#scaffolding safety

Explore tagged Tumblr posts

Video

youtube

Scaffold Steel Raw Material Tensile Strength Test -Quality Control of Sc...

#youtube#steel raw material test#scaffolding quality#scaffolding solution#scaffolding safety#wellmade scaffold#scaffolding company#scaffolding manufacturer#scaffoldfactory#wellmade

0 notes

Text

6 SCAFFOLDING SAFETY TIPS

Construction workers must adhere to scaffolding safety guidelines. Every year, thousands of construction workers are involved in scaffold-related accidents, some of which result in death. The Occupational Safety and Health Administration (OSHA) reported that 52 individuals died in 2020 as a result of scaffolding falls. Workplaces can drastically reduce these figures by providing effective training to their staff. Scaffolding Today Inc. is the best Scaffolding companies in Houston. Here are six scaffolding safety measures to keep your workplace safe and productive.

1. Carry Out Routine Scaffolding Inspections and Maintenance

Regular inspections and maintenance are essential preventative measures. Before workers utilise scaffolding, competent persons must inspect all components. Scaffolding should be cleaned regularly, repaired promptly, professionally serviced, and properly stored.

Employers should also maintain meticulous repair and maintenance records.

2. Raise Awareness About Load Capacity Specifications

Workers must be aware of scaffolding load capacity limitations and factor them in to avoid exceeding maximum weight limits. Employees must comprehend load dangers and be able to compute the total weight of people, tools, materials, and equipment at any given time to assure safety.

3. Ensure Proper Scaffolding Assembly and Dismantling

Correct scaffolding setup and removal are crucial to safety. Workers must be skilled in:

Site preparation includes base installation and stability.

Frame Assembly

Platform Installation

Ensure overall structure integrity.

4. Implement a Fall Protection System

Establishing a strong fall prevention system is required to increase worker safety. Falls remain the major cause of scaffolding-related injury and mortality for construction workers.

The online OSHA Fall Protection Training Course teaches employees how to improve workplace safety and fall control.

5. Establish Clear Communication Channels

Effective communication is essential in scaffolding safety. Miscommunication or a lack of clarity regarding operating around and on scaffolding causes accidents. Scaffolding use will be safer with clear signs, visible warnings, posted emergency information, and real-time maintenance notifications in place.

6. Ensure that All Employees Receive Scaffolding Safety Training

Scaffolding training is invaluable. Every worker who works on or around scaffolding must understand the hazards and how to mitigate them. Training must include proper equipment operation, load capabilities, weather concerns, exclusion zones, and emergency response procedures.

Register for Your Online Scaffolding Safety Training

Scaffolding Today Inc. is a leader in workplace safety training in the United States. Every year, we assist over 20,000 people in improving their safety abilities and meeting regulatory requirements. We offer premium and high-quality scaffold for sale Houston. Our skilled and highly educated instructors are available remotely 24 hours a day, seven days a week, to help students pass the course.

#scaffolding#scaffolds#scaffolding safety#safety tips#scaffolding companies#construction scaffolding#tips

0 notes

Text

he stood there for days

#like he was there all alone#with no safety measures#awful ass scaffolding#don't tell me he didn't plan this#dragon age#dragon age solas#dragon age the veilguard#solas

290 notes

·

View notes

Text

They have been Exiled From The Garden

Fradam and Sneve

#they moved inside for their safety when the chimney needed fixing and there was scaffolding#i guess we forgor

7 notes

·

View notes

Text

Chemey is preferred Global Supplier of safety railing systems, Hard yet portable Barricades, fall protection solutions and safe access equipment for working at height.

#Chemey#Chemey Mechatronics#Chemey Mechatronics LLP#Industrial Solutions#Industrial Safety#Safety Solutions#Safety Products#Safety Equipments#Industrial Safety Solutions#Industrial Safety Products#Slip-On Fittings#Modular Guard Rail Solution#Tanker Access Platform#Aluminium Slip-On Fittings#Self-Closing Industrial Safety Gates#Osha Safety Gates#Rooftop Guardrails#Skylight Safety Cover#Tanker Truck Access Platform#Aluminium Industrial Floor Grating#Portable Work Platforms#Modular Safety Railing#Mezzanine Safety Barriers#Mobile Tanker Ladder#Self-Closing Safety Gates#Aluminum Structural Fittings#Mezzanine Pallet Gate#Modular Safety Rail Systems#Rooftop Walkway#Scaffold Mobile Tower

2 notes

·

View notes

Text

I do like builders' debris tubes, such as this one in Fleetwood. They are great for preventing the bonking of the heads of passers-by with roof tiles.

2 notes

·

View notes

Text

The night construction crew. 🏗🦺🚧🔨⚙️⛓🌃🚚🌗(mixed media collage on paper)💥🚛

#cityscape#cityscape painting#cityscape art#urban sketch#real estate#art for sale#basquiat#jean michel basquiat#pop art#contemporary art#folk art#construction#construction site#construction company#construction workers#construction safety#construction crew#bulldozer#dump truck#crane operator#heavy equipment#scaffolding#flares#night world#fine art#forklift#modern art#andy warhol#street art#keith haring

7 notes

·

View notes

Text

having to do these health and safety videos for this new job is reminding me of when, at my last job, i apparently hadn't secured the hand rail on a set of scaffolding properly and i got knocked back after a sign we were removing hit me and i fell into it and almost fell a storey backwards onto the fkn concrete 🤪

#ash.txt#looooot of safety issues at that place#or the time i almost chopped half my thumb clean off#ya kno for all its issues ive never felt gender euphoria like it since fghj#not the potential grevious bodily harm part the manual labour part#somethin abt slingin giant signs and poles and scaffolding about and diggin holes#good for the soul uwu

7 notes

·

View notes

Text

i love (hate) that both fumiko and barem are explicitly/implicitly predatory and presenting themselves as 'fans' to denji

#it all ties back into yoshida's conversation about parasocial relationships and 'safety'#i just havent figured out how yet#its like im starting to recognize the shape of what fujimoto is scaffolding#gdgodkgdlhdhodkhd i cant wait to see whats gonna happen next#L.txt#chainsaw man

3 notes

·

View notes

Text

Reliable Safety Netting for Construction Sites

Protect workers and pedestrians with durable safety netting for construction. Explore custom netting solutions designed for maximum site safety and compliance. At Shreeram Nets, we believe healthy crops need the right balance of nature — sunlight, air, and water — while staying shielded from harsh weather, birds, and insects. That’s why our agriculture nets and flame retardant nets are designed to protect and nurture your crops, ensuring optimal growth with maximum safety.

#"safety netting for construction#Scaffolding nets#Flame retardant net#Square net#Monofilament net#Agriculture netting#Anti Hail Net#BLRS Net#square net#Monofilament Safety Net

0 notes

Text

viAct - Scaffolding Safety Management Software

viAct’s Scaffolding Safety Software is built for construction sites to automate scaffold risk monitoring with AI-powered precision. Using real-time Computer Vision via viMAC (Edge Device), it detects unsafe practices and enforces safety 24/7 without manual oversight.

The system alerts site teams for:

• Unsafe scaffold erection/dismantling • Incomplete/unstable platforms • Missing guardrails & mid-rails • Workers without PPE or harnesses • Unauthorized scaffold access • Fall risks and safety violations

With automated incident detection, visual proof, and digital reporting, it streamlines audits and enforces safety compliance.

Fast to deploy and integrate, viAct’s plug-and-play solution helps contractors cut scaffold-related risks, reduce delays, and maintain safer construction zones without disrupting operations.

Intended for these roles:

• Site Safety Managers • Construction Project Managers • Scaffolding Supervisors • EHS Officers • Site Engineers • General Contractors

0 notes

Text

Explore the Wide Range of High-Quality Scaffolding Tags and Holders

#Scaffolding Tags#Scaffolding Holders#Construction Site Safety#Scaffolding Tags Manufacturer#Large Size Scaffolding Tags and Holder#Scaffolding Holder Supplier#E-Square Alliance

0 notes

Text

The Benefits and Safety of LVL Scaffold Planks in Construction

Laminated veneer lumber (LVL) scaffold planks are revolutionizing the construction industry by providing a lightweight, durable, and high-strength alternative to traditional solid timber planks. These innovative planks are designed to support workers and materials efficiently and safely, making them a preferred choice for various construction activities, including building, cleaning, and repairing bridges and buildings.

What Are LVL Scaffold Planks?

LVL scaffold planks are engineered wood products made from thin layers of wood veneers bonded together with a strong adhesive. This process creates a material that is stronger and more stable than traditional solid timber scaffold planks. The elimination of defects such as knots and splits ensures that each plank has identical strength properties, making them a reliable choice for construction projects.

What Makes LVL Scaffold Planks Superior?

LVL scaffold planks are constructed from multiple layers of wood veneers glued together with a strong adhesive. This manufacturing process imparts several advantages over traditional solid timber scaffold planks:

Increased Strength and Stability: The layered construction of LVL planks enhances their strength and stability, making them less prone to warping, twisting, or bowing. This stability is crucial for maintaining a safe working platform in construction environments.

Uniform Strength Properties: Unlike solid timber, which can have natural defects like knots and splits, LVL planks are manufactured to eliminate these imperfections. Each plank possesses identical strength properties, ensuring consistent performance across all planks used in a project.

Lightweight: Despite their strength, LVL planks are relatively lightweight, which simplifies handling and installation. This ease of use can improve efficiency on construction sites.

Safety Standards and Surface Features

Safety is a paramount concern in the construction industry, and LVL scaffold planks are designed to meet and exceed rigorous safety standards:

Certifications: LVL planks are tested and certified to comply with stringent safety standards such as those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These certifications ensure that the planks can withstand the demands of construction environments.

Non-Slip Surface: To prevent accidents caused by slipping, LVL scaffold planks feature a non-slip surface. This design aspect is essential for maintaining worker safety, especially in wet or oily conditions.

Versatility in Various Conditions

LVL scaffold planks are suitable for both indoor and outdoor use across a range of climatic conditions. Their resilience to weather elements makes them an excellent choice for diverse construction projects. Additionally, LVL planks are available in various lengths, thicknesses, and widths, providing flexibility to meet specific project requirements.

Precautions for Safe Use

While LVL scaffold planks are designed for durability and safety, proper handling and storage are essential to maintain their integrity and prolong their lifespan. Here are some key precautions to follow:

Proper Storage

Store LVL planks in a dry, well-ventilated, and drained area, protected from the weather and without direct ground contact. This prevents moisture absorption, which can compromise the planks' structural integrity.

Handling and Usage

When handling LVL planks, it is important to store them lying flat to prevent warping or bending. Avoid cutting, drilling, or notching the planks, as these modifications can weaken their structure.

Load Management

It is also crucial not to overload the planks, jump or bounce on them, or drop heavy objects on them, as these actions can cause damage and reduce their load-bearing capacity.

Avoiding Physical Damage

To maintain the integrity of LVL planks, do not throw or drop them, and avoid pushing or hitting them with forklift tines or other heavy equipment. Physical damage can introduce weaknesses and defects that compromise the planks' performance and safety.

Applications of LVL Scaffold Planks

LVL scaffold planks are used in a variety of construction activities, from building and repairing bridges to cleaning and maintenance of high-rise buildings. Their high strength and stability make them ideal for scaffolding platforms where safety and reliability are paramount. In addition to construction, LVL planks are also used in industrial settings and by utility companies for tasks that require elevated work platforms.

Conclusion

LVL scaffold planks are a crucial innovation in the construction industry, offering unmatched strength, stability, and safety features. Their manufacturing process eliminates many of the defects associated with traditional timber planks, resulting in a more reliable product. By adhering to the recommended precautions, users can ensure the longevity and effectiveness of these planks in various construction applications.

For construction professionals seeking high-quality LVL scaffold planks, it is essential to choose a reputable supplier. If you have any questions or need further information, please contact us. Ensuring you have the best materials can significantly impact the safety and efficiency of your construction projects.

FAQs

What makes LVL scaffold planks better than traditional timber planks?

LVL scaffold planks are stronger, more stable, and free of natural defects like knots and splits, making them more reliable and safer than traditional timber planks.

Are LVL scaffold planks suitable for all weather conditions?

Yes, LVL scaffold planks are designed to withstand various climatic conditions, making them suitable for both indoor and outdoor use.

How should LVL scaffold planks be stored?

Store them in a dry, well-ventilated area, protected from the weather and without direct ground contact to maintain their integrity.

Can LVL scaffold planks be customized in size?

LVL planks are available in a range of lengths, thicknesses, and widths, but they should not be cut, drilled, or notched to avoid compromising their structural integrity.

What safety standards do LVL scaffold planks meet?

LVL scaffold planks meet strict safety standards such as those set by OSHA and ANSI, ensuring a safe working platform for construction workers.

Previous:No more

Next:What Is Melamine Particle Board? Comparison with Plywood

0 notes

Text

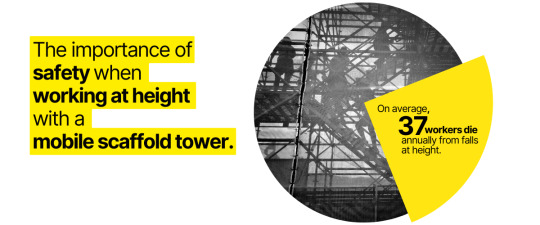

Check if You’re Making These 7 Common Mobile Scaffold Mistakes

Scaffolds are essential for tasks requiring height access, offering versatility and efficiency. However, improper use can lead to serious accidents. Here are seven common mistakes to avoid to ensure safety and efficiency when using mobile scaffolds.

Contents;

1. Choosing the Wrong Scaffold Tower

2. Failing to Inspect and Secure the Tower

3. Skipping Proper Training

4. Ignoring Assembly Instructions

5. Using Improper Access Methods

6. Overloading the Scaffold

7. Operating in Adverse Weather Conditions

1. Choosing the Wrong Scaffold Tower:

Selecting the right mobile scaffold tower is crucial. Consider your project’s height, load requirements, and working environment. For quick, light-duty tasks, ladder towers are ideal, while stairway towers are better for continuous access. In electrically hazardous areas, fiberglass (FRP) scaffolds provide the safest option. Avoid settling for the wrong type, as it compromises functionality and safety.

Article: 5 Reasons to Avoid Mixing Scaffold Tower Components

2. Failing to Inspect and Secure the Tower:

One of the simplest yet most overlooked steps is inspecting the mobile scaffold before use. Check for damaged or loose parts, as faulty components can lead to catastrophic failures. Additionally, mobile scaffolds must be stabilized to avoid tipping. Use stabilizers or outriggers, and always lock the mobile scaffold wheels once the scaffold is positioned.

Article: How Maruti Suzuki India Achieved 3X Productivity in Height Maintenance

Regular inspections and securing the tower ensure it remains steady and safe during use. These steps, though small, can significantly reduce risks and enhance overall stability on-site.

Read Full Article: Y-Access Manufacturing Blog

#mobile access tower#y access manufacturing#y access scaffold#work at height safety#safety#aluminium scaffold#scaffolding#maintenance and care products#maintenance#high maintenance

0 notes

Text

A collection of safety protocols and practices that ensure scaffoldings are used approximately and safely is known as scaffolding safety. It entails a series of proactive steps in the construction, maintenance, use and making of scaffolds. When working on scaffolding, adherence to OSHA’s standard rules and regulations can reduce the risk of drowning, falls, and falling objects.

#Scaffolding training#scaffolding safety training#scaffolding Working at Height Safety Tips#scaffolding working at height safety#ohsa training

0 notes

Text

youtube

Low Reach Podium Platform - by Mlift

0 notes