However, the switching frequency of SiC modules is very high, with the highest switching frequency reaching 30 kHz. Excessively high peak current will increase the high-frequency component of the capacitor ripple current and cause more serious heating. Therefore, silicon carbide electronic control also puts forward more stringent conditions and higher requirements for the temperature rise of the capacitor at high frequencies. .

The resonant frequency of electrolytic capacitors is only 4kHz, which is not enough to absorb the current ripple of SiC electronic control. Moreover, because the electrolytic capacitor core itself generates high heat and has a lifespan that decays too quickly, and has poor corrosion resistance, it is difficult to use it in new energy vehicles. Popularize application. In comparison, film capacitors have better temperature characteristics, can withstand the same reverse voltage, have lower equivalent series inductance (ESL) and equivalent series resistance (ESR), longer service life and more High safety and reliability. For example, on DC-Link, electrolytic capacitors are one of the most likely places to cause failure of electronically controlled inverters. In contrast, the life of film capacitors is generally more than 10 years. Therefore, film capacitors are widely used in the field of new energy vehicles.

Data shows that the installed base of main drive electronic controls based on DC-Link film capacitors will reach 5.1117 million units in 2022, accounting for 88.7%, indicating that film capacitors have replaced electrolytic capacitors and become the mainstream of the electric drive market.

In addition to main drive electronic control, film capacitors have become increasingly popular in many fields such as vehicle power supplies and optical storage and charging. According to Tsinghua University estimates, the global demand for film capacitors will increase from 827 million in 2019 to 991 million in 2024.

Made in China further reduces the cost of capacitors, Yongming promotes the development of new energy with innovation

According to sources in the capacitor industry, the current single price of film capacitors used in new energy vehicles is about 200 yuan, and the average electronic control of a new energy vehicle requires 1.3 film capacitors, worth nearly 300 yuan. Film capacitors for vehicle OBC and other components The value is about 70 yuan, and the film capacitor in a car is worth nearly 400 yuan, which is also a considerable cost.

In response to the urgent cost reduction needs in fields such as new energy vehicles, Yongming Electronics recently launched the MDP and MDR series of DC support film capacitors. By using advanced manufacturing processes and high-quality materials, they can perfectly adapt to global power semiconductor leaders such as Infineon. The working conditions of Sheep's SiC MOSFET and silicon-based IGBT will further promote the new energy industry to achieve cost reduction and efficiency improvement.

It is understood that Yongming Electronics' MDP and MDR series film capacitors have several outstanding features: lower equivalent series resistance (ESR), higher rated voltage, lower leakage current and higher temperature stability.

First of all, Yongming Electronics' film capacitors adopt a low ESR design, which can effectively reduce the voltage stress during switching of SiC MOSFET and silicon-based IGBT, reduce the loss of the capacitor, and improve the efficiency of the entire system. At the same time, the capacitor also has a higher rated voltage, which can withstand higher voltage working conditions and ensure the stable operation of the system.

According to reports, the capacity ranges of Yongming Electronics' MDP and MDR series film capacitors are 5uF-150uF and 50uF-3000uF respectively, and the voltage ranges are 350V-1500V and 350V-2200V respectively.

Secondly, Yongming Electronics’ latest film capacitors have lower leakage current and higher temperature stability. Taking the electronic control of new energy vehicles as an example, its power is usually large, which causes the film capacitor to heat up more seriously, which will reduce the life and reliability of the film capacitor. To this end, Yongming's MDP and MDR series are based on high-quality materials and advanced manufacturing processes to design better heat dissipation structures for film capacitors, so that the capacitors can maintain stable performance in high-temperature environments and will not be damaged due to temperature rise. Cause the capacitance value to drop or fail. In addition, capacitors have a longer service life and can provide more reliable support for power electronic systems.

Third, Yongming Electronics’ MDP and MDR series capacitors also have smaller size and higher power density. Taking the 800V electric drive system as an example, the technical trend is to use SiC devices to reduce the size of passive components such as capacitors, thereby promoting the miniaturization of electronic controls. Yongming adopts innovative thin film manufacturing process technology, which not only improves the integration and efficiency of the entire system, but also reduces the volume and weight of the system, providing more possibilities for device portability and flexibility.

Taken together, Yongming Electronics' DC-Link film capacitor series products have a dv/dt tolerance increased by 30% and a lifespan increased by 30% compared to other film capacitors on the market. They can not only provide SiC/IGBT circuits Providing better reliability can also provide better cost-effectiveness and break the price barrier in the popular application of film capacitors.

As an industry pioneer, Yongming Electronics has been deeply involved in the field of capacitors for more than 20 years. Its high-voltage capacitors have been stably used in high-end fields such as vehicle OBC, new energy charging piles, photovoltaic inverters, and industrial robots for many years. The launch of a new generation of film capacitor products this time has solved various problems such as film capacitor production process control, tooling and fixture equipment. It has completed reliability certification at leading global companies, achieved large-scale application, and provided services to larger customers. Prove product reliability. In the future, they will use their long-term technology accumulation and precipitation to help the rapid development of the new energy industry with highly reliable and cost-effective capacitor products.

0 notes

Text

The Impact of Electric Vehicles on The Environment and Climate Change

Electric vehicles (EVs) are rapidly transforming the transportation sector, promising a cleaner future. But how big of an impact do they truly have on the environment and climate change? While EVs offer significant advantages, a clear understanding of their lifecycle is crucial.

The Benefits: A Breath of Fresh Air

One of the most significant advantages of EVs is their lack of tailpipe emissions. Unlike gasoline-powered vehicles that spew pollutants like nitrogen oxide and particulate matter, EVs contribute directly to cleaner air, especially in urban areas. This translates to reduced respiratory illnesses, improved public health, and a more pleasant environment.

Furthermore, EVs boast superior energy efficiency. Electric motors convert a much higher percentage of energy into movement compared to traditional combustion engines, which waste a significant amount of energy as heat. This efficiency translates to lower electricity consumption and a smaller overall carbon footprint.

Beyond the Tailpipe: A Lifecycle View

However, the environmental impact of EVs goes beyond just tailpipe emissions. Manufacturing an EV battery requires significant resources and energy, which can generate pollution. Additionally, the electricity used to charge an EV plays a crucial role. In regions where the electricity grid relies heavily on fossil fuels, the environmental benefit is diminished.

Here's a breakdown of some key considerations:

Battery Production: Mining the materials for EV batteries can have environmental consequences. Lithium extraction, for example, can raise concerns about water usage and local ecosystems. However, battery technology is constantly evolving, and research is ongoing to develop more sustainable options.

The Power Source: The environmental impact of EVs hinges on the source of electricity used for charging. If the grid relies heavily on coal or natural gas, the carbon footprint of EVs increases. However, the good news is that renewable energy sources like solar and wind are becoming increasingly affordable and widespread. As the grid transitions to cleaner sources, the environmental benefit of EVs will become even more pronounced.

A Holistic Approach: Mitigating the Downsides

While there are challenges, there are also ways to mitigate the environmental impact of EV production and use.

Sustainable Manufacturing: Stricter regulations and industry initiatives can promote responsible mining practices and encourage the use of recycled materials in battery production.

Grid Modernization: Investing in renewable energy infrastructure and transitioning away from fossil fuels is crucial. This will not only benefit EVs but also reduce overall greenhouse gas emissions.

Second Life for Batteries: Used EV batteries still hold significant capacity. Developing efficient ways to reuse them in stationary applications like energy storage systems can extend their lifespan and reduce environmental impact.

Beyond Climate Change: A Wider Environmental Impact

The benefits of EVs extend beyond just climate change. They can significantly reduce noise pollution in urban areas. Traditional gasoline engines contribute to a constant hum that disrupts wildlife and reduces the overall quality of life. EVs, with their near-silent operation, can create quieter streets and a more peaceful environment.

Furthermore, EVs eliminate the need for extracting, refining, and transporting fossil fuels. This reduces the environmental damage associated with oil spills, pipeline leaks, and air pollution from refineries. Additionally, EVs require less maintenance compared to gasoline vehicles, leading to a reduction in the production and disposal of used motor oil, which can be harmful to the environment if not handled properly.

While a full understanding of the lifecycle impact is crucial, EVs offer a significant net positive effect on the environment. With continued advancements in technology, responsible manufacturing practices, and a shift towards renewable energy, electric vehicles have the potential to revolutionize transportation in a sustainable way, paving the road for a cleaner and healthier future for all.

Conclusion: A Charged Future for a Sustainable World

Electric vehicles are not a silver bullet, but they represent a powerful turning point in the fight against climate change and environmental degradation. While challenges remain in battery production and the reliance on clean energy grids, the potential benefits are undeniable.

A Catalyst for Change: The widespread adoption of EVs can create a ripple effect, driving innovation in renewable energy sources, battery technology, and sustainable manufacturing practices. This can lead to a cleaner electricity grid, reduced reliance on fossil fuels across sectors, and a more circular economy for critical materials.

A Shared Responsibility: The transition to a more sustainable transportation system requires a collaborative effort. Governments can incentivize EV adoption and renewable energy production through policies and subsidies. Manufacturers need to invest in responsible sourcing, sustainable battery design, and second-life applications. Consumers play a crucial role by choosing EVs and supporting companies committed to environmental responsibility.

A Brighter Horizon: As EV technology continues to evolve and the clean energy grid expands, the environmental impact of EVs will only become more positive. Imagine cleaner air in our cities, quieter streets, and a reduced reliance on fossil fuels. Electric vehicles have the potential to pave the way for a more sustainable future, ensuring a healthier planet for generations to come. The road ahead requires continued investment, innovation, and collaboration, but the destination – a cleaner and healthier world – is well worth the journey.

The Road Ahead: A Sustainable Future

The transition to EVs offers a powerful tool in the fight against climate change. However, it's a journey, not a destination. At Aggressive group, we are committed to continuous innovation in electric vehicle technology, sustainable manufacturing practices, and promoting renewable energy sources. By working together, we can create a cleaner, more sustainable future for generations to come.

This is just the beginning of the electric revolution. Join Aggressive Group on the road to a greener future.

1 note

·

View note

Text

#stop genocide#the silent genocide#genocide#silent genocide#congo🇨🇩#free congo#congo#go green#technology#electronic#electric vehicles#phones#iphone#murder#rape#abuse#child abuse#africa#colbat#colton#colbot#speak up#slaves#death

12 notes

·

View notes

Text

Electronic Message Centers: Revolutionizing Business Signage

In today’s fast-paced, technology-driven world, businesses are constantly seeking innovative ways to capture attention and communicate effectively with their audience. Electronic Message Centers (EMCs) have emerged as a dynamic solution to meet these needs, offering versatility, engagement, and real-time updates. This blog delves into the benefits and applications of EMCs, and why they are becoming an essential tool for modern businesses.

What are Electronic Message Centers?

Electronic Message Centers are digital displays that use LED technology to showcase messages, advertisements, and information. Unlike traditional static signs, EMCs can be programmed to display a variety of content, including text, images, animations, and videos. This flexibility allows businesses to convey multiple messages and update their content instantly based on current promotions, events, or important announcements.

Benefits of Electronic Message Centers

Dynamic Content Display: One of the most significant advantages of EMCs is their ability to display dynamic content. Businesses can easily change messages, images, and videos to keep their audience engaged. This capability is particularly useful for promoting special offers, sales events, or new products. The ability to rotate messages ensures that your display remains fresh and relevant, capturing the attention of passersby.

Real-Time Updates: EMCs allow for real-time updates, which is crucial for businesses that need to communicate timely information. For instance, a restaurant can update its menu specials or operating hours, while a retail store can announce flash sales or store events. The ease of updating content means businesses can respond quickly to changing conditions or customer needs.

Enhanced Visibility: The bright, high-resolution displays of EMCs ensure high visibility, even in low-light conditions or adverse weather. This makes them highly effective for attracting attention from a distance and standing out in a crowded marketplace. Their ability to display vibrant colors and moving graphics further enhances their impact.

Cost-Effective Advertising: While the initial investment in an EMC may be higher than traditional signage, the long-term benefits often outweigh the costs. With EMCs, businesses can avoid the recurring expenses of printing and installing new signs. The flexibility to change messages digitally means that businesses can adapt their advertising strategies without additional costs.

Increased Engagement: Interactive features and engaging content displayed on EMCs can drive customer interaction. For example, businesses can run social media promotions, interactive polls, or contests that encourage audience participation. This not only enhances customer engagement but also fosters a sense of community around the brand.

Applications of Electronic Message Centers

Retail Stores: Retailers can use EMCs to showcase promotions, sales, and new arrivals. The ability to update content frequently ensures that customers are always informed about the latest offers. Additionally, EMCs can be used to highlight customer testimonials or loyalty program updates.

Restaurants: For restaurants, EMCs can display daily specials, menu items, and nutritional information. The visual appeal of moving graphics can entice customers and create a more inviting atmosphere.

Educational Institutions: Schools and universities can use EMCs to communicate important announcements, event schedules, and emergency alerts. The ability to display educational content and news updates helps keep students, staff, and visitors informed.

Event Venues: Event venues can utilize EMCs to promote upcoming events, ticket availability, and venue information. The versatility of EMCs allows for creative and eye-catching displays that enhance the overall event experience.

Public Information: EMCs in public spaces can provide important information such as weather updates, public transportation schedules, and emergency alerts. Their visibility ensures that critical information reaches a wide audience effectively.

Conclusion

Electronic Message Centers represent a significant advancement in signage technology, offering businesses a powerful tool to communicate dynamically and effectively. With their ability to display engaging content, provide real-time updates, and enhance visibility, EMCs are an invaluable asset for any business looking to make a strong impression and stay connected with their audience. As technology continues to evolve, the potential applications and benefits of EMCs will only grow, solidifying their role as a cornerstone of modern business signage. For more details visit our website: www.a-acesignco.com

#Channel Letter Signs#Parking Lot Lighting#Channel Letter Sign Company#Lighted Channel Letter#Neon Signs Near Me#Monument Signs#Vinyl Letters Signs#Dimensional Letters Signs#Typical Architectural Signs#Pylon Signs Near Me#Electronic Message Centers#Vehicle Lettering Signs#Window Awnings Near Me#Lighted Cabinets Signs#Sandblasted Signs#Blade Signs Near Me#Aluminum Signs Near Me#Wood Signs Near Me#Sign Repair & Sign Service#Digital Printing#Krane Service

2 notes

·

View notes

Text

🎷New Books 📚 If you're interested,🌹🌹 I'll send you PDF file now ...🌹🌹🌹

#books and reading#books & libraries#books#california#usa#brazil#chicago#england#engineering#electricalengineering#electrical engineers#electric vehicles#electronic#electric cars#us elections#election 2024#elegant

2 notes

·

View notes

Text

Hooked up the solar bike to the solar trailer I built forever ago. Turned out pretty nice, the only thing I think I need to do at this point is add a few peices of reinforcing cordage to keep jank down and throw more batteries in the trailer. Have 260 watts of solar output on this, now I need to ride it across the state over several days to REALLY test this.

#solarpunk#solarpunkdiy#diy#electronics#ebikes#bikes#electric vehicles#bikelife#electric bikes#electric bicycle

75 notes

·

View notes