#drill rod and tool steel

Text

Buy Drill Rods From India's Best Manufacturer | Techo Enterprise

If you are looking to buy drill rods, Techo Enterprise is the best choice. ✔️ Call 98304 25937 ✔️ Live Chat With Us ✔️ Call Us Today .

#Buy Drill Rods#drill rods#drill bit extension rod#drill rod for sale#drill rod and tool steel#rock drill rods#drilling rods and bits#stainless steel drill rod#oil hardening drill rod#best welding rod for drill stem#drill rod for sale near me#drill rod price#earth rod drilling#extension drill rod

1 note

·

View note

Text

The Ultimate Guide to Fire Starting: Techniques, Tools, and Tips for Success

Ignite your survival skills with our Ultimate Fire Starting Guide!🔥Master traditional to modern techniques & DIY ideas for safe outdoor adventures. Ready to fuel your wilderness knowledge? Link in bio! #FireStarting #Bushcraft🌲🔥

Introduction

Why is fire starting an essential skill, you ask? Well, let’s put it this way: whether you’re a wilderness survival enthusiast or simply someone who enjoys outdoor adventures, knowing how to start a fire is a top survival skill. The ability to create heat and light from the natural surroundings isn’t just a thrilling test of your wilderness survival skills; it’s a practical…

View On WordPress

#backpacking tips#best fire starting tools#bow drill#Bushcraft#campfire techniques#camping essentials#camping skills#DIY fire starters#ferrocerium rods#fire lighting methods#fire management#fire plow#fire safety#fire starting guide#fire starting techniques#fire triangle#flint and steel#friction fire#hand drill#how to start a fire#outdoor adventures#Outdoor Education#outdoor survival#primitive fire starting#survival gear#survival skills#Survivalist Skills#wilderness camping#Wilderness survival#wilderness survival tips

0 notes

Note

nah that makes you 10x hotter daddy, wanna see you use a power drill and then drill your cock into me.

I’ll make sure to wear my tool belt 😉

I once built a flower bed in my mother’s garden with my father. Spent the whole day prepping, drilling, and assembling concrete blocks then putting cement between them to secure it before driving steel rods into the middle to hold them together, exactly how she envisioned it.

I smelled like a fucking construction worker, it was not pleasant.

2 notes

·

View notes

Photo

Learn to Build a Fire, Without Matches or Lighter, for Cooking, Heat and Light:

Building a fire for staying warm, light, cooking and signaling is a skill everyone should know. Having the tools and knowledge will make fire-building easier and effective. Without electricity, a well-built fire will build morale and provide heat and light.

FIRE BUILDING:

Building a Fire

Building a Smokeless Fire

Self Feeding Fire - 14+ Hour Fire

The Upside Down Fire Building Technique allows the fire to burn longer before having to add more wood. [Video]

Build a Dakota Fire Hole (Pit) for High Wind or Reduce Detection (Stealth)

FIRE STARTING:

Fire Starting Materials You Probably Have At Home

Friction Fire by Rubbing Sticks Together

1 - Gather a fire bundle of dry grass or other material that will quickly catch fire.

2 - Gather different sizes of wood, from small twigs to larger logs, to make a wood pile where you want to build your fire.

3 - Find hard wood for your spindle and soft wood for your fire board.

4 - Find an arm-length stick of sturdy wood for your bow and strong cordage to wrap around the spindle.

5 - Find a piece of wood to be your handhold – this will protect your skin from the heat the spindle generates.

6 - Use a knife or rock to carve out a hole for the spindle to sit in on the fire board.

7 - Sit on one knee, and prop your wrist against your shin for maximum stability.

8 - Pull your bow back and forth to allow the spindle to further carve out a hole in the fire board.

9 - Carve a notch in the fire board to allow oxygen to mix with the wood dust created by the spindle.

10 - Once again begin pulling your bow back and forth until a significant amount of smoke emerges from the fire board.

11 - Move your embers from under the fire board to fine plant material.

12 - Blow on the bundle to increase oxygen flow to the embers. Continue until the bundle produces flames.

13 - Transfer your fire bundle to your fire wood pile, adding small twigs to larger wood as the fire progresses.

Make a Fire By Rubbing Sticks Together

Make a friction fire using the Bow Drill method

Make a friction fire using the Pump Drill method

How to make a friction fire using the Hand Drill method

Using a Fire Plow: [Article] [Video]

Ferro, Flint and Magnesium: Ferrocerium (Ferro) is a synthetic pyrophoric alloy that produces hot sparks that can reach temperatures of 3,000 °C when rapidly oxidized by the process of striking the rod, thereby fragmenting it and exposing those fragments to the oxygen in the air which causes the sparks. When scraped with a metal "striker", a Flint and Ferro create sparks and can start fires when the sparks enter a tinder pile. It requires some practice to produce a spark but, once learned, they are reliable fire starters in nearly any weather condition. Magnesium is a volatile metal that ignites quickly with any spark and burns white hot (2200 °C, 4000 °F) to catch nearly anything on fire. In and of itself, it cannot burn without an ignitor (flint or ferro).

The Difference Between Flint & Steel, Ferrocerium Rod And Magnesium Bar Fire Starter

Using a Ferro Rod Fire-starter (video)

Using a Magnesium/Flint Fire-starter (video) Magnesium can burn nearly anything (article)

Battery

Starting a fire with a battery and [foil] gum wrapper

Step 1: Place foil or steel wool on a flat surface. Surround the metal with two pieces of firewood.

Step 2: Place a densely-packed bundle of kindling on top of the metal.

Step 3: Wedge a cotton ball underneath the kindling. (Pro tip: Soaking the cotton ball in petroleum jelly will make it burn much longer.)

Step 4: Contact both ends of the battery (or protruding end of a 9V battery) against the metal until the metal begins to spark and catch the cotton ball on fire.

Chemical Fire Starting:

Potassium Permanganate and Glycerin

Potassium Chloride, Sugar and Sulfuric Acid

Acetone, and Sulfuric Acid and Potassium Permanganate

Amonium Nitrate, Sodium Chloride (table salt), Zinc Powder and Water

Other Options:

How to Start a Fire with a Magnifying Glass

[Fire From Ice] [Fire From Water]

How to Start a Fire with a Soda Can (reflector)

Wet Weather Fire-Making

How to Start a Fire with Char Cloth

Other Fire-starting methods

Multiple Fire-making Methods and Information

[Reference Link]

Other Resources:

Heating and Cooking With a Wood Stove

Transport Fire From One Location to Another

Start a Fire by Rubbing Sticks Together; Yeah, it Works!

Proper Use of Ferro, Flint and Magnesium to Start a Fire

The Upside-Down Fire Building Method

Start a Fire with a Foil Gum Wrapper and Battery

Start a Fire With Clear Ice

Heat a Room With a Clay Pot

Keep the Heat in Check During a Power Outage

Build a Dakota Fire Pit for Stealth or High Wind

DIY Rocket Stove

[11-Cs Basic Emergency Kit]

[14-Point Emergency Preps Checklist]

[Immediate Steps to Take When Disaster Strikes]

[Learn to be More Self-Sufficient]

[The Ultimate Preparation]

[P4T Main Menu]

This blog is partially funded by Affiliate Program Links and Private Donations. Thank you for your support.

#fireBuilding#campfireBuilding#diy#shtf#prepping#prepper#survival#fireWood#prepare4tomorrow#fire building#campfire building#survivalist#survivalism#camping#hiking

7 notes

·

View notes

Text

Symphonie II

Having tried to make a Symphonie (box hurdy gurdy), which was not a total failure, I have decided to make another, somewhat larger, so that the wheel will be larger, it will have two melody strings so the volume will be louder and the drone strings will be above the sound board so they can be adjusted without having to take a side off.

I normally do a couple of days a week as a volunteer at an educational charity but this last term I have been doing three days and that extra day out of the studio has really slowed me up. So to the above: -

Photo 1 The most important tool in any studio is the coffee cup.

Photo 2 Putting the body together.

Photo 3 Wheel and part of the crank

My first one was somewhat ad hoc and for this "fair copy" I am trying not to have extraneous holes and bits of wood so I have made drawings and measured stuff.

Speaking of measuring, I have CorelDraw, Inkscape and various other drawing and CAD software on my laptop and none of them print out at the size I declare the objects to be. Why is that?

When I was a child my father changed jobs and brought all his tools home from work and the thing that fascinated me was a Die for cutting thread to make bolts or studs, just the thing that little fingers shouldn't be poking into.

I wanted not to use wholly threaded bar for the crank, since it tends to wind itself into the bushing as you turn the handle. This being so I acquired a tap and die set and some bits of 6mm steel rod and decided to have a go. Several YouTube clips later I took some scrap rod and cut a perfect threaded section on the end of it.

Beginners luck, unfortunately the scrap piece of rod I chose wasn't round and when spinning the wheel gave it serious wow and flutter. Found some round rod and then made all the mistakes that the YT vids had warned about, hubris! Three or four attempts later and its not too bad.

Still to do: -

Several dozen keys to cut

Drill tangent holes in each key

Fit two tangents to each key

Make the remains of the crank and its supports

Assembly, wheel trueing and stringing

Decorate the lid

And at the end of all this it will still sound rough!

2 notes

·

View notes

Text

Figuring out Round Bars' Superiority: An All-Inclusive Guide

Introduction:

Nova Steel Corporation is leading Round Bar Manufacturer in India. Round bars, the unsung heroes of the industrial world, have a significant impact on modern infrastructure and innovation. Despite their simple appearance, round bars are essential components in a variety of industries, including construction, manufacturing, automotive, and aerospace. In this comprehensive tutorial, we will look at the fundamentals of round bars, including their applications, properties, and why they are such important components in engineering and design.

Understanding Round Bars:

Round bars, often called rods or solid bars, are cylindrical metal bars with a circular cross section. They are fabricated from different materials, including steel, stainless steel round bar, High Nickel Alloy Round Bars, XM19/Nitronic Round Bar, LF2 Round Bar, and Alloy Steel 4340 Round Bar, each offering unique properties suited for specific applications. Round bars are manufactured through processes such as hot rolling, cold drawing, or machining, ensuring precise dimensions and consistent quality.

Applications Across Industries:

The versatility of round bars renders them indispensable across a myriad of industries:

1. Construction: Round bars are fundamental components of construction projects; they are used to fabricate building and bridge frameworks, create support beams, and reinforce concrete structures.

2. Manufacturing: Round bars are used in the manufacturing industry to make shafts, axles, fasteners, and precision components for machinery, equipment, and tools.

3. Automotive and Aerospace: Because of their strength, endurance, and resistance to corrosion, round bars are widely used in the automotive and aerospace industries for the fabrication of engine parts, chassis components, landing gear, and structural elements.

4. Energy Sector: Round bars are used in the energy industry to manufacture pipelines, drill rods, and components for power production and transmission equipment.

Key Characteristics:

Several key characteristics make round bars indispensable in engineering and construction:

1. Strength and Durability: Round bars provide structural integrity and endurance because of their great tensile strength and resilience, which allows them to handle large loads and harsh environments.

2. Machinability: Round bars are easily machined and built into unique components, allowing for precision shape and dimensional accuracy to fulfill design specifications.

3. Corrosion Resistance: Because of their superior corrosion resistance, materials such as aluminum and stainless steel are a good choice for outdoor and marine applications where exposure to severe conditions and moisture is common.

4. Thermal Conductivity: Round bars conduct heat well, making them ideal for applications that require heat transmission or dissipation, such as heat exchangers and thermal management systems.

Best Round Bar Manufacturer

Nova Steel Corporation is leading Round Bar Supplier in India. We have substantial expertise in the manufacturing and supplying of all sorts of Round Bars. We are Best Round Bar Manufacturers. Personnel with the necessary qualifications and a wealth of experience handling different kinds of Pipe Fittings and other products supervise the whole manufacturing process.

Finally, round bars represent the pinnacle of versatility, strength, and dependability in the field of engineering and building. From towering skyscrapers to precise machinery, round bars are the foundation of modern infrastructure and innovations, representing human ingenuity and perfection. As technology advances and businesses evolve, the importance of round bars will grow, influencing the landscapes of tomorrow and beyond.

0 notes

Text

Processing of Molybdenum metal

Molybdenum is a refractory metal with the symbol Mo and atomic number 42. It is most commonly used as a high temperature, corrosion resistant metal alloy in steel, cast iron and super alloys for the military and defense industry, semiconductor industry and specialty machine shops.

Molybdenum metal products are available in plate, sheet, strip & foil, bar, rod, tube, wire and customized parts. The metal is silvery white, very hard transition metal, but is softer and more ductile than tungsten. It is easier to be rolled in to thinner sheets and have a wider dimension limits than tungsten. It is also easier to machine molybdenum into complex parts than tungsten, that means molybdenum can be made into more precise & smaller parts. Even though, the machining process is similar.

Here we will introduce the machining process for molybdenum rod and bar roughly.

After sintering, the molybdenum blank will be forged, to make it with higher density and better mechanical properties.

Process for molybdenum rod from blank: Spin forging and drawing several times a suitable ingot, repeated annealing is necessary during the several times of drawing. Mold is engaged in the process in order to draw to desired diameter. Remove the oxide surface, graphite is used as lubricant, this step will also remove it from the surface of rod. Regular surface treatment is grinding or finish turning.

Process for molybdenum rectangular bar or square bar: 1. Forging, annealing and mold are engaged in this process. 2.Remove the oxide and grinding the surface. The narrow faces can only be turning instead of grinding. The other way to produce molybdenum bar is cut form plate, next article we will talk about process for rolling molybdenum products. The method depends on the specific dimensions of the bar. If it is thin and narrow, it will be from molybdenum plate.

Process of molybdenum tube: Small tubes (roughly with diameter <100mm) are drilled from rods, larger tubes is made by sintering directly. Will need to make mold first if the tubes are large, you can choose a more economical way to make a molybdenum tube with a critical outer diameter. Drilling from rods will waster some materials, while sintering needs a tool. We now have the capacity of providing moly tubing with length up to 2.7m.

If the complex parts are made from bar, and rod and other machining processes such as: laser cut, water jet cut, drilling, turning, wire cutting, etc. will be chosen according to drawing and process technology.

As you can see, the processes are similar with tungsten machining, but requires different tools, feed speed, and annealing process. The accuracy of the work-pieces presented is also different.

Pure molybdenum has better ductility than tungsten, while tungsten alloys (WNiFe, WNiCu) have better machining performance than molybdenum alloys (Mo-La alloy, TZM Alloy, especially TZM alloy). We will introduce this in future articles.

0 notes

Text

It is never good news when your doctor goes "I have been doing this for 30 years and I have never seen done like this before"

Back story is had a root canal when I was 10. Now 25 years, a small absence is starting to grow under it as they did it wrong. So current dentist is removing the root canal.

Here is the remaining bits I could get

But as he as literally shoving and twisting one tool in my mouth in between drilling and grinding with another, I am watching his arms tremble as he is applying extreme pressure and torque to break the tooth, he mentions how freaky the root canal is

Not surprising, the bone and tooth and metal all fused together over the years so that made it extra hard. But his plan was immediately filed when the cap was found to be installed somehow in one piece with the metal rods that are in the tooth and roots. The metal rods themselves were weird as well as there were smooth stainless steel when normally they should be textured at least and often a different metal.

It took about an hour and half to remove the stupid root canal. And now I am just sipping chocolate milkshakes as the numbing agent slowly wears off.

0 notes

Text

H13 and P20 Laser Welding Wires: A Comparative Analysis

Laser welding, a precise and efficient joining process, has gained significant traction in various industries. The choice of a laser welding wire plays a critical role in the quality and durability of the weld. Two commonly used wire types for laser welding are H13 and P20. This article explores the unique characteristics and applications of these two materials available from the Shop Castron Electrode.

H13 Laser Welding Wire

H13 is a hot work tool steel renowned for its exceptional wear resistance, high-temperature strength, and toughness. These properties make it an ideal choice for applications involving severe conditions, such as:

Mold and Die Manufacturing: H13's resistance to abrasion and deformation ensures long service life in molds and dies used for plastic injection molding, die casting, and forging.

Cutting Tools: Its hardness and toughness make it suitable for cutting tools like drills, taps, and milling cutters, enabling efficient and precise machining.

Automotive Components: H13 laser welding wire is used in the production of critical automotive components like engine valves, camshafts, and connecting rods, where durability and reliability are paramount.

Key Characteristics of H13 Laser Welding Wire:

High Hardness: H13 types of laser welding wires offer excellent hardness, providing superior wear resistance and resistance to scratching and gouging.

Good Toughness: Despite its hardness, H13 maintains a good level of toughness, reducing the risk of brittle fracture.

Excellent Heat Resistance: The alloying elements in H13 provide exceptional resistance to softening and deformation at elevated temperatures.

Good Weldability: H13 is generally weldable using laser welding techniques, ensuring strong and reliable joints.

P20 Laser Welding Wire

P20 is another popular choice for laser welding at Shop Castron Electrode. It offers a balance of strength, toughness, and machinability. It is commonly used in applications requiring high-strength, wear-resistant, and easily machinable parts. Some typical applications include:

Gears and Shafts: P20's combination of strength and toughness makes it suitable for gears and shafts subjected to high loads and cyclic stresses.

Automotive Components: It is used in the production of various automotive components, such as crankshafts, connecting rods, and steering components.

General Engineering Components: P20 laser welding wire is a versatile material used in a wide range of engineering applications, including machine parts, tools, and fixtures.

Key Characteristics of P20 Laser Welding Wire:

Good Strength and Toughness: P20 offers a balance of strength and toughness, making it suitable for applications requiring both high strength and resistance to impact.

Excellent Machinability: The alloying elements in P20 provide excellent machinability, allowing for easy and efficient machining operations.

Good Weldability: P20 is generally weldable using laser welding techniques, ensuring strong and reliable joints.

Choosing Between H13 and P20

The choice between H13 and P20 laser welding wires depends on the specific requirements of the application. H13 is ideal for applications demanding exceptional wear resistance, high-temperature strength, and toughness. P20 is a versatile option suitable for a wide range of applications requiring good strength, toughness, and machinability.By carefully considering the properties and characteristics of H13 and P20 from the Shop Castron Electrode, engineers and manufacturers can select the most appropriate wire for their laser welding needs, ensuring the production of high-quality and durable components. To get more information on H13 and P20 laser welds, visit the website of https://shop.castonelectrode.in/2024/08/24/benefits-of-laser-welding-wires-for-enhanced-product-quality-efficiency-and-cost-effectiveness/

0 notes

Text

So you can use a drill system to drill these rods into the ground, and then you start vibrating the ground. To condense the soil to remove the water to put a stronger foundation under a structure. This is what I said they could do in mexico to get the air out to get the water out to start condensing the ground, so it supports the foundation of the city.... This is why the one hotel in vegas was sinking, and my solution was exactly correct. So when they get the air out which the vibration does, it causes the air to rise up the soil collapses upon itself, and it causes the water to rise up the soil collapses upon itself, creating a denser foundational support...

How does vibration affect the strength of concrete?

Vibration of fresh concrete reduces its internal shear strength, and enables concrete to momentarily liquefy to facilitate the consolidation process.

https://docs.lib.purdue.edu › cgi › v...

Characterization of Vibration Effects on the Internal Structure and ...

Now, yes, the soil is going to collapse downward. And this is what's happening with the aquifers. In mexico the soil is losing moisture and moving downward...

So they need to rehydrate, or this city will continue to collapse... Cut my solution above with foundations. They can do this, so they have to use less steel to support the foundation... So if they had done this before they built in Mexico, they wouldn't have had these issues... Now they have to stop pumping underground water and Start rehydrating so the soil expands again.... But also, it means it can only handle a certain weight related to its structure.

As a growing population depleted natural springs, the city began to dig wells and pump groundwater to meet water demands. The soil began to contract and compress the land, like a kitchen sponge drying up. The sinking worsened over time, researchers have shown over the years.Jun 4, 2024

https://www.washingtonpost.com

Why Mexico City's water crisis is causing it to sink

AI Overview

+7

Mexico City's water crisis is rooted in its reliance on underground water, which is being drained at an unsustainable rate. The city's water supply comes from aquifers and geological formations that store groundwater, and around 60% of the city's water comes from this source. However, the aquifer is not being replenished quickly enough, and some parts of the city are sinking by up to 20 inches per year. This sinking is caused by the compaction of the ground, which can lead to fractures in buildings, sewers, and gas and water lines. The sinking also opens the ground up to contaminated surface water.

Other factors contributing to Mexico City's water crisis include:

Water infrastructure

The city's water infrastructure is unable to keep up with demand, and the city loses about 40% of its water to leaks in broken pipes.

Rainwater

Rainwater rolls off the city's hard surfaces instead of sinking into the ground.

Climate change

Mexico is facing a long drought and heat wave, which have been made worse by climate change.

You can actually mix in helium into concrete to reduce the weight of concrete....

MAN about TOOLS

November 4, 2019 · https://manabouttools.com

the Best Aircrete Recipe – a Lightweight Portland Concrete ...

This is the best aircrete formulation for my garden box panels yet. This aircrete recipe is easy to make and yields a strong lightweight

ResearchGate

https://www.researchgate.net

Characterization of the absolute volume change of cement pastes ...

Based on detection technology of helium pycnometry, this study developed a novel approach for characterizing the absolute volume change of cement pastes in ...

Innovation News Network

https://www.innovationnewsnetwork.com

The importance of helium uses in everyday life

The use of helium for welding and cutting applications affords many advantages over traditional methods using air or oxygen

ScienceDirect.com

https://www.sciencedirect.com

Effect of applied stress on the helium inflow characteristics ...

by RF Feldman · 1983 · Cited by 11 — Steel bar reinforcement benefits the strength and ductility enhancement of cement-based materials. The

Worldbuilding Stack Exchange

November 10, 2015 · https://worldbuilding.stackexchange.com

Vertical City - Using Helium to Reduce Weight?

In a novel I am considering, the near-future of Earth is populated with vertical cities. I don't mean one tower; I mean a city of towers, built close together, ...

It wouldn't be effective. The building would be lighter than a building with the same tubes ... More

Top answer · 11 votes

0 notes

Text

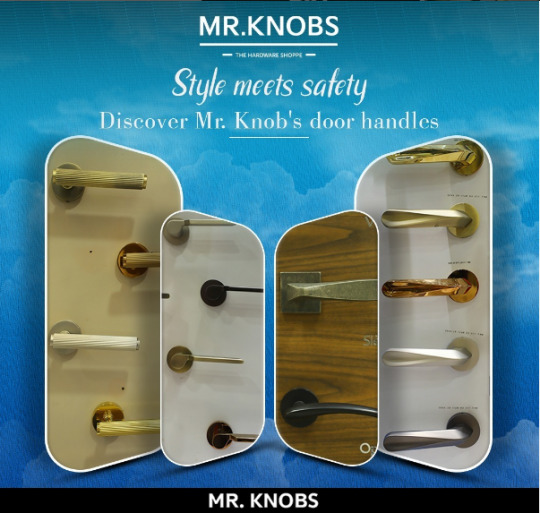

Essential Tools and Supplies at Mr. Knobs: The Leading Hardware Store in Mysore

Visit our shop today

Contact Us Today!!!

When it comes to finding the best hardware store in Mysore, Mr. Knobs stands out as the top destination for both professional contractors and DIY enthusiasts. Whether you're undertaking a large-scale renovation or a small home improvement project, our comprehensive selection of high-quality tools and supplies ensures that you'll find everything you need under one roof.

Your One-Stop Shop for Hardware Supplies in Mysore

At Mr. Knobs, we pride ourselves on being the premier hardware shop in Mysore. From construction materials to plumbing supplies, our extensive inventory covers every aspect of your project needs. We stock a wide variety of hand tools, power tools, paint supplies, and building materials, making us the go-to hardware shop near you. Our competitive prices and unparalleled customer service make every visit to our store a rewarding experience.

Comprehensive Range of Hand Tools

Whether you're a professional carpenter, an electrician, or a DIY enthusiast, the quality of your hand tools can make or break your project. At Mr. Knobs, we offer a wide range of hand tools from top brands, ensuring durability and reliability. Our selection includes hammers, screwdrivers, wrenches, pliers, and measuring tools that cater to every specific need.

Each of these tools is made from high-grade materials to withstand the rigors of daily use. Additionally, our expert staff is always on hand to help you choose the right tools for your job, ensuring you complete your projects with precision.

Power Tools for Every Project

When it comes to power tools, Mr. Knobs offers the best in class. Our collection features everything from drills and grinders to saws and routers. We stock power tools from renowned brands known for their innovation and longevity. Whether you're working on woodworking, metalworking, or general construction tasks, our power tools ensure that you get the job done efficiently.

Our knowledgeable staff is here to guide you in selecting the right power tools, providing expert advice to match your specific project requirements. With our commitment to quality, you can be confident that our tools will enhance your productivity and deliver professional results.

Extensive Plumbing and Electrical Supplies

No project is complete without the right plumbing and electrical supplies. At Mr. Knobs, we offer an extensive range of plumbing fixtures, pipes, fittings, and wiring that meet both residential and commercial needs. Our plumbing supplies are sourced from top manufacturers, ensuring they meet industry standards for quality and reliability.

Our electrical department is equally impressive, offering everything from circuit breakers, switches, and cables to lighting fixtures and electrical tools. We cater to both professional electricians and homeowners looking to upgrade their wiring or install new electrical systems.

Paint and Finishing Supplies

A fresh coat of paint can completely transform any space, and at Mr. Knobs, we carry a full range of paint supplies to help you achieve the perfect finish. From interior and exterior paints to primers, sealants, and varnishes, we offer products in various finishes and colors to match your design vision.

We also provide all the necessary accessories, including brushes, rollers, drop cloths, and painter's tape, making sure you have everything you need to complete your painting project. Our paint experts are available to offer tips on color selection, paint types, and application techniques to ensure professional-grade results.

Building Materials for Every Construction Need

For those involved in larger construction projects, Mr. Knobs offers a wide selection of building materials to meet all your requirements. From cement, bricks, and sand to steel rods, tiles, and wood, we are your reliable partner for high-quality construction materials.

Our materials are sourced from the most reputable suppliers, ensuring that they meet the highest standards for strength and durability. Whether you're building a new home, remodeling an existing structure, or working on a commercial project, our building materials will ensure that your foundation is solid.

Gardening and Outdoor Tools

In addition to our comprehensive indoor hardware supplies, Mr. Knobs is also your destination for gardening and outdoor tools. From shovels, rakes, and hoses to lawnmowers, trimmers, and pruners, we provide everything you need to maintain your garden or outdoor space.

Our range of gardening tools is designed to make outdoor maintenance easier and more efficient. With top-quality products from leading brands, you'll find the perfect tools to keep your garden in pristine condition year-round.

Safety Equipment and Accessories

At Mr. Knobs, we understand the importance of safety on every job site. That’s why we offer a wide range of safety equipment, including helmets, gloves, goggles, and protective clothing. Our safety gear is designed to keep you protected while working on any project, ensuring that you can focus on the task at hand with peace of mind.

We also stock a variety of tool accessories, such as drill bits, blades, and fasteners, so you can complete your projects efficiently and effectively.

Why Mr. Knobs is the Best Hardware Store in Mysore

VISIT US TODAY

Unparalleled Customer Service

At Mr. Knobs, customer satisfaction is our top priority. Our knowledgeable and friendly staff are always ready to assist you with any questions you have, ensuring you find the right tools and supplies for your needs. Whether you’re a first-time DIYer or a seasoned professional, our team provides personalized service to make your shopping experience seamless.

Competitive Pricing

We understand the importance of staying within budget for any project. That’s why we offer competitive pricing on all our products without compromising on quality. Our regular promotions and discounts make it even easier to get the best value for your money.

Convenient Location and Accessibility

Located in the heart of Mysore, Mr. Knobs is easily accessible from anywhere in the city. Whether you're searching for a hardware store in mysore or need to pick up supplies on your way to a job site, our store is conveniently located and stocked with everything you need.

Commitment to Quality

Every product we stock at Mr. Knobs is carefully selected for its quality and reliability. We only partner with the most reputable manufacturers to ensure that our customers receive products that stand the test of time. This commitment to quality has made us the trusted choice for hardware supplies in Mysore.

Visit Mr. Knobs Today

For all your hardware needs in Mysore, visit Mr. Knobs, the leading hardware store in the city. Whether you're undertaking a major construction project or simply need to fix a leaky faucet, we have the tools, materials, and expertise to help you get the job done right. Visit us today to experience the best hardware shopping experience in Mysore.

0 notes

Text

Thread Repair Made Easy: Why Brazing Rods are a Superior Alternative to Helicoil

Stripped threads can be a frustrating setback, whether you're working on a car repair, an industrial machine, or any other project requiring precision. Traditionally, Helicoil inserts have been a popular solution for thread repair. However, there’s a smarter, more efficient alternative: the brazing rod. Specifically, the HTS-2000 second-generation brazing rod offers a high-tech solution for thread repair that surpasses the conventional Helicoil method. Here’s why using a brazing rod for thread repair could be your best choice.

Why Choose Brazing Rods for Thread Repair?

When you encounter stripped or damaged threads, the usual approach might involve inserting a Helicoil. While effective, this method requires several steps, including drilling, tapping, and inserting the coil. In contrast, using a Brazing rod for thread repair simplifies the process significantly.

Simplicity of Use:

There is no need for numerous tools when using the brazing rod approach. Instead of dealing with taps, inserts, and gage tools, you only need an oversized drill and a heat source. The process involves filling the hole with brazing rod material, heating a steel bolt, and inserting it into the filled hole.

Strength and Durability:

HTS-2000 brazing rods are three times stronger and more flexible than earlier generation rods. The repair made with this brazing rod is stronger than the original material, providing a durable and long-lasting solution. This high-strength performance is ideal for a variety of applications, from automotive repairs to aerospace and industrial uses.

Erosion Resistance:

Unlike many other thread repair solutions, brazing rods like HTS-2000 are highly resistant to erosion. This makes them an excellent choice for high-wear environments where other repair methods might fail over time.

No Special Equipment Required:

With brazing rods, you don’t need specialized equipment like welding machines. A simple butane, propane, MAPP, or oxy-acetylene torch is sufficient to get the job done. Repairing the brazing rod is made easier because it melts at a lower temperature than aluminum.

Quick and Efficient:

The brazing rod method is fast. After applying the brazing rod material and inserting the heated bolt, the metal typically needs only 15-30 minutes to cool. Once cooled, removing the bolt leaves you with newly formed threads, ready for use.

How to Use Brazing Rods for Thread Repair

Using a brazing rod for thread repair involves a straightforward process:

Drill the Hole: To make room for the brazing rod, start by drilling out the damaged threads.

Fill with Brazing Rod: After filling the drilled hole, warm the brazing rod using a torch. This material will create a new thread base.

Insert the Heated Bolt: Heat a steel bolt to approximately 750 degrees Fahrenheit and insert it into the brazing material.

Cool and Remove: Give the metal 15 to 30 minutes to cool. Then, use a wrench to back out the bolt, revealing a newly threaded hole. This method is not only efficient but also produces stronger and more reliable results compared to traditional methods like Helicoil.

When it comes to thread repair, using a brazing rod offers a modern, effective alternative to Helicoil inserts. The simplicity, strength, and efficiency of brazing rods make them an attractive choice for anyone needing quick and durable thread repair. Whether you’re handling a complex industrial project or a routine automotive fix, Brazing rod for thread repair provide a robust solution that can get you back on track faster and more effectively.

0 notes

Video

youtube

How to build bamboo pig, Preparing to Welcome New Pigs

Absolutely! Here is a detailed guide on how to build a bamboo pig shed and prepare to welcome new pigs. ### **Bamboo Pigsty Construction Guide** #### **Prepare Materials and Tools** 1. **Ingredients:** - Bamboo (choose old, sturdy bamboo to ensure durability) - Wood (for frame and foundation, if necessary) - Nails, steel wires, or other connecting accessories - Tarpaulin or waterproof material (optional, to protect the barn from rain and wind) 2. **Tools:** - Saw for cutting bamboo - Hammer or drill to install accessories - Knives for cutting small details - Ropes or steel wires #### **Steps to build a barn** 1. **Planning:** - Determine the size of the barn based on the number of pigs and available space. - Draw detailed blueprints to visualize the structure clearly. 2. **Bamboo Selection and Preparation:** - Choose long bamboo, not rotting or warping. - Cut the bamboo into long segments that match the design. 3. **Make the cage frame:** - Use wood or bamboo to create the main frame of the barn. Install the bamboo slats according to the design, ensuring the frame is sturdy. - Attach the bamboo rods to the frame with steel wire or nails. Make sure the connection points are securely secured. 4. **Roof and Wall Making:** - Erect bamboo slats along the edges of the frame to create walls. Make sure the distance between the bamboo sticks is reasonable to keep the pigs from getting out. - Install a bamboo roof or waterproof tarpaulin to protect the barn from bad weather. 5. **Finish:** - Check all connection points to make sure there are no holes. - Clean up the construction area and remove any remaining debris. ### **Preparing to welcome a new pig** 1. **Check the barn:** - Make sure the pigsty is ready and safe before bringing the pigs in. Check the durability of the structures and make sure there are no sharp or dangerous objects in the barn. 2. **Prepare a place to eat:** - Place the bowls of food and drink water in the barn. Make sure these bowls are clean enough and accessible for pigs. 3. **Setting up the living environment:** - Make sure there is enough room for the pig to move freely. Put extra material such as straw or hay so that the pig can lie down and stay warm. 4. **Health Check:** - Make sure that new pigs are checked for health before being put in the shed. Get tested and vaccinated if necessary to protect their health. 5. **Food and Water Supply:** - Make sure that pigs have enough nutritious food and clean water to drink. Monitor your pigs' diet to make sure they grow well. 6. **Observation and Adjustment:** - Monitor the pigs in the early days to make sure they are getting used to the new environment. Adjust the conditions as needed to ensure the pigs feel comfortable and safe. Hopefully, this guide will help you build a bamboo pigsty efficiently and best prepare for welcoming new pigs!

0 notes

Text

How To Harness An Asteroid

By

Hill Bowman

Multiple Environment Biologic Exo-Shell.

How to harness an asteroid.

let say a kilometer long by half a kilometer wide.

…

Primary propulsion will be solar sail, secondary propulsion will be particle accelerator, emergency propulsion will be chemical rocket.

Obviously, the parts and equipment for the solar sail as well as primary components for particle accelerator plus heavy equipment guide rails, Arc furnace, oxy- acetylene, hydrogen oxygen welding tank (just to make life easy) must be brought with you.

Also guide rails, epoxy, adhesive, ressens, plastic rivets Carbon fiber tubing, all kinds of fasteners, must be brought with you.

The materials for the conventional rocket will be harvested from the core of the asteroid via traditional mining processes.

Your most critical tools for this project will be arc furnace, heavy drilling equipment, welding torch’s, explosives, front loader, back hoe, reinforced Crain slings ( to bag and move rubble).

Human necessities;

For crew of 12

1 year – food , water rations, inflatable warehouse shelter, full ship board surgical and general hospital set up.

2,000 wats of solar panels, 4 deep cycle marine batteries and of course all necessary peripheral like cables hook up, attachments etcetera.

The space vessel must attain synchronous trajectory with the surface of the asteroid. land and or tether to the asteroid.

…

Once accomplished crew must unload, anchor down guide rail’s and safety cables.

Use explosives front loader reinforced crane slings and back hoe to level a building pad.

Bag And remove rubble and deploy inflatable warehouse for crew and equipment.

For a multitude of reasons this must all be done within 12 standard earth hours after arrival and synchronization with the asteroid. Human safety in the project being priority One.

First.

solar equipment, arc furnace, smelting equipment, earth moving equipment, mining tools and explosives, crew must be deployed to level a building pad from which to begin heavy construction.

Once a building pad is leveled inflatable habitats are anchored down and deployed for equipment storage and temporary crew quarters.

Next:. Bolt down parallel tracks to circumnavigate width of asteroid. This will be the foundation for gravity ring .

Next:

lay down two parallel tracks that circumnavigate the length of the asteroid Along with guide cables along all tracks safety harness connect lines for crew and equipment.

The parallel track work is to provide work area along the length and width of the asteroid giving access for crew and equipment to core out the center of the asteroid down it’s length.

Next:

Coor the center of the asteroid down the length by approximately 20 meters in diameter. Something like coring an apple.

Next: Utilize all resources derived from the coring process through the center of the asteroid to produce steel rods and gutters and 1/16th sheet metal as well as fasteners.

Note.

In organic materials can be harvested from the asteroid, however organic materials such as adhesive polymers, carbon fiber, nylon rivets, and assorted fasteners as well as carbon fiber structural components must be carried with you to make the structure error tight. The mineral substances used in the process can be collected from the asteroid itself.

The Guide rails And safety cables your crew laid down in the beginning for the heavy equipment will also become the footing and tension cable’s for the tower assembly that will support a gravity ring. Ultimately, the gravity ring will be the habitat for crew, research, navigation and propulsion.

Ideally the propulsion system is hybrid.

There are multiple methods of propelling the vessel.

once it is fully assembled primary thrust being generated by solar sails. Secondary propulsion generated by particle acceleration. Finally with third backup propulsion being chemical thrust such as hydrogen - oxygen rocket thrust.

Note:

As I'm sure you're aware; hydrogen and oxygen are in abundance throughout know space (as well as nitrogen) from ice and raw mining slag from the boring process. Collected ice can be melted down into water and further divided in the hydrogen and oxygen HHO.

Raw mineral slag once harvested from the core of the asteroid can be crushed and melted down for steel, iron, copper, nickel, zink etcetera.

The metallurgic processes necessary for the project will be accomplished through use of solar power supply providing electrolysis, Electric Ark furnace or chemical processes.

NOTE:

In the long term, raw material for construction of solar panels and batteries can also be harvested and constructed with raw materials as well.

Future science:

A new genre of literature.

…

What is the difference between future science and science fiction?

…

Future science differs from science fiction in that there is very little fiction involved in it.

The objective of future science literature is to take current technology extrapolating with fifty year projections on current technology advancement.

integrated with quality creative writing.

mixed with the true human element of psychological physical in material capabilities under adverse circumstances.

The end product; digestible, Bold written material to encourage, motivate and propel the human species out into the expansion of space.

To colonize to Explorer to discover and to challenge the human species to our inevitable destiny. To grow as a species, to support sustain and clean up the only planet in the universe that we know harboring intelligent life.

And perhaps even to discover intelligent life Beyond our own species.

…

future science writers in history such is Jules Verne and others technological visionary)Are the True founders of this generation of literature that I humbly pursue. it is (in my opinion a disservice to Jules Verne or writers like him that they be qualified under the same categories as folks that right for fiction / fantasy.

Riters such as Jules Verne, Robert Hinlone, Isaac Asimov and others deserve some credit for the hard research in science and technology this type of writing requires.

~ Future Science~

Has as an accepted and standardized new genre of writing (in my opinion) is the least that we can offer in recognition of their contributions to our advancement as a species and a civilization.

Hopefully the Library of Congress will take notice of this idea.

…

I welcome you to the amazing new future that we have already entered.

…

So until then this is Hill Bowman signing off I will catch you on the next fly by

…

Sincerely ~

Hill Bowman

.

1 note

·

View note

Text

Expert Tips for Garage Door Opener Replacement in Scottsdale

Replacing a garage door opener is a critical task that enhances your garage's convenience, security, and efficiency. If you live in Scottsdale and are considering a replacement, it's essential to understand the process and make informed decisions. This guide provides expert tips for garage door opener replacement Scottsdale, ensuring a smooth and successful upgrade.

Find The Best Garage Door Repair Service in Scottsdale in Visual Map:

1. Recognizing the Need for Replacement

Signs Your Garage Door Opener Needs Replacing

Understanding when to replace your garage door opener is crucial. Here are some signs that indicate it might be time for a new one:

Frequent Malfunctions: If your opener often fails to work or works intermittently, it may be time for a replacement.

Unusual Noises: Grinding, scraping, or other unusual sounds can signify worn-out components.

Slow Response Time: If there's a delay between pressing the remote and the door opening, the opener might be failing.

Outdated Technology: Older models lack modern safety and security features.

Inconsistent Operation: If the door operates inconsistently, it might be a sign of a failing opener.

Benefits of Replacing Your Garage Door Opener

Replacing your garage door opener offers numerous benefits:

Improved Security: Modern openers have advanced security features to prevent unauthorized access.

Enhanced Safety: Features like auto-reverse ensure the door stops if an object is detected in its path.

Convenience: Newer models offer remote access and smartphone connectivity.

Energy Efficiency: Modern openers are more energy-efficient.

Reliability: Reduced risk of breakdowns and improved performance.

2. Types of Garage Door Openers

Chain-Drive Openers

Chain-drive openers are durable and powerful, making them suitable for heavy doors. However, they tend to be noisy, which might not be ideal if the garage is adjacent to living spaces.

Belt-Drive Openers

Belt-drive openers use a rubber belt instead of a chain, resulting in quieter operation. They are an excellent choice for homes where noise reduction is a priority.

Screw-Drive Openers

Screw-drive openers operate with a threaded steel rod. They require less maintenance and provide smooth and quiet operation, but can be more expensive than chain-drive models.

Direct-Drive Openers

Direct-drive openers are unique in that the motor itself moves along a stationary chain. They are extremely quiet and have fewer moving parts, reducing maintenance needs.

Smart Garage Door Openers

Smart openers come with built-in Wi-Fi and can be controlled via smartphone apps. They offer the ultimate in convenience and security features, such as real-time alerts and remote access.

3. Choosing the Right Garage Door Opener

Consider Door Type and Weight

The type and weight of your garage door influence the choice of opener. Heavy doors, such as wooden or insulated ones, require more powerful openers, typically 3/4 HP or higher.

Noise Levels

If your garage is adjacent to a bedroom or living space, consider a belt-drive or direct-drive opener for quieter operation.

Smart Features

Modern openers offer various smart features, including:

Remote Access: Control your garage door from anywhere using a smartphone app.

Security Alerts: Receive notifications if the door is left open or if there's an attempted break-in.

Integration: Some models integrate with home automation systems like Alexa or Google Home.

Budget

Garage door openers come in a range of prices. While it’s tempting to opt for the cheapest model, investing in a quality opener can save you money in the long run through reduced maintenance and longer lifespan.

4. Preparing for Installation

Gather Necessary Tools and Materials

Before starting the installation, gather all the necessary tools and materials, including:

Wrenches and Pliers

Screwdrivers

Measuring Tape

Ladder

Drill

Safety Glasses

Read the Manufacturer's Instructions

Each garage door opener model comes with specific installation instructions. Carefully read the manual provided by the manufacturer to ensure you follow the correct steps.

Ensure Safety Precautions

Safety is paramount during installation. Follow these precautions:

Disconnect Power: Ensure the power is off to prevent electric shock.

Use Safety Gear: Wear safety glasses and gloves.

Work with a Partner: Having an extra pair of hands can make the process smoother and safer.

5. Step-by-Step Installation Guide

Removing the Old Opener

Disconnect Power: Unplug the old opener and disconnect the wires.

Detach the Door Arm: Remove the arm connecting the opener to the door.

Remove the Opener: Take down the old opener unit and the bracket.

Installing the New Opener

Assemble the Opener: Follow the manufacturer’s instructions to assemble the new opener.

Install the Bracket: Secure the bracket to the ceiling joists.

Mount the Opener: Attach the opener to the bracket.

Connect the Rail: Attach the rail to the motor unit.

Install the Belt or Chain: Depending on your model, install the belt or chain.

Attach the Door Arm: Connect the arm to the door.

Wire the Opener: Connect the wires according to the manufacturer’s instructions.

Install Safety Sensors: Position the sensors on either side of the door, a few inches above the ground.

Test the Opener: Plug in the opener and test its operation, adjusting settings as needed.

6. Professional Installation vs. DIY

Benefits of Professional Installation

Expertise: Professionals have the experience to ensure correct installation.

Safety: Reduces the risk of injury or improper installation.

Warranty Protection: Professional installation often comes with a warranty.

DIY Installation Considerations

Cost Savings: DIY installation can save on labor costs.

Learning Experience: It’s a good opportunity to learn about your garage door system.

Time and Effort: Be prepared for a time-consuming and physically demanding task.

7. Post-Installation Tips

Regular Maintenance

Regular maintenance can extend the life of your garage door opener. Here are some tips:

Lubricate Moving Parts: Apply lubricant to the chain or belt, rollers, and hinges.

Check Safety Features: Test the auto-reverse feature to ensure it’s functioning properly.

Inspect the Door: Regularly check the door balance and make adjustments as needed.

Programming Remote Controls

Follow the manufacturer’s instructions to program your remote controls and any additional keypads or devices.

Securing Your Garage

Ensure your garage is secure by:

Changing Default Codes: If your opener has a keypad, change the default code immediately.

Using Vacation Mode: When away for extended periods, use the vacation mode feature to disable remote controls.

8. Troubleshooting Common Issues

Opener Doesn’t Respond

If your opener doesn’t respond, check the following:

Power Source: Ensure the opener is plugged in and receiving power.

Remote Batteries: Replace the batteries in your remote.

Sensor Alignment: Make sure the safety sensors are aligned and unobstructed.

Door Reverses Before Closing

If the door reverses before closing:

Check Sensors: Ensure nothing is blocking the sensors and they are properly aligned.

Adjust Sensitivity: Consult the manual to adjust the opener’s sensitivity settings.

Noisy Operation

If your opener is noisy:

Lubricate: Apply lubricant to moving parts.

Tighten Hardware: Ensure all bolts and screws are tightened.

Check the Type of Opener: Consider upgrading to a quieter model if noise persists.

9. Finding the Best Garage Door Opener Replacement Services in Scottsdale

Research and Reviews

Start by researching local companies. Look for those with positive reviews and a solid reputation in Scottsdale.

Services Offered

Choose a company that offers a comprehensive range of services, including:

Consultation: Initial consultation to understand your needs.

Installation: Experienced technicians for seamless installation.

Maintenance and Repair: Ongoing services to keep your opener in top condition.

Warranty: A good warranty for peace of mind.

Top Garage Door Opener Replacement Services in Scottsdale

Here are some reputable garage door opener replacement services in Scottsdale:

Arizona Garage Door Repair Guru: Known for their exceptional service and over 25 years of experience.

Scottsdale Garage Door & Opener: Offers a wide range of services and a customer-centric approach.

Dynamic Door Service: Reliable and professional with a variety of custom door options.

A1 Garage Door Service: Renowned for their prompt service and quality workmanship.

Precision Door Service: Offers detailed attention to every aspect of garage door opener installation.

10. Conclusion

Replacing your garage door opener in Scottsdale can significantly enhance your home's convenience, security, and efficiency. You can ensure a smooth and successful replacement process by understanding your options, preparing adequately, and choosing the right opener and installation method. Whether you opt for DIY or professional installation, following these expert tips will help you make the most of your new garage door opener. Regular maintenance and timely troubleshooting will ensure it continues operating efficiently for years.

0 notes

Text

How Do Stainless Steel Bright Bars Recover Machinability?

Stainless steel bright bars are treated through a series of accuracy grinding and polishing operations, ensuing in a smooth, shiny surface texture. This surface appearanceimproves the machinability of the bars by dipping friction and minimizing implement wear during machining procedures such as turning, drilling, and milling. The unchanging surface feel of bright bars allows cutting tools to brand clean, precise cuts with better ease and efficiency. Moreover, the improved surface finish of bright bars assistances maintain dimensional correctness and surface integrity, resulting in high-quality machined components appropriate for aextensive range of applications in numerous industries.

Stainless Steel Rod Suppliers in Chennai: Dependability and Value

Stainless steel rod suppliers in Chennai play a vital role in ifgood stainless steel rods to various businesses. These suppliers proposal a extensive range of stainless steel rod choices, counting bright bars, hex bars, square bars, flat bars, and round bars, cookery to the diverse wants of patrons in Chennai and beyond. They safeguard reliability by obtaining stainless steel rods from reputable constructers and adhering to stringent quality control procedures to deliver products that meet or exceed industry values.

Stainless Steel Bright Bars: Sparkly and Adaptable

Stainless steel bright bars are precision-ground and refined bars known for their flat, shiny surface finish. They are extensively used in industries such as automotive, aerospace, building, and manufacturing due to their artistic appeal and excellent machinability. Bright bars proposalimproved corrosion resistance and durability, manufacture them suitable for requests requiring superior superficial finish and dimensional accurateness.

Stainless Steel Hex Bar:Power and Constancy

Stainless steel hex bars article a hexagonal cross-section, if increased forte and stability compared to round bars. They are usually used in construction, machinery, and hardware businesses for applications requiring healthy structural support and exact machining. Stainless steel hex bar offer adaptability, allowing for easy fabrication and meeting in numerous engineering projects, creation them a popular excellent among designers and builders.

Stainless Steel Square Bar: Strength and Functionality

Stainless steel square bars are solid bars by a square cross-section, contribution excellent durability and functionality in varied applications. They are extensively utilized in architectural, marine, and food giving out industries due to their corrosion confrontation and hygienic possessions. Stainless steel square bars afford structural integrity and aesthetic application, making them appropriate for use in railing schemes, kitchen equipment, and decorative rudiments.

Stainless Steel Flat Bar: Multipurpose and Calm to Fabricate

Stainless steel flat bars article a flat surface and rectangular cross-section, making them extremely versatile and relaxed to fabricate for various requests. They are commonly used in building, automotive, and manufacturing businesses for components such as brackets, frames, and chains. Stainless steel flat bars suggestion excellent weldability and formability, permitting for seamless integration into dissimilar designs and assemblies.

Stainless Steel 304 Round Bar: Corrosion Opposition and Machinability

Stainless steel 304 round bars are amongst the most widely used stainless steel produces known for their outstanding corrosion confrontation and machinability. They are collected of an austenitic stainless steel alloy comprising chromium and nickel, providing greater resistance to rust and oxidation in harsh situations. Stainless steel 304 round bars are apposite for a extensive range of applications, counting food processing, chemical processing, and pharmaceutical engineering, due to their hygienic belongings and ease of construction.

0 notes