#fluidmechanics

Explore tagged Tumblr posts

Text

The Science Behind Mechanical Engineering: Exploring Fundamental Concepts

Mechanical engineering is one of the oldest and broadest branches of engineering. At its core, it revolves around the application of principles from physics, materials science, and thermodynamics to design, analyze, and manufacture mechanical systems. While many associate mechanical engineering with machines and devices, its foundation is deeply rooted in scientific principles that drive innovation and practical solutions across various industries.

1. Thermodynamics: The Study of Energy and Heat

Thermodynamics is a cornerstone of mechanical engineering. It focuses on how heat and energy interact, transfer, and convert between different forms. Understanding these processes is crucial when designing engines, heating systems, and refrigeration units.

The Laws of Thermodynamics form the backbone of this science, guiding engineers in creating energy-efficient systems.

First Law: Energy cannot be created or destroyed, only transformed. This is vital in designing systems where energy conservation is key, like power plants or automotive engines.

Second Law: Energy transfers naturally from a higher concentration to a lower one (i.e., heat flows from hot to cold), guiding the design of heat engines and refrigerators.

2. Fluid Mechanics: Understanding How Fluids Behave

Fluid mechanics is another essential area of mechanical engineering. It deals with the behavior of liquids and gases, focusing on how they move, interact, and exert forces.

Applications include designing pumps, turbines, HVAC systems, and even aerodynamic designs for cars and planes.

Bernoulli’s Principle explains how the pressure in a fluid decreases as its velocity increases, which is fundamental in understanding how airplane wings generate lift.

3. Materials Science: Choosing the Right Material for the Job

Mechanical engineers must understand the properties of different materials to ensure that the components they design can withstand the forces, stresses, and environmental conditions they’ll encounter.

Material Selection is based on mechanical properties like strength, ductility, hardness, and toughness.

For example, steel is often used in construction due to its high tensile strength, while aluminum is preferred in aerospace applications for its light weight and corrosion resistance.

4. Kinematics and Dynamics: The Study of Motion

Kinematics and dynamics focus on understanding the motion of objects, which is crucial in designing mechanisms that move, such as robotic arms, gears, and vehicles.

Kinematics involves the geometry of motion, such as calculating the velocity and acceleration of objects without considering the forces causing the motion.

Dynamics, on the other hand, examines the forces and torques that cause motion. This is essential in designing everything from simple levers to complex systems like the suspension of a car.

5. Vibration Analysis: Ensuring Stability and Longevity

Vibration analysis is vital in mechanical systems to prevent excessive wear, fatigue, and failure. Uncontrolled vibrations in machinery can lead to inefficiency or catastrophic failure.

Engineers use vibration analysis to predict how components will behave under varying loads and conditions, ensuring they are designed to operate smoothly and reliably. This is especially important in rotating machinery, such as turbines and engines.

6. Control Systems: Automating and Optimizing Mechanical Processes

Control systems are used to regulate and optimize the behavior of machines and processes, integrating mechanical engineering with electronics and computer science.

Feedback Control Systems are used in applications ranging from industrial robots to automotive cruise control, where sensors detect system output and adjust inputs to achieve the desired performance.

Conclusion

Mechanical engineering is a multidisciplinary field deeply rooted in scientific principles. From thermodynamics and fluid mechanics to material science and vibration analysis, each scientific concept plays a critical role in designing, analyzing, and improving mechanical systems. As mechanical engineering continues to evolve, the integration of cutting-edge science will remain at the forefront, driving innovation and solving complex challenges across industries.

Mechanical engineers who master these fundamental concepts will be well-equipped to create systems that are efficient, durable, and innovative—making their mark on industries ranging from aerospace to energy.

2 notes

·

View notes

Text

From steady-state to multiphase flow, Tesla Mechanical Designs offers a complete suite of CFD services! 💯 We'll guide you through every step, from initial analysis to prototyping and testing. See how we can help you achieve optimal performance! ➡️

0 notes

Text

youtube

The future of Computational Fluid Dynamics (CFD) is nothing short of revolutionary! From seamless integration with multi-physics tools to leveraging cloud computing, AI, and virtual reality, CFD is evolving to transform industries like aerospace, automotive, and even healthcare. In this video, we explore how cutting-edge advancements like real-time simulations, AI-driven optimizations, VR immersion, and specialized hardware are shaping the next era of CFD. Discover how engineers will soon simulate complex scenarios faster, more efficiently, and with unprecedented precision.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fAf4z4 Don’t forget to like, share, and subscribe for more insights into the future of engineering and technology!

#CFD#ComputationalFluidDynamics#EngineeringInnovation#SimulationTechnology#FluidMechanics#AerospaceEngineering#AutomotiveDesign#TechFuture#AIinEngineering#CloudComputing#VirtualReality#FutureOfEngineering#SkillLync#youtube#cae#engineering#mechanicalengineering#Youtube

0 notes

Text

The Department of Mechanical Engineering's Innovation Club is organizing a "Quiz Competition" on the theme of "Fluid Mechanics, Engineering Mechanics, Material Science, Thermodynamics" on November 22nd, 2024.

#IIMTIndia#IIMTian#IIMTNoida#IIMTGreaterNoida#IIMTDelhiNCR#MechanicalEngineering#InnovationClub#QuizCompetition#FluidMechanics#EngineeringMechanics#MaterialScience#Thermodynamics#FutureEngineers#KnowledgeMatters

0 notes

Text

We go beyond the basics and secure a smooth experience from planning to execution. With years of expertise, we redefine Honesty Your satisfaction is our priority, aiming to exceed expectations every time. Trust us for unparalleled support and efficient project management. Let’s create a future of flawless pipelines together!

#hydropneumatic #hps #pipingsolution #pipinginstallation #pipingfabrication

#hydropneumatic#hps#pipingsolution#pipinginstallation#pipingfabrication#fluidsystem#pressurevessel#pipingsystem#hydraulicengineering#pneumatictechnology#fluidpower#mechanicalengineering#industrialengineering#pipelineconstruction#mechanicaldesign#fluidhandling#hydraulicsystem#pneumaticsystem#pipelinetechnology#fabricationengineering#fluidcontrol#fluidmechanics#pipelineinstallation#engineeringdesign#mechanicalfabrication

1 note

·

View note

Text

The Crucial Role of Fluid Mechanics in Submersible Pump Manufacturing

Introduction

In the realm of fluid dynamics, few applications exemplify the importance of precision and efficiency as much as submersible pump manufacturing. These marvels of engineering play a pivotal role in various industries, from water supply and agriculture to mining and wastewater management. At the heart of their functionality lies the intricate science of fluid mechanics, a discipline that shapes the design, performance, and reliability of submersible pumps.

Understanding Submersible Pumps

Submersible pumps are specialized devices designed to operate submerged in fluid, typically water. Their primary function is to lift or move liquids from one location to another, and they find extensive use in applications where surface pumps are impractical or insufficient. This includes pumping water from deep wells, drainage systems, and sewage treatment plants.

Importance of Fluid Mechanics

Fluid mechanics, the branch of physics that studies the behavior of fluids (liquids and gases), plays a critical role in the design and manufacturing of submersible pumps. Here are some key aspects highlighting its importance:

Efficient Flow Dynamics: Fluid mechanics guides engineers in optimizing the internal components of submersible pumps to ensure a smooth and efficient flow of liquids. The design of impellers, casings, and other elements is tailored to minimize friction, turbulence, and energy losses, maximizing the overall efficiency of the pump.

Cavitation Prevention: One of the challenges in submersible pump design is the occurrence of cavitation, a phenomenon where vapor bubbles form and collapse in the liquid. This can lead to erosion and damage to pump components. Fluid mechanics aids in identifying potential cavitation zones and implementing measures to prevent its occurrence, ensuring the longevity of the pump.

Pressure and Head Calculation: Fluid mechanics principles are instrumental in calculating pressure and head requirements for different applications. Engineers use these calculations to determine the pump's specifications, ensuring it can meet the demands of the intended system. Proper pressure management is crucial for the efficient and safe operation of submersible pumps.

Material Selection: The choice of materials for pump components is influenced by fluid mechanics considerations. Corrosion resistance, wear characteristics, and compatibility with the pumped fluid are critical factors. Understanding fluid behavior helps in selecting materials that can withstand the specific challenges posed by different liquids.

Optimized Pump Sizing: Fluid mechanics aids in the sizing of submersible pumps based on the flow rate and head requirements of a particular system. Oversized or undersized pumps can lead to inefficiencies and premature wear. Accurate sizing, informed by fluid dynamics principles, ensures optimal performance and energy efficiency.

Conclusion

In the world of submersible pump manufacturing, the synergy between engineering expertise and fluid mechanics is indispensable. The intricate dance of liquids through the pump's components requires a deep understanding of how fluids behave under various conditions. As technology advances, and industries demand more sophisticated solutions, the role of fluid mechanics in submersible pump design will continue to be a driving force behind innovation and reliability. The efficient movement of liquids beneath the surface owes its success to the mastery of fluid dynamics, making submersible pumps a testament to the seamless integration of science and engineering.

1 note

·

View note

Text

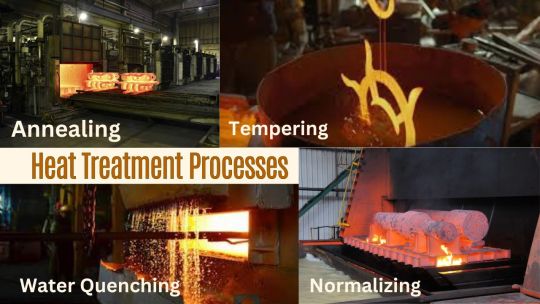

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Text

Surface tension

Surface tension is a physical property of liquids that arises due to cohesive forces between molecules at the surface. It allows certain insects to walk on water, causes water droplets to form beads on surfaces, and plays a crucial role in biological and industrial processes like capillary action, inkjet printing, and emulsification.

International Chemistry Scientist Awards

Website: chemistryscientists.org

Contact us: [email protected]

Nominate now: https://chemistryscientists.org/award-nomination/?ecategory=Awards&rcategory=Awardee

#sciencefather#researchawards#Professor,#Lecturer,#Scientist,#Scholar,#Researcher#SurfaceTension #Physics #FluidMechanics #CapillaryAction #MolecularForces #Cohesion #ScienceExplained #STEM #PhysicalChemistry #WaterProperties #SurfacePhenomena #ScienceFacts #NanoScience #Biophysics #MaterialScience

👉 Don’t forget to like, share, and subscribe for more exciting content!

Get Connected Here: =============

Blogger :https://www.blogger.com/blog/post/edit/6961521080043227535/467226973388921229

Twitter : https://x.com/chemistryS79687

Pinterest : https://in.pinterest.com/chemistryaward/

Instagram: https://www.instagram.com/alishaaishu01/

Youtube : https://www.youtu

be.com/channel/UCAD_pDvz3ZHqv_3hf-N0taQ

0 notes

Text

Wind Tunnel Market Gains Momentum – Expected to Hit $5.8B by 2034! 🌬️🏎️

Wind Tunnel Market is projected to expand from $3.2 billion in 2024 to $5.8 billion by 2034, growing at a CAGR of 6.1%. As industries push for aerodynamic efficiency, fuel optimization, and technological advancements, wind tunnel testing is becoming more critical than ever.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS10476 &utm_source=SnehaPatil&utm_medium=Article

Key Market Trends:

✈ Aerospace Leads — Aircraft manufacturers rely on wind tunnels for precision aerodynamic testing. 🚗 Automotive on the Rise — With the surge in electric vehicles (EVs), optimizing aerodynamics is a game-changer. 🏗 Expanding Applications — Wind tunnels are now used in sports performance analysis, civil engineering, and energy solutions.

Regional Insights:

🌎 North America — Leads with high R&D investments in aerospace and automotive sectors. 🌍 Europe — Strong demand from automakers and sustainable transportation initiatives. 🌏 Asia-Pacific — Rapid industrialization, infrastructure growth, and EV adoption fuel demand.

Competitive Landscape:

Top industry players like Boeing, Lockheed Martin, Honda R&D, and Aerolab are innovating with cutting-edge CFD integration, AI-based flow visualization, and high-speed data acquisition. The future of wind tunnel technology will be driven by automation, real-time analytics, and enhanced efficiency.

#windtunnel #aerodynamicdesign #aircrafttesting #aviationtechnology #evinnovation #aerospacetechnology #electricvehicles #sustainabledesign #vehicleperformance #researchanddevelopment #engineeringtech #computationalfluiddynamics #fluidmechanics #transportationinnovation #energysector #sportstechnology #racecartesting #windengineering #airflowtesting #futureofmobility #spaceexploration #automotivetesting #smartmanufacturing #climatewindtunnel #hypersonictech #aeroacoustics #dragreduction #airflowoptimization #nextgenvehicles #flightdynamics #smartcities #speedoptimization #turbulencetesting #industrialinnovation #racingtechnology #infrastructuredevelopment #defensetechnology #energyresearch #technologytrends #simulationtechnology #engineeringexcellence #aviationnews #scienceandtech #advancedmaterials #greenmobility #performanceengineering

0 notes

Text

🔷️Optimizing Pump Efficiency with #ImpellerTrimming: When Does It Make Sense?

When a centrifugal pump operates beyond the required capacity, it results in excessive energy consumption and increased operational costs. Impeller trimming is a cost-effective method to fine-tune pump performance by reducing impeller diameter, aligning flow and head with actual system demands—without replacing the pump entirely.

When Is Impeller Trimming the Right Solution?

✔ When the pump delivers excess flow or pressure beyond system requirements, leading to unnecessary energy consumption.

✔ When operating conditions change, requiring a performance adjustment without replacing the pump.

✔ When optimizing energy efficiency in a cost-effective way is a priority.

How Does Impeller Trimming Affect Pump Performance?

Performance adjustments follow the #AffinityLaws:

🔹 Flow rate (Q) decreases in direct proportion to the impeller diameter reduction.

🔹 Head (H) decreases with the square of the diameter ratio.

🔹 Power consumption (P) drops significantly, following the cube of the diameter ratio—resulting in noticeable energy savings.

Potential Risks to Consider:

⚠ Flow instability: Excessive trimming can cause turbulent flow, increasing vibrations and impacting pump reliability.

⚠ Reduced hydraulic efficiency: According to API 610 standards, trimming should not exceed 25% of the original impeller diameter to prevent significant efficiency losses.

⚠ #NPSH concerns: Improper impeller trimming may alter suction conditions, increasing the risk of cavitation.

⭕Is Impeller Trimming Always the Best Option?

While impeller trimming is a practical and economical solution in many cases, it’s not always the most efficient approach. In some applications, variable frequency drives (#VFDs) provide greater flexibility, allowing flow adjustments while maintaining optimal hydraulic efficiency. The best choice depends on a thorough analysis of operating conditions and long-term performance goals.

❓Have you used impeller trimming to optimize pump performance, or do you prefer alternative solutions?

💭Share your insights.👇🏻

#Pumps #Impeller #Innovation #CentrifugalPumps

#MechanicalEngineering #FluidMechanics #PumpEfficiency #Hydraulics #Maintenance

0 notes

Text

Relation Between Surface Energy and Surface Tension #fluidmechanics #physics #neet

https://youtube.com/shorts/W_kzYetiNtg?feature=share

1 note

·

View note

Text

Fluid mechanics is the backbone of countless innovations, enabling advancements in fields like aerospace, automotive, and energy systems. 🌊⚙️ From optimizing aerodynamics to enhancing energy efficiency, fluid mechanics engineers are transforming the way the world moves. 🌍💧

At Skill Lync, we offer industry-relevant courses to help you master tools like CFD, ANSYS Fluent, OpenFOAM, and more. With hands-on training, you'll develop the skills to tackle real-world challenges in fluid flow, heat transfer, and fluid-structure interaction. 🚀📊

Empower your career with knowledge that flows seamlessly into opportunities.

Save this post and share it with friends and family !

For more details, visit: Skill Lync https://skill-lync.com/

#FluidMechanics#SkillLync#EngineeringExcellence#CFD#ANSYSFluent#OpenFOAM#EngineeringCareers#FutureEngineer#SkillUp#TopCompanies#EngineeringInnovation#CareerGrowth#JoinTheLeaders

0 notes

Text

Hire UK Tutor for M22008 Computational Fluid Mechanics Assignment Help and Get Solution with ease!! Download University Assessment solution now! Order Instant Solution on WhatsApp: +44 141 628 6080!!

#M22008 #Computational #FluidMechanics #AssignmentHelp #Solution #AssessmentHelp #OnlineTutor #PortsmouthAssignmentHelp #AskTutor #UKAssessment #AssessmentWriting #topassignmenthelpservices #UKtopwritingservice #AssessmentWritingService #UK #BTEC #HND #HNC

0 notes

Photo

F1 Rockets at Kennedy Space Center Watercolor Ink. . more on https://www.reddit.com/r/nasa/comments/pr9xny/f1_rockets_at_kennedy_space_center_watercolor_ink/

#datamining#custompcbuild#gamingsetup#Mars#todayilearned#fluidmechanics#pcmasterrace#Android#technology#PrimitiveTechnology

1 note

·

View note

Text

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Photo

Paper airplane illustration from Artist: Muinezu 👏👏👏 / Follow @theliftndrift Send us your paper airplane videos pictures blogs and tutorials to us to get featured in our world's biggest Paper Airplane Community! . . . . . . . . . . . #paperplaneclub #paperairplanes #paperairplane #paperplanesflyingclub #liftndrift #paperplanes #howtomakepaperplanes #howtomake #scienceforkids #scienceforkids #aeronautics #fluiddynamics #fluidmechanics #walkalongglider #glider #21stcenturyskills #stemeducation #instagood #craftyculture #tuesday #apjabdulkalam #aeromodelling #aviation #engineering #lego #legobuilding #legocommunity #sciencetechnologyengineeringmath #forschoolkids #marvelcomics (at Busan, South Korea) https://www.instagram.com/p/CD3IUI5p-Mo/?igshid=yws8hrlgwc5l

#paperplaneclub#paperairplanes#paperairplane#paperplanesflyingclub#liftndrift#paperplanes#howtomakepaperplanes#howtomake#scienceforkids#aeronautics#fluiddynamics#fluidmechanics#walkalongglider#glider#21stcenturyskills#stemeducation#instagood#craftyculture#tuesday#apjabdulkalam#aeromodelling#aviation#engineering#lego#legobuilding#legocommunity#sciencetechnologyengineeringmath#forschoolkids#marvelcomics

7 notes

·

View notes