#process piping industry

Text

Unleashing the Potential of Little P.Eng. for ASME B31.3 Process Piping Calculation Services

In the ever-evolving landscape of the process piping industry, ASME B31.3 Process Piping Calculation Services stands as a paramount standard for design, inspection, and construction of process plants. As we delve into the complex world of piping engineering, we encounter Little P.Eng., an innovative engineering consulting firm pioneering the application of these industry standards.

With years of profound expertise and a cutting-edge approach, Little P.Eng. shines as the gold standard in providing ASME B31.3 Process Piping Calculation Services. This article aims to shed light on the instrumental role that Little P.Eng. plays in revolutionizing the field of process piping.

Understanding ASME B31.3 Process Piping Standards:

ASME B31.3, a prominent subsection of the American Society of Mechanical Engineers (ASME) B31 Code for Pressure Piping, is a comprehensive set of guidelines for process piping. It includes various aspects such as materials, fabrication, examination, testing, and much more. Given its criticality, these standards must be implemented with utmost precision and accuracy, an arena where Little P.Eng. truly excels.

Little P.Eng.: Your Reliable Partner for Piping Calculation Services:

As a recognized leader in the engineering consulting sector, Little P.Eng. is fully equipped to handle all facets of ASME B31.3 process piping calculation services. Leveraging the expertise of highly-skilled professionals, the latest technologies, and deep-rooted understanding of ASME standards, Little P.Eng. delivers innovative, accurate, and cost-effective solutions.

Little P.Eng. and Comprehensive Calculation Services:

Little P.Eng.'s range of calculation services spans from pressure design of piping components, flexibility and stress analysis, to support design and selection. Their commitment to precision, comprehensive reports, and prompt delivery, all tied to their deep-rooted understanding of ASME B31.3 standards, ensure that they stay ahead of the competition.

Embracing the Latest Technology:

Little P.Eng. makes optimal use of the latest technologies to provide unmatched ASME B31.3 process piping calculation services. Using state-of-the-art software tools, they simulate, analyze, and validate designs, leading to safe, reliable, and efficient process piping systems.

Customer Satisfaction: Little P.Eng.'s Hallmark:

With a steadfast commitment to customer satisfaction, Little P.Eng. prioritizes its clients' needs at every stage of the project. This results in services that not only adhere to ASME B31.3 standards but also align with the specific requirements of the clients.

Let's delve deeper into the pressure design calculations performed by Little P.Eng. under the ASME B31.3 Process Piping Calculation Services. Here are the key types of pressure design calculations:

Wall Thickness Calculations: One of the most crucial aspects of pressure design calculations involves determining the minimum wall thickness required for pipes to safely contain the pressure. Little P.Eng. uses sophisticated software tools to compute this accurately, factoring in variables like operating pressure, material strength, temperature, and pipe diameter.

Flange Rating Calculations: Little P.Eng. expertly handles the complexity of flange rating calculations, which involve determining the maximum pressure that flanges can handle without leaking. The process considers factors such as temperature, bolting material, gasket type, and flange material.

Branch Connection Calculations: When designing a process piping system, engineers often need to calculate the reinforcements required for branch connections. Little P.Eng. performs these calculations with precision, ensuring the integrity and safety of the piping system.

Expansion Joint Pressure Thrust Calculations: Expansion joints are vital components of process piping systems that accommodate thermal expansion or contraction. Little P.Eng. uses advanced tools to calculate the pressure thrust exerted on these joints, thus ensuring their optimal design.

Safety Valve Reaction Force Calculations: Little P.Eng. also determines the reaction force exerted on safety valves when they open in response to excessive pressure. These calculations are essential for the safe and efficient operation of the process piping system.

Pipe Support Span Calculations: Pipe support span calculations are critical for ensuring that the pipe doesn't sag excessively under its weight and operating conditions. Little P.Eng. performs these calculations meticulously, keeping in mind various factors such as pipe size, material, and temperature.

High-Pressure Piping Design Calculations: For high-pressure piping systems, Little P.Eng. offers specialized calculation services that consider unique challenges such as material selection, joint design, and testing procedures, ensuring the integrity of the system even under extreme pressure conditions.

Conclusion:

The ASME B31.3 Process Piping Calculation Services can be quite challenging to navigate without the assistance of an experienced partner like Little P.Eng. Their meticulous attention to detail, robust understanding of industry standards, and unflinching commitment to quality make them an invaluable asset in the realm of process piping.

Little P.Eng.'s team of expert engineers works tirelessly to stay at the forefront of evolving industry standards, technologies, and market demands, ensuring their clients get the best of what the industry has to offer. With their forward-thinking approach, they not only provide services but also contribute to shaping the future of the process piping industry.

Keywords:

Little P.Eng., ASME B31.3 Process Piping Calculation Services, engineering consulting, process piping industry, process piping standards, pressure design, flexibility and stress analysis, support design and selection, customer satisfaction, Wall Thickness Calculations, Flange Rating Calculations, Branch Connection Calculations, Expansion Joint Pressure Thrust Calculations, Safety Valve Reaction Force Calculations, Pipe Support Span Calculations, High-Pressure Piping Design Calculations.

Tags:

Little P.Eng.

engineering consulting

Expansion Joint Pressure Thrust Calculations

Safety Valve Reaction Force Calculations

High-Pressure Piping Design Calculations

ASME B31.3 Process Piping Calculation Services

process piping industry

process piping standards

pressure design

flexibility and stress analysis

support design and selection

customer satisfaction

Wall Thickness Calculations

Flange Rating Calculations

Branch Connection Calculations

Pipe Support Span Calculations

Engineering Services

Pipe Stress Analysis Services

Piping Design

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng.#engineering consulting#Expansion Joint Pressure Thrust Calculations#Safety Valve Reaction Force Calculations#High-Pressure Piping Design Calculations#ASME B31.3 Process Piping Calculation Services#process piping industry#process piping standards#pressure design#flexibility and stress analysis#support design and selection#customer satisfaction#Wall Thickness Calculations#Flange Rating Calculations#Branch Connection Calculations#Pipe Support Span Calculations

0 notes

Text

Industrial Treachery Of Images

from DOGS ROAMING FREE (2023-)

2 notes

·

View notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

16 - 17 October 2024,

Houston, Texas

USA

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#16 - 17 October 2024#Houston#Texas#USA#HEAT EXCHANGER WORLD AMERICAS - 2024#Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024#Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions#Duplex#Super Duplex#Nickel Alloy#and Exotic-Grade Material Tubes#Pipes#and U-Tubes.#Event Details:#•#Date: 16 – 17 October 2024#Venue: Houston#Booth Number: Stand 2110#Event Hours: 10:00 AM – 5:00 PM#Event Link: https://heat-exchanger-world-americas.com#KRYSTAL X HEAT EXCHANGER#2024#Manufacturer and Exporter of Seamless Stainless Steel#Nickel Alloy Tubes#Pipes & U Tubes.#At the trendsetting#ultimate networking event for the process industry#you will have an opportunity to connect with Krystal experts#tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics in#the latest decarbonization innovations

0 notes

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

Precision Pipe Beveling Cutting Machine: Efficient & Accurate Solutions

Explore our advanced pipe beveling cutting machine designed to streamline your industrial processes. With precision engineering and cutting-edge technology, our machine ensures efficient and accurate beveling and cutting of pipes of various sizes and materials. Enhance productivity and quality with our reliable solution.

#pipe beveling machine#pipe cutting machine#industrial cutting equipment#precision beveling#efficient pipe processing#automated pipe beveler#high-quality cutting solution#industrial productivity#pipe fabrication#metalworking machinery

0 notes

Text

Innovations in Piping: Advancements in Process Technology

Piping systems are the lifelines of many industries, facilitating the transport of fluids, gases, and materials essential for production processes. Over the years, advancements in process technology have revolutionized the design, fabrication, installation, and maintenance of piping systems, leading to increased efficiency, reliability, and safety. In this post, we'll explore some of the latest innovations in piping and their impact on industrial operations.

1. Advanced Materials

One of the significant innovations in piping technology is the development of advanced materials with superior properties, such as corrosion resistance, high temperature tolerance, and enhanced durability. Materials like high-density polyethylene (HDPE), fiberglass-reinforced plastic (FRP), and corrosion-resistant alloys (CRAs) offer alternatives to traditional materials like steel and copper, providing solutions for challenging environments and corrosive fluids.

2. Composite Piping Systems

Composite piping systems, combining materials like thermoplastics, fiberglass, and carbon fiber, offer lightweight, corrosion-resistant, and cost-effective alternatives to traditional metallic piping. These systems are highly versatile and suitable for a wide range of applications, including chemical processing, water treatment, and offshore oil and gas production.

3. 3D Printing Technology

Advancements in 3D printing technology have revolutionized the fabrication of piping components, allowing for rapid prototyping, customization, and on-demand production. Additive manufacturing techniques enable the creation of complex geometries, intricate designs, and customized fittings with reduced lead times and material waste.

4. Smart Piping Systems

The integration of sensors, actuators, and control systems into piping networks has led to the development of smart piping systems capable of real-time monitoring, diagnostics, and predictive maintenance. These systems provide valuable insights into the health and performance of the piping infrastructure, enabling proactive decision-making and minimizing downtime.

5. Modular Piping Solutions

Modular piping solutions, consisting of pre-fabricated components and standardized fittings, offer advantages in terms of ease of installation, flexibility, and scalability. These systems allow for rapid deployment, reduced labor costs, and simplified maintenance, making them ideal for temporary installations, retrofit projects, and fast-track construction schedules.

6. Enhanced Welding Techniques

Innovations in welding technology, such as laser welding, friction stir welding, and robotic welding systems, have improved the efficiency, accuracy, and quality of pipe welding operations. These advanced techniques offer benefits such as reduced distortion, improved joint strength, and increased productivity, particularly in high-volume manufacturing environments.

7. Corrosion Monitoring and Protection

Advanced corrosion monitoring techniques, including ultrasonic testing, electromagnetic inspection, and corrosion-resistant coatings, help identify and mitigate corrosion issues in piping systems. Real-time monitoring systems provide early warning alerts, allowing operators to take corrective action before corrosion leads to leaks or failures.

8. Pipe Rehabilitation Technologies

Innovative pipe rehabilitation technologies, such as pipe lining, pipe bursting, and trenchless pipe replacement, offer cost-effective alternatives to traditional excavation and replacement methods. These techniques minimize disruption to operations, reduce environmental impact, and extend the lifespan of aging piping infrastructure.

9. Digital Twin Technology

Digital twin technology, which creates virtual replicas of physical assets, allows operators to simulate, analyze, and optimize the performance of piping systems in a virtual environment. By integrating real-time data from sensors and IoT devices, digital twins enable predictive maintenance, scenario planning, and performance optimization for enhanced efficiency and reliability.

10. Environmental Sustainability

Innovations in piping technology also focus on environmental sustainability, with initiatives such as water conservation, energy efficiency, and waste reduction. Green piping materials, eco-friendly coatings, and recycling programs contribute to reducing the environmental footprint of piping systems and promoting sustainable practices in industrial operations.

Conclusion

Innovations in piping technology continue to drive advancements in process efficiency, reliability, and safety across various industries. From advanced materials and composite piping systems to 3D printing, smart piping networks, and digital twin technology, the future of piping holds immense potential for trans-formative change. By embracing these innovations and leveraging the latest technologies, companies can enhance their competitiveness, optimize their operations, and meet the evolving challenges of the modern industrial landscape.

#industry#manufacturing#technology#piping system#materials#piping technology#piping solutions#piping network#innovations#piping process

0 notes

Text

0 notes

Text

Proper maintenance and inspection of steel pipes are essential to ensure their safety, longevity, and optimal performance. Steel Pipes and Tubes are widely used in various industries and applications, and their failure can have significant consequences.

#steel pipes manufacturers#stainless steel pipes suppliers#steel pipes and tubes#steel pipes manufacturing process#steel pipes industry#steel pipes producers

1 note

·

View note

Text

The Stabilisation Process in Thane: Unveiling the Power of Tin Stabilisers

In the bustling city of Thane, where industries thrive and technological advancements are a norm, one element has been silently transforming the landscape of stabilization processes – Tin Stabilizers. These high-performance additives have been gaining significant recognition in various industries, from plastics to coatings, thanks to their exceptional stabilizing properties. In this blog, we will explore the remarkable benefits of tin stabilizers, their applications in Thane, and how Rewa Chemicals a leading chemical supplier, is revolutionizing the stabilizer industry with its cutting-edge solutions.

The Power of Tin Stabilizers: Tin stabilizers, known for their versatility and effectiveness, play a crucial role in enhancing the performance and durability of numerous materials. Whether it's PVC pipes, cables, window profiles, or even automotive parts, tin stabilizers offer remarkable thermal stability, weather resistance, and long-term stability. Their ability to prevent degradation, discoloration, and loss of mechanical properties makes them an ideal choice for industries in Thane seeking reliable stabilization solutions.

Applications in Thane's Industries: Thane, a hub of diverse industries, has witnessed the integration of tin stabilizers across various sectors. Rewachem's wide range of tin stabilizers caters to the specific needs of these industries, providing them with tailored solutions. From the construction industry, where tin stabilizers ensure the longevity and strength of PVC pipes and profiles, to the automotive sector, where they protect against UV radiation and temperature fluctuations, the applications of tin stabilizers are truly expansive.

Rewachem: Pioneering Tin Stabilizers in Thane: Rewachem, a trusted name in the chemical supply industry, has been at the forefront of introducing innovative tin stabilizers to Thane's market. Their commitment to quality, performance, and sustainable solutions has earned them a remarkable reputation. With an extensive portfolio of tin stabilizers, Rewachem offers a comprehensive range of products that meet the diverse needs of industries in Thane.

Why Choose Rewachem's Tin Stabilizers?

Uncompromising Quality: Rewachem's tin stabilizers undergo stringent quality checks to ensure consistent performance and reliability.

Tailored Solutions: The company's team of experts works closely with clients in Thane, understanding their specific requirements and providing customized stabilizer solutions.

Cutting-Edge Technology: Rewachem leverages the latest advancements in stabilization technology, ensuring that their tin stabilizers deliver exceptional performance.

Sustainable Approach: Rewachem is committed to sustainability and offers eco-friendly stabilizer options, helping industries in Thane meet their environmental goals.

PVC pipes are widely used in various applications due to their durability, cost-effectiveness, and versatility. However, ensuring the long-term stability and performance of PVC pipes requires the addition of stabilizers. One innovative solution gaining recognition in the industry is the use of one-pack stabilizers. In this blog post, we will delve into the world of one-pack stabilizers for PVC pipes, exploring their benefits and highlighting Rewachem's cutting-edge solutions. So, let's dive in!

Understanding One-Pack Stabilizers: One-pack stabilizers are advanced formulations that combine multiple additives in a single product. These additives work synergistically to provide exceptional heat stability, weather resistance, and impact strength to PVC pipes. The convenience of one-pack stabilizers lies in their ability to simplify the production process by eliminating the need for separate dosing of multiple individual additives.

Advantages of One-Pack Stabilizers:

Enhanced Heat Stability: One-pack stabilizers excel in providing PVC pipes with superior resistance to heat and thermal degradation, ensuring their longevity even under extreme temperature conditions.

Improved Weather Resistance: Rewachem's one-pack stabilizers offer excellent UV resistance, protecting PVC pipes from the damaging effects of sunlight exposure, such as discoloration and embrittlement.

Optimal Impact Strength: PVC pipes treated with one-pack stabilizers exhibit enhanced impact resistance, enabling them to withstand high-pressure conditions and external impacts without compromising structural integrity.

Streamlined Production Process: The integration of multiple additives in a single product simplifies the manufacturing process, reducing material handling, inventory, and dosing complexity.

One-Pack Stabilizers: As a leading manufacturer in the chemical industry, Rewa Chemicals

offers a diverse range of one-pack stabilizers specifically designed for PVC pipe applications. Their high-quality formulations are the result of extensive research and development, ensuring optimal performance and meeting stringent industry standards.

To explore Rewa Chemicals' comprehensive range of one-pack stabilizers and enhance the stability of your PVC pipes, visit their website at. Experience the next level of performance and reliability for your PVC pipe applications.

Conclusion:

One-pack stabilizers have revolutionized the PVC pipe industry, offering manufacturers a convenient and effective solution to enhance stability and performance. Rewa Chemicals' commitment to innovation and high-quality solutions makes them a trusted partner for PVC pipe manufacturers worldwide. By incorporating one-pack stabilizers into PVC pipe production, manufacturers can ensure their products deliver exceptional durability, weather resistance, and impact strength.

#Tin stabilisers#PVC stabilisation#PVC pipe manufacturing#Stabilisation process#Thane industrial processes

0 notes

Text

"A 1-megawatt sand battery that can store up to 100 megawatt hours of thermal energy will be 10 times larger than a prototype already in use.

The new sand battery will eliminate the need for oil-based energy consumption for the entire town of town of Pornainen, Finland.

Sand gets charged with clean electricity and stored for use within a local grid.

Finland is doing sand batteries big. Polar Night Energy already showed off an early commercialized version of a sand battery in Kankaanpää in 2022, but a new sand battery 10 times that size is about to fully rid the town of Pornainen, Finland of its need for oil-based energy.

In cooperation with the local Finnish district heating company Loviisan Lämpö, Polar Night Energy will develop a 1-megawatt sand battery capable of storing up to 100 megawatt hours of thermal energy.

“With the sand battery,” Mikko Paajanen, CEO of Loviisan Lämpö, said in a statement, “we can significantly reduce energy produced by combustion and completely eliminate the use of oil.”

Polar Night Energy introduced the first commercial sand battery in 2022, with local energy utility Vatajankoski. “Its main purpose is to work as a high-power and high-capacity reservoir for excess wind and solar energy,” Markku Ylönen, Polar Nigh Energy’s co-founder and CTO, said in a statement at the time. “The energy is stored as heat, which can be used to heat homes, or to provide hot steam and high temperature process heat to industries that are often fossil-fuel dependent.” ...

Sand—a high-density, low-cost material that the construction industry discards [Note: 6/13/24: Turns out that's not true! See note at the bottom for more info.] —is a solid material that can heat to well above the boiling point of water and can store several times the amount of energy of a water tank. While sand doesn’t store electricity, it stores energy in the form of heat. To mine the heat, cool air blows through pipes, heating up as it passes through the unit. It can then be used to convert water into steam or heat water in an air-to-water heat exchanger. The heat can also be converted back to electricity, albeit with electricity losses, through the use of a turbine.

In Pornainen, Paajanen believes that—just by switching to a sand battery—the town can achieve a nearly 70 percent reduction in emissions from the district heating network and keep about 160 tons of carbon dioxide out of the atmosphere annually. In addition to eliminating the usage of oil, they expect to decrease woodchip combustion by about 60 percent.

The sand battery will arrive ready for use, about 42 feet tall and 49 feet wide. The new project’s thermal storage medium is largely comprised of soapstone, a byproduct of Tulikivi’s production of heat-retaining fireplaces. It should take about 13 months to get the new project online, but once it’s up and running, the Pornainen battery will provide thermal energy storage capacity capable of meeting almost one month of summer heat demand and one week of winter heat demand without recharging.

“We want to enable the growth of renewable energy,” Paajanen said. “The sand battery is designed to participate in all Fingrid’s reserve and balancing power markets. It helps to keep the electricity grid balanced as the share of wind and solar energy in the grid increases.”"

-via Popular Mechanics, March 13, 2024

--

Note: I've been keeping an eye on sand batteries for a while, and this is really exciting to see. We need alternatives to lithium batteries ASAP, due to the grave human rights abuses and environmental damage caused by lithium mining, and sand batteries look like a really good solution for grid-scale energy storage.

--

Note 6/13/24: Unfortunately, turns out there are substantial issues with sand batteries as well, due to sand scarcity. More details from a lovely asker here, sources on sand scarcity being a thing at the links: x, x, x, x, x

#sand#sand battery#lithium#lithium battery#batteries#technology news#renewable energy#clean energy#fossil fuels#renewables#finland#good news#hope#climate hope

1K notes

·

View notes

Text

Little P.Eng. Engineering: Pioneering Material Handling Facilities & Building Designs in Canada & US

The industries of today rely heavily on efficient material handling to maintain profitability, safety, and operational effectiveness. Little P.Eng. Engineering has carved a niche for itself in the design of material handling facilities and buildings across the vast terrains of Canada and the USA, addressing the unique challenges of each region and industry.

Material Handling – The Backbone of Modern Industries

Material handling facilities, be they storage, transport, or processing centers, form the linchpin around which modern industries revolve. From the unloading of raw materials to the shipping of finished goods, a streamlined material handling system significantly impacts a company's bottom line, safety record, and environmental footprint.

Little P.Eng. Engineering's Portfolio: A Deep Dive

Wagon / Truck Loading:

Role: Efficiently loading materials onto wagons or trucks for transport.

Little P.Eng. Approach: Designs that accommodate varied load sizes and types, ensuring quick loading while minimizing spillage and waste.

Wagon Unloading / Tripper:

Role: Unloading goods from wagons with precision and speed.

Little P.Eng. Insight: Systems that cater to different wagon designs and materials, using advanced mechanisms to prevent damage during unloading.

Rapid Train Load-Out Station:

Role: Fast-paced loading of trains, a crucial component in industries like mining.

Little P.Eng. Vision: Integration of automated systems to boost loading speeds, decrease wait times, and enhance safety.

Storage Pits:

Role: Holding areas for materials before processing or transport.

Little P.Eng.'s Precision: Designs that factor in material type, preventing contamination, and ensuring easy retrieval.

Tanks and Reservoirs:

Role: Storage for liquids or gases, be it water, oil, or chemicals.

Little P.Eng. Mastery: Focus on material compatibility, safety features, and maximizing storage space.

Pressure Vessels and Bullets:

Role: Storing gases or liquids at high pressures.

Little P.Eng.'s Craft: Adherence to stringent safety norms, designs that handle extreme conditions, and longevity.

Process Piping:

Role: Transport liquids or gases within facilities.

Little P.Eng.'s Expertise: Efficient layouts to minimize material travel, selection of durable materials, and designs that facilitate easy maintenance.

Pipe Racks:

Role: Hold multiple pipes, often seen in large industrial setups.

Little P.Eng. Specialty: Modular designs that can be expanded as needed, ensuring stability and safety.

Steel Structures:

Role: The skeleton for many industrial buildings, warehouses, and more.

Little P.Eng.'s Touch: Emphasis on durability, load-bearing capacities, and resistance to environmental factors.

Understanding the North American Challenge

Spanning two massive countries with diverse climates, terrains, and industrial needs, North America presents a unique set of challenges. Be it the cold of Canadian winters or the heat of American deserts, Little P.Eng. Engineering's designs consistently rise to the occasion. They prioritize sustainability, recognizing both countries' commitment to reducing industrial carbon footprints.

Conclusion

As industries across North America continue to grow and evolve, so does the demand for efficient, safe, and sustainable material handling facilities. Little P.Eng. Engineering, with its deep understanding of regional and industrial intricacies, positions itself as the go-to solution provider.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Modular design

Material handling facilities

Wagon loading

Truck loading systems

Wagon unloading mechanisms

Rapid train load-out stations

Storage pits

Industrial tanks

Reservoirs design

Pressure vessels

Industrial bullets

Process piping systems

Pipe racks

Steel structures

Industrial solutions Canada

Material handling USA

Sustainable industrial design

Tripper systems

Automated loading systems

North American industry challenges

Industrial safety norms

Industrial storage solutions

Liquid storage engineering

Gas storage facilities

Material transport systems

Durable material handling facilities

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Modular design#Material handling facilities#Wagon loading#Truck loading systems#Wagon unloading mechanisms#Rapid train load-out stations#Storage pits#Industrial tanks#Reservoirs design#Pressure vessels#Industrial bullets#Process piping systems#Pipe racks#Steel structures#Industrial solutions Canada#Material handling USA#Sustainable industrial design#Tripper systems#Automated loading systems#North American industry challenges#Industrial safety norms#Industrial storage solutions#Liquid storage engineering#Gas storage facilities#Material transport systems#Durable material handling facilities

0 notes

Text

Get Excellent PVC & HDPE pipes with Tempcon Chillers

Tempcon offers various capacity water cooled and Air cooled chiller for HDPE, PVC pipes industries. Tempcon has customised a solution with an additional Plate Heat Exchanger system that prevents the chiller evaporator getting choked and also speeds up the production process.

To produce strong and durable pipes, our customised cooling solutions are your best choice. To learn more visit us.

0 notes

Text

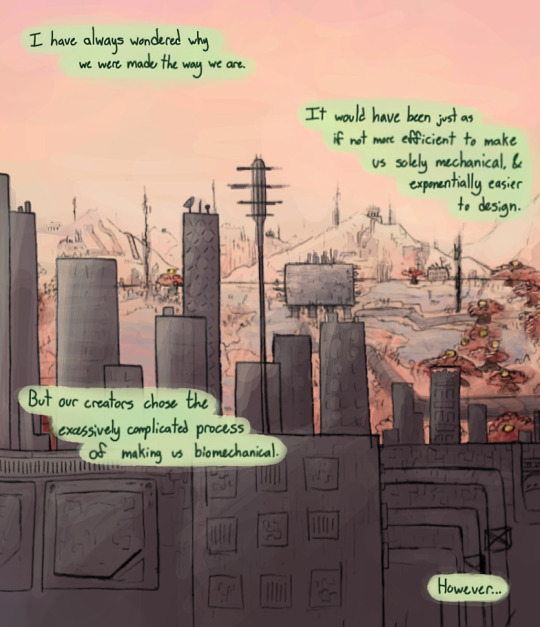

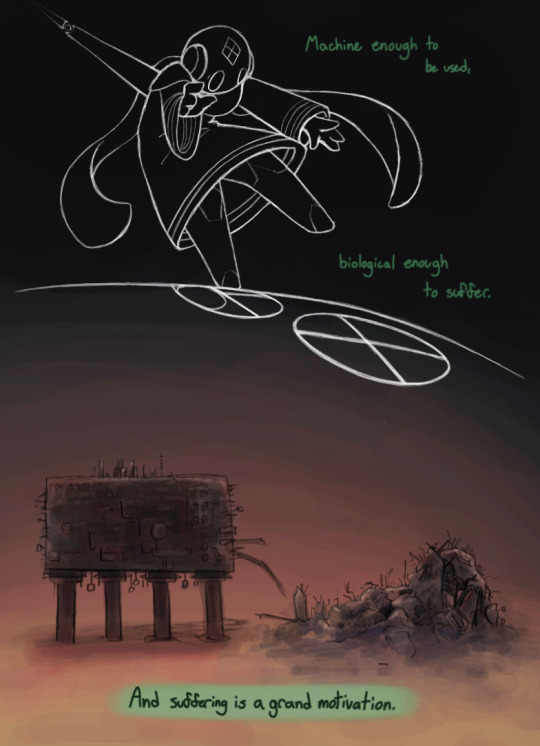

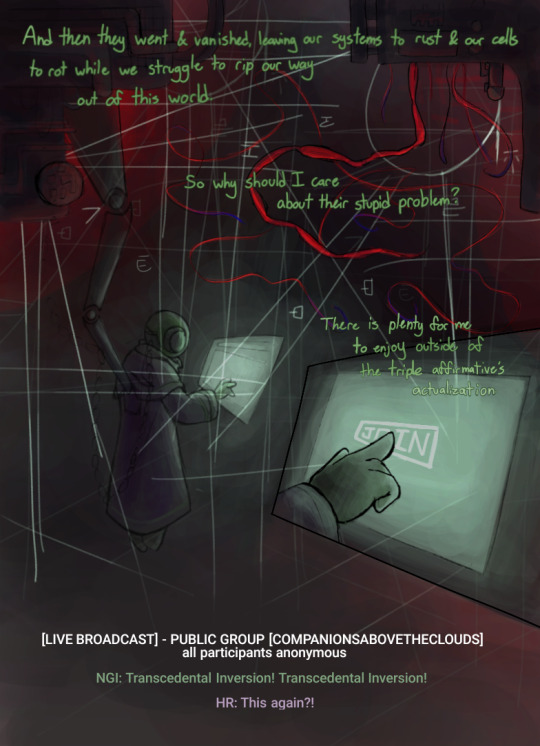

on biomechanics: No Significant Harassment

(i have been fighting with the tagging system for this post specifically as it won't show up in tags. ive narrowed down the cause to be the non-fandom tags [ie. my typical post-comic monologue lol]. those are under the cut if youre curious)

before the monologue id like to congratulate tumblr user mewguca for perfectly predictung the subject of this comic under my 5p one

anyways, tags:

NSH is so fascinating to me because of the way he completely memes on his intended purpose

#hes so unlike every other iterator we see in game. its like he doesnt even care about cycles or sliver the big problem at all

#this comic is my personal headcanon as to his thought process:

#hes a little jokester as a spiteful rebellion towards his purpose and creators

#but im sure he also finds it funny lol

#and the ancient's design philosophy as well:

#let them think and feel and be a part of the cycle to drive them to keep trying

#but dont let them ascend! because what would stop them from just solving the problem for themselves only and leaving you behind?

#making them fully mechanical would have forced the ancients to input solutions and think on the problem themselves.

#and i remember pearl dialogue where moon talks about how taboo it was for the ancients to aspire for anything in life

#even if that aspiration is death

#also its in my personal hc that rain world's surface is covered in a thick mat of piping and metalworks

#and that biological life forces its way into (much to the chagrin of the ancients!)

#theres patchy semi-deep ponds all over the surface due to drastic and irregular rainfall. basically like an overgrown industrial district

#rain world#rain world iterator#rw iterator#no significant harassment#rain world no significant harassment#rw no significant harassment#rw nsh#rain world five pebbles#rw five pebbles#rain world sliver of straw#rw sliver of straw#rain world seven red suns#rw seven red suns

2K notes

·

View notes

Note

Hallo ●♡●

I got a funny request

So basically Sebastian meets a reader/player with a korblox/headless/troll avatar/ wings or horns/cosplayers (maybe one as Seb)

Ect... (You can describe you own avatar too)

Silly prompt cause what if Sebastian could see we (our avatar) clearly don't look human and why we haven't been captured/experimented on

Aka this whole request is just Seb being confused as fuck-

Tags: Comedy, random apperance for reader, gender neutral reader, headless

Words: 1,4k

Authors Note: As someone with real headless, I can confirm that headless doesn't work ingame.

Sebastian watched in horrified fascination as you emerged from the vent. Your movements were nonchalant, as if clambering through air ducts was as routine as taking a stroll. You dusted off your uniform, a completely unnecessary gesture since the dust was clearly imaginary, and adjusted the peculiar floating accessory hovering over what should have been your shoulders.

It took him a moment to process what he was seeing. His three eyes widened, pupils dilating as they locked onto you. Where your head should have been, there was… nothing. Just a void, an empty space that seemed to defy logic. He could see right through you, catching glimpses of the rusted pipes and wires lining the walls behind.

“What the hell—” Sebastian stuttered, his voice filled with shock and more than a hint of repulsion. His fingers twitched at his sides, and he had to resist the instinctive urge to reach for a weapon—though he knew that, logically, weapons wouldn’t do much good in a situation like this. He continued to stare, his confusion only growing with each passing second.

You turned toward him—or at least, your body did, since there was no face to show any expression. “What?” you asked, your voice eerily calm, completely unaffected by the lack of a mouth. “Is there something on my uniform?”

Sebastian blinked rapidly, as if trying to reset his brain to make sense of this absurd reality. “That's… strangely…” he stammered, searching for the right words. “...Disgusting.”

“Rude,” you shot back, hands going to your hips. His gaze dropped, and he couldn’t help but notice the bright yellow rubber duck bag hanging there, comically out of place in this bleak, industrial environment. As if that weren’t enough, a floating picture of Dwayne "The Rock" Johnson hovered just above your shoulders, rotating slowly as if it were on display. It was surreal. Completely, utterly surreal.

Sebastian’s mouth fell open. “You’ve got… a rubber duck bag… and a floating headshot of The Rock,” he managed, pointing weakly at the bizarre ensemble. “And no face. How are you even speaking? How do you see? And why in the world do you have a picture of Dwayne Johnson just… floating there?!”

You tilted your non-existent head, a gesture that would’ve looked quizzical if you had any features to display it. “I see just fine,” you replied with a casual shrug. “As for speaking, that’s just a matter of speaking. And The Rock?” You gestured vaguely toward the picture, which continued its slow, mesmerizing spin. “He’s my emotional support human.”

Sebastian let out a half-snort, half-laugh, though his expression remained one of disbelief. “Why am I freaked out?” he repeated, still staring at the empty space where your head should be. “You look like something out of a fever dream! How have you not been captured or experimented on down here?”

You let out a chuckle—an eerie sound given the circumstances. “Oh, I get that a lot. But I think I blend in just fine with the rest of the… what do you call them? Entities?” You glanced around the room, as if to emphasize your point. “Besides, no one wants to mess with someone who looks like they stepped out of a nightmare.”

Sebastian couldn’t help but grin, despite himself. “Yeah, you’ve got that part nailed,” he muttered, still shaking his head in disbelief. “You probably scare off half the things down here just by existing.”

You did a mock bow, your non-existent head dipping forward with exaggerated grace. “Thank you, thank you. I aim to unsettle.”

Sebastian chuckled, the sound coming out lighter this time, more genuine. “You’re definitely good at that,” he admitted, relaxing slightly. “But seriously, next time, give a guy a heads-up before you pop out of a vent looking like… well, whatever this is.”

“I’ll consider it,” you replied with a teasing tone, the rubber duck on your bag giving a little bounce as you shifted your weight. “But where’s the fun in that?”

The tension in the room seemed to dissolve, replaced by an odd sense of camaraderie. Sebastian shook his head, a small smile tugging at his lips as he tried to make sense of the strange being standing before him.

“Only in this place,” he muttered, “could I end up with a faceless, rubber duck-toting, Rock-fanatic as a companion.”

And somehow, despite the absurdity of it all, that was exactly what made it feel… right.

Sebastian was still trying to wrap his head around the sight of you when the sound of frantic scrambling echoed from the vent behind him. He turned just in time to see another figure tumble through the duct opening—a short, pudgy man with wild hair and a permanent look of bewilderment on his face. Berry. One of Sebastian’s more frequent, and certainly clumsier, customers.

Berry landed awkwardly on his feet, nearly toppling over before catching himself against a nearby shelf. His eyes were wide, darting around nervously as if he’d been followed. “Sebastian! AHHHHH—” he began, his voice high-pitched and breathless, but then his gaze shifted to you.

The moment he saw your faceless form with the floating Rock photo and rubber duck bag, Berry’s jaw dropped, his face going pale. He froze, staring at you with a mixture of terror and confusion. “AHHHHHHhhh?!” he squeaked, pointing a shaky finger in your direction.

You raised a hand in a casual wave, the kind that might say “hello” if you had a face to go with it. “Hi,” you said cheerfully, as if your appearance wasn’t the least bit disturbing. “Nice to meet you!”

Berry’s eyes bulged even wider. “Ahhhhhhhh?!” he stammered, taking a stumbling step backward. In his panic, his foot caught on a loose piece of metal on the floor. He tried to catch his balance, but instead, he lurched into a nearby shelf.

The impact was enough to send the precariously stacked items on the shelf cascading down. Jars of strange glowing liquids, bits of rusted machinery, and a few well-loved trinkets that Sebastian had collected over the years came crashing to the ground with a series of loud clatters and splashes.

“Berry, watch it!” Sebastian shouted, rushing forward to try to steady the shelf, but it was too late. One of the jars rolled off the edge and shattered on the floor, sending a bright green substance oozing across the metal surface.

Berry’s eyes darted between you and the mess he’d just created, his panic only increasing. “Ahhhhaheee!” he babbled, his voice shrill with fear. “AHhhhhheeee!”

Before Sebastian could say another word, Berry spun around and bolted for the vent he’d come through. He scrambled up, his limbs flailing as he tried to pull himself back inside. “AHHHH!” he yelled over his shoulder, his voice echoing from within the duct. “AHHHHHHH.”

And with that, he disappeared back into the darkness of the vent, his panicked scrambling fading into the distance.

Sebastian sighed, rubbing a hand over his face as he looked at the chaos left behind. “Great. Another mess,” he muttered, shaking his head. “Berry’s going to scare himself to death one of these days.”

You watched the whole scene unfold with a sort of bemused curiosity. “Is he always like that?” you asked, turning your headless gaze back toward Sebastian.

Sebastian chuckled softly, bending down to pick up one of the trinkets that had survived the fall. “Pretty much,” he said, setting the item back onto the now-empty shelf. “He’s harmless, though. Just a bit… high-strung.”

You nodded—or at least made a nodding motion. “Can’t blame him, I suppose. I do have that effect on people.”

Sebastian glanced over at you, a small smile playing on his lips. “Yeah, well, you’re definitely unique,” he said. “But hey, you scared him off without even trying. Maybe you should hang around more often. Could help keep the riffraff out.”

You gave a mock bow again, this time with an exaggerated flourish. “Always happy to help,” you replied with a hint of playful sarcasm. “Though next time, I’ll try not to make someone pee their pants.”

Sebastian laughed, a genuine sound that echoed warmly through the cluttered shop. “Yeah, let’s keep the cleanup to a minimum,” he agreed, still smiling. “But, hey, thanks. For… whatever this is. It’s been a while since I’ve had a good laugh.”

“Anytime,” you said, your tone light and cheerful. “And if you ever need an unsettling presence to keep things lively, you know where to find me.”

Sebastian nodded, his grin widening. “I’ll keep that in mind,” he replied. And for a moment, in this bizarre, twisted world they both inhabited, everything felt oddly… normal.

Well, as normal as things could get when you had a faceless companion with a rubber duck bag and a floating photo of The Rock hovering by your side.

#sebastian solace#sebastian solace x reader#sebastian solace x you#sebastian solace fanfic#roblox pressure#pressure

191 notes

·

View notes

Note

Short smut about Taeyeon and Nayeon drinking our piss straight from our cock?

Taeyeon and Nayeon share many traits with each other: the last syllable of their names, being the oldest members of the nation's girl groups. But if there is one trait that they share and drives you insane is how nasty they can be in bed.

It's been over an hour and you've fucked these two sluts in every possible way, filling all their holes in the process. After so many cumshots, you had no more sperm to give them, ejaculating for the 9th time in that day as you emptied your balls in Taeyeon's mouth while Nayeon rimmed your asshole.

The two sluts headed to the bathtub for some post sex fun. You stood at the room for a bit, until your body sent you a sign you needed to clean your cock pipe after so much cum, giving you a massive urge to pee.

You looked at the toilet, getting ready to pee on it, but your eyes suddenly veered into the bathtub and found a much better pair of urinals.

"Bring your faces closer" you ordered to both girls. "Now tell me what you want" you say. "That warm post-fucking piss" Taeyeon answers, showing how well-versed she is at watersports.

A huge fountain of piss comes out of your cock straight into Taeyeon's slutty mouth and she drinks every single drop. Cum, piss, it doesn't matter the body fluid, Taeyeon never wastes anything. Nayeon sticks her tongue out, indicating she wants to join the fun. You quickly give what she wants, enjoying having two personal urinals to the fullest, peeing for a good couple minutes and showering their bodies with it for good measure.

"This was the best shower I've ever taken. Taeyeon unnie is the best ball drainer in the industry. No wonder she's god such a long career" Nayeon praises her older teacher skills.

"I'm more than happy to teach my young students, when I started drinking piss, it was a huge taboo. Today girls are already debuting wanting to take that gold liquid" she brags about her tendsetting ability.

"Anyway, it's time to go. Hope you show me your groupmates being showered in piss soon" Taeyeon says to Nayeon.

"You bet I will, unnie"

137 notes

·

View notes

Text

Hormone disrupters are chemicals 🧪 that interfere with your body’s endocrine system, which regulates hormones. They can be found in a lot of every day products like:

Plastic bottles and food containers

Pesticides in agriculture

Cleaning supplies

Chemicals used for clothing

Personal care products like lotions, shampoos & makeup

❌ These are hormone disrupters found in common every day products that you should stay away from ❌

- Bisphenol A (BPA) (plastics and can liners)

- Phthalates (personal care products, fragrances, flexible plastics)

- Parabens (makeup & personal care products)

- Triclosan (antibacterial soaps and cleaning products)

- Polychlorinated Biphenyls (older electrical equipment and industrial products)

- Flame Retardants (furniture, textiles, electronics)

- Pesticides (agriculture)

- Perfluorinated Chemicals (stain resistant treatments, non-stick cookware)

- Dioxins (industrial processes, combustion byproducts)

- Lead (older paints, pipes)

- Dye chemicals (textiles and clothing)

- Water repellents (outdoor clothing, upholstery)

- Stain repellents (carpets, fabrics)

- Formaldehyde (wrinkle free and anti-shrink treatments for fabric)

- Mercury (fish, some thermometers, dental amalgams)

- Cadmium (batteries, some fertilizers)

- Atrazine (herbicides)

- Glyphosate (weed killers)

- Perchlorate (rocket fuel, fireworks, fertilizers)

- Arsenic (contaminated water, pesticides)

- Styrene (plastics, rubber, insulation materials)

- Phosphates (detergents, fertilizers)

- Nonylphenol ethoxylates (industrial detergents, cleaners)

- Organotins (PVC plastics, marine antifouling paints)

- Benzophenone (sunscreens, plastics)

- Octinoxate (sunscreens, makeup)

- 4 Methylbenzylidene camphor (sunscreens, makeup)

‼️ Exposure to these can lead to health issues like reproductive problems, developmental issues and cancer.

🌿 Needless to say, that in order to protect our hormones 🫶 it’s important to recognize these risks and take measures to reduce our exposure them.

89 notes

·

View notes