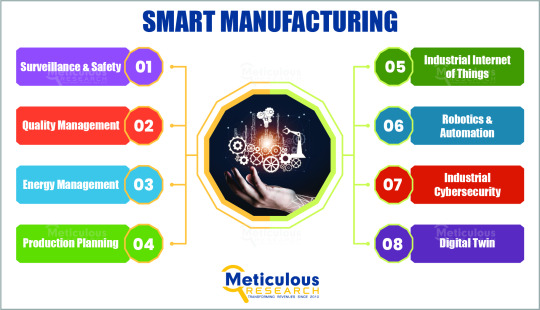

#smart manufacturing solutions

Text

Gain maximized shop floor visibility by streamlining your production processes and reducing machine downtime by utilising smart manufacturing solutions.

2 notes

·

View notes

Text

What are the key benefits of using Python for machine learning in consumer behavior analysis?

Introduction

In the dynamic field of consumer behavior analysis, the ability to forecast consumer purchasing patterns is extremely valuable. Businesses always strive to forecast their customers' purchasing patterns in order to better serve them, facilitate easier customer conversions, increase customer happiness, and eventually increase sales. Many tools are used for this kind of analysis, but Python is one of the most popular choices. The advantages of using Python in machine learning in the analysis of customer behavior will be discussed in this article.

Ease of Learning and Use

Python is well known for being easy to use, especially for people with little experience with programming. For data scientists who must concentrate on solving complex problems rather than creating complex code, its straightforward syntax facilitates rapid learning and effective code writing. Because technological expertise is highly sought after by Israeli enterprises, programmers with strong Python skills are always in demand, which lowers the entry barrier for projects in machine learning.

Extensive Libraries and Frameworks

Python's large and comprehensive libraries and frameworks for data analysis and machine learning are among its most evident advantages. Tools for data mining and analysis are provided by Scikit-learn, and crucial libraries for building deep learning models are TensorFlow and PyTorch. These libraries are used by businesses to create sophisticated machine-learning models that anticipate customer behavior more accurately.

Community Support and Collaboration

Python has a large and active community of programmers and data scientists. This helps developers share their collective knowledge and solve problems and bugs in the code. Moreover, Python is open-source, therefore, it ensures continuous updates among the community, which keeps the libraries and frameworks current and updated.

Integration Capabilities

Since Python is open-source and versatile, it enables developers to integrate it with other programming languages and technologies. This feature is especially beneficial to those businesses who are looking to incorporate machine learning into their already existing systems. Python is highly versatile and therefore can easily combine with other databases, web applications, and other enterprise tools which ensures that machine learning insights are easily accessible and actionable.

Cost-effectiveness

Since developers who have limited knowledge in coding can also handle Python easily, it becomes easier for businesses to hire entry-level programmers which makes it cost-effective. Moreover, Python and its vast ecosystem whether its libraries or frameworks are open-source and this reduces the cost heavily.

Conclusion

Predicting buying behavior using machine learning Python in Israel is becoming more and more common for businesses because of Python’s simplicity and lower entry barrier. Diagsense can help your business predict consumer buying behavior using its latest machine-learning models. Give your business an unmatched edge using our machine learning tools and make your business the best it can be.

#leak detection software#leak detection software israel#predicting energy consumption#predicting energy consumption israel#smart manufacturing solutions#pdm solutions

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Revolutionising Infrastructure Maintenance: The Role of Leak Detection Software in Preventing Costly Damage

Introduction:

Leak detection has turned up as one of the fundamental things of infrastructure maintenance since leaks, however mild they can be, lead to overwatering and consequently cause damages if they are not attended; to correct them it will need financial resources. Consequently, leak detection software is an essential stake in the technology of the present age to fight against the leaks around, before the leaks become uncontrollable. Making use of superior algorithms and data analysis, the software can quickly locate a source of a leak and discharge managerial teams to straightaway respond to the situation.

The Main Advantages of Leak Detection:

Early Detection and Prevention

The De-trending technique wins in the early stage of leak detection. A mix of sensors, data analysis, and machine learning is used to discover discrepancies in pressure, flow, or some other sign faster. Such an early warning system helps to prevent parts failure and high repair costs, offering a way to deal with problems even without costly downtime.

Reduced Maintenance Costs

Finding leaks before they become big problems is one way to save a large amount of cash on maintenance and other repair work. So long as these leaks are not fixed, they can cause bigger and bigger problems, which will require expensive repair and sometimes will even replace the equipment that has been affected. Detection of a leak prevents such intense waste situations by allowing the situation to be solved immediately.

Improved Safety and Compliance

For overlooked leaks, the risk of accidents comes in, especially in an industrial environment where dangerous substances are handled. Leaks detection helps uphold the commitment of manufacturing facilities to regulatory law and order safety act by providing actual time notification. This company takes a proactive approach and not reacting to safety instances can prevent accidents and reduce liability.

Enhanced Sustainability

Leaks can have that amount of loss which is usually natural resources like water, oil, or gas causing environmental defoliation. Making leak detection at different levels will help preserve water resources and environmental security. Recognizing and fixing leaks soon, the company can be among those institutions fighting for a sustainable world.

Customizable Alerts and Reporting

Leak detection systems often arrive accompanied by tailor-made settings as regards alerts and report generation. This flexibility empowers workers to make decisions and plan the order in which they should accomplish the tasks thereby optimizing their workflow. This capacity allows companies to analyze data from history and reveal patterns so that they can handle recurring problems with preventive measures.

Conclusion:

Leak detection software is an amazing advance in infrastructure maintenance, which, in its turn, makes equipped with early detection of any leaks, lower costs, increased safety, and better sustainability. By finding leakages first, companies escape damaging water loss and dangerous situations at work. Utilizing the technologies of the system such as customizable alerts and detailed reporting, the maintenance experts can act intelligently and quickly to tackle the problems. With growing fares coming along with a more important infrastructure requirement, these solutions can be more necessary than ever.

#leak detection software#predicting energy consumption#smart manufacturing solutions#pdm solution#detection software#machine learning

0 notes

Text

0 notes

Text

The Impact of PDM Solutions on Manufacturing Systems

Introduction:

Product Data Management (PDM) solutions are among the most important tools that have been developed for the manufacturing industry to ensure effective management of the production processes in a dynamic environment. All these tools help bring order into data, improve collaboration, and increase productivity. This introduction discusses the changes that the PDM solutions bring into the manufacturing systems and reveals how the smart manufacturing solutions benefit from them.

Streamlining Data for Efficiency:

It facilitates the easy flow of information in manufacturing. Visualize it as a digital secretary that systems data into tidiness, so that teams can have quick access to the data and work as a team. This is a time-saving measure that minimizes the chances of mistakes and ensures everyone is on the same path, culminating in better efficiency.

Enhancing Collaboration:

It enables the people on the manufacturing team to easily share information and work with the same information. This teamwork aid improves the ability to communicate well as no one misunderstands and everyone contributes to the process of producing better products.

Reducing Errors:

PDM is a superhero for mistakes related to manufacturing. By ensuring that all information about products is accurate and up-to-date, your organization eliminates the possibility of making mistakes with things. This accuracy leads to high-quality products with which the customer can be sure.

Cost-Efficiency in Manufacturing:

A clever saver for manufacturing firms. It enables them to manage the resources effectively, avoid extravagant funding, and run smarter. This financial influx acts as a money-saving partner that ensures the good fortune of the company.

Real-time Monitoring:

It lurks like a watchful sentinel over manufacturing. It offers real-time information on how things are happening, thus, making it easy to correct and resolve any problem immediately. Continuous monitoring ensures that production doesn’t go wrong and problems are solved before they escalate to major ones.

Adapting to Change:

It is like a metformin for manufacturing processes. It adjusts to changes in products or procedural methods quickly enough to ensure that the manufacturing team can shift gears when required. This flexibility is in itself an opportunity for companies to remain adaptable in an environment that is continuously changing.

Ensuring Data Security:

The most reliable guard of manufacturing secrets. It makes sure only the right people have access to and can change confidential data. This guarding ensures that sensitive information is kept away from prying eyes and that companies’ secrets remain just that, secret.

Case Studies:

The success storyteller in the context of manufacturing firms. It highlights various real-world cases that demonstrate how the adoption of PDM improved production. These stories depict the tremendous benefits of PDM, which helps people to apply these solutions to achieve success in manufacturing.

Conclusion:

On the path of manufacturing optimization, PDM becomes an essential partner, making the processes more manageable, and efficient in teamwork, and information security. Examples of its success stories show its positive effects. The inclusion of innovative approaches such as Diagsense only accelerates the move toward the future of smart manufacturing solutions, which transforms industries and enables more efficient and agile production.

#smart manufacturing solutions#leak detection software#predicting energy consumption#predicting energy consumption using machine learning#predicting buying behavior using machine learning python#PdM Solutions#Manufacturing PdM Solutions#predicting energy#buying behavior using machine learning#behavior using machine learning python#consumption using machine learning

0 notes

Text

Power of Manufacturing Predictive Maintenance Solutions

In the fast-paced world of manufacturing, downtime can be a costly and disruptive issue. Every minute counts and unexpected equipment failures can result in lost production, increased maintenance costs, and frustrated customers. This is where Predictive Maintenance (PdM) solutions step in as a game-changer, offering manufacturers a proactive approach to maintenance that saves time, money, and headaches. In this blog, we are going to discuss some points related to it.

Let's read it out:

Essence of Predictive Maintenance

Traditional reactive maintenance means fixing equipment after it breaks down, causing production delays and increasing repair costs. Predictive Maintenance, on the other hand, uses real-time data and analytics to predict when equipment is likely to fail. This proactive approach allows for scheduled maintenance before problems occur, reducing unplanned downtime.

Data-Driven Insights

PdM solutions rely on sensor data, IoT devices, and machine learning algorithms to continuously monitor the health of machinery. This data is analyzed to detect anomalies and identify patterns indicative of potential issues. By collecting and analyzing this data, manufacturers gain valuable insights into the condition of their equipment.

Cost Reduction and Efficiency Improvement

One of the most significant benefits of PdM solutions is cost reduction. With predictive maintenance, you can avoid the high costs associated with emergency repairs and unscheduled downtime. Instead, you schedule maintenance during planned downtime, optimizing the use of your resources and minimizing production interruptions.

Increased Equipment Lifespan

Regularly scheduled maintenance and the early detection of issues through PdM can extend the lifespan of your machinery. By addressing problems before they escalate, you reduce wear and tear, leading to longer-lasting equipment and a higher return on investment.

Customer Satisfaction and Competitive Edge

Consistently delivering products on time and meeting customer demands is vital in manufacturing. PdM solutions help you meet production schedules, avoid delays, and ensure product quality, which ultimately leads to satisfied customers and a competitive advantage in the market.

Conclusion

Manufacturing PdM solutions are not just a smart investment; they are a strategic imperative for modern manufacturers. By harnessing the power of real-time data and analytics, you can transform your maintenance approach, maximize efficiency, minimize downtime, reduce costs, and gain a competitive edge in the manufacturing landscape. Embrace PdM, and watch your production line thrive with precision and reliability.

0 notes

Text

#leak detection software#smart manufacturing solutions#pdm solutions#predicting energy consumption#pdm system

0 notes

Link

#Predictive Maintenance#predictive maintenance solutions#predictive maintenance for factory#predictive maintenance for manufacturing#predictive maintenance smart factory#predictive maintenance in manufacturing industry#predictive maintenance for pumps#predictive maintenance semiconductor#predictive maintenance semiconductor industry#preventive maintenance semiconductor#factory automation software#manufacturing automation software solutions

3 notes

·

View notes

Text

Smart Labels: Revolutionizing Product Interaction and Transparency

Discover how smart label technology is revolutionizing the way we interact with products. These advanced labels, featuring QR codes, NFC, RFID, and IoT integration, provide instant access to essential information, ensuring authenticity and enhancing consumer experience. Explore the rise of smart label companies, the importance of rigorous testing, and the transformative benefits of this innovation across industries—from enhanced traceability in food and pharmaceuticals to improved inventory management and anti-counterfeiting measures. Dive into the future of product transparency and interaction with smart labels.

#Smart label packaging#smart labels#smart label QR codes#smart label tracking#smart packaging#smart labels and packaging solutions#Technology-Based Smart Label#smart label services#smart label barrcode#smartlabel QR code generator#smart labels solutions#smartlabel QR code testing#smart label service provider#smart label technology#Smart Labels companies#Smart Labels Manufacturers#smart labels Data Embedded Barcodes#smart labels Temperature-Sensitive Labels#smart labels Tamper-Evident Labels#smart labels Near Field Communication#smart labels Holograms and Security Labels

0 notes

Text

Blog - 800Pergola

Add splendor to your backyard with 800Pergola's luxurious Pergola. Explore wide variety of Pergola designs & styles, by leading pergola contractors in Dubai

#Top Pergola Company in Dubai#Best Pergola Builders in Dubai#Pergola installation service providers in UAE#Best Pergola Designers in Dubai#Pergola Companies in UAE#Leading Pergola Suppliers in UAE#Trusted Pergola professionals in Dubai#800Pergola#Outdoor Shade providers in Dubai#Thermowood pergola developers in dubai#traditional pergola developers#modern pergola developers#Patio and Decking Solutions Dubai#Custom Pergola Design Dubai#Reliable Pergola service provider in Dubai#retractable pergola designers in Dubai#wooden pergola developers in Dubai#Aluminium pergola manufacturers in UAE#CNC cut design pergola suppliers in Dubai#Smart pergola builders in dubai#Automatic pergola developers in dubai#Bioclimatic pergola installers in dubai#Motorised pergola developers in dubai#pergola subcontractors in Dubai#pergola developers in Dubai#pergola development company in Dubai#luxurious pergola developers#pergola development company#patio shades dubai#outdoor gazebo uae

0 notes

Text

Real-Time Energy Monitoring: Enhancing Efficiency in Factory Operations

Introduction

Efficiency and sustainability are more important than ever in the quickly changing industrial world of today. Manufacturers everywhere are looking for creative ways to maximize energy efficiency, cut expenses associated with running their operations and lessen their environmental effects. Machine learning-enhanced real-time energy monitoring is becoming a potent tool for achieving these objectives. With a focus on predicting energy consumption using machine learning, especially in Israel, this article explores how real-time energy monitoring might improve manufacturing processes' efficiency.

The Need for Real-Time Energy Monitoring

One of the biggest operational expenses for industries is energy. In light of contemporary problems, traditional energy monitoring techniques which frequently entail manual readings and recurring audits, are no longer adequate. These techniques offer a limited view of patterns of energy consumption in addition to being labor-intensive. On the other hand, real-time energy monitoring provides a dynamic and ongoing understanding of energy consumption, enabling more strategic long-term planning as well as quick modifications.

Leveraging Machine Learning for Predictive Insights

Factory energy management is being transformed by Machine Learning (ML). Machine learning algorithms can accurately predict future energy usage by scanning past data and detecting trends. For industries, where energy requirements can vary depending on production schedules, equipment usage, and other factors, this predictive capability is very useful.

Factories in Israel, a nation known for its technological advancements, are progressively implementing Machine Learning (ML) driven solutions to optimize their energy efficiency. Israeli factories can predict energy consumption and adjust their operations accordingly by integrating machine learning (ML) with real-time monitoring systems. This decreases expenses, promotes ecological initiatives, and minimizes energy waste.

Benefits of Real-Time Energy Monitoring in Factory Operations

Enhanced Efficiency: Factories may quickly discover inefficiencies and implement remedial measures thanks to real-time monitoring. As a result, energy usage is optimized, which can drastically reduce operating expenses.

Predictive Maintenance: Manufacturers can predict when equipment is likely to break down or need maintenance by keeping an eye on patterns in energy consumption. This proactive strategy increases machinery longevity and reduces downtime.

Sustainability: By cutting down on energy waste, real-time energy monitoring promotes environmental sustainability. Manufacturers can monitor their carbon footprint in real time and take steps to lessen the same.

Regulatory Compliance: There are strict laws governing energy use and environmental effects in many nations, including Israel. Accurate data for reporting and audits are provided via real-time monitoring, which aids factories in maintaining compliance.

Conclusion

Global factory operations are about to change as real-time energy monitoring and machine learning are integrated. The implementation of these technologies in Israel is already yielding encouraging outcomes, thereby establishing a model for other nations to emulate. Factories will have access to ever-more advanced instruments as technology develops to boost productivity, cut expenses, and encourage sustainability. Predicting energy consumption using machine learning Israel is revolutionary for manufacturing processes. It helps industries maximize their energy use, boost operational effectiveness, and contribute to a more sustainable future by offering actionable information and predictive capabilities.

#leak detection software#leak detection software israel#predicting energy consumption israel#predicting energy consumption#smart manufacturing solutions#pdm solutions

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Why the Behavior of data Pipelines matters for today's Businesses

Introduction:

Modern data pipelines play a crucial role in businesses as they guarantee the smooth transfer of information from different sources to analysis. Pipelines allowing for secure data transfer are important in order to be up-to-date and make timely decisions. On the other hand, there is the vulnerability to data leaks as a result of pipeline failure while emphasizing the necessity of implementing security measures and leak detection software to maintain data.

There are a few things to learn more about:

Efficiency and Timeliness:

The highly crucial reason for the analysis of the data pipeline behavior is the efficiency. Companies will make rational decisions based on the timely and correctness of the data they have. Low or unstable data pipelines can result in slowing down the data delivery, and in effect, decision-making processes are impeded. In the context of a high-speed business world, every microsecond is important, and this deprivation of information availability will mean missed business opportunities or even losses.

Data Integrity and Quality:

Data integrity and quality that adhere to making reliable business decisions are very important. Suboptimal data pipelines may lead to data corruption, issues in data consistency/duplicity, or data loss. Flawed data, wrong or inadequate can misguide all parties – analysts and decision-makers – making them the wrong strategy or action. Compliance with acceptable data stream behavior is critical for safeguarding data integrity as well as upholding the authenticity of the conclusions garnered from it.

Scalability and Flexibility:

The data needs of businesses also increase with the growth. Scalability and flexibility of data pipelines are in demand to deal with the data volume increasing and business requirements becoming more dynamic and unpredictable. The behavior of pipelines determines how good pipelines are in case changes in data sources, processing logic, and destination systems happen. Pipelines that are both scalable and flexible help to deal with the growth occurring naturally without any sacrifice of performance or dependability.

Cost Optimization:

Suboptimal pipelines increase data processing costs. Whether it comes from using more resources than are needed, inefficient data processing or unnecessary duplication, the operating expenses are increased with the pipelines that exhibit these behaviors poorly. Managing data delivery pipelines efficiently enables enterprises to minimize their data handling expenses without affecting performance and reliability.

Compliance and Security:

Data pipelines take on a higher significance in places where data privacy and compliance with regulations are top issues. The usage of pipelines that are noncompliant or insecure imposes the risk of regulatory penalties and lawsuits, as well as damage to a business's reputation. With the security best practices and compliance standards, organizations can expect the mitigation of risks and maintain trust with their customers and stakeholders.

Conclusion:

Efficient data pipeline systems significantly increase the chances of a successful business. Diagsense supplies the crucial leak detection software that ensures line integrity. With the help of automated data flow which is timely and accurate, business owners can make informed decisions, uphold compliance, and reduce costs. They can move in the right direction of success in the digital era.

#leak detection software#predicting energy consumption#smart manufacturing solutions#pdm solution#detection software#machine learning

0 notes

Text

0 notes

Text

The Impact of Fast-Charging Technology on the EV Charging Cable Market

The global electric vehicle (EV) charging cable market is poised for significant growth, driven by the increasing adoption of electric vehicles and the need for efficient and reliable charging solutions. As the demand for EVs continues to rise, the market for EV charging cables is expected to reach $3.45 billion by 2031, growing at a compound annual growth rate (CAGR) of 18.1% from 2022 to 2031.

Market Trends and Drivers

The EV charging cable market is driven by several key trends and factors. The increasing adoption of electric vehicles, particularly in regions such as Europe and Asia, is a major driver of the market. Governments worldwide are implementing policies to promote the adoption of EVs, which is expected to further boost demand for EV charging cables. Additionally, the development of fast-charging technology and the need for efficient and reliable charging solutions are also driving the market.

Key Players and Market Segmentation

The EV charging cable market is dominated by several key players, including Aptiv, Besen International Group Co., Ltd., BRUGG Group AG, Chengdu Khons Technology Co., Ltd., DYDEN CORPORATION, Guangdong OMG Transmitting Technology Co. Ltd., Leoni AG, Phoenix Contact, Sinbon Electronics, and TE Connectivity. The market is segmented based on power type, application, cable length, shape, charging level, and region. The power type segment includes alternate charging (AC) and direct charging (DC), while the application segment is categorized into private charging and public charging. The cable length segment includes 2–5 meters, 6–10 meters, and above 10 meters, and the shape segment includes straight and coiled.

Regional Analysis

The EV charging cable market is analyzed across several regions, including North America, Europe, Asia-Pacific, and LAMEA. The Asia-Pacific region dominated the global EV charging cables market in 2022, with China holding the dominant position. The North American market is expected to grow significantly due to the increasing adoption of EVs and the need for efficient and reliable charging solutions.

Challenges and Opportunities

Despite the significant growth potential of the EV charging cable market, there are several challenges that need to be addressed. High operational costs of EV charging cables and the adoption of wireless EV charging technology are some of the key challenges facing the market. However, the increasing adoption of EVs and the need for efficient and reliable charging solutions are expected to drive the market growth.

Conclusion

The EV charging cable market is poised for significant growth, driven by the increasing adoption of electric vehicles and the need for efficient and reliable charging solutions. The market is dominated by several key players and is segmented based on power type, application, cable length, shape, charging level, and region. The Asia-Pacific region dominated the global EV charging cables market in 2022, and the North American market is expected to grow significantly due to the increasing adoption of EVs and the need for efficient and reliable charging solutions.

#EV Charging Cable Market#electric vehicle charging cables#EV charging solutions#charging cable technology#wireless EV charging#sustainable EV charging#EV infrastructure#charging cable advancements#electric vehicle market#EV cable manufacturers#fast charging cables#recyclable charging cables#universal charging standards#regional EV markets#smart grid EV charging#future of EV charging

0 notes