#motor control using plc

Explore tagged Tumblr posts

Text

Explore precision motor control using plc with our guide on "Three-Phase Induction Motor Control Using PLC Technology.

0 notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

We provide a reliable, cost effective and efficient service to various industries throughout the UK and indeed worldwide. Our key areas of expertise are repairing, variable speed drives including; Frequency Inverters, Spindle, Servo, Stepper; HMI’s, Power Supplies, Programmable Logic Controller’s (PLC’s), Printed Circuit Boards (PCB’s), Servo Motors, Encoders and many other types of industrial equipment. Occasionally we use our worldwide network of suppliers to effect a repair.

#electronic restoration services#circuit board repair#printed circuit board repair#electronics repairs#pcb repair

2 notes

·

View notes

Text

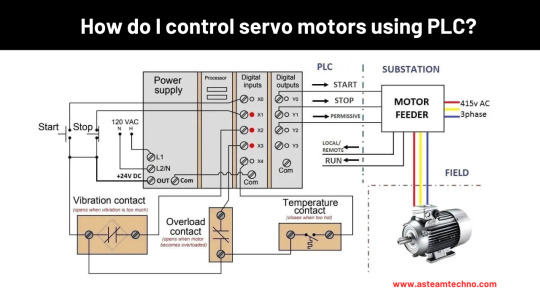

How do I control servo motors using PLC?

Select the appropriate PLC and Servo Drive

Connect the hardware

Program the PLC

Configure Servo Drive Parameters

Implement Motion Control Commands

Testing and Debugging

Safety Considerations

Documentation

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#servo motor#today on tumblr

2 notes

·

View notes

Text

Tooth Granulator: Core Equipment for Efficient Fertilizer Production

The tooth granulator is a mechanical device that extrudes materials into granules through high-speed rotating teeth, widely used in organic fertilizer, compound fertilizer and other fertilizer production fields, with significant advantages such as high granulation efficiency and good particle uniformity.

Working Principle

The tooth granulator completes the granulation process through three main steps:

Material Mixing: Thoroughly mix raw materials with binder

Extrusion Forming: High-speed rotating teeth extrude and shear materials

Particle Shaping: Form uniform granules through screen

Key Advantages

Selection Guide

Choose appropriate model based on capacity needs (Small:5-10t/h, Medium:10-15t/h, Large:15-20t/h)

Consider material characteristics: Match equipment performance with moisture content, viscosity etc.

Focus on key components: Tooth material (wear-resistant alloy steel recommended), motor power

Automation level: Modern equipment should have PLC control system

References:

International Fertilizer Equipment Association "Granulation Technology Guide" (2023)

Wang et al. "Advanced granulation technologies in fertilizer production" (2022)

0 notes

Text

Electrical and Instrumentation Engineering – Techcem

In an increasingly automated and technology-driven world, electrical and instrumentation (E&I) engineering is essential to ensure safe, efficient, and intelligent operations across industries. At Techcem, we offer expert electrical and instrumentation engineering services designed to meet the diverse needs of industrial and infrastructure projects.

What is Electrical and Instrumentation Engineering?

Electrical engineering deals with the design, development, and maintenance of electrical systems. This includes power distribution, control systems, lighting, and wiring infrastructure.

Instrumentation engineering focuses on the design and implementation of devices that measure, monitor, and control process variables like pressure, temperature, level, and flow.

Together, these disciplines ensure operational reliability, automation, energy efficiency, and safety.

Why Techcem for Electrical & Instrumentation Services?

With deep industry knowledge and proven technical capabilities, Techcem delivers tailor-made E&I engineering solutions. Our team is proficient in handling projects from concept to commissioning, ensuring compliance with industry standards and client expectations.

Our Strengths:

Extensive domain expertise in E&I

Integration of automation systems (PLC/SCADA/DCS)

Emphasis on safety, energy efficiency, and compliance

Project execution support from design to commissioning

Use of international codes and modern software tools

Our Electrical & Instrumentation Engineering Services

Techcem provides a complete suite of E&I services for industrial, manufacturing, and infrastructure sectors.

Electrical Engineering Services:

Power distribution system design (HT & LT)

Lighting and cabling layouts

Earthing and lightning protection systems

Motor control centers (MCCs) and switchgear specifications

Energy audits and power factor correction

Electrical load calculations and panel designs

Instrumentation Engineering Services:

Instrument selection and specification

Control system design (PLC, SCADA, DCS)

Field instrumentation layout and wiring

Installation drawings and loop diagrams

Calibration and testing of instruments

Integration with safety and interlock systems

Industries We Serve

Our E&I solutions are designed for various sectors, including:

Cement & Mineral Processing Plants

Power & Energy Projects

Oil & Gas

Water Treatment & Utilities

Manufacturing & Automation Plants

Benefits of Our E&I Solutions

Enhanced system performance and uptime

Improved safety through smart instrumentation

Real-time process monitoring and automation

Energy cost savings with efficient design

Easy compliance with electrical and industrial codes

Final Words

At Techcem, we understand the importance of electrical and instrumentation systems in modern industrial setups. With our detail-oriented approach, cutting-edge tools, and a commitment to quality, we deliver E&I engineering solutions that help businesses operate smarter and safer.

Contact Techcem today for reliable and efficient electrical and instrumentation engineering services tailored to your industry.

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Precision and Productivity: A Deep Dive into Bag Making Machines

Bag making machines play a pivotal role in the global packaging industry, transforming flat materials into functional containers used in countless sectors—from retail and food services to industrial shipping. As consumer demand for convenience and sustainability grows, the bag making machine industry has responded with more versatile, efficient, and environmentally friendly technologies.Get more news about paper bag making machine,you can vist our website!

What is a Bag Making Machine? A bag making machine is a highly specialized piece of equipment that automates the production of various types of bags, including plastic bags, paper bags, woven sacks, and biodegradable alternatives. These machines typically handle processes such as feeding raw material, folding, sealing, cutting, and sometimes even printing or punching. The automation not only accelerates production but also ensures consistency and precision, which is crucial in large-scale manufacturing.

Types and Applications There are numerous types of bag making machines, each suited for a specific application:

Plastic Bag Making Machines: These can produce T-shirt bags, garbage bags, zip-lock bags, and more. Some machines are engineered to handle biodegradable plastics in response to environmental regulations.

Paper Bag Making Machines: As many companies shift toward paper to reduce plastic waste, these machines are gaining popularity in retail and food packaging.

Non-woven Bag Making Machines: Ideal for reusable shopping bags, these have seen a surge in demand due to bans on single-use plastics in many regions.

Each category has subtypes equipped with options for side sealing, bottom sealing, or center sealing, depending on the design and purpose of the bag.

Key Features Driving Innovation Modern bag making machines are equipped with programmable logic controllers (PLCs), touch screen interfaces, and servo motors for greater accuracy and user-friendly operation. Some high-end models come with online printing and lamination systems, integrating multiple processes into a single production line. Energy efficiency and material flexibility are also top priorities in today's designs, enabling manufacturers to work with different substrates like PE, PP, kraft paper, and recycled materials.

Sustainability and Market Trends One of the most significant developments in the bag making machine industry is the pivot toward eco-friendly materials and processes. Governments across the globe are regulating plastic usage, which has led to a sharp increase in demand for machines that handle recyclable or compostable materials. As a result, manufacturers are redesigning equipment to accommodate thinner films and recyclable blends without compromising on strength or seal quality.

China, India, and Southeast Asia remain key manufacturing hubs due to lower labor costs and expanding domestic demand. However, Western markets are increasingly investing in automation to reduce dependency on imports and meet stricter environmental standards.

Conclusion Bag making machines may not often be in the spotlight, but they are indispensable in our everyday lives. From the paper sack at the bakery to the heavy-duty bags used in construction, these machines quietly power the global flow of goods. As technology advances and sustainability becomes non-negotiable, bag making machines will continue to evolve—offering smarter, cleaner, and more efficient solutions to meet the demands of a changing world.

0 notes

Text

How Do Contact Output Modules Improve Flexibility in Turbine Control Systems?

In modern industrial automation and turbine control environments, scalability and signal expansion are essential. As systems grow in complexity, they often require additional I/O capabilities—especially for sending command signals to auxiliary devices, alarms, and field relays. This is where Contact Output Expansion Modules, like the IS200DTBDG1A, come into play. These modules allow you to extend the number of dry contact outputs available within GE Mark VI or VIe control systems, providing greater control flexibility without the need for complete system overhauls. Let’s explore what contact output modules do, where they are used, and why they are essential for scalable and reliable turbine control architectures. What Is a Contact Output Expansion Terminal Module? A contact output module is a terminal board that provides additional relay outputs or dry contact points used to control field devices. The IS200DTBDG1A is a GE-designed board that interfaces with the main control processor to output discrete signals when triggered by automation logic. Each contact acts like an electrical switch, opening or closing based on the controller’s command—ideal for controlling: Relays Circuit breakers Solenoids Warning indicators Shutdown signals Key Functions of the IS200DTBDG1A Board 1. Signal Expansion for Complex Systems As control systems grow—whether through added sensors, alarms, or safety functions—the need for more outputs increases. This board adds dedicated dry contact outputs without needing to replace or upgrade the main controller. 2. Discrete Command Signal Control Each contact output can represent a binary state (on/off) to trigger critical field equipment. This makes it ideal for alarm systems, motor starters, and interlock systems. 3. Integration with GE Mark VI Systems The module is fully compatible with GE’s Mark VI/VIe platforms, ensuring seamless integration without signal mismatch or configuration issues. 4. Rugged, Industrial Design Designed for harsh conditions found in turbine enclosures and control panels, the IS200DTBDG1A can operate reliably in environments with high vibration, temperature fluctuations, and electrical noise. Where Is It Used? The IS200DTBDG1A contact output module is commonly used in: Gas and steam turbine control panels Power plant automation systems Industrial DCS/PLC cabinets Oil & gas skids and compressor control units Its key role is to transmit safe, isolated command signals to field devices from the central control logic. Operational Benefits ✔ Scalability Instead of replacing a controller when output points are maxed out, you can simply add modules like the IS200DTBDG1A for quick expansion. ✔ Isolation and Protection Contact outputs are electrically isolated, which protects the main controller from voltage spikes or grounding issues in field wiring. ✔ Simplified Maintenance With clearly labeled terminals and test points, these boards make it easy for technicians to troubleshoot and verify control signals during shutdowns or commissioning. Installation and Maintenance Considerations To ensure long-term reliability: Use shielded cables to avoid interference Regularly check terminals for secure connections Verify logic mapping in the controller to confirm that outputs are assigned correctly Also, replacing these modules with OEM-certified hardware—such as the IS200DTBDG1A—ensures continued compatibility and system reliability. Conclusion In critical control systems like those found in gas and steam turbines, every signal matters. The IS200DTBDG1A Contact Output Expansion Terminal Module ensures that your control system has the flexibility, reliability, and capacity to scale with operational needs. Whether you're automating alarms, controlling breakers, or sending trip signals, this module provides a trusted, field-proven interface for executing your most essential commands. For operators and engineers alike, it's an indispensable component for robust and responsive turbine automation.

0 notes

Text

Shape with Confidence – Advanced C Channel Roll Forming by Jugmug

In today’s age of industrial precision and structural performance, C channel profiles are more than just pieces of metal—they are the backbone of strong, dependable frameworks. At the heart of these robust profiles lies the C Post Channel Roll Forming Machine, and no one understands this better than Jugmug RollForming. With years of engineering expertise, Jugmug has become a name synonymous with precision forming, durability, and customer-focused innovation.

What Is a C Channel Roll Forming Machine?

A C Channel Roll Forming Machine, also known as a C Post Roll Former, is used to manufacture C-shaped steel sections from metal coils. These profiles are widely used in:

Construction (purlins, wall studs)

Industrial shelving

Cable tray supports

Solar panel mounting structures

Automotive and transportation frames

The forming process ensures accurate dimensions, clean edges, and consistent shapes, which are critical for structural stability and assembly efficiency.

Why Jugmug RollForming?

With a heritage of craftsmanship and a passion for innovation, Jugmug RollForming has revolutionized how industries view roll forming. Here's why Jugmug leads the pack in C Channel Roll Forming:

1. Precision Engineering

Jugmug’s machines are designed using advanced CAD/CAM systems and assembled with CNC-manufactured components. The result is ultra-precise forming even at high speeds, with tolerance control up to ±0.5mm.

2. Heavy-Duty Build Quality

Built with rugged structural frames, hardened rollers, and wear-resistant shafts, these machines are engineered for long-term, high-volume performance without breakdowns.

3. High-Speed Automation

Equipped with PLC control systems, servo motors, and hydraulic punching/cutting, Jugmug’s C Post machines reduce human error and improve productivity. The touchscreen HMI makes operation simple and intuitive.

4. Customization on Demand

Every business has unique needs. Jugmug provides tailor-made C channel forming machines, whether you require:

Variable sizes and gauges (1.2 mm to 3 mm)

Manual or fully automatic operation

In-line punching, embossing, or logo marking

Quick-change cassette design for multiple profiles

Applications of C Channel Profiles

The C profiles manufactured using Jugmug’s machines find applications in:

Construction

Used as wall studs, roof purlins, girts, and base plates due to their load-bearing capacity and resistance to warping.

Solar Panel Mounting

C channels are widely used to fabricate the structural framework for solar PV systems.

Automotive Chassis & Framework

Because of their strength-to-weight ratio, C channels are ideal for reinforcing vehicle bodies and cargo enclosures.

Racking & Storage Systems

Industrial shelving systems often rely on C profiles for their modular, load-bearing structure.

Customer Success Stories

Jugmug RollForming has delivered its C channel machines across India and globally. Many manufacturers in the solar, automotive, construction, and logistics sectors report:

30% increased output

Reduced material wastage

Quick ROI (within 12-18 months)

Minimal downtime

After-Sales Support & Training

Jugmug doesn’t stop at selling the machine—it partners with you throughout the journey. Their post-sale support includes:

Installation & operator training

Preventive maintenance plans

Spare parts availability

Remote troubleshooting support

Annual servicing packages

Their team of qualified engineers is just a call away, offering pan-India coverage and global service reach.

Green Manufacturing with Jugmug

In alignment with sustainability goals, Jugmug machines are designed to optimize energy usage and reduce raw material waste. The machines feature:

Servo-driven motors for low energy consumption

Smart sensors for real-time quality control

Eco-friendly hydraulic systems

By adopting Jugmug’s forming systems, manufacturers not only boost output but also reduce their carbon footprint.

Conclusion: Shape with Confidence

When strength, accuracy, and speed matter, Jugmug RollForming’s C Channel Roll Forming Machine delivers with unmatched precision. Whether you are scaling up production or entering new markets, Jugmug ensures your foundation is strong—both literally and technically.

Shape your future with confidence—partner with Jugmug RollForming.

#C channel roll forming machine#C post forming machine manufacturer#C profile making machine India#Jugmug RollForming machines#Structural roll forming equipment#Roll forming machine for solar structures#Best C channel machine in India

0 notes

Text

A10VSO Pump An In-Depth Overview

The A10VSO pump, developed by Bosch Rexroth, is a high-performance axial piston pump widely recognized for its reliability, efficiency, and versatility in hydraulic systems. Commonly used in industrial and mobile hydraulic applications, the A10VSO pump provides precise control of fluid flow and pressure. This article explores the design, features, working principle, benefits, and applications of the A10VSO pump, offering a comprehensive understanding for engineers, technicians, and industrial users alike.

What is an A10VSO Pump?

The A10VSO is an axial piston variable displacement pump designed for use in open-circuit hydraulic systems. It belongs to the axial piston swashplate design family, where pistons are arranged parallel to the drive shaft in a circular pattern. The swashplate mechanism controls the stroke of each piston, allowing the pump to adjust the volume of hydraulic fluid delivered based on system requirements.

The term “variable displacement” indicates the pump's ability to vary the flow output, which is crucial for energy savings and system flexibility. The A10VSO series is particularly popular in applications requiring fine speed and force control.

Design and Construction

The A10VSO pump features a robust and compact design suitable for demanding environments. Key design elements include:

Swashplate mechanism: This controls the piston stroke, and hence the flow rate, by altering the angle of the plate.

Cylinder block: Houses multiple pistons that rotate with the drive shaft.

Valve plate: Ensures that the suction and pressure sides of the pump are properly sealed.

Pressure and flow controllers: Integrated to manage output based on system demand.

Drive shaft: Connects the pump to the motor or engine that provides mechanical input.

Its modular construction allows for easy customization, maintenance, and integration with various control devices.

Working Principle

The A10VSO pump operates on the axial piston principle with a variable swashplate angle. Here's a step-by-step explanation of its working mechanism:

Drive input: The pump is connected to a motor that rotates the drive shaft.

Piston movement: As the shaft rotates, it causes the cylinder block and pistons to rotate. The pistons are forced to reciprocate due to the angled swashplate.

Intake stroke: During the downward stroke, pistons draw hydraulic fluid from the reservoir through the intake port.

Compression stroke: As the pistons move upward, they compress the fluid and discharge it through the outlet port at high pressure.

Flow control: The swashplate angle determines the length of the piston stroke, which in turn regulates the flow rate. A flatter angle results in less displacement and lower flow; a steeper angle increases both.

This ability to vary displacement makes the A10VSO ideal for applications needing dynamic flow control.

Control Options

A standout characteristic of the A10VSO pump is its versatile control options. These include:

Pressure compensator (DR): Automatically adjusts displacement to maintain constant pressure.

Load-sensing (DFE): Varies output according to system demand, ideal for mobile machinery.

Remote control (DRG): Enables pressure control from a remote location.

Electro-hydraulic controls (ED, EDR, etc.): Offers integration with programmable logic controllers (PLCs) for advanced automation.

These options provide designers with the flexibility to tailor system performance precisely to application requirements.

Applications of the A10VSO Pump

Due to its adaptability and performance, the A10VSO pump is used in a wide range of industries. In each of these applications, the pump provides consistent pressure, responsive control, and long-term durability.

Maintenance and Service

While the A10VSO pump is engineered for durability, proper maintenance ensures its longevity. Recommended practices include:

Regular inspection of hydraulic fluid: Contamination is a leading cause of wear.

Monitoring for leaks and noise that may indicate internal damage.

Following manufacturer-recommended service intervals

Replacing filters and seals periodically

Ensuring correct installation alignment and avoiding over-tightening during mounting

By adhering to preventive maintenance schedules, users can significantly extend pump life and reduce downtime.

Conclusion

The A10VSO pump is a cornerstone of modern hydraulic systems, offering a blend of performance, efficiency, and flexibility. Whether in high-demand industrial environments or rugged mobile machinery, its ability to adapt to varying pressure and flow needs makes it an invaluable asset.

With its proven design and wide range of displacement sizes and control types, the A10VSO pump continues to be a preferred choice for engineers and technicians seeking reliable and responsive hydraulic solutions. As automation and energy efficiency become increasingly important, pumps like the A10VSO are poised to play an even greater role in the evolution of hydraulic technology.

0 notes

Text

How Mechanical System Design Enhances Efficiency in Industrial Engineering

Introduction

Efficiency is a need, not just a goal, in the fast-paced field of industrial engineering. Retaining a competitive edge requires the capacity to optimize resource consumption, reduce downtime, and streamline processes. The design of mechanical systems is among the most important factors that contribute to this optimization. Mechanical systems are designed to increase overall productivity, decrease waste, and improve performance through clever planning, integration, and innovation.

Mechanical System Design: What Is It?

The process of organizing and developing mechanical systems and components that cooperate to carry out particular tasks in industrial settings is known as mechanical system design. It covers the design, dimensions, material choice, temperature and stress analysis, and incorporation of mechanical components such automated equipment, conveyors, gear mechanisms, HVAC systems, robotics, and gear mechanisms. Reliable operation under a variety of conditions is ensured by a well-crafted design, which is essential in industrial settings with high demand.

Essential Elements of an Energy-Efficient Mechanical System Design

Energy conservation is a key component of modern mechanical system design. Energy-efficient motors, regenerative braking systems, and intelligent load management are some of the methods used in systems designed to lower power usage.

Design Modularity

Without completely redesigning the system, modular components make it simple to upgrade, expand, or replace individual pieces. This method promotes ongoing development and increases adaptability.

Integration of Automation

Automation is becoming more and more important in today's industrial operations. In order to ensure accurate and reliable performance, mechanical systems are now made to seamlessly interface with sensors, robotic components, and programmable logic controllers (PLCs).

Compliance and Safety

Adherence to industry safety standards and regulations is a crucial factor in the design of mechanical systems. To safeguard employees and equipment, well-designed systems incorporate built-in safety features and fail-safes.

Efficiency via Optimization

Load capacity, temperature ranges, material durability, and anticipated wear and tear are all taken into account during the design process. Mechanical system design reduces unplanned failures and increases uptime by foreseeing operational issues and designing solutions prior to deployment. This prolongs the equipment's lives and increases productivity.

Industrial Engineering Case Applications

In industries such as heavy machinery, chemical processing, and automobile manufacture, customized mechanical system design guarantees optimal equipment performance. For instance, on an assembly line, specially made conveyor systems minimize manual handling, increasing productivity and reducing the possibility of mistakes or accidents. In a similar vein, well-designed HVAC systems in industrial facilities effectively control temperature, improving working conditions and reducing energy expenses.

Conclusion

To sum up, one of the key pillars of industrial engineering efficiency is mechanical system design. Automation, safety, adaptability, and energy-saving technology can all be included into a facility's mechanical infrastructure to increase production, decrease downtime, and ensure long-term sustainability. Investing in high-quality mechanical design is a business strategy that directly supports profitability and expansion, not just an engineering choice.

0 notes

Text

Why Siemens HMI is a Game-Changer in Automation

In the present days of industrial developments, there has been an unusual demand for intelligent, reactive, and reliable interfaces. At the core of this innovation lies the Siemens HMI solution, an interface bridging the gap between human operators and complex machines. From managing a small production setup to a fully automated facility, Siemens offers HMI panels for differing operational requirements.

A real-world example of Siemens HMI in action can be seen in aviation - learn how Siemens HMI is streamlining airport baggage handling systems with precision and automation.

Why Choose Siemens HMI?

The Siemens HMI technology ensures that your machines are not simply connected, but intelligent, intuitive, and easy to control. Under the SIMATIC series, Siemens offers a range of HMI systems allowing operators to easily monitor, control, and adjust a machine's processes. Whether it's changing the temperature in a food processing unit or setting the speed of motors in a manufacturing plant — Siemens HMI gives you utmost control and real-time data access.

These HMI solutions are flexible and scalable. As your needs for production grow, your Siemens SIMATIC HMI system will be able to grow with you to support new functions, new users, and new machines.

Explore the Power of Siemens SIMATIC HMI

The Siemens SIMATIC HMI portfolio ranges from simple key panels to high-performance interface panels with multi-touch capabilities. With a fast processor, high-resolution display, and intuitive navigation controls, these panels ensure quick operation for the most demanding applications.

Besides the fast speed, Siemens HMI panels also promise a long life supported by frequent firmware updates and enhanced security features, making sure that your investment stays secure and ready for the future.

Touchscreens That Are Really Easy to Use with Siemens SIMATIC Panel Touch

The days of clunky buttons with limited interaction are over. The Siemens SIMATIC panel touch range brings the highest level of touch capability with easy navigation, gesture support, and brilliant displays. These panels are ideal for control systems that demand both time sensitivity and ease of access.

Touch panels make for great user experience, letting you make fast adjustments to the workings of machines yourself, view detailed information, and recognize faults, all at a glance. And built rugged, they work their way almost everywhere into the industries of oil & gas, pharmaceuticals, food & beverage, and logistics, to name a few.

Learn more in Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Integration Made Easy

Seamless integration with other Siemens automation products such as PLCs and SCADA systems is one of the principal advantages of using Siemens SIMATIC HMI systems. Incidentally, this causes efficient consolidations in industrial control systems-and alongside that, lesser maintenance-related stresses and minimized error rates.

Apart from the support for communication protocol offered by Siemens HMI panels making it rather easy to interface with third-party systems should there be a need for such interaction, it is this flexibility that makes Siemens a very popular choice among system integrators and plant managers all over the world.

For deeper insights, check out Human Machine Interface Siemens: Improving Operational Productivity.

Real Results from Every Industry

The Siemens HMI systems have proved their efficacy in real-time situations ranging from factory automation and process control to building management and energy monitoring. With fast boot-up times, customizable user interfaces, and sophisticated data visualization, these panels greatly enhance operational productivity and machine availability.

Conclusion

If your plan is to improve control in industrial automation with Naksh Technology Solutions LLP or to update a rather dated set of operator interfaces, then consider picking Siemens HMI systems. The company provides a whole range of solutions, which include Siemens SIMATIC HMI and Siemens SIMATIC panel touch, so you can count on market-leading innovativeness, reliability, and performance.

Smart HMI is a big difference; Siemens means technology plus efficiency.

0 notes

Text

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Enhancing Industrial Efficiency: The Role of Motors, Adapters & Circuit Breakers

In the age of Industry 4.0, automation is no longer just about moving parts—it’s about intelligent power management, secure connectivity, and system safety. At Dropship Automation Solutions, we supply the essential components that support high-performance industrial systems and resilient infrastructures.

In this blog, we explore three foundational elements of automation hardware: electric motors, industrial adapters, and circuit breakers—each playing a vital role in energy transfer, system compatibility, and operational safety.

1. Motors: Driving Industrial Motion

What Motors Do

Electric motors convert electrical energy into mechanical motion, making them fundamental in powering conveyor belts, pumps, fans, and more. Their reliability and precision keep operations running smoothly across countless industries.

Types & Applications

Types: AC motors, DC motors, servo motors, stepper motors

Applications: Conveyor systems, HVAC units, manufacturing robots, elevators

Benefits: High efficiency, consistent torque, reduced manual labor

Why Motors Matter

Motors are the force behind physical movement in automated systems. With high energy efficiency and precise control, modern motors minimize downtime and optimize mechanical output.

2. Adapters: Connecting Systems Seamlessly

What Adapters Do

Adapters serve as connectors that allow two otherwise incompatible devices or systems to work together. In industrial settings, they enable cross-device compatibility for data, power, or signal transmission.

Common Adapter Types & Uses

Types: Electrical plug adapters, signal adapters, communication protocol converters

Applications: Sensor integration, PLC expansion, international power conversion

Benefits: Device compatibility, simplified upgrades, reduced wiring complexity

Why Adapters Matter

Industrial adapters bridge gaps between old and new technologies, allowing systems to scale without costly replacements. They’re key to maintaining flexible and future-proof automation architectures.

3. Circuit Breakers: Safeguarding Electrical Systems

What Circuit Breakers Do

Circuit breakers protect electrical circuits from overloads or short circuits by interrupting power flow when abnormal conditions are detected. They ensure both equipment and personnel safety.

Types & Use Cases

Types: Miniature circuit breakers (MCB), molded case circuit breakers (MCCB), ground fault circuit interrupters (GFCI)

Applications: Control panels, power distribution, renewable energy systems

Benefits: Overcurrent protection, system isolation, fire prevention

Why Circuit Breakers Matter

Without circuit breakers, electrical faults could lead to equipment damage, fires, or system-wide failures. These devices serve as first-line defenders, ensuring your facility operates within safe power limits.

Building a Safer, Smarter Industry

Imagine an automated facility where:

Motors drive production lines with precision,

Adapters ensure seamless system connectivity,

Circuit breakers protect everything from faults and overloads.

This combination supports efficiency, safety, and adaptability—all key ingredients in modern industrial success.

Conclusion: Power Your Automation with Confidence

Smarter factories rely on trusted components for performance, safety, and scalability. At Dropship Automation Solutions, we provide robust motors, versatile adapters, and reliable circuit breakers to help build your next-gen industrial environment.

Empower your automation strategy—today.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes