#plywood market by type

Text

#global plywood market#plywood market#global plywood market share#global plywood market size#global plywood market report#plywood market by type#plywood market by grade#plywood market by application#plywood market by countries

1 note

·

View note

Text

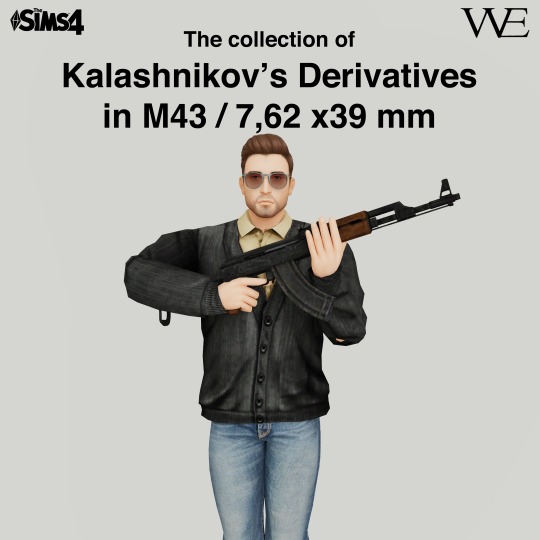

Avtomat Kalashnikova's Rifle Series

Part 1: 7,62 x39 (Soviet M43)

DOWNLOAD🔽

Author's Note

Greetings, dear customers!

I’m excited to be back providing great military content for your Sims 4 game! These past five months have been challenging due to various personal issues, including illness and other setbacks that slowed my progress. Managing everything on my own has been tough, especially since my partner has shifted focus away from our shared projects. But life must goes on.

Enough about the woe story—I'm happy to share that I’ve started by remastering some of my older content for those who enjoy classic items. Don’t worry, though; new items are also on the way. So sit back and enjoy! I hope you’ll find the new content up to your usual high standards.

Cheers!

Information

Right after World War II ended, the Red Army began searching for a new service rifle. They sought a rifle that would fire a cartridge based on the M43—a shortened version of the 7.62 x 54mm round, which became the 7.62 x 39mm. This new round was chosen for its moderate recoil and suitability for automatic fire. Initially, the semi-automatic Simonov SKS was selected as an interim solution while the search continued.

In 1946, Mikhail Kalashnikov entered his design into a competition alongside others. However, the Central Committee was not satisfied with the initial results, and all contestants were required to make improvements. A year later, Kalashnikov returned with a modified version, which he named the "Avtomat Kalashnikova model 47." Tests showed that Kalashnikov's design met all the Central Committee's requirements. Ultimately, his design was standardized as the Red Army's main service rifle, simply named the "AK" or "Avtomat Kalashnikov."

🇷🇺Original Releases🇷🇺

The rifle that started it all—the AK-47—is Mother Russia’s proudest gift to the world, born from the genius of Mikhail Kalashnikov. This section details the original AK model produced by the Soviet Union and it's Successcor States, Russian Federation, mark the beginning of an iconic rifle series

AK-47 (Avtomat Kalashnikova 1947)

Of all the weapons in the vast Soviet arsenal, nothing was more The One that Started all. nothing is more profitable than Avtomat Kalashnikova model of 1947, more commonly known as the AK-47, or Kalashnikov. It's the world's most popular assault rifle. A weapon all fighters love. An elegantly simple 9 pound amalgamation of forged steel and plywood. It doesn't break, jam, or overheat. It will shoot whether it's covered in mud or filled with sand. It's so easy, even a child can use it; and they do. The Soviets put the gun on a coin. Mozambique put it on their flag. Since the end of the Cold War, the Kalashnikov has become the Russian people's greatest export. After that comes vodka, caviar, and suicidal novelists. One thing is for sure, no one was lining up to buy their cars.

This Particular Model is first adoption of the AK family by the Red Army in 1949 & Contray to Popular Believe This Type Of Rifle Along With It's Folded Stock Variant Are So Rare and inteded as Red Army Trial Model. It got short service lenght in the Advent Of AKM.

AKS-47 (Avtomat Kalashnikova Skladnoy Model 1947)

Later versions of the original AK-47 are basically standard AK-47s but with a downward-folding metal stock (like the one on the German MP40 submachine gun). This design makes it easier to use in cramped spaces, like inside BMP infantry combat vehicles, and for paratroopers use. It was adopted for use by the Soviet military.

AKM (Avtomat Kalashnikova modernizirovanny)

The AKM is a improved & modernized variant of the AK-47 and was produced in much larger numbers. The most notable difference is that the AKM has a stamped receiver, making it lighter and less costly to produce, a slant compensator on the tip of the barrel (to reduce recoil) & an improved gas tube to ensuring Reliability. The Most Obiquotous AK Variant In Market.

AKMS (S – Skladnoy – Folding), A Variant Of AKMS which was equipped with an under-folding metal shoulder stock. The metal stock of the AKMS is somewhat different from the folding stock of the previous AKS-47 model as it has a modified locking mechanism, which locks both support arms of the AKMS stock instead of just one (left arm) as in the AKS-47 folding model. Like The perk From it's Main Rifle. This Variant Also Featuring More Lighter, Cheaper to Produce and better Recoil Management

AK-103/ Kastov 762

Note:Some of You young folks might knowed this gun from New Call of Duty LOL

The Trend of Weapon Modernization of 21st Century Finally Fall into Kalashnikov's Ear And AK 103 is the Answer for that. The AK-103 is a newer version of the AK-47. It still uses the same 7.62×39mm ammo but comes with some upgrades like a more comfortable synthetic stock and better materials like it's 5.45 Version brother. It’s designed to be more accurate and reliable, making it a solid choice for military and law enforcement use. Overall, it’s a tough like What you expect from Kalashnikov Rifle, modern rifle that handles well in different situations.

AK-104

A Russian Modern Answer to M4 Carbine. The AK-104 is a modernized version of the AK-47, designed to compete with the American M4. Chambered in 7.62×39mm, it’s more compact and features a folding stock, making it easier to handle in tight spaces. The AK-104 incorporates updated materials and design elements to stay relevant in today's weapon trends. Kalashnikov's ability to adapt and innovate has kept the AK series influential and trendy, maintaining its status as a leading choice in firearms across the globe.

☭Warsaw Pacts Derivatives & Foreign Copies☭

Due to the popularity of the Kalashnikov rifle and the heightened Cold War marked by the foundation of the Warsaw Pact (Soviet's defense pact to match Western NATO), many communist-aligned nations started copied Kalashnikov designs, both legally and illegally. The following section covers the foreign derivatives of the legendary Kalashnikov!

🇭🇺FEG AMD-65 (Automata Módosított Deszantfegyver 1965)🇭🇺

Another Masterpiece from Hungarian Factory Fegyver- és Gépgyártó Részvénytársaság. Popular Amongst Afghanistan National Army (Afghan's Army during occupation of United states of America, Until the fall of Afghanistan in 2021) is a modified compact version of the AKM-63 made for use by specialist troops like paratroopers and vehicle crews. The AMD-65 featured a shorter barrel, a muzzle brake, and an Iconic side folding stock.

The AMD-65 is the most famous variant of the Hungarian AKs, due to its distinctive appearance and more widespread availability in the United States compared to other variants.

🇵🇱FB RADOM Wz. 96 Beryl M762🇵🇱

representing Poland's efforts to develop modernized indigenous 5.45x39mm and 5.56x45mm Kalashnikov Rifle in response to late Cold War Warsaw Pact and NATO cartridge standardizations. This particular Model is is an export version of the kbs Wz. 96C chambered in 7.62x39mm. It is most notably used by Nigeria. and Mostly Popular Amongst "PlayerUnknown's Battlegrounds" Gamers or PUBG.

🇷🇴Pistol Mitralieră model 1963/1965🇷🇴

PM md. 63 (Romanian: Pistol Mitralieră model 1963; lit. "model 1963 submachine gun") is the Romanian military designation of Romanian manufactured clones of the Soviet AKM. Produced at the Cugir Arms Factory (today a subsidiary of ROMARM), early Romanian Kalashnikov rifles were almost indistinguishable from Soviet AKMs, but a number of Romanian domestic features were introduced in later production models, making them more and more distinct from Soviet Kalashnikovs. it is better known under the export name of AIM.

PM md. 65 The PM md. 65 is the Romanian clone of the AKMS. As with the md. 63, the rifle features a foregrip integrated into the handguard; in order to accommodate the underfolding stock, however, the foregrip of the PM md. 65 notably slants backwards. The rifle is exported to the west under the export name AIMS.

The Mini Draco (imported by Century Arms) is an ultra-short export variant of the Romanian AK featuring a 7.75" barrel. intended For US Civilians. Straight From Grand Theft Auto V

🇫🇮SAKO/Valmet Assault Rifle Series🇫🇮

The Finnish firearms manufacturer Valmet built assault rifles, in co-operation with Sako, based in part on the Kalashnikov action in the early 1960s, and continued to manufacture them up until 1994. Valmet later merged into Sako (in the late 1980s), and the some of their designs are currently being manufactured.

The model M62 (known as Rk 62 in Finland) was adopted by the Finnish Defence Forces, and still serves as the standard infantry weapon of the Finnish Army.The M62 has an unusual T-shaped tubular buttstock, compared to other Kalashinkov pattern rifles. The gas block and front sight design is very similar to the Israeli Galil rifle, as the Galil was designed based on the Valmet.

The RK 95 TP (known commercially as M95) is an upgraded variant of the M62, designed and manufactured by Sako. It has a folding stock, and can be fitted with suppressors. It was adopted into service by the Finnish Army, although in relatively small numbers, and it is still used by Finnish Special Forces. An export variant in 5.56mm was also produced in extremely limited numbers.

🇨🇳Norinco Type 56🇨🇳

The Type 56 assault rifle is the Chinese clone of the Soviet AK-47 rifle. It was China's service rifle from 1956 to the adoption of the QBZ-95 in around 1997. The Type 56 is the most commonly used AK variant in American film and television productions. This came about because China exported civilian AK variants (both Type 56 patterened and less commonly Soviet AK patterened) to the West in large numbers during the 1980s, primarily by the export companies Norinco

QBZ-56C (Type 56C) – Short-barrel version, introduced in 1991 for the domestic and export market. The QBZ-56C as it is officially designated in China, is a carbine variant of the Type 56-2 and supplied in limited quantities to some PLA units. The Chinese Navy is now the most prominent user. The QBZ-56C is often carried with a twenty-round box magazine, although it is capable of accepting a standard Type 56 thirty-round magazine. It also has a sidefolding stock in addition to a muzzle booster, giving it a similar appearance to the AKS-74U.

Type 56-2 – Improved variant introduced in 1980, with a side-folding stock and dark orange bakelite furniture. The stock also houses a cleaning kit, which both underfolding AKs (all nations) and other sidefolding AKs lacked, instead requiring a separate pouch. It also allows a traditional detachable bayonet, both AK-47 and AKM styles, as an option in addition to the folding spike style. Mainly manufactured for export and rare in China.

Type 56-2M - Basically Norinco Type 56-2 fitted with an aftermarket LHV-47 handguard and ergonomic pistol grip. Perfect for Customization. Model Straight From Grand Theft Auto V

💀Special Role And Novelty Items🤡

This Section will Covering Some Specialized Roles of Kalashnikov Rifle And some just a novelty Items of it which is specifically designed to serve no practical purpose, and is sold for its uniqueness

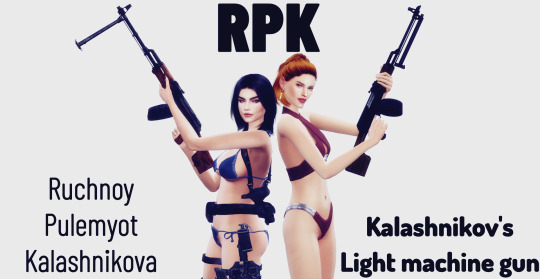

RPK-47

The Light Machine Gun Version of Legendary Kalashnikov's Assault Rifle. Featuring A Heavier Barrel for supporting Sustained fire, Bipod To enhance stability and accuracy during sustained fire, the RPK includes a bipod. This feature allows the operator to stabilize the weapon while firing from a prone or kneeling position, which is crucial for maintaining accuracy and control in a support role. along with the RPK often features a sturdier stock, which helps manage recoil and enhance overall stability while firing. this particular Version is Using 7.62X39mm

Golden AK Series

Note:Special Thanks For @bluexxxxx For magnificent Watergun Pose in Second Picture.

Alright, picture this: the iconic AK-47, but with a dazzling twist. That’s the Golden AK Series for you! Imagine the legendary Kalashnikov rifle decked out in a sleek, gold finish that screams both style and power. These rifles aren’t just about looking cool (though, let’s be honest, they definitely do). They’re also built with all the rugged reliability and firepower you expect from an The Cold War champion. So, if you want a rifle that combines legendary performance with a touch of glamour, the Golden AK Series is where it’s at. It’s not just a tool; it’s a statement.

@exzentra @exzentra-reblog

#the sims 4#the sims 4 custom content#ts4#ts4 cc#ts4 gun#ts4 military#call of duty modern warfare 2#cod mw2#pubg#pubg: battlegrounds#the sims 4 cc#the sims 4 gun#the sims 4 military#warsaw pact#soviet union#russia#ak 47 gun#ak 47 rifle#kalashnikov#romania#hungary#finland

23 notes

·

View notes

Text

The Gliders

Note: I wrote this five years ago for a blog and it was even published in The Prairie Times in the September 2019 issue. Since today is the 80th Anniversary of D-Day, I thought this would be the perfect article to post in honor of it. God Bless the Greatest Generation!

~*~

Growing up, I heard my grandfather fought in WWII, but as a kid I really didn’t know in what capacity. My family knew the basics: he was in the ETO; at various points he was in Iceland, England, France, and Germany. He had medals and he was involved with the gliders. He rarely spoke of his service and on the off-chance he did, he was vague. On the 50th anniversary of June 6th (June 6, 1994) my grandfather was in the nursing home and his younger brother Allen came to visit him. The whole family was there.

Allen made an off-handed comment to him saying, “Well, Bud, you know where we were fifty years ago today.”

“Yeah, D-Day.” And my grandfather began to cry.

Nothing more was said.

Everyone knew better than to pry too much. He avoided flying and planes, and later in life, he suffered PTSD. When he passed, his secrets and experiences died with him. A couple of years later, the miniseries “Band of Brothers” was released and it renewed my family’s interest in Grandpa’s service in WWII. We went through his papers with a fine-tooth comb, rediscovered the medals and patches, and that he had both paratrooper and glider wings. Uncle Allen filled us on a few things. We were able to piece together a little of his story. Then, thanks to the internet, we were able to learn exactly what the gliders were and what their function during the war.

The Germans were the first to use the gliders, in their invasion of France. In response to the German’s success, both America and British created their own versions. Nicknamed the “Flying Coffins,” a high-wind cabin aircraft, the gliders’ framing consisted of plywood and sometimes aluminum, and they were covered in canvas fabric. The glider would be connected to a C-47 aircraft, via a cable, and when both were air borne, the glider would be towed behind, “gliding” along. Without an engine and propellers, it flew silently and undetected by the enemy. The men, the “glider riders,” on the other hand, insisted it was extremely loud inside.

Depending on the type of glider, it would either be transporting fifteen men, or supplies, jeeps, and other equipment. When the glider was near its LZ (Landing Zone), it would be detached from the C-47 and it would crash land. Yes, you read that correctly: crash land. The survival rate wasn’t promising. It was suicidal, really. The glider pilots would have to navigate the engineless aircraft best they could, avoiding trees and stakes that had been erected by the enemy. Hopefully they’d land somewhere near the LZ. The gliders would also be under assault from the Germans. One testimony I heard was of a glider rider awaiting the glider’s detachment from the C-47, he was stunned when the laces on his boots suddenly stood on end. Numb from the adrenalin coursing through his veins, he later learned he had been shot in the foot. Following the crash landing, if the men survived, they would climb out of the glider and immediately enter into combat. Uncle Allen once told us that he had considered joining the airborne and asked my grandfather about it. Grandpa dissuaded him from it. He thought it was too dangerous for his younger brother.

The gliders were used in many major airborne operations throughout WWII: the invasion of Sicily, D-Day, Operation Market Garden, Operation Varsity, and in Operation Thursday in the Far East. In the various operations, the causalities were heavy. The gliders were instrumental during the war, and the glider riders proved themselves over and over again.

After WWII, the gliders were discontinued in favor of the helicopter. In comparison with the paratroopers, the glider riders involved were largely forgotten. There are books out there for those who want to do more in depth research, but more often than naught, the gliders are relegated to a footnote in the history books. Or a small mention on a documentary.

Looked down by many, including the paratroopers, they weren’t issued jump boots, and it wasn’t until July 1944 that they “earned” their right to wear glider wings and receive hazard-duty pay. During WWII, eventually most men were drafted into the military, but to be a “glider rider,” it was voluntary. The strongest and the best persevered against all odds. Why and how could these young men – including my grandfather – do such a dangerous, and in many cases, thankless job?

In my opinion, only the deepest and strongest patriotism could have emboldened them…Along with the fact that they were young and away from their homes for the first times in their lives. The gliders were something relatively new, untested, and risky. It was an adventure like no other and in the end the young men played their part in fighting against evil.

4 notes

·

View notes

Text

Packard Patricia pickup

Chris Coleman

Former Test Driver & Mechanic at Automotive Industry (2007–2008

What were the original reasons for Chevrolet coming out with the El Camino?

The El Camino, and other similar vehicles, like the Ford Ranchero, Subaru BRAT, Dodge Rampage and others, were designed to offer car-like comfort, performance and convenience, with the cargo capability of a light truck. Three of the forerunners to this were the Packard Patrician pickup, the Chevrolet Cameo and the Dodge Sweptline pickups.

1957 Dodge Sweptline with tailfins

Chevrolet Cameo Fleetside

The El Camino was based on the full-sized Impala originally, and was enormous. The low ground clearance and hefty weight made it a poor choice as a pickup. Most owners purchased them for styling reasons, especially with the cat eye taillights and horizontal tail fins.

1959 Chevrolet El Camino

Later, Chevrolet downsized the El Camino and based it on the Chevelle/Malibu, where it remained until it was discontinued.

1968 El Camino SS

With nothing in the rear, other than an empty bed, it was difficult to make it competitive as a muscle car, since the weight distribution was heavily biased towards the front.

Also, the bed used curved sheet metal in many places, to accommodate the rounded body panels, and this wasn’t a good fit with common pickup cargo, like plywood, hay bales and crates.

With the passenger compartment realistically holding two people, it was worthless as a family car, while a station wagon version of the Chevelle would be perfect. These things made it an odd fit with a very limited customer base.

Holden Ute, from Australia

Paradoxically, in Australia, cars like these, called Utes (short for utility) were and are extremely popular. Australia has a more rural environment and remote ranches and homes, which make this type of vehicle perfect for them. However in a more suburban setting, like the U.S., the El Camino was always an odd choice.

1972 Ford Ranchero - Based on the Torino

Dodge Rampage

Dodge Rampage, built on the K-car platform

Subaru Baja

Today, no one makes a ute for the American market, but that doesn’t mean these may not resurface from time to time. As kids grow up and nests are emptied, we may once again see a demand for the ubiquitous El Camino, Ford Ranchero and others.

17 notes

·

View notes

Text

The Technology behind Modern Furniture Designs

These days, technological advancement is seen influencing our lives, adding cutting-edge technologies, brand-new ideas & lasting materials to everything from mobiles to modern furniture that we use daily. It has resulted in more comfortable, durable & safer modern office furniture & made our lives full of luxury.

It is no secret that modern furniture has a great demand in the international market & a growing number of people choose it to give their homes or offices a contemporary look. However, some people are of the view that modern office furniture lacks new technology & ideas & appears more like the conventional ones. This is not found to be true.

To their surprise, more & more furniture manufacturers are using cutting-edge technologies & special materials to produce revolutionary, sustainable & portable modern furniture in attractive shapes & sizes. Most of these furniture makers maintain their own websites. So, people who want to go for remodeling in their home or office can start searching for them on the web.

A few decades back, we don't have enough options for modern furniture except a few common types of dining rooms, bedrooms & wall units. The technological advancement in modern furniture design has now given us the freedom to choose from hundreds of contemporary modern office furniture in different looks, materials & sizes so as to make our offices look more beautiful.

In earlier times, wood was highly used in the making of all kinds of furniture. Therefore the traditional furniture was too heavy, dull looking & was susceptible to water, light & other weather conditions. In an effort to increase the acceptability of conventional furniture, researchers introduced new furniture materials like plywood, and plastic etch. The furniture makers have started using these materials in furniture making & made the modern furniture light in weight & lovely in look. Even today, some of the furniture models are made of wood with plywood on the sides. This makes the furniture cost & weigh less & look classic. The furniture designers often make experiments with the furniture supplies including materials, using a combination of glass, wood, chrome & steel in the furniture-making process. Many are aware of the deteriorating global condition & want to use eco-friendly furniture designs. That's why the furniture for gardens & terraces is made from recycled materials. This is not all as the furniture makers are largely using a mixed variety of materials to produce more reliable & durable products. Now, heavy plasma TVs can be kept on fortified glass-made wall hangings.

Modern home & office furniture needs a fashionable look to draw the attention of more buyers. That's why the furniture makers keep on working with different colors, styles, patterns & shapes to bring an improvement in its value & functionality. Such transforming & sustaining furniture assures to give comfort to normal buyers who don't live in plush bungalows or apartments. It is a sophisticated technology that helps convert your comfy sofa into a perfect bed. Due to this technology, you can now purchase a convertible & smart-looking dining table with multiple moves to accommodate your whole family & friends whenever the necessity arises. Have you ever seen a modern armchair that can get transformed into a nice-looking lounge with just a button press? This is all the result of technological advancement in furniture making & designing.

Get the latest updates on modern office furniture, Meeting Tables, office chairs, office desks, Office Workstations, Office Sofas, Filling Cabinets, and Reception Desks in Dubai, for detailed office furniture, please visit our website officemaster.ae

Office Furniture Abu Dhabi, Office Furniture Sharjah, Office Furniture Doha – Qatar, Office Furniture Kuwait, Office Furniture Riyadh, Office Furniture Oman

OfficeMaster Al Quoz Branch – Office Furniture Dubai, Office Fit-out Dubai, Commercial Fit out Dubai, Residential Fit-out Dubai

No. 3, 34, 6 St., Dubai - UAE

+971 (0)50 651 9769

+971 (0)4 33 66 360

#office furniture#modern armchair#modern office furniture#Meeting Tables#office chairs#office desks#Office Workstations#Office Sofas#Filling Cabinets#Reception Desks#Office Furniture Abu Dhabi#Office Furniture Sharjah#Office Furniture Doha – Qatar#Office Furniture Kuwait#Office Furniture Riyadh#Office Furniture Oman#Office Furniture Dubai#Office Fit-out Dubai#Commercial Fit out Dubai#Residential Fit-out Dubai#modern furniture#furniture design#technology in furniture#furniture manufacturing#modern design#contemporary furniture#cutting-edge technology#innovative furniture#smart furniture#furniture engineering

2 notes

·

View notes

Text

What should I look for in a custom cabinet maker?

If you’re in the market for new kitchen cabinets, bath vanities or any other cabinetry project, it’s important to choose a reputable company. A bad choice could result in a shoddy product and an unsatisfactory experience.

The right cabinet maker will take accurate measurements and use modern software to make precision cuts, design and construction. This intimate process ensures that no details are missed and that the finished product lives up to your expectations.

A good cabinet maker will seek your approval on things such as color, molding and other details during the design stage. This will keep you from having to go through a second round of changes and save you time and money in the long run.

Choosing the right cabinet materials is also key to achieving a quality result. A well-built cabinet will be made using woods and boards that are strong enough to stand up to wear and tear over the years.

For example, a custom cabinet maker can recommend a type of case construction that uses low-pressure laminate, melamine or veneer core plywood instead of face-frame construction that requires a frame around the front or face of the cabinet box.

It’s also important to consider if the custom cabinet maker has their own showroom where they show off their work. This can be a good indicator of how well they understand their craft and what they’re capable of, in terms of craftsmanship.

If you are looking for the same, Contact Cabernet Kitchen & Fine Cabinetry, a top notch custom cabinet maker in Vaughan.

https://cabernetkitchens.ca/

5 notes

·

View notes

Text

J S Plywood & Timber: Plywood & Timber Seller

In the ever-evolving world of construction and interior design, the materials you choose can make all the difference. Plywood and timber are foundational elements that not only support structures but also enhance aesthetics. At J S Plywood & Timber, we pride ourselves on being a leading plywood and timber seller, providing high-quality products that meet the diverse needs of our clients in Jaipur and beyond.

Understanding Plywood and Timber

Plywood is an engineered wood product made from layers of thin wood veneer glued together. This construction method offers enhanced strength, flexibility, and stability compared to solid wood. Plywood is available in various grades, types, and finishes, making it suitable for a wide range of applications, from furniture making to flooring.

Wholesale Plywood and Timber Supply

As a leading plywood and timber seller in Jaipur, we specialize in wholesale supplies for contractors and builders. We understand the demands of large projects and offer competitive pricing on bulk orders. Our efficient supply chain ensures timely deliveries, so you can keep your projects on schedule without compromising on quality.

Sustainable Practices

We recognize the importance of sustainability in today’s market. At J S Plywood & Timber, we are committed to responsible sourcing practices, ensuring that our timber comes from sustainably managed forests. By choosing our products, you are making a positive impact on the environment, supporting responsible forestry practices that help preserve our planet for future generations.

Exceptional Customer Service

We believe that great service is just as important as quality products. Our dedicated team of experts is always ready to assist you in selecting the right plywood and timber for your specific needs. Whether you have questions about product specifications or need advice on project planning, we are here to help.

Our Information

Name :- J S Plywood & Timber

Add :- G2, Plot No 175, Ajmer Rd, opposite Midas Residency, Sanjay Nagar, Doctors Colony, Chouraha, Jaipur, Rajasthan 302021

Phone :- 9414014260

Conclusion

When it comes to plywood and timber, J S Plywood & Timber stands out as your premier seller in Jaipur. With a wide range of high-quality products, competitive wholesale pricing, and a commitment to sustainability and customer satisfaction, we are here to support your construction and design needs.

0 notes

Text

Sustainable Construction: How the Particle Board Market is Evolving in 2024-2034

Particle board, also known as chipboard, is an engineered wood product made from wood chips, sawdust, and resin. It has become a cost-effective alternative to solid wood and plywood, used extensively in the construction, furniture, and packaging industries. The global particle board market is expected to see considerable growth from 2024 to 2034, driven by increasing urbanization, rising demand for affordable furniture, and a growing focus on sustainable building materials.

The global particle board industry, valued at US$ 25.1 billion in 2023, is projected to grow at a CAGR of 5.6% from 2024 to 2034, reaching US$ 45.3 billion by the end of 2034. Factors such as the expansion of the construction sector in emerging economies, the increasing demand for eco-friendly products, and innovations in particle board manufacturing technologies are contributing to this growth.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/particle-board-market.html

Market Segmentation

The particle board market is segmented based on various parameters:

By Service Type:

Raw particle boards: Used for structural purposes in construction and furniture.

Laminated particle boards: Used for aesthetic purposes in interior decoration and cabinetry.

Melamine-coated particle boards: Used for surfaces requiring water resistance, primarily in kitchens and bathrooms.

By Sourcing Type:

Softwood-based particle boards: Primarily used in construction and insulation due to durability.

Hardwood-based particle boards: Preferred for furniture making and decorative items for finer finishes.

By Application:

Furniture: The largest application segment, driven by the demand for cost-effective materials in household and office furniture.

Construction: Used in flooring, wall panels, and insulation.

Packaging: Gaining popularity as a sustainable material for packaging.

Others: Applications in exhibitions, partitions, and shelving units.

By Industry Vertical:

Residential Construction: High demand due to urbanization and affordable housing.

Commercial Construction: Used extensively in office spaces, hotels, and retail outlets.

Furniture Manufacturing: Essential for producing mass-market furniture.

Packaging Industry: Growing demand for eco-friendly packaging solutions.

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America

The particle board market in North America is driven by increasing demand in the residential and commercial construction sectors. Sustainable building practices and a growing preference for eco-friendly materials are key drivers in the region, with the United States and Canada being major markets.

Europe

Europe holds a significant share of the global particle board market, particularly in the furniture manufacturing industry. Countries like Germany, Italy, and Poland are leaders in particle board production. The European Union's emphasis on sustainability and circular economy principles further boosts the demand for particle boards.

Asia-Pacific

Asia-Pacific is the fastest-growing market for particle boards, with China and India leading the way. Rapid urbanization, a booming construction industry, and increasing consumer demand for affordable furniture are key growth drivers. The region’s strong industrial base in wood-based manufacturing supports particle board production.

Latin America

In Latin America, countries like Brazil and Mexico are witnessing growth in the particle board market due to increasing construction activities and growing demand for budget-friendly housing materials.

Middle East & Africa

The particle board market in the Middle East & Africa is relatively nascent but growing due to increased investments in infrastructure and construction projects.

Market Drivers and Challenges

Drivers

Cost-effectiveness: Particle boards are cheaper compared to solid wood and plywood, making them a popular choice in construction and furniture production.

Sustainability: As a product made from wood waste, particle boards align with the growing global focus on sustainability and reducing deforestation.

Urbanization and Infrastructure Development: Increasing construction activities, especially in emerging economies, are driving demand for particle boards.

Furniture Demand: The growing trend of affordable, ready-to-assemble (RTA) furniture has expanded the market for particle boards, especially in the residential and commercial sectors.

Challenges

Durability Issues: Particle boards are less durable compared to plywood and MDF, limiting their use in high-load applications.

Moisture Sensitivity: Particle boards are prone to damage when exposed to moisture, requiring additional treatments and coatings for certain applications.

Environmental Concerns: The use of synthetic resins, often containing formaldehyde, in particle board production has raised health and environmental concerns.

Market Trends

Sustainable Materials: The shift toward environmentally friendly building materials is pushing manufacturers to develop particle boards with minimal environmental impact, using bio-based resins and recycled wood materials.

Technological Advancements: Innovations in resin technology and production processes are enhancing the strength, water resistance, and overall performance of particle boards.

Rising Popularity of RTA Furniture: Ready-to-assemble furniture, particularly in the e-commerce sector, is boosting demand for particle boards, which are a key material in such products.

Future Outlook

The global particle board market is expected to continue its upward trajectory through 2034, with substantial growth opportunities in emerging markets. Increasing environmental awareness, combined with technological innovations in particle board production, will create a favourable market landscape. Additionally, advancements in coatings and laminates will enhance particle board durability, expanding its use in diverse applications.

Key Market Study Points

Market Size and Forecast: Evaluation of market value from 2024 to 2034.

Key Market Drivers: Identification of factors driving growth, including cost-effectiveness and sustainability.

Challenges: Analysis of issues like durability and moisture resistance.

Technological Innovations: Overview of advancements in resin and production processes.

Regional Insights: A detailed analysis of regional markets with growth potential in Asia-Pacific and North America.

Competitive Landscape: Insight into the leading market players and their strategies.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86230<ype=S

Competitive Landscape

Major players in the global particle board market include:

Kronospan: A leading manufacturer with a strong global presence.

Egger Group: Known for innovations in wood-based products, including particle boards.

Norbord Inc.: Specializes in engineered wood products, including particle boards.

Weyerhaeuser Company: One of the largest producers of wood-based products, focusing on sustainability.

These companies are focusing on product innovation, expanding production capacities, and enhancing sustainability initiatives to maintain their market positions.

Recent Developments

Sustainability Initiatives: Several manufacturers are investing in bio-based resins to reduce the environmental impact of particle board production.

New Product Launches: Companies are introducing particle boards with enhanced moisture resistance and improved surface finishes for high-end furniture applications.

Capacity Expansions: Increasing demand for particle boards has led to new production facilities being established, particularly in the Asia-Pacific region.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Why Choose Engineered Wood Flooring for Your Home?

Choosing the right flooring for your home can be a daunting task, with countless materials and styles available on the market. Engineered wood flooring has become a popular option for homeowners looking for the timeless appeal of hardwood, but with additional durability and versatility. Combining the beauty of natural wood with the resilience of modern engineering, this type of flooring offers a wide range of benefits that make it suitable for nearly any room in the house. In this article, we’ll explore why engineered wood flooring might be the perfect fit for your home, covering its key features, installation methods, and long-term advantages.

What is Engineered Wood Flooring?

Engineered wood flooring is a type of hardwood flooring that consists of multiple layers of wood, rather than a single solid piece. The top layer, known as the wear layer, is made of real hardwood, providing the authentic appearance and texture of solid wood. Below this wear layer, multiple layers of plywood or high-density fiberboard (HDF) are stacked in a cross-grain configuration. This layered construction increases the floor’s stability, making it more resistant to changes in temperature and humidity compared to solid wood.

The beauty of engineered wood flooring is that it offers the same rich and elegant look as traditional hardwood, but with improved durability and performance. The wear layer can come in a variety of wood species, including oak, maple, walnut, and cherry, allowing homeowners to match their flooring with any design style. The thickness of the wear layer varies by product, and thicker layers can even be sanded and refinished multiple times, extending the floor’s lifespan.

Overall, engineered wood flooring offers a combination of aesthetic appeal and practical benefits that make it a popular choice for modern homes. Its versatility and ease of installation make it a viable option for a range of spaces, from living rooms to basements.

How is Engineered Wood Different from Solid Wood Flooring?

While both engineered wood and solid wood flooring have a similar appearance, they are constructed in very different ways. Solid wood flooring is made from a single piece of wood, which gives it a classic, timeless look but also makes it more susceptible to environmental changes. Solid wood expands and contracts with fluctuations in humidity and temperature, making it more prone to warping, especially in areas like basements or humid climates.

In contrast, engineered wood is designed to counteract these issues. Its multi-layered construction provides more dimensional stability, meaning it is less likely to warp, shrink, or expand. This makes engineered wood ideal for areas that experience temperature or moisture changes, such as kitchens or bathrooms, where solid wood would be a risky choice.

Another key difference is installation flexibility. Solid wood floors typically need to be nailed or glued down, whereas engineered wood can be installed in various ways, including floating installations, making it easier and quicker to install. Engineered wood is also compatible with underfloor heating systems, which is not the case for most solid wood floors. While solid wood can be sanded and refinished multiple times over its lifespan, engineered wood can also be refinished, depending on the thickness of its wear layer, but usually not as often.

The Key Benefits of Engineered Wood Flooring

Engineered wood flooring offers several benefits that make it an attractive choice for homeowners. One of its most significant advantages is its stability. Thanks to its multi-layered construction, engineered wood is less susceptible to warping and movement caused by temperature and humidity fluctuations. This makes it suitable for installation in areas where solid wood flooring would struggle, such as basements or rooms with radiant heating systems.

Another key benefit is its aesthetic versatility. With a wide range of species, finishes, and styles available, engineered wood can closely mimic the look of solid hardwood flooring while offering a broader selection of design options. Homeowners can choose from various plank widths, colors, and textures to match their interior decor.

Durability is another strong point for engineered wood. The wear layer of engineered wood is made from real hardwood, providing the same resistance to scratches and dents as solid wood. Thicker wear layers allow for refinishing, which can extend the floor’s lifespan by many years.

Lastly, engineered wood is easier to install compared to solid wood, with several installation options including floating, glue-down, and nail-down methods. Its versatility, stability, and aesthetic appeal make it an excellent flooring solution for virtually any room in your home.

Durability and Longevity of Engineered Wood

One of the standout features of engineered wood flooring is its durability. Unlike solid wood, which can be sensitive to environmental conditions, engineered wood’s layered construction offers increased resistance to the effects of humidity and temperature changes. This makes it less prone to issues like warping or shrinking over time, particularly in areas where moisture levels fluctuate, such as bathrooms or basements.

The lifespan of engineered wood largely depends on the thickness of its wear layer. Thicker wear layers, typically 3-6 mm, can be sanded and refinished multiple times, much like solid hardwood, extending the floor’s longevity to 20-30 years or more. Even engineered wood with a thinner wear layer can last over a decade with proper care.

In addition to resisting moisture, engineered wood is tough enough to withstand daily wear and tear. Its durability makes it a great option for high-traffic areas like hallways and living rooms. While scratches and dents are possible, especially with softer wood species, these imperfections can often be minimized with routine maintenance or refinishing.

For households with pets, children, or heavy furniture, engineered wood offers a resilient and long-lasting flooring solution. Its durability, combined with its timeless aesthetic, ensures that it remains a smart investment for years to come.

Installation Methods for Engineered Wood Flooring

Engineered wood flooring is prized for its ease of installation, with several methods available depending on the homeowner's preference and the condition of the subfloor. The three most common installation methods are floating, glue-down, and nail-down.

The floating method involves laying the engineered wood planks over an underlayment without adhering them directly to the subfloor. The planks are connected via a tongue-and-groove system or a click-lock mechanism. This method is often the simplest and most cost-effective, making it popular for DIY installations. Floating floors are also ideal for areas with radiant heating systems, as the lack of adhesives allows the floor to expand and contract freely.

Glue-down installation involves applying adhesive to the subfloor before laying the engineered wood planks on top. This method provides a more secure and permanent installation, making it well-suited for high-traffic areas. However, it requires more skill and preparation, as the subfloor must be clean, dry, and level to ensure a smooth installation.

The nail-down method is similar to the installation of solid hardwood floors, where the planks are secured to the subfloor with nails or staples. This method is typically used for installations over wooden subfloors and provides a very stable, long-lasting floor. Although more labor-intensive, this method ensures that the engineered wood remains securely in place for decades.

Conclusion

Engineered wood flooring is a versatile, stylish, and practical choice for homeowners looking for the beauty of hardwood without the drawbacks of solid wood. With its superior resistance to environmental changes, easy installation methods, and wide range of design options, engineered wood offers the perfect balance of form and function. Whether you’re upgrading your living room, renovating a basement, or installing new floors in a high-traffic area, engineered wood flooring provides a durable and aesthetically pleasing solution for any space.

#jordans flooring#jordans wood flooring wimbledon#pro tek flooring#flooring wimbledon#wimbledon flooring#jordan wood#bespoke wooden flooring#wandsworth wood flooring#wandsworth flooring#bespoke wood flooring#woodflooring#engineered wood flooring london#wood flooring#wooden floors london#hardwood flooring london#parquet flooring#engineered wood flooring#herringbone flooring#laminate flooring#lvt flooring#luxury vinyl flooring#oak flooring#engineered herringbone#engineered wood#solid wood flooring#white oak flooring#wood laminates#real wood flooring#grey wood floors

0 notes

Text

Discover Premium Laminates at Uro Veneer World: Your Trusted Laminates Store in Bangalore

For premium plywood options and competitive pricing in Bangalore, visit Uro Veneer World.

Introduction

When it comes to elevating the aesthetics and functionality of your interiors, choosing the right laminates is crucial. Uro Veneer World, a leading laminates store in Bangalore, offers an extensive range of premium laminates that cater to all your design needs. Whether you're renovating your home or designing a new office space, Uro Veneer World provides top-quality laminates that combine durability with style. Let’s explore what makes Uro Veneer World the go-to destination for laminates in Bangalore.

The Role of Laminates in Modern Interior Design

Laminates have become an essential element in modern interior design, offering a versatile and cost-effective solution for enhancing the look and feel of any space. These thin, protective layers are applied over surfaces like wood, particleboard, or MDF to provide a decorative finish that mimics the appearance of more expensive materials like wood or stone. From kitchen cabinets to office furniture, laminates are widely used for their durability, easy maintenance, and endless design possibilities.

In today’s interior design landscape, laminates are more than just a practical choice—they are a statement of style. With a wide range of colors, textures, and patterns available, laminates allow homeowners and designers to experiment with different looks without breaking the bank.

Why Choose Uro Veneer World for Laminates?

Uro Veneer World has established itself as a trusted name in the laminates market, thanks to its unwavering commitment to quality and customer satisfaction. Founded with the vision of providing the best laminates to Bangalore’s discerning customers, Uro Veneer World offers a curated selection of laminates that cater to various design preferences and project requirements.

At Uro Veneer World, you’ll find an extensive range of laminates sourced from leading manufacturers, ensuring that every product meets the highest standards of durability and aesthetic appeal. The store’s knowledgeable staff is always ready to assist you in finding the perfect laminate for your project, offering personalized recommendations based on your specific needs.

Exploring the Variety: Types of Laminates Offered

One of the key reasons to visit Uro Veneer World is the sheer variety of laminates available. Whether you’re looking for something sleek and modern or warm and traditional, the store offers multiple options to suit your taste:

High-Pressure Laminates (HPL): Known for their strength and durability, HPLs are perfect for high-traffic areas and commercial spaces.

Compact Laminates: These are thicker and more robust, ideal for countertops and surfaces that require extra durability.

Decorative Laminates: Featuring a variety of patterns and colors, decorative laminates are great for adding a personal touch to your interiors.

Textured Laminates: These laminates offer a tactile experience, mimicking natural materials like wood grain or stone.

Glossy vs. Matte Finishes: Whether you prefer a shiny, reflective surface or a subdued, matte look, Uro Veneer World has options to match your aesthetic.

Premium Laminates Collection

For those looking to add a touch of luxury to their interiors, Uro Veneer World’s premium laminates collection is a must-see. These laminates are designed to offer superior aesthetics and durability, making them a popular choice for high-end residential and commercial projects. The premium collection features exclusive designs, including exotic wood grains, metallic finishes, and artistic patterns that can transform any space into a masterpiece.

Applications of Laminates

Laminates are incredibly versatile and can be used in various applications throughout your home or office:

Laminates for Kitchen Cabinets: Offering resistance to heat, moisture, and stains, laminates are a practical and stylish choice for kitchen cabinetry.

Laminates for Wardrobes and Closets: Enhance your storage spaces with laminates that provide both beauty and durability.

Laminates for Office Furniture: Create a professional yet inviting office environment with laminates that combine functionality with modern design.

Laminates for Wall Panels and Doors: Add texture and depth to your interiors with decorative laminates used on walls and doors.

Durability and Maintenance of Laminates

One of the standout features of laminates is their durability. When properly maintained, laminates can retain their look and performance for years. To keep your laminates looking their best, it’s important to follow a few simple maintenance tips:

Regular Cleaning: Use a soft, damp cloth to wipe down the surfaces regularly. Avoid using abrasive cleaners that can damage the laminate’s finish.

Heat and Scratch Resistance: Although laminates are resistant to heat and scratches, using trivets and cutting boards can help prolong their lifespan.

Water Resistance: Laminates are generally water-resistant, but it’s a good idea to wipe up spills promptly to prevent any potential damage.

Customization Options at Uro Veneer World

Understanding that every project is unique, Uro Veneer World offers customization options to help you achieve the exact look you desire. Whether you need a specific color, pattern, or finish, the store’s experts can work with you to create custom laminates that match your vision. This service is particularly valuable for designers and architects looking to make a distinct impression in their projects.

Eco-Friendly and Sustainable Laminates

Sustainability is increasingly important in today’s design world, and Uro Veneer World is committed to offering eco-friendly laminate options. These laminates are made from sustainable materials and processes that minimize environmental impact. Uro Veneer World’s eco-friendly laminates meet various environmental certifications, ensuring that your design choices are as green as they are stylish.

Pricing and Affordability

While Uro Veneer World is known for its premium products, the store also offers laminates at a range of price points, ensuring there’s something for every budget. The quality of the laminates ensures that you get excellent value for your money, making it a cost-effective solution for both large and small projects. Additionally, Uro Veneer World frequently runs special offers and discounts, making it easier for you to get premium products at competitive prices.

Customer Experience and Testimonials

Uro Veneer World takes pride in its commitment to customer satisfaction. From the moment you step into the showroom to the completion of your project, the store’s staff is dedicated to providing you with a seamless shopping experience. Many satisfied customers have shared their positive experiences, highlighting the helpfulness of the staff, the quality of the products, and the ease of finding exactly what they needed.

Visit Uro Veneer World Showroom

Located in the heart of Bangalore, Uro Veneer World’s showroom is easily accessible and well worth a visit. Here, you can explore the wide variety of laminates in person, get a feel for different textures, and consult with experts who can guide you through your choices. Whether you’re a homeowner, designer, or contractor, a visit to the showroom will provide valuable insights and inspiration for your next project.

How to Choose the Right Laminate for Your Space

Selecting the right laminate involves considering various factors such as color, texture, and finish. Uro Veneer World’s experts recommend choosing laminates that complement your overall interior design theme. For example, glossy laminates work well in modern spaces, while textured or matte finishes may be better suited for rustic or traditional interiors. It’s also important to consider the functionality of the space—high-traffic areas may benefit from more durable, scratch-resistant laminates.

The Future of Laminates in Interior Design

As technology advances, the possibilities for laminate design and application continue to expand. Future trends in laminates include more realistic textures, advanced digital printing techniques, and greater use of sustainable materials. Uro Veneer World stays ahead of these trends by continually updating its product offerings and incorporating the latest innovations in laminate technology.

Conclusion

Laminates are a versatile, durable, and stylish solution for enhancing any interior space. Uro Veneer World in Bangalore offers an unparalleled selection of premium laminates, making it the ideal destination for all your laminate needs. Whether you’re looking to revamp your kitchen, office, or living room, Uro Veneer World has the expertise, variety, and quality to help you achieve your design goals. Visit the showroom today and discover why Uro Veneer World is Bangalore’s trusted source for premium laminates.

#home improvement#interior design#uro veneer world#laminates#laminates for kitchen cabinets#decor#living room#kitchen#interiors

0 notes

Text

Transform Your Home with Wood Flooring in NJ

When it comes to enhancing the beauty and value of your home, few options rival the elegance and durability of wood flooring. For homeowners in New Jersey, choosing wood flooring not only adds a touch of sophistication but also offers long-term benefits that can withstand the test of time. Here's why Wood Flooring NJ is a top choice for NJ homes and what you need to consider when making your decision.

Benefits of Wood Flooring

Timeless Appeal: Wood flooring exudes a classic charm that complements any home decor, from traditional to modern. Its natural beauty and variety of styles—from rich mahogany to light oak—make it versatile for any room. Unlike some flooring options that may go out of style, wood flooring remains a staple in home design, providing timeless appeal.

Durability and Longevity: One of the most compelling reasons to choose wood flooring is its durability. High-quality hardwood floors can last for decades, even centuries, with proper care. They are resistant to wear and tear, making them ideal for high-traffic areas such as living rooms and hallways.

Easy Maintenance: Maintaining wood floors is relatively simple compared to other flooring types. Regular sweeping and occasional mopping are usually sufficient to keep them looking their best. Additionally, unlike carpets that can trap dust and allergens, wood floors are hypoallergenic and easier to clean.

Increased Home Value: Investing in wood flooring can significantly increase the value of your property. Many homebuyers consider wood flooring a desirable feature, which can make your home more attractive in a competitive real estate market. This return on investment can be particularly beneficial if you plan to sell your home in the near future.

Choosing the Right Wood Flooring

Types of Wood: When selecting wood flooring, you have a variety of options. Hardwood floors, such as oak, maple, and cherry, are popular for their durability and classic look. Engineered wood flooring, which consists of a veneer of hardwood over a plywood base, offers more stability and is less prone to expanding and contracting with changes in humidity.

Finish and Stain: The finish of your wood flooring can greatly impact its appearance and maintenance. Options range from matte to high gloss. Additionally, stains can be applied to achieve the desired color and tone, allowing you to customize the look to match your interior design.

Installation: Professional installation is key to ensuring the longevity and performance of your wood floors. Experienced installers can handle the complexities of laying wood flooring, including acclimating the wood to your home's environment and ensuring proper subfloor preparation. DIY installations are possible but may require a higher level of skill and tools.

Budget Considerations: Wood flooring can vary in cost based on the type of wood, finish, and installation complexity. It's important to establish a budget and explore options that meet both your aesthetic preferences and financial constraints. Remember to account for additional costs such as underlayment, baseboards, and potential subfloor repairs.

Finding Wood Flooring in NJ

New Jersey offers a range of options for purchasing and installing wood flooring. Local showrooms and flooring retailers can provide samples and expert advice tailored to your specific needs. Additionally, many companies offer online consultations and virtual showrooms, making it easier to find the perfect Local Flooring Installers NJ for your home.

0 notes

Text

Which brand of plywood is best?

Plywood is a versatile material, widely used in construction and furniture making. Its strength, durability, and affordability make it a popular choice among homeowners and professionals alike.

But with so many brands on the market, how do you determine which is the best? What factors should you consider when choosing a plywood brand for your project?

In this article, we will delve into the world of plywood. We'll explore what makes a plywood brand superior, from the quality of the wood to the certifications it holds.

We'll take a closer look at some of the top brands in the market, such as Sylvan Ply. We'll also discuss the importance of BWR(Boiling Water Resistant) and BWP (Boiling Water Proof) plywood in certain applications.

We'll touch on the growing demand for sustainable plywood options. And we'll guide you through the different types of plywood available, helping you understand which is best suited for your needs.

Whether you're a DIY enthusiast, a professional contractor, or simply a homeowner planning a renovation, this guide is for you. Let's embark on this journey to find the best plywood brand for your project.

0 notes

Text

DIY Built-In Shelving: Adding Storage and Style to Your Inner West Home Renovation

Home renovations in the Inner West of Sydney offer homeowners the opportunity to not only increase the functionality and value of their homes but also to inject a sense of personal style into their living spaces. One of the most effective ways to achieve both of these goals is by incorporating built-in shelving into your renovation plans. This DIY project can transform any room in your Inner West home, offering additional storage space while enhancing the aesthetic appeal of your interiors.

In this comprehensive guide, we will explore the benefits of built-in shelving, the steps involved in creating your own, and how this addition can elevate your home renovation in the Inner West. We'll also address common questions and provide practical tips to ensure your DIY project is a success.

The Appeal of Built-In Shelving in the Inner West

1. Maximizing Space in Compact Homes

The Inner West is known for its charming, yet often compact homes. Built-in shelving is an ideal solution for maximizing space in these residences. Unlike freestanding furniture, built-in shelves are integrated into the walls, making use of otherwise wasted space. This is particularly beneficial in smaller rooms where floor space is limited.

2. Enhancing Aesthetic Appeal

Built-in shelving adds a sense of sophistication to any room. Whether you opt for sleek, modern designs or more traditional styles, these shelves can be tailored to complement the existing décor of your home. The seamless integration of built-ins can create a more cohesive and polished look, elevating the overall aesthetic of your living spaces.

3. Increasing Home Value

Incorporating custom built-in shelving into your home renovation can also increase the value of your property. Potential buyers often appreciate the added functionality and style that built-ins provide, making your home more attractive on the market.

Planning Your DIY Built-In Shelving Project

Before you start your DIY built-in shelving project, it’s essential to plan carefully to ensure that the finished product meets your needs and enhances your home.

1. Assess Your Space

The first step is to assess the space where you plan to install the built-in shelves. Consider the dimensions of the room, the layout, and any existing architectural features that may affect your design. For example, if you're installing shelves in a living room, you might want to incorporate them around a fireplace or under a staircase.

2. Determine the Purpose

Consider what you will be using the shelves for. Will they primarily serve as storage for books, or do you plan to display decorative items? The purpose of the shelves will influence the design, size, and spacing of the shelves. For example, if you’re storing books, you’ll need sturdy, deep shelves that can bear significant weight.

3. Choose the Right Materials

Selecting the right materials is crucial for both the durability and appearance of your built-in shelving. Plywood, MDF (medium-density fibreboard), and solid wood are popular choices. Plywood is strong and lightweight, MDF offers a smooth finish that’s easy to paint, and solid wood provides a classic, high-end look.

4. Design Considerations

When designing your built-in shelving, think about the style of your home. In the Inner West, many homes feature a blend of classic and contemporary styles. Your built-in shelving should complement this aesthetic. Consider factors such as the type of trim, the color scheme, and whether you want open or closed shelving.

Step-by-Step Guide to Building Your DIY Shelving

Building your own built-in shelves can be a rewarding project that enhances your home renovation in the Inner West. Follow these steps to create a stunning and functional addition to your home.

Step 1: Measure and Mark

Begin by measuring the space where you plan to install the shelves. Use a tape measure to determine the height, width, and depth of the shelving unit. Mark these dimensions on the wall with a pencil, ensuring that the lines are straight and level.

Step 2: Cut the Materials

Using your measurements, cut the plywood or MDF to create the sides, shelves, and back panel of the unit. If you're using solid wood, make sure to cut it carefully to avoid splintering. A circular saw or table saw is ideal for making precise cuts.

Step 3: Assemble the Frame

Assemble the frame of the shelving unit by attaching the sides to the back panel. Use wood glue and screws to secure the pieces together. Ensure that the frame is square and level before tightening the screws.

Step 4: Install the Shelves

Attach the shelves to the frame by drilling pilot holes and securing them with screws. If your shelves will hold heavy items, consider adding additional supports or brackets underneath for extra stability.

Step 5: Install the Built-In Unit

Carefully position the assembled shelving unit into the designated space on the wall. Use a level to ensure that the unit is straight. Secure the unit to the wall studs using screws, making sure it is firmly attached.

Step 6: Finish the Shelves

Once the unit is installed, you can finish the shelves by sanding any rough edges and filling any gaps with wood filler. Paint or stain the shelves to match your desired look, and add any trim or molding to complete the design.

Styling Your Built-In Shelves

After successfully installing your DIY built-in shelving, the next step is to style them in a way that enhances the overall aesthetic of your room.

1. Mix Functionality with Style

When styling your shelves, aim for a balance between functionality and style. Incorporate a mix of items, such as books, decorative objects, plants, and personal mementos. This approach not only adds visual interest but also ensures that your shelves are both practical and beautiful.

2. Create Visual Balance

Arrange items on the shelves in a way that creates visual balance. For example, if you have a large, heavy object on one side, balance it with a group of smaller items on the opposite side. Varying the height and size of objects also adds depth and dimension to the display.

3. Incorporate Lighting

Consider adding lighting to your built-in shelves to highlight your displays and create a warm, inviting atmosphere. LED strip lights or small recessed lights work well and can be easily installed along the top or bottom of the shelves.

Conclusion

DIY built-in shelving is an excellent way to add both storage and style to your Inner West home renovation. By carefully planning and executing this project, you can create a custom feature that not only enhances the functionality of your living spaces but also adds value to your property. Whether you're looking to maximize space in a compact room or elevate the aesthetic appeal of your interiors, built-in shelving offers a versatile and stylish solution.

FAQs

1. Can I install built-in shelves in any room of my Inner West home?

Yes, built-in shelves can be installed in virtually any room of your home. They are particularly useful in living rooms, bedrooms, home offices, and even kitchens, where they can provide additional storage and display space.

2. Do I need professional help to build and install built-in shelving?

While it's possible to build and install built-in shelving as a DIY project, it's important to have basic carpentry skills and the right tools. If you're unsure about your ability to complete the project, you may want to consult a professional for assistance.

3. What materials are best for built-in shelves?

Plywood, MDF, and solid wood are popular choices for built-in shelving. The best material for your project will depend on your budget, desired finish, and the weight of the items you plan to store.

4. How do I ensure my built-in shelves are sturdy enough?

To ensure your shelves are sturdy, make sure they are properly anchored to the wall studs and that the shelves themselves are supported by brackets or additional framing if necessary. Using quality materials and construction techniques will also contribute to the durability of your shelves.

5. Can built-in shelving increase the value of my home?

Yes, built-in shelving can increase the value of your home by adding both functionality and aesthetic appeal. Potential buyers often view built-ins as a desirable feature, particularly in homes where space is at a premium.

By following these guidelines and tips, you can successfully create DIY built-in shelving that enhances both the style and functionality of your home renovation Inner West.

0 notes

Text

What makes Calibrated Plywood the best plywood for manufacturing modern furniture?

Today’s modern world requires modern furniture solutions, and calibrated plywood is considered the best for manufacturing them. There are different types of plywood available in the market, but calibrated plywood is considered the best due to the availability of multiple features. Especially when you buy them from a reliable and certified calibrated plywood supplier, as they treat them well to make them suitable for diverse applications. Though unaware of the features and benefits of calibrated plywood, people often ignore it and consider using other plywood. But in this blog, we are sharing all the benefits offered by calibrated plywood, which makes them the best. After discovering these benefits, you will know why you should use this plywood for all modern furniture needs.

Plywood with even thickness

Whether one needs to use plywood in the construction industry, for manufacturing furniture, or for flooring or roofing applications, everyone desires to use plywood with uniform thickness. Calibrated plywood is manufactured using the best veneers, which are sanded properly to give them even thickness. They are then glued together by using an excellent quality adhesive. They are pressed using a hydraulic machine and then undergo a calibration machine to ensure that the plywood achieves the same level of thickness. The even thickness of calibrated plywood makes them the best for multiple applications. But to ensure that you get precisely manufactured calibrated plywood, always come from a renowned calibrated plywood supplier.

Aesthetically appealing Plywood for different applications

Calibrated plywood is not only known for its even thickness but is also known for its even surface. It is cut and treated in a way that it is free from any kind of marks, bumps, cracks, and holes. One need not use any such material over them to hide any flaws. The smooth surface of this plywood allows one to work on this plywood easily. Whether one desires to overlay a layer of laminate over them or whether one wishes to paint or varnish them, it can be done easily. It makes calibrated plywood a perfect material for manufacturing both home and office furniture.

Can be modified and transformed with ease

We already mentioned above that calibrated plywood is perfect for manufacturing modern furniture. It is one such plywood which can be cut and drilled easily due to its uniform thickness and smooth surface. It can be cut and modified into different shapes, which are required for modern furniture these days. Unlike the other plywood materials, they can be treated with ease without taking much time. The ease of using them in multiple applications makes them one of the best plywood to go for.

Other than these benefits, calibrated plywood is also being treated to offer resistivity from water, termites, warping, deforming, and several other such factors. But you will only be able to avail all these benefits when you buy them from a trusted calibrated plywood supplier. We only trust Kridha Laminates for all our calibrated plywood requirements, as being a certified manufacturer and supplier, the brand offers optimum quality plywood at affordable market prices.

0 notes

Text

What makes Calibrated Plywood the best plywood for manufacturing modern furniture?

Today’s modern world requires modern furniture solutions, and calibrated plywood is considered the best for manufacturing them. There are different types of plywood available in the market, but calibrated plywood is considered the best due to the availability of multiple features. Especially when you buy them from a reliable and certified calibrated plywood supplier, as they treat them well to make them suitable for diverse applications. Though unaware of the features and benefits of calibrated plywood, people often ignore it and consider using other plywood. But in this blog, we are sharing all the benefits offered by calibrated plywood, which makes them the best. After discovering these benefits, you will know why you should use this plywood for all modern furniture needs.

Plywood with even thickness

Whether one needs to use plywood in the construction industry, for manufacturing furniture, or for flooring or roofing applications, everyone desires to use plywood with uniform thickness. Calibrated plywood is manufactured using the best veneers, which are sanded properly to give them even thickness. They are then glued together by using an excellent quality adhesive. They are pressed using a hydraulic machine and then undergo a calibration machine to ensure that the plywood achieves the same level of thickness. The even thickness of calibrated plywood makes them the best for multiple applications. But to ensure that you get precisely manufactured calibrated plywood, always come from a renowned calibrated plywood supplier.

Aesthetically appealing Plywood for different applications

Calibrated plywood is not only known for its even thickness but is also known for its even surface. It is cut and treated in a way that it is free from any kind of marks, bumps, cracks, and holes. One need not use any such material over them to hide any flaws. The smooth surface of this plywood allows one to work on this plywood easily. Whether one desires to overlay a layer of laminate over them or whether one wishes to paint or varnish them, it can be done easily. It makes calibrated plywood a perfect material for manufacturing both home and office furniture.

Can be modified and transformed with ease

We already mentioned above that calibrated plywood is perfect for manufacturing modern furniture. It is one such plywood which can be cut and drilled easily due to its uniform thickness and smooth surface. It can be cut and modified into different shapes, which are required for modern furniture these days. Unlike the other plywood materials, they can be treated with ease without taking much time. The ease of using them in multiple applications makes them one of the best plywood to go for.

Other than these benefits, calibrated plywood is also being treated to offer resistivity from water, termites, warping, deforming, and several other such factors. But you will only be able to avail all these benefits when you buy them from a trusted calibrated plywood supplier. We only trust Kridha Laminates for all our calibrated plywood requirements, as being a certified manufacturer and supplier, the brand offers optimum quality plywood at affordable market prices.

0 notes

Text

Balancing Form and Function: Frame & Truss Cladding in Sydney Architecture

It is a beautiful feeling to construct your home in Sydney with a frame and truss system. Not only does such construction involve sustainable and environmentally friendly practices but it also allows the homeowner to design every detail of the house. After the structure is set, choosing the cladding is possibly one of the most important decisions you will make for your house. Therefore, let us explore the cladding options available for your building to allow it to balance both form and function.

What types of frame and truss cladding are there?

There are several types of frame and truss cladding options available on the market. With all the different materials, styles and profiles, the options are practically endless. Following is a list of the most common cladding options available for frames and truss structures:

Timber

Aluminium

Steel

Brick veneer

Compressed cement sheeting and much more

What are the Advantages of Using Frame and Truss Cladding in Your Build?

Aesthetic Appeal: Cladding improves the appearance of your property. Timber cladding offers a naturally warm and appealing look whereas fibre cement cladding has a sleek and modern finish.

Durability: Cladding makes your building more durable as it is engineered to withstand the elements and harsh weather conditions If maintained properly, frame and truss cladding can last for decades adding both form and functionality to your building.