#stainless steel drill rod

Text

Buy Drill Rods From India's Best Manufacturer | Techo Enterprise

If you are looking to buy drill rods, Techo Enterprise is the best choice. ✔️ Call 98304 25937 ✔️ Live Chat With Us ✔️ Call Us Today .

#Buy Drill Rods#drill rods#drill bit extension rod#drill rod for sale#drill rod and tool steel#rock drill rods#drilling rods and bits#stainless steel drill rod#oil hardening drill rod#best welding rod for drill stem#drill rod for sale near me#drill rod price#earth rod drilling#extension drill rod

1 note

·

View note

Video

youtube

FIXDEX & GOODFIX technical department explains new energy technology

#youtube#Wedge anchor bolts#threaded rods#din975#self drilling screws#chemical anchor#drop in anchor#foundation bolt#hex nut#flat washer#hex bolt#Photovoltaic Bracket#angle brackets#Stainless steel bracket#Bracket Clamp

3 notes

·

View notes

Text

1930 Ford Highboy Coupe

There’s always lots of detail work with any build and this ’30 Ford highboy coupe is no exception. Look closely and you will find Craftworks Fabrication handmade steel motor mounts. The license plate and valve covers were painted by Jeremy Seanor of Luckystrike Designs. He also painted all the accompanying engine and tranny parts. The powdercoat was handled by Pittsburgh Powder Coat while the chrome plating was conducted by Jon Wright’s Custom Chrome Plating.

The chassis is comprised of a Roadster Shop custom frame that was stepped, stretched, and features contoured ’32 Ford-style framerails. It was also then boxed, capped, and has hole punch flared front framehorns. From here the frame is outfitted with a Super Bell 4-inch drop, drilled and plated I-beam axle, low-profile monoleaf spring with Ridetech tubular shocks paired to custom-made drilled billet radius rods from Johnson’s Hot Rod Shop. Steering falls to the Flaming River box and a LimeWorks Hot Rod column topped with a four-spoke Billet Specialties Sprint Car–style leather-wrapped wheel. In back there’s a Currie 9-inch rearend outfitted with 3.70 gears, 31-spline axles, QA1 coilovers, a Pete & Jakes Panhard bar, and a parallel four-link setup. Braking is a combination of disc/drum front to rear. The forward braking dark gray–painted Wilwood Dynalite calipers are neatly hidden behind the Pete & Jakes finned backing plates. While in back the 9-inch is outfitted with 11-inch brakes, this time hidden beneath the SO-CAL Speed Shop finned drums all the while the chassis rides on a full set of 16-inch Dayton wire wheels wrapped with Coker/Excelsior rubber measuring 5.50R16 in front and 7.00R18 in the back.

All hot rods have something fun settled between the ’rails and beneath the hood (well if they have a hood). In the case of our ’30 Ford highboy coupe it sure appears to be a vintage Ford Y-block but after more than a cursory look we begin to see the telltale signs that there’s something more. Indeed, while it may look like a Ford it truly is a 376-inch LSX iron block, with aluminum heads and ARP studs, plus adapter-equipped small-block Ford (Windsor) valve covers all from Don Hardy Race Cars and then assembled by Talik and Marc Mullin. The intake is an Edelbrock LS dual quad with a pair of Thunder AVS EnduraShine carbs dressed in OTB air cleaners. Delivering the gas from the Tanks stainless reservoir is an Earl’s Performance billet fuel pump. More engine accessories include an MSD 6AL box to go along with the MSD billet Ford small-block distributor that functions through a timing cover adapter from Chevrolet Performance all the while using an MSD coil and Lokar vintage plug wires. Powermaster also supplied the alternator and starter, the battery is an XS Power AGM, and a Wegner Motorsports water pump is used as well as a Wegner front accessory drive unit. This 500-plus hp V-8 utilizes custom headers made at Craftworks Fabrication based on Ultimate Headers LS header flanges. The pseudo-Ford small-block is backed up to a TCI StreetFighter 700-R4 with a 2,800-stall speed converter operated by a Lokar shifter. The trans cooler comes by way of Derale Performance and moves the power through a 3-inch-diameter custom-made driveshaft.

205 notes

·

View notes

Text

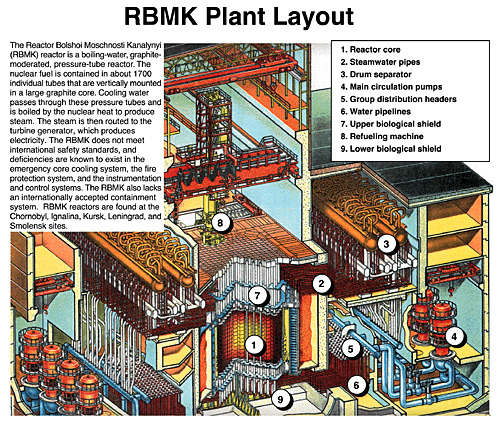

Principles of the RBMK Reactor

The RBMK-1000 Boiling Water Reactor is a Soviet-designed nuclear reactor capable of generating 1,000 megawatts of electricity. The core of the reactor is a short, wide cylinder. The active zone is contained inside a large metal drum, known as the core shroud. The reactor assembly is supported by a large metal disk known as the Lower Biological Shield. This sits on top of a larger metal cross labeled “Structure S”. On top of all this rests the 2,000 ton Upper Biological Shield of the reactor, known as "Structure E". The reactor sits in a large reinforced concrete shell which provides structural support and shields plant personnel from radiation.

The core region of the reactor is a large pile of graphite 14.52m × 9.7m. This pile is composed of graphite blocks 25cm by 25cm, with a height of between 20 and 60cm depending on its location in the reactor. Drilled through these blocks is a 11.4cm diameter hole, through which a zirconium alloy tube (known as a ‘technological channel’) is inserted. These contain either a fuel assembly, a control rod, or reactor monitoring equipment. These channels can be opened in situ or removed completely to replace any fuel or equipment inside them. Zirconium is used due to its high melting point and because it allows the neurons that produce the fission reaction in the core to pass through it far easier than other alloys such as stainless steel.

These metal technological channels have water pumped into them from the bottom by the Main Circulation Pumps. The entire reactor vessel is pressurized with a helium-nitrogen mixture, to prevent the oxidization of the graphite. Graphite is flammable in oxygen, but removed from it it can become quite an efficient thermodynamic conductor.

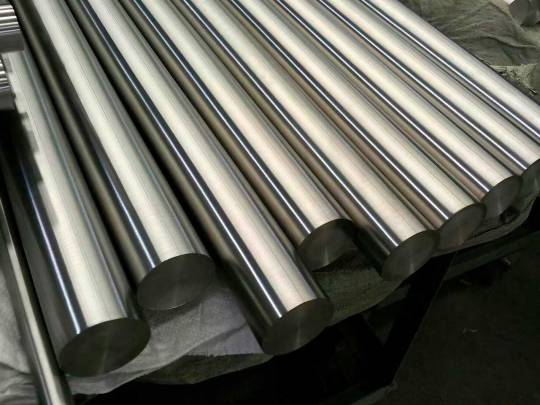

Below: A photo of RBMK technological channels at Chernobyl Unit 2. The length of these gives a good idea as to how massive the core of the RBMK is.

This picture is a screencap from this video.

The fuel of an RBMK is small uranium oxide pellets, stacked into small metal pipes and bundled together into fuel assemblies. Uranium oxide is a ceramic material composed of Uranium 235. This element, under special conditions, can create a nuclear chain reaction which generates heat. The RBMK has three primary components that help create these special conditions to create the controlled fission reactions in the core. These are graphite, water, and boron.

Graphite is used in the core of an RBMK as a moderator. Basically, it slows down the neutrons discarded by U-236 atoms (a U 235 atom which a neutron has collided with) when they split apart. When they are released they are travelling at a tremendous speed, and have very little chance of coming into contact with another atom of uranium. Slowing them down, however, creates a higher chance of the neutrons coming into contact with an atom of U-235, creating the unstable U-236 and then pulling itself apart, thereby creating more neutrons (as well as several other elements) and sustaining a nuclear chain reaction. This sustained reaction is what creates the heat in the core of a nuclear reactor. The more neutrons there are in the core, the more reactivity (and therefore heat) is created. It should be noted that graphite is combustible at high temperatures. The core contained 1,700 tons of graphite.

Water in the core of an RBMK serves as a coolant. Because the core of a nuclear reactor gets extremely hot, it becomes necessary to cool its components if you wish to avoid destructive melting within the core region. Water is the most common coolant in nuclear reactors, as it is cheap and abundant. The water is pumped in under high pressure at about 265 C by the Main Circulation Pumps from the bottom of the reactor up into the technological channels containing the fuel and other components of the reactor. After passing through the channels and heating up to about 284 C, the water is piped out of the top of the reactor. Some of the coolant water heats up so much that it forms into steam bubbles inside the reactor. When the water is pumped out of the core it is then sent into four steam separator drums, where the steam is separated from the water. The water is then pumped back into the reactor, while the steam is sent to the turbine generators of the plant to create electricity. After this, the steam is condensed back into water using cool water from the plant cooling pond and recirculated into the cooling system.

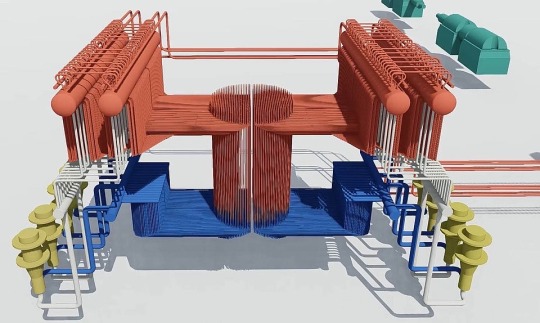

Below: A model showing the circulation system of an RBMK-1000 reactor. Coolant water is in blue and hot water/steam is in red. The yellow structures are the main cooling pumps, and the green structures are steam turbines. This model is spatially to scale, essentially what you would see if you removed every part of the reactor except for the coolant circuit.

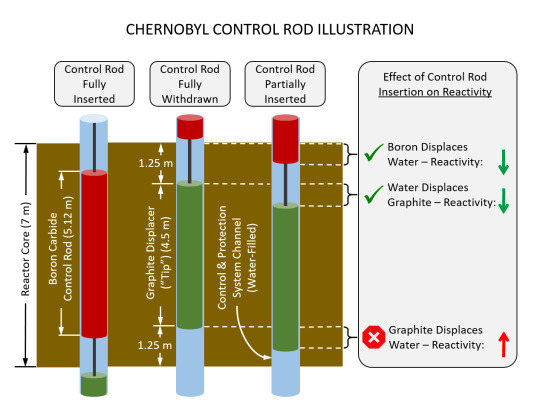

Some of the channels in the RBMK contain control rods (large boron carbide rods) that move up and down in the channel as necessary to keep the reactor within operational limits. Boron is a neutron sponge. It absorbs neutrons and can effectively eliminate a chain reaction. It functions as the brakes on a human made nuclear reaction, useful both in making sure a chain reaction does not become a runaway criticality and also in being the off switch on a nuclear reactor. The RBMK has 211 of these control rods, some of which are under operator control and some of which are under the control of a computer. A design quirk of the RBMK is that at the end of each standard control rod was a 14ft 9in graphite displacer. When a control rod was withdrawn out of the core it left behind a space that would be filled with water, a neutron absorber. Since more water in the core would kill reactivity, the designers of the reactor hung this displacer from the control rods to replace the space left by the control rod with something that would increase reactivity rather than kill it. This was a sound design choice, but it was a major factor in the events of the accident at Chernobyl.

Below: An illustration of the control rod displacers in an RBMK.

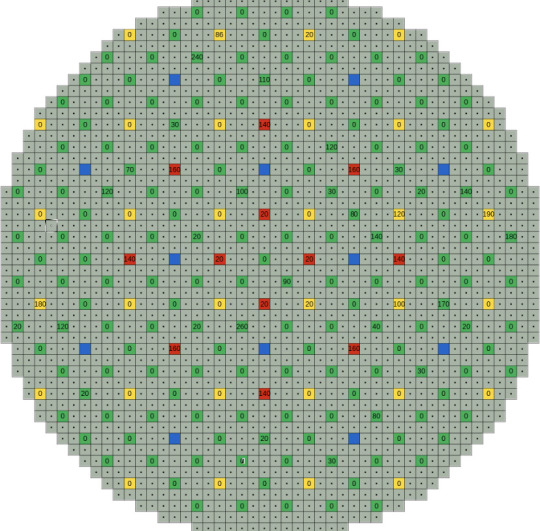

Below: A top down view of the channels of an RBMK. You can see the layout of the control rods (green), neutron detectors (blue), shortened control rods inserted from below the reactor (yellow), automatic control rods (red), and the fuel channels (grey). The number on the green, yellow, and red squares are the last recorded insertion depths of control rods in Chernobyl Unit 4 1m 30s before the explosion. Only one is fully inserted.

Below: A cutaway of the RBMK system layout.

Two additional factors also come into play regarding the water. Water is naturally a neutron absorber, albeit a far less effective one than boron. The more water in the core, the less neutrons are present and therefore the lower the reactivity. However, when transformed into steam, water loses nearly all of its neutron absorbing properties. The more steam in the core, the higher reactivity is. This is called a ‘positive void coefficient’, and it was a known quirk of the RBMK and indeed several other reactor designs. However, the RBMK had a much higher level of this effect in its core due to its design. This is important to the accident sequence.

It is also important to note that the RBMK is an enormous construction. It is temperamental, unstable unless operating at full power, and requires constant monitoring and guidance from its operators. It requires three operators just to run it normally, and it was notoriously difficult to operate. The core region is so large that the equipment used to monitor it could not accurately read a large portion of it, and hotspots of reactivity would often form resulting in alarming and unexplained jumps in power output and temperature. While in theory not a bad design, the RBMK was a deeply flawed machine.

An enormous thank you is owed to @nicotinebeige , who was extremely helpful in the creation of this post. If you like film photography, you should check out their blog!

This is a technical explanation of the RBMK design. For a history of the RBMK, check out this post. Apologies for any mistakes! I’m most definitely not an expert on nuclear physics, and if anything is unclear you should absolutely check out other sources for more info. As always, thank you for your interest!

#chernobyl#nuclear reactor#history#radiation#accidents and disasters#nuclear power#autism#nuclear#reactor#chnpp#rbmk#rbmk 1000

122 notes

·

View notes

Note

Hey Cy (can I call you Cy? What about Cybal?) What's your favorite or strongest welding process? What's the most difficult metal or alloy you've welded successfully? What's your least favorite process and alloy? Do you have any favorite stories in the shop you currently work at or just from engineering or welding jobs in general? If you've already told those stories then what are the tags?

Sure thing! I haven't actually thought of any sort of tumblr name other than my URL and I guess those work.

So my favorite welding process is, by far, stick welding. It's my first arc, first love, and the first prices I felt like I was actually good at. It's also the last time I really had a ton of fun welding, when I got ahold of a pound of general purpose stainless rods for a personal project. It's really fun to strike an arc and then just being along for the ride, and it smells like woodsmoke. The great tragedy is that I actually kind of hate most professional situations that call for stick welding. I like working on a table or saw horses in a shop, not in a mud pit or crawling across beams.

My strongest process is semiautomatic wire fed. I'm particularly fond of flux core, as it's the one I actually use at work. I'm good for everything from like ⅛" to... technically my certification is for unlimited thickness, but I've only done up to 2".

Either way, I prefer welding if I get to crack a slag layer when I'm done.

Honorable mention for TIG: I love you, but it's been fucking ages and these days I'm lucky if I can run a stack of dimes and not a stack of blobs.

My most difficult metal... So, most of the time I'm just working with structural steel. You know, boring, low alloy stuff. I've worked with stainless and aluminum, and both of those were pretty fun, but they were the sorts we use in a trade school, so pretty easy, all things considered.

The actual worst stuff I've had to work with is zinc. Ok, technically I'm not actually welding the zinc, I'm welding through it, but it's still the actual worst. It spits and sputters and spatters and tries to throw the whole damn weld back out at me. The only times I've been genuinely concerned that I'd say myself on fire with sparks was from going slightly too fast/slow and having the weld shot out, over my mask, on top of my head. Yesterday, I also got up close and personal with how much it can fuck up a job, even if you don't have to weld it. The place that does our galvanizing charges by weight, so they basically smear on as much as they can, and in addition too warping the fuck out of our precisely drilled holes, and made them so much larger the frames would no longer fit where they needed to go. Even grinding it gums up my wheels and smells like cherries if you lean hard enough to actually get through all that shit.

For whatever reason, my work frequently breaks the "weld first, then galvanize" rule for logical reasons. I once had to weld through galvanized shit for three months because the job only called for half of each piece to be galvanized, and we were too cheap to do the whole thing after I'd done them.

Galvanization sucks and I hate it.

Most of my stories from work are along the lines of spot the OSHA violation, we almost built an entire floor backwards because apparently I'm the only one who can read prints, and we actually built this flight of wall rails backwards because the engineers programed these cuts, why would the fabricator need prints? At least that last time I finally got proper respiration PPE, because both me and my helper were getting sick welding through the paint fixing that job, and my helper is the owners son.

Oh, and one day I watched two people in a row set themselves on fire with the acetylene torch, and a third one almost setting his fuel line on fire when he set the torch down, still lit, and walked off to move the stuff he set it down on.

When I lay it all out like that, it almost sounds like I'm not paid enough to deal with this shit.

5 notes

·

View notes

Text

What are Electric Resistance Welding (ERW) Pipes?

Welding Utilizing Electric Resistance Pipes and tubes find widespread application in a variety of industries, such as fencing, engineering, scaffolding, line pipe installation, and much more. The agricultural and irrigation industries are two of the most common places to find ERW pipes being put to use. These pipes are typically utilised in water mains, sewage systems, plant plumbing, deep tube wells, industrial water lines, and many other similar applications. In addition, they find widespread application in the gas pipeline industry, particularly in the production of pipelines that are used to transfer natural gas, LPG, and other non-hazardous gases.

Rolling the metal and then welding it longitudinally along its length is the process that is used to make ERW pipes. If you examine the process of making seamless pipes, you'll see that the metal is extruded to the required length before the pipes are made. This indicates that there are no joints in the cross-section of seamless pipes anywhere along their length. On the contrary, the joints of ERW pipes are welded together in the cross-section of the pipe. Tube Trading Co. is an excellent MSERW Pipe dealer in Gujarat that can fulfil all of your industrial piping and tubing needs.

Pipes that are seamless are made by passing a solid billet across the piercing rod, giving them a round shape and a hollow interior. They find widespread application in hydrocarbon refineries & industries, oil and gas exploration, drilling and transportation, air and hydraulic cylinders, automobiles, boilers, bearings, as well as other high-pressure applications. Because of the intricate manufacturing process and a limited number of competitors in the seamless pipe industry, the unit cost of seamless pipe is more expensive per tonne.

Strip or coil is used throughout the manufacturing process of ERW pipes. The transfer of low- or medium-pressure fluids, such as water and oil, respectively, are examples of common applications for these pipes. If you are seeking ERW pipes of good quality, then you need to choose one of the leading manufacturers of ERW stainless steel pipes. If you are looking for the most prominent as well as distinguished MSERW Pipe supplier in Gujarat, Tube Trading Co., is the best pick for you.

Particular characteristics of ERW tubes and pipes of the highest grade

● High-strength corrosion resistance

● High malleability

● Superior strength

● Durable and sturdy

In order to guarantee that ERW pipes are of the highest possible quality, they are put through a series of rigorous examinations, such as a hydro-test, an ultrasonic weld inspection, a micrometre check, a straightness evaluation, as well as a ring gouge test. ERW pipes, in a nutshell, are pipes that are more economical, have tighter dimensional tolerances, and are lighter in weight. ERW pipes have been used in a variety of different sectors. In addition to the transportation of oil, water, and gas, ERW pipes are also seeing widespread use in the fields of agriculture and vehicle manufacturing. ERW pipes are frequently used in collieries for water extraction, thermal power stations, drinking water, as well as employed as hand pumps for boring wells, and as protection for cables by the telecom sector. This is due to the fact that ERW pipes have a diverse range of applications and are reliable. Get in touch with the most distinct as well as noteworthy MSERW Pipe provider in Gujarat, Tube Trading Co., for your industrial pipes and tubes requirements. The following is a list of some of the most common applications for ERW pipes:

● Structural as well as Engineering purposes such as line pipes, Fencing, scaffolding, etc.

● Automobiles Sector

● Water and gas transportation, oil country tubular

● Agriculture Sector

● Collieries for Water extraction as well as Thermal Powers

● Hand pumps that are used for deep boring wells, Drinking water in houses

● Robust cable protection by the Telecom Department

The Bottom Line:

You should choose a quality-aware manufacturer that creates high-quality pipes in India if you are the MSERW Pipe dealer in Gujarat, MSERW Pipe supplier in Gujarat or MSERW Pipe provider in Gujarat. This is true regardless of the type of pipe you are searching for. The selected manufacturer must be able to create pipes of high quality in a variety of specifications, sizes, and grades to accommodate the requirements of various industries, such as public health, agriculture, housing, oil and gas, engineering, irrigation, etc.

5 notes

·

View notes

Text

Top Suppliers and Distributors of Earth Rods in Dubai, UAE | Translight Electricals

For the safety of your life and appliances, earthing is essential and cannot be avoided. It eliminates electrostatic discharge, protecting your equipment and property. As top suppliers and distributors of earth rods in Dubai, UAE, Trans Light Electricals offers the best quality earthing rods and accessories at affordable prices.

Our products include:

Stainless Steel Earth Rods: With drilled holes at both ends, suitable for wide areas.

Solid Copper Earth Rods: Ideal for aggressive soil conditions.

Copper Bond Earth Rods: High tensile strength, cost-effective earthing solution.

Choose Trans Light Electricals for the best earthing solutions in Dubai.

1 note

·

View note

Text

How Do Stainless Steel Bright Bars Recover Machinability?

Stainless steel bright bars are treated through a series of accuracy grinding and polishing operations, ensuing in a smooth, shiny surface texture. This surface appearanceimproves the machinability of the bars by dipping friction and minimizing implement wear during machining procedures such as turning, drilling, and milling. The unchanging surface feel of bright bars allows cutting tools to brand clean, precise cuts with better ease and efficiency. Moreover, the improved surface finish of bright bars assistances maintain dimensional correctness and surface integrity, resulting in high-quality machined components appropriate for aextensive range of applications in numerous industries.

Stainless Steel Rod Suppliers in Chennai: Dependability and Value

Stainless steel rod suppliers in Chennai play a vital role in ifgood stainless steel rods to various businesses. These suppliers proposal a extensive range of stainless steel rod choices, counting bright bars, hex bars, square bars, flat bars, and round bars, cookery to the diverse wants of patrons in Chennai and beyond. They safeguard reliability by obtaining stainless steel rods from reputable constructers and adhering to stringent quality control procedures to deliver products that meet or exceed industry values.

Stainless Steel Bright Bars: Sparkly and Adaptable

Stainless steel bright bars are precision-ground and refined bars known for their flat, shiny surface finish. They are extensively used in industries such as automotive, aerospace, building, and manufacturing due to their artistic appeal and excellent machinability. Bright bars proposalimproved corrosion resistance and durability, manufacture them suitable for requests requiring superior superficial finish and dimensional accurateness.

Stainless Steel Hex Bar:Power and Constancy

Stainless steel hex bars article a hexagonal cross-section, if increased forte and stability compared to round bars. They are usually used in construction, machinery, and hardware businesses for applications requiring healthy structural support and exact machining. Stainless steel hex bar offer adaptability, allowing for easy fabrication and meeting in numerous engineering projects, creation them a popular excellent among designers and builders.

Stainless Steel Square Bar: Strength and Functionality

Stainless steel square bars are solid bars by a square cross-section, contribution excellent durability and functionality in varied applications. They are extensively utilized in architectural, marine, and food giving out industries due to their corrosion confrontation and hygienic possessions. Stainless steel square bars afford structural integrity and aesthetic application, making them appropriate for use in railing schemes, kitchen equipment, and decorative rudiments.

Stainless Steel Flat Bar: Multipurpose and Calm to Fabricate

Stainless steel flat bars article a flat surface and rectangular cross-section, making them extremely versatile and relaxed to fabricate for various requests. They are commonly used in building, automotive, and manufacturing businesses for components such as brackets, frames, and chains. Stainless steel flat bars suggestion excellent weldability and formability, permitting for seamless integration into dissimilar designs and assemblies.

Stainless Steel 304 Round Bar: Corrosion Opposition and Machinability

Stainless steel 304 round bars are amongst the most widely used stainless steel produces known for their outstanding corrosion confrontation and machinability. They are collected of an austenitic stainless steel alloy comprising chromium and nickel, providing greater resistance to rust and oxidation in harsh situations. Stainless steel 304 round bars are apposite for a extensive range of applications, counting food processing, chemical processing, and pharmaceutical engineering, due to their hygienic belongings and ease of construction.

0 notes

Text

The Ultimate Guide to Installing a Rod Locker

Why You Need a Fly Rod Locker

Before we dive into the installation process, let’s discuss why a fly rod locker is a must-have for any serious fly fisher. A fly rod locker keeps your rods safe from damage, whether you’re transporting them in your vehicle or storing them at home. These lockers prevent your rods from bending, breaking, or tangling, ensuring they last longer and perform better.

Benefits of a Fly Rod Locker

Protection: A rod locker offers padded compartments that protect your rods from impact and abrasions.

Organization: Rod locker organizers help you keep your rods neatly arranged, making it easy to find the right rod when you need it.

Durability: Durable fly-fishing lockers are built to withstand harsh conditions, ensuring your gear stays safe even in rugged environments.

Convenience: With a rod locker, transporting your gear becomes hassle-free, as it consolidates all your rods in one secure place.

Choosing the Right Fly Rod Locker

Selecting the perfect rod locker for your needs is the first step. Here are some factors to consider:

Size and Capacity

The size of the rod locker should match the number and length of your fly rods. Ensure the locker can accommodate your longest rod without bending it. For anglers with multiple rods, look for a locker with multiple compartments.

Material and Durability

Opt for a durable fly-fishing locker made from high-quality materials like aluminum, stainless steel, or heavy-duty plastic. These materials offer excellent protection and can withstand the rigors of outdoor use.

Padding and Interior Protection

A padded fly rod locker is essential to prevent damage during transport. Look for lockers with foam padding or soft lining inside to cushion your rods.

Locking Mechanism

Security is crucial, especially if you travel frequently with your gear. Choose a rod locker with a reliable locking mechanism to keep your rods safe from theft.

Tools and Materials Needed for Installation

Installing a rod locker is a straightforward process if you have the right tools and materials. Here’s what you’ll need:

Fly rod locker

Mounting brackets or hardware (usually included with the locker)

Drill with appropriate bits

Screwdriver

Measuring tape

Marker or pencil

Level

Step-by-Step Guide to Installing Your Rod Locker

Now that you’ve chosen the perfect rod locker and gathered your tools, it’s time to install it. Follow these steps for a secure and professional installation.

Measure and Mark the Mounting Location

Begin by determining where you want to install the rod locker. It could be on the roof of your vehicle, inside your garage, or on your boat. Use the measuring tape to find the ideal spot, ensuring there’s enough space for the locker to open and close easily.

Mark the mounting points with a marker or pencil. Double-check the measurements to ensure accuracy, as improper alignment can affect the locker’s functionality.

Drill the Mounting Holes

Using the drill and appropriate bits, carefully drill holes at the marked points. Ensure the holes are clean and free of debris. If you’re mounting the locker on a vehicle or boat, double-check that you’re not drilling into any important components or wiring.

Attach the Mounting Brackets

Most rod lockers come with mounting brackets or hardware. Attach these brackets to the drilled holes using screws and a screwdriver. Ensure the brackets are securely fastened and level, as uneven brackets can cause the locker to sit improperly.

Mount the Rod Locker

Test the Locker

Once installed, open and close the locker several times to ensure it operates smoothly. Check that the locking mechanism works correctly and that the rods fit comfortably inside without bending or jamming.

Tips for Maintaining Your Fly Rod Locker

Proper maintenance will extend the life of your rod locker and keep your rods in top condition. Here are some tips:

Regular Cleaning

Clean your rod locker regularly to remove dirt, dust, and moisture. Use a soft cloth and mild detergent for the exterior, and vacuum or wipe the interior to remove debris.

Inspect for Damage

Periodically inspect the locker for any signs of wear or damage. Check the padding, hinges, and locking mechanism to ensure everything is in working order.

Store in a Dry Place

When not in use, store your rod locker in a dry, cool place to prevent rust and corrosion. Avoid exposing it to direct sunlight for extended periods, as UV rays can degrade the materials over time.

Lubricate Moving Parts

To keep the hinges and locks functioning smoothly, apply a small amount of lubricant to the moving parts. This will prevent rust and ensure easy operation.

Customizing Your Fly Rod Locker

One of the great things about rod lockers is that they can be customized to fit your specific needs. Here are some ideas for personalizing your locker:

Add Extra Padding

If you frequently travel over rough terrain, consider adding extra padding to your locker. This provides additional protection for your rods and prevents them from shifting during transport.

Install Additional Compartments

For anglers with a variety of rods and accessories, installing extra compartments or dividers can help keep everything organized. You can purchase these or make custom dividers from foam or other materials.

Personalize the Exterior

Make your rod locker stand out by personalizing the exterior. Add stickers, decals, or a custom paint job to reflect your personality and make your locker easily identifiable.

Conclusion

Installing a fly rod locker is a wise investment for any fly fisher, offering unparalleled protection and organization for your valuable gear. By following the steps outlined in this guide, you can ensure a secure and professional installation, allowing you to focus on what matters most — enjoying your time on the water.

Remember to choose a durable fly-fishing locker that meets your needs, and don’t skimp on quality. With the right care and maintenance, your rod locker will provide years of reliable service, keeping your rods safe and ready for your next fishing adventure.

Investing in a padded fly rod locker is not just about convenience; it’s about preserving the integrity of your fishing equipment. So take the time to install it correctly, maintain it well, and you’ll reap the benefits every time you head out to fish. Happy fishing!

1 note

·

View note

Text

How Do I Maintain a Round Bar for Longevity?

Shashwat Stainless Inc. is the largest Round Bars Manufacturers in India. One of our popular products in the Metal Market is Round Bars. Round bars, also known as rods or solid bars, are cylindrical metal rods usually composed of stainless steel, aluminum, or brass. When it comes to extending the life of round bars, proper care is essential. Round bars, which are often used in many sectors for structural support, machining, and fabrication, require special care to retain their quality and durability over time. In this detailed article, we'll look at the most important strategies for keeping round bars looking good for a long time.

Understanding Round Bars

Round bars are cylindrical metal bars having a circular cross-section. They are often referred to as round steel bars or rods. They are used in many different sectors, including aerospace, automotive, manufacturing, and construction. They are often composed of carbon steel, stainless steel, or alloy steel.

Proper Handling and Storage

Proper handling and storage of round bars is one of the most important aspects impacting their lifetime. To avoid damage and corrosion, round bars must be handled carefully during shipping and storage. Here are some important considerations:

Handling:

Make sure round bars are securely fastened when being transported to avoid rolling or moving.

To properly handle big bars, use the proper lifting equipment, such as cranes or forklifts.

Steer clear of falling or hitting the bars as this may result in surface deformation or damage.

Storage:

To reduce the danger of corrosion, store round bars in a clean, dry environment.

To avoid moisture absorption, keep the bars elevated using pallets or racks.

Protect the bars against harsh factors including high temperatures, humidity, and corrosive chemicals.

Regular Inspection and Maintenance

Routine inspection and maintenance are essential for identifying any signs of damage or deterioration early on and addressing them promptly. Here's what you should include in your maintenance routine:

Visual Inspection:

Regularly inspect round bars for signs of surface damage, such as scratches, dents, or rust.

Check for any cracks, fractures, or other structural issues that may compromise the integrity of the bars.

Pay attention to any changes in appearance or dimensions that could indicate wear or corrosion.

Cleaning and Lubrication:

Clean round bars regularly using a mild detergent and water to remove dirt, debris, and surface contaminants.

Dry the bars thoroughly after cleaning to prevent moisture buildup.

Apply a thin layer of lubricant, such as oil or grease, to protect the surface and reduce friction during machining or fabrication processes.

Corrosion Protection:

Implement corrosion protection measures, such as applying rust inhibitors or coatings, to safeguard round bars from environmental corrosion.

Monitor the effectiveness of corrosion protection methods and reapply as necessary to maintain optimal protection.

Proper Machining and Fabrication Practices

It's critical to adhere to standard practices while machining or fabrication round bars in order to reduce stress and avoid damage. Here are some pointers to think about:

Cutting and Drilling:

Use proper cutting tools and procedures to reduce heat generation and prevent the material from overheating.

Use suitable coolant systems to disperse heat and lubricate cutting surfaces during drilling or milling operations.

Choose modest and steady cutting rates to avoid excessive friction and vibration, which can cause surface damage.

Welding and Joining:

Adhere to the specified welding processes and guidelines to guarantee correct fusion and reduce the possibility of weld imperfections.

To lessen thermal loads and avoid cracking during welding, preheat the round bars as needed.

Without sacrificing the integrity of the bars, create strong and long-lasting weld connections by using suitable filler metals and welding procedures.

Conclusion

Maintaining round bars for longevity requires a proactive approach that includes proper handling, storage, inspection, and maintenance practices. By following the tips outlined in this guide, you can ensure that your round bars remain in optimal condition, providing reliable performance for your applications.

Follow For More Detail

Website: shashwatstainless.com

Product Source: Round Bar Supplier in India

Other Product Source: Nickel Alloy Seamless Pipe Manufacturer in India.

0 notes

Text

The Use of SS Round Bars in the Oil and Gas Industry

Introduction to SS Round Bars

The possible areas that the round bars would be put to use are unlimited within the dynamic world of the oil and gas industry: ranging from the drilling process to the construction of pipelines, these rough cylindrical bars exude the strength, durability, and reliability necessary for survival under the tough conditions the industry is known for.Hans Metal India is the major Stainless Steel Round Bar Manufacturer in India

SS Round Bars: A Vital Ingredient to Oil and Gas Infrastructure

The round bar, solid bar, or rod is nothing but a cylindrical metal bar of a circular cross-section. Such bars are most commonly made out of high-strength steel alloys—carbon, stainless, or alloyed steel. They have been proven very appropriate for the hostile conditions during oil and gas exploration and production. We are alos the top supplier of Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE.

Applications of SS Round Bars in Oil and Gas Operations

Drilling Equipment: Used as a drill string, a drill collar, and in the making of a stabilizer, it provides structural support and stabilization as one drills through. They transfer both torque and weight to the drill bit and support the effective penetration of the earth's crust to expose potential oil and gas deposits.You could possible like SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India

Pipes and Tubing: Round bars are used for the manufacturing of pipes and tubing, in addition to cases made for oil and gas wells. These are the elements that convey unprocessed crude oil, natural gas, and other fluids from the reservoir to the surface in addition to bearing the structure of downhole equipment.

Valves and Fittings: Valves, flanges, and fittings for pipes in oil and gas pipelines and processing facilities can be found with round bars as well. This equipment gives room for the control and direction of fluid flow, pressure control, and connection of the different portions of the pipeline system.Also, check out:Round Bar Manufacturer in Mumbai and Round Bar suppliers in Saudi Arabia

Benefits of Using Round Bars in the Oil and Gas Operations

Strength and Durability: Round bars with high tensile strength and resistance to corrosion will ensure reliability and a long life in critical infrastructure needed to support the working of oil and gas operations.

Versatile: Round bars can be custom-designed in size, diameter, and material composition as per the specific needs of varied applications in the oil and gas industry. Economically

Viable: Though robust, round bars prove to be an economically viable solution for oil and gas companies in the long run, as they require less maintenance.

Conclusion

In conclusion, round bars are supportive in activities of oil and gas as they serve the integrity of structures and strength, and versatility of drilling equipment, piping systems, and processing facilities. These are some of the main aspects that any oil and gas company has to understand and know about the products in order to have efficient, safe, and reliable operations.

#Stainless Steel Round Bar Manufacturer in India#Stainless Steel Sheet Manufacturer in India#Round Bar Suppliers in UAE#SS Round Bar Manufacturer in India#Copper Sheet Manufacturers in India#Round Bar Manufacturer in Mumbai#Round Bar suppliers in Saudi Arabia

0 notes

Text

A Guide to the Working, Benefits, Installation and Applications of Pivot Hinges

Pivot hinges ensure stability, durability, and smooth operation of heavy duty doors and gates. Whether you are an architect, contractor, or homeowner, a clear understanding of pivot hinges can be highly beneficial. In this post, we will delve into the world of pivot hinges, exploring their working principles, benefits, installation methods and applications.

What are Pivot Hinges?

Pivot hinges are one of the popular choices for today's doors and cabinets owing to their unique design. These hinges enable the door or cabinet to pivot on a single point, usually positioned at the top or bottom of the door. This design guarantees smooth and seamless movement while opening and closing doors. Pivot door hinges are generally opted in situations where there isn't enough clearance for a traditional hinge to swing fully open.

How do Pivot Hinges Work?

The working of pivot door hinges is simple and straight forward. These hinges comprise two components: a pivot plate that is affixed to the door or gate, and a pivot mechanism that fits into the pivot plate enabling seamless rotation. The pivot plate is installed on the top and bottom of the door or gate, housing the pivot mechanism within it. This pivotal setup includes a pin or rod that is inserted into the pivot plate, enabling the door or gate to pivot smoothly. Manufactured from a robust material like stainless steel, this pin or rod is designed to endure the weight and motion of the door or gate. When a user pushes or pulls on the door or gate, the pivot hinges attached permits the gate/door to swing open or shut. The pivot mechanism ensures controlled and smooth movement, preventing rapid swinging or awkward positioning of the door or gate.

Benefits

The following points substantiate the use of pivot hinges in various applications.

Smooth Operation: Pivot door hinges allow for smooth and effortless opening and closing movement of doors. They enable full range of motion, making them suitable for doors that require swing in both directions. Moreover, these hinges are made to provide excellent weight distribution, minimizing the chance of door sagging or misalignment.

Space-Saving Design: Pivot hinges serve as an ideal solution in situations where space is limited for door swing. Unlike conventional hinges that demand room for the door to open, pivot hinges enable doors to rotate at a fixed point, eliminating the need for extra space. As a result, they have become a preferred option for closets, small rooms, and areas with restricted entry.

Security and Safety: Pivot hinges provide an additional layer of security with their unique design. The pivot point, positioned either at the top or bottom of the door, poses a challenge for potential intruders who try to remove the door from its frame. Owing to this, pivot hinges are highly recommended for entry doors and other locations where security is a top priority.

Durability and Strength: Pivot hinges are wisely engineered to offer exceptional durability and reliability, even under heavy loads and frequent use. Made from the finest quality materials such as stainless steel or brass, these hinges guarantee unmatched endurance and long-lasting performance. Their strength makes them an ideal option for demanding situations, including supporting heavy doors, gates, and cabinets.

Steps to Install Pivot Hinges on Doors

With the right steps and tools, installing pivot hinges on doors can be a straightforward process. The following are the major steps involved in the process.

Get Necessary Tools: Ensure that you have all the necessary tools to start with the installation. A few of the must-have tools include; a drill, drill bits, screwdriver, measuring tape, pencil, and pivot hinge kit.

Measure: Use a measuring tape and determine the placement of pivot door hinges. Once the placement has been identified, you can go ahead making precise markings using a pencil to indicate where the hinges will be affixed.

Pre-drill the Holes: Pre-drill holes for the screws used to hold the pivot hinges in place. Take note of the screw size provided in your pivot hinge kit and select a drill bit that matches it. Now, align the drill bit with the pencil marks that indicate the desired placement of the hinges and proceed to carefully drill the necessary holes.

Install the Hinges: Once the holes are drilled, you can actually start installing the pivot hinges. Place the hinge leaf on the door, aligning it with the pre-drilled holes, and secure it in place using the screws provided. Repeat this step for all the hinges you plan to install.

Test the Movement: Testing the movement of the door is one of the most crucial steps. Open and close it to ensure that it swings smoothly and without any problems. In case of any obstruction detected, you can make necessary adjustments by loosening the screws slightly and reposition the hinges until the desired movement is achieved.

Secure the Door Frame: In some instances, your hinges demand additional support on the door frame side. During such situations, check if your kit includes additional hardware for this purpose. If you find additional hardware, follow the manufacturer's instructions to install it. Doing so will guarantee additional stability and longevity of the door installation.

Applications

Pivot hinges find immense applications as listed below.

Heavy-duty doors that demand extra support.

Architectural and design applications where aesthetics play an important role.

Bookcase doors, hidden doors, or doors that need to swing in both directions.

Glass doors, particularly for frameless glass doors.

Wide and oversized doors like entrance doors in commercial buildings or industrial settings.

Impressed with these types of hinges? Planning to invest on them for your next project? If

yes, then getting them from leading sources like EuroArt makes a great impact on overall quality and longevity. EuroArt, known for its expertise and industry-leading products, offers a wide range of pivot door hinges that are carefully crafted to meet the highest standards. Investing on these hinges will undoubtedly guarantee smooth operation, and enhanced functionality for your doors and gates for a long run.

0 notes

Video

youtube

The Korea Metal Week 2023 that FIXDEX & GOODFIX participated in came to ...

#youtube#korea metal week 2023#Korea Metal Week#대한민국 금속주간#Wedge Anchor#Wedge Anchor Bolts#Wedge Bolt#Stainless Steel Wedge Anchors#Trubolt#Through Bolt#Threaded Rods#Threaded Bar#Stainless Steel Threaded Rod#Galvanized Threaded Rod#Din975#Galvanized Threaded Bar#B7 Galvanized Threaded Rod#Chemical Anchors#Wood Screw#Self Drilling Screws#Self Tapping Screw#Drop In Anchor#Stainless Steel Drop In Anchors#Knurled Drop In Anchors#Hex Bolt#Hex Head Bolt#Galvanized Hex Bolts#Ss Hex Bolt#Din933#Din934

0 notes

Text

Supplier of Stainless Steel Fasteners in Uttar Pradesh

Company Overview:

Meghmani Metal is an ISO 9001:2015 certified Manufacturer and Supplier of Stainless Steel Fasteners in Uttar Pradesh, India.

They offer a diverse range of stainless steel products including steel flanges, steel butt welding, steel pipe fittings, steel rods, wires, coils, flats, and SS fasteners.

Specializing in Austenitic grade fasteners, they maintain a well-equipped inventory and provide customer-specific manufacturing facilities with standard technologies.

Stainless steel fasteners, made from an alloy containing iron, chromium, nickel, and other elements, are hardware devices used to mechanically join or affix objects together securely. Renowned for corrosion resistance, durability, and aesthetic appeal, they are essential components in various industries.

Types of SS Fasteners:

SS Bolts: Used with nuts to fasten materials together.

SS Screws: Ideal for fastening materials into pre-drilled holes.

SS Nuts: Paired with bolts to secure materials through threaded connections.

SS Washers: Distribute pressure and prevent damage beneath nuts or bolts.

SS Rivets: Permanent fasteners used to join materials together by deforming the rivet.

Applications of SS Fasteners:

Construction Industry

Automotive Sector

Manufacturing Sector

Marine Industry

Food and Beverage Industry

Pharmaceutical and Healthcare Sector

Aerospace and Aviation Industry

Electronics and Electrical Engineering

Supplier Coverage in Uttar Pradesh:

Meghmani Metal supplies Stainless Steel Fasteners across Uttar Pradesh, including cities like Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, and Varanasi.

For further information, feel free to contact us.

Read the full article

#Agra#Aligarh#Amroha#andVaranasi#Ayodhya#Azamgarh#Bahraich#Ballia#Banda#BaraBanki#Bareilly#Basti#Bijnor#Bithur#Budaun#Bulandshahr#Deoria#Etah#Etawah#Faizabad#Farrukhabad-cum-Fatehgarh#Fatehpur#FatehpurSikri#Ghaziabad#Ghazipur#Gonda#Gorakhpur#Hamirpur#Hardoi#Hathras

0 notes

Text

Buy Super Duplex S32760 Flanges | Bhagyalaxmi Industrial

In the area of metallurgy, in which precision, sturdiness, and reliability are paramount, the name "Super Duplex S32760" stands proudly as a testament to engineering brilliance. As industries continue to evolve, the demand for superior materials that could resist the most hard environments is on the rise. Enter Super Duplex S32760 flanges—the unsung heroes that ensure seamless connectivity and structural integrity in essential programs.

Understanding Super Duplex S32760 Flanges

The Manufacturing Marvel

Super Duplex S32760 flanges are made from a unique alloy that blends chromium, molybdenum, and nitrogen to create a material with high-quality corrosion resistance and mechanical energy. These flanges play a pivotal role in connecting pipes and facilitating the clean flow of fluids in industries ranging from oil and fuel to chemical processing.

Key Features of Super Duplex S32760 Flanges

Corrosion Resistance: The alloy composition of Super Duplex S32760 offers extraordinary resistance to corrosion, making it a perfect choice for harsh environments.

High Strength: These flanges boast superior mechanical energy, ensuring toughness and reliability in annoying programs.

Versatility: Super Duplex S32760 flanges locate programs in diverse industries, which include offshore oil rigs, chemical processing plants, and desalination facilities.

The Role of Bhagyalaxmi Industrial

Amidst the myriad of picks to be had in the market, Bhagyalaxmi Industrial emerges as an extraordinary participant as a Super Duplex S32760 Flanges Manufacturer, Super Duplex S32760 Flanges Supplier, Super Duplex S32760 Flanges Stockist, Super Duplex S32760 Flanges Exporter, Super Duplex S32760 Flanges Dealer. Specializing in an intensive variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial has carved a spot for itself as a reliable issuer of extremely good commercial additives.

Bhagyalaxmi Industrial Advantage

Diverse Product Range: Bhagyalaxmi Industrial offers a complete array of merchandise, together with pipes, tubes, pipe fittings, cast fittings, flanges, sheets, plates, coils, bars, rods, and fasteners, among others.

Material Expertise: The agency deals in diverse metals, such as stainless steel, duplex, and splendid duplex metallic alloy steel, carbon metallic, titanium, Inconel, Hastelloy, monel, nickel, cupro nickel, etc.

Quality Assurance: All products from Bhagyalaxmi Industrial are made from advanced high-quality uncooked substances, adhering to international requirements. Customization options ensure that clients obtain products tailored to their precise specs.

Competitive Pricing: Despite supplying top-notch first-class, Bhagyalaxmi Industrial keeps a commitment to affordable pricing, ensuring accessibility without compromising on excellence.

Super Duplex S32760 Flanges: Applications and Industries

The versatility of Super Duplex S32760 flanges extends throughout various industries, gambling a vital position in ensuring the efficient and dependable operation of critical strategies.

1. Offshore Oil and Gas

In the cruel conditions of offshore drilling rigs, Super Duplex S32760 flanges provide the durability and corrosion resistance required for seamless operations. These flanges contribute to the integrity of the pipeline community, ensuring the safe extraction and transportation of oil and gasoline.

2. Chemical Processing

Chemical processing flora calls for materials that can withstand corrosive chemicals and intense temperatures. Super Duplex S32760 flanges excel in such environments, ensuring the sturdiness and reliability of the difficult piping systems vital to chemical production approaches.

3. Desalination Facilities

As the worldwide call for freshwater increases, desalination facilities play a vital role in providing a sustainable answer. Super Duplex S32760 flanges, with their corrosion-resistant residences, contribute to the performance and longevity of desalination plants, wherein exposure to saltwater is a constant task.

Ensuring Quality and Satisfaction

The credibility of vendors is an important aspect of the industrial delivery chain, and Bhagyalaxmi Industrial places a robust emphasis on keeping the best standards. The continuous effort to stabilize and improve quality guarantees that clients acquire products that no longer best meet but exceed their expectations.

Customization for Client Satisfaction

Recognizing the various needs of customers, Bhagyalaxmi Industrial offers customization options for Super Duplex S32760 flanges. This guarantees that the products align with the unique necessities of each assignment, contributing to more desirable purchaser pride.

Conclusion: Connecting Excellence with Bhagyalaxmi Industrial

In the ever-evolving landscape of industrial additives, Super Duplex S32760 flanges have become a symbol of excellence. Bhagyalaxmi Industrial, with its commitment to quality, diversity, and customer delight, stands as a reliable accomplice for industries seeking top-notch merchandise.

As industries push the boundaries of what's viable, the selection of substances becomes increasingly vital. Super Duplex S32760 flanges from Bhagyalaxmi Industrial provide a robust answer, combining power, sturdiness, and corrosion resistance.

For those seeking to elevate their commercial approaches with the quality-in-magnificence Super Duplex S32760 flanges, Bhagyalaxmi Industrial is the name to trust. Contact them today and enjoy the difference that first-rate and commitment can make for your operations. Bhagyalaxmi Industrial – Connecting Excellence in Every Flange!

#Super Duplex S32760 Flanges Manufacturer#Super Duplex S32760 Flanges Supplier#Super Duplex S32760 Flanges Stockist#Super Duplex S32760 Flanges Exporter#Super Duplex S32760 Flanges Dealer

0 notes

Text

Round Bars Are Versatile And Strong

Shashwat Stainless is the top Round Bar Manufacturer in India. Round bars are cylindrical metal rods that have a wide range of uses throughout industries. Round bars, known for their flexibility and strength, are used extensively in structural support, equipment manufacture, and a variety of other applications. Round bars are meticulously manufactured to assure their quality and dependability.

The first stage in making a round bar is the careful selection of raw materials. Round bar Manufacturers choose high-quality steel or other metals based on the desired properties of the final product. After selecting the raw materials, they are heated to increase their malleability. Skilled specialists then use specialized tools to mold the hot metal into the appropriate round bar form. Precision machining ensures that round bars meet rigorous specifications. Advanced CNC machines are used to accurately cut, drill, and polish round bars, ensuring uniformity and consistency in outcomes.

Round bars are sturdy and flexible, making them valuable in many different fields. Because they guarantee the lifetime of many components and offer structural support, round bars are crucial to both building and aviation. Round bars Suppliers in India, with their remarkable qualities and many uses, remain a cornerstone of contemporary engineering and industry.

We are the best Round Bar Manufacturer in India, In Round Bar Varieties, We are leading Duplex Steel F53 Round Bars Manufacturers and Duplex Steel 2205 Round Bars Manufacturers.

For more details:

Website: shashwatstainless.com

Product Source: Round Bar Supplier in India

Other Product Source: Pipes and Tubes Manufacturers in India.

0 notes