#industry40

Text

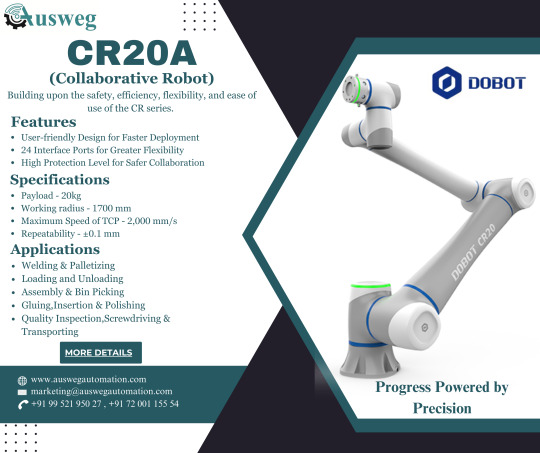

DOBOT CR20A

Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com

[email protected]

+91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

Innovations in Manufacturing: Smart Factory Technology at the Forefront

Are you ready to take your manufacturing process to the next level? Look no further than iPlus MOBOT's innovative Smart Factory Technology. With IPLUSMOBOT ‘s Smart Factory Technology, you can streamline your manufacturing process, reduce downtime, and increase productivity. Our technology allows for real-time data monitoring and analysis, enabling you to make informed decisions and optimize your operations. iPlus MOBOT's Smart Factory Technology is at the forefront of the manufacturing industry, utilizing cutting-edge technology such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). With our technology, you can automate routine tasks, reduce errors, and enhance quality control.

#SmartFactoryTechnology#ManufacturingInnovations#Industry40#DigitalManufacturing#AutomatedManufacturing#IoTinManufacturing#AIinManufacturing

2 notes

·

View notes

Photo

Robotics System Toolbox helps to design, simulate, and test manipulators, mobile robots, and humanoid robots in a single integrated design environment. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CpUW5ujLD0i/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Link

#nanotechnology#sensors#internetofthings#gas#environment#industry40#smartcities#engineering#technology

2 notes

·

View notes

Text

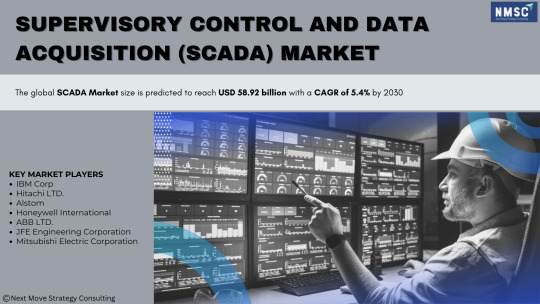

𝐄𝐱𝐜𝐢𝐭𝐢𝐧𝐠 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐒𝐂𝐀𝐃𝐀 𝐌𝐚𝐫𝐤𝐞𝐭!

𝑮𝒆𝒕 𝒂 𝒇𝒓𝒆𝒆 𝒔𝒂𝒎𝒑𝒍𝒆 𝑷𝑫𝑭 𝒓𝒆𝒑𝒐𝒓𝒕 @ https://www.nextmsc.com/scada-market/request-sample?utm_source=debashree_linkedin&utm_medium=debashree_sp&utm_campaign=debashree_scada&utm_id=debashree_apr&utm_term=debashree_sp&utm_content=debashree_sp

As industries worldwide continue to embrace digital transformation, the 𝐒𝐮𝐩𝐞𝐫𝐯𝐢𝐬𝐨𝐫𝐲 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 𝐚𝐧𝐝 𝐃𝐚𝐭𝐚 𝐀𝐜𝐪𝐮𝐢𝐬𝐢𝐭𝐢𝐨𝐧 (𝐒𝐂𝐀𝐃𝐀) 𝐌𝐚𝐫𝐤𝐞𝐭 is witnessing remarkable growth and innovation. SCADA systems play a pivotal role in monitoring, controlling, and optimizing various industrial processes, making them indispensable in sectors ranging from manufacturing and energy to transportation and utilities.

𝑯𝒆𝒓𝒆 𝒂𝒓𝒆 𝒔𝒐𝒎𝒆 𝒌𝒆𝒚 𝒕𝒓𝒆𝒏𝒅𝒔 𝒔𝒉𝒂𝒑𝒊𝒏𝒈 𝒕𝒉𝒆 𝑺𝑪𝑨𝑫𝑨 𝒍𝒂𝒏𝒅𝒔𝒄𝒂𝒑𝒆:

𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧 𝐨𝐟 𝐈𝐨𝐓 𝐚𝐧𝐝 𝐀𝐈: The convergence of SCADA with Internet of Things (IoT) technologies and Artificial Intelligence (AI) is revolutionizing industrial automation. This integration enables real-time data analysis, predictive maintenance, and enhanced decision-making capabilities, driving efficiency and productivity gains.

𝐂𝐲𝐛𝐞𝐫𝐬𝐞𝐜𝐮𝐫𝐢𝐭𝐲 𝐅𝐨𝐜𝐮𝐬: With the increasing connectivity of SCADA systems, cybersecurity has become a paramount concern. Industry players are investing heavily in robust security measures to safeguard critical infrastructure against cyber threats, ensuring operational resilience and data integrity.

𝐂𝐥𝐨𝐮𝐝 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧: Cloud-based SCADA solutions are gaining traction due to their scalability, flexibility, and cost-effectiveness. Cloud deployment enables remote monitoring and management, empowering organizations to streamline operations and adapt to evolving business needs with ease.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝟒.𝟎 𝐈𝐧𝐢𝐭𝐢𝐚𝐭𝐢𝐯𝐞𝐬: As industries embrace the principles of Industry 4.0, SCADA systems are evolving to support advanced automation, interoperability, and data-driven decision-making. Integration with emerging technologies such as edge computing and digital twins is driving innovation and unlocking new possibilities for industrial optimization.

𝐅𝐨𝐜𝐮𝐬 𝐨𝐧 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲: Sustainable practices are becoming increasingly important across industries. SCADA systems are instrumental in optimizing energy consumption, reducing waste, and minimizing environmental impact through efficient resource management and predictive analytics.

The future of the SCADA market is filled with exciting possibilities, driven by technological advancements and the relentless pursuit of operational excellence. Organizations that harness the full potential of SCADA solutions will gain a competitive edge in today's dynamic business landscape.

𝑨𝒄𝒄𝒆𝒔𝒔 𝒇𝒖𝒍𝒍 𝒓𝒆𝒑𝒐𝒓𝒕 @ https://www.nextmsc.com/report/scada-market

#SCADA#IndustrialAutomation#DigitalTransformation#IoT#AI#Industry40#Cybersecurity#CloudComputing#Sustainability#Innovation#LinkedInNetworking

0 notes

Text

DIGITAL TWINS: ENHANCING MANUFACTURING THROUGH VIRTUAL SIMULATION

0 notes

Photo

(Exploring the Top 10 Emerging Trends in Robotics and Automation)

🤖✨ Unlocking the Future: Discover the Top 10 Emerging Trends in Robotics and Automation shaping industries worldwide ✨🤖

Buckle up, fellow tech enthusiasts! 🚀 The future is knocking, and it's dressed in circuits and algorithms. Let's dive into the exciting world of robotics and automation, where innovation knows no bounds! Here are the top 10 emerging trends that are revolutionizing industries across the globe:

1. Collaborative Robots (Cobots): Say hello to your new work buddies! Cobots are designed to work alongside humans, boosting efficiency and safety in manufacturing and beyond.

2. AI-Powered Automation: Artificial Intelligence isn't just a buzzword; it's the brains behind the operation. From predictive maintenance to autonomous decision-making, AI is transforming how robots interact with the world.

3. Internet of Things (IoT) Integration: Everything's connected! IoT allows robots to communicate with each other and with other devices, creating seamless, efficient workflows.

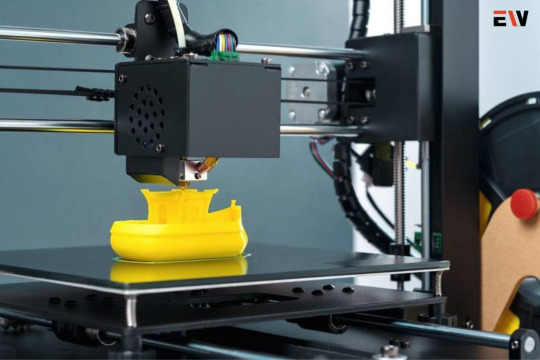

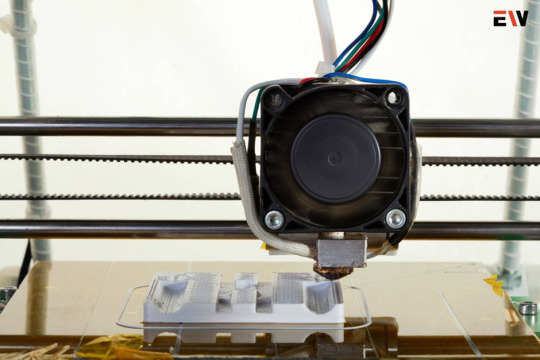

4. 3D Printing Revolution: Imagine printing your own robot parts on demand! 3D printing is democratizing manufacturing and enabling rapid prototyping like never before.

5. Exoskeletons and Wearable Robotics: Superhuman strength, anyone? Exoskeletons are enhancing human abilities in industries like healthcare, construction, and logistics.

6. Autonomous Vehicles: From self-driving cars to drones, autonomous vehicles are reshaping transportation and logistics, making deliveries faster, safer, and more efficient.

7. Robotics in Healthcare: Robots aren't just for assembly lines anymore. From surgical assistants to caregiving companions, robotics is revolutionizing healthcare delivery.

8. Agile Manufacturing: Flexibility is the name of the game! Agile manufacturing systems are enabling rapid adaptation to changing market demands, keeping industries competitive in a fast-paced world.

9. Sustainability in Robotics: Green is the new black! Sustainable practices, from energy-efficient designs to recyclable materials, are shaping the future of robotics and automation.

10. Human-Robot Interaction: It's all about harmony! Designing robots that understand and respond to human behavior is key to creating a future where man and machine coexist peacefully.

So there you have it, folks! The future of robotics and automation is bright, bold, and brimming with possibilities. Whether you're a tech aficionado or simply curious about what lies ahead, one thing's for sure: the age of robots is upon us, and it's going to be one heck of a ride! 🤖✨

1 note

·

View note

Text

Edge Computing: Revolutionizing Connectivity and Data Management Across Industries

The global edge computing market size is expected to reach USD 155.90 billion by 2030, and is expected to expand at 36.9% CAGR from 2024 to 2030, according to a new report by Grand View Research, Inc. Artificial Intelligence (AI) integration into the edge environment is projected to drive market growth. An edge AI system is estimated to help businesses make decisions in real time in milliseconds. The need to minimize privacy concerns associated while transmitting large amounts of data, as well as latency and bandwidth issues that limit an organization's data transmission capabilities, are factors projected to fuel market growth in the coming years.

Edge Computing Market Report Highlights

Over the projected period, the edge server segment is expected to be the booming hardware segment. The increased demand for edge servers throughout several industrial verticals accounts for the segment's promising growth prospects

In terms of application, the AR/VR segment is projected to progress at a substantial CAGR because of the developing cellular network, which offers potential development for edge computing. For instance, to provide a high-quality VR experience to users, Ericsson has improved its radio infrastructure and 5G core

In terms of industry vertical, the data center segment is projected to experience the highest CAGR over the estimated period. This can be ascribed to the fact that edge data centers overcome inconsistent connections and compute and store data close to the end-user

The Asia Pacific region is anticipated to expand at the highest CAGR over the estimated period due to the advent of 5G in the region and the increasing number of IoT-incorporated devices. The evolution of telco edge infrastructure to support 5G-enabled applications is expected to be accelerated by the launch of 5G networks

For More Details or Sample Copy please visit link @: Edge Computing Market Report

Machinery control and precision monitoring are a few use cases that are well-suited for AI on the edge. The latency requirement for a fast-running production line must be maintained to a bare minimum, which can be accomplished by using edge computing. Bringing data processing closer to the manufacturing facility can prove to be extremely important, which can be accomplished using AI. Artificial intelligence-based edge devices can be utilized in a wide range of end-point devices, including sensors, cameras, smartphones, and other IoT devices.

Moreover, the telecom edge is estimated to grow exponentially over the projected period. The telecom edge executes computing adjacent to the telco's mini-data centers, which are operated on the telco-owned property. Several telecom operators, including Telstra and Telefonica, are developing prototypes and pilot projects of open-access networks integrated with edge computing. Edge will be at the forefront of the telecom industry once 5G technology is fully deployed. The telecom industry is in a great position to enhance edge computing, but telecom businesses risk being abridged by irrelevant edge suppliers if they do not move up the value chain.

Presently, Edge computing use cases have outpaced initial infrastructure deployments, and are projected to provide momentum to edge computing infrastructure and use case investments. Edge computing is predicted to become more ubiquitous and evolve toward platform-centric solutions over the projection period. With this development, edge platforms can reduce the infrastructure intricacy using orchestration software and sophisticated management, and provide user-friendly environments for programmers to implement innovative edge services and applications.

#EdgeComputing#DecentralizedData#IoT#CloudComputing#EdgeDevices#DataAnalytics#InternetOfThings#DistributedComputing#DigitalTransformation#RealTimeProcessing#EdgeInfrastructure#EdgeSecurity#NetworkOptimization#EdgeApplications#Industry40#CyberPhysicalSystems#EdgeDeployment#EdgeSolutions#EdgeNetworking#EdgeAI

0 notes

Text

Ready to elevate your career? Our PLC & SCADA training offers hands-on learning experiences and industry-relevant knowledge. Don't miss out! #PLC #SCADA #Training

Reach Us: 8807148869

PLC and SCADA

#PLC#SCADA#Training#IndustrialAutomation#SkillDevelopment#Engineering#Industry40#LearnWithUs#livewire#hopecollege

0 notes

Text

Advancing Manufacturing: A Comprehensive Guide to Fused Deposition Modeling (FDM) Technology

Fused Deposition Modeling (FDM) has emerged as a transformative force in the realm of additive manufacturing, providing a cost-effective and versatile solution for creating three-dimensional objects. Developed by Scott Crump in the late 1980s, FDM has evolved into a widely adopted 3D printing technology with applications across various industries. This comprehensive guide explores the principles behind Fused Deposition Modeling, its applications, advantages, challenges, and the future landscape of this innovative manufacturing process.

Understanding Fused Deposition Modeling (FDM)

1. Core Principles

FDM is an additive manufacturing technology that builds objects layer by layer using thermoplastic materials. The process begins with a 3D model created using computer-aided design (CAD) software. The model is then sliced into thin layers, and the FDM machine interprets these slices to deposit molten thermoplastic material layer by layer, gradually building the final three-dimensional object.

2. Materials Used in FDM

The versatility of FDM lies in its compatibility with a wide range of thermoplastic materials. Common materials used in FDM include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyethylene terephthalate glycol (PETG), and more. The choice of material depends on the specific requirements of the intended application, considering factors such as strength, flexibility, and heat resistance.

Applications of Fused Deposition Modeling

1. Prototyping

FDM is widely employed in the rapid prototyping process, allowing designers and engineers to create physical prototypes quickly and cost-effectively. The ability to iterate designs rapidly facilitates a more efficient product development cycle.

2. Customized Manufacturing

FDM enables the production of highly customized and intricate designs that may be challenging or impossible with traditional manufacturing methods. Industries such as healthcare, aerospace, and automotive leverage FDM to create personalized components and products tailored to individual specifications.

3. Tooling and Jigs

Manufacturers utilize FDM to produce tooling and jigs used in various production processes. These custom tools aid in assembly, quality control, and other manufacturing functions, contributing to improved efficiency on the production floor.

4. Education and Research

FDM technology has found a prominent place in educational institutions and research facilities. It serves as a valuable tool for teaching students about design, engineering, and manufacturing processes. Additionally, researchers leverage FDM to create prototypes for scientific experiments and studies.

Advantages of Fused Deposition Modeling

1. Cost-Effectiveness

Compared to traditional manufacturing methods, FDM offers cost-effective solutions for producing prototypes and small batches of customized products. The ability to use a variety of thermoplastic materials further contributes to cost savings.

2. Rapid Prototyping

FDM’s layer-by-layer construction process enables rapid prototyping, significantly reducing the time required to transform a digital design into a physical model. This speed enhances the overall product development cycle.

3. Design Flexibility

FDM provides designers with unparalleled flexibility in creating complex and intricate geometries. The layering process allows for the production of intricate shapes, internal structures, and interlocking components that may be challenging with other manufacturing techniques.

4. Material Variety

The compatibility with various thermoplastic materials gives FDM a versatility that extends across different industries. Whether the application requires high strength, flexibility, or biocompatibility, there is likely a suitable material for the task.

Challenges and Considerations in Fused Deposition Modeling

1. Layer Resolution and Surface Finish

While FDM excels in creating functional prototypes, achieving high levels of detail and surface finish can be challenging. Layer lines may be visible, impacting the overall aesthetics of the printed object.

2. Material Limitations

While FDM supports a variety of materials, each material has its own set of limitations. For instance, some materials may have lower heat resistance or tensile strength, limiting their use in specific applications.

3. Post-Processing Requirements

Certain FDM prints may require post-processing steps to enhance their appearance or functionality. Sanding, painting, or additional treatments may be necessary, adding to the overall production time and cost.

Future Trends in Fused Deposition Modeling

1. Continuous Innovation in Materials

The development of new and advanced thermoplastic materials is a key trend in FDM. Researchers and manufacturers are continually exploring materials with enhanced properties such as greater strength, flexibility, and even conductivity.

2. Integration with Industry 4.0

FDM is poised to play a crucial role in the Industry 4.0 landscape, with the integration of smart technologies, automation, and data analytics. This integration aims to enhance the efficiency and connectivity of the FDM process within larger manufacturing ecosystems.

3. Large-Scale Printing

Advancements in FDM technology are pushing the boundaries of print size, enabling the production of larger objects. This trend opens up new possibilities for applications in construction, aerospace, and other industries requiring substantial components.

Conclusion

Fused Deposition Modeling stands at the forefront of additive manufacturing, offering a versatile and cost-effective solution for bringing digital designs into the physical realm. From rapid prototyping to customized manufacturing, FDM has found applications across diverse industries. While challenges such as surface finish and material limitations persist, ongoing research and innovation promise to address these concerns. As FDM continues to evolve, its role in shaping the future of manufacturing, particularly in the context of Industry 4.0, is poised to expand, driving advancements in materials, processes, and application possibilities.

#fuseddepositionmodeling#3dprinting#Manufacturing#Technology#industry#innovations#rapidprototyping#customized#manufacturing#Industry40

0 notes

Text

Industrial Robotics Market Business Summation, Industry Examination, Standpoint 2024 to 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Robotics Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Robotics market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Robotics Market from a Global and Regional perspective.

The global industrial robotics market was valued at 15.8 billion in 2022, and is projected to reach USD 40.22 billion by 2029, growing at a CAGR of 14.3% from 2022 to 2029.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/17446/industrial-robotics-market/

#IndustrialRobotics#RoboticsTechnology#FactoryAutomation#ManufacturingAutomation#RoboticAutomation#IndustrialAutomation#RoboticsIndustry#Industry40#AutomationTechnology#RoboticSystems#SmartManufacturing#RoboticsEngineering#RoboticsInnovation#RoboticSolutions#AutomationEngineering#RoboticManufacturing#RoboticsDevelopment#RoboticAssembly#RoboticArm#RoboticsResearch

0 notes

Text

ThirdEye AI- Transforming Infinite Possibilities into Products & Solutions

ThirdEye AI is a next-generation global technology solutions company backed by USD 2.2B JBM Group, assisting companies to expedite their digital transformation journeys with end-to-end Industry 4.0 and AI based solutions. We support businesses in effectively managing digital initiatives and achieving tangible growth by harnessing the collective strength of our experience and extensive network of expertise.

0 notes

Photo

Robot Operating System, a framework for building robot applications, allows developers to assemble a complex system by connecting existing solutions for small problems. ROS provides functionality for hardware abstraction, device drivers, communication between processes over multiple machines, tools for testing and visualization, and much more. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #ros #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CoB2P6BLo8s/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#ros#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Text

#siemens#ruggedcom#industrialautomation#ethernet#switches#industrialcommunication#networking#industrialswitches#digitaltransformation#industrialethernet#industry40#industrialinfrastructure#industrialnetworking#connectivity

0 notes

Text

𝐓𝐡𝐞 𝐀𝐮𝐭𝐨𝐧𝐨𝐦𝐨𝐮𝐬 𝐌𝐨𝐛𝐢𝐥𝐞 𝐑𝐨𝐛𝐨𝐭 (𝐀𝐌𝐑) 𝐌𝐚𝐫𝐤𝐞𝐭 𝐢𝐬 𝐨𝐧 𝐚 𝐭𝐫𝐚𝐣𝐞𝐜𝐭𝐨𝐫𝐲 𝐨𝐟 𝐫𝐞𝐦𝐚𝐫𝐤𝐚𝐛𝐥𝐞 𝐠𝐫𝐨𝐰𝐭𝐡!

𝐆𝐞𝐭 𝐚 𝐟𝐫𝐞𝐞 𝐬𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐫𝐞𝐩𝐨𝐫𝐭 @ https://www.nextmsc.com/autonomous-mobile-robot-amr-market/request-sample?utm_source=debashree_linkedin&utm_medium=debashree_ip&utm_campaign=debashree_amr&utm_id=debashree_apr&utm_term=debashree_ip&utm_content=debashree_ip

the 𝐀𝐮𝐭𝐨𝐧𝐨𝐦𝐨𝐮𝐬 𝐌𝐨𝐛𝐢𝐥𝐞 𝐑𝐨𝐛𝐨𝐭 𝐌𝐚𝐫𝐤𝐞𝐭 is poised for substantial expansion, projected to reach an impressive 𝐔𝐒𝐃 𝟑.𝟏𝟑 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 by 2030. This signifies a robust 𝐂𝐀𝐆𝐑 𝐨𝐟 𝟏𝟑.𝟒% by 2030.

𝐖𝐡𝐚𝐭 𝐝𝐨𝐞𝐬 𝐭𝐡𝐢𝐬 𝐦𝐞𝐚𝐧 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐟𝐮𝐭𝐮𝐫𝐞?

It signifies a transformative era where autonomous mobile robots are revolutionizing industries worldwide. From logistics and manufacturing to healthcare and retail, AMRs are streamlining operations, enhancing efficiency, and driving productivity to new heights.

As we navigate this dynamic landscape, let's seize the opportunities that lie ahead and harness the power of autonomous mobile robotics to shape a brighter, more connected future.

𝐀𝐜𝐜𝐞𝐬𝐬 𝐟𝐮𝐥𝐥 𝐫𝐞𝐩𝐨𝐫𝐭 @ https://www.nextmsc.com/report/autonomous-mobile-robot-amr-market

0 notes

Text

Unlock Superior Lifting Power with Our Double Girder Overhead Crane!

Experience the pinnacle of strength and precision with our 15/7.5 MT Double Girder Overhead Crane. Elevate your operations to new heights with Endeavour's cutting-edge lifting solutions!

For inquiries and consultations:

📞 +91-98-2413 5305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com

#DoubleGirderCrane#ElevateWithEndeavour#PrecisionLifts#HeavyLifting#manufacturinglife#industry40#Endeavour#EndeavourWeigh#EndeavourInstruments#WeighWithEndeavour#EIPLOfficial

1 note

·

View note