#linear modules multi-axis systems

Text

1 note

·

View note

Text

0 notes

Text

IGUS "MOTION PLASTICS" LEADING IN DURABLE, LONG-LASTING DRIVE SYSTEMS

About Igus

Founded in 1964 and headquartered in Germany, Igus is a manufacturer of high-performance plastics and provides reliable, cost-effective solutions for various industries worldwide. With the advancement of modern technology, Igus' product lines have also been upgraded. The products are made from lubrication-free plastics, known for their durability and ability to operate in harsh environments.

To ensure quality before reaching customers, Igus commits to conducting rigorous tests in laboratories and providing the most accurate data.

Products and Solutions of Igus

Igus plastic products are used in various industries and can effectively replace traditional metal products. To optimize performance and lifespan for motion systems, consider the following product lines:

E-chain® and Chainflex®: Protect and extend the lifespan of cables in continuous motion applications, including:

E-chains® cable carriers: Protect cables and hoses from damage, extending their lifespan in moving applications.

Chainflex® cables: Bend-resistant cables, ensuring high performance and durability in harsh environments.

Readycable® pre-assembled cables: Pre-assembled cables, ready to use, saving installation time and costs.

Readychain® pre-assembled cable carrier systems: Pre-assembled solutions for cable carriers, simplifying the installation process.

Industrial cable connectors: High-quality connectors, ensuring safe and stable connections.

Dry-tech® Components: Enhance the performance and lifespan of mechanical devices, including:

Iglidur® plain bearings: Lubrication-free bearings, reducing friction and wear.

Igubal® spherical bearings and rod ends: Self-aligning components, wear-resistant and maintenance-free.

Drylin® linear guides: Lubrication-free linear guides, operating smoothly and precisely.

Drylin® electric cylinders: Precise and reliable motion solutions for automation applications.

Dryspin® lead screws: Wear-resistant lead screws, operating efficiently without lubrication.

Xiros® ball bearings: Lubrication-free ball bearings, suitable for harsh environments.

Iglidur® bar stock: Bar stock for machining custom parts, wear-resistant and heat-tolerant.

Iglidur® PRT slewing ring bearings: Lubrication-free slewing rings, high load capacity, and stable operation.

Conveyor rollers: Noise-reducing rollers, ensuring high performance and long lifespan.

Piston rings: Reducing friction and wear, enhancing the durability and reliability of piston systems.

Application of Igus Products in Industry

Igus plastic products are widely used across various industries. Notable fields include:

Automation: Multi-axis modules, easy to install and fast to integrate.

Automotive Manufacturing: Corrosion-resistant and lightweight.

Aerospace: Robust, fire-resistant, and reducing maintenance time.

Medical: Plain bearings used in X-ray robots, lab equipment, patient treatment chairs, hospital beds, and other parts.

Machinery Manufacturing: Lightweight plastic solutions.

Renewable Energy: High durability in all weather conditions, resistant to dirt and water.

Shipbuilding: Safe and maintenance-free cable carrier systems.

Food Industry: Cost-effective and compliant with FDA and EU standards.

TESFA – Strategic Partner of Igus in Vietnam

TESFA CO., LTD is proud to be Igus' partner in the Central region, offering advanced industrial products and solutions to meet diverse customer needs. TESFA is committed to providing genuine, high-quality products, prioritizing customer benefits. Additionally, our team is extensively trained and ready to support customers in finding suitable products for each industry. Contact us for advice and support for your needs or to request a product demonstration.

1 note

·

View note

Text

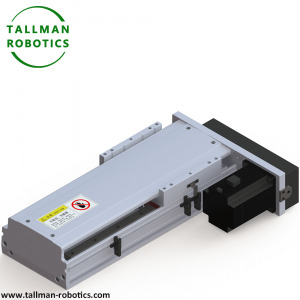

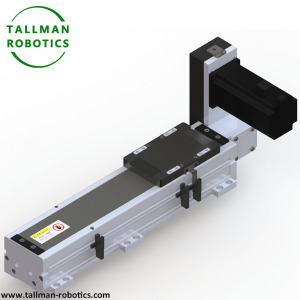

Linear Motor Actuators Will be Delivered to Germany

Linear Motor and Actuators from Tallman Robotics Will be Delivered to Germany.

Here are some details about linear servo motor modules:

1. Types of Linear servo Motors: Linear motor modules can be categorized into different types based on their design and configuration:

- Single-Axis Linear Motors: These actuators provide linear motion along a single axis. They are commonly used for applications that require linear positioning or pushing/pulling tasks.

-Multi-Axis Linear Motors: These actuators consist of multiple linear motors combined in a coordinated manner to provide motion in multiple axes. They are used in applications that require precise and synchronized movements in different directions, such as robotics or multi-axis machining.

- Planar Linear Motors: Planar linear motor modules are designed to provide motion in a two-dimensional plane. They can offer linear motion in both X and Y axes, making them suitable for applications such as gantry systems or XY tables.

- Curved Linear servo Motors: Curved linear motor modules are designed to provide linear motion along a curved path. They are used in applications that require motion along curved surfaces or tracks, such as in packaging or material handling systems.

2. Feedback Systems: Linear motor actuators often incorporate feedback systems to provide accurate position control and feedback information. These feedback systems can include optical encoders, linear scales, or Hall effect sensors. The feedback signals are used by the control system to ensure precise positioning and closed-loop control of the actuator.

3. Control Options: Linear motor actuators can be controlled in various ways depending on the application requirements. They can be controlled manually using switches or buttons, or they can be integrated into automated control systems. Automated control options include using programmable logic controllers (PLCs), motion controllers, or computer-based control systems. These control systems allow for precise control of motion parameters such as speed, acceleration, deceleration, and position.

4. Environmental Considerations: Linear motors can be designed to meet specific environmental requirements. For example, they can be built to withstand harsh conditions such as extreme temperatures, humidity, or exposure to dust or chemicals. This makes them suitable for applications in industries such as automotive, aerospace, or manufacturing where environmental conditions can be challenging.

5. Integration with Other Systems: Linear motors can be easily integrated with other systems or components to create complete motion solutions. They can be combined with mechanical components such as guide rails, bearings, or couplings to ensure smooth and precise linear motion. Additionally, they can be integrated with control interfaces, communication protocols, or network systems to enable seamless integration into larger automation systems.

6. Safety Considerations: Safety features can be incorporated into linear motor actuators to ensure safe operation. These features may include emergency stop buttons, limit switches to prevent overtravel, position sensors for accurate positioning, or torque sensing to detect abnormal loads or obstructions.

7. Cost Considerations: The cost of linear motors can vary depending on factors such as the type of linear motor used, the size and load capacity of the actuator, the level of precision required, and additional features or customization. It is essential to consider the specific application requirements and balance them with the associated costs to determine the most suitable linear motor actuator solution.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data.

Read the full article

#ElectricLinearActuators#LinearDCmotors#Linearmagneticmotorsandactuators#LinearMotorActuator#LinearMotorActuators#Linearmotorsingleaxisrobots#LinearMotors&Actuators#motorisedlinearactuator#StepperMotorLinearActuators#TubularLinearMotors

0 notes

Text

Linear Module

Continuing the decades-long tradition of high-quality, innovative and precise linear motion products, VXO linear guideways are available in a variety of sizes and styles with features that can be matched to your exact application requirements. VXO offers a variety of linear guide rail series, each with different sizes, load capacity, precision and more other option. The optimized U-rail not only guides the movement of the slider being driven by the ballscrew, but also can be used as a structural component when assembled into a multi-axis motion system.

Types of Linear Module

when choosing an single axis based on different conditions and restrictions, you may refer to the following selection process: user requirements, demand for precision, configuration motor selection, motor load calculation, operation analysis.

Benefits Of Linear Module

An integrated system

Easy installation and maintenance

Compact and lightweight

High accuracy

High stiffness

Complete line of accessories

The structure of rail is analyzed by FEA to get the best rigidity and weight. The analysis results are show as the right figures

Features Of Linear Module

Integrated drive motor for positioning

High and medium speed solutions

Maximum accuracy thanks to precision rails

Various motor versions and direct drives

Applications Of Linear Module

The company’s linear slide module products are widely used in automated production equipment, dispensing, painting, welding, packaging, handling, inkjet, laser, engraving machine, robot, photographic slide, electric slide, scientific research, functional demonstration, etc., Whatever the project is, we minimize your engineering effort and take care of it for you.

0 notes

Text

Gx works2 network parameters

GX WORKS2 NETWORK PARAMETERS MANUALS

GX WORKS2 NETWORK PARAMETERS DRIVER

GX WORKS2 NETWORK PARAMETERS MANUAL

GX WORKS2 NETWORK PARAMETERS SOFTWARE

GX WORKS2 NETWORK PARAMETERS PC

If that selection is 2 than see if any of the two boxes are checked on I/O Sharing When Using Multiple CPUs. Top left selection will tell you if it is set up as a Multiple CPU set up. So under PLC parameters click the Multiple CPU Setting Tab Then lets check some of the multiple CPU settings. So go parameters then double click PLC Parameters.įirst look at the I/O assignment tab you can set any start address for a card so lets make sure Y1000 is not start for the output card on the rack. I guess how do you know it exists at all? Like what is your reason for finding it? Is it in a drawing or in the keyence vt3-s12 set up?Īlso what do the comments say for these devices that may give some insight to where they are from. If the goal is to find out where Y1023 is coming from there is one more area I know to check, but if you go find/replace then click device list it should show up in there.

GX WORKS2 NETWORK PARAMETERS SOFTWARE

So I have looked through the software and found some stuff on the Multiple CPU setting,

GX WORKS2 NETWORK PARAMETERS MANUALS

I will get you some manuals that will probably help more than me rambling. So this is most likely moving the input status at X1000 over a network to the other PLC. X is an input and B is a link relay to another device with a CPU. So this means BMOV K4X1000 K4B500 K9 is moving X1000 through X1008 into B500 through B508. The last value is how many words to move in the block. So to group them together into words of any bit length you can designate them in the command with a K value.Īn easy way to find how many bits in that groups is multiply it by four.īMOV is a block move so you cant use single bits you have to group it into words. So the K4 thing is a little more complicated. If you have done much PLC stuff it should start looking familiar from there. Most the tools in the Find/Replace menu could help you with finding this. Typing the "label" in the Device/Label box and pressing find will show you all its instances. Clicking Cross Reference should pop up a menu in the bottom of the screen. You can click Find/Replace in the top tool bar. There are a few different ways to find a device or tag. (the command pulse of the open collector positioning module is highest 200kpps.Those are not the same tag those are separate Devices. Transmission distance of up to 10 meters, to achieve high speed and high precision control QJ71FL71-T-F01. 4 axes, open collector output type.Ģ axis /4 axis /3 axis linear interpolation.īased on the usee of open collector outputs and differential drive output type 2 types QJ71FL71-T-F01. Therefore, it is not necessary to spend time to manage the backup data, but also can shorten the recovery time of the system shutdown. Restore the system by using the data storage card in advance MITSUBISHI QJ71FL71-T-F01. In the event of a CPU failure, after the replacement of CPU, can be a simple operation, Through regular backup, can be the latest parameters, procedures, etc. With a simple operation, you can back up all the data in the CPU to the memory card. (the command pulse of the open collector positioning module is highest 200kpps.) Transmission distance of up to 10 meters, to achieve high speed and high precision control MITSUBISHI QJ71FL71-T-F01.

GX WORKS2 NETWORK PARAMETERS DRIVER

To speed up the speed of positioning control to start processing MITSUBISHI QJ71FL71-T-F01.īased on the use of open collector outputs and differential drive output type 2 types.ĭifferential driver output type positioning module can transmit high speed instruction pulse (up to 4Mpps) to the servo amplifier reliably, Plus deceleration smooth, speed change subtle. Perfect match with stepper motor control. Ideal solution for simple multi axis positioning. Therefore, this connection method and the use of USB, can easily communicate with the CPU,Įven the operators are not familiar with the network settings can easily establish a connection. And there is no need to select the cable, the straight line and the cross line can be used. No need to carry out the IP address settings. Programming tools (Works2 GX, Developer GX) and CPU direct connection (1 to 1), In order to provide support for improving production efficiency and equipment value.Įasy connection programming tool via ethernet. Real time data analysis using user applications, Realize the previous communication method can not achieve the detailed control of data transmission,

GX WORKS2 NETWORK PARAMETERS PC

The high accuracy data that can be synchronized with the sequential scanning to the user program on the PC can be transmitted through the Ethernet. Real time transmission control data, to improve the production efficiency and the value of the equipment to provide support for the high-speed data communication module. MITSUBISHI QJ71FL71-T-F01 Product information and technical parameters:

GX WORKS2 NETWORK PARAMETERS MANUAL

MITSUBISHI QJ71FL71-T-F01 Manual And Instructions

1 note

·

View note

Text

8X8 Armored Vehicle Market – Industry Trends and Forecast to 2026

8X8 Armored Vehicle Market By Product (Armored Personnel Carrier, Infantry Fighting Vehicle, Light Protected Vehicle, Main Battle Tank, Mine-Resistant Ambush Protected (MRAP) Vehicle, Tactical Vehicle, Others), Application (Defense, Homeland Security, Security), Geography (North America, Europe, Asia-Pacific, South America, Middle East and Africa) – Industry Trends and Forecast to 2026

Market Definition: 8X8 Armored Vehicle Market

Armoured fighting vehicle are those vehicles which are usually protected by armour and usually have defensive and offensive capabilities. Infantry fighting vehicle, light protected vehicle, armored personnel carrier and others are some of the common product of the armoured fighting vehicle. These vehicles usually consist of mounted machines guns and are widely used for application such as defense, homeland security and others. Increasing criminal and terrorism worldwide is the factor fuelling the growth of this market.

Request-a-sample@https://www.databridgemarketresearch.com/request-a-sample/?dbmr=-8x8-armored-vehicle-market

8X8 Armored Vehicle Market Size, Status and Forecast 2026

8X8 Armored Vehicle Market Overview

8X8 Armored Vehicle Market Manufacturers Profiles

8X8 Armored Vehicle Market Sales, Revenue, Market Share and Competition by Manufacturer

8X8 Armored Vehicle Market Analysis by Regions

8X8 Armored Vehicle Market by Countries

8X8 Armored Vehicle Market Segment by Type

8X8 Armored Vehicle Market Segment by Application

8X8 Armored Vehicle MarketForecast

Sales Channel, Distributors, Traders and Dealers

Research Findings and Conclusion

Appendixes

Get Detailed Toc @https://www.databridgemarketresearch.com/toc/?dbmr=-8x8-armored-vehicle-market

Market Analysis: 8X8 Armored Vehicle Market

8X8 armored vehicle market is set to witness a steady CAGR in the forecast period of 2019- 2026. The report contains data of the base year 2018 and historic year 2017. Increasing terrorist activities and rising focus in homeland security department are the factor for the growth of this market.

Market Drivers:

Rising insurgencies is the factor driving market

Technological advancement and development in armored vehicle will also propel market

Increasing militarization of law enforcement agencies is driving market

Growing awareness associated with the safety and security among population will also drive market

Market Restraints:

High investment cost will also restrain market

Rising usage of unmanned vehicles will also hamper market

Decrease in the national defense budget will also restrict the growth

8X8 Armored Market Segmentation:

By Product

Armored Personnel Carrier

Infantry Fighting Vehicle

Light Protected Vehicle

Main Battle Tank

Mine-Resistant Ambush Protected (MRAP) Vehicle

Tactical Vehicle

Others

By Application

Defense

Homeland Security

Security

By Geography

North America

U.S.

Canada

Mexico

Europe

Germany

Italy

U.K.

France

Spain

Netherlands

Belgium

Switzerland

Turkey

Russia

Rest of Europe

Asia-Pacific

Japan

China

India

South Korea

Australia

Singapore

Malaysia

Thailand

Indonesia

Philippines

Rest of Asia-Pacific

South America

Brazil

Argentina

Rest of South America

Middle East and Africa

Saudi Arabia

UAE

South Africa

Egypt

Israel

Rest of Middle East and Africa

Key Developments in the Market:

In February 2019, Paramount Group announced the launch of their armoured personnel carrier Mbombe 4 which is specially designed for the local manufacturing within countries. This new Mbombe 4 is available in 4 X4, 6X 6 and 8 X8 IFVs. This new launch will increase the defence capabilities of the country. It also provides excellent mobility, stability and reliability.

In February 2019, Calidus announced the launch of their new Wahash 8×8 armoured vehicle which is specially designed for high agility and mobility. It is very suitable for surveillance and other security purposes. It has the ability to work in temperature rom -30- 55 degree celsus. It is specially designed to provide excellent security so that they can meet th need and requirement of the people.

Competitive Analysis:

8X8 armored vehicle market is highly fragmented and the major players have used various strategies such as new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others to increase their footprints in this market. The report includes market shares of 8X8 armored vehicle market for , Europe, North America, Asia-Pacific, South America and Middle East & Africa.

Key Market Competitors:

Few of the major competitors currently working in the 8X8 armored vehicle market are BAE Systems, General Dynamics European Land Systems, IVECO DEFENCE VEHICLES - A CNH INDUSTRIAL COMPANY, Lockheed Martin Corporation, Oshkosh Defense, LLC., Rheinmetall AG, Patria, TATRA TRUCKS A.S., INKAS Armored Vehicle Manufacturing, FNSS Defence Systems, EXCALIBUR ARMY spol. s r.o., Yugoimport SDPR J.P., Tata Motors., Streit Group, OCCAR-EA, MITSUBISHI HEAVY INDUSTRIES, LTD.,ĐĐ Specijalna vozila d.d., Navistar Defense, LLC., Horstman Defence Systems Ltd and others.

Speak-to-analyst@https://www.databridgemarketresearch.com/speak-to-analyst/?dbmr=-8x8-armored-vehicle-market

Research Methodology: 8X8 Armored Vehicle Market

Data collection and base year analysis is done using data collection modules with large sample sizes. The market data is analysed and forecasted using market statistical and coherent models. Also market share analysis and key trend analysis are the major success factors in the market report. To know more please request an analyst call or can drop down your enquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market, and primary (industry expert) validation. Apart from this, other data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Company Market Share Analysis, Standards of Measurement, Top to Bottom Analysis and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Key Insights in the report:

Complete and distinct analysis of the market drivers and restraints

Key market players involved in this industry

Detailed analysis of the market segmentation

Competitive analysis of the key players involved

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Related Report

Automotive Helicol Coil Spring Market

Automotive Multi Axis Positions Sensors Market

Automotive Linear Positions Sensors Market

0 notes

Text

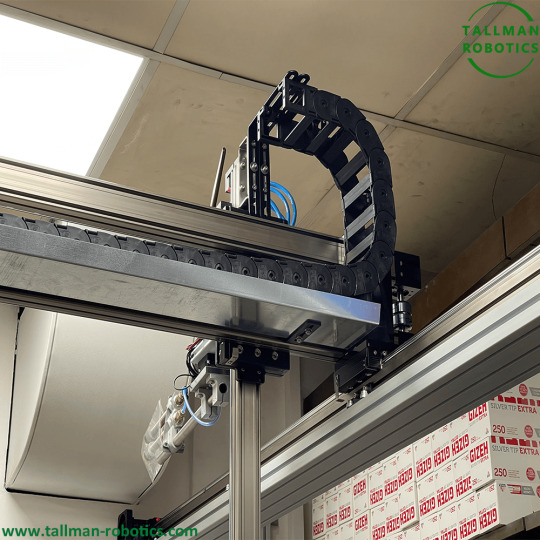

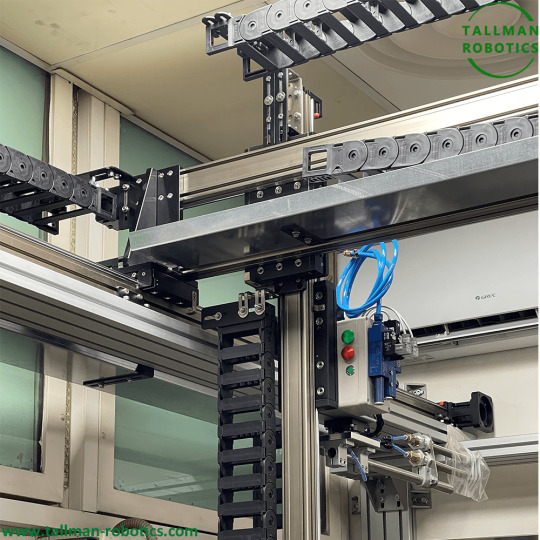

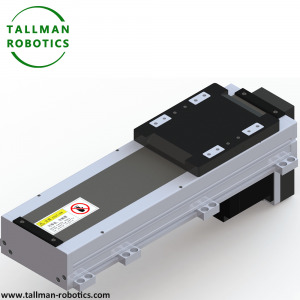

Multi Axis Linear Systems Are Working in Italy Client's Stores

Multi-axis linear systems, also known as multi-axis linear stages or multi-axis positioning systems, are mechanical systems designed to provide precise and controlled movement in multiple linear directions. These systems are commonly used in various applications where precise positioning and motion control are required, such as industrial automation, manufacturing, semiconductor manufacturing, microscopy, and research.

A multi-axis linear module typically consists of multiple linear stages or actuators that are combined and coordinated to enable movement in two or more linear axes. These axes can be orthogonal (perpendicular) to each other or arranged in any other desired configuration. The number of axes can vary depending on the specific application requirements.

Each linear stage in a multi-axis system is equipped with a motor or actuator that generates the necessary force to move the stage along its linear path. The stages are usually guided by precision linear bearings or linear guides to ensure smooth and accurate motion. The stages may also incorporate position feedback sensors, such as encoders, to provide feedback on the position and enable closed-loop control.

To achieve coordinated motion in multiple axes, a multi-axis linear modules relies on a control system. The control system coordinates the movement of each stage, ensuring synchronized motion and accurate positioning. It receives input commands or trajectories and translates them into appropriate control signals for each axis. The control system may include a motion controller, servo drives, and software algorithms for trajectory planning and motion synchronization.

Multi-axis linear systems offer several advantages, including:

1. Precise positioning: These systems provide high-precision positioning capability, allowing for accurate alignment and motion control.

2. Flexibility: Multi-axis systems can be customized and configured to meet specific application requirements, such as the number of axes, travel range, load capacity, and motion profiles.

3. Compact design: The integration of multiple axes into a single system results in a compact and space-saving design, making them suitable for applications with limited space.

4. Increased throughput: By enabling simultaneous motion in multiple axes, multi-axis systems can improve overall productivity and throughput in automated processes.

5. Versatility: These systems can be used in various applications, including pick-and-place operations, assembly, inspection, testing, and scanning.

It's important to note that the specific characteristics and capabilities of multi-axis linear modules can vary depending on the manufacturer, design, and intended application. Therefore, it's recommended to consult with system suppliers or experts to determine the most suitable system for a particular use case.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data.

Read the full article

#Cartesianmulti-axissystems#linearsystems#MiniatureMulti-AxisSystems#Multi-Axis(XY)LinearActuator#multi-axislinearstages#Multi-AxisPositioningSystems#Multi-AxisSystems#Multi-axissystemswithlinearmotors

0 notes

Text

Evaluative Report, Consolidating Practices II

Joseph Horton

18032218

26/5/19

Progressing into the second chapter of this work I have been looking to develop the thinking around its visual construct, away from the original research into post war American documentary and the likes of Soth, Adams and Evans. I wanted to acknowledge the works cultural identity and so I began to look into the practices of European documentary photographers and their conceptual counter parts such as Broomberg and Chanarin, Thomas Struth and the history of Dutch documentary photography with regard to Hans Aarsman and Theo Baart. This progression in visual research helped develop my perspective on the environment I was looking at in regard to its cultural formation and the complexities that complete it. As much as I am fascinated by the American formation of documentary the relationship between the work and the landscape was not applicable toward a British/European dialect. The European artists were working with a European voice which felt much more in key with my own subject matter, therefore my thinking since has been toward ideas of social constructs, landscape identity as well as social and anthropological thinking toward landscape. These views reflect more the cultural identity found within the area as unlike the American landscapes these spaces are a web of overlapping perspectives each relating to and sharing identity. What was originally a narrow focus has now become much broader through accepting the complex relationships found within pockets of the British Isles. Taking this further I am now interested in how the complexity of social identity operates to form current thoughts of modern rurality and the idyll. Stepping further from the formulaic notion set by Cloke (1977) in ‘An Index of Rurality for England and Wales’ the work will examine other theories of landscape thought in order to bridge the seemingly separate worlds of pastoral environments, suburban living and the idea of non-places (Marc Augé Introduction to an Anthropology of Supermodernity, 1995). These ideas of structuralism/post-structuralism give room for the work to incorporate elements which may not initially be thought of as connecting. By placing seemingly separate perspectives together I hope to give the work space for ambiguity and serendipity in the attempt to lead the viewer away from preconceived formations of rural environments. I believe that without counterbalance the work would fall into stereotypical accounts of what we believe to be true about the countryside and the nuance of the environments would be lost.

Attempting to build a narrative around something so broad and engulfing is a perplexing task but what is breathing new life into it is the thought of working in multi-faceted ways that connect on levels which need to be felt as well as thought. The original ideas around the work were becoming stuffy and muddied by personal connections to place that drew romantic and nostalgic notions toward it, these were then interpreted in a way (pier review) that coincided with pre-conceived ideas toward agricultural environments. By involving juxtaposition in the work it will allow for the gaps to be filled by the viewer rather than the photographer an idea that is in line with contemporary thinking in documentary photography but still relates to some form of linear formation. This way of working also allows for a personal style to build, as many of my interests had seemed to have shown to conflict when beginning this project. However, by allowing my intuition to lead the work I have been able to draw parallels around my thinking. Finding structure in the chaos and analysing their relationships. The thematic nature of the work then has continued to form around the border of England/Wales, but developed further to thinking more conceptually around the idea of the border, allowing for continued fascination of the frontier and these areas of unstudied environments (originally termed as black spots on the map in part I). These are now seen in new areas such as the road which borders industrial south wales with rural mid Wales (A456) and a continued look at historically rural living along the English/welsh border. Adjoining these physical barriers are areas which blur ideas of what is and isn’t rural, e.g. modern suburbia against the untamed, the slag heaps of south wales and rolling hills of pastoral land. Their elemental nature connecting via border but still remaining seemingly culturally separate. The idea therefore is that by looking at the spaces between what is known you can formulate a better understanding of its ‘true’ identity and as such talk collectively about an area. In the example below fig (a) shows us the under passage of motorway, with its cathedral like pillars and rib-vaulted ceiling and beside fig (b) we see the remnants of a bible and prayer book. The prayer book when places beside fig (a) can be seen as resembling the pink lid strewn onto the floor.

Fig (a) Fig (b)

This example of pairing indicates the current thinking in the visualisation of the work and narrative. By taking elements and bringing them together I hope to convey both the similarities and ambiguity found in the landscapes which branch off this axis (the country and industrial border), their location being relatively irrelevant. This style of working I hope bridges to some extent the gap between my interests in the contemporary American style of documentary and my hope to embody a more European stance in subject matter. When applied to a formal construction the work then appears as continuous series of relationships, however this relies heavily on the continuation of new work. As with the nature of the work it is a steady progression and only now with the structure of my axis does it feel manageable.

Another way of looking at the work would be to draw it into segments e.g; roads, church interiors, hill walkers. Much like the methodology found in the ‘Index of Rurality’, you can then build relationships through structural analysis; however, that may destroy an essence of poetry in the work. But what would be interesting in doing so would be that you’d be hinting toward a classification system that, by nature, is a comment on our perceptions of place and cultural constructs. This technique has been used to success in the book ‘Field studies’ by Stephen Gill. Where he pulls together somewhat abstract stories of mundane scenes, ‘including cash points, lost people, the back of advertising billboards and people traveling on the London to Southend train’. A technique which adds weight to the subject matter and humanises the stories by building more detailed pictures of each element, rather than fleeting passes. Either of these techniques whether it be structuralised or image informed relationships the work will rely heavily on linear constructs which suit themselves well to book based media. The works final formation then will be a book which allows for the attention to detail in the imagery and pace created by page.

It is important to acknowledge the projects status in its completion as, as it stands, the project is still in construction in terms of imagery. However, after the completion of this module its conceptual structure and visual identity is much more solidified and I feel confident in its continuation. The following steps will be to continue to acknowledge and investigate areas which resonate with me in describing elements of ruralityand borderand their intended subjects thus far: people at reservoirs, walkers on hills/slag heaps south wales (near to the A465 border road), rural homesteads, housing developments and found objects. It is also important that whilst I explore these elements I am vigilant to other signifiers which could be compiled. The projects progress has been slow but I feel that the nature of the subject matter has been difficult to pin down due to its complexity but the next step will be taking lead via the imagery and the photographic strengths of an area.

In its broader context the work will be an investigation into contemporary culture outside of urban environments. In line with the thinking found in anthropological papers noted in my critical journal, notably What is Ruralityby Nicolette Rousseau - ‘Study of rurality is important, not least to counteract the urban bias of research and political power in Britain today’. In its conceptual form the work could be said to tackle contemporary themes of national identity and border which in the current political climate is a topic of on-going debate. It will also serve as reflection toward our interests in the environment and how we perceive places as beautiful and idyllic, a reaction to environmental issues currently being discussed. These metaphorical relationships coincide with the conceptual structure of the work but are not intended as its figurative backbone as I hope the work to carry a subtlety which promotes more of a humanistic response.

0 notes

Text

Новости сайта #ENGINEERING - 工程

New Post has been published on http://engineer.city/mechanics-drive-technology-and-control-in-one/

Mechanics, drive technology and control in one

Doris Knauer presents a multi-axis motion solution with high precision and dynamics

Precision, multi-axis positioning solutions that are intended to work in an industrial environment must be viewed as an overall system, because their performance does not only depend on the mechanics and the type of drive selected, but also on their control.

An industry-capable motion controller must synchronise the individual axes, move according to multidimensional motion profiles, respond quickly to changing servo-control parameters and allow convenient integration into the higher-level automation environment.

Therefore PI has acquired the majority shares in ACS Motion Control, a w leading developer and manufacturer of modular motion controllers for multi-axis drive systems.

This was an important requirement for enabling PI to supply customised complete systems for industrial applications with the highest demands on precision and dynamics and also add its extensive experience in high-end projects for industrial applications intended to combine precision, productivity, and reliability all over the world.

High-performance motion controllers

The ACS motion controllers are also EtherCAT masters, responsible for managing all the network nodes of the EtherCAT network.

The controllers are modular by design, interchangeable, scalable and communicate with the host PC of the machines via various Ethernet protocols. Universal control module (UCM) drives are responsible for the servo control.

All current, velocity and position loops are processed at a frequency of 20kHz regardless of the numbers of axes, which is a pre-requisite for achieving high synchronisation and dynamics with minimal errors. In conjunction with the linear and rotational axes, parallel kinematics and planar scanners, the controllers are part of a customer-specific customer-selectable complete system from PI.

The motion controller systems optimise standstill jitter and settle times by using intelligent control algorithms, such as ServoBoost, as well as by profile shaping for example, which prevents vibration. Proprietary technology such as NanoPWM and the DRBoost feature makes it possible to achieve a dynamic range higher than 100,000:1 and as a result to achieve nanometre level of tracking errors while scanning a wafer and standstill jitter at a sub-nanometre level for applications in metrology.

The integrated 3-DOF compensation of positioning errors and yaw compensation for gantry solutions make it possible to realise applications with the highest demands on accuracy.

Real-world application

An example of this is the air-bearing two-axis linear stage that was developed for wafer inspection. Over the entire travel range of 500 x 1,000mm, it operates with a straightness/flatness of ±10nm per 10mm travel range.

To achieve exact right-angled alignment, the motion controller controls axis yaw via the X axis. The controller also dampens oscillation actively using the profile-shaping algorithm.

The air-bearing planar stage, which is moved by magnetic direct drives, is modular, which means that the strokes are scalable and, depending on the positioning accuracy required, allows the installation of various different encoders.

The stage carries loads of up to 24.5kg. The wear-free air bearing not only ensures extremely level motion, but also a long lifetime. The EtherCat interface of the controller also allows the position system to be easily integrated into a higher-level control environment.

Doris Knauer is with PI.

Tags:

design

pi

ACS Motion Control

Images:

Categories:

Design Engineer

[9] Instrumentation

Source: engineerlive.com

0 notes

Text

Hydraulic Press Brake for Sale

Hydraulic Press Brake machine belong to the universal machine tools, mainly used for metal sheet and plate bending, by both sides is two pieces of C type steel plate and work table with horizontal beam assembly into a three-dimensional structure. The slider suspension on the oil cylinder, powered by oil cylinder movement up and down for bending momentum.

The bending objects are carbon steel, galvanized sheet, stainless steel, aluminum plate, copper plate, alloy plate and so on.

The hydraulic press brake machine are widely used in automobile manufacturing, nuclear industry, environmental protection, construction, shipbuilding, war industry, electric pole, aerospace, petroleum equipment manufacturing, machinery manufacturing, steel structure, decoration, hardware and other industries.

The general press brake bending machine is divided into manual bending machine, hydraulic bending machine and CNC bending machine. The manual bending machine is divided into mechanical manual bending machine and electric manual bending machine. Here at Gilde, we focus on the production of hydraulic press brake, which can be also divided in NC and CNC types. The hydraulic bending machine can be also divided into two modes: torsion shaft synchronization and electro-hydraulic synchronization.

The press brake made by Gilde is made of high qualified steel plate, with whole structure floor boring and milling. Overall frame annealing, mechanical parts are made by FANUC CNC machining center which have excellent production technology. Machine configuration by Siemens motor, rexroth valve , schneider electric and HWIN ball screw and many other famous brand components.

WC67K NC Hydraulic Plate Press Brake With E21 Controller

1. 8- axis Dutch Delem DA66T CNC controller.

2. Full synchronization of 2 cylinders(Y1, Y1) with proportional hydraulic valve system and constant monitoring by CNC system to +/- 0.01mm accuracy.

3. Linear guide rail and ball screw accuracy of 0.01mm(HIWIN, TAIWAN).

4. Steel mono-block construction.

5. fully closed-loop electro-hydraulic servo synchronously controls the system.

6. Standard electrics from Schneider, France.

7. Standard oil tube connectors from EMB Germany.

8. Standard valves and oil pump from Bosch Rexroth Germany.

9.Standard main motor from Siemens Germany.

10. Hydraulic and electrical overload protection.

11. Light guards ensure the safety of operators during operation.

12. 8+1 axes:Y1,Y2,X1,X2,Z1,Z2,R1,R1 and V axis.

Dutch Delem DA56S Controller:

·10,4” LCD broadband TFT color display

·2D graphical programming

·Bend sequence determination

·Developed length calculation

·Tool/material/product library, 30 upper dies, 60 lower dies

·USB keyboard and mouse interface, power-off memory, integrated valve amplifier

·Support multiple language Settings

·Automatically calculate workbench deflection compensation value

·Angle corrections and material stretching database

·Delem Modusys compatibility (module scalability and adaptability)

·The basic machine control functions are Y1 + Y2 + X + R –axis. A second back gauge axis can also be used as Z1 + Z2+ X1 + X2 or R2 axis.

DELEM DA66T controller:

WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s System

1. Dutch Delem DA41S CNC controller.

2. Servo drive and control positioning of 2 axes(X, Y).

3. Linear guide rail and ball screw accuracy of 0.01mm (HIWIN,TAIWAN).

4. Steel mono-block construction.

5. Adjustable stop fingers.

6. Standard electrics from Schneider, France.

7. Standard oil tube connectors from EMB Germany.

8. Standard valves and oil pump from Bosch Rexroth Germany.

9. Standard main motor from Siemens Germany.

10. Hydraulic and electrical overload protection.

11. Light guards ensure the safety of operators during operation.

Holland Delem DA41S Controller

Using servo control and servo drive.

4.7”high bright LCD screen with multi-nation language interface.

Angle programming and setting die parameters.

Die parameter setting, bending angle programming.

100 programs ate stored, and 25 operations in each program.

The escaped material is programmable, the processing quantity is accountable, there is memory to power off, and conversion between metric system and inches system.

MB8 3+1 axis CNC Hydraulic Servo Press Brake Machine -DELEM DA52S

MB8 series steel sheet servo press brake bending machine with Delem DA52S CNC system

3+1 axis driven by servo motors:Y1,Y2,X and V axis.

Main motor:Siemens Germany

Valve:Bosch Rexroth Germany

Oil pump:Sunny America

Oil tube connectors:EMB Germany

Electrics:Schneider,France

MB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S System

1. 4- axis Dutch Delem DA56S CNC controller.

2. Full synchronization of 2 cylinders(Y1, Y1) with proportional hydraulic valve system and constant monitoring by CNC system to +/- 0.01mm accuracy.

3. Linear guide rail and ball screw accuracy of 0.01mm(HIWIN, TAIWAN).

4. Steel mono-block construction.

5. fully closed-loop electro-hydraulic servo synchronously controls the system.

6. Standard electrics from Schneider, France.

7. Standard oil tube connectors from EMB Germany.

8. Standard valves and oil pump from Bosch Rexroth Germany.

9. Standard main motor from Siemens Germany.

10. Hydraulic and electrical overload protection.

11. Light guards ensure the safety of operators during operation.

Dutch Delem DA56S Controller:

·10,4” LCD broadband TFT color display

·2D graphical programming

·Bend sequence determination

·Developed length calculation

·Tool/material/product library, 30 upper dies, 60 lower dies

·USB keyboard and mouse interface, power-off memory, integrated valve amplifier

·Support multiple language Settings

·Automatically calculate workbench deflection compensation value

·Angle corrections and material stretching database

·Delem Modulus compatibility (module scalability and adaptability)

·The basic machine control functions are Y1 + Y2 + X + R –axis. A second back gauge axis can also be used as Z1 + Z2+ X1 + X2 or R2 axis.

MB8 CNC 8+1 Axis Hydraulic Press Brake Machine With DA66T System

1. 8- axis Dutch Delem DA66T CNC controller.

2. Full synchronization of 2 cylinders(Y1, Y1) with proportional hydraulic valve system and constant monitoring by CNC system to +/- 0.01mm accuracy.

3. Linear guide rail and ball screw accuracy of 0.01mm(HIWIN, TAIWAN).

4. Steel mono-block construction.

5. fully closed-loop electro-hydraulic servo synchronously controls the system.

6. Standard electrics from Schneider, France.

7. Standard oil tube connectors from EMB Germany.

8. Standard valves and oil pump from Bosch Rexroth Germany.

9.Standard main motor from Siemens Germany.

10. Hydraulic and electrical overload protection.

11. Light guards ensure the safety of operators during operation.

12. 8+1 axes:Y1,Y2,X1,X2,Z1,Z2,R1,R1 and V axis.

Dutch Delem DA56S Controller:

·10,4” LCD broadband TFT color display

·2D graphical programming

·Bend sequence determination

·Developed length calculation

·Tool/material/product library, 30 upper dies, 60 lower dies

·USB keyboard and mouse interface, power-off memory, integrated valve amplifier

·Support multiple language Settings

·Automatically calculate workbench deflection compensation value

·Angle corrections and material stretching database

·Delem Modusys compatibility (module scalability and adaptability)

·The basic machine control functions are Y1 + Y2 + X + R –axis. A second back gauge axis can also be used as Z1 + Z2+ X1 + X2 or R2 axis.

DELEM DA66T controller:

Hydraulic Press Brake For Sale From China's Largest Sheet Metal Fabrication Machines Production Enterprise - GILDE, Welcome to Place Your Order!

Contacts:

Manufacturers: Maanshan Gilde CNC Machine Tool Co., Ltd

Email:[email protected]

Web::http://www.gldma.com/

TELL: +86-18298235825(whatsapp)

0 notes

Text

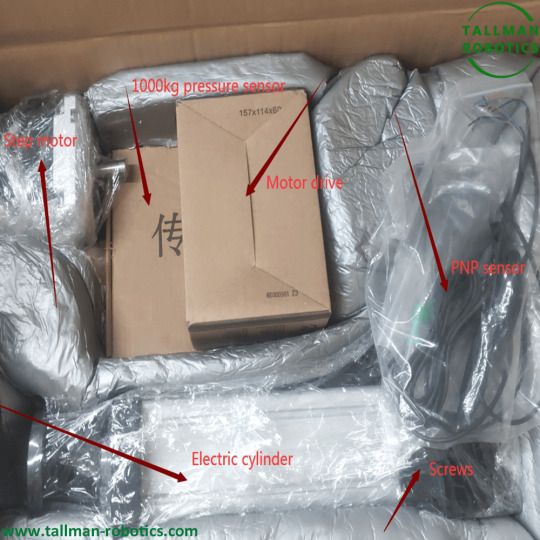

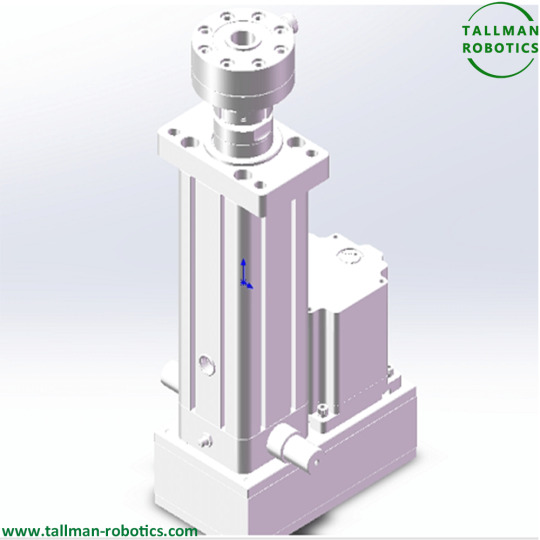

Linear Electric Cylinders will be Delivered to USA

Linear electric cylinders are finished for delivery to client from USA. You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

Today, I'm going to share an interesting product from Tallman Robotics Limited.

But first of all, before talk about Linear Electric Cylinders, I'd like to briefly introduce Tallman Robotics Limited, which is a one-stop linear motion system solution service provider, and a R&D, professional manufacturer. We serve global clients with linear modules, intelligent electric grippers, hollow rotary tables, automation components and precision motion system.

Respectively speaking,

Linear modules include single axis linear modules, multi axis linear modules, screw driven type, belt driven type, semi-closed type, fully-closed type, and water-proof type.

Intelligent electric grippers consist of 2-finger Adaptive Electric Robotic Grippers, 3-Jaw Self-Centering Electric Grippers, long stroke electric grippers, rotating electric grippers, Freely Programmable Electric Grippers etc.

As regards to Hollow rotary tables, there are large aperture hollow rotary tables, heavy duty hollow rotary tables, Right Angle Hollow Indexing Table, reinforced hollow rotary tables.

And then, now let's get down to this linear electric cylinders.

Thrust : 4.5-6KN

lead 5mm, stroke 100mm, with 2 magnetic switches PNP type.

1000kg pressure sensor

Step motor and drive

Electric cylinder is a modular product with integrated design of servo motor and lead screw. it can convert rotary motion of the motor into linear motion, and at the same time convert the best advantages of the servo motor, accurate rotating speed control, accurate rotating number control, accurate torque control into - accurate speed control, accurate position control, accurate force control, this can achieve high-precision linear motion. Linear electric cylinder integrates servo motor, servo driver, high-precision ball screw or planetary ball screw in module design and other technologies in compact structure.

Finally, Let's me introduce the application of Linear Electric Cylinders:

- Entertainment industry: robot arms and joints, dynamic seats

- Military industry: simulation aircraft, Analog simulation

- Automobile industry: press mounting machine, testing instrument

4.General Industry: food machinery, ceramic machinery, welding machinery, lifting platform

For further technical information, please feel free to contact us by e-mail or visit our website www.tallman-robotics.com.

Read the full article

0 notes

Text

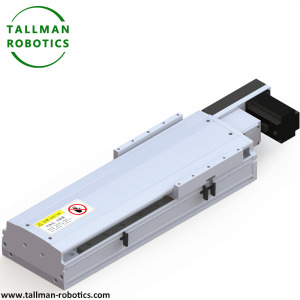

Ball Screw Driven Linear Modules

Ball Screw Driven Linear Modules

You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

The transmission method of Ball Screw Driven Linear Modules is characterized by high repeatability, up to ±0.005mm, high accuracy and high load. Usually used in the production process with a certain precision in industrial production. In the selection process of the ball screw drive, attention should be paid to the selection of the screw, which is usually determined according to factors such as load, speed, and torque. Pay attention to the maintenance of the screw when using the linear module of the ball screw. After cleaning a long distance, clean dirt and grease should be replaced in time, usually every half a month.

Ball screw is an ideal product that converts rotary motion into linear motion, or converts linear motion into rotary motion. The ball screw is composed of a screw, a nut and a ball. Its function is to convert rotary motion into linear motion, which is a further extension and development of ball screws. The important significance of this development is to change the bearing from rolling motion to sliding motion. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

What are the Basic Specification of Ball Screw Driven Linear Modules from Tallman Robotics Limited

Model No

Max Payload(kgs)

Max Stroke

(mm)

Repeatability

(mm)

Drive Solution

Motor Power (W)

TMS30

4

400

±0.01/±0.005

screw

30

TMS45

10

800

±0.01/±0.005

screw

50/100

TMB45

4

800

±0.04

belt

50/100

TMS62

20

1050

±0.01/±0.005

screw

100/200/400

TMB62

16

2000

±0.04

belt

100/200/400

TMS65

30

800

±0.01/±0.005

screw

50/100

TMB65

4

800

±0.04

belt

50/100

TMS85

50

1050

±0.01/±0.005

screw

100/200/400

TMB85

16

2000

±0.04

belt

100/200/400

TMS100

65

1050

±0.01/±0.005

screw

100/200/400

TMB100

40

3500

±0.04

belt

100/200/400

TMS135

110

1250

±0.01/±0.005

screw

200/400/750

TMB135

42

3500

±0.04

belt

200/400

TMS150

120

1500

±0.01/±0.005

screw

400/750

TMB150

75

3500

±0.04

belt

400/750

TMS170

130

1500

±0.01/±0.005

screw

400/750

TMB170

75

3500

±0.04

belt

400/750

TMS220

150

1500

±0.01/±0.005

screw

750

TMB220

75

3500

±0.04

belt

750

Ball Screw Driven Linear Modules are composed of multiple single-axis robots to realize multi-axis combination through different combination styles, to achieve applications such as Cartesian actuators, XYZ multi-axis actuators (XY table), and so on. It is widely used in the positioning, transfer, handling, inspection, dispensing, welding, cutting, etc. of LCD panels, semiconductors, home appliances, daily chemicals, automobiles, batteries and other fields.

Related Knowledge: The main features of the application of the ball screw in the module.

The ball screw is the most commonly used transmission element in machine tools and precision machinery. Its main function is to convert rotary motion into linear motion, or convert torque into axial repetitive force, and it has both high precision, reversibility and high Features of efficiency. Ball screw is also called ball screw and ball screw.

1) High positioning accuracy

The ball screw pair realizes rolling friction between the nut and the screw by ball rolling. The motion of the rolling linear guide is realized by rolling of the steel ball. The friction resistance of the guide pair is small, the difference between dynamic and static friction resistance is small, and no crawling occurs at low speeds. . High repeat positioning accuracy, suitable for moving parts that frequently start or change directions.

2) Less wear

Due to the low frictional energy consumption of rolling contact, the friction loss of the rolling surface is also reduced correspondingly, so the rolling linear guide system can be in a high-precision state for a long time. At the same time, the use of lubricating oil is also very small, which makes it very easy to design and use and maintain the lubrication system of the machine tool.

3) Long life

For the nut of the ball screw pair, the screw hardness reaches HRC58-62, and the ball hardness reaches HRC62-66, and there is rolling friction between them, so higher fatigue life and accuracy life can be achieved.

4) Adapt to high-speed movement

Due to the low friction resistance of the rolling linear guide module, the required power source and power transmission mechanism can be miniaturized, and the driving torque can be greatly reduced. It can realize high-speed linear motion and improve the working efficiency of the machine tool.

5) Strong carrying capacity

Rolling linear guides have good load-bearing performance and can withstand forces and moment loads in different directions, such as up, down, left, and right directions, as well as bump moments, rocking moments and swing moments. Therefore, it has good load adaptability.

6) Easy to assemble and interchangeable

The ball screw and rolling guide are interchangeable. As long as the slider or the guide rail or the entire rolling guide pair is replaced, the module can regain high precision.

7) Micro and high-speed feed can be realized

The ball screw pair will not produce such as sliding phenomenon, can realize the micro-feed; as long as the feed pulse is small enough, the ball screw pair can realize the micron-level feed. Because of the low heat generation of the ball screw pair and the ability to manufacture a large lead screw, high-speed feed can be achieved.

Read the full article

#BallScrewDrivenLinearModules#BallScrewLinearModule-BallScrewLinearStage#LinearModuleswithballscrewdrive#LinearMotionStages#Miniaturesizedlinearmotion#PrecisionLinearStages#ScrewDrivenActuators#ScrewDrivenModularLinearActuators#X-YStages

0 notes

Text

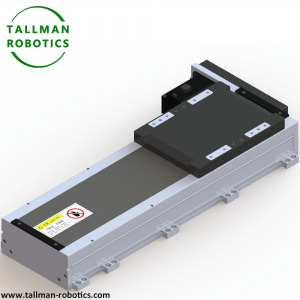

Modular Electric Slides

Modular Electric Slides

You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

Modular Electric Slides, also can be named as High Precision Linear Modules, Linear Motion Module, Industrial Linear Motion, Linear Actuator Bundle, etc in this industrial automation.

Tallman Robotics’s Modular Electric Slides type TM220 with body with by 220mm have 4 series. These Linear slides have 0 mm to 3500 mm stroke, and 8kgs up to 150kgs input payload.

TM Modular Electric Slides can be integrated with many brand motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in extruded super quality AL frame system to ensure requirement of precision and common projects. Precision, Stroke, lead, Brake and no Brake can be selected depending on your specific details.

TM by Tallman Robotics, which is located in Shenzhen, has strong ability in design and engineering experience. We have exported all kinds of Modular Electric Slides such as screw driven modules, belt driven modules, and also ,also there are semi sealed type and fully sealed type for common and dust free applications.

Our Modular Electric Slides perform all kinds of application such as:

Winding Machine by eliminating the clearance of the traverse axis

Circuit Board Mounting with linear modules used in high-precision and compact circuit board mounted.

Driller with high rigidity linear module used in the drilling machine

Positioning Device with linear module used for the moving parts of the work piece and the welding moving parts.

Dispenser with linear module used in the dispenser, the movement is smooth and the coating is even., Laser Marking with linear module used in the laser marking machine in a clean room, etc.

Basic Specification of TM220 Modular Electric Slides series

Model No

TMS220-CM

TMS220CR

Drive solution

Ball screw

Sealed or not

Semi closed

Fully closed

Motor power AC (W)

400W/750

Repeatability (mm)

±0.01/±0.005

Ball screw outer diameter (mm)

25

lead (mm)

5

10

25

50

Fastest speed Motor speed 3000 (rpm)

250

500

1250

2500

Max

Load(kg)

Acceleration

Deceleration

Horizontal

0.3G

150

150

120

50

Vertical

0.3G

55

45

20

8

Rate Thrust (N)

2100

1050

420

210

Linear guide (mm)

23*18.5-2

Origin sensor:

Plug-in

EE-SX672(NPN)EE-SX672P(PNP)

Inside

EE-SX951(NPN)EE-SX951P(PNP)

Model No

TMB220-CM

TMB220-CR

Drive solution

Timing Belt

Timing Belt

Sealed or not

Semi closed

Fully closed

Motor power AC (W)

750w

Repeatability (mm)

±0.04

Reduction Ratio

1:1

1:2

lead (mm)

90

45

Fastest speed Motor speed 3000 (rpm)

4500

2250

Max

Load(kg)

Acceleration

Deceleration

Horizontal

0.3G

35

75

Vertical

0.3G

-

Rate Thrust (N)

163

326

Linear guide (mm)

23*18.5-2

Origin sensor:

Plug-in

EE-SX672(NPN)EE-SX672P(PNP)

Inside

EE-SX951(NPN)EE-SX951P(PNP)

Related knowledge:

Common problems and countermeasures for installation and use of single-axis and multi-axis robotic arms

a. The flatness of the bottom surface of the single-axis manipulator installation does not meet the standard.

If the flatness of the bottom surface of the single-axis manipulator is too large, the bottom surface of the electric slide table will be forcibly locked, resulting in strong bending deformation of the bottom surface of the slide table, linear guide rails and ball screws. If it is light, it will increase the running resistance of the single-axis manipulator. If it is heavy, the electric slide may not be able to run, and the life of the electric slide will be shortened sharply.

According to the accuracy level of the single-axis manipulator, the flatness of the general installation level should be less than 0.05mm/m. For the precision grade, the flatness of the bottom surface of the installation should be less than 0.02mm/mm.

b. The locking order of the fixing screws at the bottom of the single-axis manipulator is wrong.

The fixing screw at the bottom of the single-axis manipulator should follow the principle of first middle, then both ends, and then locked in sequence. If the two ends are locked first, the arch deformation caused by the deformation cannot be eliminated, resulting in the linear guide rail not running smoothly, reducing the walking parallelism and straightness accuracy.

c. The motor shaft of the single-axis manipulator and the end of the screw shaft are not concentric.

Although the coupling can eliminate a certain degree of eccentricity, if the value of the concentricity runout of the shaft end of the single-axis manipulator screw and the motor shaft exceeds the allowable range of the coupling, the damage of the coupling will be accelerated, causing the coupling to be different. Sound, or shrapnel breaks. It should be avoided as much as possible.

d. The installation height of both sides of the multi-axis gantry combined mechanical arm is uneven.

When the mechanical arm is installed in a gantry type, if the height of the guide rails on both sides is uneven, or the two slides are not parallel, the electric slide will be held back and the damage of the electric slide will be accelerated.

f. The single-shaft electric slide timing belt tension is too loose or too tight.

The tension of the timing belt of the electric sliding table should be kept moderate. If the belt tension is too tight, the tension of the timing wheel and the timing belt will be too large, and there will be abnormal noise. If the belt tension is too loose, it will cause gaps in the transmission process and reduce accuracy. In severe cases, it will produce tooth skipping. The tension of the synchronous belt is generally determined by the tension and deflection. The measurement method is: use a thrust meter to press the vertical direction of the belt midpoint and apply a certain amount of installation force to measure the resulting deflection value. Reference values corresponding to different center distances and belt specifications.

g. The installation of the timing belt of the single-axis electric slide is not aligned.

The synchronous belt-driven electric slide table, or the motor-mounted electric slide table on the side of the motor, should keep the synchronous wheel flush, otherwise, it will cause the belt to deviate, and then the belt edge and the synchronous belt rib friction will occur, the synchronous belt within a short time Will be damaged and broken.

h. The single axis electric slide induction switch collides with the sensor due to deformation.

The induction slide of the electric slide induction switch is damaged due to deformation and collision with the photoelectric switch.

Countermeasure: Before energizing and sliding the slider, first check the photoelectric switch. You can pass the photoelectric switch normally.

i. The stroke of the cantilever shaft of the mechanical arm (electric slide) is too long, and the overhang length is too large.

If the cantilever length of the robot arm is too large, the allowable torque of the guide rail will be overloaded. Under different accelerations and decelerations, the closing time will change. The vibration generated at the end of the beam is finally absorbed by the electric slide table. Long-term vibration will shorten the life of the guide rail.

j. The load of the robot arm/electric slide exceeds the range of use.

When selecting the robotic arm, in addition to referring to the loadable load data in the selection manual, the effects of the dynamic allowable torque, acceleration and deceleration changes, and cantilever length should also be checked, and sufficient safety factors should be reserved.

k. The wiring of the robot arm sensor switch is wrong or burned due to overvoltage.

The electric slide induction switch generally uses a photoelectric switch. The reverse connection of the positive and negative poles of the photoelectric switch will cause damage to the photoelectric switch. The photoelectric switch cannot share the power supply with the motor driver or other inductive loads. Otherwise, the back electromotive force generated by the motor or the inductive load will cause a large voltage fluctuation, which will burn the photoelectric switch.

Read the full article

#BeltdriveLinearMotionGuideActuators#BeltDrivenLinearModules#Gearballscrewdrivenactuators#Leadscrewlinearactuators#Leadscrewlinearmodules#LinearGuideWays#LinearMotionSystems#LinearStages#ModularElectricSlides#ModularStages#Motionbeltdrivelinearactuators#Precisionlinearactuators#StainlessBearingActuators

0 notes

Text

Linear Actuator Bundle

Linear Actuator Bundle

You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

Tallman Robotics, as a professional manufacturer of Linear Actuator Bundle, supplies diverse TM Linear Actuator Bundles, such as Screw and Belt driven modules with different driven solution, also Semi and fully closed modules for different environment application.

Linear Actuator Bundles, also named as Linear Axis Actuator, Linear Motion Module, Linear Modular Actuator, etc.

Linear Actuator Bundle can work with famous band motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 in quality aluminum profile to ensure precise and speed target of various precision and common linear automation use. Based on different application, brake and no brake is can be chosen.

Tallman Robotics Linear Actuator of type TM85 with body with by 85mm have 4 series respectively by Screw semi closed, Screw fully closed, and Belt semi closed, Belt fully closed. These linear modules have strokes from 0 mm to 2000 mm, and payload from 3kg to 50kgs.

It could applied in material handing, components inspection system auto up and down material, components picked at the appointed position, flexible picking, electronic components inspection etc.

Basic Specification of TM85 series

Model No

TMS85-CM

TMS85-CR

TMB85-CM

DMB85-CR

Drive solution

Ball screw

Ball screw

Timing belt

Timing belt

Sealed or not

Semi closed

Fully closed

Semi closed

Fully closed

Motor power AC (W)

100/200/400W

Repeatability (mm)

±0.01/±0.005

±0.04

Ball screw outer diameter (mm)

6

Reduction Ration: 1:1

lead (mm)

5

10

16

20

32

66

Fastest speed Motor speed 3000 (rpm)

250

500

800

1000

1600

3300

Max

Load(kg)

Acceleration

Deceleration

Horizontal

0.3G

50/50/50

30/50/50

20/30/50

15/25/50

7/14/20

4/8/16

Vertical

0.3G

10/12/15

5/10/12

3/6/12

1/2/4

-

-

Rate Thrust (N)

341/682/1364

170/360/720

106/212/424

85/170/340

53/106/212

30/60/120

Linear guide (mm)

20*15.5-1

Origin sensor:

Plug-in

EE-SX674(NPN)EE-SX674P(PNP)

Inside

E2S-W13

Related knowledge: Linear module applications in equipment in the automation industry

Market applications of linear modules include factory automation, medical, packaging, machine tools, semiconductors, printing, automotive assembly, aerospace and food processing. We provide linear modules and accessories of various sizes. You can find the product display options on our linear module official website. You can now purchase the appropriate model linear module. From simple linear guides to custom-designed multi-axis linear module systems.

The ideal design solution is usually not to find a fast, sturdy, accurate or even cheap option. Instead, the ideal solution is a balance of performance, life and cost.

The TM high-precision linear module has very little frictional resistance, so only a small driving force is needed to move the load. Low frictional resistance contributes to a small heating effect. Therefore, compared with the conventional sliding system, the friction resistance of the linear module is reduced and the accuracy can be maintained for a long time.

When engineers are looking for cost-effective linear modules or silent linear slides, they will see TM Robot. We focus on linear modules for linear slides. We are famous for high quality, low friction, and high speed and smooth operation in the entire industry, and good customer service. Linear modules are suitable for various automation applications.

If you have engineering problems or concerns, our TM linear module manufacturer customer service will immediately provide technical support to help you find a solution so that custom or standard solutions can be used for design and development. To provide personalized attention in the industry, we always regard customer service and products as our top priority.

3D printing, vacuum packaging, Ipad test, time-lapse photography, dispensing machine, mobile transportation system, gluing machine, model painting, laser cutting / engraving, material sorting, printing machine, labeling machine, spraying equipment, injection molding machine, and other automation equipment applications.

Read the full article

#ElectricLinearCylinders#ElectricLinearSlides#LinearActuatorBundle#LinearActuatorController#LinearActuators#LinearActuatorsKits#LinearGuideSystems#LinearMotionProducts#LinearSlides#ModularLinearActuators#SignatureMotionLinearActuators

0 notes

Text

OPPO released the Reno Ace mobile phone, which is a brand-new product series launched by OPPO. It is positioned as a super player. OPPO Ace 2 has two major trump cards of 65W super flash charge and 90Hz e-sports screen. Ace attracted the attention of many hardcore players at the time.

Half a year later, the Ace series officially announced its independence. The protagonist of this article-Ace2 is the first product after the Ace independent series. The OPPO official said that the birth of the Ace series is OPPO’s ultimate response to the love of super players. Then the newly upgraded Ace2 mobile phone will bring players What kind of experience? Let ’s get a deeper understanding of this product.

OPPO Ace2 Design

I do n’t know if my friends have noticed. In the past two years, the recognition of OPPO mobile phones has become higher and higher. For example, the Reno series, such as the Find X2 series, even if they use the ID layout design similar to that of Youshang products. But OPPO ’s Mobile phones can always give you a different feeling, as does Ace2.

OPPO Ace2 is not the first smartphone with Oreo lens design. But Ace 2 still has high brand recognition. In the round Oreo camera module, there are four rectangular cameras arranged with raised lens edges There are also four hollowed-out grooves on the ring. Giving the entire lens module a mechanical feel similar to gears.

However, the author personally believes that the glass cover of the Oreo lens is still slightly monotonous, is it better to add some texture design?

OPPO Ace2 has three colors: moonrock gray, fantasy purple, and aurora silver. The moon rock-gray version, which uses a high-gloss glass back cover. Of course, it inevitably becomes a fingerprint collector. The overall look is not bad, like black is not black, close to silver-gray and more ink blue. And the back shell and the middle frame of the phone are also the same color, without any color difference, the sense of unity is stronger.

Appearance

On the front, OPPO Ace2 is equipped with a 6.55-inch OLED screen with a resolution of 2400 * 1080. A local peak brightness of 1100nit, a dynamic contrast of 5000000: 1. And supports HDR10 + certification and Rhine Global Eye Protection certification.

OPPO Ace2 has a 90Hz screen refresh rate and a 180Hz touch sampling rate.

In terms of system, OPPO Ace2’s screen color mode has two modes of vivid and soft. Supports screen refresh rate switching, has OSIE ultra-clear visual effects. Supports low-light and no-strobe eye protection, and so on.

The screen appearance of OPPO Ace2 is still good, especially the high refresh rate screen of 90Hz. The whole screen is smooth like butter, and it is very easy to follow.

As a flagship mobile phone with high performance for gamers. OPPO Ace 2 has a body size of 160.0mmx75.4mmx8.6mm and a weight of 185g. This data is very good. For players, even a long game will not appear because of the machine. Wrist pain caused by being too heavy.

At present, too many 5G flagship mobile phones on the market weigh more than 200g. Especially some game mobile phones. Perhaps to ensure the ultimate gaming performance, weight control can be said to be very unrestrained. Imagine some players with small hands. Or, sisters, holding a fitness instrument all day in their hands, it is really miserable.

However, it should be noted that the middle frame of OPPO Ace 2 is made of plastic. But the entire middle frame adopts a matte spraying process. And it is difficult to discern which material it is in terms of look and feel. The advantage is that thanks to the design of the plastic middle frame, Ace 2 uses a 360-degree surround antenna. Different holding states. And intelligently matches the best antenna group to ensure that the mobile phone signal is always kept in the best state.

OPPO Ace2 Hardware

In terms of core configuration. OPPO Ace 2 is equipped with Qualcomm Snapdragon 865 + X55. It has 8GB / 12GB (LPDDR4X / 5) + 128GB / 256GB (UFS3.0 + TurboWrite + HPB). Uses a 4000 mAh battery, supports 65W SuperVOOC 2.0. 40W AirVOOC wireless flash charging, 10W wireless reverse charging.

Qualcomm Snapdragon 865 represents the highest performance of the current Android camp. It uses TSMC’s 7nm process technology, has a Kryo 585 Prime super-large core customized based on A77, the main frequency reaches 2.84Ghz, and three A77 architecture Kryo 585 Gold Large core, clocked at 2.42Ghz, and 4 A55 architecture Kryo 585 Sliver small cores, 1.8Ghz.

Compared with the previous generation Snapdragon 855 processor, CPU performance has increased by 25%, and power consumption has also been reduced by 25%. In terms of GPU, the new Adreno 650 graphics processor also has a 25% performance improvement compared to the previous generation Adreno 650, and power consumption is reduced by 35%.

In the Antutu (V8.3.2) test, OPPO Ace2 reached 590,756 points.

We obtained through GeekBench4 running points, OPPO Ace 2 single-core reached 4278 points, multi-core reached 13057 points;

In 3DMark, OPPO Ace2 benchmark test results were 7188 and 6404 respectively.

The above three sets of running points data are in line with the normal performance of Snapdragon 865, and also represent the highest performance release level of the current Android camp.

A careful partner may have discovered that OPPO Ace2 is equipped with UFS3.0, but it additionally supports TurboWrite and HPB technologies. In fact, these two technologies are from UFS3.1.

According to official information, compared with UFS3.0, UFS3.1 mainly adds three functions of Write Turbo, Deep Sleep, and HPB. Among them, “Deep Sleep” technology helps to extend the battery life of the device and Write. Turbo write enhancement technology can provide long-term stable high-speed writing speed, and HPB mainly uses the mobile phone’s RAM to cache the L2P Map table to improve read performance and solve the problem of “more use and more cards” on the mobile phone.

In our actual test, OPPO Ace 2’s sequential read speed reached 1636MB / s, sequential write speed reached 671MB / s, random read speed reached 218MB / s, and random write speed reached 202MB / s. As a comparison, UFS 3.1 normally performs sequential reads up to 1800MB / s and sequential writes up to 700MB / s. The standard UFS3.0 is 1500MB / s and 500MB / s.

After talking about the performance of running points, let’s take a look at the game performance.

2. Games

In OPPO Ace2, it is equipped with the new Hyper Boost 3.0 technology. Most users of Ace2 are mobile game players. How to improve the experience on the game? In addition to performance, it is the optimization of the underlying system.

In Hyper Boost 3.0, OPPO is optimized for scene issues with the most user feedback, such as game fever and fast power consumption. These upgrades include the Game Zone engine, temperature control callback, and open capabilities. Specifically, Hyper Boost 3.0 can intelligently adjust system resource allocation according to demand. The optimization directions include intelligent scheduling strategies, unified control resources, special scene optimization, low power scene optimization, etc. According to OPPO laboratory data, Ace2’s CPU resources The utilization efficiency is increased by up to 30%, and the overall power consumption is reduced by up to 12%.

OPPO Ace 2 “Peace Elite” game, we can see through the frame rate graph, whether it is to open the smooth picture quality + 90hz ultra-high frame rate mode, or turn on the HDR HD + extreme frame rate mode, its performance level Almost all achieved the effect of full frame, the frame rate fluctuation is very stable, the average frame rate of the former is 89.3FPS, and the latter is 59.6FPS.