#lathe-turning

Text

Lathlyria fullbody for artfight! I finally have (mostly) decided on a design for his jacket...

#hubble draws#oc#lathlyria#is it a jerkin actually? hrm. I can't seem to fully decide on how long it should be in any case lmfao#There are some things still bothering me about the drawing a bit but alas. I think it's good enough for now#ahhh. my (ostensibly) elf jeff the killer. I love him very dearly#his colouring was WAY easier than Ven's by the way. As much as I love embroidery its time consuming to draw#Even in a simplified form#HOWEVER Lath's pose took me forever to hammer down but I really like how it turned out

27 notes

·

View notes

Text

Had the most amazing experience on Saturday. Was dropping off a couple plush mages to the store that sells them for me downtown, because a couple had sold over the past few weeks and I try to be a good supplier.

It only takes a few minutes and I'd already paid for parking, so I decided to linger and look around the shop a bit, because it's a cool place where there's always a chance something new has arrived if you haven't been there for over a week. It's fantastic. If you told me there was some actual magic in this place I'd believe you, and I've been in the employees-only area.

Which is why I was present, leafing curiously through a book on the making of the movie Chicken Run, to hear a guy behind me loudly proclaim, "Forty dollars for this?! I could make this!" I'm aware that the things in this store can be pricy, but also that a lot of the stock is made by local crafters, like me, meaning prices can be a bit higher due to the fact that you're getting something hand-crafted instead of mass-produced. So I turn around to see what he's complaining about.

And this guy is holding a wooden wand that is unique, one-of-a-kind, hand-crafted from solid wood. All things I know at a glance because, as it happens, I'm not the only person in my family who sells stuff at this store... my dad does as well. And he's the one who made that wand.

Now here's the thing. My dad's part of the local woodturner's group, wood turning being a method of carving that involves spinning a chunk of wood on a high-speed lathe while holding a bit of sharp metal against it until it turns into a wand, bowl, cup, vase, what-have-you. It's a highly-skilled craft that requires a lot of practice and and specialized tools, which he picked up after retiring but before going back to work, and he's been practicing and perfecting the required skills for at least fifteen years. If he likes (and he does like), he can get a wooden sphere carved and polished to such a sheen and smoothness that it both reflects the light and feels like plastic, which is highly impressive on a technical scale and extremely disconcerting on a tactile one.

And this guy just said one of his pieces wasn't worth the price on the tag because 'he could do it too.' Which, as any crafter knows, is not the sort of statement fellow crafters make at volume.

Now, I'm a reasonable sort of trickster. As I said, my dad's part of a woodturning group, I'm well-aware that there genuinely are other people in this area who are as skilled as, if not more skilled than, my dad. Maybe he's just a skilled creep or disagrees with the pricing. So I turn to the guy and go, "Oh? It took my dad a couple years to learn how to make those."

To which he smiles at me and asks if I know what kind of wood the wand is made of.

"Purple Heart."

"Wow, you really know your stuff!"

I stare at him for a moment, because 1) Purple Heart wood is literally the easiest wood to identify on the planet because, as the name suggests, it's actually purple, which is a thing woods generally are not. And also 2) he has apparently not grasped that the reason I know this is because my father made the thing he is holding.

I do not say these things. Instead I clue him in on the situation he's in by saying, "Yes, my dad made that wand."

"Oh. Um. Thank-you!" he holds out his hand.

I look at the hand, then at him. "For what?"

"For your dad!"

...

...I do not shake his hand, and I'm beginning to suspect that this guy does, indeed, not have any clue what he's talking about when he said he could make this himself. But I could be wrong. He could just be socially awkward, I get that. So time for the final question. With a polite smile that no customer yet has been able to tell is completely fake, I ask, "Are you part of the local woodturner's group?"

"The what?"

"The local woodturner's group," I repeat, "My dad turned that wand by hand, on a lathe."

Guy, smiling, about to seal his own fate, "Ah. That is a tool I do not have."

Me, also smiling, because he's just proven beyond all shadow of a doubt that no he could not, in fact, make it himself. "Mm. And that's why it costs forty dollars."

You know, he didn't have anything to say to that?

Put a bit of a spring in my step as I left.

#my life#crafting woes#crafting community#vengeance is mine#wood turning#also just to be clear#any lathe worth using is going to set you back WELL past $40 even before you get to the rest of the tools and safety equipment you need#and that's without even getting into the time and material investment it takes to be able to make stuff with them

35 notes

·

View notes

Text

Did some wood turning last weekend and finally got around to applying some shellac.

This started off as a 6x6 beam of ash, that I turned into this vase. Originally had a bit more of a lip at the top but I delved too deep and it cracked so I shortened it.

#woodworking#hobby#lathe#turning#woodturning#vase#crafts#wood art#arts and crafts#ash#shellac#random project#getting it round was an experience#wood#wooden#turned

58 notes

·

View notes

Text

George Orr = working class hopelessness and depersonalization // William Haber = the near-sadistic selfishness and tunnel vision of the capitalist mindset. Is this anything.

#started reading the lathe of heaven on my lunch break. do you guys remember reading.....that's good shit. i forgot!!#anyway i'm only like a third of the way through so if this turns out to be a wack interpretation don't @ me

4 notes

·

View notes

Text

Flatmate discovered the woodturning club and uh

New hobby unlocked

#that's her in the photo but i figure it's sufficiently anonymous#lovely group of mostly old men standing around lathes and old women knitting and chatting#although there were a couple of other women actually turning things#we showed up and they just kinda allocated us a tutor each and a lathe each it was great#and i think a rolling pin was a great choice for first project#it's about 2/3 my work and 1/3 the guy who was teaching me#made things#rowena adventures

7 notes

·

View notes

Text

fuck me i've been so gd weak and shaky all day. feels like my knees have 50lb weights on them.

#personal#keeping it fun and funky fresh#i need a chronic illness tag#i'm also like. depressed bc i haven't been feeling physically or mentally up to using the tools i've been setting up in the basement#or indeed getting the basement adequately re-straightened to safely use them w/o tripping on stuff#i want to use my lathe!! but there are so so many preliminary steps#like. reading the whole manual & making sure my secondhand shopsmith is safely set up to actually do that#and i don't have good wood for turning. or good dust collection.#and i'm so so tired physically. constantly.

5 notes

·

View notes

Text

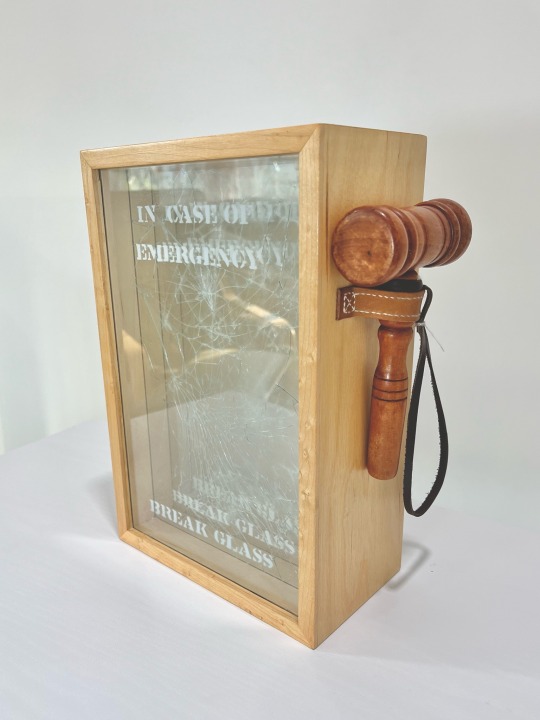

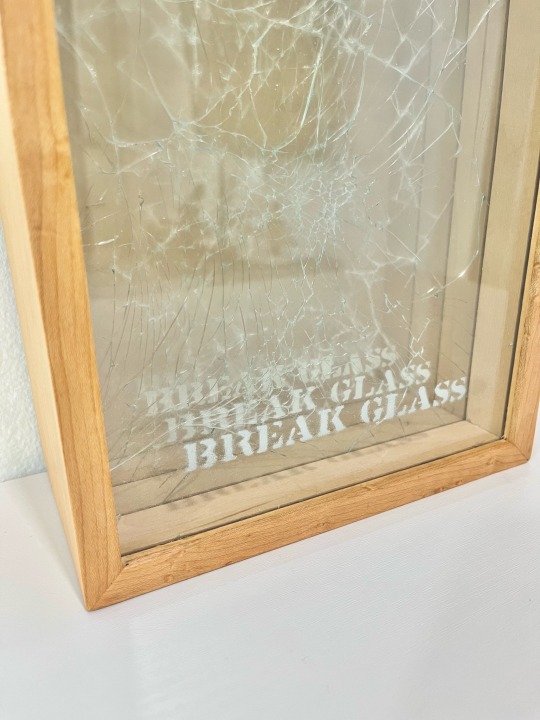

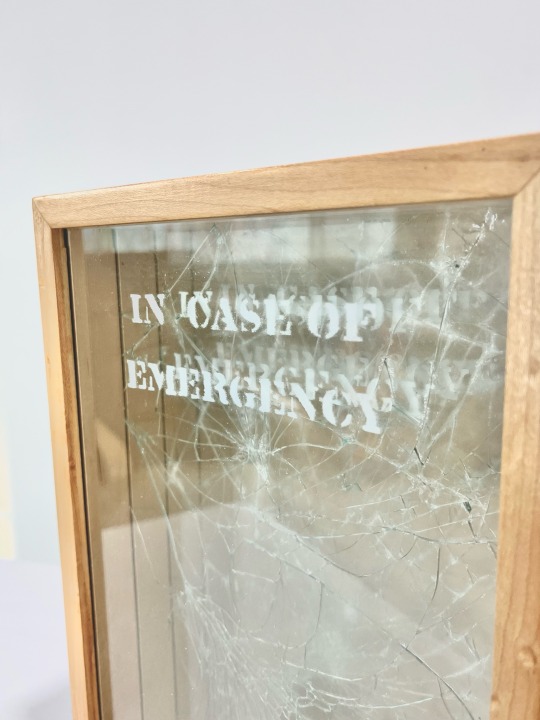

Have You Eaten Yet? (2016)

Mixed media sculpture - Plywood, maple veneer, laminated glass, spraypaint, cherry wood (hammer), leather

#wood#art#sculpture#woodworking#leather#leatherworking#wood turning#lathe#hammer#gavel#in case of emergency#break glass#broken glass#installation#public art#assemblage#design

8 notes

·

View notes

Text

Hybride bowl and plate

#woodturning#wood#woodworking#art#lathe#resin#maple#resinart#burl#epoxy#wood turning#workshop#artist#artistsoninstagram#vase#wood lathe#youtube#resin art#walnut#woodshop

47 notes

·

View notes

Text

what

#homestuck#liveblogging homestuck#okay so the cool arm is doing the laser again#and this time instead of making pogos#it made a blue tree that poops a single fruit and then makes like a tree and disappears#i guess that makes sense#wait wait wait#it was the#pre punched card#wasn't it?#that was used in the totem lathe on the blue cylinder#turning it from something that makes a pogo when exposed to the laser#into something that makes a blue pooping tree#are there something like 10 seconds left?#blue tree#blue fruit#research tells me its a peach#peaches were once revered as a symbol of female fertility#or so I've been told

5 notes

·

View notes

Text

A Ruin, Sunset 1820-30 by J.M.W Turner

#turner#art#alexturner#arcticmonkeys#polaris#painting#lathe#turning#love#woodworking#am#contemporaryart#salem#photography#salemkids#salemoregonsmallbusiness#salempartyrentals#adhdmom#adhdbusinessowners#salemor#downtownsalemoregon#salemoregon#salemoregonlife#oregonbusiness#salemismopo#keepsalemawesome#salemjumperrentals#workshop#oregonkidsinbusiness#keizeroregon

2 notes

·

View notes

Text

Making a bamboo cup 🎍🍵

3 notes

·

View notes

Text

After someone asked if I could do a whiskey barrel pen I decided to try out the concept. While this is not the wood from some oak barrel infused with alcohol and flavor - it is the first attempt at making a lower look like a barrel. It was fun and I plan to do it again with proper wood burning on the raised “bands” to really get that burnished difference.

3 notes

·

View notes

Text

I completed my mallet from the other day, got it glued up a couple days back and then turned the handle this afternoon. It ended up being a bit bigger than it really has any reason to be. I'll likely end up making a smaller version sometime in the future

It's a hard maple head with an oak handle.

Decided to put a single coat of shellac on, it really makes the grain stand out.

#woodworking#shop tools#hand tools#woodturning#lathe#turning#handmade#woodgrain#oak#maple#chonky#crafts#it seemed reasonable at the start#chonk#its pretty at least#make your own tools#carpentry#mallet#its good at hitting things

48 notes

·

View notes

Text

Everything You Should Know Regarding CNC Lathe Machines

There are several types of CNC machining processes available today. CNC turning Parts, for example, employ a helix route to cut through the material, whereas CNC milling uses rotary cutters to remove the extra material. All of these need the use of specialized machining tools for the workpiece to perform the appropriate function. A CNC lathe is one such essential piece of equipment. The lathe is regarded as the first metal-cutting machine.

Let's take a closer look at the operation, characteristics, and different types of CNC lathe machines.

Introduction

A lathe machine with CNC lathe parts is primarily used to shape the material into the required shape by eliminating extra material from a particular workpiece (generally cylindrical). A lathe is used to accomplish sophisticated operations such as knurling, deformation, metal spinning, woodturning, thermal spraying, metallurgy, and more, in addition to cutting and facing.

The manual lathe was invented by reformers in Ancient Egypt and Greece, according to machine historians. The European nation commonly used the two-person lathe variant, with the former rotating the workpiece (wood) and the latter cutting off the extra material with a single-point cutting tool. The modern lathe arrived with the Industrial Revolution; it was sophisticated, quick, and better!

How Does a CNC Lathe Machine Work?

A standard lathe consists of a bed, headstock, tailstock, chuck, tool turret, carriage, and a spindle for feeding purposes, as detailed in the previous section. The following steps describe how this machine works:

· First, a cylindrical workpiece is mounted to the chuck after the machine has been checked for operational flaws. Its location might change depending on the situation.

· Second Step: We now adjust the spindle to the desired speed, causing the chuck and workpiece to rotate. The spindle speed must be monitored closely since any variation might result in cutting mistakes. Examine if the workpiece is rotating correctly.

· Third, move the tool turret and carriage to place the cutting tool at the appropriate feed. Pay close attention to the feeding rate. Remove any superfluous metal by moving the carriage to obtain the completed result in CNC machining parts.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Components of CNC Lathe Machining

Lathe machines are commonly identified by a swing, the maximum working diameter that swings the lathe bed. A lathe swing is used to spin things that can be chopped, sanded, or drilled. Other lathe machine parameters include the length of the bed. Let’s examine the key components of a CNC Lathe Turning:

Headstock

CNC The lathe machine makes use of a headstock, which is an important component of…

View On WordPress

0 notes

Text

Mastering Precision Engineering with WIDMA’s Advanced Machinery

In the fast-paced world of manufacturing, precision and efficiency are paramount. WIDMA, a leading name in the industry, is pushing the envelope with its cutting-edge solutions. Among their standout innovations are the vertical turning lathe, the 5-axis turnmill, and special-purpose machines designed to meet the unique demands of modern engineering. Let's dive into how these machines are revolutionizing manufacturing processes and why they are essential for businesses aiming to stay ahead in the competitive landscape.

vertical turning lathe, the 5-axis turnmill, and special-purpose machines designed to meet the unique demands of modern engineering. Let's dive into how these machines are revolutionizing manufacturing processes and why they are essential for businesses aiming to stay ahead in the competitive landscape.

The Power of Vertical Turning Lathes

A vertical turning lathe (VTL) is a game-changer for many industries. Unlike traditional horizontal lathes, a VTL positions the workpiece vertically, which provides several advantages. The vertical orientation allows gravity to aid in the machining process, ensuring better stability and accuracy. This is particularly beneficial for handling large, heavy workpieces that might otherwise deflect under their own weight.

WIDMA's vertical turning lathes are renowned for their robustness and precision. They are equipped with advanced features such as automated tool changers and state-of-the-art control systems. These features not only enhance productivity but also reduce the margin for error, ensuring that every component produced meets the highest quality standards. Whether it's for aerospace, automotive, or heavy machinery manufacturing, WIDMA's VTLs deliver unparalleled performance.

The Versatility of 5-Axis Turnmills

In the realm of complex machining, the 5-axis turnmill is a true marvel. Combining the capabilities of a lathe and a milling machine, this versatile equipment can perform multiple operations in a single setup. This not only saves time but also significantly improves accuracy, as the workpiece does not need to be moved between different machines.

WIDMA's 5-axis turnmills are designed for precision and efficiency. These machines can handle intricate geometries and complex surfaces with ease, making them ideal for industries that require high precision, such as medical device manufacturing, aerospace, and high-tech engineering. With WIDMA's turnmills, manufacturers can achieve tighter tolerances and smoother finishes, enhancing the overall quality of their products.

Custom Solutions with Special-Purpose Machines

Every industry has unique needs, and off-the-shelf solutions often fall short. This is where (SPMs) come into play. SPMs are tailored to perform specific tasks, providing bespoke solutions that address particular manufacturing challenges.

WIDMA excels in designing and developing special-purpose machines that cater to diverse industrial requirements. Whether it's a machine for a unique assembly process or a device for a specific type of material handling, WIDMA's engineering team works closely with clients to create custom solutions. These machines are built with the latest technology, ensuring high efficiency, reliability, and productivity. The ability to customize means that businesses can optimize their operations, reduce downtime, and achieve better overall performance.

Why Choose WIDMA?

With the increasing demand for precision and efficiency in manufacturing, choosing the right machinery partner is crucial. WIDMA stands out for its commitment to innovation, quality, and customer satisfaction. Their machines are not only state-of-the-art but are also built to last, offering excellent return on investment.

WIDMA's expertise in vertical turning lathes, 5-axis turnmills, and special-purpose machines ensures that businesses have the tools they need to excel. By integrating these advanced machines into their operations, manufacturers can achieve higher precision, improved productivity, and greater competitiveness in their markets.

Conclusion

In the competitive world of manufacturing, having the right machinery is key to success. WIDMA's range of vertical turning lathes, 5-axis turnmills, and special-purpose machines provide the precision, efficiency, and customization that modern industries demand. Investing in WIDMA's advanced solutions means investing in the future of your business. Whether you’re looking to enhance quality, boost productivity, or tackle unique manufacturing challenges, WIDMA has the expertise and technology to help you succeed.

0 notes