#mechanical properties

Text

Carburizing, also known as a case-hardening process, is a heat treatment process used to harden the surface of low carbon steel parts by infusing carbon into the surface layer of the steel. This process enhances the surface hardness and wear resistance while maintaining a tough and ductile interior. The process is crucial in applications where the wear resistance of the material is critical, such as gears, camshafts, and other high-stress components.

The primary purpose of carburizing is to increase the carbon content at the surface of a low-carbon steel part.

#materials science#science#engineering#materials#materials science and engineering#mechanical properties#mechanical properties of materials#carbon#steel#carburizing

32 notes

·

View notes

Text

Machine learning uses X-ray diffraction data from polymers to predict the behavior of new materials

Polymers such as polypropylene are fundamental materials in the modern world, found in everything from computers to cars. Because of their ubiquity, it's vital that materials scientists know exactly how each newly developed polymer will perform under different preparation conditions. As described in a new study, which was published in Science and Technology of Advanced Materials, scientists can now use machine learning to determine what to expect from a new polymer.

Predicting the mechanical properties of new polymers, such as their tensile strength or flexibility, usually involves putting them through destructive and costly physical tests. However, a team of researchers from Japan, led by Dr. Ryo Tamura, Dr. Kenji Nagata, and Dr. Takashi Nakanishi from the National Institute for Materials Science in Tsukuba, showed that machine learning can predict the material properties of polymers.

They developed the method on a group of polymers called homo-polypropylenes, using X-ray diffraction patterns of the polymers under different preparation conditions to provide detailed information about their complex structure and features.

Read more.

#Materials Science#Science#X Rays#Diffraction#Polymers#Machine learning#Materials characterization#Computational materials science#Mechanical properties

11 notes

·

View notes

Link

1 note

·

View note

Text

Causes, effects, detection and reduction methods of residual stress in injection molded parts

I. What is residual stress in injection molded parts

Residual stress is stress that still exists inside object after various external factors that generate stress (external force, temperature change, processing process, etc.) are removed. It is called residual stress. Generally speaking, residual stress refers to stress that exists in object in order to keep object in self-phase balance when it…

View On WordPress

#injection molded part structure#injection molded parts#injection molding process#Mechanical Properties#mold flow analysis#molding process#plastic deformation#residual stress in injection molded parts

0 notes

Text

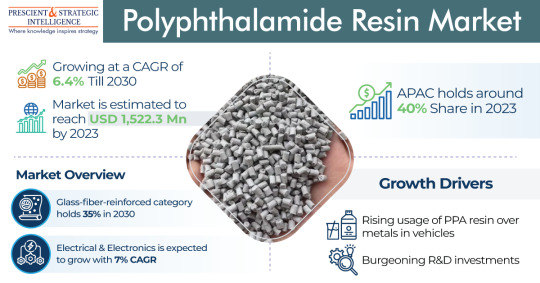

Polyphthalamide Resin Market Insights and Growth Prospects

Introduction

In the dynamic landscape of polymer resins, Polyphthalamide (PPA) emerges as a key player, offering a myriad of applications across various industries. This article delves into the intricacies of the Polyphthalamide Resin Market, shedding light on its burgeoning growth, market dynamics, and future prospects.

The polyphthalamide resin market witnessed a size of USD 1,522.3 million in 2023. Projections indicate a steady advancement with a compound annual growth rate (CAGR) of 6.4% anticipated during the period from 2024 to 2030. By 2030, it is forecasted to reach a substantial value of USD 2,320.6 million.

Understanding Polyphthalamide Resin

Polyphthalamide resin, a high-performance thermoplastic resin, exhibits exceptional mechanical, thermal, and chemical properties, making it suitable for demanding applications. With its superior strength, stiffness, and dimensional stability, PPA finds extensive usage in automotive, electrical, electronics, and industrial sectors.

Market Segmentation

1. Automotive Industry

Polyphthalamide Resin plays a vital role in the automotive industry, where lightweight, high-performance materials are essential for enhancing fuel efficiency and reducing emissions. From engine components to under-the-hood applications, PPA offers excellent heat resistance and mechanical strength, making it an ideal choice for critical automotive parts.

2. Electrical and Electronics Sector

In the realm of electrical and electronics, Polyphthalamide Resin serves as a reliable material for connectors, sockets, and circuit boards. Its ability to withstand high temperatures, moisture, and chemical exposure makes it indispensable for electronic devices, ensuring reliable performance and longevity.

3. Industrial Applications

In industrial settings, Polyphthalamide Resin finds diverse applications in machinery, equipment, and tooling components. Its exceptional mechanical properties, including high tensile strength and abrasion resistance, make it well-suited for demanding industrial environments, where durability and reliability are paramount.

Market Trends and Growth Drivers

The Polyphthalamide Resin Market is driven by several key trends and factors, including technological advancements, increasing demand for lightweight materials, and growing emphasis on sustainability. As industries strive for enhanced performance and efficiency, the demand for high-performance thermoplastics like PPA continues to rise, propelling market growth.

Challenges and Opportunities

While the Polyphthalamide Resin Market presents lucrative opportunities for manufacturers and suppliers, it is not without its challenges. Factors such as fluctuating raw material prices, regulatory compliance, and competition from alternative materials pose significant hurdles. However, proactive strategies, such as product innovation, market diversification, and strategic partnerships, can help industry players overcome these challenges and capitalize on emerging opportunities.

Polyphthalamide Resin Market: FAQs

What are the key properties of Polyphthalamide Resin? Polyphthalamide Resin exhibits exceptional mechanical, thermal, and chemical properties, including high strength, stiffness, and heat resistance.

What are the primary applications of Polyphthalamide Resin? Polyphthalamide Resin finds usage in automotive, electrical, electronics, and industrial sectors for components requiring high performance and reliability.

Is Polyphthalamide Resin recyclable? Yes, Polyphthalamide Resin is recyclable, offering sustainable solutions for various applications and industries.

What factors drive the growth of the Polyphthalamide Resin Market? Technological advancements, increasing demand for lightweight materials, and stringent regulatory standards contribute to the growth of the Polyphthalamide Resin Market.

How do manufacturers ensure the quality of Polyphthalamide Resin products? Manufacturers employ stringent quality control measures and testing protocols to ensure the quality and consistency of Polyphthalamide Resin products, meeting industry standards and customer expectations.

What are the emerging trends in the Polyphthalamide Resin Market?

Emerging trends include the development of bio-based Polyphthalamide Resins, advancements in compounding technologies, and expanding applications in emerging sectors such as 3D printing.

#Polyphthalamide resin market#Insights#Growth prospects#Automotive#Electrical and electronics#Industrial manufacturing#Mechanical properties#High temperature resistance#Chemical resistance#Product design#Market dynamics

0 notes

Text

Hastelloy C276: Chemical Composition, Mechanical Properties

Introduction:

Hastelloy C276, known by its UNS N10276 designation, is a versatile and highly sought-after nickel-molybdenum-chromium alloy. In this comprehensive guide, we will delve into its chemical composition, explore its remarkable properties, and shed light on its wide range of applications across various industries. Additionally, we will discuss its exceptional resistance to corrosion, and the essential aspects of fabrication and heat treatment.

Hastelloy C276 Chemical Composition:

ElementContent (%)Nickel, Ni57Molybdenum, Mo15-17Chromium, Cr14.5-16.5Iron, Fe4-7Tungsten, W3-4.50Cobalt, Co2.50Manganese, Mn1Vanadium, V0.35Silicon, Si0.080Phosphorous, P0.025Carbon, C0.010Sulfur, S0.010

Hastelloy C276 Physical Properties:

PropertiesMetricImperialDensity8.89 g/cm³0.321 lb/in³Melting point1371°C2500°F

Hastelloy C276 Mechanical Properties:

PropertiesMetricImperialTensile strength (@thickness 4.80-25.4 mm, 538°C/@thickness 0.189-1.00 in, 1000°F)601.2 MPa87200 psiYield strength (0.2% offset, @thickness 2.40 mm, 427°C/@thickness 0.0945 in, 801°F)204.8 MPa29700 psiElastic modulus (RT)205 GPa29700 ksiElongation at break (in 50.8 mm, @thickness 1.60-4.70 mm, 204°C/@thickness 0.0630-0.185 in, 399°F)56%56%Hardness, Rockwell B (plate)8787

Hastelloy C276 Thermal Properties:

PropertiesMetricImperialThermal expansion co-efficient (@24-93°C/75.2-199°F)11.2 µm/m°C6.22 µin/in°FThermal conductivity (-168 °C)7.20 W/mK50.0 BTU in/hr.ft².°F

Equivalent materials to Hastelloy C276:

ASTM B366ASTM B574ASTM B622ASTM F467DIN 2.4819ASTM B575ASTM B626ASTM B619ASTM F468

Chemical Composition:

Hastelloy C276 primarily consists of the following key elements:

Nickel (Ni): The primary component, providing a strong base for the alloy’s exceptional performance.

Molybdenum (Mo): Enhances corrosion resistance, particularly in reducing environments.

Chromium (Cr): Contributes to the alloy’s resistance to oxidizing agents like chlorides and oxidizing acids.

Iron (Fe): An essential element, which when present in controlled amounts, maintains the required mechanical properties.

Tungsten (W) and Cobalt (Co): Elements that further strengthen the alloy and provide stability against crevice corrosion.

Properties:

Hastelloy C276 boasts several remarkable properties that make it an ideal choice for challenging environments:

Corrosion Resistance: Its outstanding resistance to a wide range of aggressive media, including strong acids, chlorides, and seawater, sets it apart from conventional alloys.

High Temperature Resistance: The alloy retains its mechanical strength and integrity even at elevated temperatures, making it suitable for high-temperature applications.

Excellent Fabricability: Hastelloy C276 can be easily formed, welded, and machined, providing flexibility during fabrication processes.

Good Mechanical Properties: The alloy exhibits excellent tensile and impact strength, further enhancing its suitability for various industrial applications.

Applications:

Due to its exceptional properties, Hastelloy C276 finds applications in diverse industries, including:

Chemical Processing: It is extensively used in handling corrosive chemicals and acidic solutions.

Petrochemical Industry: The alloy is employed in reactor vessels, heat exchangers, and other equipment exposed to aggressive media.

Oil and Gas: In offshore drilling environments and sour gas wells, Hastelloy C276 ensures reliable performance.

Pollution Control: It plays a vital role in the construction of flue gas desulfurization systems and other pollution control equipment.

Pharmaceutical and Pulp & Paper: Its corrosion resistance makes it valuable in pharmaceutical production and pulp and paper processing.

Resistance to Corrosion:

Hastelloy C276 stands out for its exceptional resistance to both uniform and localized corrosion. It maintains its integrity in aggressive environments, where other materials might fail. The alloy’s resistance to pitting, crevice corrosion, and stress corrosion cracking makes it highly reliable, especially in chloride-rich conditions.

Fabrication and Heat Treatment:

Hastelloy C276 offers ease of fabrication, allowing it to be formed into various shapes using standard techniques. Weldability is excellent, and the alloy can be joined using common welding processes like TIG and MIG welding. To achieve the desired properties, post-weld heat treatment is recommended.

Conclusion:

Hastelloy C276 is a remarkable nickel-based alloy that excels in demanding environments, thanks to its exceptional properties and resistance to corrosion. Its wide range of applications across industries underscores its versatility and reliability. Whether in chemical processing, petrochemicals, or other challenging settings, Hastelloy C276 Pipe continues to prove its worth, ensuring the integrity and longevity of critical equipment. Contact Now for more information

Learn More: Erw vs Spiral Pipe : Difference

0 notes

Text

Innovating with Liquid Crystal Polymer: Market Overview and Growth Trends

As per a statement by a market research institution, P&S Intelligence, the liquid crystal polymer market generated revenue of USD 1,313 million in 2022, and it will reach USD 2,360 million by 2030, growing at a rate of 7.60% during this decade.

The growth in the industry is mainly credited to the booming sales of lightweight vehicles and the increasing demand for customer-oriented electronic…

View On WordPress

#Aerospace#Automotive#Electronics#growth opportunities#Key players#LCP applications#Liquid Crystal Polymer market#mechanical properties#thermal properties

0 notes

Text

this person got arrested for eating a spaceship. god i love hsr readables

#LMFAO?????????????????????????????????#now when they say Beast Ship i'm assuming there's some bizarre biological properties and it's not solely mechanical like a standard ship#but this is still really funny.

25 notes

·

View notes

Note

what would the cowbians be doing with their lives in a modern au? :3

Mattie would’ve gone to juvie as a teen because she set fire to her dads barn. But once she got out she apprenticed under a car mechanic a few states away and eventually became one, she then made a tiktok account showing people how to fix their cars but got internet famous because of how effortlessly attractive she is

Flora would’ve grown up in a very big Italian family in nyc that (as the eldest daughter and first grandchild) expected her to become a doctor or a lawyer and to marry a nice man and have children. Flora did not like that. So she decided to convert a van into a make shift home and drive across the country without telling anyone.

(Can you see where this is going)

Floras car breaks down in the middle of nowhere utah trying to get to California. She needs to get it repaired,, Mattie’s shop is the only one around. Flora doesn’t have any money so mattie offers her a deal: flora helps out around the shop for a few weeks while mattie fixes the car

(Flora and mattie keep finding more reasons for her to stay “the break pedal is kinda sticky, what’s an oil change? The radio won’t turn on etc”)

They fall in love

#they buy a nice piece of property#in a valley with a beautiful mountain view#oh and Arthur was the car mechanic mattie apprenticed#under#Cowbians#cowboy lesbians#Flora and mattie#mattie and flora

76 notes

·

View notes

Text

ok today's bug discovery: the fade-touched nevarrite ability that makes the target explode on death says it does 75% weapon damage, but im pretty sure it actually does 200%

#da#dai#i see the mistake they made. the property used for the amount of damage is property 2 and that's set to 0.75#but when it's called later it doesnt call the property it just calls the number 2. so instead of 75% it's 200%#not something im bothered checking in-game but once again ive just accidentally stumbled into a probable bug#tbf the whole point of what im doing rn (going through these specific files) is to make sure they do exactly what they say#or more so to understand the mechanics but that just ends up being 'make sure they do what they say'#so i kinda AM looking for bugs. but im still surprised when i find them. esp when they're completely undocumented#that said. if any bugs are gonna be undocumented they're gonna be random side mechanics that you use so rarely that you'll never notice the#like who's going around checking that fade-touched nevarrite does 75% weapon damage when you kill something? certainly not i#if anyone WANTS to test it they're welcome to but im content to just be pretty sure i understand what im reading#personal

5 notes

·

View notes

Text

What is the forging process?

Forging is the working of metal into a useful shape by using localized compressive forces. These forces are applied through various tools such as hammers or presses. This process is integral to producing high-strength components for various industries, including automotive, aerospace, and construction.

Most forging operations are carried out hot, although certain metals may be cold forged. Two major classes of equipment are used for forging operations: the forging hammer, or drop hammer, which delivers rapid impact blows to the surface of the metal, and the forging press, which subjects the metal to a slow speed compressive force.

#science#materials science#engineering#materials science and engineering#materials#metals#alloys#mechanical properties#mechanical properties of materials#metal forging#cold forging#hot forging#forging tools#forging

15 notes

·

View notes

Text

Researchers reveal new method for calculating mechanical properties of solids using machine learning

A research team from Skoltech introduced a new method that takes advantage of machine learning for studying the properties of polycrystals, composites, and multiphase systems. It attained high accuracy, nearly as good as that of quantum-mechanical methods, which are only applicable to materials with less than a few hundred atoms.

The new method also benefits from active learning on local atomic environments. The paper is published in the Advanced Theory and Simulations journal.

"Many industrial materials are synthesized as polycrystals or multiphase systems. They contain both a single crystal and amorphous components between single crystal grains. The large number of atoms makes it hard to calculate the properties of these systems using modern quantum-mechanical methods. Density functional theory can only be applied to materials with a few hundred atoms."

Read more.

#Materials Science#Science#Mechanical properties#Computational materials science#Machine learning#Skoltech

12 notes

·

View notes

Text

11 Tips for PC Injection Molding Process

PC is commonly known as polycarbonate. Due to its excellent mechanical properties, it is commonly known as bulletproof glue. PC has characteristics of high mechanical strength, wide operating temperature range, good electrical insulation performance (but arc protection performance remains unchanged), good dimensional stability, and transparency.Process characteristics of PC: melt viscosity is…

View On WordPress

#back pressure#holding pressure#injection molding#injection molding process#injection pressure#injection speed#injection temperature#injection volume#Mechanical Properties#Mold temperature#molding process#PC injection molding#PC Injection Molding Process

0 notes

Text

I'm choosing to interpret this mecs blog entry as Jonny doesn't know what a cat is (he only ever saw octokittens) and would be shocked to see an octokitten with only four ACTUAL PAWS and CLAWS!! This also confirms Ashes knows what cats are and there was cats on their planet (maybe Ashes had a cat? maybe they are neutral over the octokittens because cool but real cats are better? maybe I have a new HC).

#jonny d'ville#ashes o'reilly#pre mecs ashes with a cat makes me very happy and now it's my most important hc#that and that the toy soldier steals people's clothes all the time it has no sense of private property but it has a great fashion sense#the mechanisms#mecs

17 notes

·

View notes

Text

Today I (re)learned that "Schrödinger's cat" was Schrödinger making fun of a facet of quantum mechanics and suddenly realized why the experiment always seemed stupid

#bc in quantum physics there ARE things that only exist once observed and things wherein you can only know one property at a time#but they don't apply on a macro scale#i DID hear the reply to Einstein's 'god does not play dice with the universe' which infinitely makes it better#listening to podcasts on Quantum mechanics has given me a slight beef with Einstein#as any good academic subject should#if you don't have beef are you really learning#personal;

4 notes

·

View notes

Text

My ideal Gravity Falls AU is one where Ford gets to go to West Coast Tech and his family realizes that he is never going to make millions because everything he studies is increasingly niche and not in a profitable way

#gravity falls#stanford pines#'so ford what are you working on?' 'there's a species of octopus with nine tentacles! isn't that great?' *collective sighs*#'does the octopus have any special healing properties or anything?' 'nope just a regular octopus. or maybe nonapus is more accurate-"#meanwhile stan went to trade school and is thriving as a mechanic or something

4 notes

·

View notes