#machine monitoring

Explore tagged Tumblr posts

Text

Machine monitoring helps detect issues before they turn into failures. From vibration analysis to thermal sensors, today’s tools offer deep insights. Maximize uptime with a smart monitoring strategy.

0 notes

Text

AI-Based Machine Monitoring Systems: Use Cases, Trends, Challenges, and Benefits

In recent years, Artificial Intelligence (AI) has become a cornerstone of Industry 4.0, enabling smarter, more efficient operations across industries. One of the most promising applications is AI-based machine monitoring systems. These systems leverage advanced algorithms and real-time data analysis to optimize equipment performance, predict failures, and improve operational efficiency. In this blog, we explore the use cases, trends, challenges, and benefits of AI-driven machine monitoring systems.

What is AI-Based Machine Monitoring?

AI-based machine monitoring refers to the use of artificial intelligence and machine learning technologies to oversee and assess the performance of industrial equipment in real time. Traditional monitoring systems often rely on manual data collection and rule-based automation. AI-based systems, however, harness vast amounts of data from sensors, controllers, and other industrial components to make predictive and autonomous decisions.

With these systems, businesses can identify issues before they cause downtime, reduce human errors, and enhance productivity. The technology typically uses predictive analytics, anomaly detection, and real-time monitoring, providing insights that can preempt costly breakdowns or inefficiencies.

Use Cases of AI-Based Machine Monitoring Systems

Predictive Maintenance One of the most common applications of AI-based monitoring is predictive maintenance. AI systems analyze data from machinery sensors, such as temperature, vibration, and pressure, to predict when equipment will likely fail. This allows maintenance teams to service the machines before breakdowns occur, reducing unplanned downtime and extending the equipment’s life cycle.

Quality Control AI can monitor production quality by analyzing data from various stages of the manufacturing process. It can detect defects or deviations in real-time, improving product consistency and reducing waste. AI systems can automatically adjust machine parameters to ensure quality standards are maintained.

Energy Efficiency Optimization AI-driven monitoring systems can track and analyze energy consumption patterns across machines, helping to identify inefficiencies. By optimizing machine performance and reducing energy waste, these systems contribute to significant cost savings and more sustainable operations.

Supply Chain Management Machine monitoring systems can be integrated into supply chain management to improve scheduling, inventory management, and demand forecasting. AI can analyze machine performance data to predict delays or bottlenecks, allowing businesses to adapt their supply chains accordingly.

Remote Monitoring In industries like oil and gas, AI-based machine monitoring enables remote tracking of equipment performance. It can be especially useful for monitoring machinery in geographically remote or hazardous environments, reducing the need for on-site personnel and increasing operational safety.

Trends in AI-Based Machine Monitoring

Edge Computing Edge computing, where data processing occurs at or near the data source, is becoming increasingly common in AI-based machine monitoring. This reduces latency and allows for real-time decision-making, even when connected to cloud-based analytics.

Integration with IoT AI systems is often integrated with the Internet of Things (IoT), enabling seamless data collection from various devices and sensors. The fusion of AI and IoT accelerates data-driven decision-making, making industrial operations smarter and more interconnected.

Adoption of Digital Twins Digital twins — virtual replicas of physical systems — are becoming a significant trend. AI monitors the digital twin to simulate different operational conditions and predict how the real machine will perform under various scenarios, further enhancing predictive maintenance and optimization.

AI in Small and Medium Enterprises (SMEs) While AI adoption in machine monitoring was once reserved for large industries, SMEs are now increasingly adopting these technologies due to decreasing costs and easier implementation. This democratization is driving the expansion of AI-based monitoring across sectors.

Challenges of AI-Based Machine Monitoring

Data Quality and Availability AI algorithms rely heavily on high-quality, clean data. If the data is incomplete, noisy, or inconsistent, it can lead to inaccurate predictions and decisions. Ensuring a continuous stream of reliable data can be challenging, especially in older industries with legacy systems.

Implementation Costs The initial setup of AI-based monitoring systems, including hardware, software, and training, can be expensive. For small companies, the cost can be a significant barrier to entry. However, as the technology matures, costs are expected to decrease over time.

Integration with Legacy Systems Many industries still rely on legacy systems that were not designed for AI or real-time data integration. Retrofitting these systems can be complex, time-consuming, and costly, requiring specialized expertise.

Workforce Training AI-based monitoring requires new skill sets, such as data analytics, AI model management, and machine learning operations. Employees need to be trained to work effectively with these systems, which can be a time-consuming and resource-intensive process.

Benefits of AI-Based Machine Monitoring Systems

Reduced Downtime Predictive maintenance helps prevent unexpected equipment failures, significantly reducing downtime. This not only improves productivity but also enhances overall operational efficiency.

Cost Savings By identifying inefficiencies and optimizing machine performance, AI-based monitoring reduces energy consumption and maintenance costs. Predictive maintenance also minimizes the need for emergency repairs, saving on labor and parts.

Enhanced Decision-Making AI provides actionable insights from vast amounts of data that would be impossible for humans to process manually. These insights help organizations make data-driven decisions, improving operational planning and execution.

Improved Safety AI-based systems can detect potential safety hazards in machinery before they escalate, protecting workers and preventing accidents. Remote monitoring capabilities further reduce the need for human presence in dangerous environments.

Conclusion

AI-based machine monitoring systems represent a transformative technology that enhances operational efficiency, reduces costs, and improves safety across industries. While challenges such as data quality and implementation costs exist, the long-term benefits, including predictive maintenance, energy optimization, and quality control, make AI-driven machine monitoring a valuable investment for businesses looking to stay competitive in the era of Industry 4.0. As the technology evolves, the barriers to entry will lower, making it more accessible to industries of all sizes.

#AI-Based Machine Monitoring#AI-based machine monitoring systems#Machine Monitoring#AI-Based Machine Monitoring System#Artificial Intelligence (AI)#thirdeye#thirdeye ai

0 notes

Text

Video Autogenerated by Faceless.Video

Micro AI is revolutionizing the way we interact with technology.

Micro AI is transforming our interaction with technology by providing lightweight, hyper-efficient models tailored for Edge devices such as smartwatches, IoT sensors, drones, and home appliances. This cutting-edge innovation facilitates real-time data processing and decision-making directly on the device, eliminating reliance on constant cloud connectivity. Imagine your smartwatch instantly analyzing health data or your smart home system making immediate adjustments based on real-time inputs—all thanks to micro AI. One of the key benefits of micro AI lies in its low latency and local processing capabilities. In industrial automation, it can monitor machinery in real time to predict failures before they occur. For smart homes, it enhances convenience and security by allowing appliances to learn from user behavior while optimizing energy consumption. In healthcare, wearable devices equipped with micro AI can provide critical monitoring of vital signs and alert medical professionals during emergencies—ensuring timely interventions that could save lives.

#microai #EdgeComputing

#neturbiz#micro AI#AI technology#Edge devices#SmartWatches#IoT sensors#drones#home appliances#real-time data#local processing#low latency#industrial automation#smart homes#healthcare technology#productivity enhancement#energy efficiency#wearable devices#health monitoring#smart thermostat#security systems#user behavior#machine monitoring#predictive maintenance#autonomous appliances#emergency alerts#continuous monitoring#technology revolution#intelligent systems#operational costs#data processing

0 notes

Text

CBAM reporting software is a specialized tool designed to help businesses comply with the Carbon Border Adjustment Mechanism (CBAM) regulations set by the European Union. CBAM is a policy initiative aimed at reducing carbon leakage by imposing carbon costs on imports of certain goods into the EU, ensuring that EU climate policies are not undermined by cheaper, carbon-intensive imports from outside the EU.

0 notes

Text

Elevate your operational efficiency with Mavarick AI’s cutting-edge Machine Monitoring solution. Designed to provide real-time insights into your machinery’s performance, our advanced platform enables you to track, analyze, and optimize equipment usage with precision. By leveraging sophisticated sensors and data analytics, Mavarick AI’s Machine Monitoring solution helps you anticipate maintenance needs, reduce downtime, and improve overall productivity. Our user-friendly interface offers actionable insights and comprehensive reports, allowing you to make informed decisions and enhance the reliability of your operations. Transform your approach to equipment management with Mavarick AI, and ensure your machines operate at peak performance.

0 notes

Text

Mavarick offers AI-Driven Carbon Reporting technology to accurately monitor and report manufacturing carbon emissions at corporate, organizational and product levels. Our comprehensive solutions include Carbon Accounting Software, Carbon Reporting Software, and Carbon Management Systems to provide carbon emissions analysis, audit-ready carbon footprint reports, and actionrecommendations for carbon emission reduction. Track – Track your carbon emissions with accurate data capture using our advanced Carbon Accounting Software. Analyse – Gain automated insights into your carbon emissions with our Carbon Reporting Software. Report – Generate audit-ready reports compliant with CSRD, CBAM, and ESRS standards using our Carbon Reporting Software.

0 notes

Text

Revolutionize Heavy Machine Maintenance: Elevate Equipment Performance

Unleash the power of Fault Finder, your go-to solution for heavy machine maintenance. This innovative app streamlines fault organization, allowing you to categorize issues by machine type, manufacturer, and fault type in easily accessible folders. Capture and store images or videos linked to specific vehicles/machines, creating a visual archive for efficient troubleshooting. Simplify your maintenance routine and boost equipment performance with Fault Finder.

1 note

·

View note

Text

iDataOps-Industrial Machine Monitoring Software & Predictive Maintenance. Streamline machine monitoring with predictive maintenance with real-time reports, oee, predictive maintenance, preventive maintenance, and reduced downtimes.

#machine monitoring software#predictive machine maintenance#preventive maintenance#asset maintenance management#machine monitoring

0 notes

Text

oh hey look more misc. sketches/doodles of the guy and his lion who won't leave my head (and the tiniest yarnabies)

(I gotta work on more polished wips but he's so fun to draw, human and mechanical)

#poppy playtime#poppy playtime chapter 4#harley sawyer#poppy playtime the doctor#yarnaby#schellisart#sketches#still fiddling around with his human self so im switching between his face being hidden & shown#also definitely drawing yarnaby more fluffy than he actually is but like. he deserves it i need this creature to be holdable#i think machine sawyer should be taller in that first sketch but i didnt feel like trying to draw his legs then#also added a lil heart monitor screen to his mechanical chest to get a lil closer to the concept art bc i think its neat#can yall tell im like at least a little obsessed with him rn#also that character in red petting yarnaby in the sketchpage is my persona because i want to pet the beast lovingly

3K notes

·

View notes

Text

Enhancing Your Business Portal with Device Monitoring: Challenges and Advantages

📊 Looking to enhance your business with a Device Monitoring Portal? 📈 Discover the Challenges & Benefits in my latest video! 🔍

👉 Watch the video for expert insights. Link in bio! 👈

💼 Challenges: 🔹 Data Security 🔹 Integration Complexities 🔹 User Adoption

💡 Benefits: 🔸 Real-time Insights 🔸 Improved Efficiency 🔸 Cost Savings

Read More: https://aixtor.com/blog/device-monitoring-portal-challenges-benefits/

What's your take on implementing device monitoring? Share your thoughts below! 👇

DeviceMonitoring #BusinessSolutions #EfficiencyBoost #DataSecurity #TechInnovation #LinkedInInsights

#aixtor#device monitoring#portal#device management#business solutions#manufacturing software#liferay#liferay dxp#digital transformation#machine monitoring

0 notes

Text

Teksun Industrial IoT solution helps factories & process industries to boost overall equipment productivity and efficiency through the Connecting device. To know more, visit @ https://teksun.com

#iot solutions#Smart Logistics#Machine Monitoring#INDUSTRIAL IOT#product engineering company#product engineering services#product engineering solutions#IoT and AI Solutions Company#technology solution partner

1 note

·

View note

Text

Machine monitoring gives you real-time insight into equipment status and performance. Catch issues early, reduce downtime, and increase machine availability. Stay proactive and informed with smart monitoring tools.

0 notes

Text

Man cave

#digitalismmm#digitalism#digital#computers#wires#machines#tech#techcore#retro#aesthetic#vintage#photography#old computers#electronics#monitor

852 notes

·

View notes

Text

CBAM reporting software facilitates the collection, management, and reporting of data related to the carbon content of imported goods. It automates the process of calculating carbon emissions, ensures accurate reporting, and assists businesses in meeting their regulatory obligations under the CBAM framework. By leveraging such software, companies can streamline compliance, improve transparency, and optimize their approach to carbon management.

1 note

·

View note

Text

hrt that makes you a robot

#i dont mean androids btw#i mean something like a robot with a screenface/monitor head#or even something wilder like giant sentient machines#is it too much to ask to just be able to be a funky little beep boop„#wwhat do i tag thtis with

616 notes

·

View notes

Text

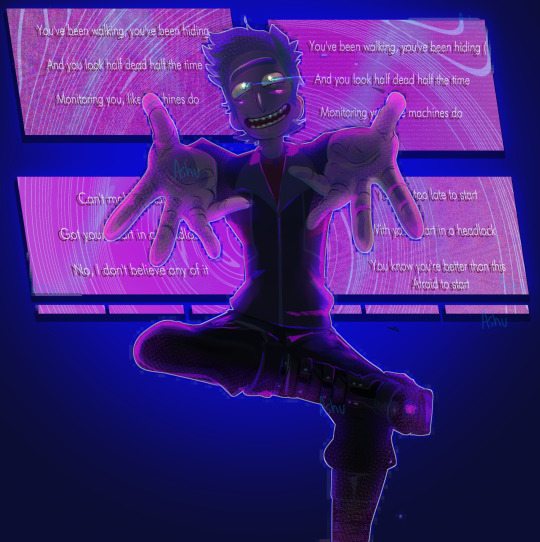

"You know you're better than this -"

#rick and morty fandom#rick and morty fanart#evil rick#rick and morty#rick sanchez#evil morty#morty smith#morty prime#morty c137#headlock#got your head in a headlock#monitoring you like machines do#artists on tumblr#digitalart#rick prime#fanart#🔞#old man yaoi#stanchez#alternate rick#angst#rickcest#ricksona

172 notes

·

View notes