#process engineer

Explore tagged Tumblr posts

Text

1 pm and all is well

2 notes

·

View notes

Text

SiC Seeding for Sustainable Green Energy: An Overview of SiC Crystal Growth and Wafer Processing

Silicon carbide (SiC) is rapidly emerging as a game-changing material in the semiconductor industry. Its superior performance in high-power applications — such as electric vehicles, power grids, and renewable energy — sets it apart from traditional silicon-based solutions. With a wide bandgap, high electron mobility, and excellent thermal conductivity, SiC enables more efficient power devices, reducing energy loss and enhancing performance.

This article explores SiC crystal growth and wafer processing techniques, shedding light on the challenges and innovations driving the scalability and cost-effectiveness of SiC semiconductor manufacturing.

1. Fundamentals of SiC Crystal Growth and Material Properties

1.1 SiC Requirements

SiC is integral to modern power applications due to its exceptional properties, including a bandgap three times wider than silicon and a significantly higher critical electric field. These characteristics enable SiC-based power devices to operate at higher voltages and temperatures while reducing power losses and heat dissipation requirements.

Orbit & Skyline Semiconductor Fab Services specializes in precision processing and advanced fabrication solutions tailored for SiC technology, ensuring high-performance outcomes for semiconductor manufacturers.

1.2 SiC Crystal Structure

Silicon carbide exists in over 250 polytypes, each with unique electrical properties. Among them, 4H-SiC is the most favored due to its high electron mobility, breakdown voltage, and thermal conductivity. However, growing SiC crystals at industrial scales presents significant challenges, primarily due to the high processing temperatures (exceeding 2000°C) and the slow growth rates required to maintain quality and minimize defects.

1.3 SiC Boule Growth Methods

The semiconductor industry primarily employs three major methods for growing SiC boules, with the Physical Vapor Transport (PVT) method being the most prevalent. PVT relies on sublimation due to the lack of a stable liquid phase for SiC. Despite its advantages, challenges such as micropipes, stacking faults, and dislocation densities persist.

Orbit & Skyline’s process engineering team optimizes growth techniques to maximize yield and reduce defects, ensuring superior wafer quality. By fine-tuning parameters such as temperature control and pressure regulation, we enhance SiC crystal production efficiency.

1.4 Physical Vapor Transport (PVT) Process

The PVT process involves melting high purity SiC powder in a growth chamber at temperatures exceeding 2000°C. The sublimated vapor then deposits onto a seed crystal, gradually forming a high-quality SiC boule. This method enables precise control over doping levels, essential for tailoring electrical characteristics. N-type doping (typically using nitrogen) enhances conductivity, while p-type doping (using aluminium) influences the polytype formation, affecting overall device performance.

2. From Boule to Epi-Ready Wafer

2.1 SiC Hardness and Processing Challenges

SiC is one of the hardest materials known, ranking 9–9.5 on the Mohs scale. This extreme hardness complicates the slicing and processing of SiC boules into wafers. Specialized grinding, lapping, and polishing techniques are required to achieve the precise dimensions necessary for semiconductor applications.

Orbit & Skyline’s Equipment Engineering services provide tailored solutions to overcome these challenges, ensuring precise wafer preparation for further processing.

2.2 Wafer Slicing and Surface Preparation

SiC boules undergo slicing using multi-wire saws coated with diamond slurry. This process must balance kerf loss (material waste) and throughput efficiency. Following slicing, wafers undergo lapping to ensure uniform thickness and surface quality, crucial for subsequent epitaxial growth.

2.3 Epi-Ready Polishing and Surface Finishing

To achieve EPI-ready surfaces, wafers undergo Chemical Mechanical Polishing (CMP), combining mechanical abrasion with chemical etching. Innovations in CMP technology, such as rapid thinning techniques, enhance material removal rates while maintaining surface integrity. This ensures defect-free epitaxial layers, which are critical for high-performance semiconductor applications.

3. Epitaxial Growth and Doping of SiC

3.1 High-Temperature Chemical Vapor Deposition (HT-CVD)

Epitaxial growth involves depositing thin, defect-free SiC layers on wafers to enhance electrical performance. HT-CVD is the industry standard, offering precise control over doping concentration and layer thickness. By using silicon and carbon precursors, diluted in hydrogen or argon carrier gases, HT-CVD facilitates uniform SiC layer growth.

3.2 Alternative Epitaxy Methods

Other epitaxy methods, such as Molecular Beam Epitaxy (MBE) and Liquid Phase Epitaxy (LPE), have been explored. However, challenges in impurity control, growth rate limitations, and scalability make HT-CVD the preferred approach for large-scale SiC production.

3.3 Scaling to 8” and 200mm Wafers

With the industry shifting towards 8” (200mm) SiC wafers, significant improvements in slicing and polishing processes have been made. Advanced wafer thinning and surface finishing techniques ensure high yield and minimal defect rates. The transition to larger wafers increases device yield per wafer while optimizing fabrication costs.

Conclusion

SiC wafer technology continues to evolve, with advances in boule growth, wafer slicing, and epitaxial deposition driving the transition from 6” to 8” wafers. The industry’s focus on improving material quality and reducing processing costs ensures that SiC remains a competitive alternative to silicon in high-power applications.

Orbit & Skyline brings 15+ years of expertise, and a global team of 500+ engineers dedicated to advancing semiconductor technologies. As a trusted partner in the industry, we provide innovative solutions for SiC processing, fabrication, and equipment engineering.

For partnership inquiries, reach out to us at [email protected]

#semiconductor#Top Semiconductor Companies in India#Semiconductor Companies#Semiconductor Fab#Process Engineer

1 note

·

View note

Text

#Hiring Senior Process Engineer – Rubber Industry – Dover, NH (with relocation)

0 notes

Text

This is the second attempt to go into drawing without a line. The picture is drawn under the impressions of an analog horror from tiktok "Angel engine"

#art#digital art#aspiring artist#artists on tumblr#my art#illustration#my post#arg#analog horror#angel engine#angelcore#angel#dystopia#post apocalyptic#horror art#horror#art practice#art process#art digital#digital artist#digital arwork#digital painting#digital drawing#digital illustration#illustration art#illustrators on tumblr#without lines

175 notes

·

View notes

Text

Laz.EE / Physical Kitbash Maquette

166 notes

·

View notes

Text

wiggliestwobbliest girl

(godot wigglebone addon vere good :thumbsup:)

1K notes

·

View notes

Text

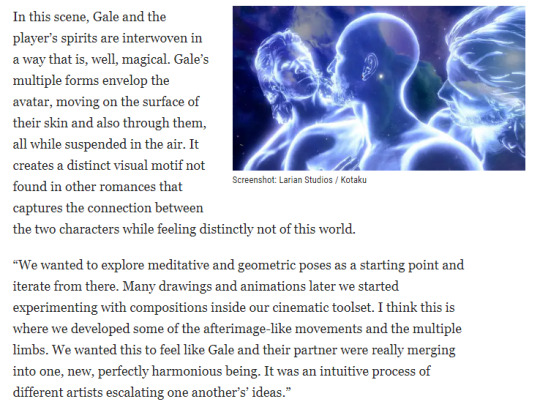

"It creates a distinct visual motif not found in other romances that captures the connection between the two characters while feeling distinctly not of this world."

"We wanted this to feel like Gale and their partner were really merging into one, new, perfectly harmonious being."

[source]

#gale dekarios#gale of waterdeep#baldur's gate 3#bg3#bg3 spoilers#not only is this very interesting#to hear the thought process behind the people who created the scene#but also this makes my heart ache in the best way possible#'our souls intertwine with one another' hhhhh#i would have loved to see their original vision though had the engine / time / budget allowed it#it's beautiful either way#tagging for those who are interested as well#otp: a soul that steels my own#ch: gale dekarios#vg: baldur's gate 3#series: baldur's gate

1K notes

·

View notes

Text

Oh, Killerwatt and Wrench and your self worth directly tied to your job performance, how I love making your emotionally competent partners make sure you know you're loved.

#starlight express#stex london 2024#joule the dynamite truck#electra the electric engine#killerwatt the security truck#volta the freezer truck#wrench the repair truck#my writing#the writing process

75 notes

·

View notes

Text

Another day, another steam trap

1 note

·

View note

Text

ok rat we gotta set some small but real goals for comics fr this time

62 notes

·

View notes

Text

Western Electric Co, 1953

#Bell Telephone System#1953#ad#midcentury#illustration#American Telephone and Telegraph#advertisement#engineering#1950s#vintage#mid century#Ma Bell#AT&T#advertising#phone wire#process improvements#technology#mid-century

138 notes

·

View notes

Text

2002's The Authority Vol.1 #29 cover by artist Art Adams, inker Tim Townsend and colorist David Baron. Source Source

#The Authority#Art Adams#wildstorm#midpollo#midnighter#apollo#comics#comic books#dc#DC#dc comics#wildstorm productions#wildstorm comics#art#jack hawksmoor#Swift#dc characters#the engineer#the doctor#comic covers#mark millar#process#art process#early 00s comics#early 2000s comics#authority comics#authority#arthur adams#angela spica#cover

31 notes

·

View notes

Text

Speedpaint!

I have a separate window of the file in black and white to keep track of the values! Helps not to get too into lost in the details :) The whole thing took only a about a week! Having a self-imposed deadline is doing wonders for me (atm). If I worked on this longer I would have started fussing over the smallest details and never get it done lmao

40 notes

·

View notes

Text

Working on the next chapter of radio nowhere rn (everyone's fine and nothing is wrong! nothing at all!), and i felt it might be a good time to let people know that it will be ending in a few chapters!

This isn't due to lack of interest on my part or anything- I'm ending the story where I planned, I just didn't want people to be blind sighted by the fact- ive changed the chapter numbers on ao3 to reflect this.

(Don't worry- there will be more within this verse- the electrics need to find out what living in a proper yard is like at some point!! :))

#starlight express#stex london 2024#the writing process#joule the dynamite truck#wrench the repair truck#volta the freezer truck#electra the electric engine#killerwatt the security truck

28 notes

·

View notes

Text

Steam drum inspection

0 notes